BMW 528i 1997 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 201 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

NOTE-

The camshaft bearing caps are coded with a letter and a

number. For example, "A

1" is the first exhaust camshaft

bearing cap

at the front of the engine, and "El "is the intake

camshaft bearing cap at the front of the engine.

-. -

The camshafts are stamped with a code letter - "E for the

intake side and

'X" for the exhaust side.

"E is for Einlap. (German for intake) and 'XA7s for Auspuff.

(German for exhaust).

- Repeat procedure for exhaust camshaft

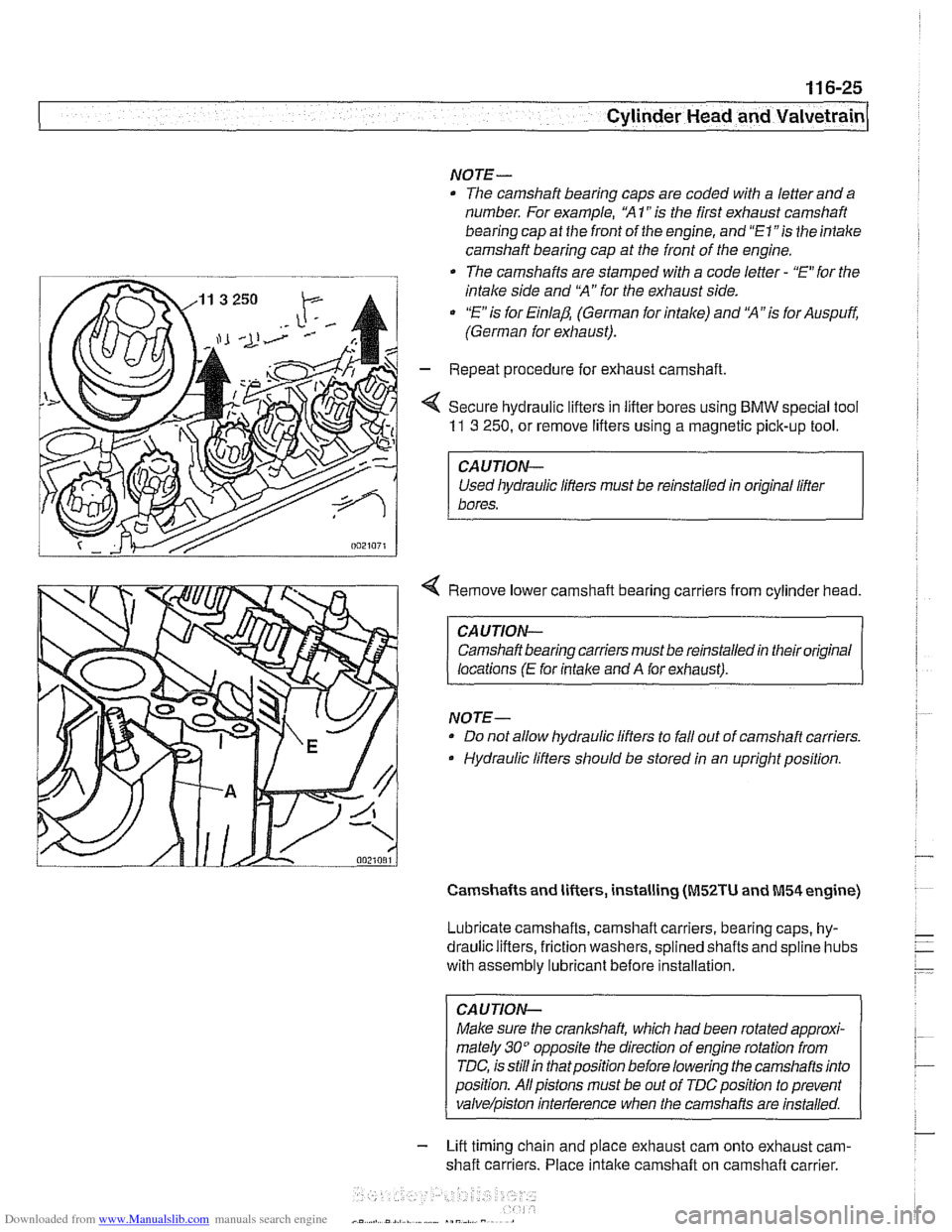

< Secure hydraulic lifters in lifter bores using BMW special tool

11 3 250, or remove lifters using a magnetic pick-up tool.

I CAUTION-

Used liydraulic lifters must be reinstalled in original lifter

1 bores.

4 Remove lower camshaft bearing carriers from cylinder head.

CAUTION- Camshaft bearing carriers must be reinstalled in their original

locations

(E for intalce and A for exhaust).

NOTE- Do not allow hydraulic lifters to fall out of camshaft carriers.

Hydraulic lifters should be stored in an upright position.

Camshafts and lifters, installing (M52TU and M54 engine)

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and

spline hubs

with assembly

lubricant before installation.

CAUTION-

Make sure the crankshaft, which had been rotated approxi-

mately

30" opposite the direction of engine rotation from

TDC, is

stillin thatposition before lowering the camshafts into

position. Allpistons must be out of

TDCposition to prevent

valve/piston inteiference when the carnshafis are installed.

- Lift timing chain and place exhaust cam onto exhaust cam-

shaft carriers. Place

intake camshaft on camshaft carrier.

Page 202 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-26

I Cylinder Head and Valvetrain

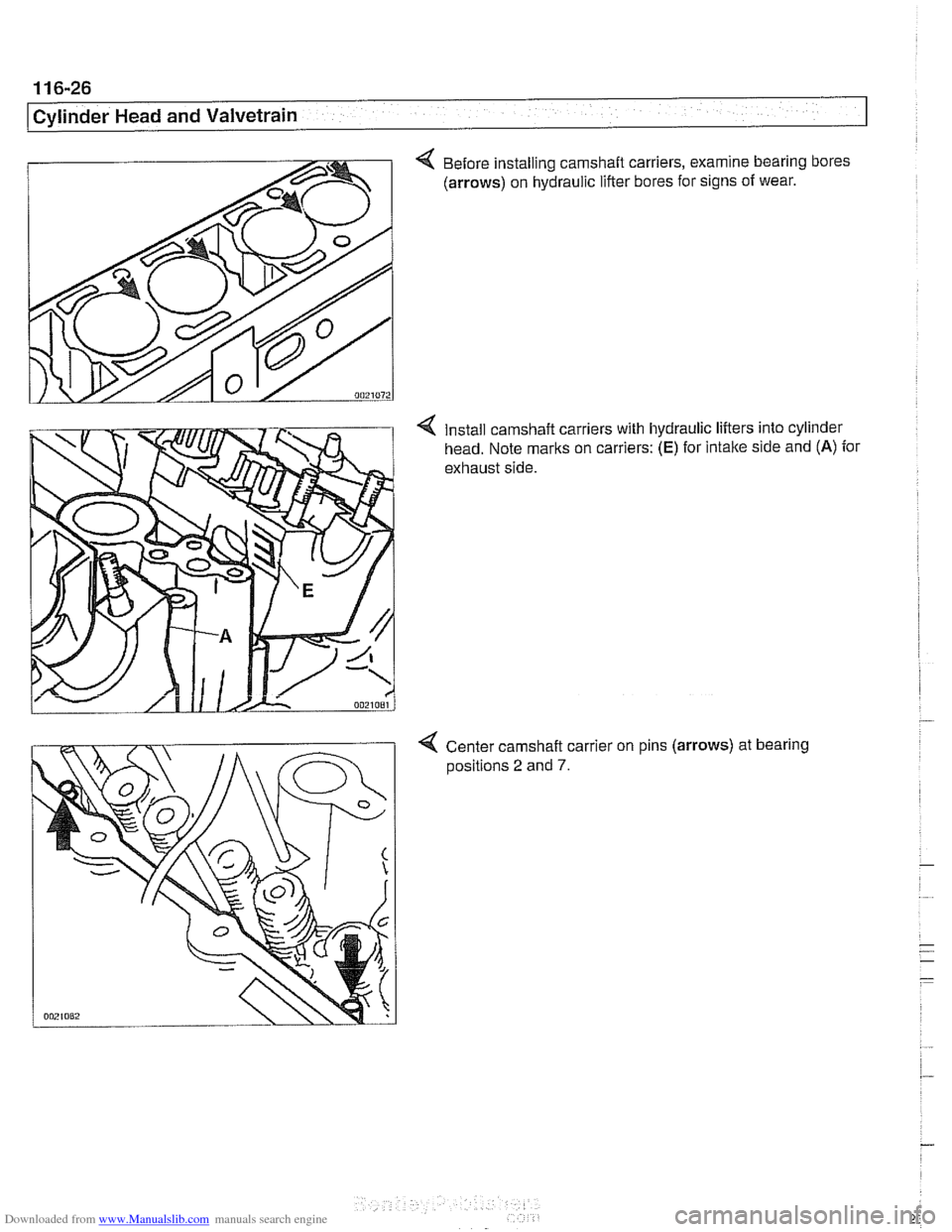

4 Before installing camshaft carriers, examine bearing bores

(arrows) on hydraulic lifter bores for signs of wear.

Install camshaft carriers with hydraulic lifters into cylinder

head. Note marks on carriers:

(E) for intake side and (A) for

exhaust side.

4 Center camshaft carrier on pins (arrows) at bearing

aositions 2 and 7.

Page 203 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- - . .- -,

Cylinder Head and Valvetrain

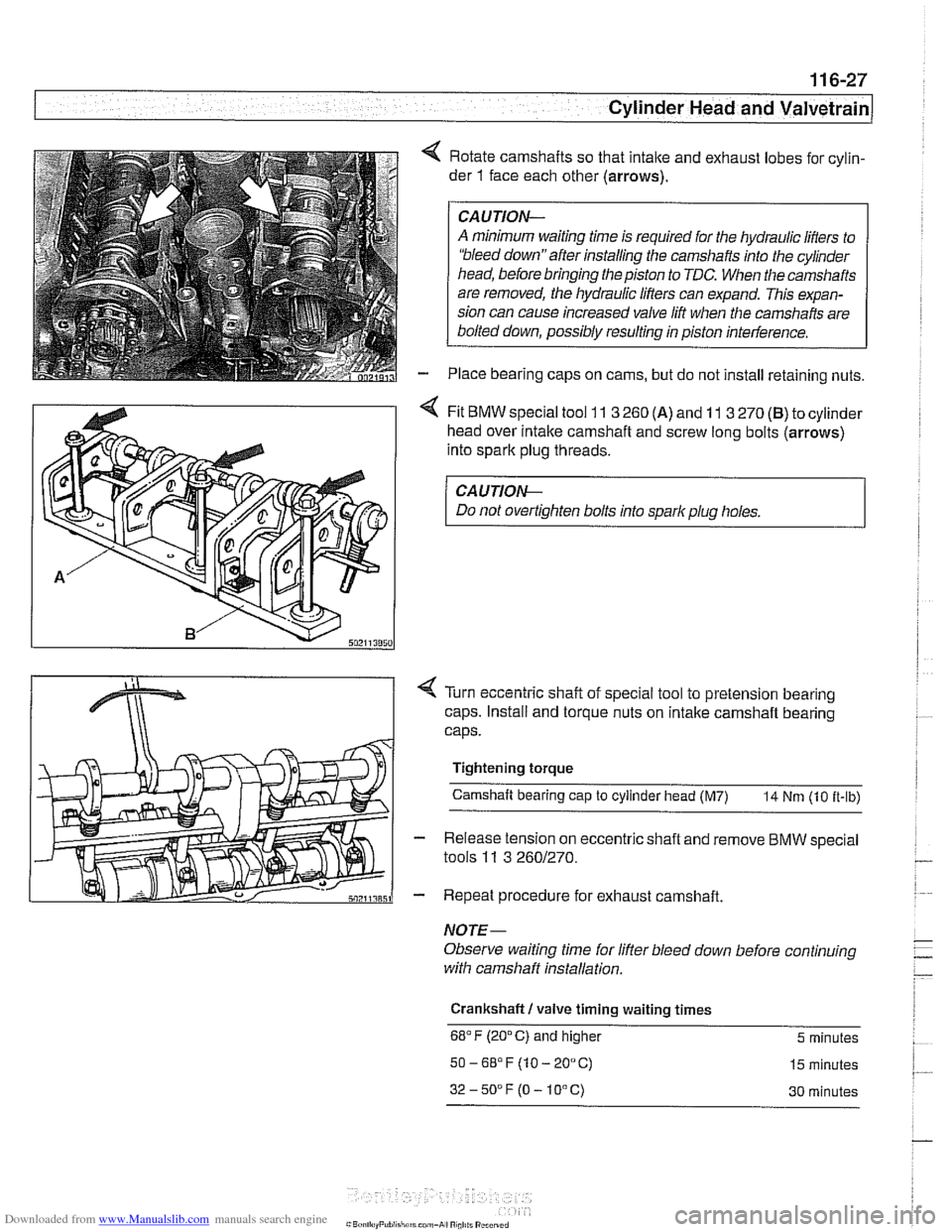

4 Rotate camshafts so that intalte and exhaust lobes for cylin-

der

1 face each other (arrows).

CAUJION-

A minimum waiting time is required for the hydraulic lifters to

'bleed down"after installing the camshafts into the cylinder

head, before bringing the piston to TDC. When the camshafts

are removed, the hydraulic lifters can expand. This expan-

sion can cause increased valve lift when the camshafts are

bolted down, possibly resulting in piston interference.

Place bearing caps on cams, but do not install retaining nuts.

4 Fit BMW special tool 11 3 260 (A) and 11 3 270 (B) to cylinder

head over

intalte camshaft and screw long bolts (arrows)

into spark plug threads.

CA UTION-

Do not overtighten bolts into spark plug holes.

< Turn eccentric shaft of special tool to pretension bearing

caps. Install and torque nuts on intake camshaft bearing

caps.

Tightening torque Camshaft bearing cap

to cylinder head (M7) 14 Nm (10 it-ib)

- Release tension on eccentric shaft and remove BMW special

tools

11 3 2601270.

- Repeat procedure for exhaust camshaft.

NOTE-

Observe waiting time for lifter bleed down before continuing

with camshaff installation.

Crankshaft

I valve timing waiting times

68°F (20°C) and higher 5 minutes

50-6S°F(10-20°C) 15 minutes

32-50DF(O-10°C) 30 minutes

Page 204 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-28

Cylinder Head and Valvetrain

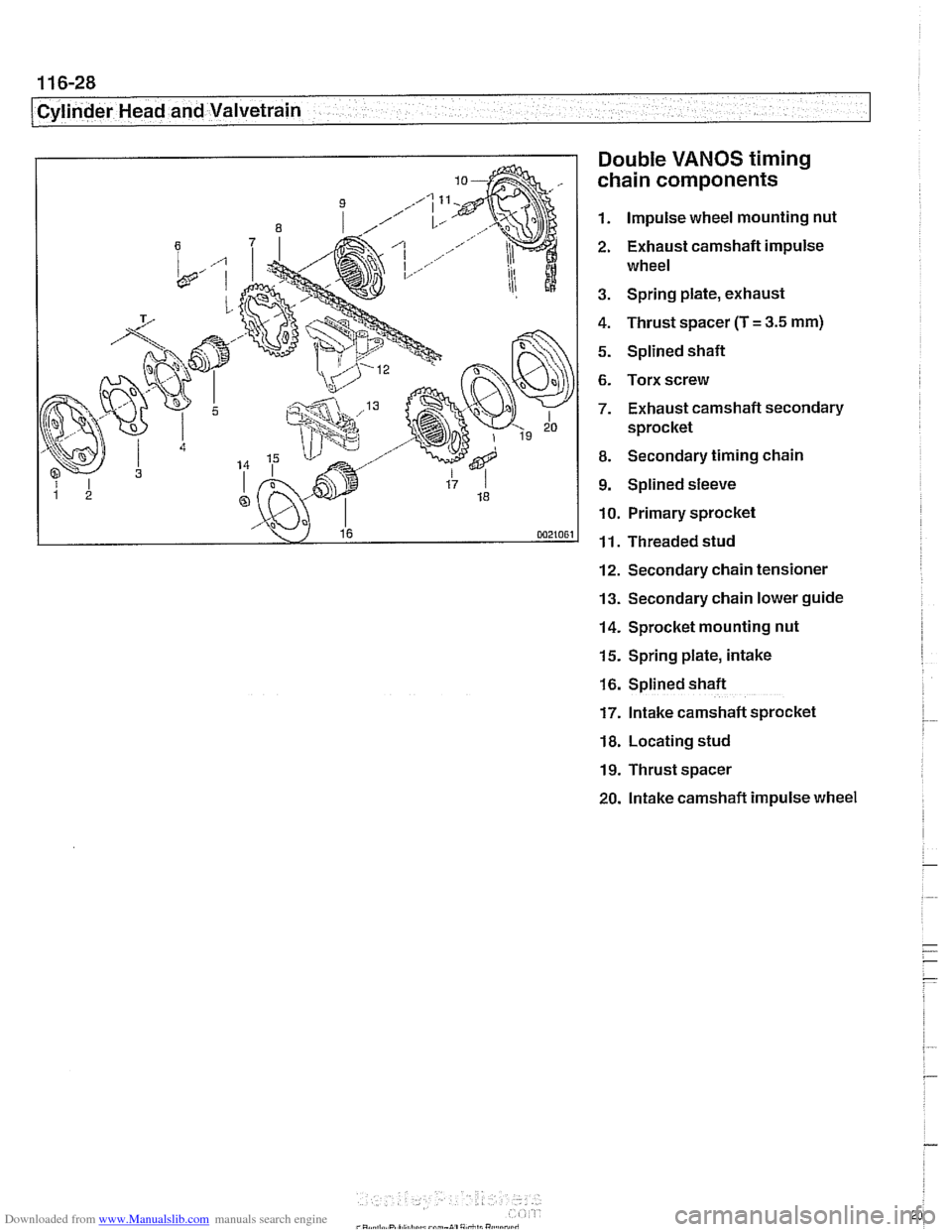

Double

VANOS timing

chain components

1. Impulse wheel mounting nut

2. Exhaust camshaft impulse

wheel

3. Spring plate, exhaust

4. Thrust spacer (T

= 3.5 mm)

5. Splined shaft

6. Torx screw

7. Exhaust camshaft secondary

sprocket

8. Secondary timing chain

9. Splined sleeve

10. Primary sprocket

11. Threaded stud

12. Secondary chain tensioner

13. Secondary chain lower guide

14. Sprocket mounting nut

15. Spring plate, intake

16. Splined shaft

17. Intake camshaft sprocket

18. Locating stud

19. Thrust spacer

20. lntake camshaft impulse wheel

Page 205 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Cylinder Head and valvetrain1

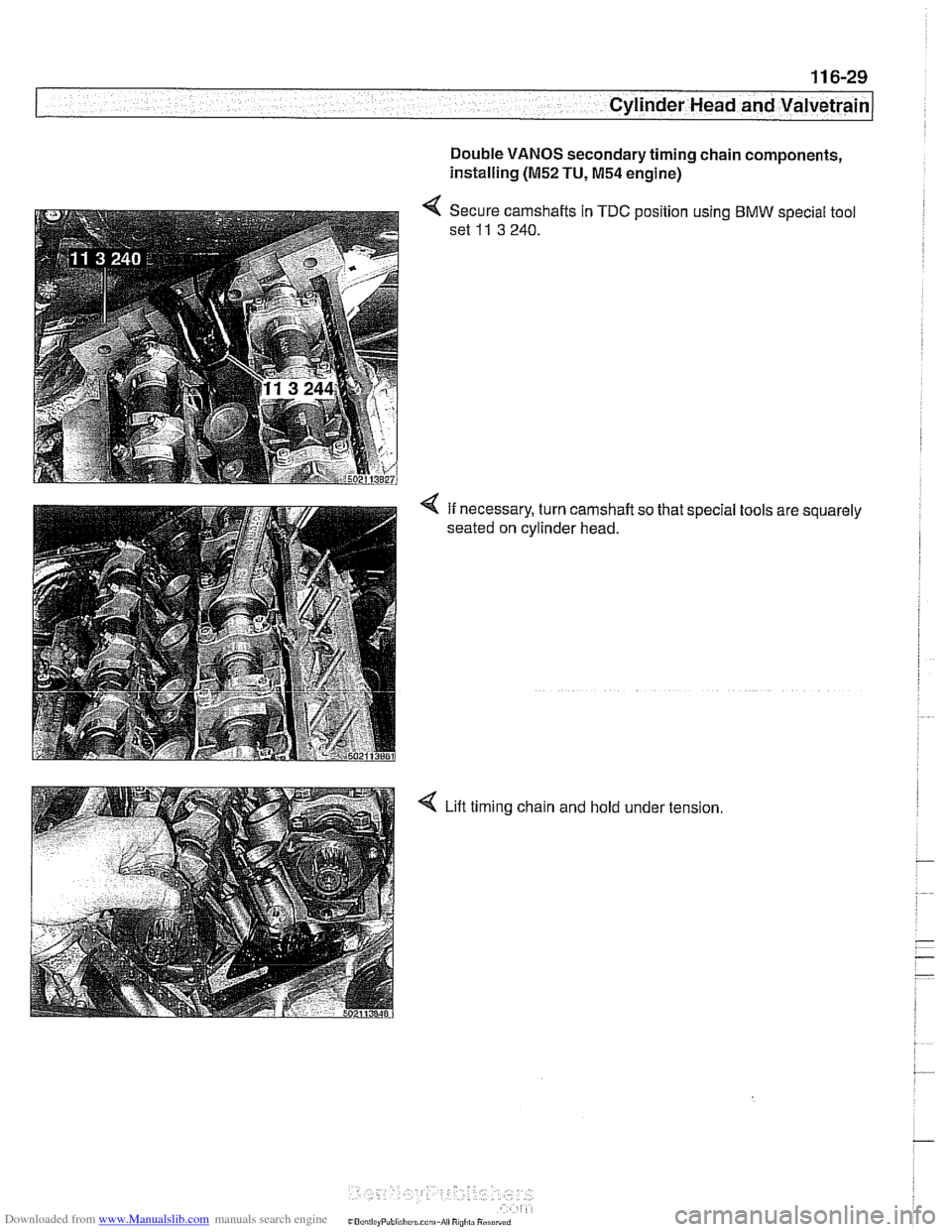

Double VANOS secondary timing chain components,

installing

(M52 TU, M54 engine)

< Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 If necessary, turn camshaft so that special tools are squarely

seated on cylinder head.

4 Lift timing chain and hold under tension

Page 206 of 1002

Downloaded from www.Manualslib.com manuals search engine

~ ~. --

Cylinder Head and Valvetrain .-

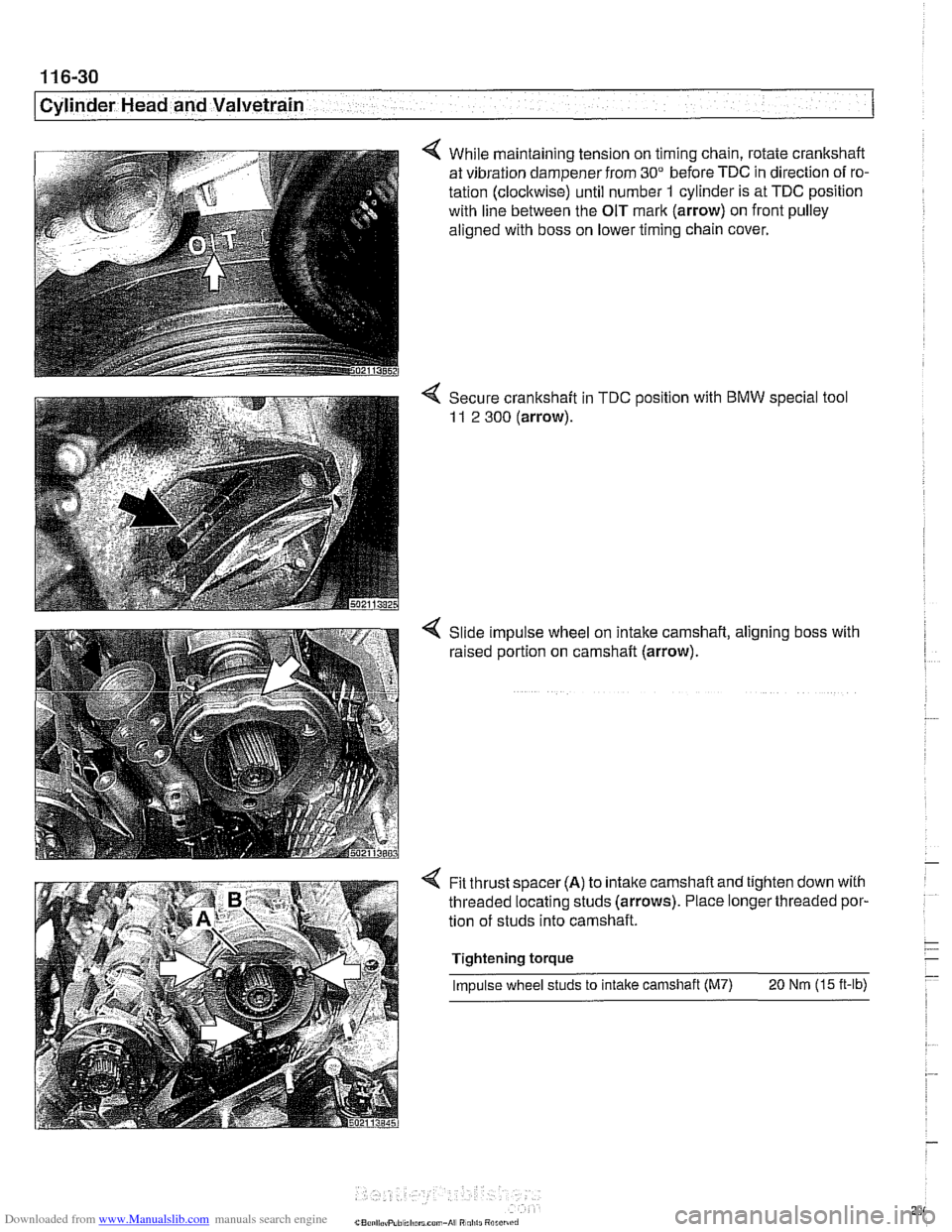

4 While maintaining tension on timing chain, rotate crankshaft

at vibration dampener from

30" before TDC in direction of ro-

tation (clockwise) until number

1 cylinder is at TDC position

with line between the OIT mark (arrow) on front pulley

aligned with boss on lower timing chain cover.

4 Secure crankshaft in TDC position with BMW special tool

11 2 300 (arrow).

Slide impulse wheel on intake camshaft, aligning boss with

raised portion on camshaft (arrow).

Fit thrust spacer

(A) to intalte camshaft and tighten down with

threaded locating studs (arrows). Place longer threaded por-

tion of studs into camshaft.

Tightening torque

Impulse wheel studs to intake camshaft (M7)

20 Nm (15 ft-lb)

Page 207 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-31

Cylinder Head and Valvetrain

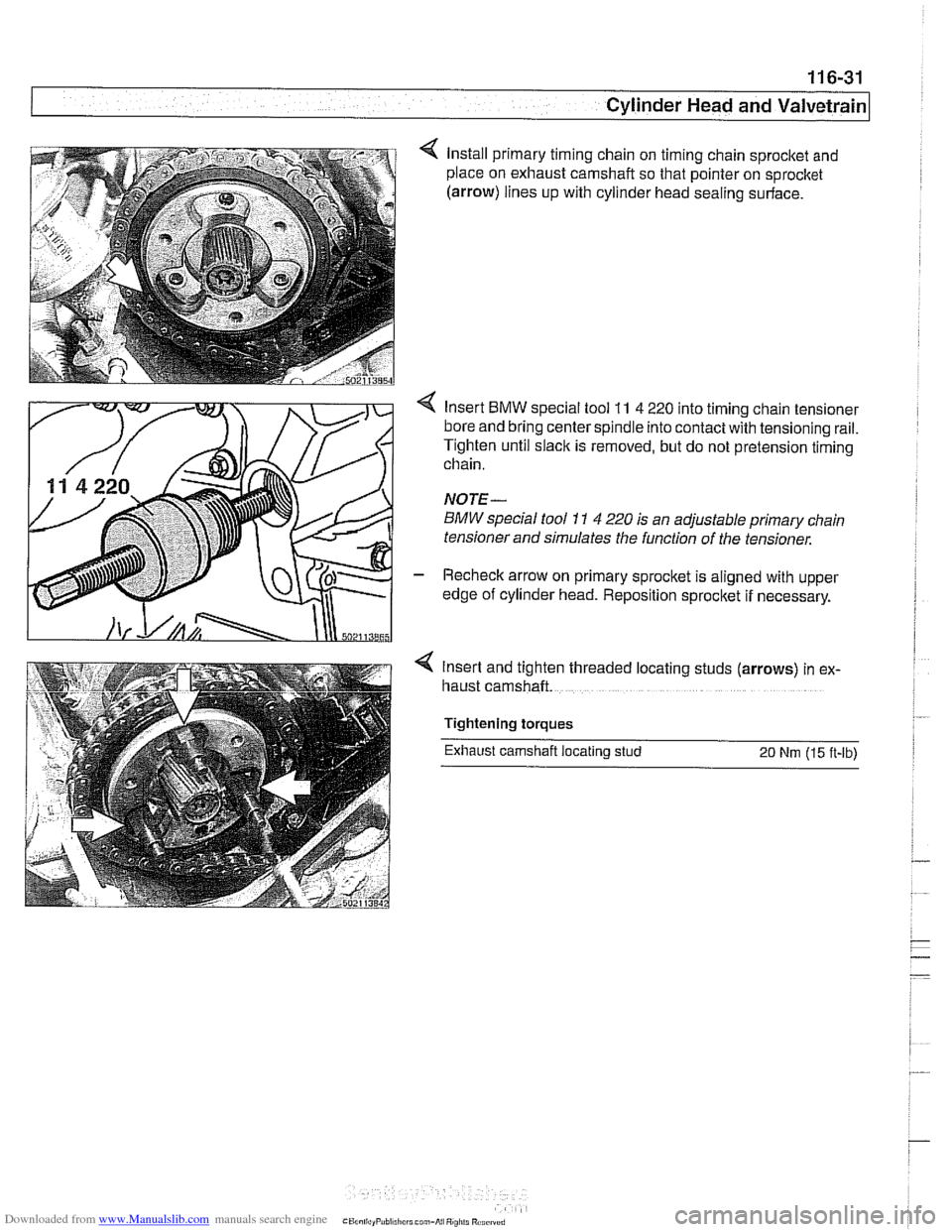

< Install primary timing chain on timing chain sprocket and

place on exhaust camshaft so that pointer on sprocket

(arrow) lines up with cylinder head sealing surface.

4 Insert BMW special tool 11 4 220 into timing chain tensioner

bore and bring center spindle into contact with tensioning rail.

Tighten until slack is removed, but do not pretension timing

chain.

NOTE-

BMW special tool 11 4 220 is an adjustable primary chain

tensioner and simulates the function of the tensioner.

- Recheck arrow on primary sprocket is aligned with upper

edge of cylinder head. Reposition sprocket if necessary.

4 Insert and tighten threaded locat~ng studs (arrows) in ex-

haust camshaft.

Tightening

torques

Exhaust camshaft locating stud 20 Nm (15 ft-lb)

Page 208 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-32

Cylinder Head and Valvetrain

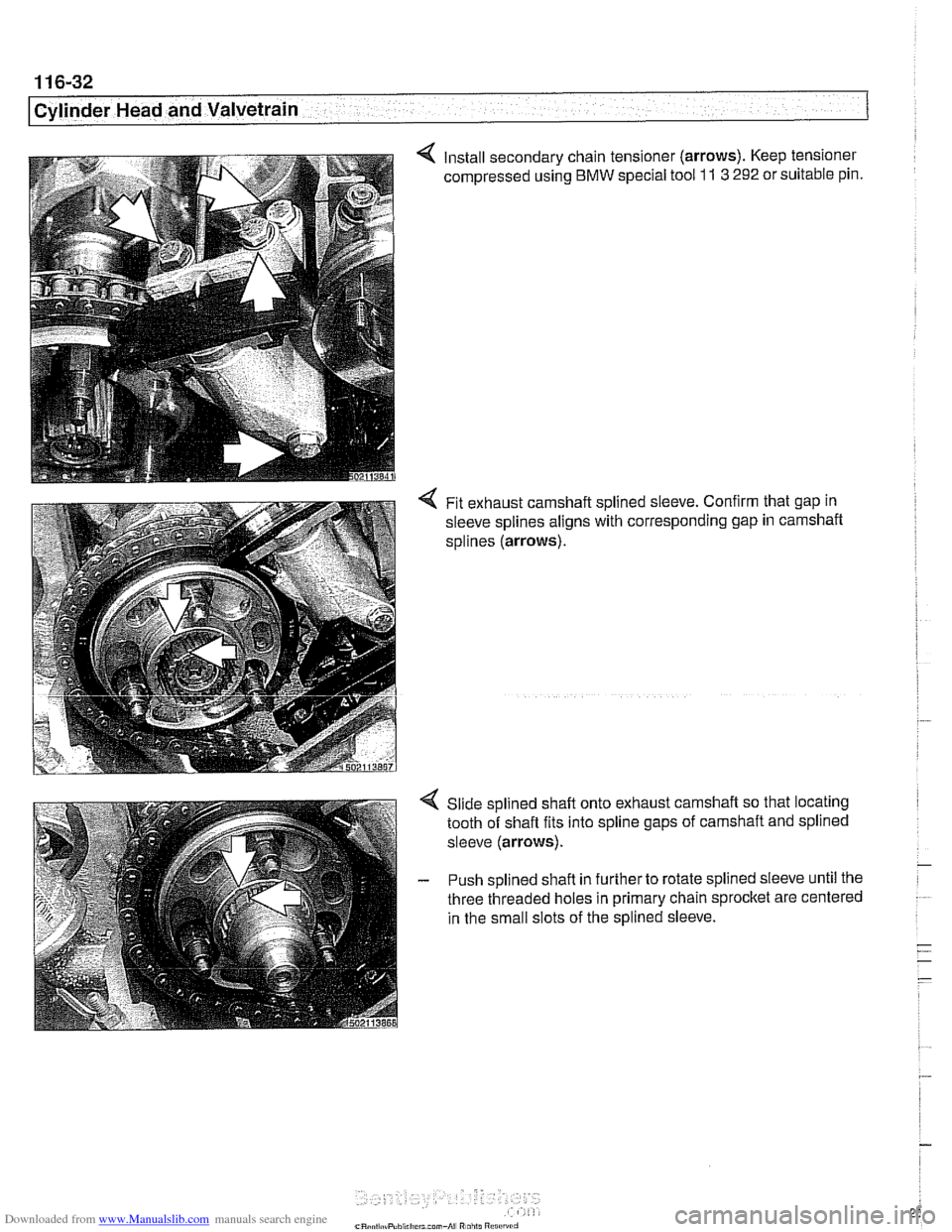

4 Install secondary chain tensioner (arrows). Keep tensioner

compressed using

BMW special tool 11 3 292 or suitable pin.

4 Fit exhaust camshaft splined sleeve. Confirm that gap in

sleeve splines aligns with corresponding gap in carnshaft

splines

(arrows).

Slide splined shaft onto exhaust camshaft so that locating

tooth of shaft fits into spline gaps of camshaft and splined

sleeve

(arrows).

- Push splined shafl in further to rotate splined sleeve until the

three threaded holes in primary chain sprocket are centered

in the small slots of the splined sleeve.

Page 209 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

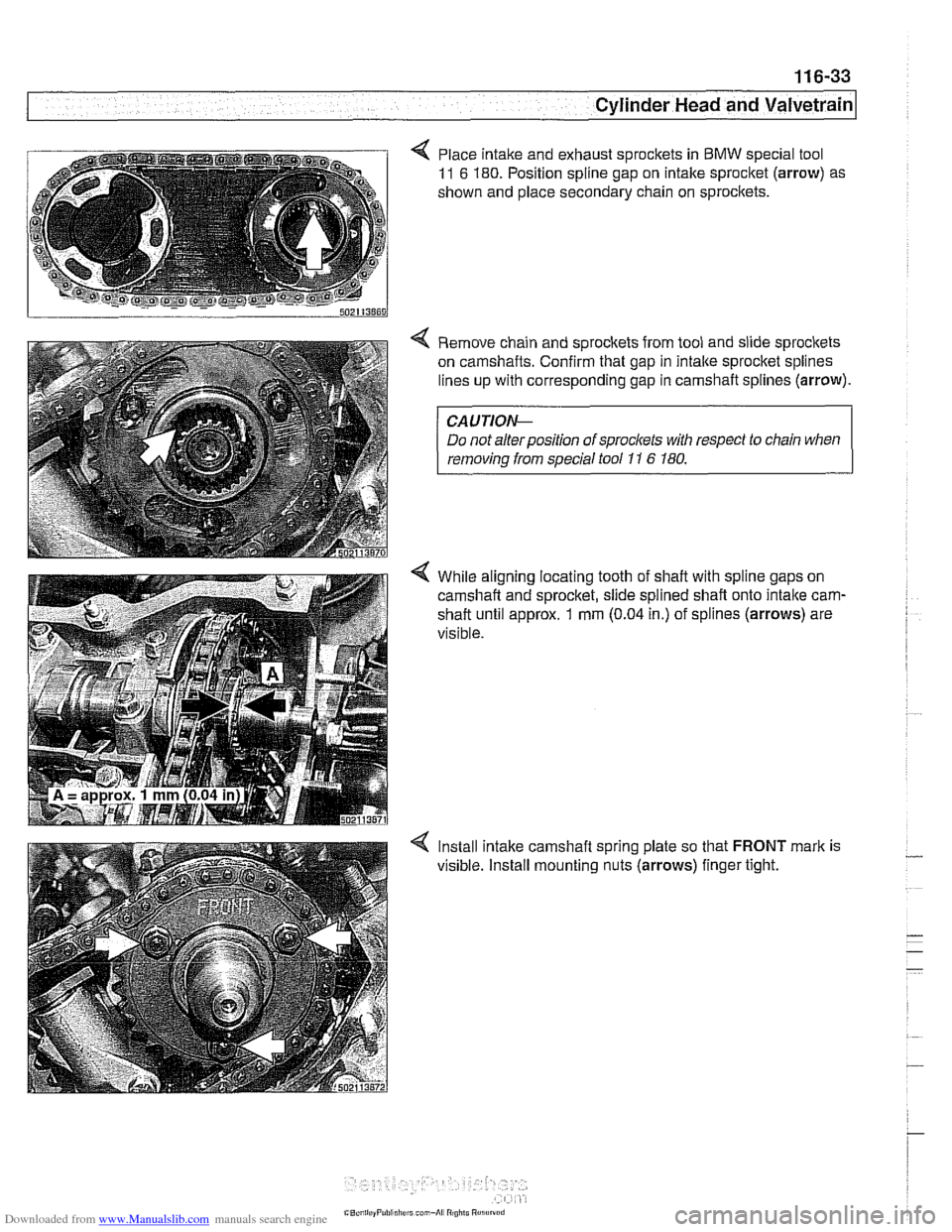

< Place intake and exhaust sprockets in BMW special tool

11 6 180. Position spline gap on intake sprocket (arrow) as

shown and place secondary chain on

sprocitets.

< Remove chain and sprockets from tool and slide sprockets

on camshafts. Confirm that gap in intalte sprocket splines

lines up with corresponding gap in camshaft splines (arrow).

CAUTIOI\C

Do not alter position of sprockets with respect to chain when

removinq from saecial tool 11 6 180.

4 While aligning locating tooth of shaft with spline gaps on

camshaft and sprocket, slide spiined

shaft onto intalte carn-

shaft until approx. 1 mm (0.04 in.) of splines (arrows) are

visible.

4 lnstall intake camshaft spring plate so that FRONT mark is

visible. install mounting nuts (arrows) finger tight.

Page 210 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Cylinder Head and Valvetrain

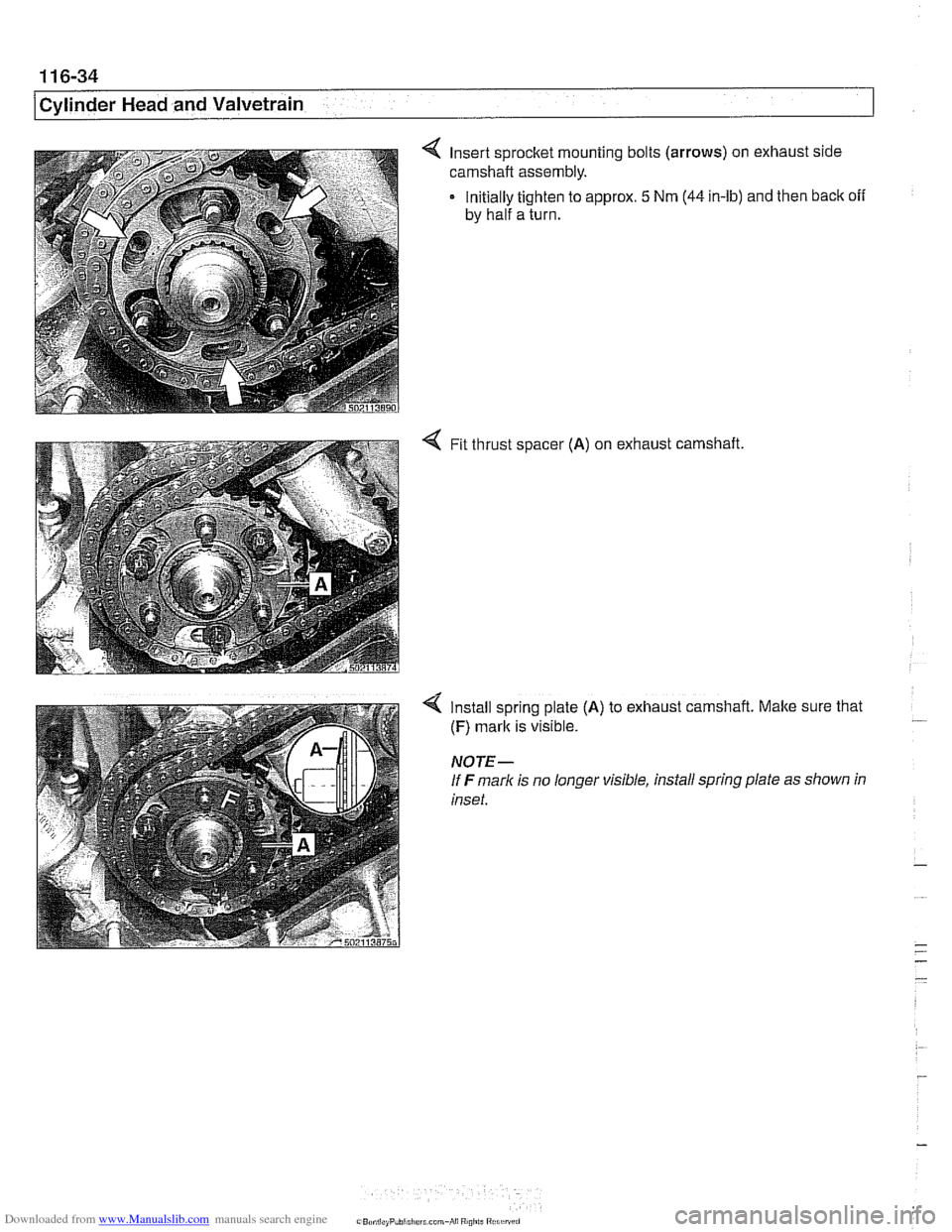

4 Insert sprocket mounting bolts (arrows) on exhaust side

carnshaft assembly.

Initially tighten to approx.

5 Nrn (44 in-lb) and then back off

by half a turn.

4 Fit thrust spacer (A) on exhaust

camshaft.

4 Install spring plate (A) to exhaust camshaft. Make sure that

(F) mark is visible.

NOTE-

If F marlc is no longer visible, install spring plate as shown in

inset.