sensor BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 775 of 1002

Downloaded from www.Manualslib.com manuals search engine

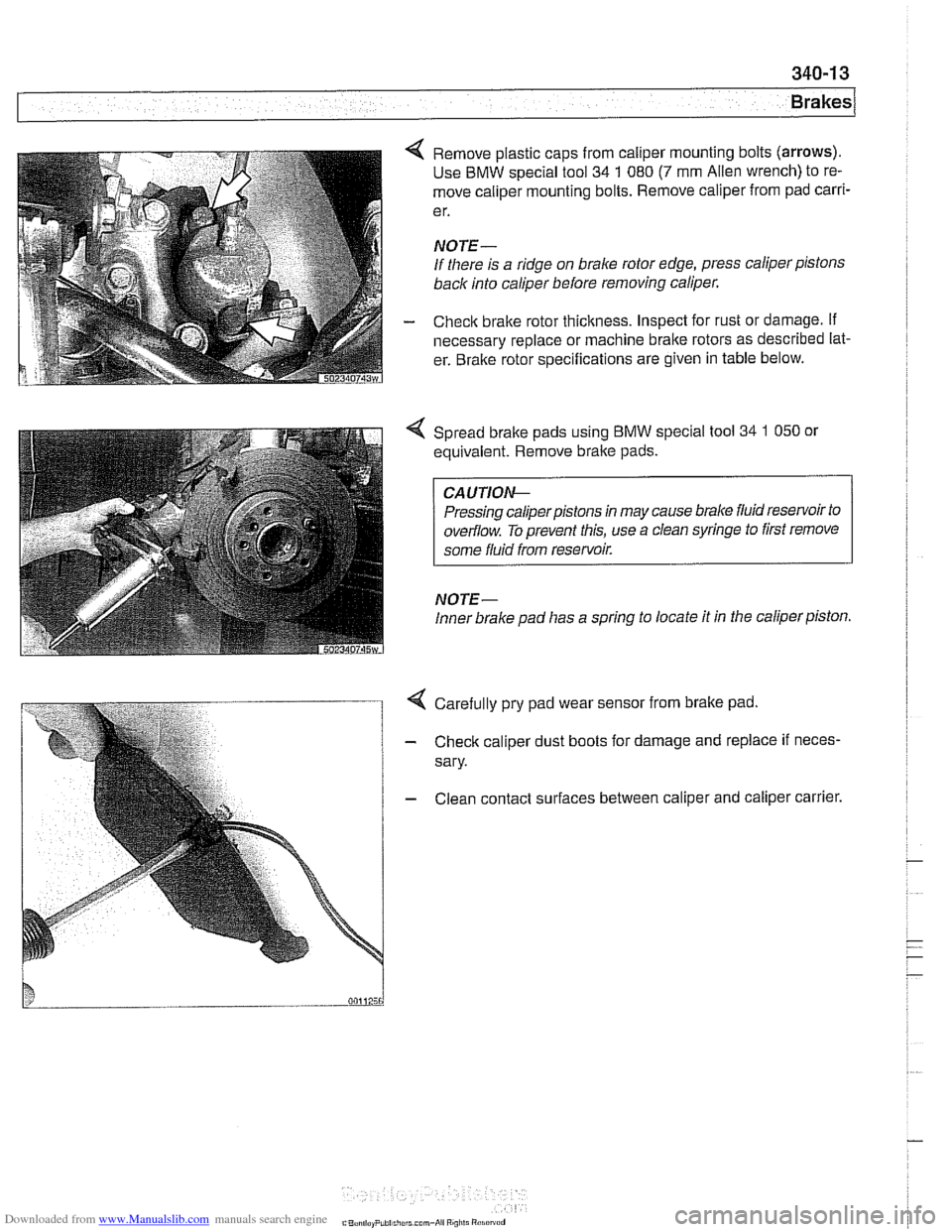

4 Remove plastic caps from caliper mounting bolts (arrows).

Use BMW special tool 34 1 080 (7 mm Alien wrench) to re-

move caliper mounting bolts. Remove caliper from pad

carri-

e r.

NOTE-

If there is a ridge on brake rotor edge, press caliper pistons

back into caliper before removing caliper.

- Check brake rotor thickness. Inspect for rust or damage. if

necessary replace or machine brake rotors as described lat-

er. Bralte rotor specifications are given in table below.

Spread bralte pads using BMW special tool

34 1 050 or

equivalent. Remove brake pads.

CA UTIOG

Pressing caliperpistons in may cause brake fluid reservoir to

overflow. To prevent this, use a clean syringe to first remove

some fluid from reservoir.

NOTE-

Inner brake pad lias a spring to locate it in the caliper piston.

4 Carefully pry pad wear sensor from brake pad

- Check caliper dust boots for damage and replace if neces-

sary.

- Clean contact surfaces between caliper and caliper carrier.

C"..., I,.. P,hi..,,,.r.. mm-*ii Ai"i,li "1.i"~"d

Page 776 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 4

Brakes

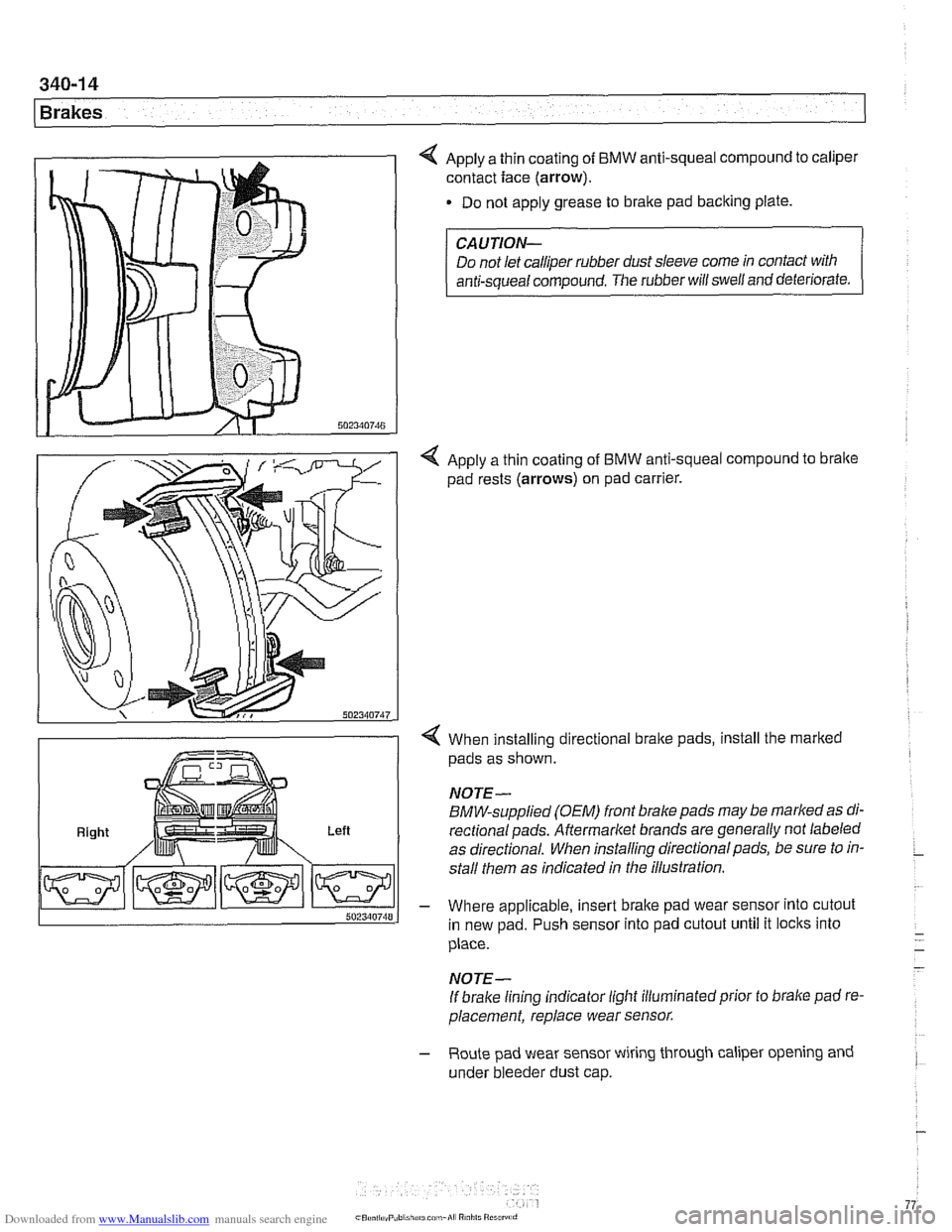

4 Apply a thin coating of BMW anti-squeal compound to caliper

contact face

(arrow).

Do not apply grease to brake pad backing plate.

Right Left

CAUTION-

Do not let calliper rubber dust sleeve come in contact with

anti-squeal compound. The rubber will swell and deteriorate.

4 Apply a thin coating of BMW anti-squeal compound to bralte

pad rests (arrows) on pad carrier.

4 When installing directional brake pads, install the marked

pads as shown.

NOTE-

BMW-supplied (OEM) front brake pads may be marked as di-

rectionalpads. Aftermarket brands are generally not labeled

as directional. When installing directional pads, be sure to in-

stall them as indicated in the illustration.

- Where applicable, insert brake pad wear sensor into cutout

in new pad. Push sensor into pad cutout until it locks into

place.

- -

- NOTE-

If brake lining indicator light illuminatedprior to brake pad re-

placement, replace wear sensor.

- Route pad wear sensor wiring through caliper opening and

under bleeder dust cap.

Page 779 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

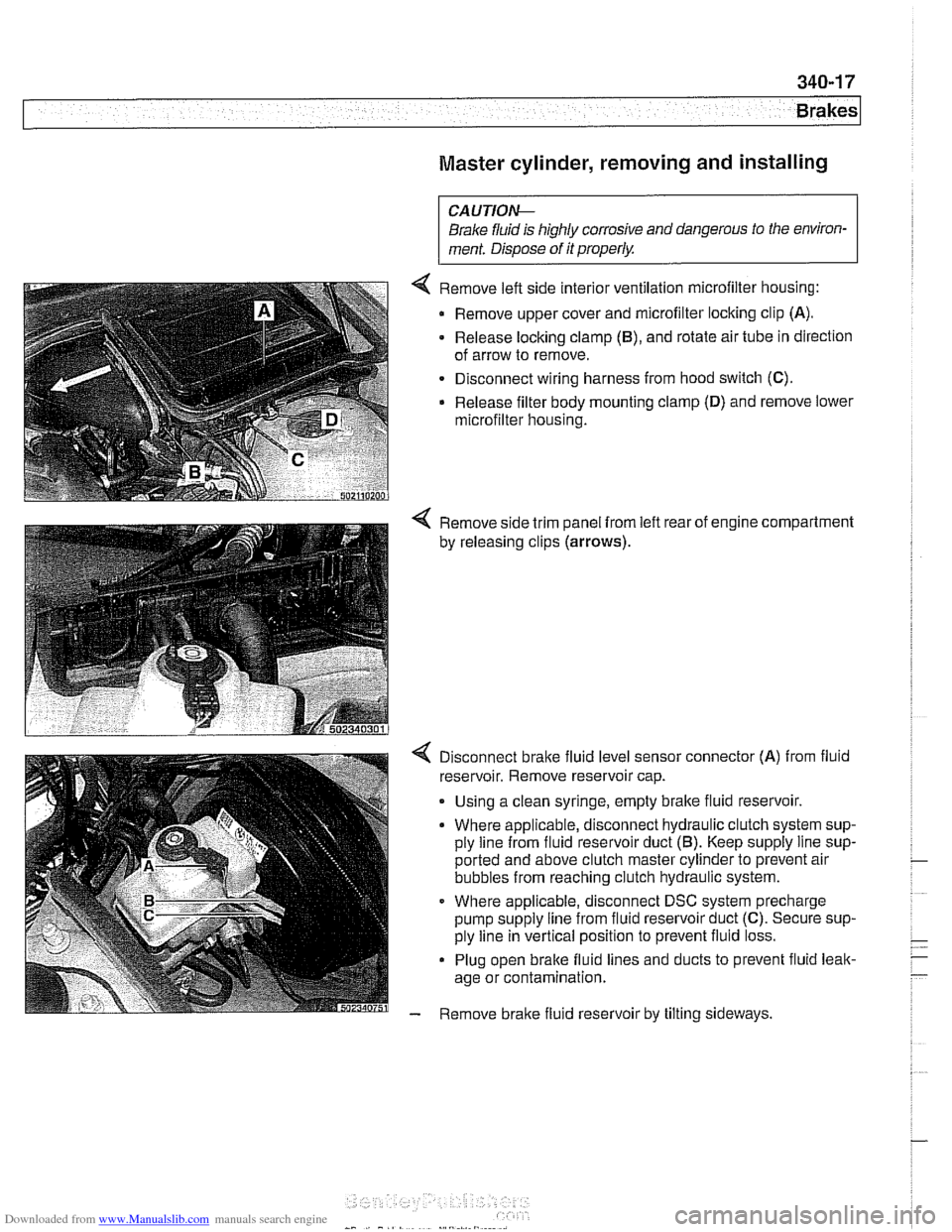

Master cylinder, removing and installing

CAUTlOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it properly.

4 Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter locking clip

(A).

- Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

4 Remove side trim panel from left rear of engine compartment

by releasing clips

(arrows).

4 Disconnect bralte fluid level sensor connector (A) from fluid

reservoir. Remove reservoir cap.

. Using a clean syringe, empty bralte fluid reservoir.

Where applicable, disconnect hydraulic clutch system sup-

ply line from fluid reservoir duct

(5). Keep supply line sup-

ported and above clutch master cylinder to prevent air

bubbles from reaching clutch hydraulic system.

Where applicable, disconnect DSC system precharge

pump supply line from fluid reservoir duct

(C). Secure sup-

ply line in vertical position to prevent fluid loss.

Plug open brake fluid lines and ducts to prevent fluid leak-

age or contamination.

- Remove brake fluid reservoir by tilting sideways.

Page 788 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

ABS COMPONENT REPLACEMENT

CA UTIOW-

If the tires on the car are of different makes, the ABS/trac-

tion controlsystem may overreact. Only fit tires of the same

make and treadpattern.

In adverse conditions, such as trying to rock the car out

of deep snow or other soft surface, or when snow

chains are fitted, it is advisable to switch off traction

control and allow

tlie car driveline to operate conven-

tionally.

All E39 vehicles are equipped with

Antilock Braking System

(ABS). Early production models featured ABS with Automatic

Stability Control (ABS

I ASC). Later models came equipped

with ABS and Dynamic Stability Control (ABS

/ DSC). This

manual will refer to these systems as ABS. ASC or DSC will

be specified when necessary.

For ABS system and component descriptions, see

300 Sus-

pension, Steering and Brakes-General.

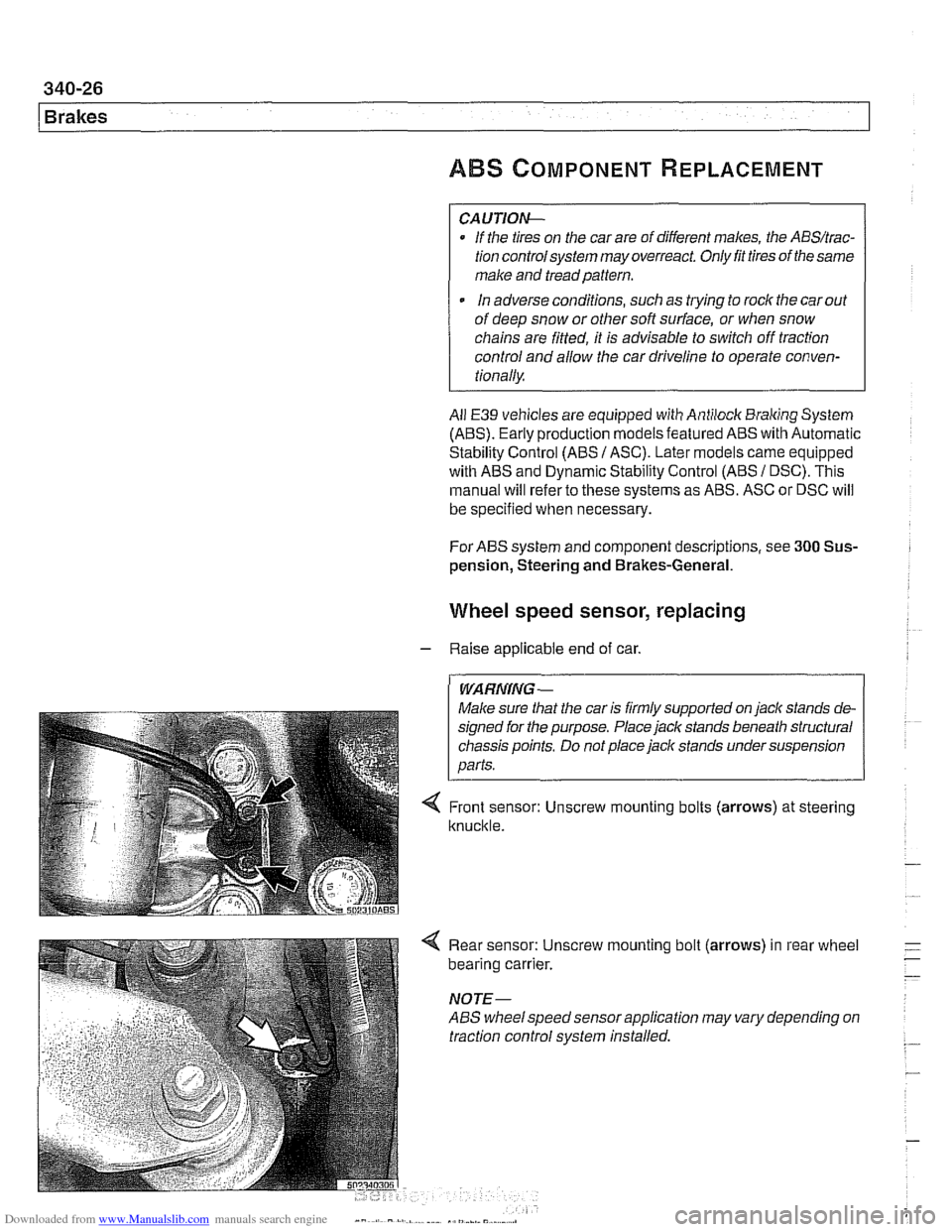

Wheel speed sensor, replacing

- Raise applicable end of car.

Make sure that the car is firmly supported on

jack stands de-

signed for the purpose. Place

jack stands beneath structural

chassis points. Do not place jack stands under suspension

< Front sensor: Unscrew mounting bolts (arrows) at steering

knuckle.

4 Rear sensor: Unscrew mounting bolt (arrows) in rear wheel

bearing carrier.

NOTE-

ABS wheelspeed sensor application may vary depending on

traction control system installed.

Page 789 of 1002

Downloaded from www.Manualslib.com manuals search engine

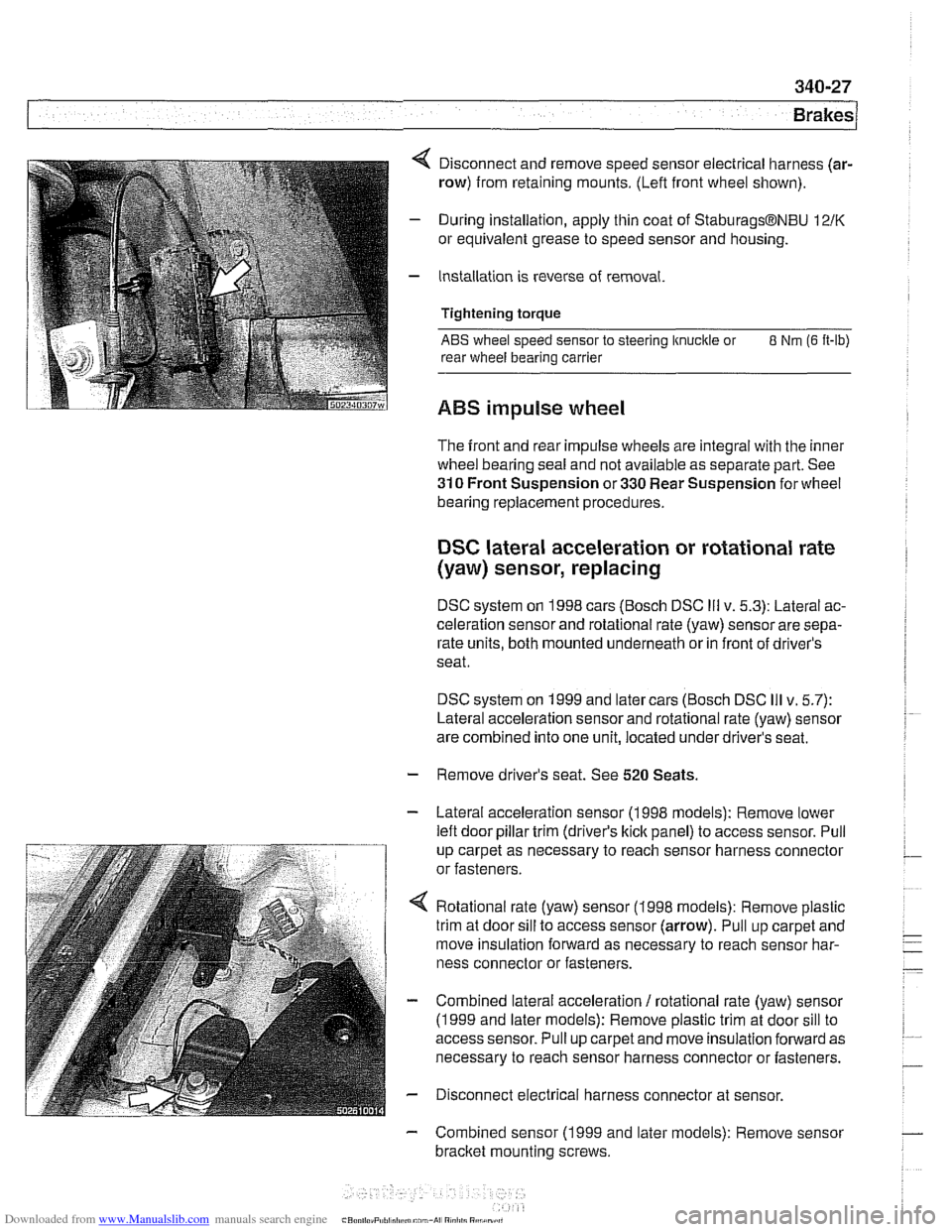

4 Disconnect and remove speed sensor electrical harness (ar-

row) from retaining mounts. (Lefl front wheel shown).

- During installation, apply thin coat of StaburagsBNBU 12/K

or equivalent grease to speed sensor and housing.

- Installation is reverse of removal.

Tightening torque

ABS wheel speed sensor to steering knuckle or 8 Nm (6 It-lb)

rear wheel bearing carrier

ABS impulse wheel

The front and rear impulse wheels are integral with the inner

wheel bearing seal and not available as separate part. See

310 Front Suspension or 330 Rear Suspension for wheel

bearing replacement procedures.

DSC lateral acceleration or rotational rate

(yaw) sensor, replacing

DSC system on 1998 cars (Bosch DSC Ill v. 5.3): Lateral ac-

celeration sensor and rotational rate (yaw) sensor are sepa-

rate units, both mounted underneath or in front of driver's

seat.

DSC system on 1999 and later cars (Bosch DSC

Ill v. 5.7):

Lateral acceleration sensor and rotational rate (yaw) sensor

are combined into one unit, located under driver's seat.

- Remove driver's seat. See 520 Seats.

- Lateral acceleration sensor (1 998 models): Remove lower

lefl door pillar trim (driver's

kick panel) to access sensor. Pull

up carpet as necessary to reach sensor harness connector

or fasteners.

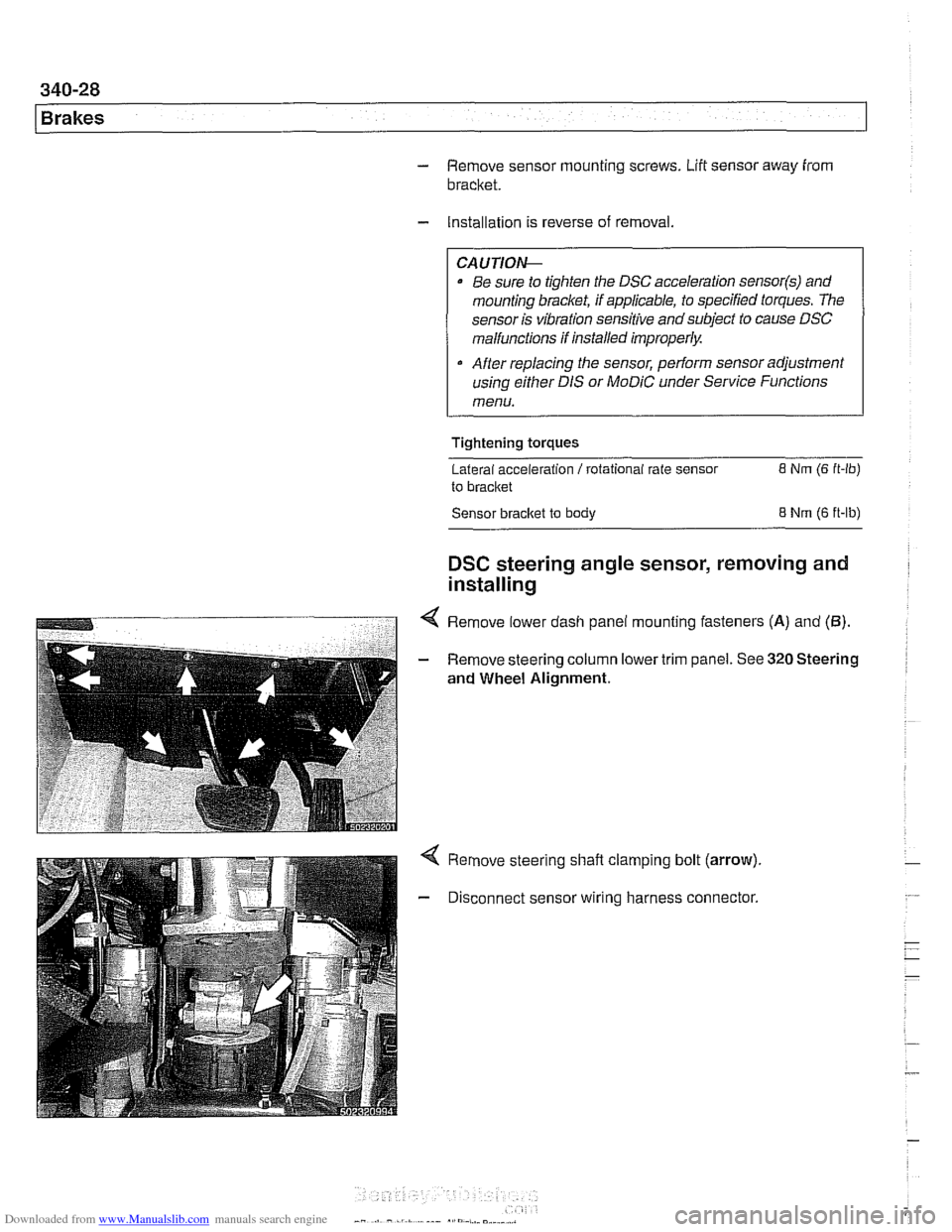

4 Rotational rate (yaw) sensor (1998 models): Remove plastic

trim at door sill to access sensor (arrow). Pull up carpet and

move insulation forward as necessary to reach sensor har-

ness connector or fasteners.

- Combined lateral acceleration / rotational rate (yaw) sensor

(1 999 and later models): Remove plastic trim at door sill to

access sensor. Pull up carpet and move insulation forward as

necessary to reach sensor harness connector or fasteners.

- Disconnect electrical harness connector at sensor.

- Combined sensor (1 999 and later models): Remove sensor

bracket mounting screws.

Page 790 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-28

Brakes

- Remove sensor mounting screws. Lift sensor away from

bracket.

- Installation is reverse of removal.

CAUTION-

Be sure to tighten the DSC acceleration sensor(s) and

mounting bracket, if applicable, to specified torques. The

sensor

is vibration sensitive and subject to cause DSC

malfunctions if installed improperly.

a After replacing the sensor, perform sensor adjustment

using either DIS or

MoDiC under Service Functions

menu.

Tightening

torques

Lateral acceleration I rotational rate sensor 8 Nm (6 R-ib)

to bracket

Sensor bracket to body

8 Nm (6 ft-lb)

DSC steering angle sensor, removing and

installing

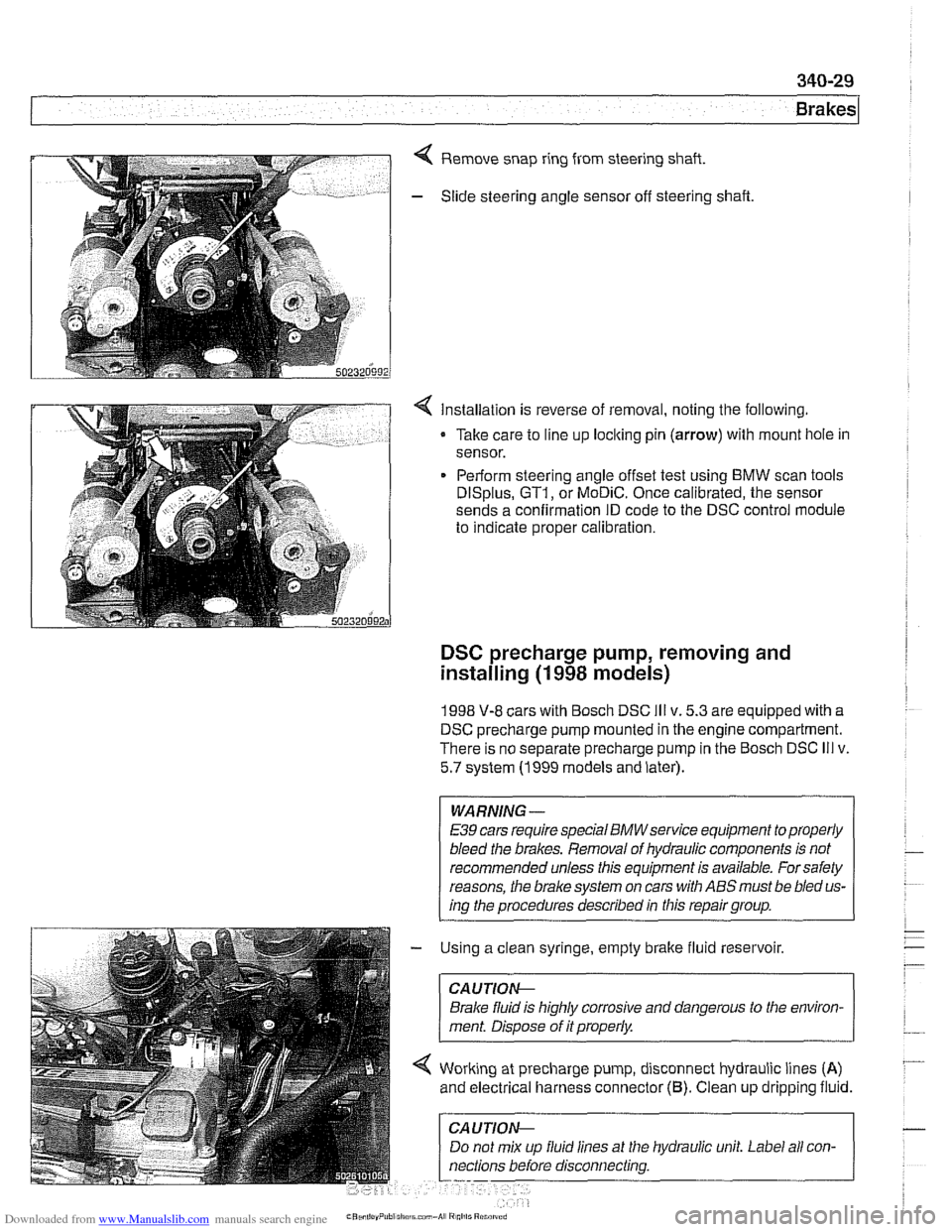

4 Remove lower dash panel mounting fasteners (A) and (5).

- Remove steering column lower trim panel. See 320 Steering

and Wheel Alignment.

Remove steering shaft clamping bolt (arrow).

Disconnect sensor wiring harness connector.

Page 791 of 1002

Downloaded from www.Manualslib.com manuals search engine

Remove snap ring from steering shaft.

- Slide steering angle sensor off steering shaft

< Installation is reverse of removal, noting the following.

Take care to line up loclting pin

(arrow) with mount hole in

sensor.

Perform steering angle offset test using BMW scan tools

DISplus, GT1, or MoDiC. Once calibrated, the sensor

sends a confirmation ID code to the DSC control module

to indicate proper calibration.

DSC precharge pump, removing and

installing

(1 998 models)

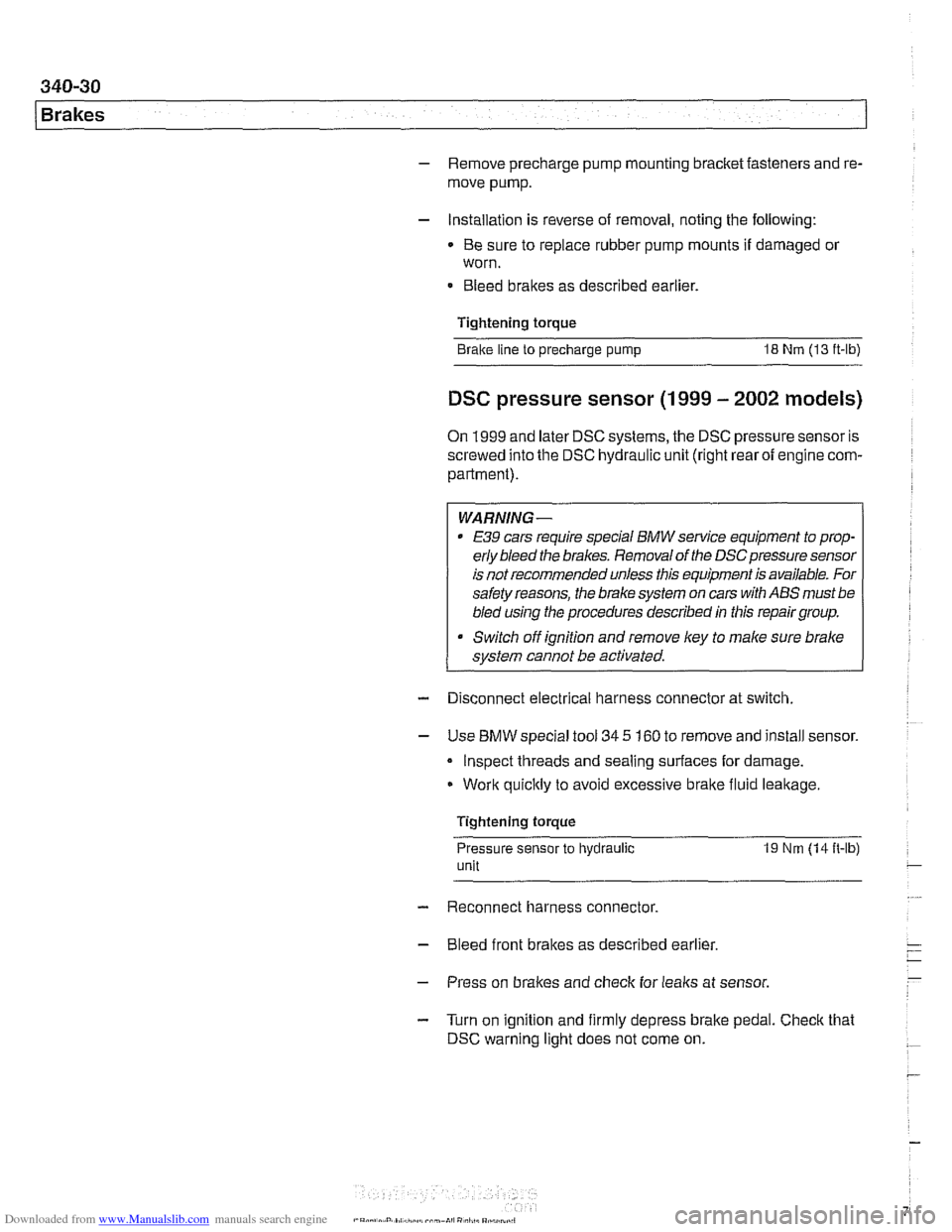

1998 V-8 cars with Bosch DSC Ill v. 5.3 are equipped with a

DSC precharge pump mounted in the engine compartment.

There is no separate precharge pump in the Bosch DSC

Ill v.

5.7 system (1999 models and later).

WARNING-

E39 cars require special BMWservice equipment to properly

bleed the brakes. Removal of hydraulic components is not

recommended unless this equipment is available. For safety

reasons, the

brake system on cars with ABS must be bled us-

ing the procedures described in this repair group.

- Using a clean syringe, empty brake fluid reservoir.

CAUTIOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Disoose of it

orooerlv.

Working at precharge pump, disconnect hydraulic lines (A)

and electrical harness connector (6). Clean up dripping fluid.

hydraulic unit. Label all

con-

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 793 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-31

Brakes

ABS 1 traction electronic control module

(1 997 -1 998 models)

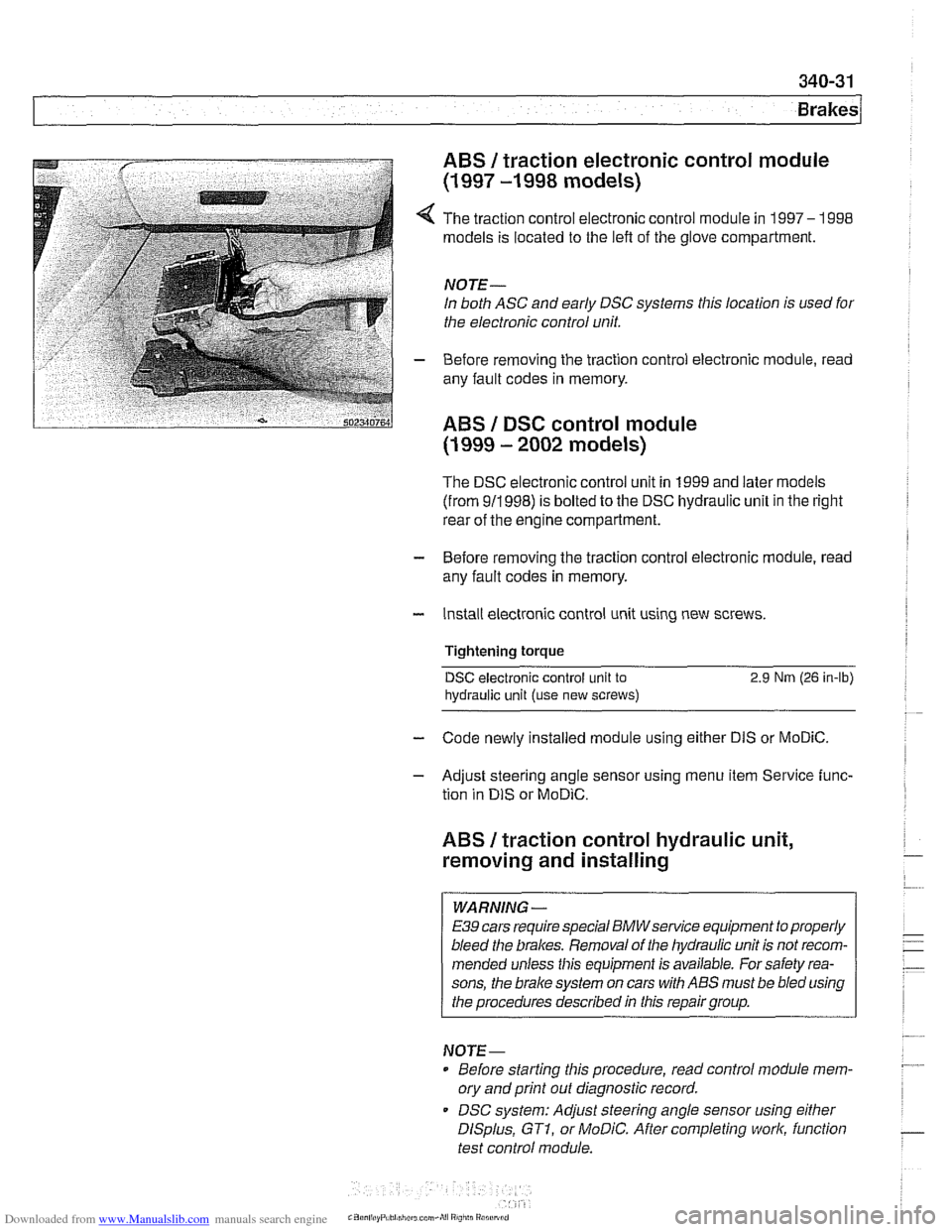

4 The traction control electronic control module in 1997- 1998

models is located to the left of the glove compartment.

NOTE-

In both ASC and early DSC systems this location is used for

the electronic control unit.

- Before removing the traction control electronic module, read

any fault codes in memory.

ABS I DSC control module

(1 999 - 2002 models)

The DSC electronic control unit in 1999 and later models

(from 911998) is bolted to the DSC hydraulic unit in the right

rear of the engine compartment.

- Before removing the traction control electronic module, read

any fault codes in memory.

- Install electronic control unit using new screws.

Tightening torque

DSC electronic control unit to 2.9 Nrn (26 in-lb)

hydraulic

unit (use new screws)

- Code newly installed module using either DIS or MoDiC.

- Adjust steering angle sensor using menu item Service func-

tion in

DIS or MoDiC.

ABS I traction control hydraulic unit,

removing and installing

WARNING -

E39 cars require special BMWsewice equipment to properly

bleed the brakes. Removal of the hydraulic unit is not recom-

mended unless this equipment is available. For safety rea-

sons, the

brake system on cars with ABS must be bled using

the procedures described in this repair group.

NOTE-

Before starting this procedure, read control module mem-

ory and print

out diagnostic record.

DSC system: Adjust steering angle sensor using

either

DISplus, GTI, or MoDiC. After completing work, function

test control module.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

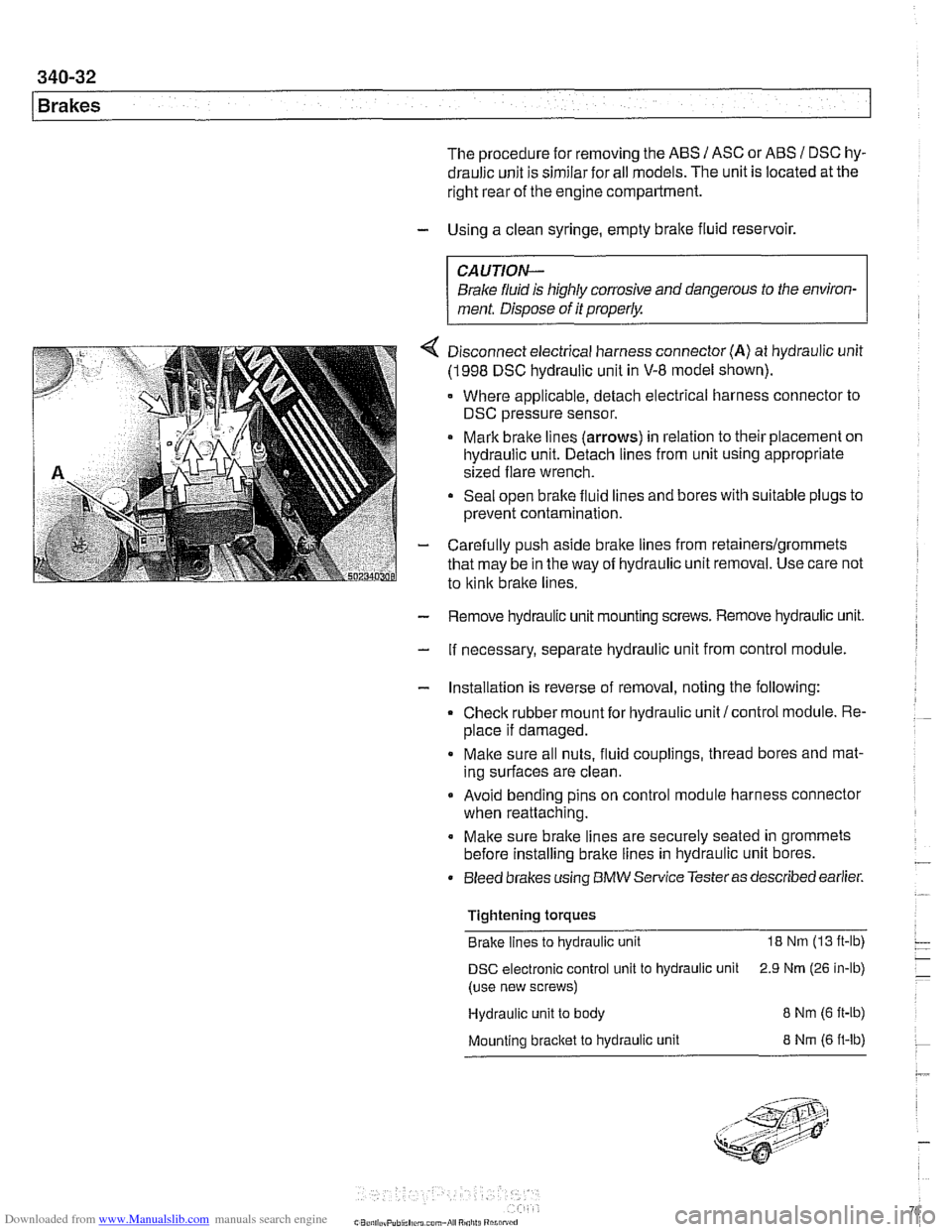

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)