Secondary air pump BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

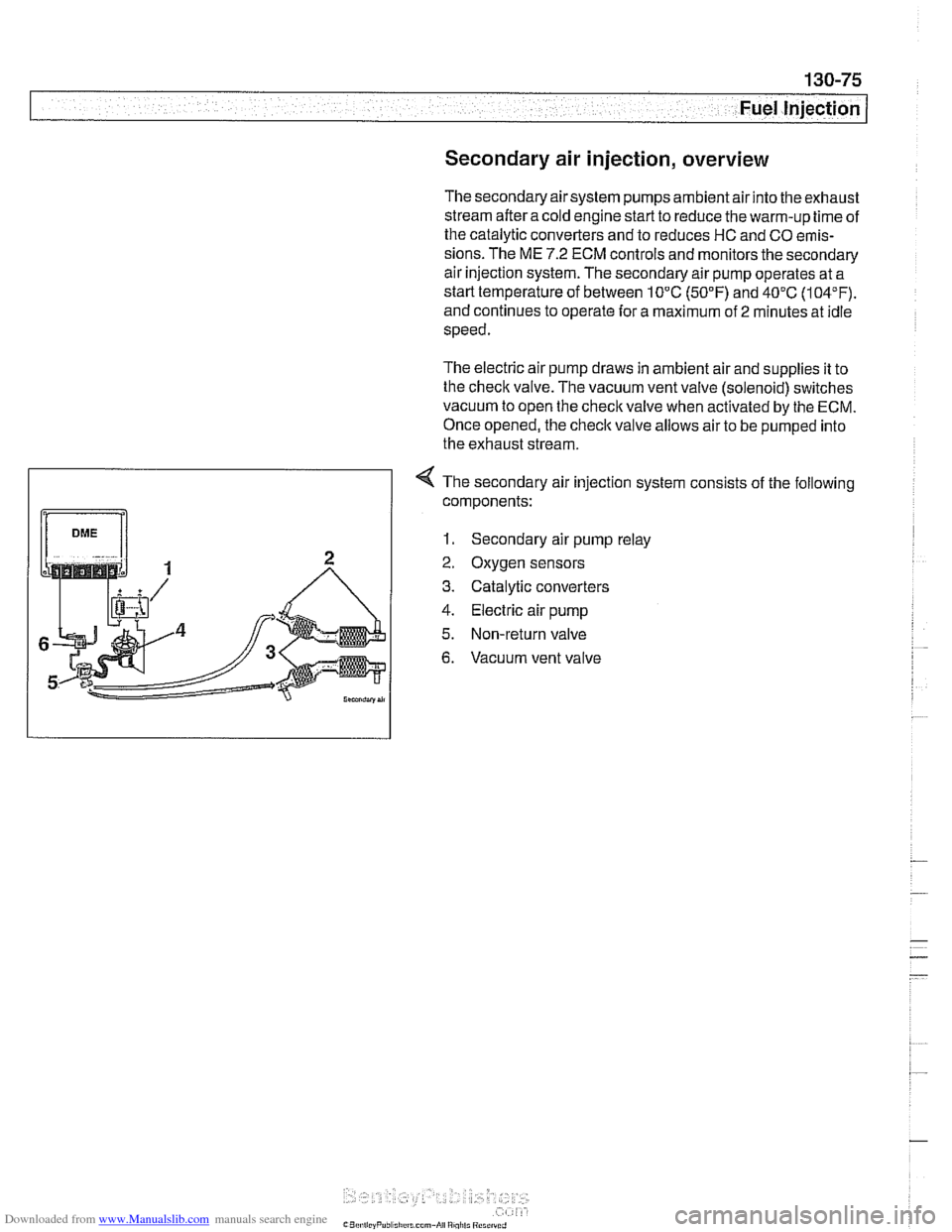

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 468 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

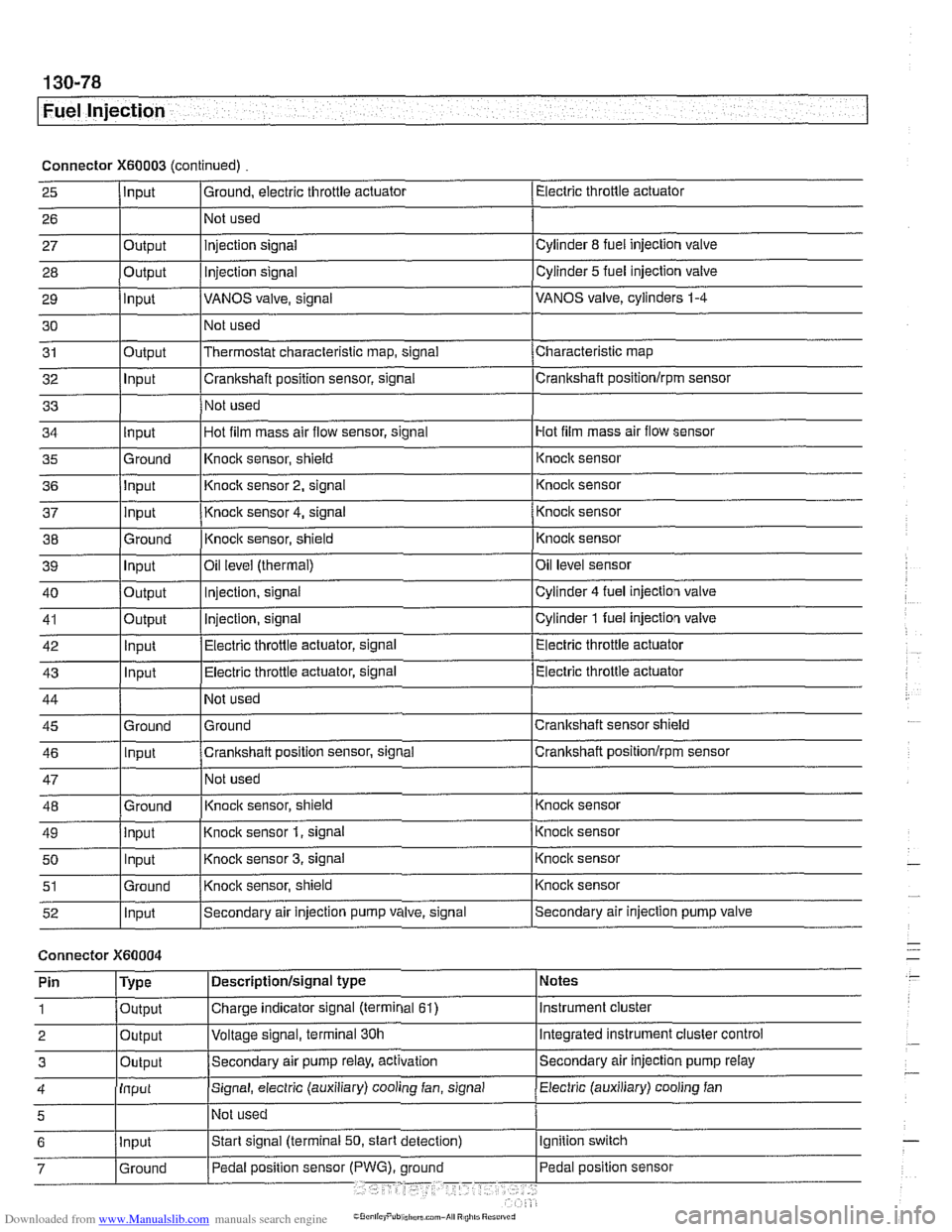

Connector X60003 (continued) Electric throttle actuator

25

- 27 28

29

30

31

32

33

I I I

36 jlnput I Knoclc sensor 2, signal 1 Knock sensor

I I I

Input

26

Output

Output

input

Output

Input

I ' I . I

43 1 ln~ut I Electric throttle actuator, signal (Electric throttle actuator

Ground, electric throttle actuator

1 Not

used

Hot film mass air flow sensor

34

- 37

38

39

40

41

42

injection signal

Injection

signal

VANOS valve, signal

Not used

Thermostat characteristic map, signal

Crankshaft position sensor, signal

Not used

35 l~round I~nock sensor, shield 1 ~nock sensor

Cylinder

8 fuel injection valve

Cylinder

5 fuel injection valve

VANOS valve, cylinders

1-4

Characteristic map

Crankshaft positionlrpm sensor

input

input

Ground

Input

Output

Output

Innut

Hot film mass air flow sensor, signal

I

44

45 46

47

48

49

50

51

52

Connector )(GO004

Knock sensor 4, signal

Knock sensor, shield

Oil

level (thermal)

Injection, signal

Injection, signal

Electric throttle actuator, signal

Not used

Ground

Crankshaft position sensor, signal

Not used

Knoclc sensor, shield

Knock sensor

1, signal

Knock sensor

3, signal

Knock sensor, shield

Secondary air injection pump valve, signal

'

Ground

Input

Ground

input Input

Ground

Input

I' I ... I . ~

Knock sensor

Knocic sensor

Oil level sensor

Cylinder

4 fuel injection valve

Cylinder

1 fuel injection valve

Electric throttle actuator

Crankshaft sensor shield

Crankshaft

positionlrprn sensor

Knock sensor

Knock sensor

Knock sensor

Knock sensor

Secondary air injection pump valve

Notes

Instrument cluster

Integrated instrument cluster control

Secondary air injection pump

relay

Pin

1

2

3

Electric (auxiliary) cooling fan 4

Type

Output

Output

Outout

Descriptionlsignal type

Charge indicator signal (terminal

61)

Voltage signal, terminal 30h

Secondam air pump relay, activation

Input

5

Signal, electric (auxiliary) cooling fan, signal

I~ot used

Page 531 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Exhaust System

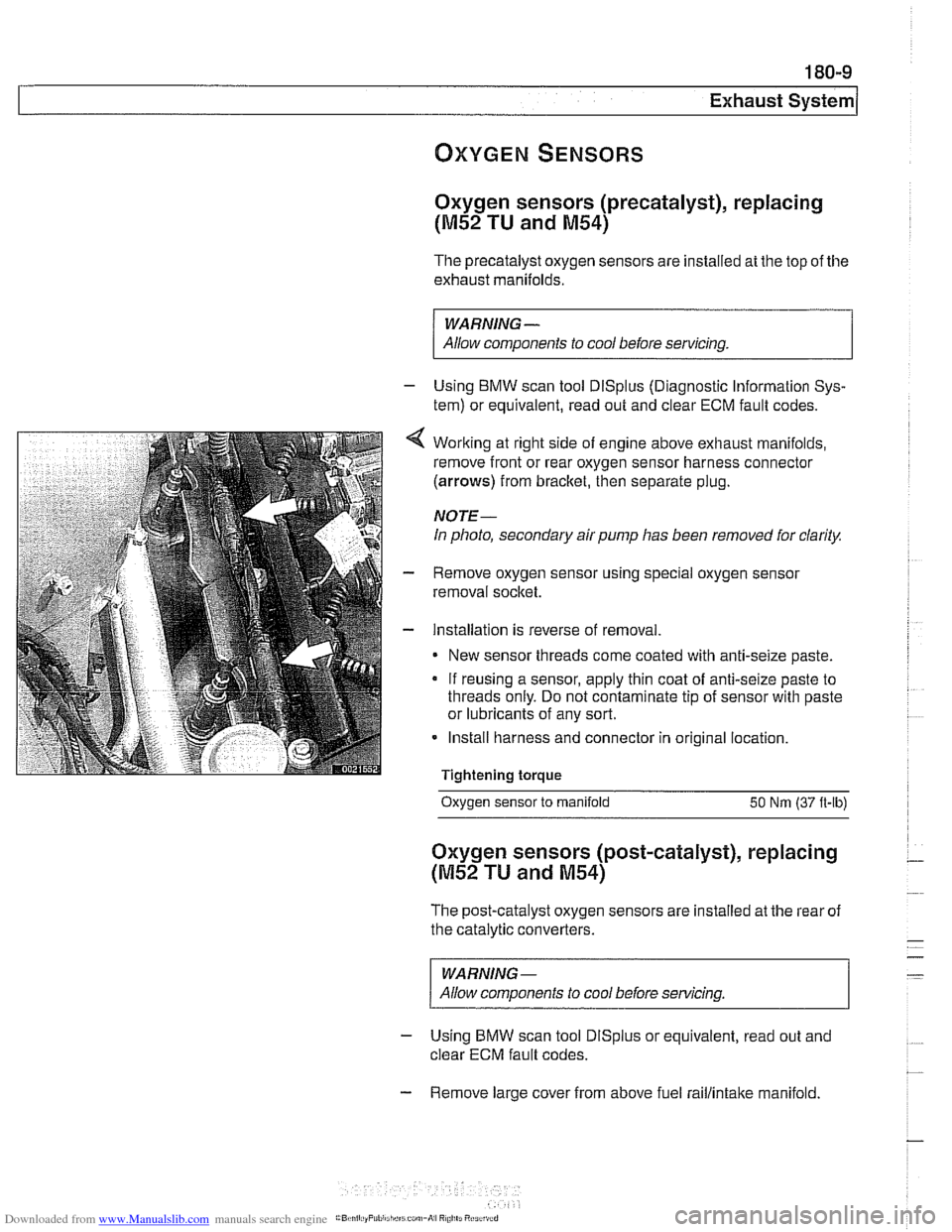

Oxygen sensors (precatalyst), replacing

(M52 TU and M54)

The precatalyst oxygen sensors are installed at the top of the

exhaust manifolds.

WARNING-

Allow components to cool before servicing.

- Using BMW scan tool DlSplus (Diagnostic Information Sys-

tem) or equivalent, read out and clear ECM fault codes.

Working at right side of engine above exhaust manifolds,

remove front or rear oxygen sensor harness connector

(arrows) from bracket, then separate plug.

NOTE-

In photo, secondary air pump has been removed for clarity.

Remove oxygen sensor using special oxygen sensor

removal socket.

Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing a sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

- -.

Oxygen sensor to manifold 50 Nm (37 ft-lb)

Oxygen sensors (post-catalyst), replacing

(M52 TU and M54)

The post-catalyst oxygen sensors are installed at the rear of

the catalytic converters.

WARNING-

Allow components to cool before servicing

- Using BMW scan tool DlSplus or equivalent, read out and

clear ECM fault codes.

- Remove large cover from above fuel raillintake manifold.

Page 965 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

Catalyst monitoring. Thisstrategy monitors the outputofthe

precatalyst and post-catalyst oxygen sensors, comparing the

oxygen content going into the catalytic converter to the

oxygen leaving the converter.

The diagnostic executive

lknows that most of the oxygen

should be used up during the oxidation phase. If it detects

higherthan programmed values, afault is set and the MIL

illuminates.

Misfire detection. This strategy monitors crankshaft speed

fluctuations and determines if an enoine misfire occurs bv

monitoring variations in speed between each crankshaft

sensortrigger point. This strategy is so finely tuned that it can

determine the severity of the misfire.

The system determines

if a misfire is occurring, as well as

other pertinent misfire

information such as:

Specific

cylinder(s)

Severity of the misfire event

Emissions relevant or catalyst damaging

Misfire detection is an on-going monitoring process that is

only disabled under certain limited conditions.

Secondary air injection monitoring. Secondary air

injection is used to reduce HC and CO emissions during

engine warm up. Immediately following a cold engine start

(-1 0" to 40°C), fresh air (and therefore oxygen) is pumped

directly into the exhaust

manifold. By injecting additional

oxygen into the exhaust manifold, catalyst warm-up time is

reduced.

Secondary air system components are:

Electric air injection pump

* Electric pump relay

* Non-return valve

Vacuum

I vent valve

- Stainless steel air injection pipes

Vacuum reservoir

The secondary air system is monitored via the use

of the pre-

catalyst oxygen sensors. Once the air pump is active and air

is injected into the system, the signal at the oxygen sensor

reflects a lean condition. If the oxygen sensor signal does not

change, a fault is set and the faulty

bank(s) identified. If after

completing the next cold startafault is again present, the MIL

illuminates.

Page 982 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-22

I On-Board Diagnostics

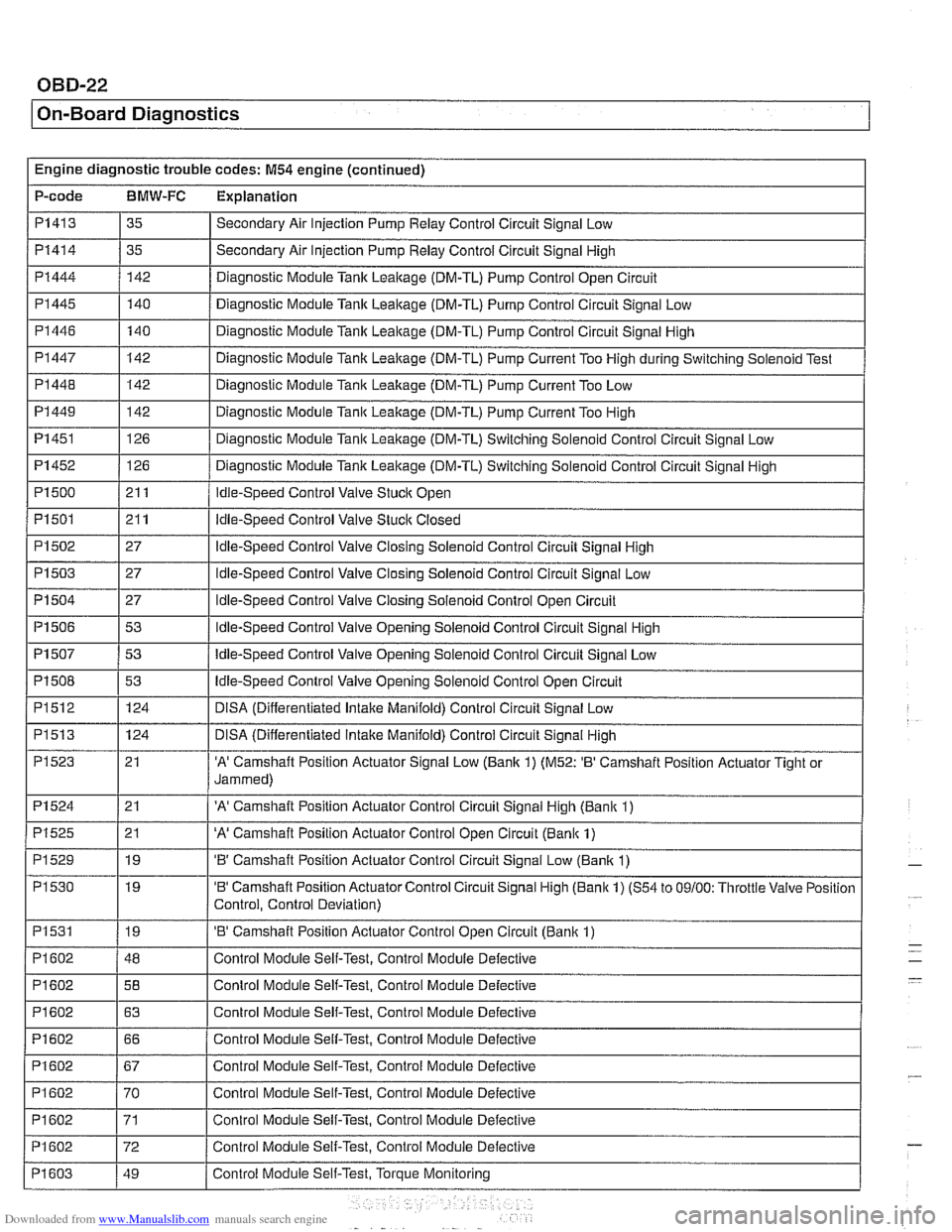

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

PI 41 3

PI414

PI444

PI 445

PI446

PI447

PI 448

PI 449

PI 451

35

35

142 140

140

142

142

142

126

Secondary Air Injection Pump Relay Control Circuit Signal Low

Secondary Air Injection Pump

Relay Control Circuit Signal High

Diagnostic Module Tank Leakage (DM-TL) Pump Control Open Circuit

Diagnostic Module Tank

Leaitage (DM-TL) Pump Control Circuit Signal Low

Diagnostic Module Tank Lealtage (DM-TL) Pump Control Circuit Signal High

Diagnostic Module

Tanlc Leakage (DM-TL) Pump Current Too High during Switching Solenoid Test

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too Low

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High

Diagnostic Module

Tank Leaitage (DM-TL) Switching Solenoid Control Circuit Signal Low

Page 989 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

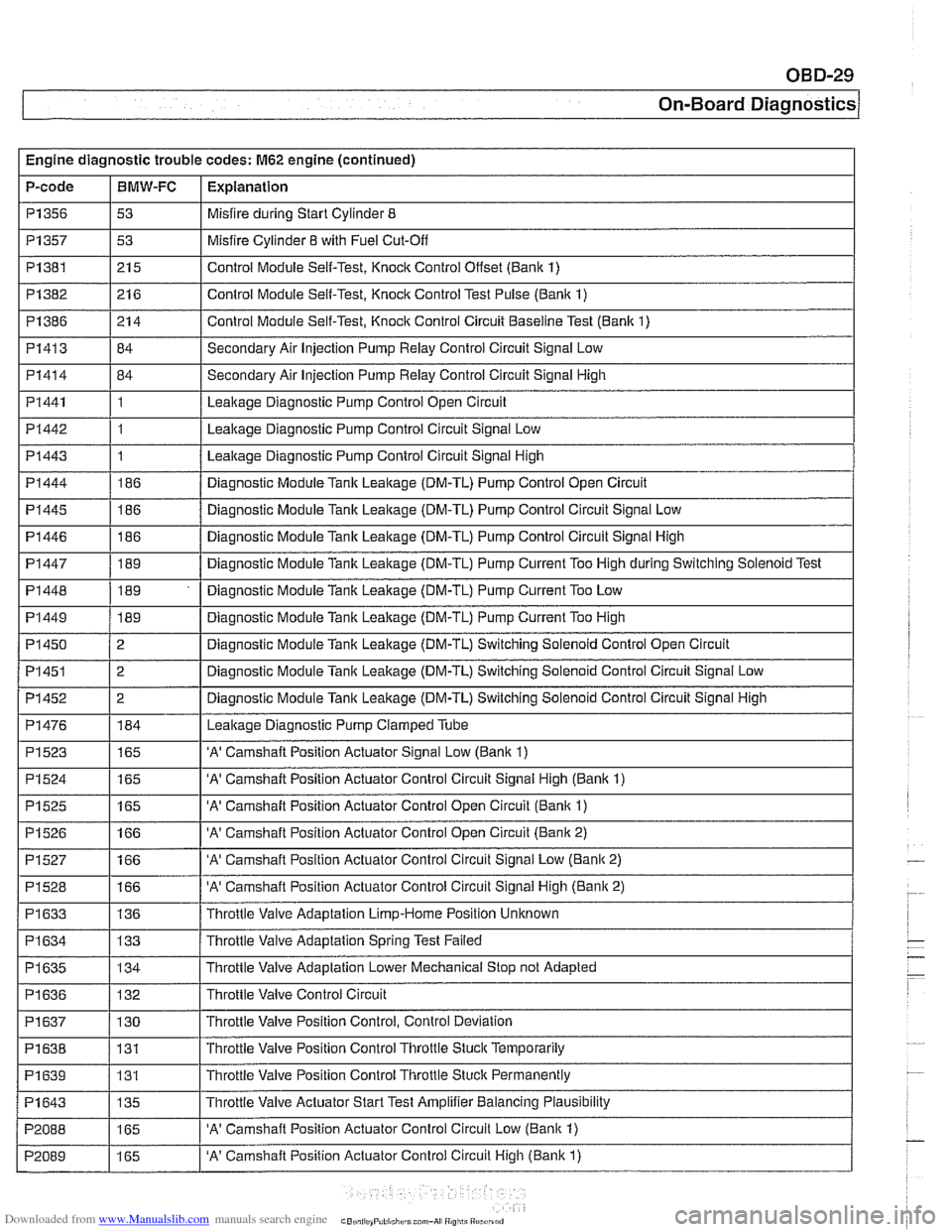

Engine diagnostic trouble codes: M62 engine (continued)

P-code

I I -

I I - -.

PI445 1186 / Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal Low

PI357

PI382

PI386

PI413

PI414

PI441

PI442

PI443

PI444

P1356 1 53 I Misfire during Start Cylinder 8

BMW-FC

I P1523

I

I - -

1165 I 'A' Camshaft Position Actuator Signal Low (Banlc 1)

Explanation

P1381 1215 I Control Module Self-Test, Knock Control Onset (Bank 1)

53

21 6

21 4

84

84

1

1

1

186

PI 446

PI 447

PI 448

PI449

PI 450

PI451

PI452

PI476

Misfire Cylinder 8 with Fuel Cut-Off

Control Module Self-Test, Knock Control Test Pulse (Bank 1)

Control Module Self-Test, Knock Control Circuit Baseline Test (Bank 1)

Secondary Air Injection Pump Relay Control Circuit Signal Low

Secondary Air Injection Pump

Relay Control Circuit Signal High

Leakage Diagnostic Pump Control Open Circuit

Leakage Diagnostic Pump Control Circuit Signal Low

Leakage Diagnostic Pump Control Circuit Signal High

Diagnostic Module Tank Leakage (DM-TL) Pump Control Open Circuit

186

189

189

189

2

2

2

184

P1524

P1525

P1526

PI527

PI528

PI633

PI 634

PI 635

I I

PI 638 / 131 I Throttle Valve Position Control Throttle Stuck Temporarily

. -

Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal High

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High during Switching Solenoid Test

Diagnostic Module Tank Leakage (DM-TL) Pump Current Too Low

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High

Diagnostic Module Tank Leakage (DM-TL) Switching Solenoid Control Open Circuit

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal Low

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal High

Leakaqe Diaqnostic Pump Clamped Tube

I I

165

165

166

166

166

136

133

134

'A' Camshaft Position Actuator Control Circuit Signal High (Banlc 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal Low (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal High (Bank 2)

Throttle Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

PI 636

PI639

P1643

P2088

P2089

PI 637 / 130 I Throttle Valve Position Control, Control Deviation

132

131

135

165

165 Throttle

Valve Position Control Thronle Stuck Permanently

Throttle Valve Actuator Start Test Amplifier Balancing Plausibility

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Bank 1)

Page 991 of 1002

Downloaded from www.Manualslib.com manuals search engine

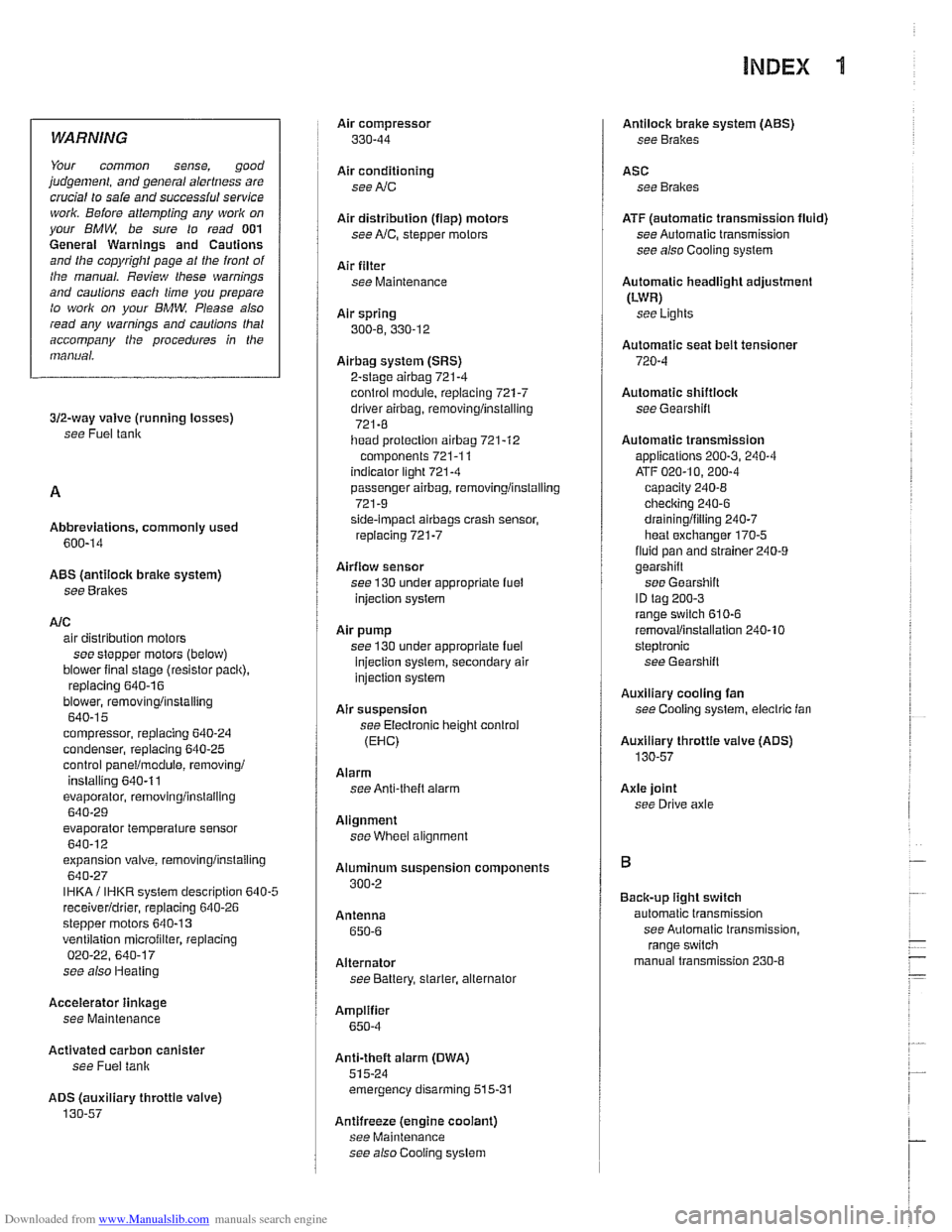

INDEX 'tl

WARNING

Your common sense, good

judgemenl, and general alertness are

crucial to sale and successiul service

worlr. Belore attempting any work on

your

BMM be sure lo read 001

General Warnings and Cautions

and the

copyriglll page at the front 01

the manual. Review these warnings

and

caulions each lime you prepare

lo work on your BMW. Please also

read any warnings and cautions that

accompany

tile procedures in the

manual.

312-way valve (running losses)

see Fuel tank

Abbreviations, commonly used 600-14

ABS (antilock brake system)

see

Bral(es

A/C air distribution motors

see stepper motors (below)

blower final stage (resistor pack),

replacing

640-16

blower, removinglinslalling

640-1 5

compressor, replacing

640-24 condenser, replacing 64045

control panellmodule, removing1

installing

640-1 1

evaporakr, removinglinstalling 640-29

evaporator temperature sensor

640-12 expansion valve, removinglinstailing

640-27

IHKA/ IHKR system description 640-5

receiveridrier, replacing 640-26

stepper motors 640-1 3 ventilation microiilter, replacing

020-22. 640-17

see also Heating

Accelerator

iinlcage

see Maintenance

Activated carbon canister

see Fuel tank

ADS (auxiliary throttle valve)

130-57

Air compressor

330-44

Air conditioning

see

AIC

Air distribution (flap) motors

seeNC, stepper motors

Air filter see Maintenance

Air spring

300-6, 330-12

Airbag system (SRS)

2-stage

airbag 721-4

control module, replacing 721-7 driver airbag, removinglinstalling

721-8

iiead protection airbag 721-12 components 721-1 1

indicator

lighl721-4

passenger airbag, removinglinstalling

721-9 side-impact airbags crash sensor,

replacing

721-7

Airflow sensor see 130 under appropriate

fuel

injection system

Air pump

see 130 under appropriate fuel

injection system, secondary air

injection system

Air suspension

see Electronic height control

(EHC)

Alarm

see Anti-theft alarm

Alignment see

Wheei alignment

Aluminum suspension components

300-2

Antenna 650-6

Alternator see Battery, starter, alte rnator

Amplifier

650-4

Anti-theft alarm (DWA)

515-24 emergency disarming 515-31

Antifreeze (engine coolant)

see Maintenance

see also Cooling system

Antilock brake system (ABS) see Brakes

ASC see Brakes

ATF (automatic transmission fluid)

see Automatic transmission

see also Cooling systern

Automatic headlight adjustmenl

(LWR) see Lights

Automatic seat belt tensioner

720-4

Automatic shiftloclc

see

Gearshift

Automatic transmission

applications

200-3, 240-4

ATF 020-10, 200-4

capacity 240-8 checking 240-6

drainingifilling 240-7

heat exchanger 170-5

fluid pan and strainer 240-9 gearshift

see Gearshift

ID tag

200-3 range switch 610-6

removaliinstallation 240-10

steptronic see Gearshift

Auxiliary cooling fan

see

Coollng system, electric Ian

Auxiliary throttle valve (ADS)

130-57

Axle joint

see Drive axle

Back-up light switch

automatic transmission see Automatic transmission. range switch

- .~.~~~

manual transmission 230-8 -

- I