Ignition key BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 606 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-8

Gearshift Linkage

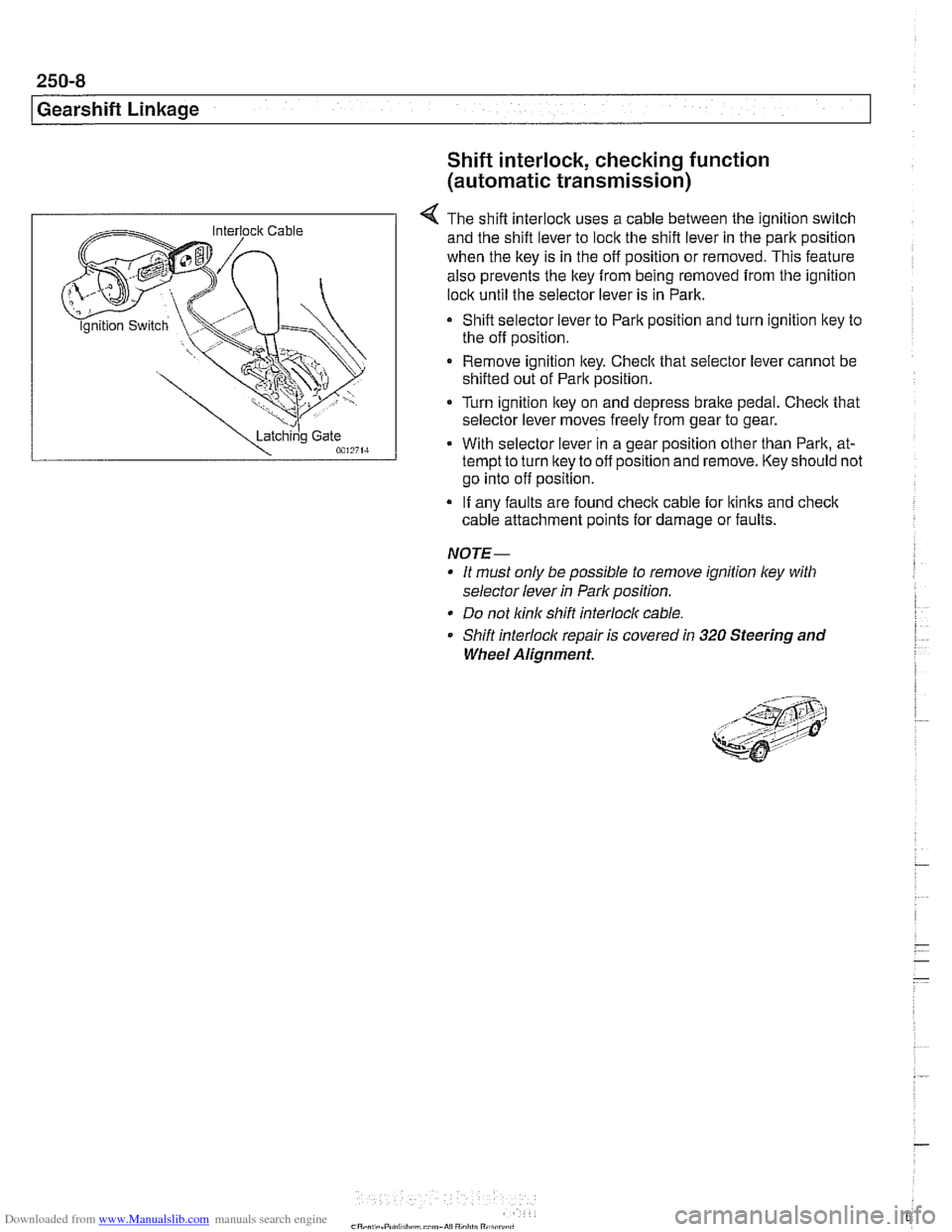

-;Ag Gate "",?it.,

Shift interlock, checking function

(automatic transmission)

4 The shift interlock uses a cable between the ignition switch

and the shift lever to lock the shift lever in the park position

when the key is in the off position or removed. This feature

also prevents the key

from being removed from the ignition

lock until the selector lever is in Park.

Shift selector lever to Park position and turn ignition key to

the off position.

Remove ignition key. Checlc that selector lever cannot be

shifted out of Park position.

Turn ignition lkey on and depress

brake pedal. Checlc that

selector lever moves freely from gear to gear.

With selector lever in a gear position other than Park, at-

tempt to turn lkey to off position and remove. Key should not

go into off position.

If any faults are found check cable for lkinks and

check

cable attachment points for damage or faults.

NOTE-

* It must only be possible to remove ignition ley with

selector lever

in Park position.

* Do not link shift interlocl( cable.

Shift interlock repair is covered

in 320 Steering and

Wheel Alignment.

Page 670 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

With ignition key in ON position (60" from LOCKED):

- Disconnect ring antenna harness connector.

Insert

BMW special tool 32 3 110 or a thin piece of stiff wire

into opening (arrow) in lock cylinder.

Turn tool forward (clockwise) approximately 90" and re-

move lock cylinder.

* Reinstallation is reverse of removal.

NOTE-

Using the valet ley during this procedure will provide better

access to lock opening.

Steering column lock, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTIO&

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove steering wheel as described earlier.

- Remove steering column trim panels as described earlier.

- Remove collar and circlip from steering shaft. Refer to illus-

tration of steering column components.

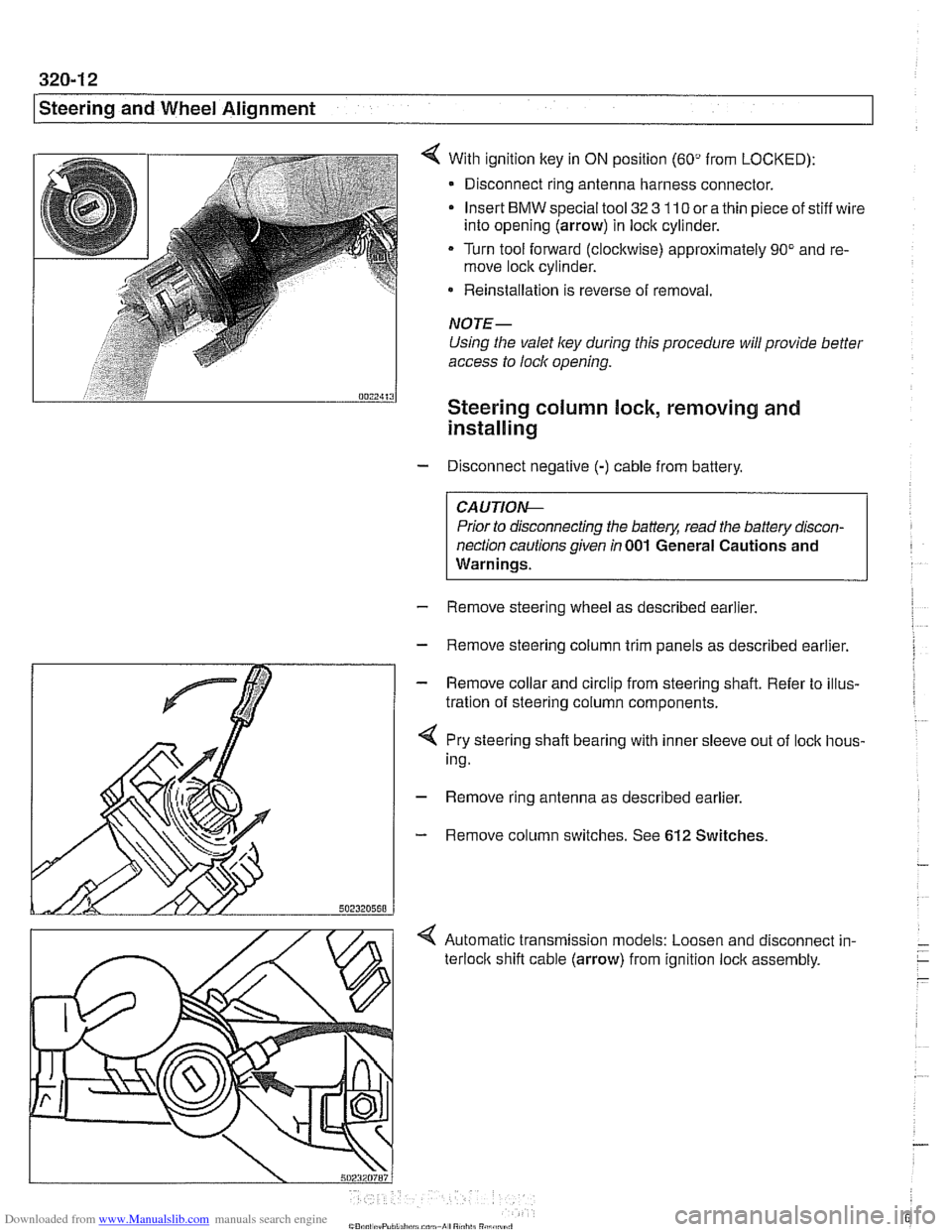

4 Pry steering shaft bearing with inner sleeve out of lock hous-

ing.

- Remove ring antenna as described earlier.

- Remove column switches. See 612 Switches.

< Automatic transmission models: Loosen and disconnect in-

terloclc shift cable (arrow) from ignition lock assembly.

Page 672 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-1 4

Steering and Wheel Alignment

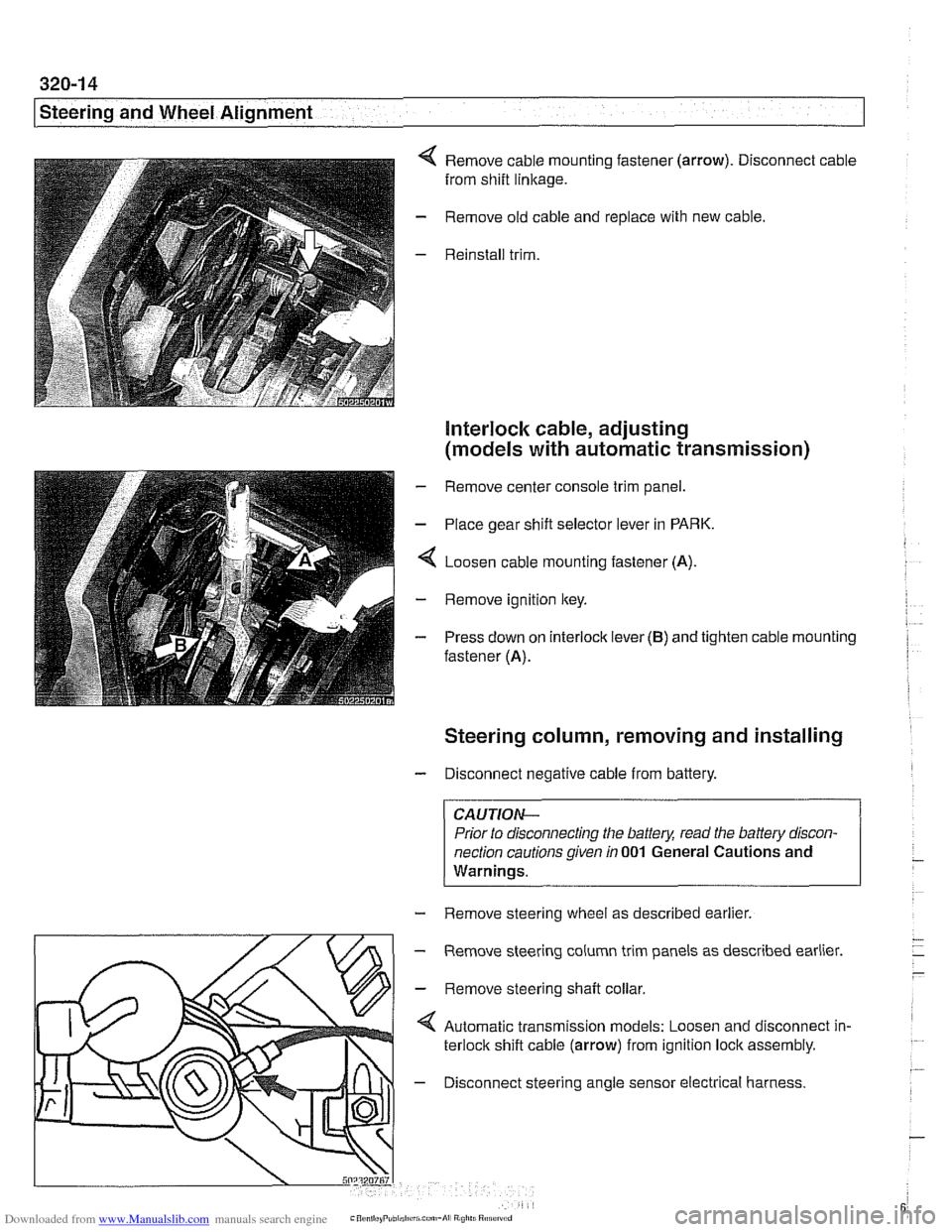

Remove cable mounting fastener (arrow). Disconnect cable

from shift

linkage.

Remove old cable and replace with new cable.

Reinstall trim.

Interlock cable, adjusting

(models with automatic transmission)

- Remove center console trim panel.

- Place gear shift selector lever in PARK.

4 Loosen cable mounting fastener (A).

- Remove ignition key.

- Press down on interlock lever (B) and tighten cable mounting

fastener (A).

Steering column, removing and installing

- Disconnect negative cable from battery.

CAUTIOI\C

Prior to disconnecting the battea read the battery discon-

nection cautions given

in 001 General Cautions and

Warninqs.

- Remove steering wheel as described earlier.

m

- Remove steering column trim panels as described earlier.

' \L/>I - Remove steerinq shaft collar

Automatic transmission models: Loosen and disconnect in-

terlock shift cable (arrow) from ignition lock assembly.

4 - Disconnect steering angle sensor electrical harness.

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

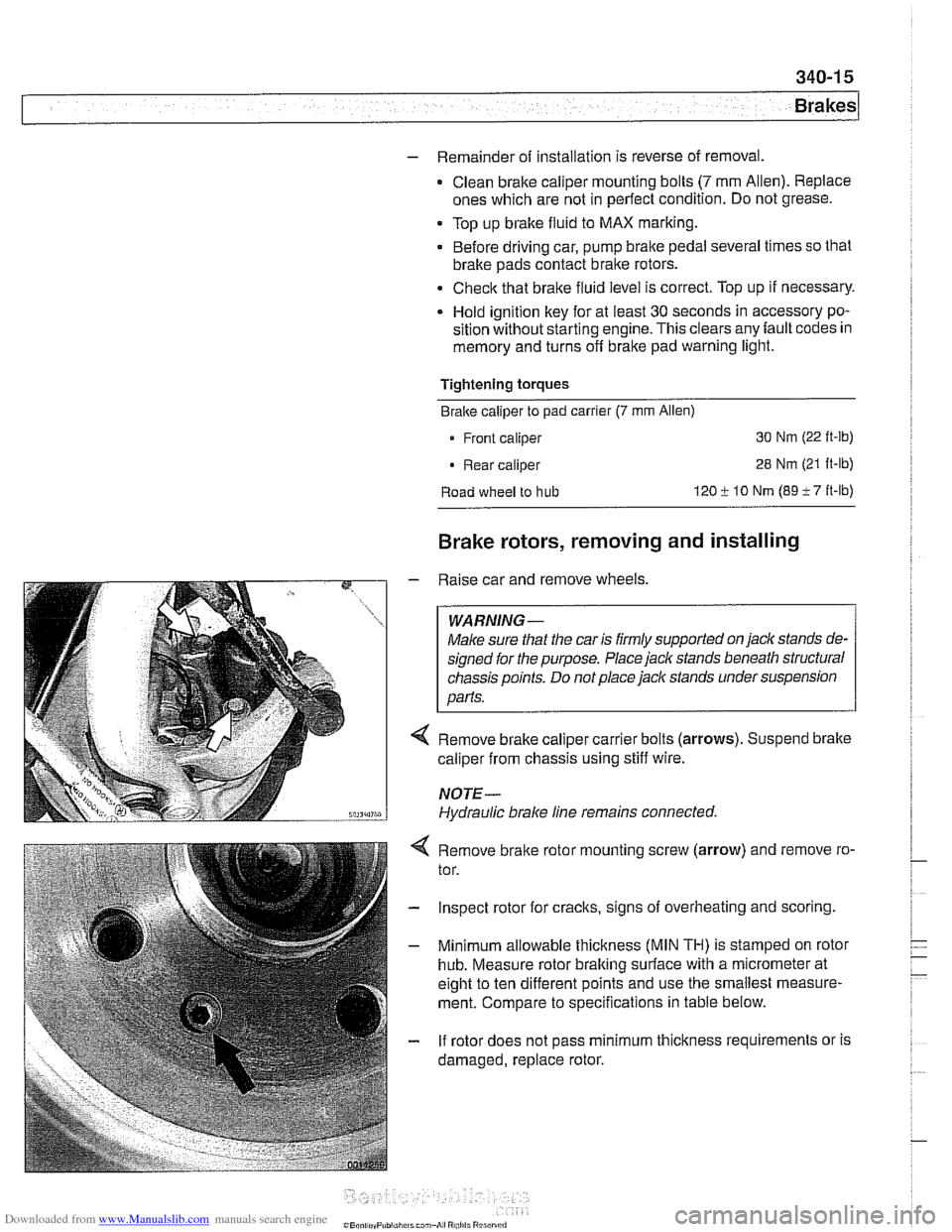

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

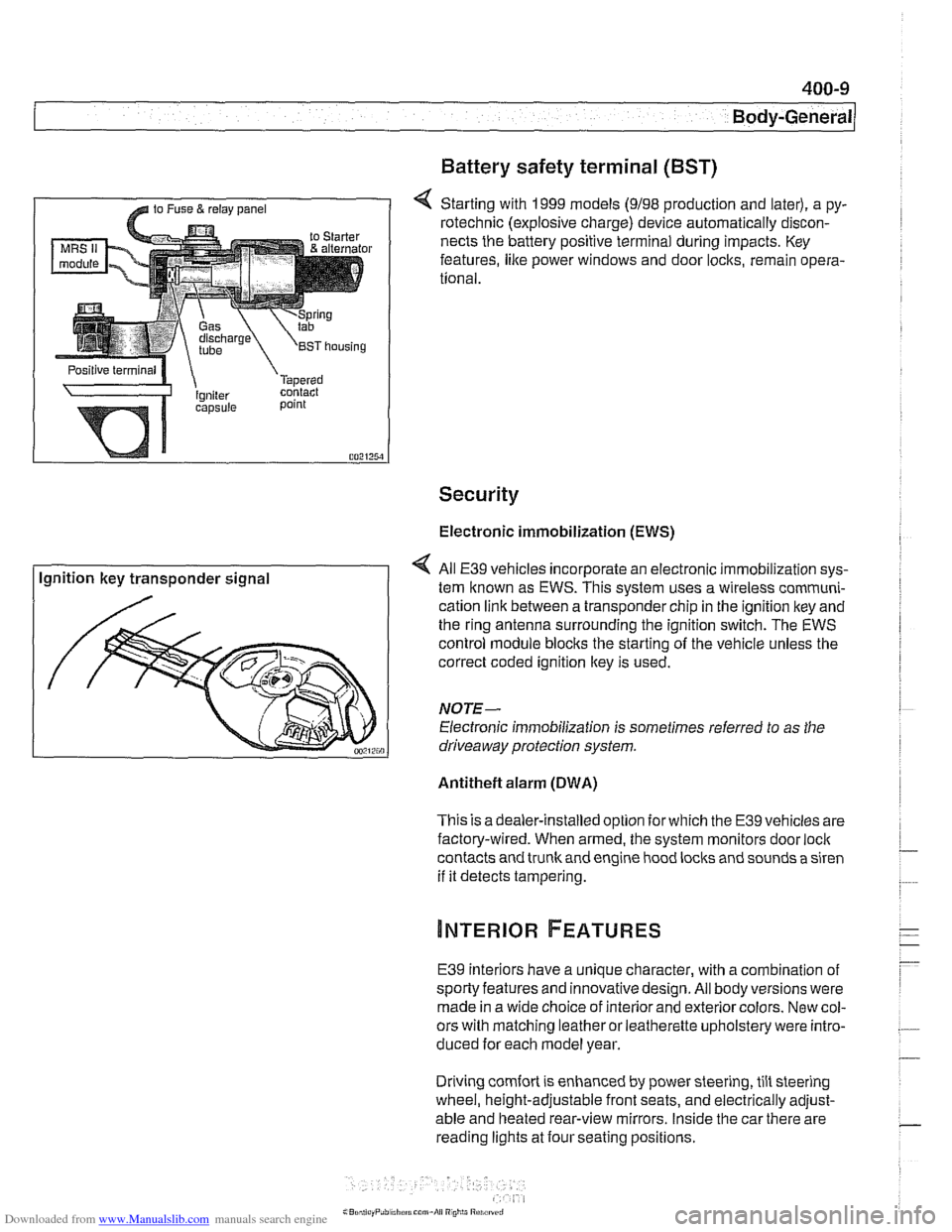

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.

Page 866 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-2

I Door Windows 1

This repair group covers door glass, window regulator and

power window motor repair information.

CA U JIO&

All E39 models are equipped with side-impact airbags in the

front doors. Some models are also equipped with

airbags in

the rear doors. Be sure to read the

airbag warnings and cau-

tions in 721

Airbag System (SRS).

Electric window switch replacement is covered in 612

Switches.

The windshield, rear window, fixed rear doorglass, and cargo

compartment glass (Sport Wagon only) are bonded using

special adhesives and tools. It is recommended that bonded

glass replacement be done by an authorized

BMW service fa-

cility or an automotive glass installer.

Special tools

Some window repair operations require special tools.

Power windows

- Power window features in E39 models include:

Control of the front and rear door window motors is carried

out directly by the General Module (GM

Ill).

One-touch operation in both directions on all four windows.

Cable type window regulator used for all door windows.

. Anti-trap protection provided by pressure sensitive finger

guard.

Right front and each rear door has a single window switch

located in door handle trim.

Rear door window switches can be deactivated by press-

ing child lock-out switch in the driver's window switch block.

Convenience closinglopening of the windows from driver's

loci( cylinder or convenience opening only from remote un-

lociting feature (FZV) remote key.

Window (FZV) operation can be owner customized with

Car Memory function. See 515 Central Locking and Anti-

Theft.

After ignition is switched off, electric windows can be oper-

ated until a door is opened or until

I6 minutes has elapsed.

The GM

IiI bases window motor end position on current

draw (load). There is a maximum window motor run time of

6 seconds. The motor is then switched off even if the end

position load sensor fails.

Page 900 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-6

(Central Locking and Anti-Theft

Each rear door is equipped with the child lock-out lever, pre-

venting the door from being opened from the inside regard-

less of loclc button position.

Starting with models produced afler

911997, the General

Module and electronic immobilizer (EWS) interface via the

K-

Bus to monitor double lock status and to initiate double loclc

override. This feature allows the doors to be opened from the

inside if a key accepted by EWS is switched on in the ignition.

See Single lock and double lock function.

The door loclc buttons are mechanically uncoupled from the

actuators when locked. The remote keyless entry system

(FZV) is standard equipment. This allows for elimination of

the passengers side door

loclt cylinder.

Another function of the locking system is the

sofl close trunk

(SCA) system, where applicable.

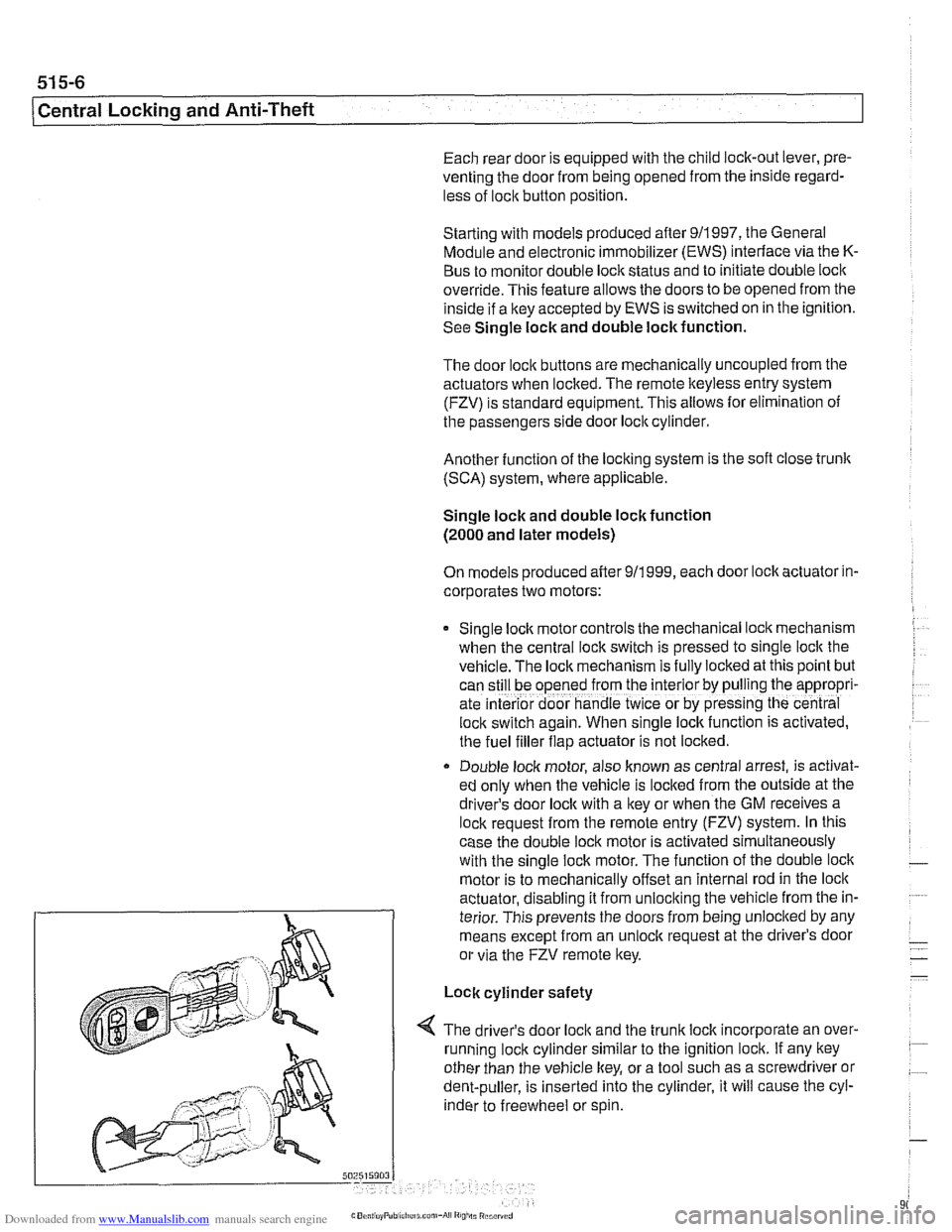

Single lock and double lock function

(2000 and later models)

On models produced after

911999, each door lock actuator in-

corporates two motors:

Single lock motor controls the mechanical loclc mechanism

when the central lock switch is pressed to single loclc the

vehicle. The loclc mechanism is fully locked at this point but

can stil. be openeo from

the interor by pulng the appropri-

are interior door nandle lwce or by pressing rhe central

lock switch again. When single

lock'function is activated,

the fuel filler flap actuator is not locked.

Double lock motor, also known as central arrest, is activat-

ed only when the vehicle is locked from the outside at the

driver's door lock with a key or when the GM receives a

lock request from the remote entry (FZV) system. In this

case the double lock motor is activated simultaneously

with the single lock motor. The function of the double loclc

motor is to mechanically offset an internal rod in the loclc

actuator, disabling it from unlocking the vehicle from the in-

terior. This prevents the doors from being unloclted by any

means except from an unlock request at the driver's door

or via the FZV remote key.

Lock cylinder safety

4 The driver's door loclc and the trunk loclc incorporate an over-

running loclc cylinder similar to the ignition lock. If any key

other than the vehicle key, or a tool such as a screwdriver or

dent-puller, is inserted into the cylinder, it will cause the cyl-

inder to freewheel or spin.

Page 904 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Central Locking and Anti-Theft

NOJE-

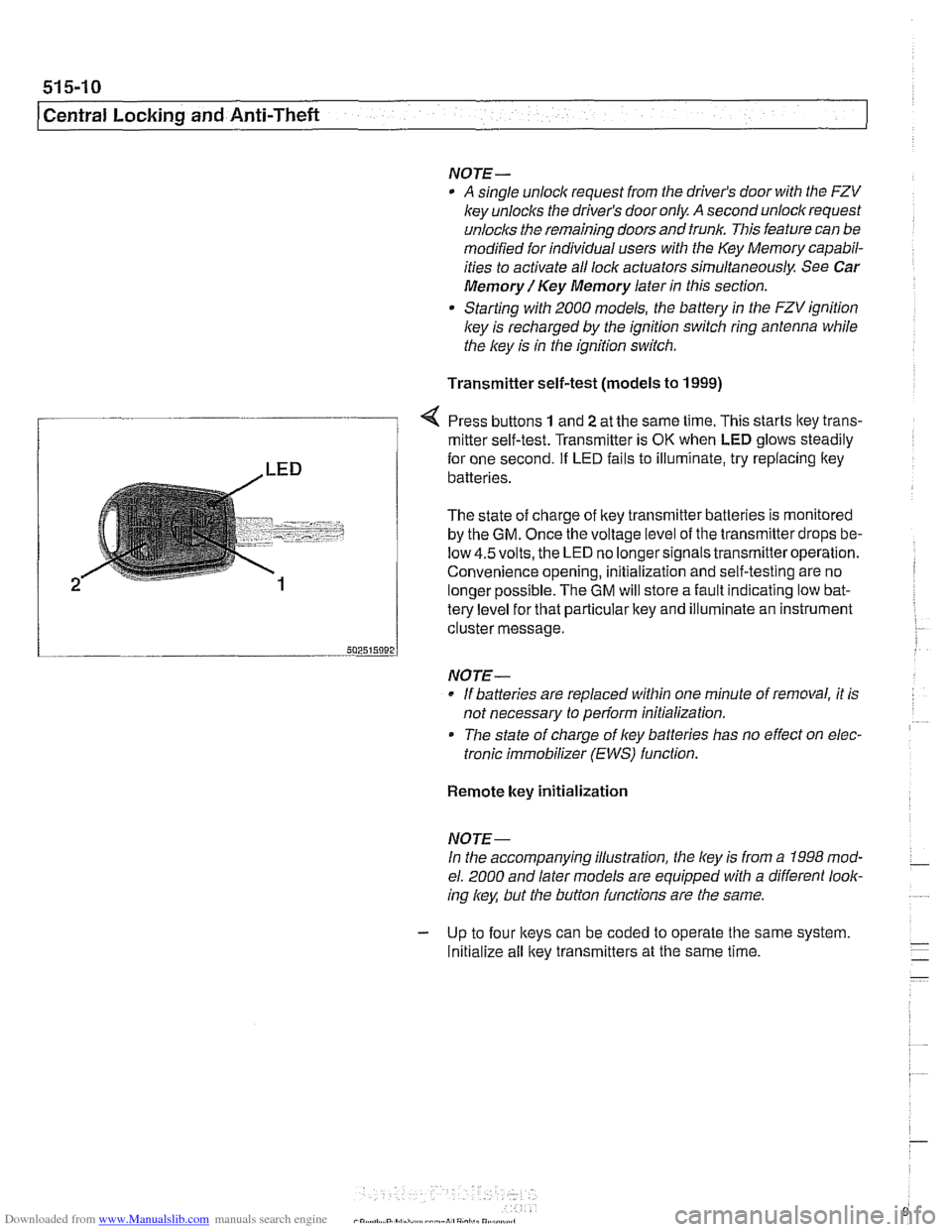

A single unlock request from the driver's door with the FZV

key unlocks the driver's door only.

A second unlock request

unlocls the remaining doors and trunk. This feature can be

modified for individual users with the Key Memory capabil-

ities to activate all lock actuators simultaneously See Car

Memory

/ Key Memory later in this section.

Starting with 2000 models, the battery in the FZV ignition

Icey is recharged by the ignition switch ring antenna while

the ley is in the ignition switch.

Transmitter self-test (models to

1999)

Press buttons 1 and 2 at the same time. This starts ltey trans-

/ mitter self-test. Transmitter is OK when LED glows steadily

te{le"el for that particular key and illuminate an instrument

cluster message.

-- 502515092 J

NO JE-

If batteries are replaced within one minute of removal, it is

not necessary to

periorm initialization.

Tlie state of charge of key batteries has no effect on elec-

tronic immobilizer (EWS) function.

2

Remote key initialization

for one second. If LED fails to illuminate, try replacing ltey~

batteries.

The state of charge of key transmitter batteries is monitored

by the

GM. Once the voltage level of the transmitter drops be-

low

4.5volts, the LED no longersignals transmitteroperation.

Convenience opening, initialization and self-testing are no

lonaer ~ossible. The GM will store a fault indicatina low bat-

NOJE-

In the accompanying illustration, the key is from a 1998 mod-

el. 2000 and later models are equipped with a different look-

ing

/

Initialize all key transmitters at the same time.

Page 905 of 1002

Downloaded from www.Manualslib.com manuals search engine

515-11

Central Lockinq and ~nti-l heft/

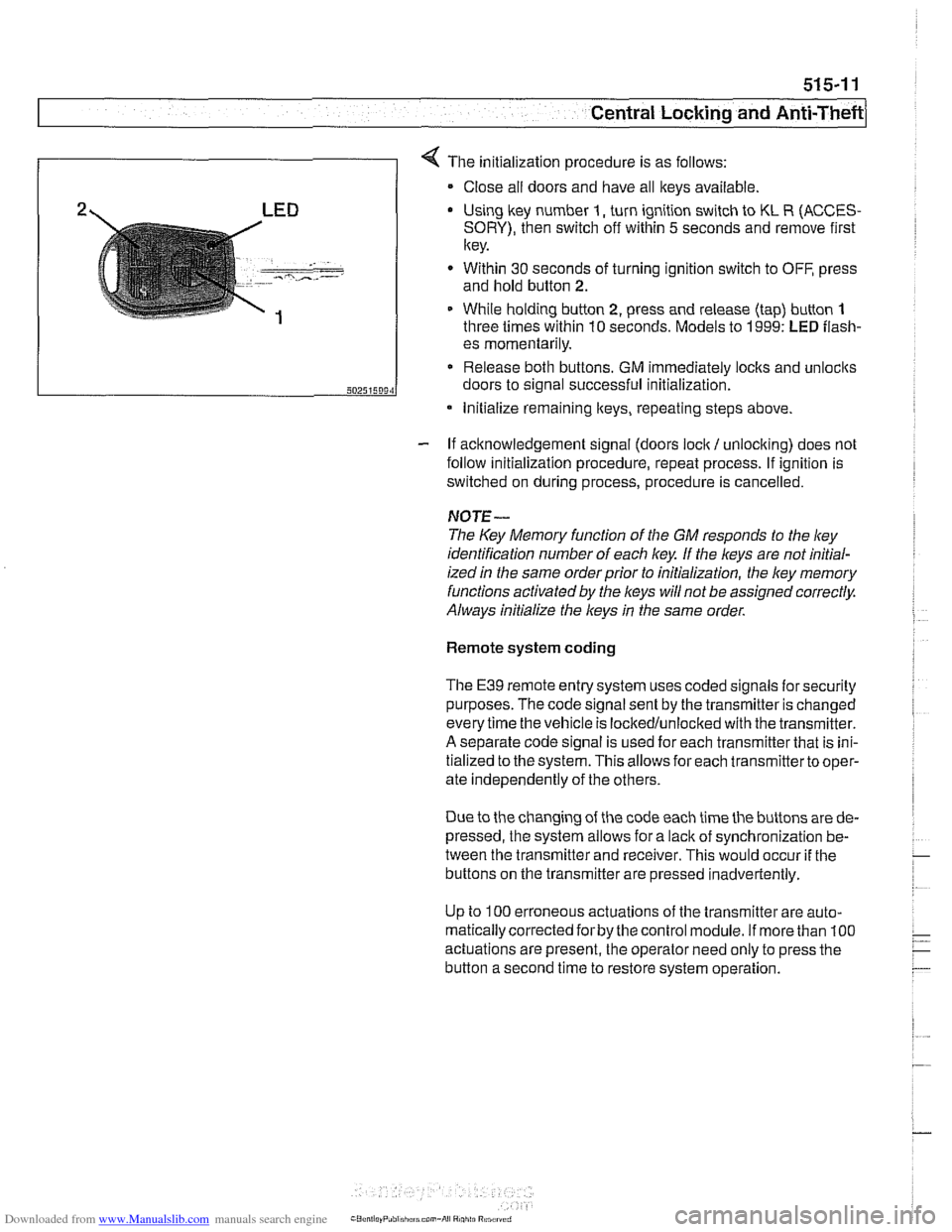

4 The initialization procedure is as follows:

Close ail doors and have all keys available

2 LED Using lkey number I, turn ignition switch to KL R (ACCES-

SORY), then switch off within 5 seconds and remove first

key.

. - -- , ..-.---- - Within 30 seconds of turning ignition switch to OFF, press

and hold button

2.

1 While holding button 2, press and release (tap) button 1

three times within 10 seconds. Models to 1999: LED flash-

- If acknowledgement signal (doors lock / unlocking) does not

follow initialization procedure, repeat process. If ignition is

switched on during process, procedure is cancelled.

50251509‘1

NOTE-

The Key Memory function of the GM responds to the ley

identification number of each key If the keys are not initial-

ized

in the same orderprior to initialization, the ley memory

functions activated by the

l(eys will not be assigned correctly.

Always initialize the keys

in the same order.

es momentarily.

Release both buttons. GM immediately locks and unlocits

doors to signal successful initialization.

Remote system coding

* Initialize remaining lteys, repeating steps above.

The E39 remote entry system uses coded signals for security

purposes. The code signal sent by the transmitter is changed

every time the vehicle is lockedlunlocked with the transmitter.

A separate code signal is used for each transmitter that is ini-

tialized to the system. This allows for each transmitterto oper-

ate independently of the others.

Due to the changing of the code each time the buttons are de-

pressed, the system allows for a

lacit of synchronization be-

tween the transmitter and receiver. This would occur

if the

buttons on the transmitter are pressed inadvertently.

Up to

100 erroneous actuations of the transmitter are auto-

matically corrected

forby the control module. If more than 100

actuations are present, the operator need only to press the

button a second time to restore system operation.