Coolant hose BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 31 of 1002

Downloaded from www.Manualslib.com manuals search engine

Spare parts kit

Carrying a basic set of spare parts can prevent a rninorbreak-

down from turning into a major repair annoyance. The list be-

low is a good place to start.

Spare parts kit

- basic

Polyribbed drive

belt(s)

BMW engine oil: one or two quarts

BMW engine coolant:

1 gallon of premixed 50150 BMW

anti-freeze and water

Fuse assortment:

7.5A. IOA, 1 5A, 20A, 30A. 50A

Radiator hoses: upper and lower

Spare parts

kit - additional contents

Exterior lighting bulbs: headlight, bralte light, turn signal,

and taillight

* Wiper blades or blade inserts

Brake fluid: new, unopened bottle, DOT

4 specification

Main relay for DME system

Page 39 of 1002

Downloaded from www.Manualslib.com manuals search engine

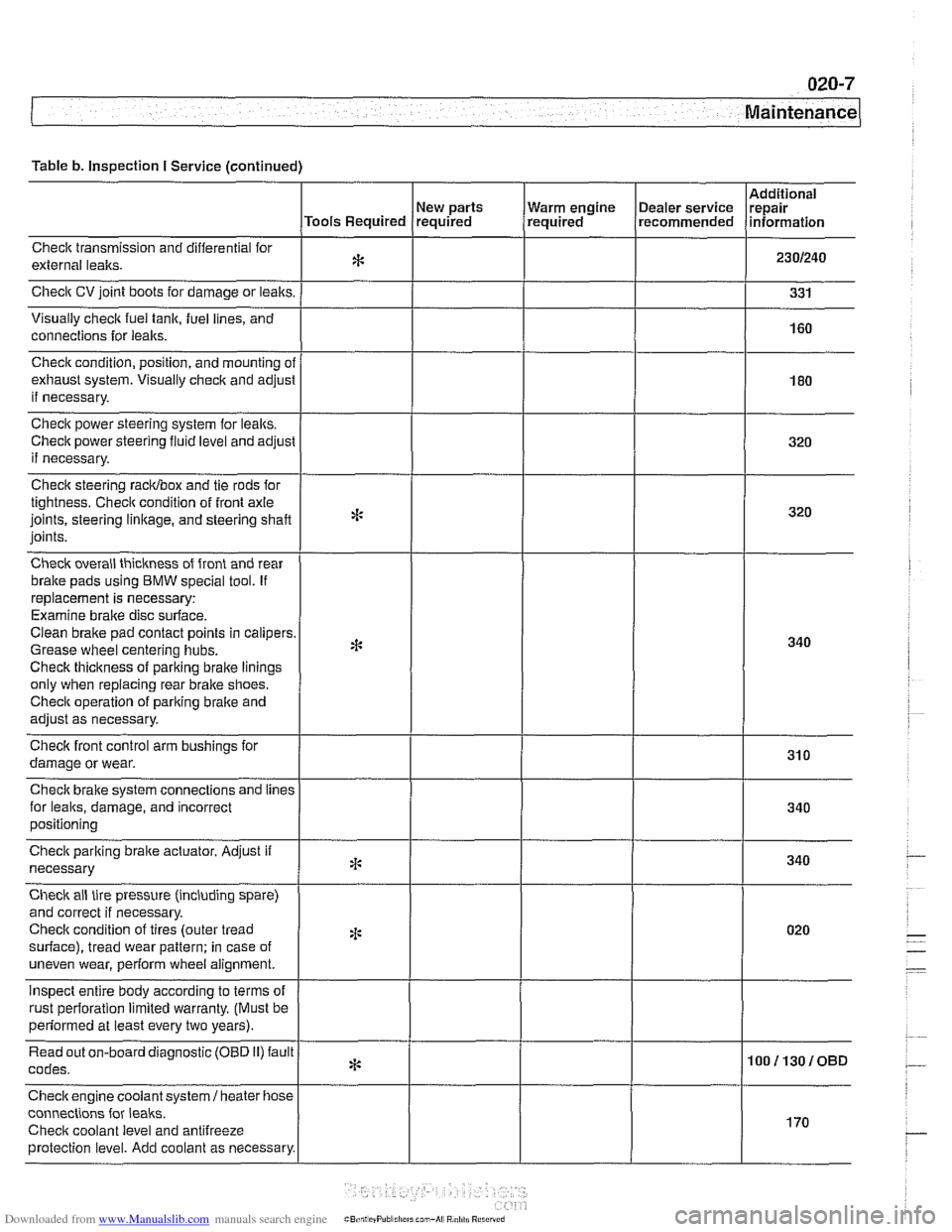

Table b. Inspection I Service (continued)

Checlt transmission and differential for

external lealts.

Check CV joint boots for damage or leaks.

Visually

check fuel tank, fuel lines, and

connections for

leaks.

New parts

Tools Required required

Check condition, position, and mounting

ol

exhaust system. Visually check and adjusl

if necessary.

Check power steering system for lealts.

Check power steering

fluid level and adjust

if necessary.

Check steering racidbox and tie rods for

tightness. Checit condition of front axle

joints, steering

linkage, and steering shaft

joints.

Check overall thickness of front and rear

bralte pads using

BMW special tool. If

replacement is necessary:

Examine brake disc surface.

Clean brake pad contact points in calipers

Grease wheel centering hubs.

Checlt thickness of parking brake linings

only when replacing rear brake shoes.

Checit operation of pariting brake and

adjust as necessary.

Checlt front control arm bushings for

damage or wear.

Check brake system connections and

lines

for leaks, damage, and incorrect

positioning Warm

engine

(~ealer service Irepair , required recommended lnformat~on

Check parking braite actuator. Adjust if

necessary

Check ail tire pressure (including spare)

and correct if necessary.

Checlt condition of tires (outer tread

surface), tread wear pattern: in case of

uneven wear, perform wheel alignment.

inspect entire body according to terms of

rust oerforation limited warrantv. (Must be

*:

4:

2 ~ perfdrmed at least every two years). I

Read out on-board diagnostic (OBD 11) fault

codes.

Checkengine coolant

system1 heater hose

connections for

leaks.

Checit coolant level and antifreeze

protection level. Add coolant as necessary.

* 100113010BD

I

170

Page 47 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

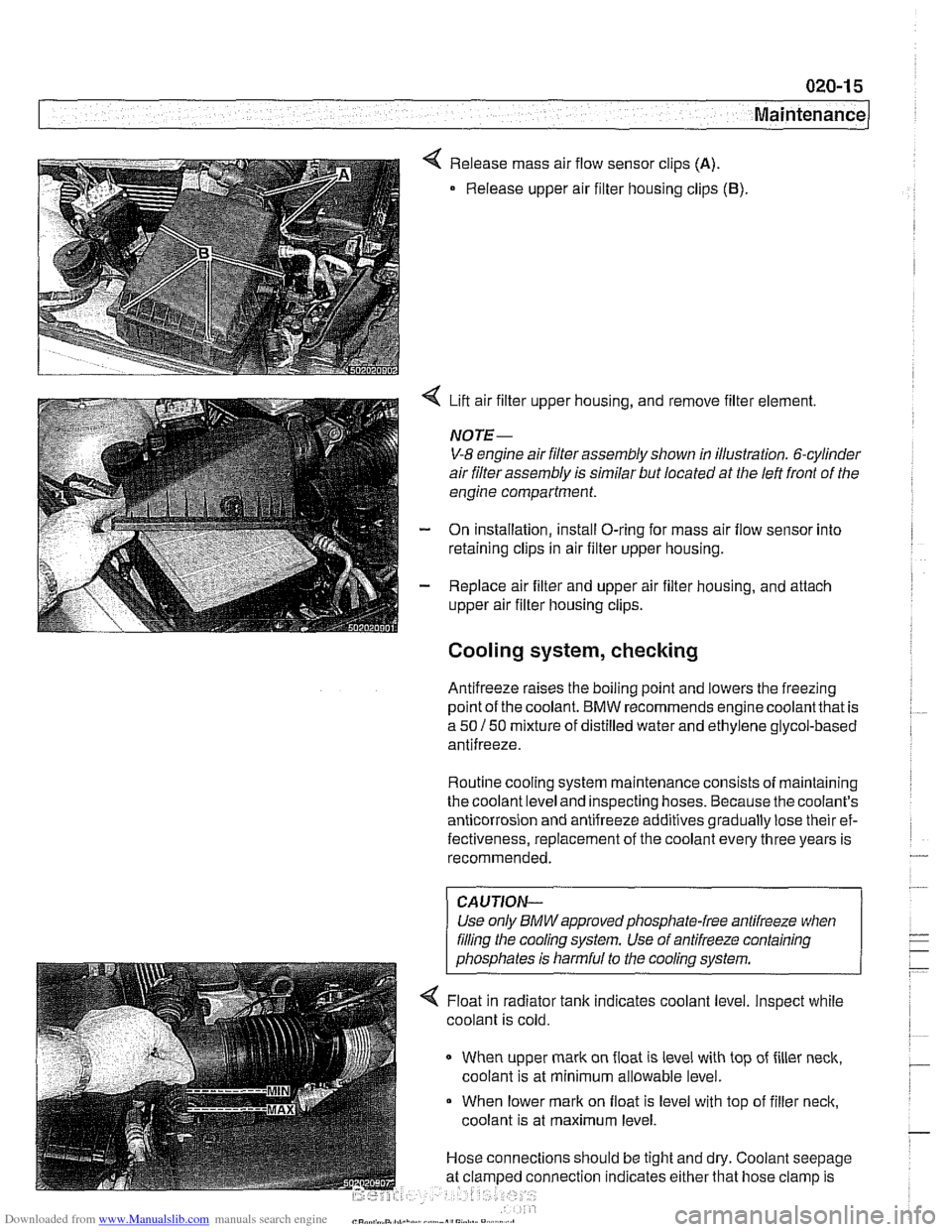

< Release mass air flow sensor clips (A).

Release upper air filter housing clips (B).

4 Lift air filter upper housing, and remove filter element.

NOTE-

V-8 engine air filter assembly shown in illustration. 6-cylinder

air filter assembly is similar but located at the left front of the

engine compartment.

- On installation, install O-ring for mass air flow sensor into

retaining clips in air filter upper housing.

- Replace air filter and upper air filter housing, and attach

upper air filter housing clips.

Cooling system, checking

Antifreeze raises the boiling point and lowers the freezing

~oint of the coolant. BMW recommends enaine coolantthat is

a 50 150 mixture of distilled water and ethGene glycol-based

antifreeze.

Routine cooling system maintenance consists of maintaining

the coolant level and inspecting hoses. Because the coolant's

anticorrosion and antifreeze additives gradually lose their ef-

fectiveness, replacement of the coolant every three years is

recommended.

CAUJION-

Use only BMWapprovedphosphate-free antifreeze when

filing the cooling system. Use of antifreeze containing

phosphates is harmful to the cooling system.

4 Float in radiator tank indicates coolant level. Inspect while

coolant is cold.

When upper mark on float is level with top of filler neck,

coolant is at minimum allowable level.

When lower mark on float is level with top of filler neck,

coolant is at maximum level.

Hose connections should be tight and dry. Coolant seepage

nnection indicates either that hose clamp is

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 6

Maintenance

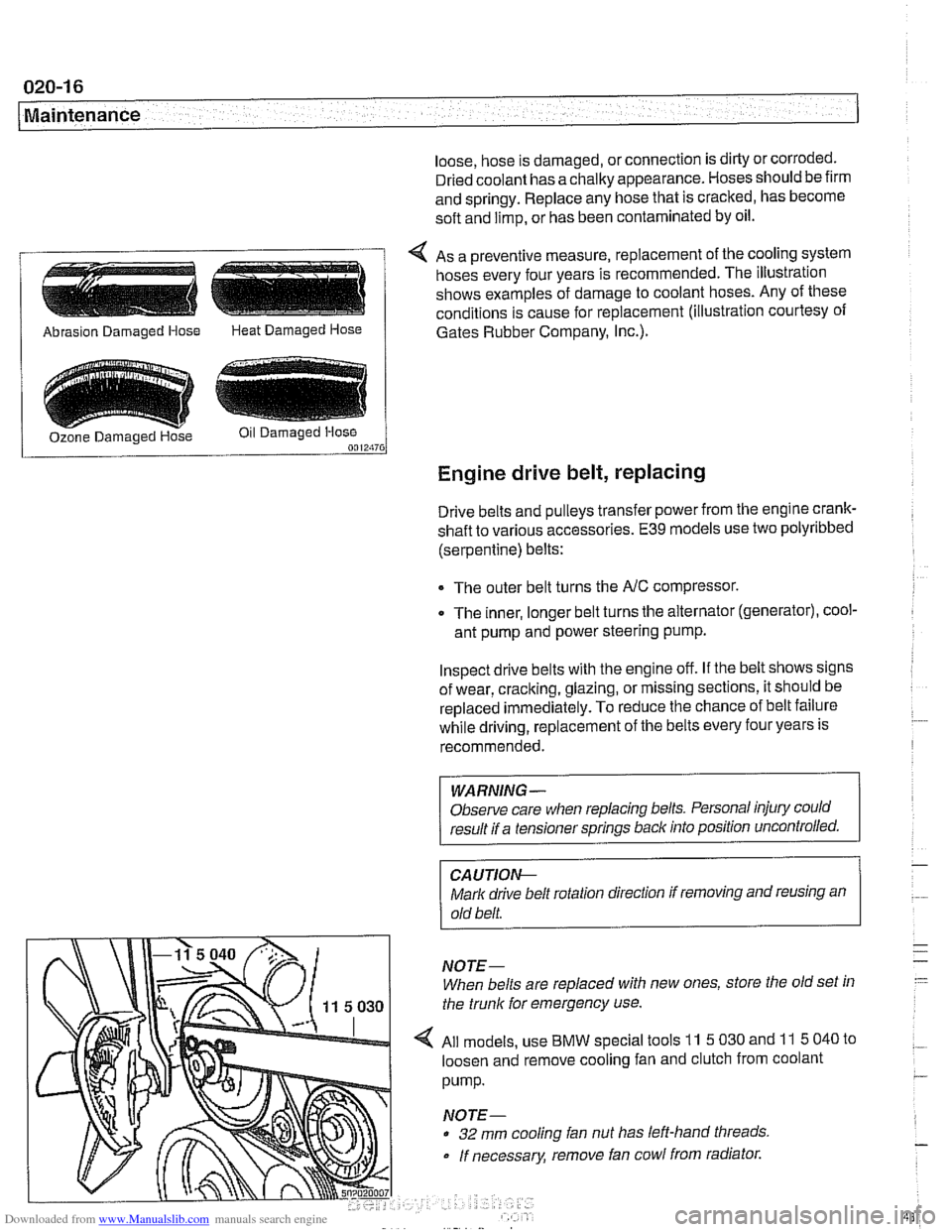

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 79 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and lnstallationl

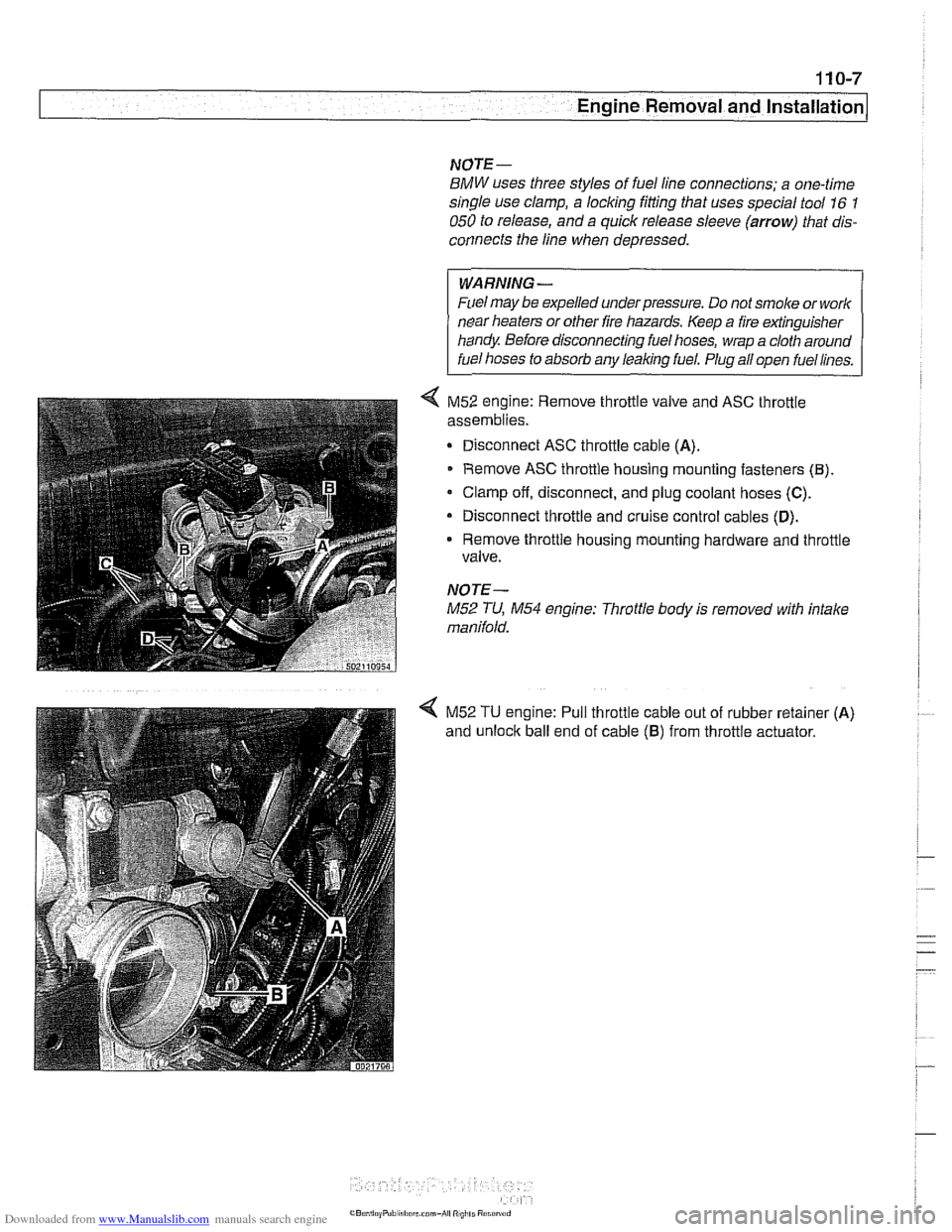

NOTE-

BMW uses three styles of fuel line connections; a one-time

single use clamp, a locking fitting that uses special tool

16 1

050 to release, and a quick release sleeve (arrow) that dis-

connects the line when depressed.

WARNING-

Fuel may be expelled under pressure. Do not smoke or work

near heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth around

fuel hoses to absorb any leaking fuel. Plug all

oDen fuel lines.

< M52 engine: Remove throttle valve and ASC throttle

assemblies.

Disconnect ASC throttle cable

(A).

Remove ASC throttle housing mounting fasteners (El).

Clamp off, disconnect, and plug coolant hoses (C).

Disconnect throttle and cruise control cables (D).

Remove throttle housing mounting hardware and throttle

valve.

NOTE-

M52 TU, M54 engine: Throttle body is removed with intake

manifold.

< M52 TU engine: Pull throttle cable out of rubber retainer (A)

and unloclc ball end of cable (6) from throttle actuator.

Page 83 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and installatid

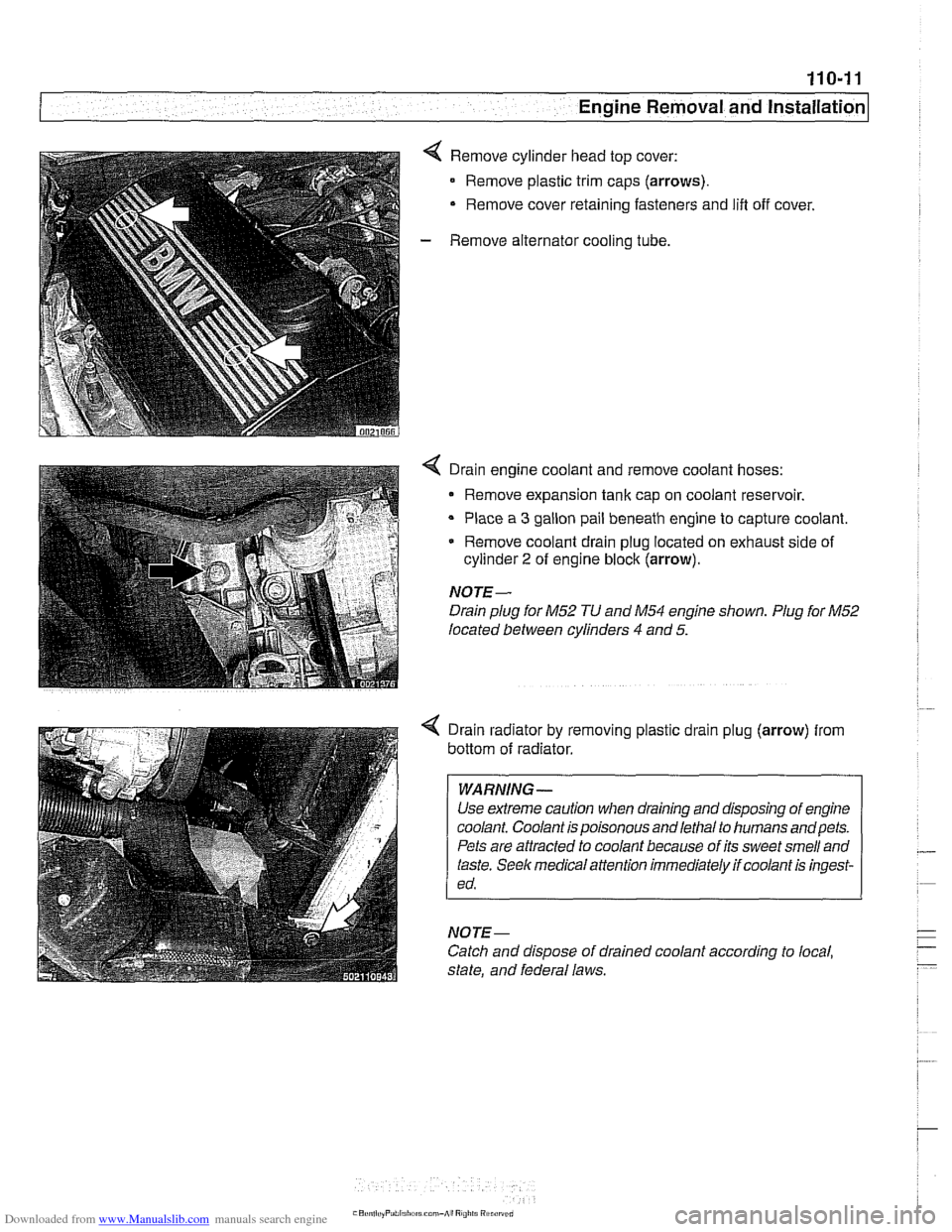

4 Remove cylinder head top cover:

Remove plastic trim caps

(arrows).

Remove cover retaining fasteners and lifl off cover.

- Remove alternator cooling tube.

4 Drain engine coolant and remove coolant hoses:

* Remove expansion tank cap on coolant reservoir.

Place a

3 gallon pail beneath engine to capture coolant,

* Remove coolant drain plug located on exhaust side of

cylinder

2 of engine block (arrow).

NOTE-

Drain plug for M52 TU and M54 engine shown. Plug for M52

located between cylinders 4 and 5.

Drain radiator by removing plastic drain plug (arrow) from

bottom of radiator.

WARNING-

Use extreme caution when draining and disposing of engine

coolant Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

ed.

NOTE-

Catch and dispose of drained coolant according to local,

state, and federal laws.

Page 84 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-12

Engine Removal and Installation

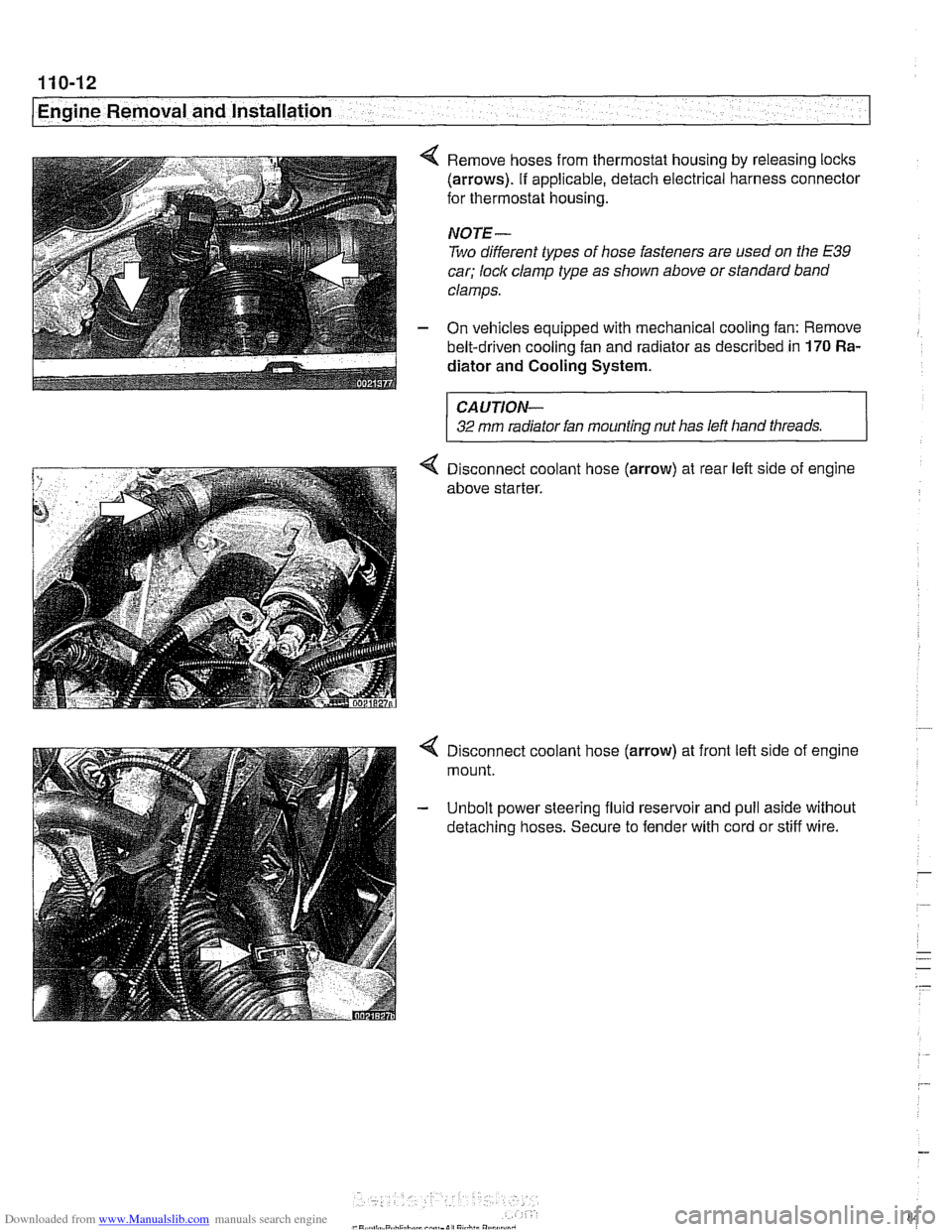

4 Remove hoses from thermostat housing by releasing locks

(arrows). If applicable, detach electrical harness connector

for thermostat housing.

NOTE-

Two different types of hose fasteners are used on the E39

car; lock clamp type as shown above or standard band

clamps.

- On vehicles equipped with mechanical cooling fan: Remove

belt-driven cooling fan and radiator as described in

170 Ra-

diator and Cooling

System.

CAUTION-

32 mm radiator fan mounting nut has left hand threads.

4 Disconnect coolant hose (arrow) at rear left side of engine

above starter.

4 Disconnect coolant hose (arrow) at front left side of engine

mount.

- Unbolt power steering fluid reservoir and pull aside without

detaching hoses. Secure to fender with cord or stiff wire.

Page 90 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Engine Removal and Installation

WARNING -

Use extreme caution when draining and disposing of engine

coolant. Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

---

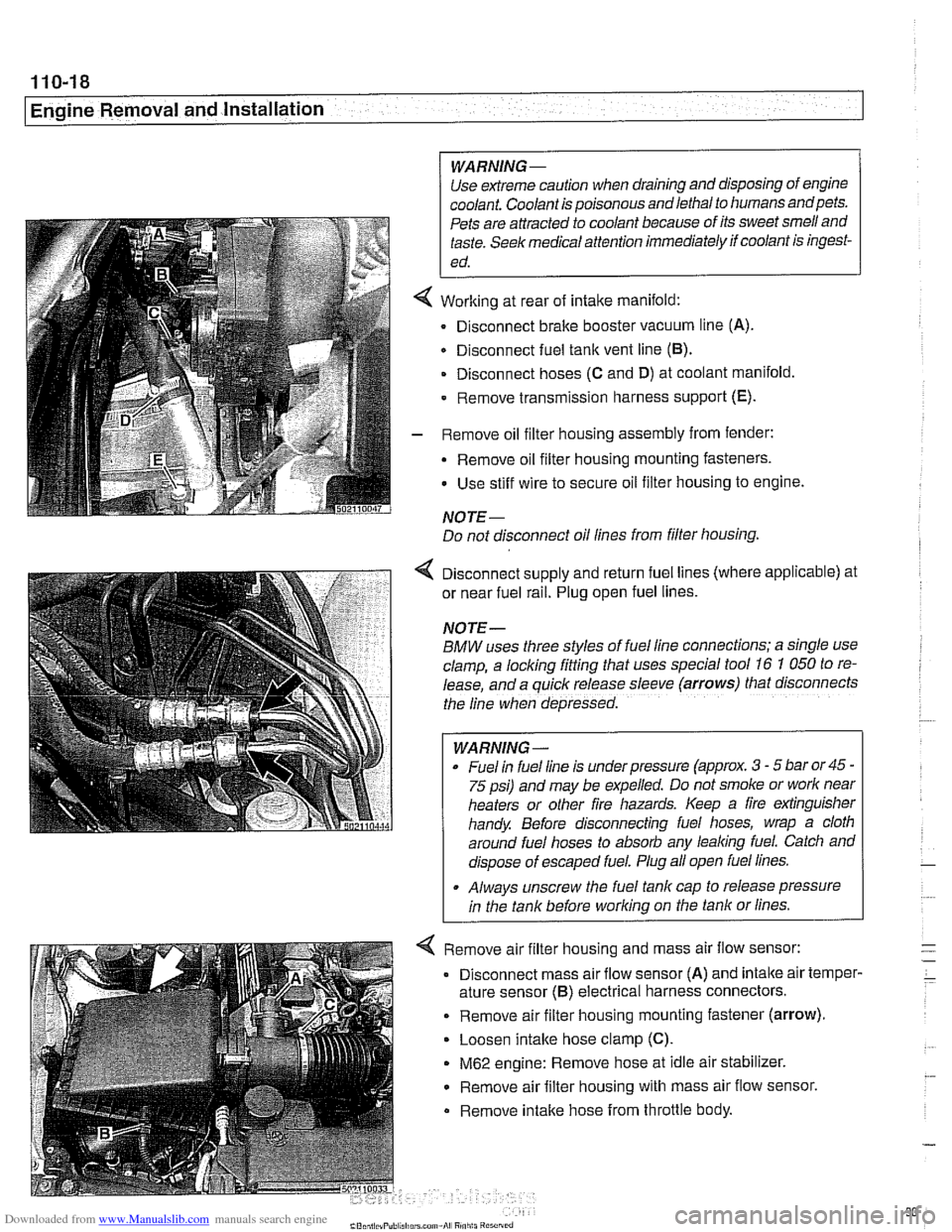

Working at rear of intake manifold:

Disconnect brake booster vacuum line (A).

Disconnect fuel tank vent line

(6).

Disconnect hoses (C and D) at coolant manifold

- Remove transmission harness support (E).

- Remove oil filter housing assembly from fender:

- Remove oil filter housing mounting fasteners.

Use stiff wire to secure oil filter housing to engine.

NOTE-

Do not disconnect oil lines from filter housing.

4 Disconnect supply and return fuel lines (where applicable) at

or near fuel rail. Plug open fuel lines.

NOTE-

BMW uses three styles of fuel line connections; a slngle use

clamp, a locking fitting that uses special tool

16 7 050 to re-

lease, and a

quiclc release sleeve (arrows) that disconnects

the line when depressed.

WARNING-

Fuel In fuel line is under pressure (approx. 3 - 5 bar or45 -

75 psi) and may be expelled. Do not smoke or worlc near

heaters or other fire hazards. Keep a fire extinguisher

handy. Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any lealcing fuel. Catch and

dispose of escaped fuel. Plug all open fuel lines.

. Always unscrew the fuel tank cap to release pressure

in the tank before worlcing on the tank or lines.

< Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor (A) and

intalte air temper-

ature sensor

(6) electrical harness connectors.

. Remove air filter housing mounting fastener (arrow).

Loosen intake hose clamp (C).

M62 engine: Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

Remove intalte hose from throttle body.

Page 92 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 0-20

Engine Removal and Installation

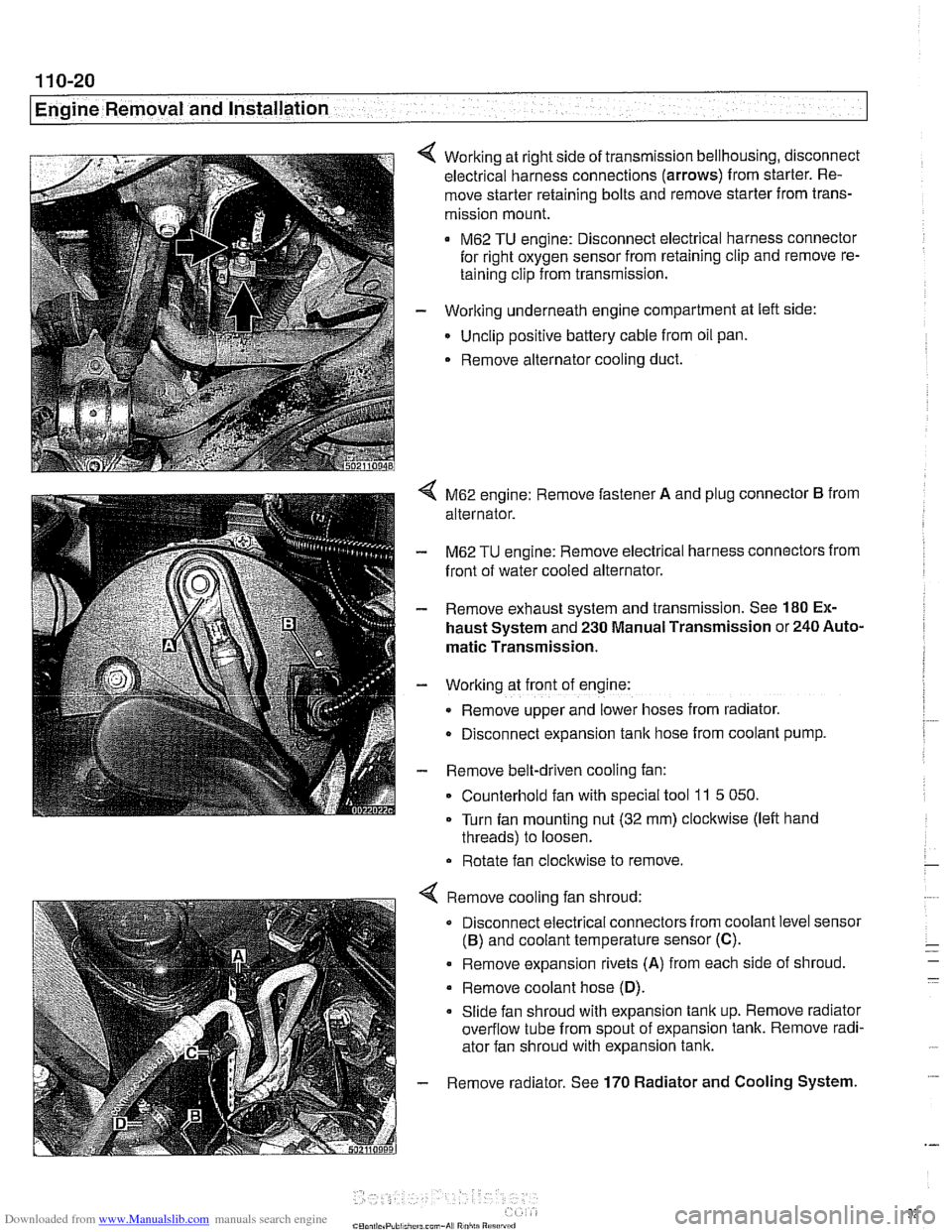

Working at right side of transmission bellhousing, disconnect

electrical harness connections (arrows) from starter. Re-

move starter retaining bolts and remove starter from trans-

mission mount.

M62 TU engine: Disconnect electrical harness connector

for right oxygen sensor from retaining clip and remove re-

taining clip from transmission.

- Working underneath engine compartment at left side:

Unclip positive battery cable from oil pan.

. Remove alternator cooling duct.

4 M62 engine: Remove fastener A and plug connector B from

alternator.

- M62 TU engine: Remove electrical harness connectors from

front of water cooled alternator.

- Remove exhaust system and transmission. See 180 Ex-

haust System and 230 Manual Transmission or 240 Auto-

matic Transmission.

- Working at front of engine:

Remove upper and lower hoses from radiator.

D~sconnect expansion tank hose from coolant pump.

- Remove belt-driven cooling fan:

Counterhold fan with special tool

11 5 050.

Turn fan mounting nut (32 mm) clockwise (left hand

threads) to loosen.

Rotate fan clockwise to remove.

Remove cooling fan shroud:

Disconnect electrical connectors from coolant level sensor

(B) and coolant temperature sensor (C).

. Remove expansion rivets (A) from each side of shroud

Remove coolant hose

(D).

Slide fan shroud with expansion tank up. Remove radiator

overflow tube from spout of expansion tank. Remove radi-

ator fan shroud with expansion tank.

Remove radiator. See

170 Radiator and Cooling System.

Page 105 of 1002

Downloaded from www.Manualslib.com manuals search engine

..

Cylinder Head Removal and Installation 1

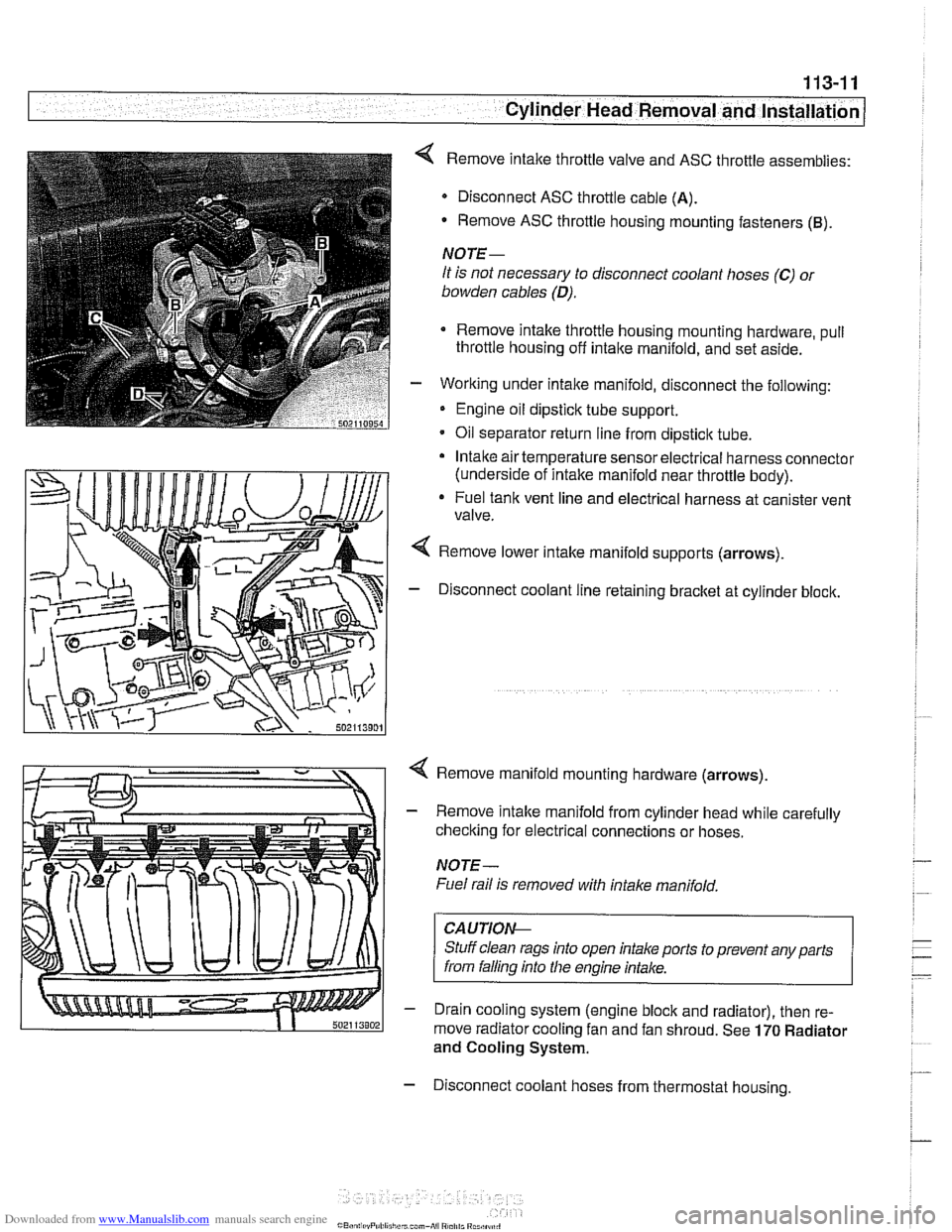

< Remove intake throttle valve and ASC throttle assemblies:

Disconnect ASC throttle cable

(A).

- Remove ASC throttle housing mounting fasteners (B).

NOTE-

It is not necessary to disconnect coolant hoses (C) 01

bowden cables (D).

Remove intake throttle housing mounting hardware, pull

throttle housing off

intake manifold, and set aside.

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Intake air temperature sensor electrical harness connector

(underside of intake manifold near throttle body).

* Fuel tank vent line and electrical harness at canister vent

valve.

Remove lower intake manifold supports (arrows).

- Disconnect coolant line retaining bracket at cylinder block.

4 Remove manifold mounting hardware (arrows).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections or hoses.

NOTE-

Fuel rail is removed with intake manifold,

CAUTIOI\C

Stuff clean rags into open intake ports to prevent any parts

from falling into

Nie engine intake.

- Drain cooling system (engine block and radiator), then re-

move radiator cooling fan and fan shroud. See

170 Radiator

and Cooling System.

- Disconnect coolant hoses from thermostat housing.