Coolant hose BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 109 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation / -

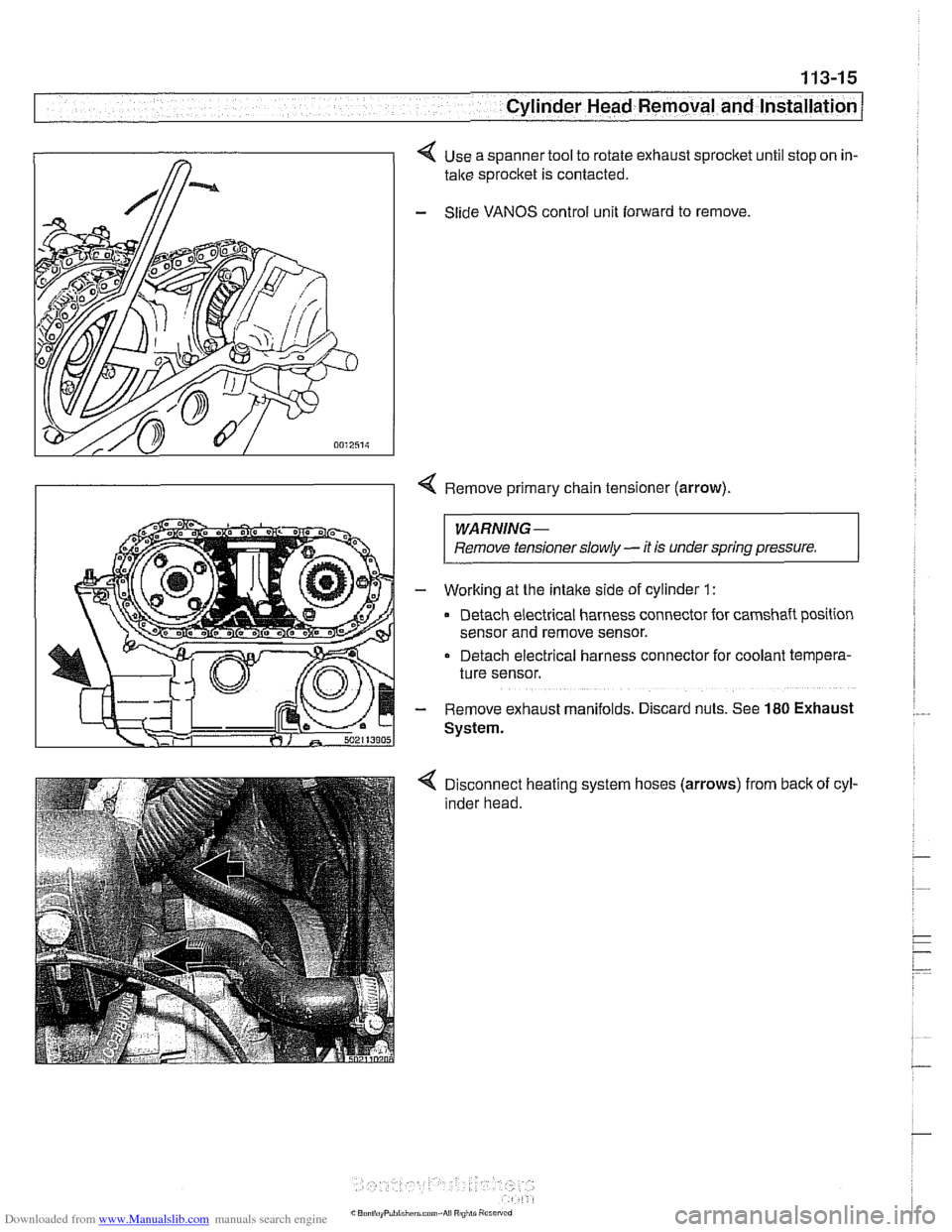

< Use a spanner tool to rotate exhaust sprocket until stop on in-

take sprocket is contacted.

- Slide VANOS control unit forward to remove

Remove primary chain tensioner (arrow)

WARNING -

Remove tensioner slowly - it is under spring pressure. I

- Working at the intake side of cylinder 1 :

Detach electrical harness connector for camshaft position

sensor and remove sensor.

Detach electrical harness connector for coolant tempera-

ture sensor.

- Remove exhaust manifolds. D~scard nuts. See 180 Exhaust

System.

Disconnect heating system hoses (arrows) from back of cyl-

inder head.

Page 122 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation

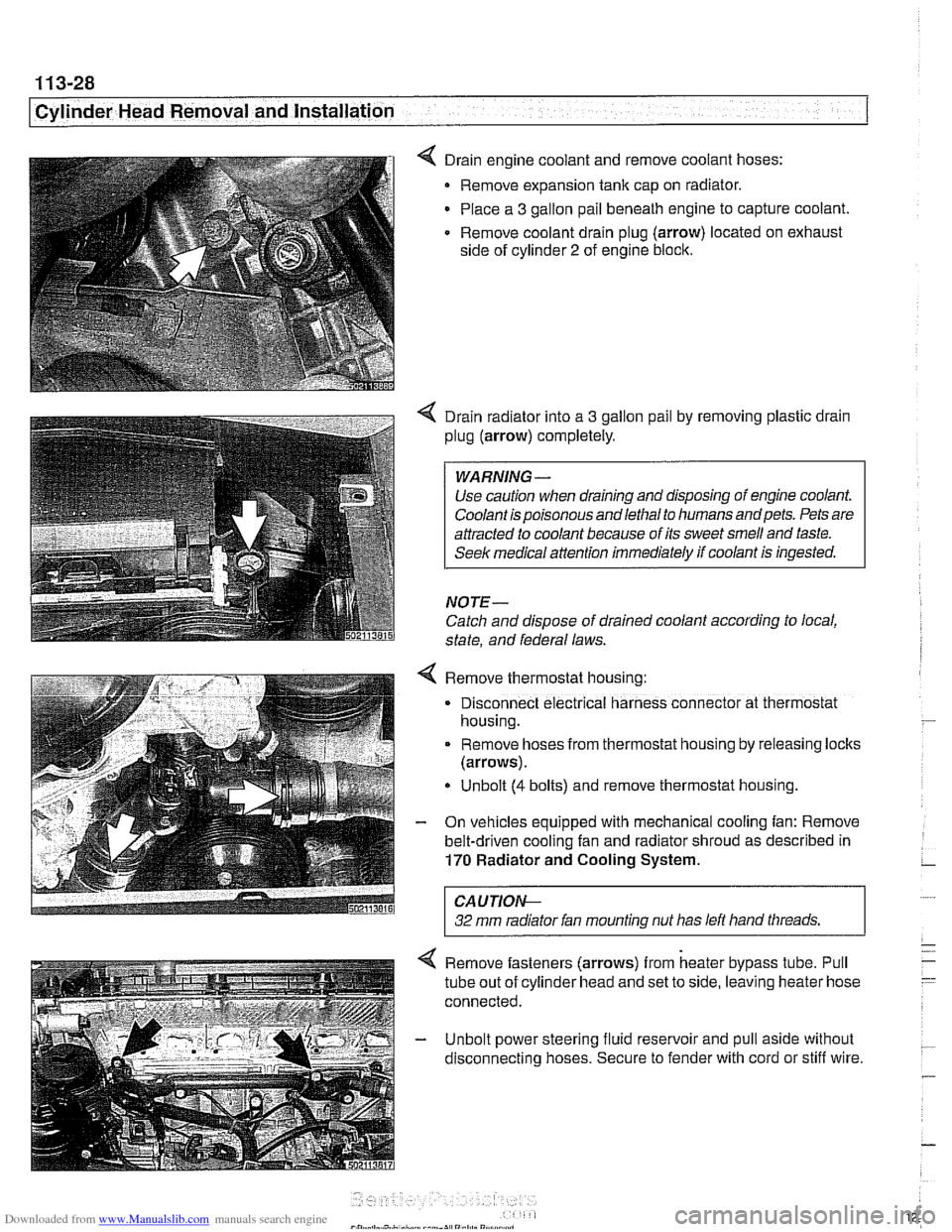

4 Drain engine coolant and remove coolant hoses:

Remove expansion tank cap on radiator.

Place a

3 gallon pail beneath engine to capture coolant

Remove coolant drain plug (arrow) located on exhaust

side of cylinder

2 of engine block.

4 Drain radiator into a 3 gallon pail by removing plastic drain

plug (arrow) completely.

Use caution when draining and disposing of engine coolant.

Coolant is poisonous andlethal to humans andpets. Pets are

attracted to coolant because of its sweet smell and taste.

Seek medical

attention immediately if coolant is ingested.

NOTE-

Catch and dispose of drained coolant according to local,

state, and federal laws.

4 Remove thermostat housing:

. Disconnect electrical harness connector at thermostat

housing.

. Remove hoses from thermostat hous~ng by releasing loclts

(arrows).

Unbolt

(4 bolts) and remove thermostat hous~ng.

- On vehicles equipped with mechanical cooling fan: Remove

belt-driven cooling fan and radiator shroud as described in

170 Radiator and Cooling System.

CAUTIOI\C

32 mm radiator fan mounting nut has left hand threads. r

4 Remove fasteners (arrows) from heater bypass tube. Pull

tube out of cylinder head and set to side, leaving heater hose

connected.

- Unbolt power steering fluid reservoir and pull aside without

disconnecting hoses. Secure to fender with cord or stiff wire.

Page 155 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-61

Cylinder Head Removal and installation I

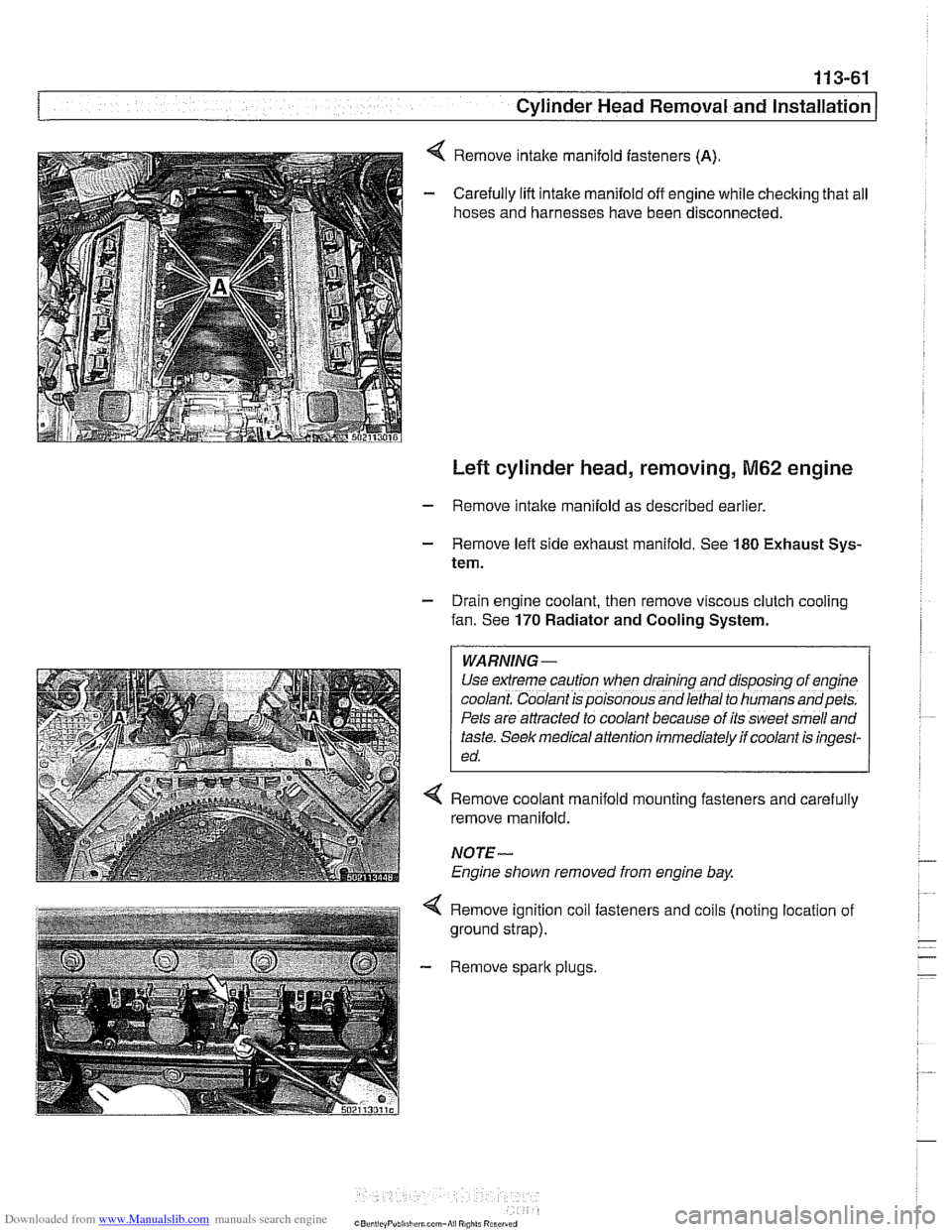

Remove intake manifold fasteners (A).

Carefully lift intake manifold off engine while checking that all

hoses and harnesses have been disconnected.

Left cylinder head, removing, M62 engine

- Remove intake manifold as described earlier

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Drain engine coolant, then remove viscous clutch cooling

fan. See

170 Radiator and Cooling System.

WARNING -

Use extreme caution when draining and disposfng of eng~ne

coolant. Coolant is poisonous and lethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste.

Seek med~cal attention immediately if coolant is ingest-

ed.

4 Remove coolant manifold mounting fasteners and carefully

remove manifold.

NOTE-

Engine shown removed from engine bay

4 Remove ignition coil fasteners and coils (noting location of

ground strap).

- Remove spark plugs.

Page 218 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-42

/ Cvlinder Head and Valvetrain

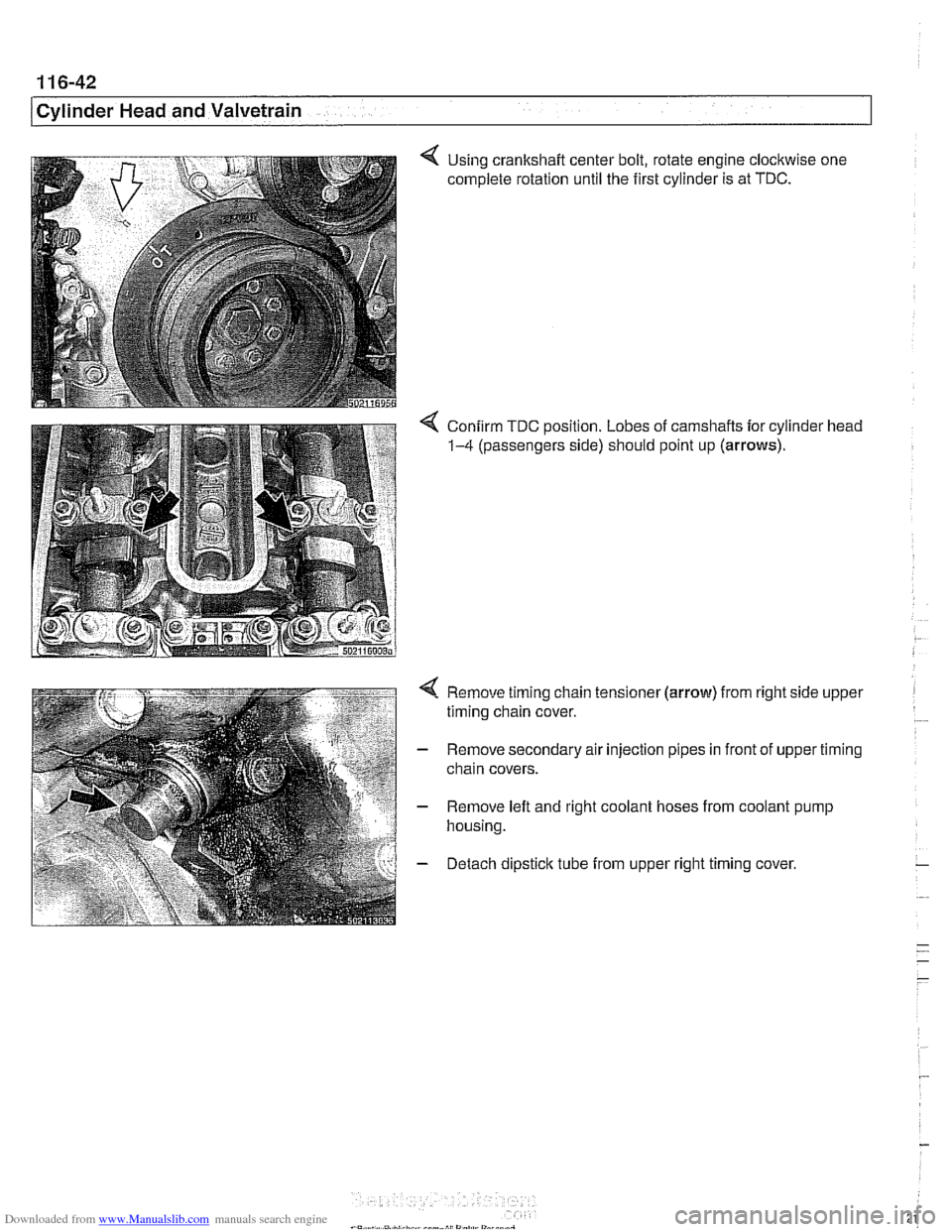

4 Using crankshaft center bolt, rotate engine clockwise one

complete rotation until the first cylinder is at TDC.

4 Confirm TDC position. Lobes of camshafts for cylinder head

1-4 (passengers side) should point up (arrows).

4 Remove timing chain tensioner (arrow) from right side upper

timing chain cover.

- Remove secondary air injection pipes in front of upper timing

chain covers.

- Remove left and right coolant hoses from coolant pump

housing.

- Detach dipsticlc tube from upper right timing cover,

Page 262 of 1002

Downloaded from www.Manualslib.com manuals search engine

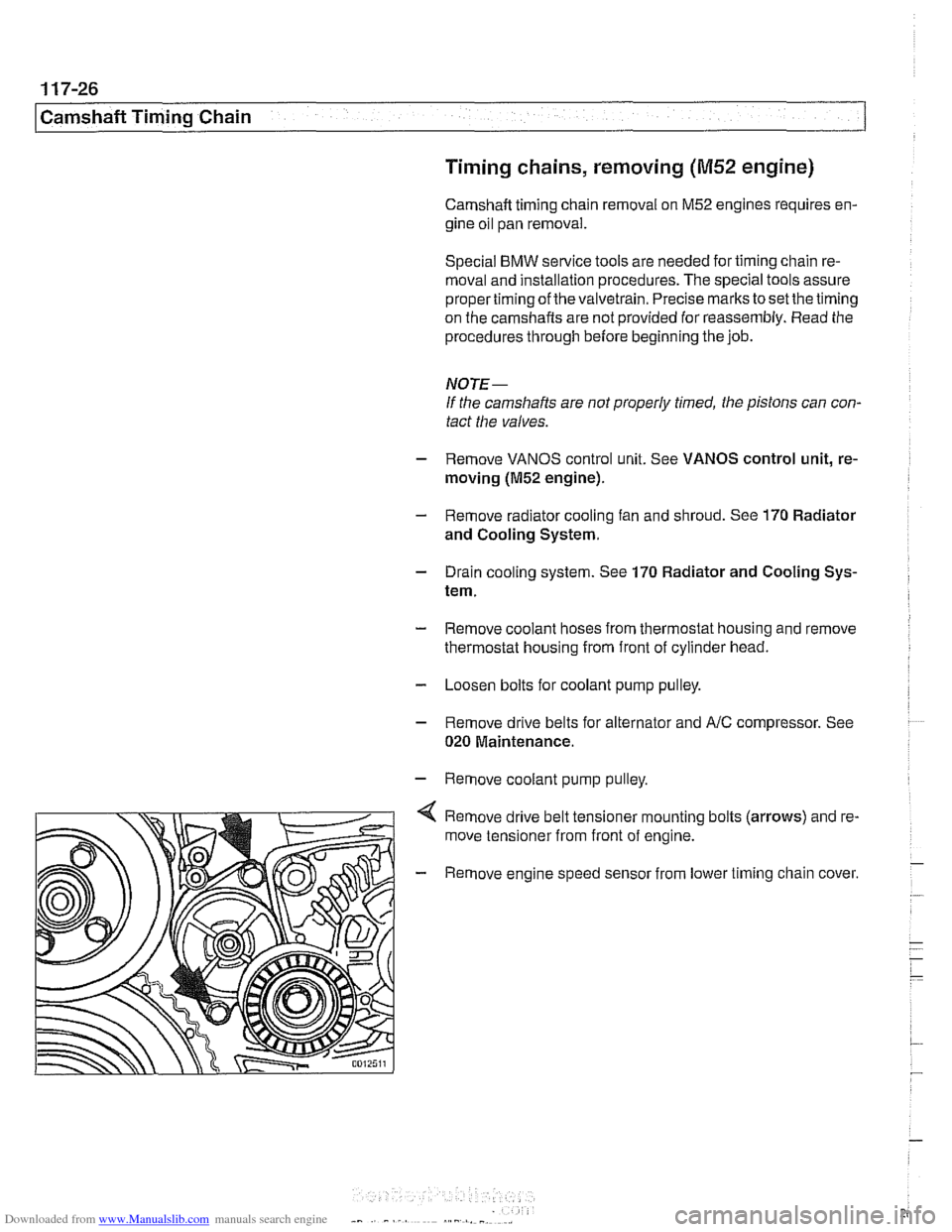

Camshaft Timing Chain Timing chains, removing

(M52 engine)

Camshaft timing chain removal on M52 engines requires en-

gine oil pan removal.

Special

BMW sewice tools are needed for timing chain re-

moval and installation procedures. The special tools assure

propertiming of thevalvetrain. Precise marks to

setthe timing

on the camshafts are not provided for reassembly. Read the

procedures through before beginning the job.

NOTE-

If the camshafts are not properly timed, the pistons can con-

tact the valves.

- Remove VANOS control unit. See VANOS control unit, re-

moving (M52 engine).

- Remove radiator cooling fan and shroud. See 170 Radiator

and Cooling System.

- Drain cooling system. See 170 Radiator and Cooling Sys-

tem.

- Remove coolant hoses from thermostat housing and remove

thermostat housing from front of cylinder head.

- Loosen bolts for coolant pump pulley.

- Remove drive belts for alternator and AIC compressor. See

020 Maintenance.

- Remove coolant pump pulley.

Remove drive belt tensioner mounting bolts (arrows) and re-

move tensioner from front of engine.

- Remove engine speed sensor from lower timing chain cover.

Page 302 of 1002

Downloaded from www.Manualslib.com manuals search engine

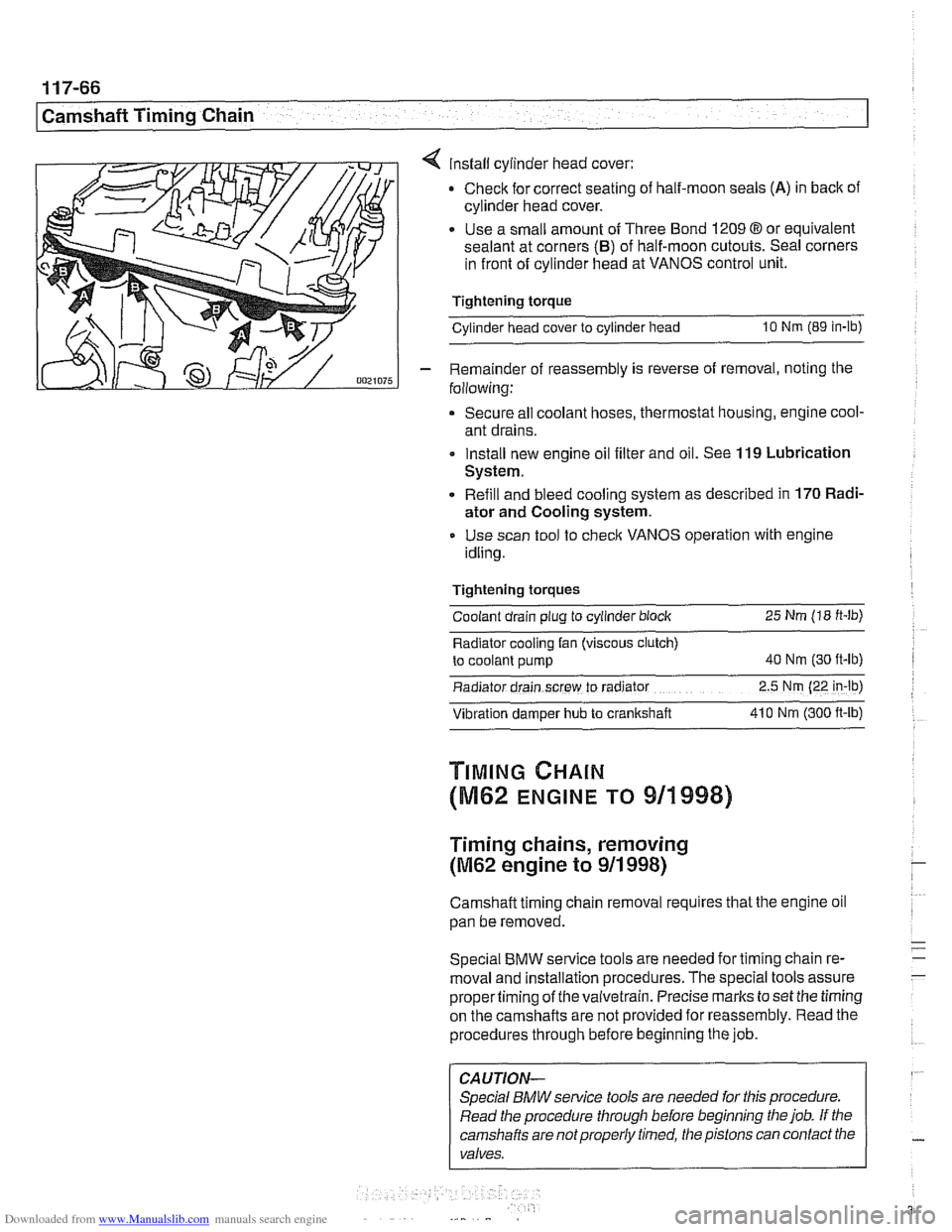

11 7-66

I Camshaft Timing Chain

4 install cylinder head cover:

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts. Seal corners

in front of cylinder head at VANOS control unit.

Tightening torque

Cylinder head cover to cylinder head

10 Nm (89 in-lb)

- Remainder of reassembly is reverse of removal, noting the

following:

Secure all coolant hoses, thermostat housing, engine cool-

ant drains.

Install new engine oil filter and oil. See

119 Lubrication

System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling system.

Use scan tool to check VANOS operation with engine

idling.

Tightening torques Coolant drain plug to cylinder block

25 Nm (18 ft-lb)

Radiator cooling fan (viscous clutch)

to coolant pump

40 Nm (30 ft-lb)

Radiator drain screw to radrator 2.5 Nm (22 in-lb)

Vibration damper hub to crankshaft 41 0 Nm

(300 ft-ib)

TIMING CHAIN

(M62 ENGINE TO 911998)

Timing chains, removing

(M62 engine to 911 998)

Camshaft timing chain removal requires that the engine oil

pan be removed.

Special

BMW service tools are needed for timing chain re-

moval and installation procedures. The special tools assure

propertiming of thevaivetrain. Precise marks to set the timing

on the camshafts are not provided for reassembly. Read the

procedures through before beginning the job.

CAUTION-

Special BMW service tools are needed for this procedure.

Read the procedure through before beginning the job. If the

camshafts are notproperly timed, the pistons can contact the

valves.

Page 307 of 1002

Downloaded from www.Manualslib.com manuals search engine

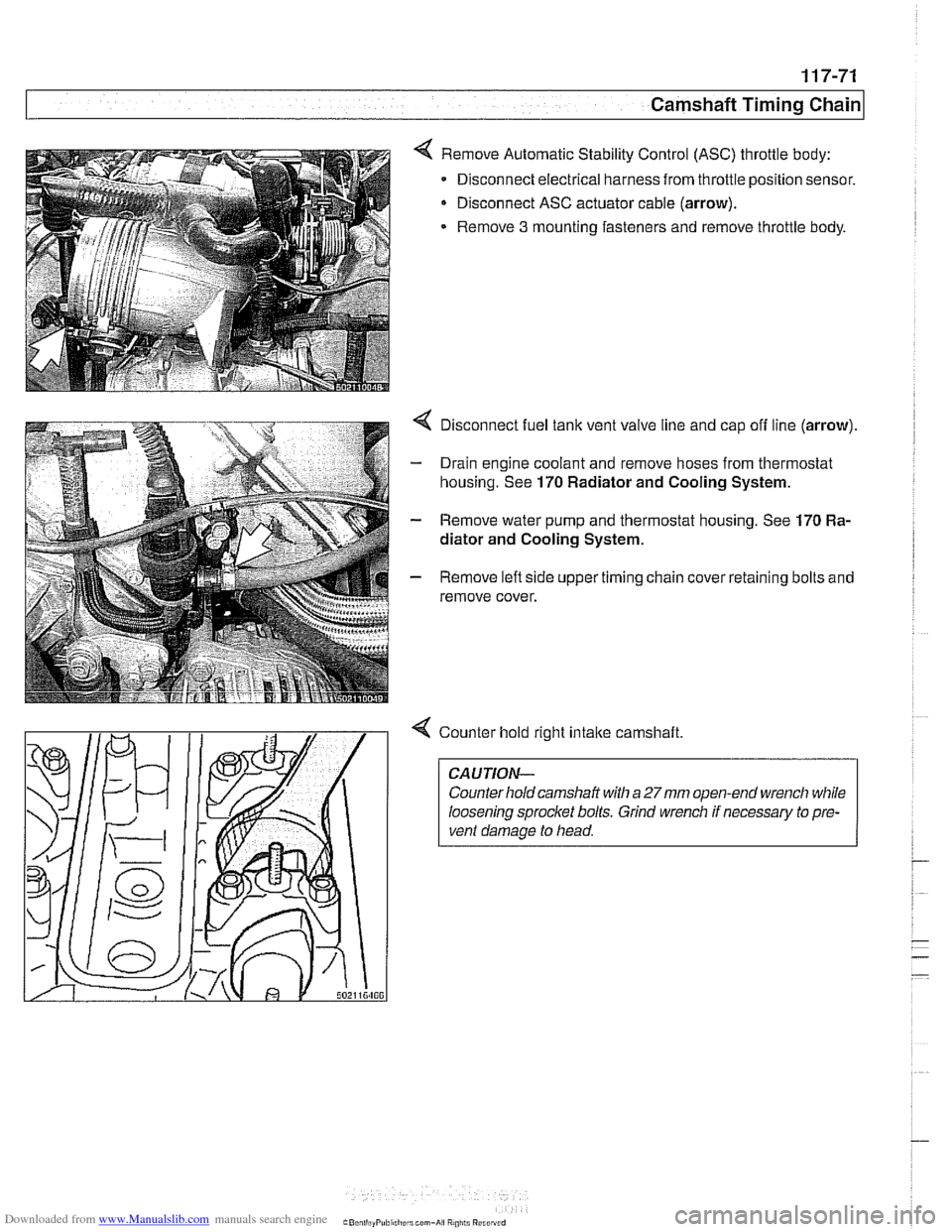

Camshaft Timing chain1

< Remove Automatic Stability Control (ASC) throttle body:

Disconnect electrical harness from throttle position sensor.

Disconnect ASC actuator cable (arrow).

Remove

3 mounting fasteners and remove throttle body.

4 Disconnect fuel tank vent valve line and cap off line (arrow).

- Drain engine coolant and remove hoses from thermostat

housing. See

170 Radiator and Cooling System.

- Remove water pump and thermostat housing. See 170 Ra-

diator and Cooling System.

- Remove left side upper timing chain cover retaining bolts and

remove cover.

4 Counter hold right intake camshaft

CAUTION-

Counter hold camshaft with a 27mm open-end wrench while

loosening sprocket bolts. Grind wrench if necessary to pre-

vent damage to head.

Page 384 of 1002

Downloaded from www.Manualslib.com manuals search engine

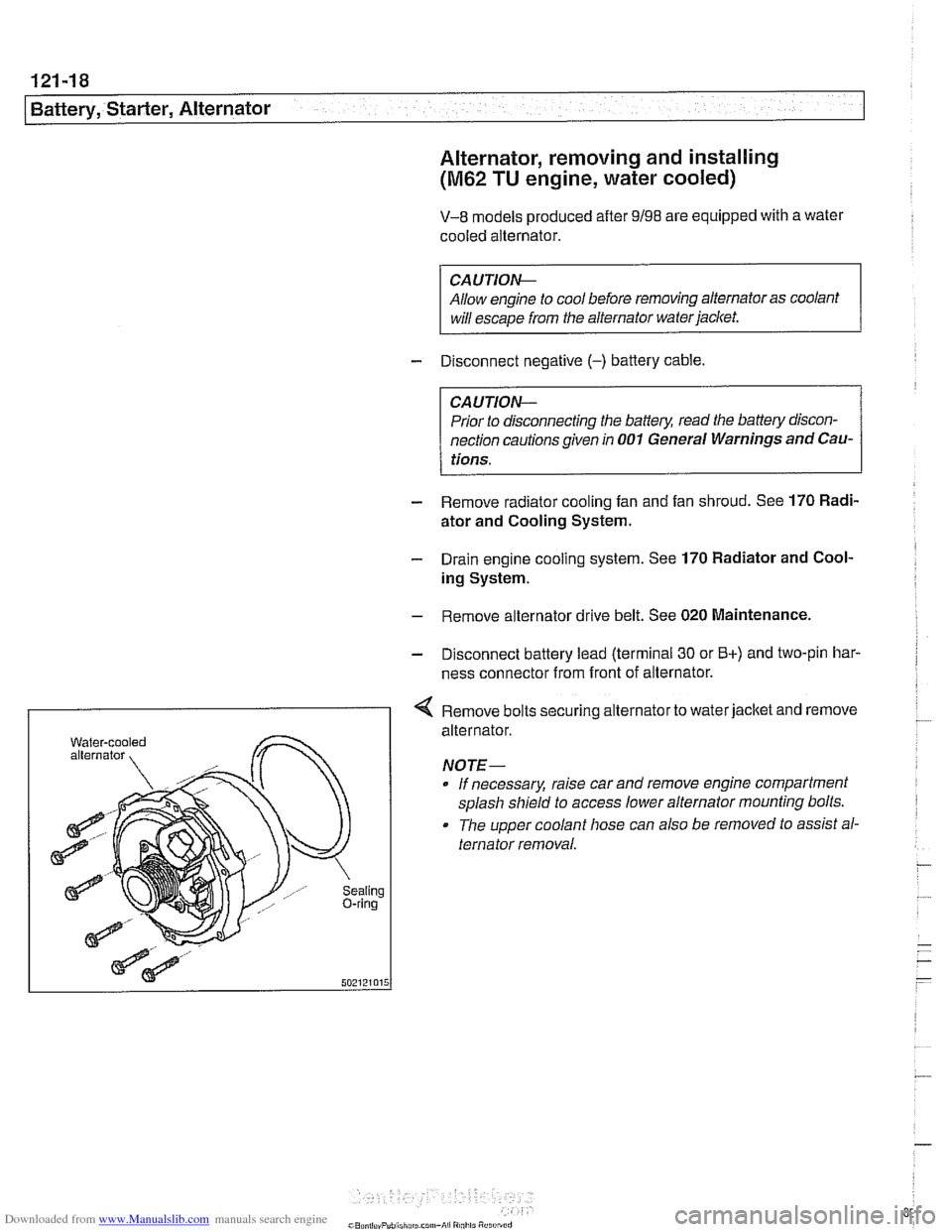

121-18

I Battery, Starter, Alternator

Alternator, removing and installing

(M62 TU engine, water cooled)

V-8 models produced after 9/98 are equipped with a water

cooled alternator.

CAUTION-

Allow engine to cool before removing alternator as coolant

will

escape from the alternator water jacket.

- Disconnect negative (-) battery cable

CAUTION- Prior to disconnecting the

battew read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

- Drain engine cooling system. See 170 Radiator and Cool-

ing System.

- Remove alternator drive belt. See 020 Maintenance.

- Disconnect battery lead (terminal 30 or B+) and two-pin har-

ness connector from front of alternator.

I < Remove bolts securing alternator to water jacket and remove

aling ring

alternator.

NOTE- If necessary, raise car and remove engine compartment

splash shield to access lower alternator mounting bolts.

The upper coolant hose can also

be removed to assist al-

ternator removal.

Page 400 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 0

Fuel Injection

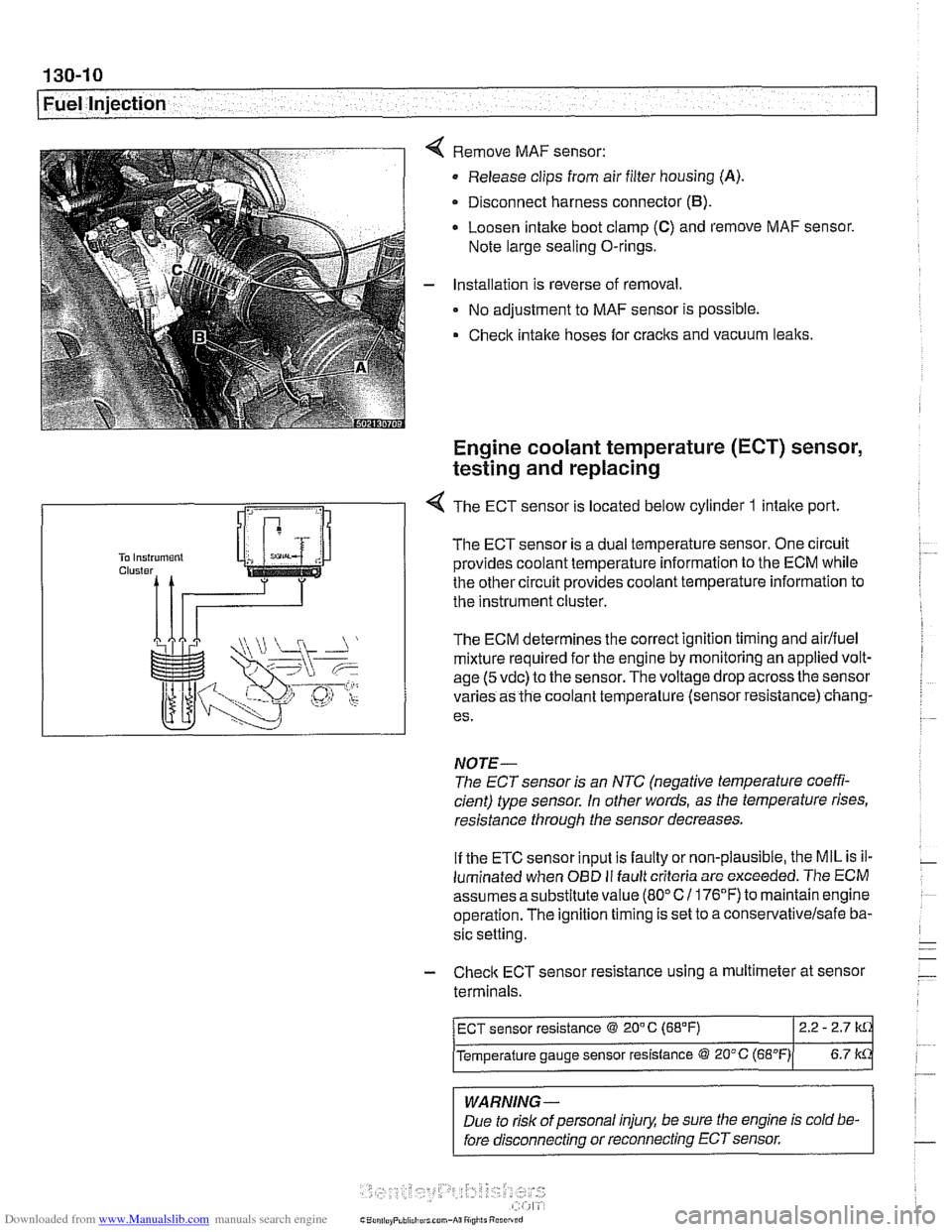

Remove MAF sensor:

Release clips from air filter housing

(A).

Disconnect harness connector (B).

Loosen intake boot clamp (C) and remove MAF sensor.

Note large sealing O-rings.

Installation is reverse of removal.

No adjustment to MAF sensor is possible.

Check intake hoses for cracks and vacuum leaks.

Engine coolant temperature (ECT) sensor,

testing and replacing

R

1 -4 The ECT sensor is located below cylinder 1 intake port

The ECT sensor is a dual temperature sensor. One circuit

provides coolant temperature information to the ECM while

the other circuit provides coolant temperature information to

the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. in other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when

OED II fault criteria are exceeded. The ECM

assumes asubstitute value

(80°C1 176°F) to maintainengine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

- Check ECT sensor resistance using a multimeter at sensor

terminals.

-

WARNING -

Due to risk of personal injury, be sure the engine is cold be-

fore disconnecting or reconnecting ECT sensor.

ECT sensor resistance @ 20" C (68°F) 2.2 - 2.7

Temperature gauge sensor resistance @ 20°C (~B"F)( 6.7 k

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

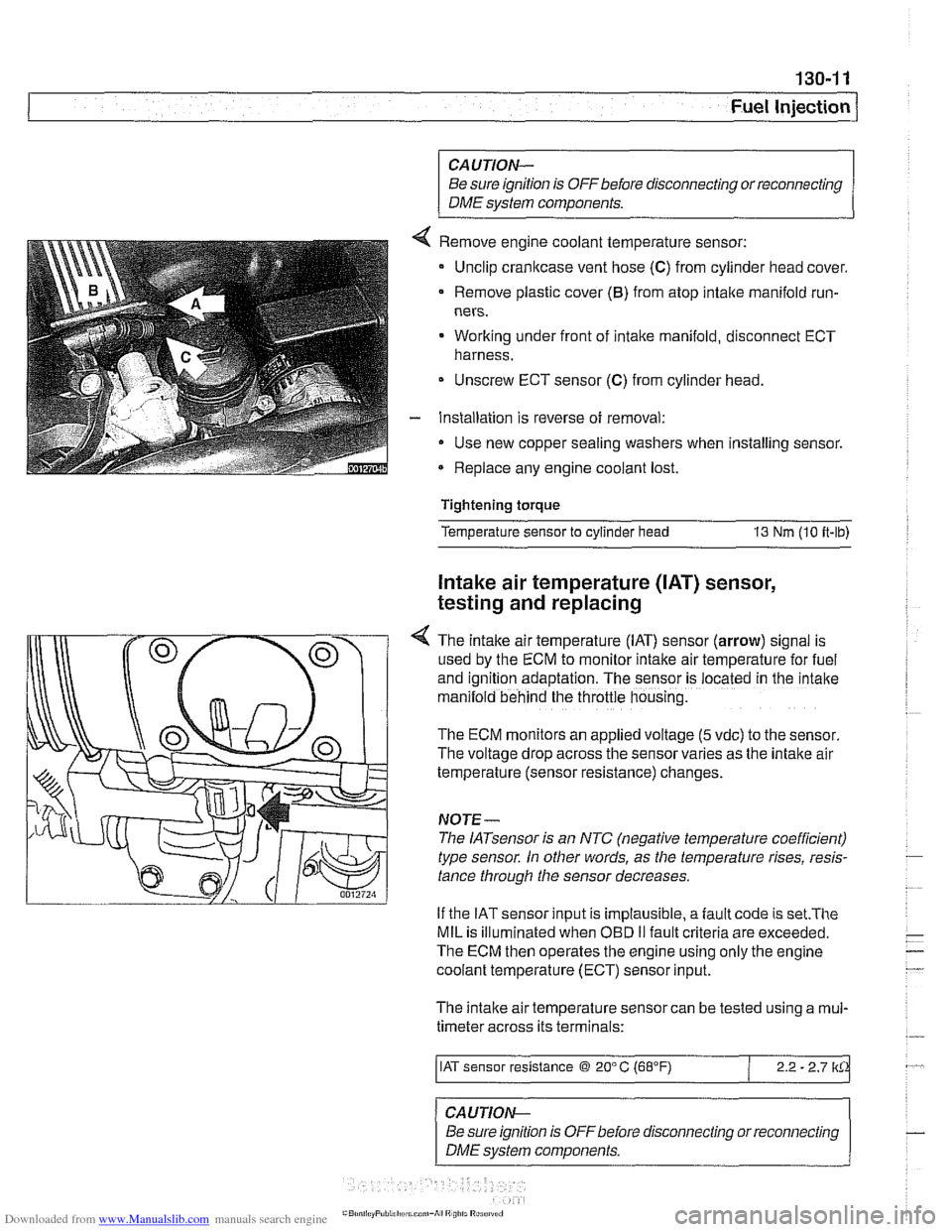

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.