Intake manifold hose BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 118 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

Cylinder Head Removal and Installation

- Working at side of intake manifold near left strut tower, dis-

connect intake manifold resonance valve electrical harness

connector.

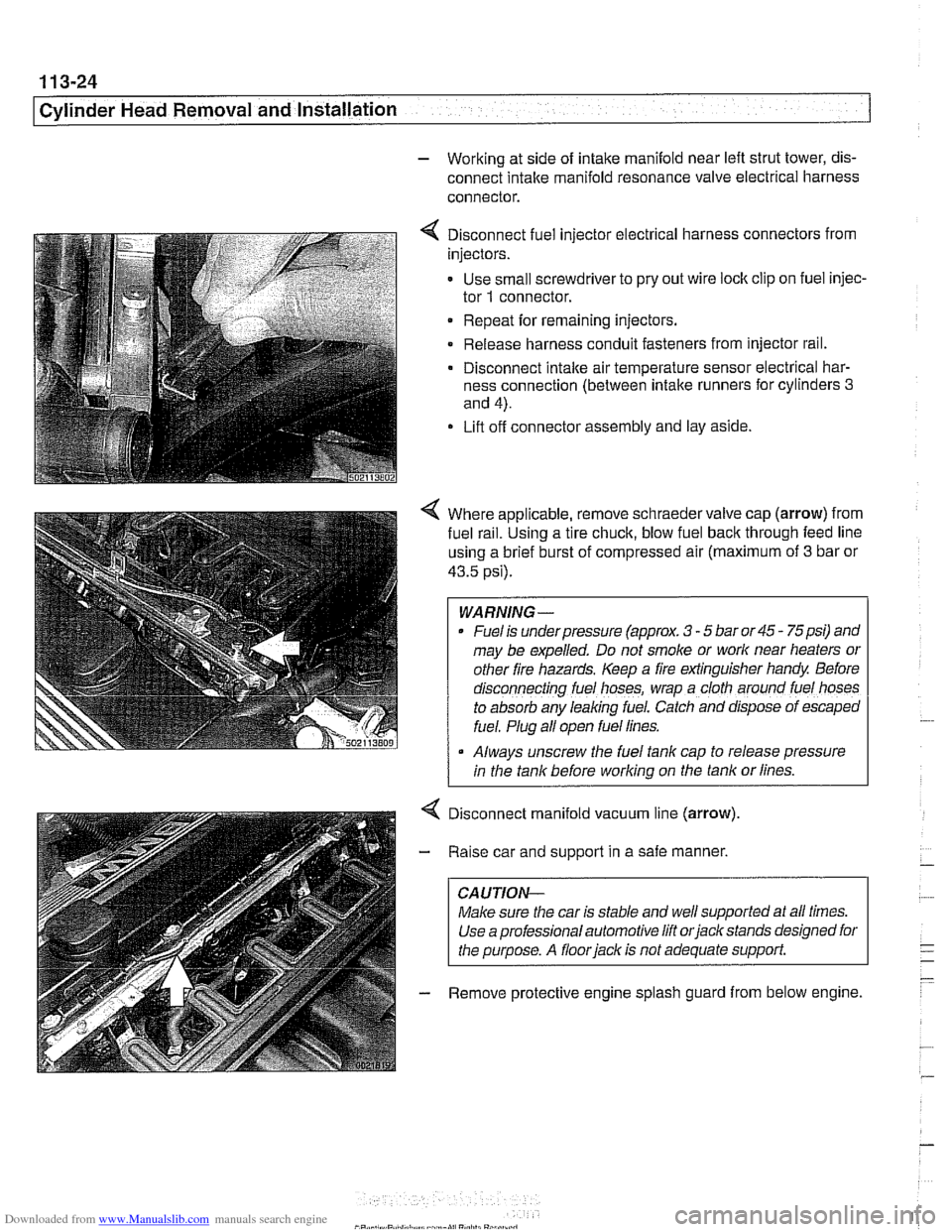

4 Disconnect fuel injector electrical harness connectors from

injectors.

- Use small screwdriver to pry out wire lock clip on fuel injec-

tor

1 connector.

Repeat for remaining injectors.

Release harness conduit fasteners from injector rail.

- Disconnect intake air temperature sensor electrical har-

ness connection (between intake runners for cylinders

3

and 4).

Lift off connector assembly and lay aside.

4 Where applicable, remove schraeder valve cap (arrow) from

fuel

ra~l. Using a tire chuck, blow fuel back through feed line

using a brief burst of compressed air (maximum of

3 bar or

43.5 psi).

WARNING-

Fuel is underpressure (approx. 3 - 5 bar or 45 - 75psi) and

may be expelled. Do not smoke or

work near heaters or

other fire hazards. Keep a fire extinguisher handy Before

d~sconnecting fuel hoses, wrap a cloth around fuel hoses

to absorb any leaking fuel. Catch and

dfspose of escaped

fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

I in the tank before working on the tank or lines.

Disconnect manifold vacuum line (arrow)

Raise car and support in a safe manner,

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A

floorjack is not adequate support.

Remove protective engine splash guard from below engine.

Page 120 of 1002

Downloaded from www.Manualslib.com manuals search engine

. - --

j Cylinder Head Removal and Installation

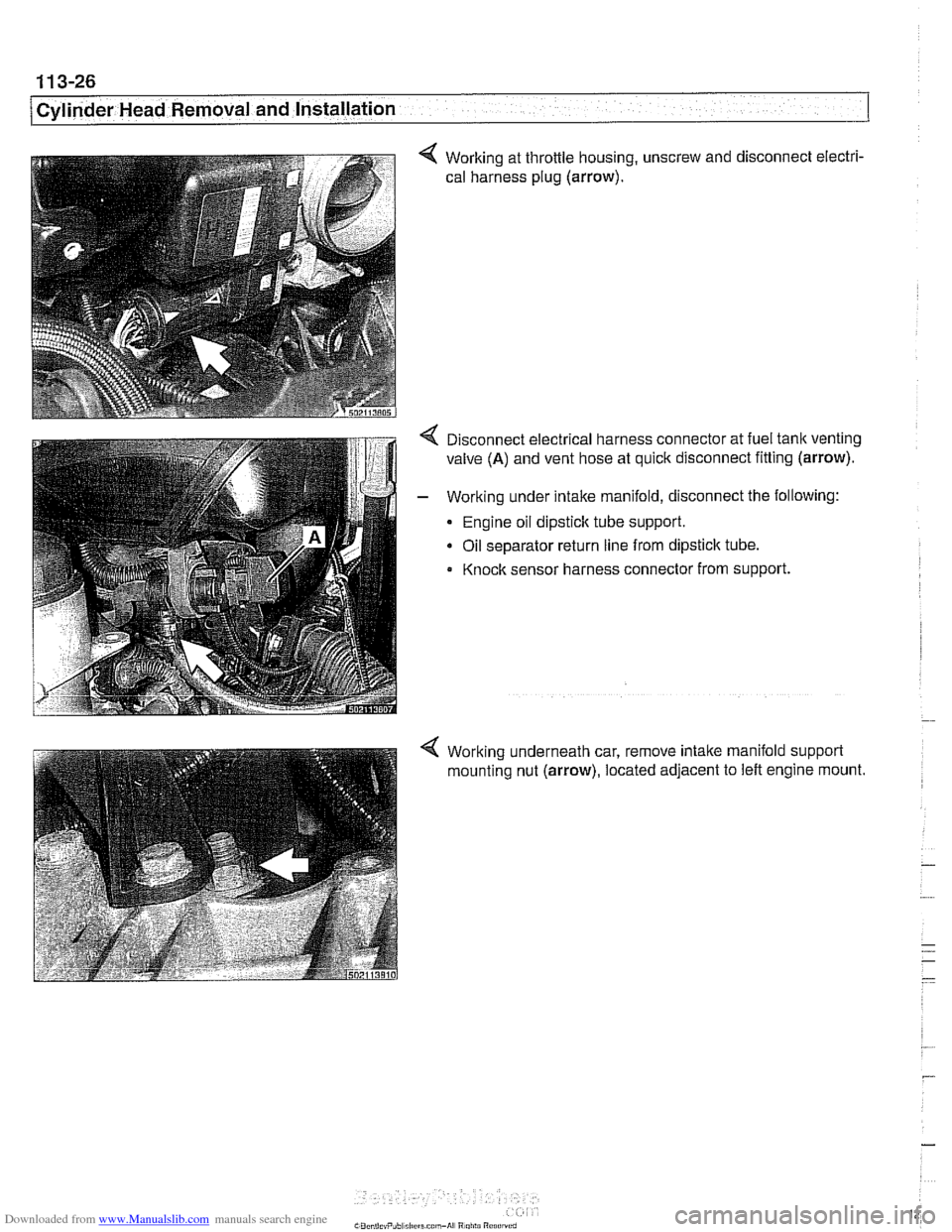

4 Working at throttle housing, unscrew and disconnect electri-

cal harness plug

(arrow).

4 Disconnect electrical harness connector at fuel tank venting

valve

(A) and vent hose at quick disconnect fitting (arrow).

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Knock sensor harness connector from support.

4 Working underneath car, remove intake manifold support

mounting nut

(arrow), located adjacent to left engine mount.

Page 154 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-60

Cylinder Head Removal and Installation

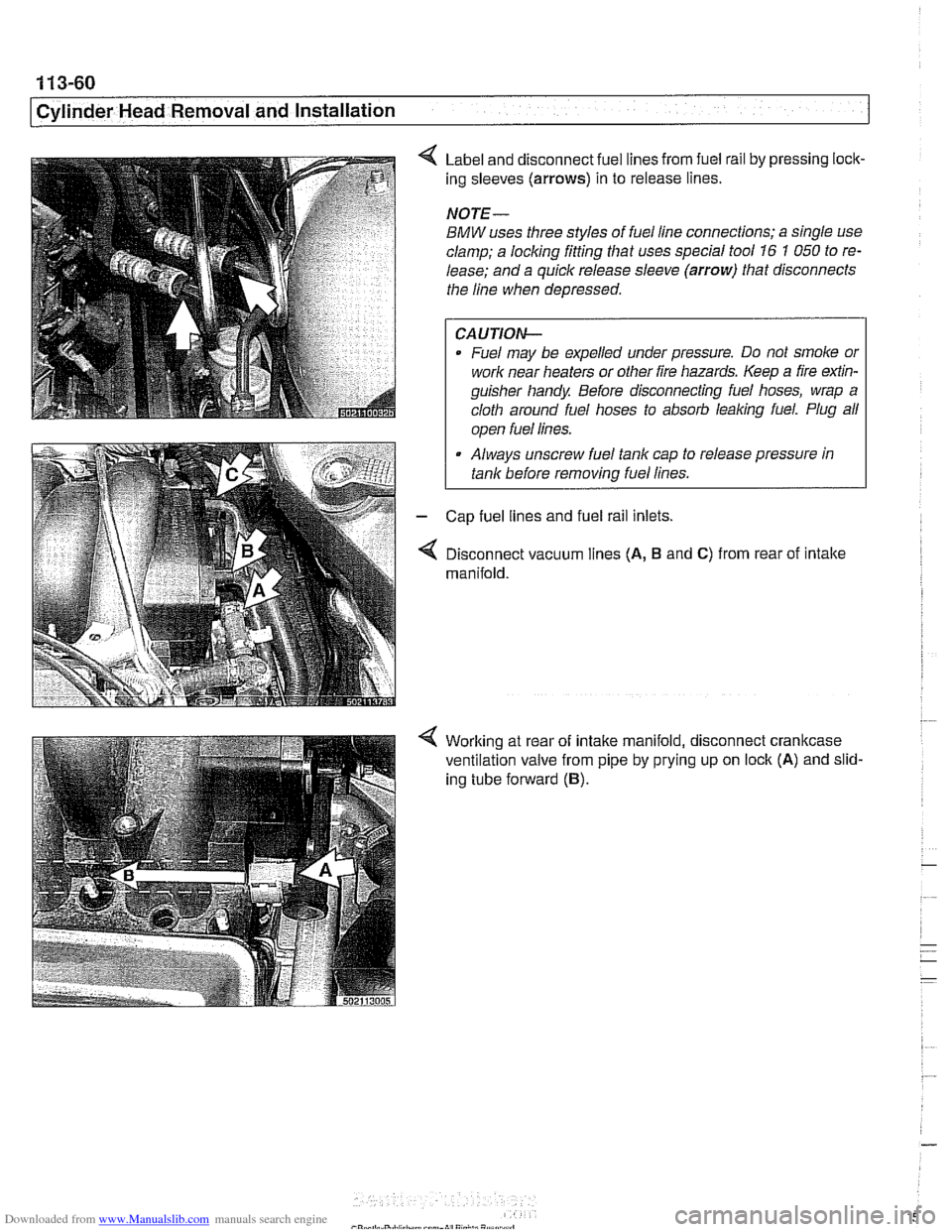

Label and disconnect fuel lines from fuel rail by pressing lock-

ing sleeves

(arrows) in to release lines.

NOTE-

BMW uses three styles of fuel line connections; a single use

clamp; a locking fitting that uses special tool

16 1 050 to re-

lease; and a quick release sleeve

(arrow) that disconnects

the line when depressed.

CAUTION-

Fuel may be expelled under pressure. Do not smoke or

work near heaters or other fire hazards. Keep a fire

exfin-

guisher handy Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb

leaking fuel. Plug all

I ooen fuel lines. I

Always unscrew fuel tank cap to release pressure in

tank before

removinq fuel lines.

Cap fuel lines and fuel rail inlets.

Disconnect vacuum lines

(A, B and C) from rear of intake

manifold.

Working at rear of intake manifold, disconnect crankcase

ventilation valve from pipe by prying up on lock

(A) and slid-

ing tube forward

(B).

Page 155 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-61

Cylinder Head Removal and installation I

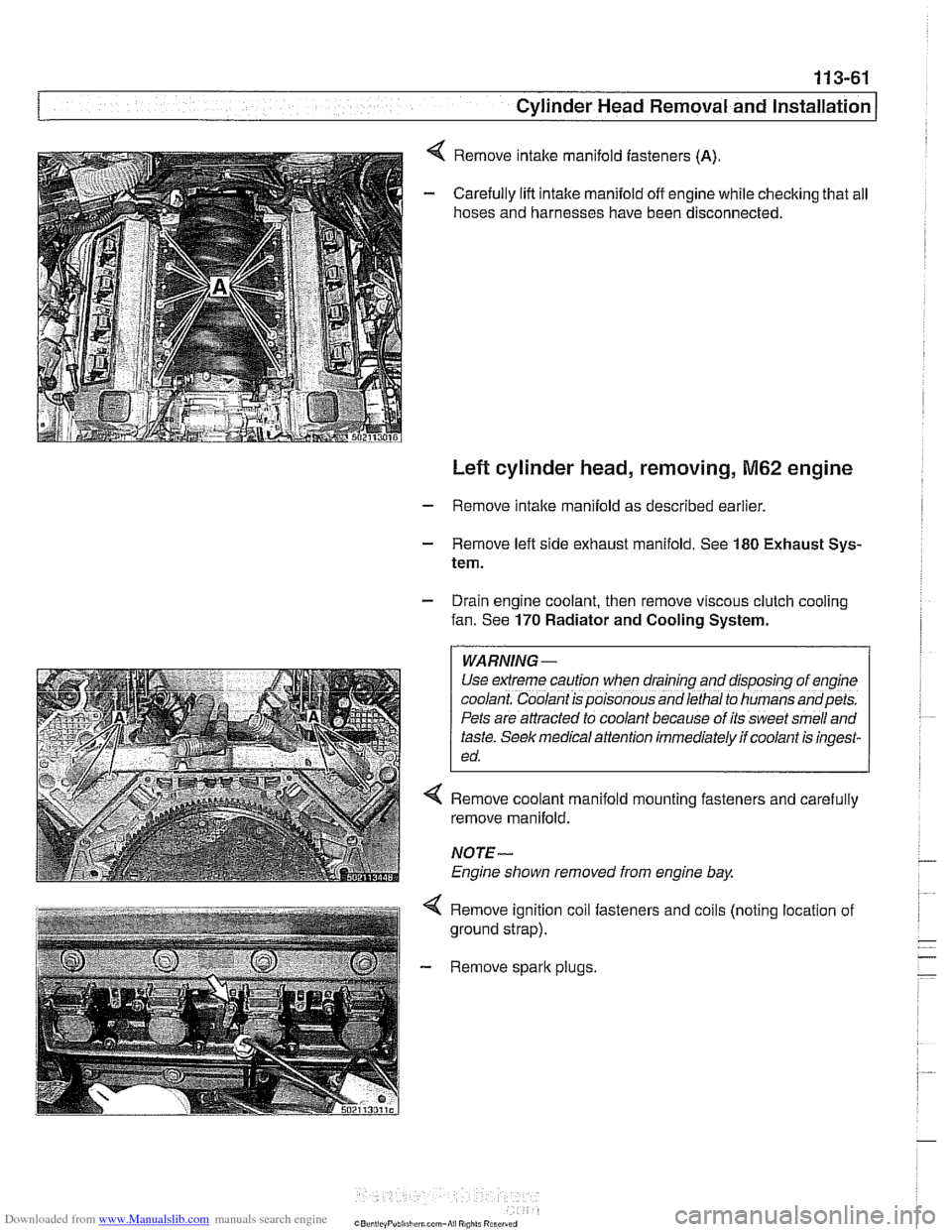

Remove intake manifold fasteners (A).

Carefully lift intake manifold off engine while checking that all

hoses and harnesses have been disconnected.

Left cylinder head, removing, M62 engine

- Remove intake manifold as described earlier

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Drain engine coolant, then remove viscous clutch cooling

fan. See

170 Radiator and Cooling System.

WARNING -

Use extreme caution when draining and disposfng of eng~ne

coolant. Coolant is poisonous and lethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste.

Seek med~cal attention immediately if coolant is ingest-

ed.

4 Remove coolant manifold mounting fasteners and carefully

remove manifold.

NOTE-

Engine shown removed from engine bay

4 Remove ignition coil fasteners and coils (noting location of

ground strap).

- Remove spark plugs.

Page 303 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

- Disconnect negative cable (-) from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

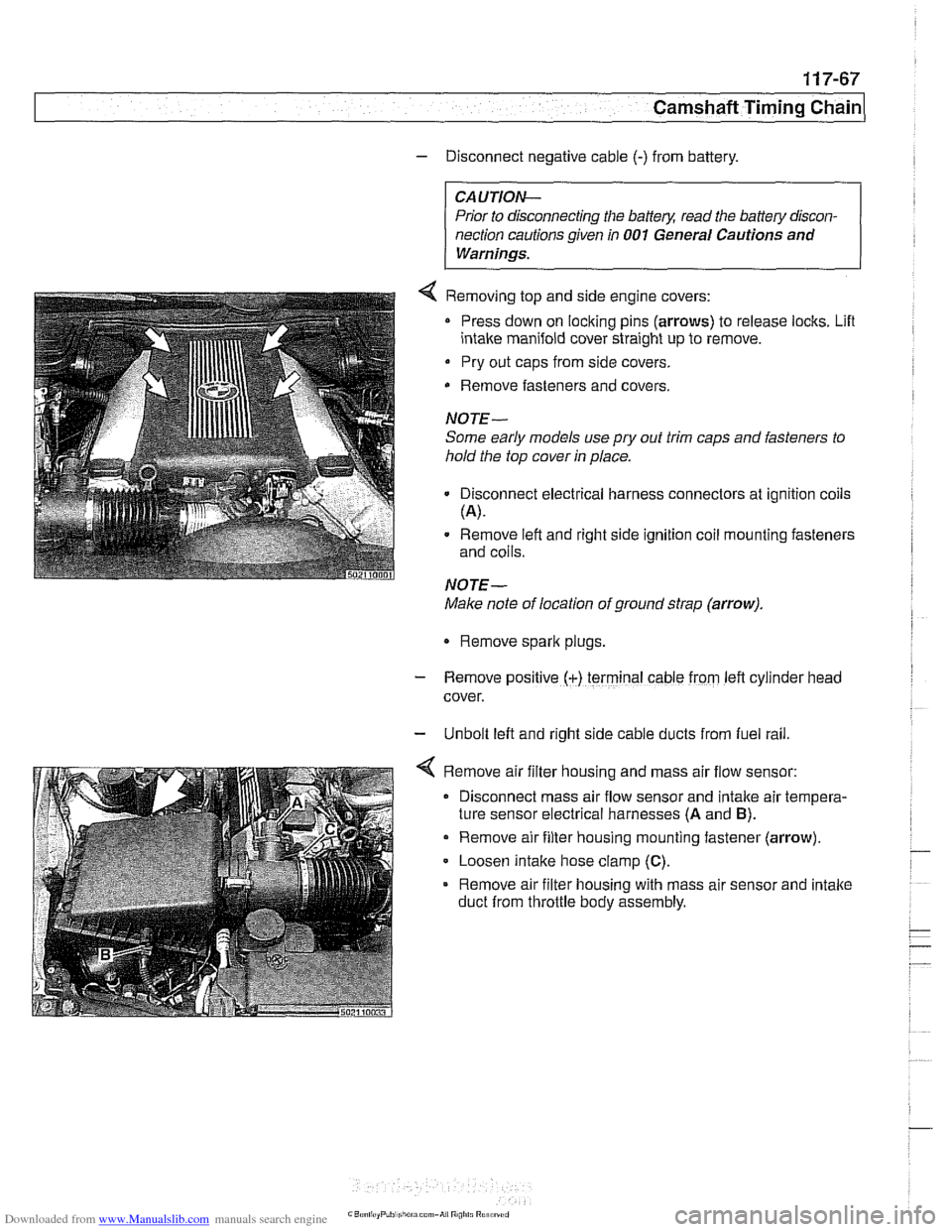

4 Removing top and side engine covers:

Press down on locking pins (arrows) to release locks. Lifl

intake manifold cover straight up to remove.

Pry out caps from side covers.

Remove fasteners

and covers.

NOTE-

Some early models use

pry out trim caps and fasteners to

hold the top cover in place.

Disconnect electrical harness connectors at ignition coils

(A).

Remove left and right side ignition coil mounting fasteners

and coils.

NOTE-

Make note of location of ground strap (arrow).

Remove spark plugs.

- Remove posltlve (+) terminal cable from left cylrnder head

cover.

- Unbolt left and right side cable ducts from fuel rail

Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor and intake air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow)

Loosen intake hose clamp

(C).

Remove air filter housing with mass air sensor and intake

duct from throttle body assembly.

Page 315 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

Camshaft timing, checking and adjusting

(M62 engine)

WARNING -

Allow engine to cool before beginning this procedure. 1

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTIOI\C

Prior to disconnecting battery cable, read the battery discon-

nection cautions given

in 001 General Cautions and

Warninss.

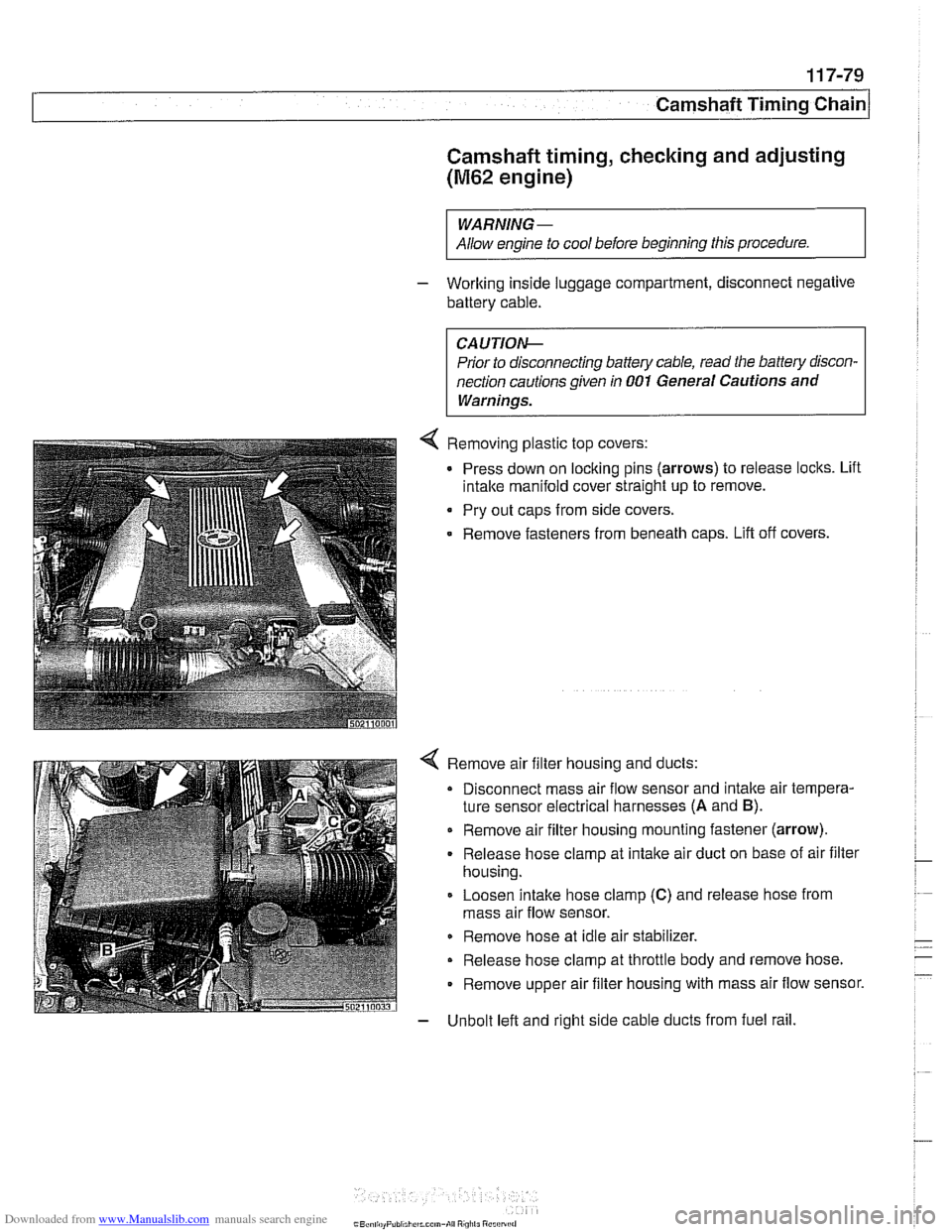

4 Removing plastic top covers:

Press down on locking pins (arrows) to release locks. Lift

intake manifold cover straight up to remove.

Pry out caps from side covers.

Remove fasteners from beneath

caDs. Lift off covers.

4 Remove air filter housing and ducts:

Disconnect mass air flow sensor and intake air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow).

Release hose clamp at intake air duct on base of air filter

housing.

Loosen intake hose clamp

(C) and release hose from

mass air flow sensor.

Remove hose at idle air stabilizer.

Release hose clamp at throttle body and remove hose.

Remove upper air filter housing with mass air flow sensor.

- Unbolt left and right side cable ducts from fuel rail.

Page 362 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Ignition System

Camshaft position sensors

The camshaft position sensors are used by the englne man-

agement system for VANOS control, sequential fuel injection

and knock control.

Intake camshaft position sensor, replacing

(M52,M52 TU

and M54 engines)

- Make certain ignition has been turned off.

- Remove plastic cover from above fuel injectors by prying off

bolt covers and removing cover mounting bolts.

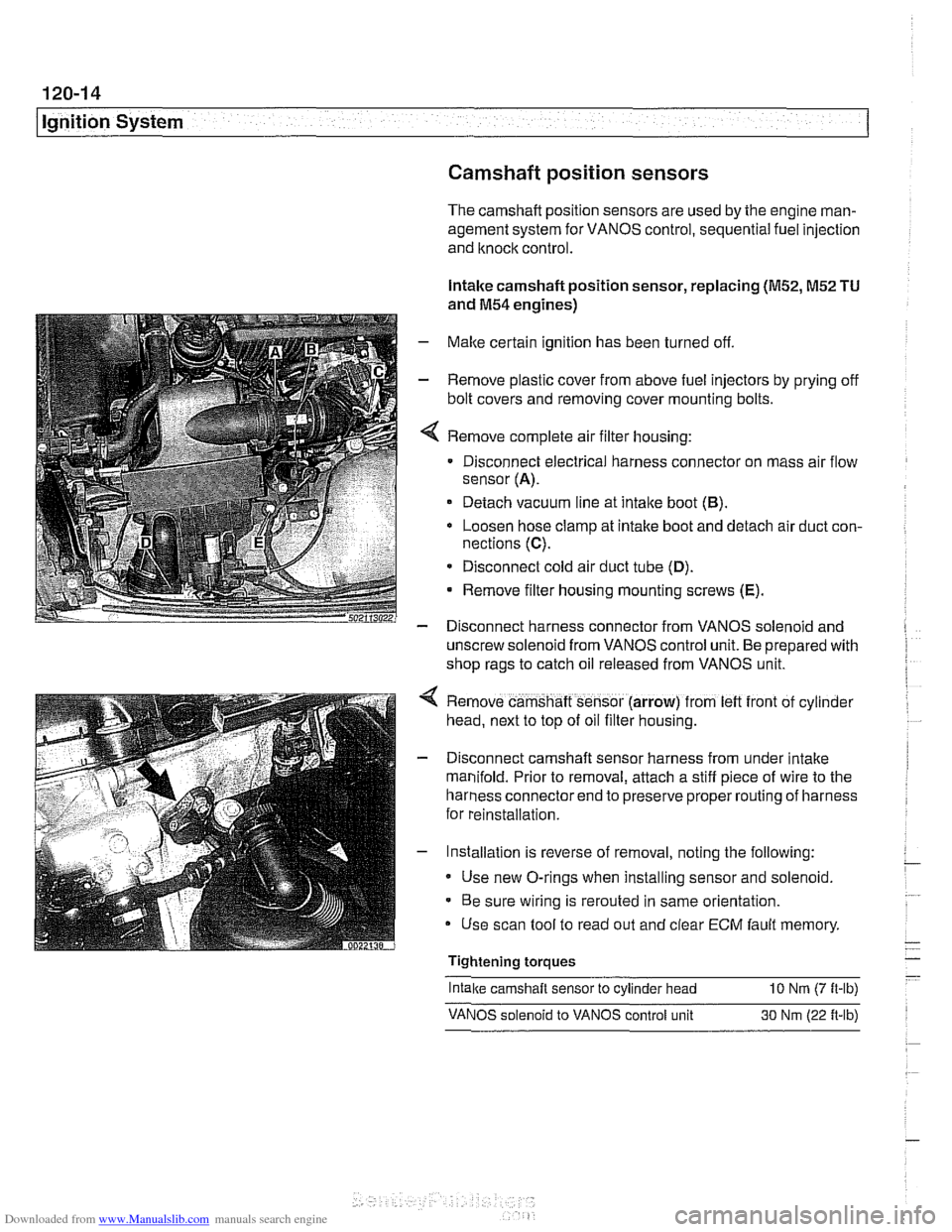

Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Detach vacuum line at intake boot (B).

Loosen hose clamp at intake boot and detach air duct con-

nections

(C).

* Disconnect cold air duct tube (D).

Remove filter housing mounting screws (E).

- Disconnect harness connector from VANOS solenoid and

unscrew solenoid from VANOS control unit. Be prepared with

shop rags to catch oil released from VANOS unit.

Remove camshaft sensor (arrow) from

left front of cyl~nder

head, next to top of oil filter housing.

Disconnect camshaft sensor harness from under intake

manifold. Prior to removal, attach a stiff piece of wire to the

harness connector end to preserve proper routing of harness

for reinstallation.

Installation is reverse of removal, noting the following:

Use new O-rings when installing sensor and solenoid.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear

ECM fault memory

Tightening torques

-

Intake camshaft sensor to cylinder head 10 Nrn (7 ft-lb)

VANOS solenoid to VANOS control unit 30 Nm (22 ft-lb)

Page 386 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Battery, Starter, Alternator

- Check for battery voltage at terminal 50 of starter motor with

key in start position. If voltage is not present, check wiring be-

tween ignition switch and starter terminal. Check the EWS

system and other inputs that disrupt terminal

56 to the start-

er. See ELE Electrical

Wiring Diagrams. If voltage is

present and no other visible wiring faults can be found, prob-

lem is most likely in starter motor.

Starter, removing and installing

(6-cylinder engine)

The starter is removed from below. Access to starter bolts is

difficult. Be sure to have the proper tools on hand before pro-

ceeding.

NOTE-

Access to the starter wiring is very limited. Forbetteraccess,

it may be necessary to remove the intake manifold.

- Disconnect negative (-) battery cable.

CAUTIOI\C

Prior to disconnecting the battern read the baltery discon-

nection cautions

in OOlGeneral Cautions and Warnings.

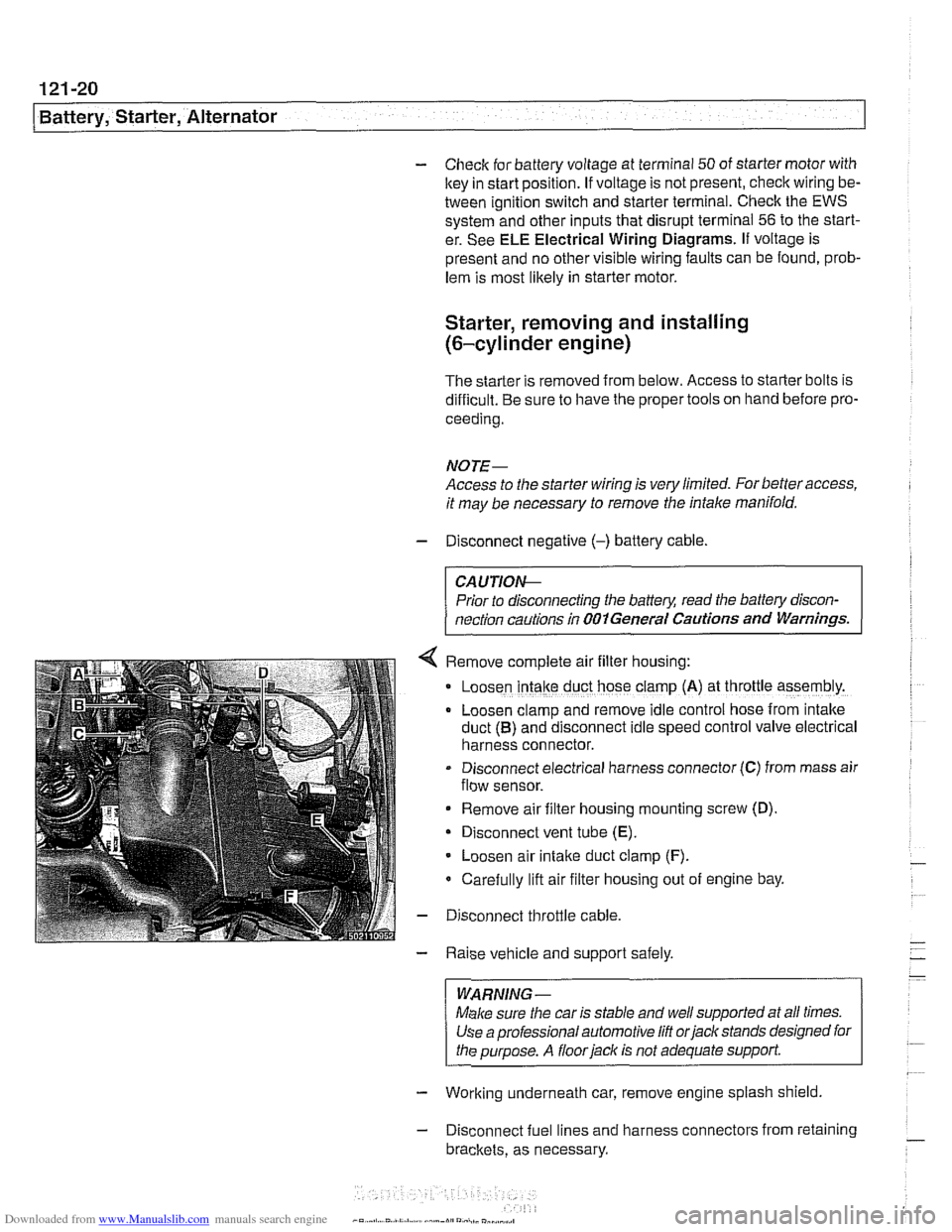

Remove complete air filter hous~ng:

Loosen intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw (D)

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Disconnect throttle cable.

Raise vehicle and support safely.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjack stands designed for

the purpose. A

floorjaclc is not adequate support

- Working underneath car, remove engine splash shield

- Disconnect fuel lines and harness connectors from retaining

brackets, as necessary.

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

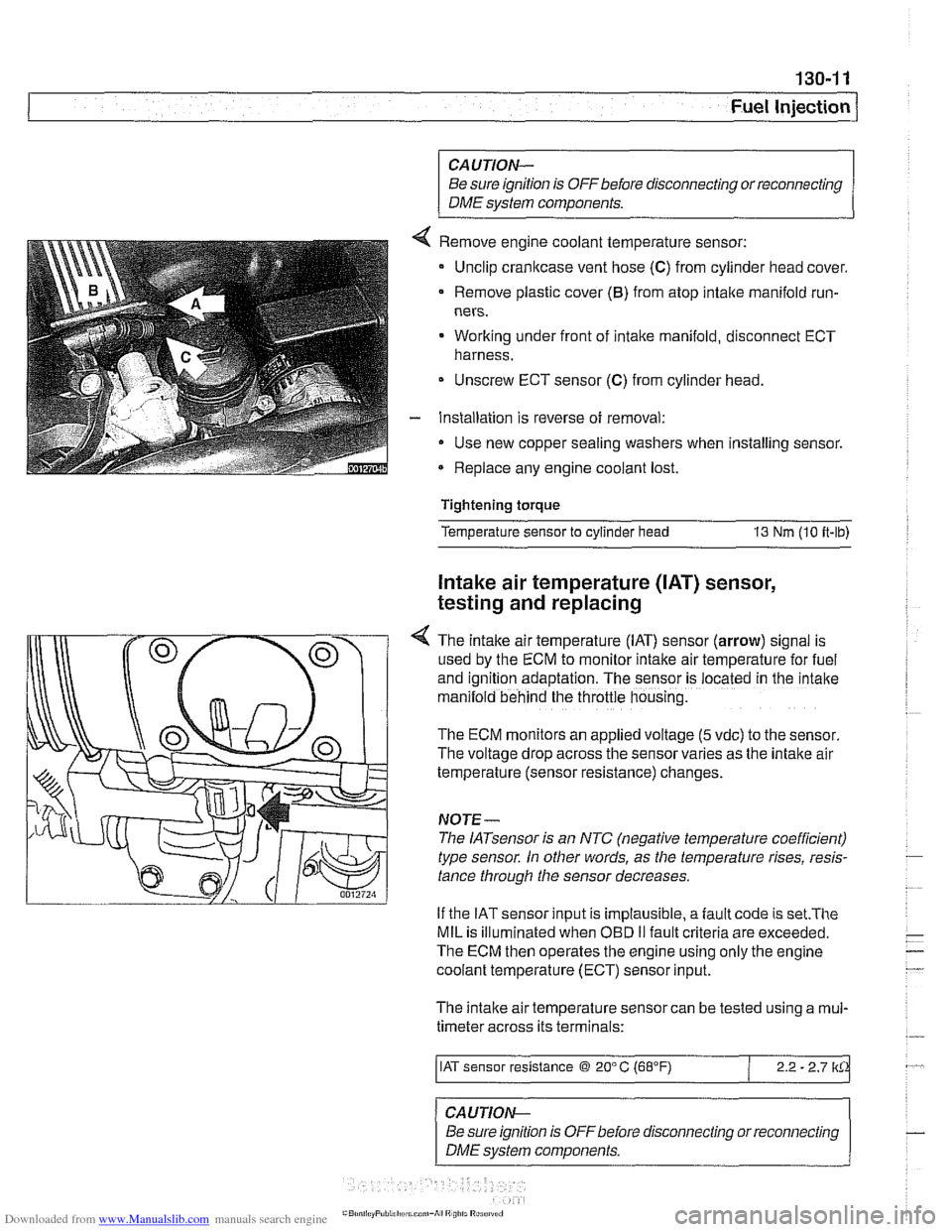

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.

Page 404 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

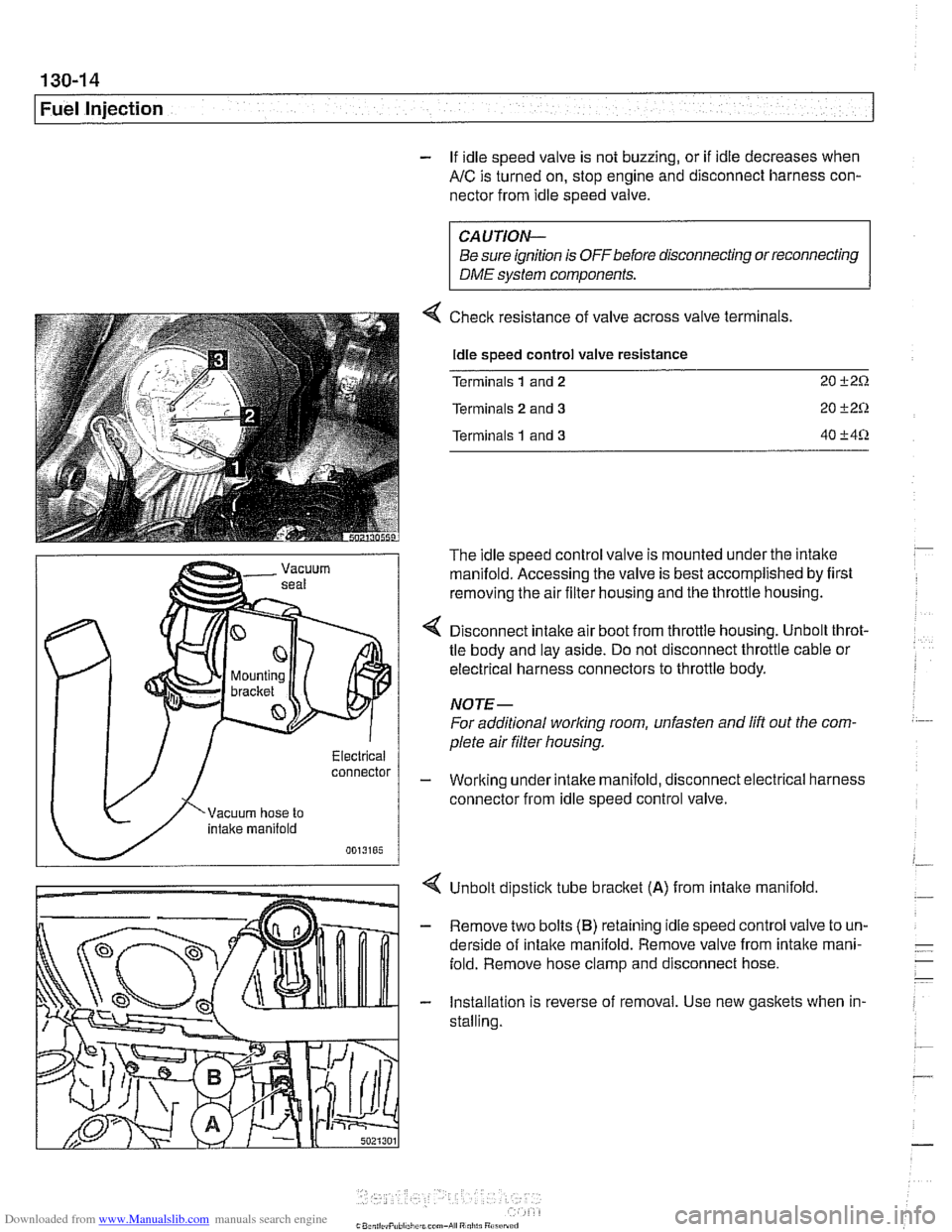

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

connector

CAUTION-

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

Checlc resistance of valve across valve terminals.

Idle speed control valve resistance

Terminals

1 and 2 20 i-2Q

Terminals 2 and 3 20 C2Q

Terminals 1 and 3 40 C4Q

The idle speed control valve is mounted under the intake

manifold. Accessing the valve is best accomplished by first

removing the air filter housing and the throttle housing.

< Disconnect intake air boot from throttle housing. Unbolt throt-

tle body and lay aside. Do not disconnect throttle cable or

electrical harness connectors to throttle body.

NOTE-

For additional worlcing room, unfasten and lift out the com.

plete air filter housing.

- Working under intake manifold, disconnect electrical harness

connector from idle speed control valve.

Unbolt dipstick tube

bracket (A) from intalte manifold.

- Remove two bolts (B) retaining idle speed control valve to un-

derside of intalte manifold. Remove valve from intalte mani-

fold. Remove hose clamp and disconnect hose.

- Installation is reverse of removal. Use new gaskets when in-

stalling.