jack points BMW 528i 1997 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 715 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 9

Rear suspension1

Swing arm ball joint, replacing

- Raise rear end of car and remove wheel.

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension

parts.

- Sport Wagon model: Support wheel bearing carrier from be-

low.

CA

UTION-

The shock absorberprevents the drive axle and wheel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the

shoclc absorber

mounting fastenerprevents damage to the brake hose, park-

ing

brake cable and drive axle CVjoints.

- Model with air shock absorbers: Detach air supply line from

shoclc absorber. Plug ports and lines to keep out dirt.

- Sport Wagon model: Remove shock absorber lower mount-

ing bolt.

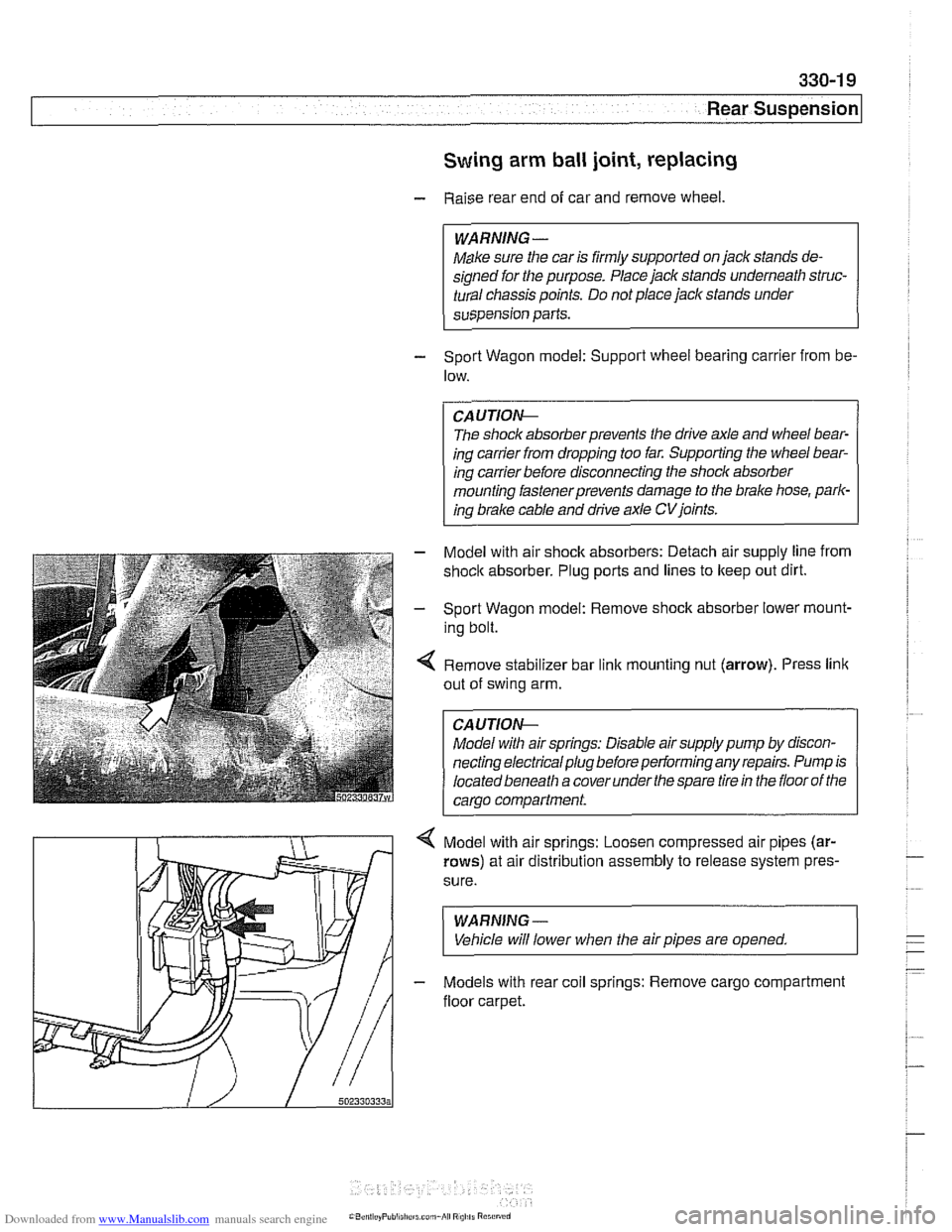

4 Remove stabilizer bar link mounting nut (arrow). Press link

out of swing arm.

Model with air springs: Disable air supply pump by discon-

necting electrical plug before performing any repairs. Pump is

located beneath a cover under

the spare tire in the floor of the

carao

comoartment.

4 Model with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres.

sure.

WARNING-

Vehicle will lower when the air pipes are opened.

- Models with rear coil springs: Remove cargo compartment

floor carpet.

Page 718 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-22

I Rear Suspension

s

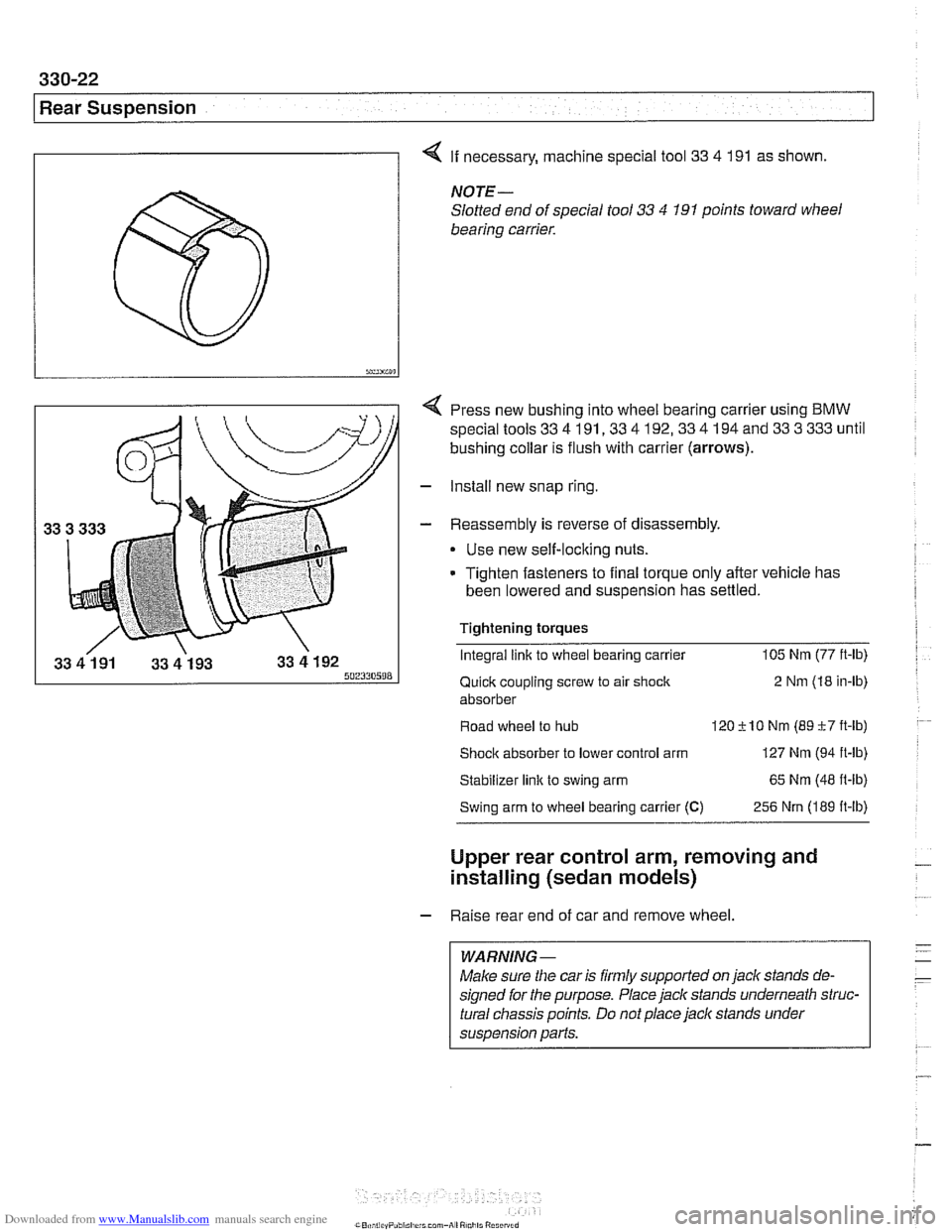

4 If necessary, machine special tool 33 4 191 as shown.

NOTE-

Slotted end of special tool 33 4 191 points toward wheel

bearing carrier.

Press new bushing into wheel bearing carrier using BMW

special tools

33 4 191,33 4 192,33 4 194 and 33 3 333 until

bushing collar is flush with carrier (arrows).

- Install new snap ring

- Reassembly is reverse of disassembly

Use new self-locking nuts.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Tightening torques Integral link to wheel bearing carrier 105

Nm (77

ft-lb)

Quick coupling screw to air shock 2

Nm (18 in-ib)

absorber

Road wheel to hub

120+lO Nm (89c7ft-ib)

Shock absorber to lower control arm 127 Nm (94 ft-lb)

Stabilizer link to swing arm 65

Nm (48

fl-lb)

Swing arm to wheel bearing carrier (C) 256 Nrn (189 ft-lb)

Upper rear control arm, removing and

installing (sedan models)

- Raise rear end of car and remove wheel.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jaclc stands under

suspension parts.

Page 719 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-23

Rear Suspension

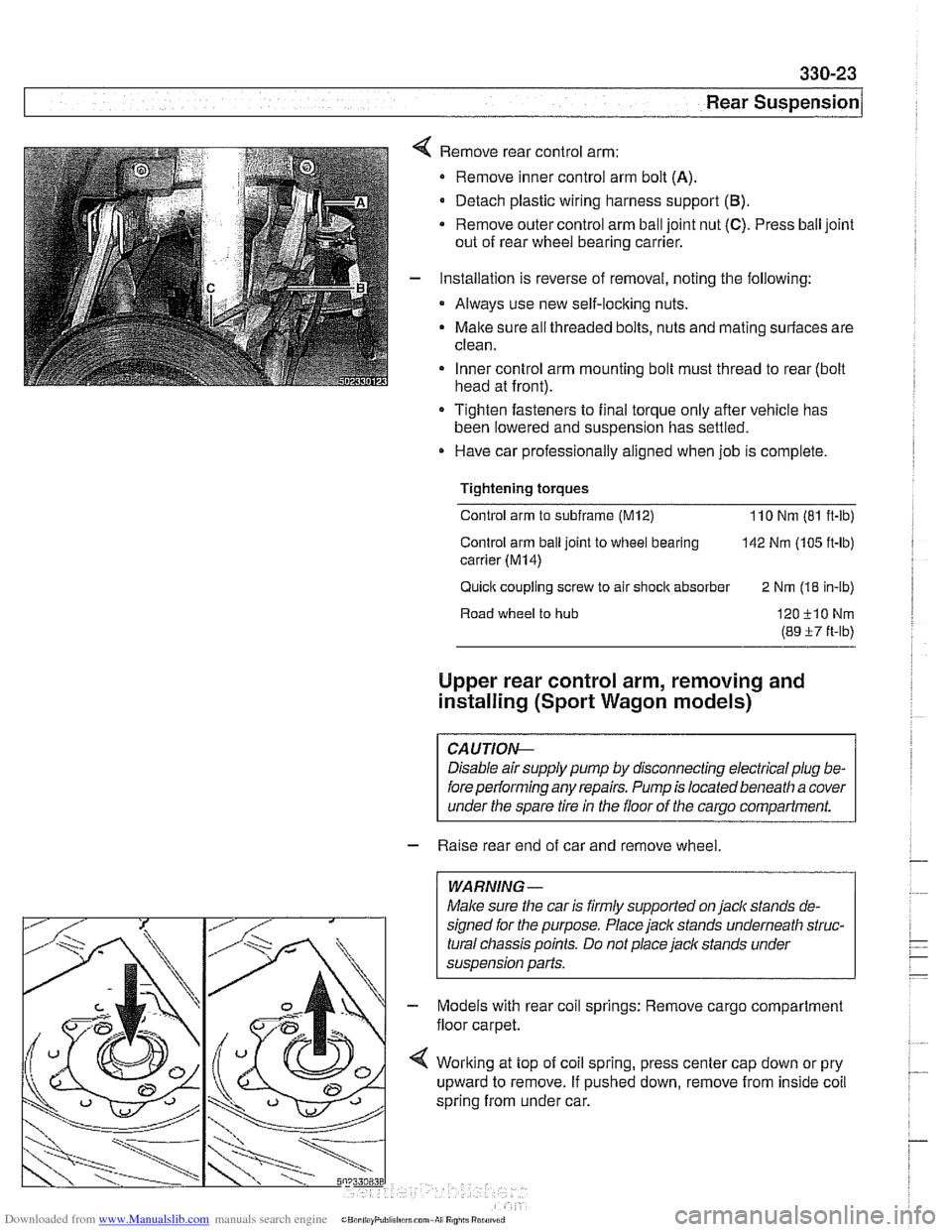

Remove rear control arm:

Remove inner control arm bolt

(A).

Detach plastic wiring harness support (B).

* Remove outer control arm ball joint nut (C). Press ball joint

out of rear wheel bearing carrier.

Installation is reverse of removal, noting the following:

Always use new self-locking nuts.

Malte sure all threaded bolts, nuts and mating surfaces are

clean.

Inner control arm mounting bolt must thread to rear (bolt

head at front).

Tighten fasteners to final torque only afler vehicle has

been lowered and suspension has settled.

Have car professionally aligned when job is complete.

Tightening

torques

Control arm to subframe (M12) 110 Nm (81 ft-ib)

Control arm

ball joint to wheel bearing 142 Nm (105 ft-lb)

carrier

(M14)

Quick coupling screw to air shock absorber

2 Nm (18 in-lb)

Road wheel

to hub 120-flONm

(89 i7 ft-lb)

Upper rear control arm, removing and

installing (Sport Wagon models)

CAUTIOG

Disable air supply pump by disconnecting electrical plug be-

fore

perlorming any repairs. Pump is located beneath a cover

under the spare tire in the floor of the

carqo compartment.

- Raise rear end of car and remove wheel.

WARNING -

Make sure the car is firmly supported on jaclc stands de-

signed for the purpose.

Place jaclc stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

Models with rear coil springs: Remove cargo compartment

floor carpet.

Worlting at top of coil spring, press center cap down or pry

upward to remove. If pushed down, remove from inside coil

spring from under car.

Page 721 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-25

Rear Suspension

Remove rear control arm:

Remove inner control arm bolt

(A). Push shock absorber

out of the way to slide bolt out.

Detach plastic wiring harness support

(B).

Remove outer control arm ball joint nut (C). Press ball joint

out of rear wheel bearing carrier.

Installation is reverse of removal, noting the following:

* Always use new self-locking nuts.

Maite sure

ail threaded bolts, nuts and mating surfaces are

clean.

Inner control arm mounting bolt must thread to front

(bolt . head at rear).

Make sure long lower shock absorber bushing fits in hole

in suspension swing arm.

* Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Have car professionally aligned when job is complete.

Tightening torques Control arm to

subframe (M12) 110 Nm (81 ft-ib)

Control arm ball joint to wheel bearing

142 Nm (105 ft-lb)

carrier

(M14)

Quick coupling screw to air shocit absorber

2 Nm (18 in-lb)

Road wheel to hub

Shoclc absorber to lower control arm 127 Nm (94 it-lb)

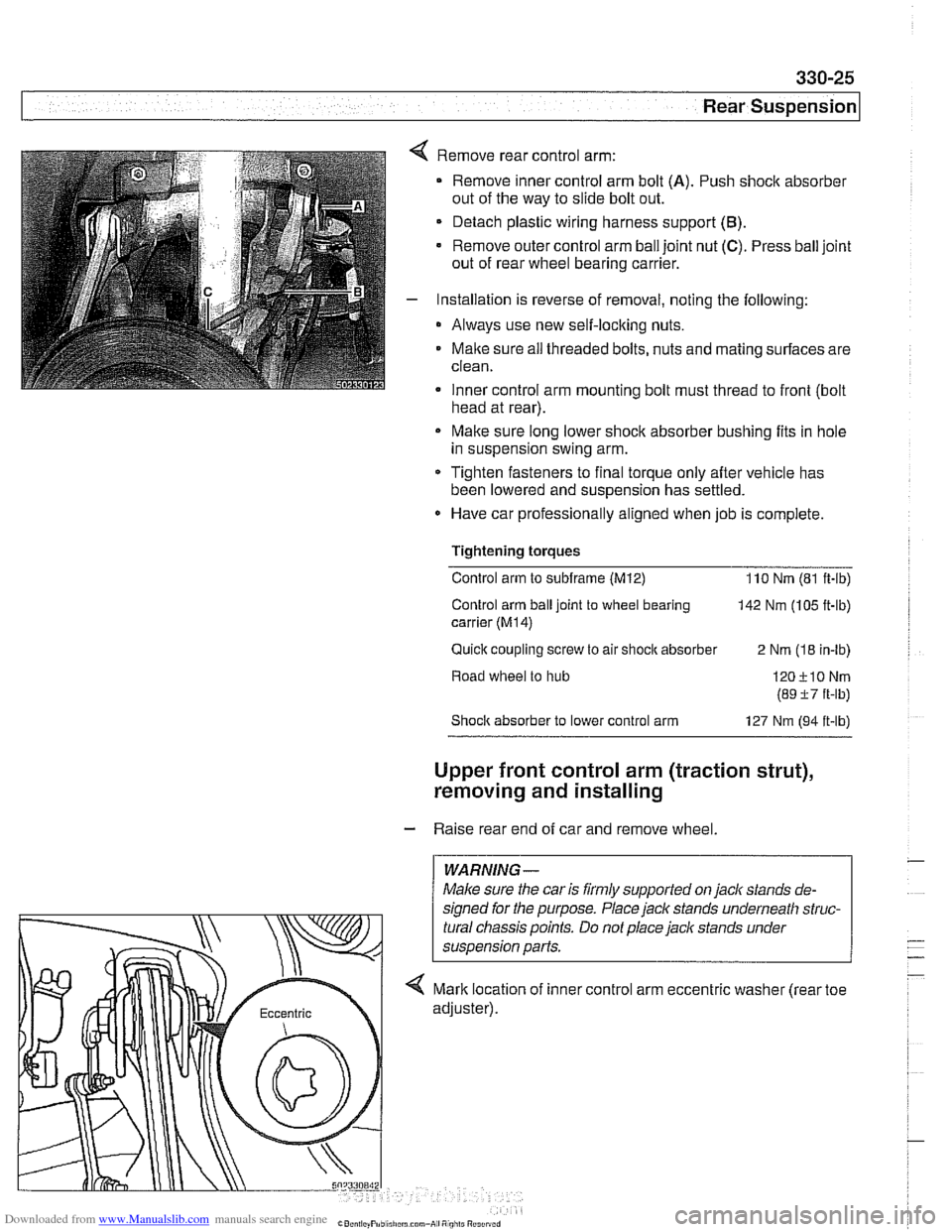

Upper front control arm (traction strut),

removing and installing

- Raise rear end of car and remove wheel.

WARNING-

Maice sure the car is firmly supported on jack stands de-

signed for the purpose. Place

jack stands underneath struc-

tural chassis points. Do not place jack stands under

< Mark location of inner control arm eccentric washer (rear toe

Page 722 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-26

/ Rear Suspension

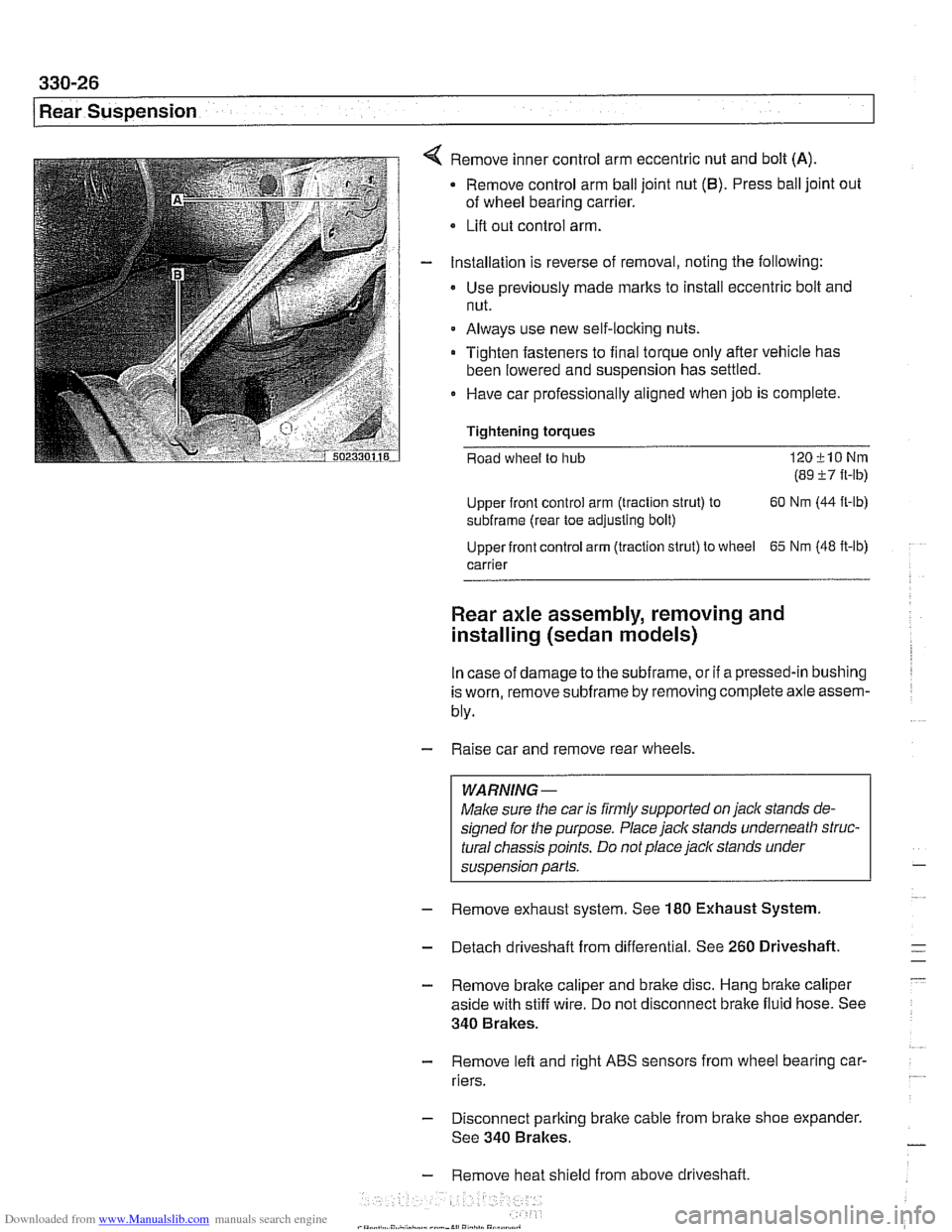

Remove inner control arm eccentric nut and bolt (A)

Remove control arm ball joint nut (6). Press ball joint out

of wheel bearing carrier.

Lifl out control arm.

Installation is reverse of removal, noting the following:

Use previously made

marks to install eccentric bolt and

nut.

Always use new self-locking nuts.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

0 Have car professionally aligned when job is complete.

Tightening

torques

Road wheel to hub 120klONm

(89 i7 ft-lb)

Upper front control arm (traction strut) to 60

Nm (44

ft-lb)

subframe (rear toe adjusting bolt)

Upper front control arm (traction strut) to wheel

65 Nm (48 ft-lb)

carrier

Rear axle assembly, removing and

installing (sedan models)

In case of damage to the subframe, or if a pressed-in bushing

is worn, remove

subframe by removing complete axle assem-

bly.

- Raise car and remove rear wheels.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

suspension parts.

- Remove exhaust system. See 180 Exhaust System

- Detach driveshaft from differential. See 260 Driveshaft.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect brake fluid hose. See

340 Brakes.

- Remove lefl and right ABS sensors from wheel bearing car-

riers.

- Disconnect parking brake cable from brake shoe expander.

See 340 Brakes.

- Remove heat shield from above driveshaft.

Page 731 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-35

Rear Suspension

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Always use new self-loclting nuts.

Make sure all threaded bolts, nuts and mating suriaces are

clean.

Make sure long lower strut bushing fits in hole in wheel

bearing carrier.

Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Stake axle collar nut after tightening.

Tightening torques

ABS pulse sensor to wheel bearing carrier

8 Nm (6 ft-lb)

Brake rotor to hub 16 Nm (12 ft-lb)

Rear brake pad carrier (caliper) to wheel 65

Nm (48

ft-lb)

bearing carrier

Rear axle shaft to hub

(M27) 300 Nm (221 ft-lb)

Rear strut to wheel bearing carrier 127

Nrn (94 ft-lb)

Road wheel to hub

120+10 Nm

(89

i7 ft-lb)

Swing arm to wheel bearing carrier 256

Nrn (189 ft-lb)

Upper front control arm (traction strut) to 65 Nrn

(48

ft-lb)

wheel carrier

Upper rear control arm to wheel carrier 142

Nrn (105

ft-lb)

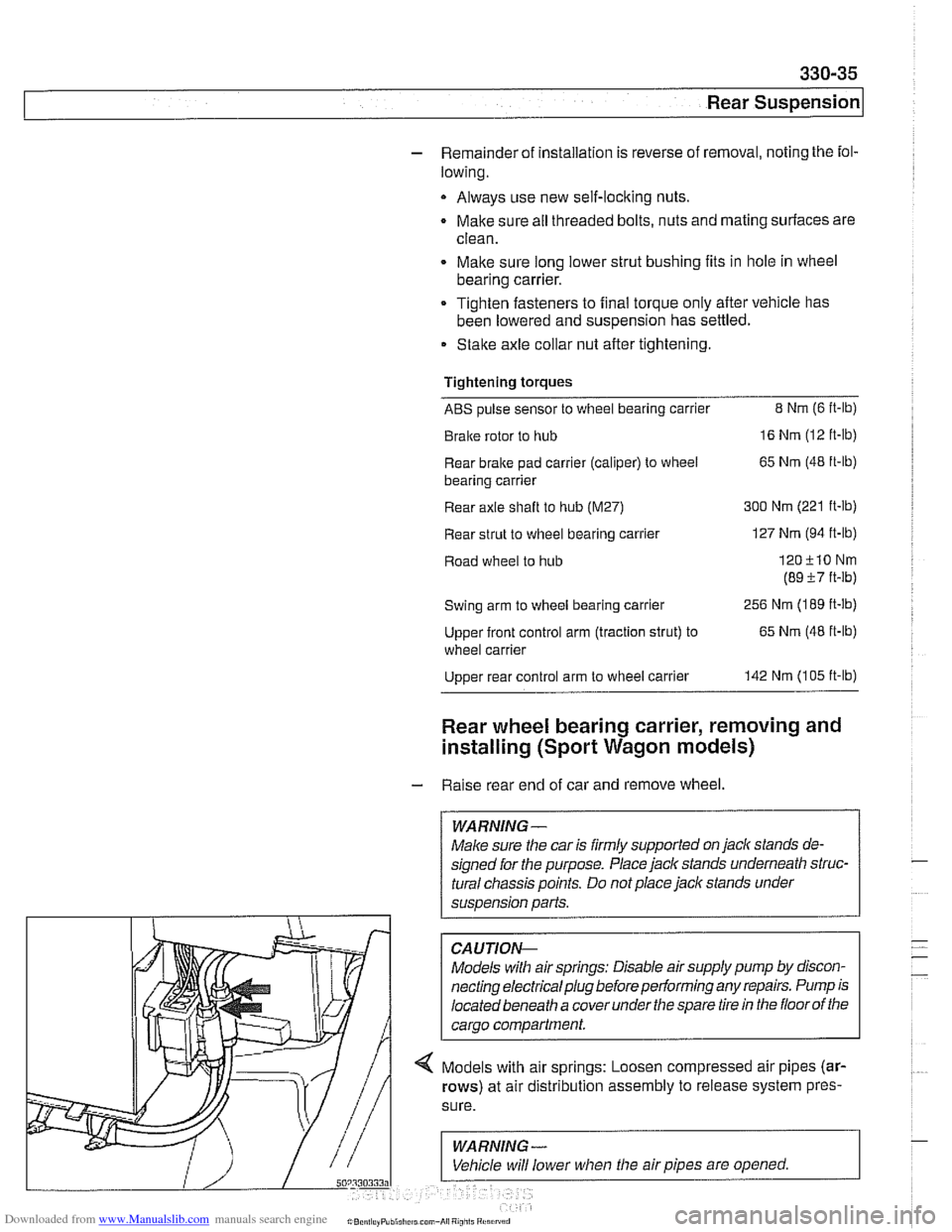

Rear wheel bearing carrier, removing and

installing (Sport Wagon models)

- Raise rear end of car and remove wheel.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

Models

with air springs: Disable air supply pump by discon-

necting electricalplug

beforepedormingany repairs. Pump is

located beneath a cover under the spare tire in the floor of the

cargo compartment.

-- 4 Models with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

Page 735 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-39

I Rear suspension1

- Remainder of installation is reverse of removal, noting the fol-

lowing.

Models with coil springs: Fit spring correctly in lower spring

seat.

* Models with air suspension: Fit eccentric lug at bottom of

air spring in recess of wheel carrier spring seat.

Always use new self-locking nuts.

- Make sure all threaded bolts, nuts and mating surfaces are

clean.

a Tighten fasteners to final torque only after vehicle has

been lowered and suspension has settled.

Stake axle collar nut afler tightening.

Tightening torques

ABS pulse sensor to wheel bearing 8 Nm (6

ft-lb)

carrier

Air spring to wheel bearing carrier 20 Nm (15 ft-lb)

Brake rotor to hub 16 Nm (12

it-lb)

Rear axle shaft to hub (M27) 300 Nm (221 ft-lb)

Rear brake pad carrier (caliper) to wheel 65 Nm (48 ft-lb)

bearing carrier

Road wheel to hub

120ilONm

(89 k7 ft-lb)

Swing arm to wheel bearing carrier 256 Nm (189 it-lb)

Upperfrontcontrol arm (traction strut) to 65 Nm (48 ft-lb)

wheel carrier

Upper rear control arm to wheel carrier 142 Nm (105 ft-lb)

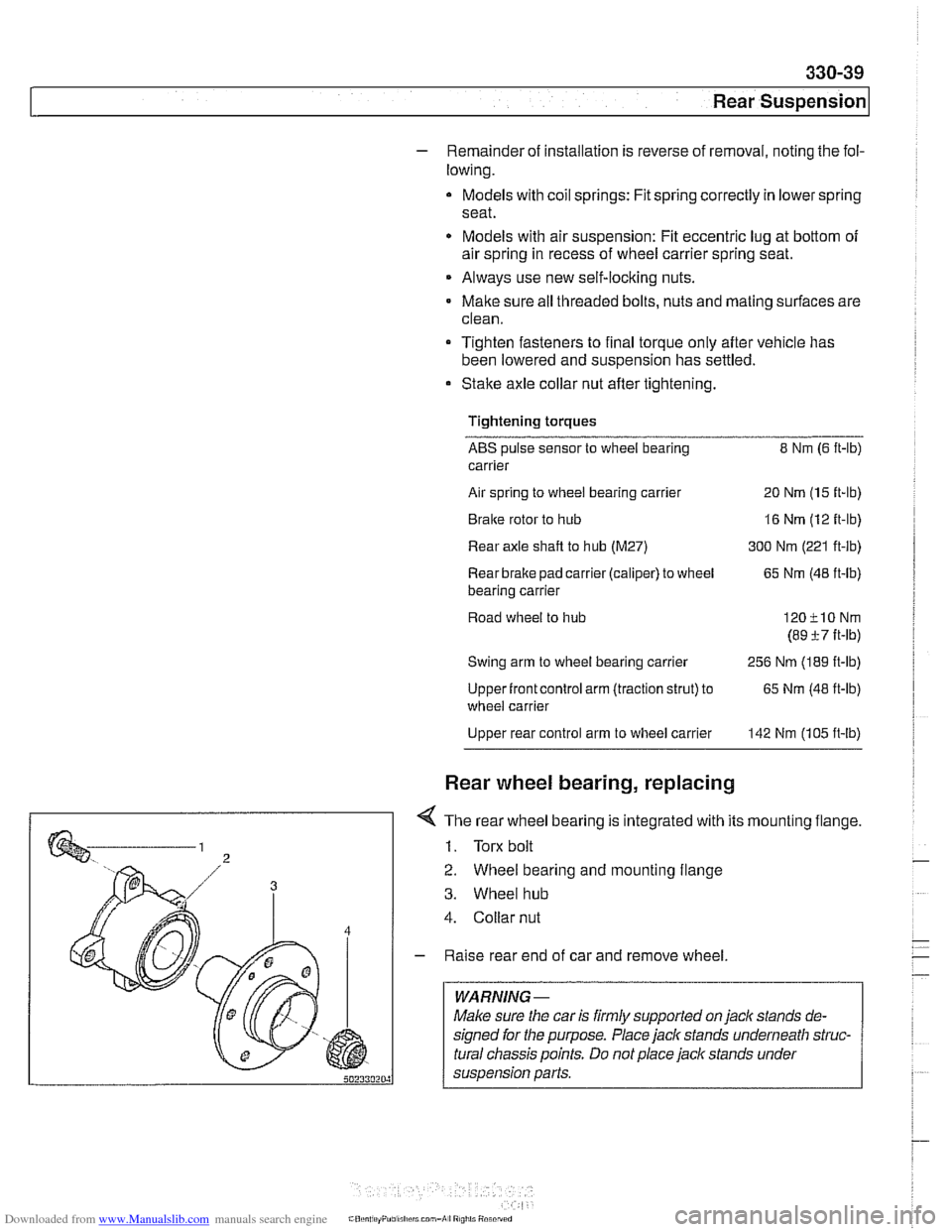

Rear wheel bearing, replacing

< The rear wheel bearing is integrated with its mounting flange.

1. Torx bolt

2. Wheel bearing and mounting flange

3. Wheel hub

4. Collar nut

- Raise rear end of car and remove wheel.

WARNING -

Make sure the car is firmly supported on jaclc stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

Page 738 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-42

/Rear Suspension

- Install ABS sensor and road wheel.

- Lower car to ground. With an assistant applying brakes, use

new axle collar nut to tighten to final torque. Stake nut.

- Remainder of installation is reverse of removal

Tightening torques ABS pulse sensor to wheel bearing carrier

8 Nm (6 ft-lb)

Brake disc to hub

16 Nm

Rear

brake pad carrier (caliper) to wheel

65 Nm (48 ft-lb)

bearing carrier

Rear axle shaft to hub

(M27) 300 Nrn (221 ft-lb)

Road wheel to hub 120F10 Nm

(89 ?7 ft-lb)

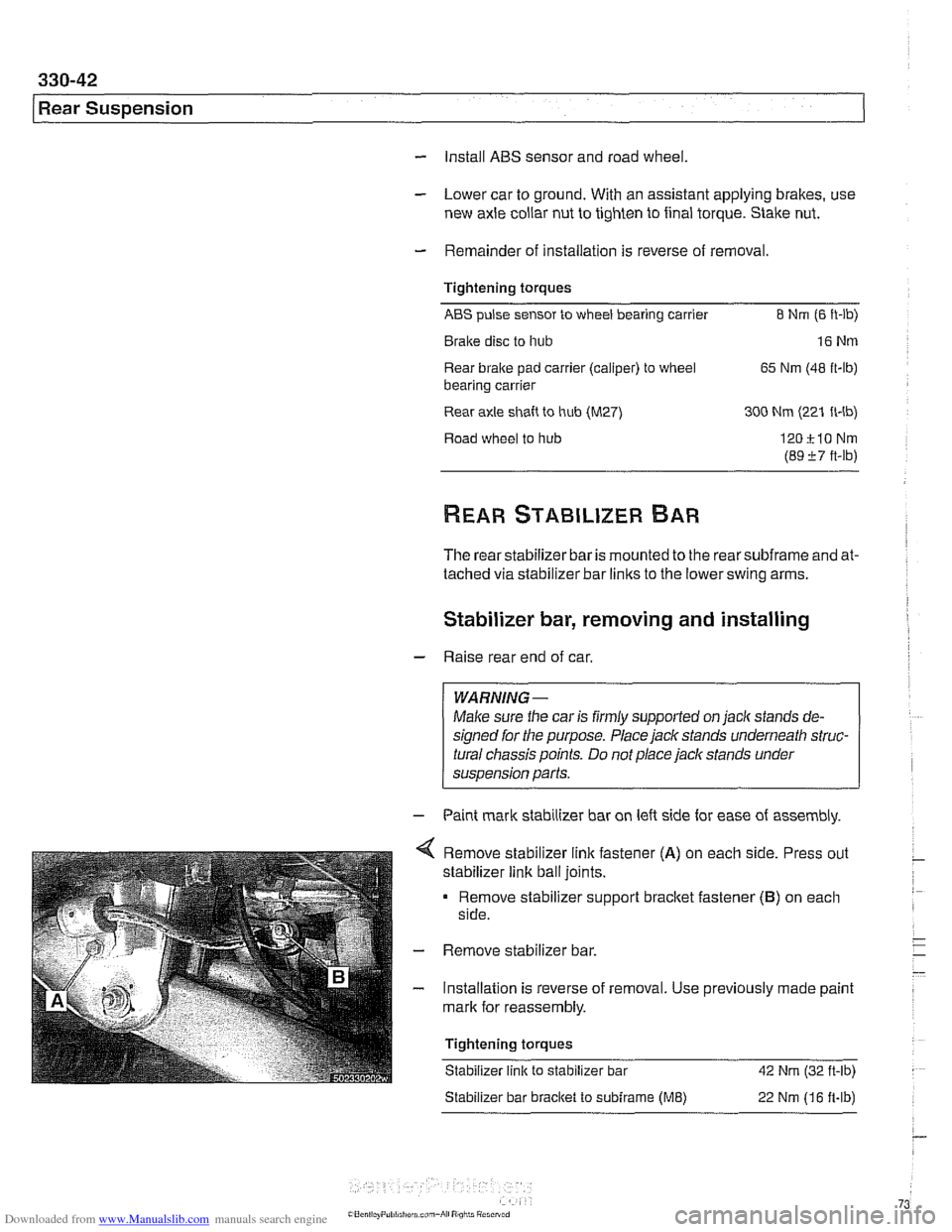

The rearstabilizer bar is mounted to the rear

subframe and at-

tached via stabilizer bar

linlts to the lower swing arms.

Stabilizer bar, removing and installing

- Raise rear end of car.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension parts.

- Paint mark stabilizer bar on left side for ease of assembly.

Remove stabilizer link fastener

(A) on each side. Press out

stabilizer link ball joints.

Remove stabilizer support bracket fastener

(B) on each

side.

Remove stabilizer bar.

Installation is reverse of removal. Use previously made paint

mark for reassembly.

Tightening torques Stabilizer link to stabilizer bar

42 Nm (32 ft-lb)

Stabilizer bar bracket to sublrame (ME) 22 Nm (1 6 fi-lb)

Page 758 of 1002

Downloaded from www.Manualslib.com manuals search engine

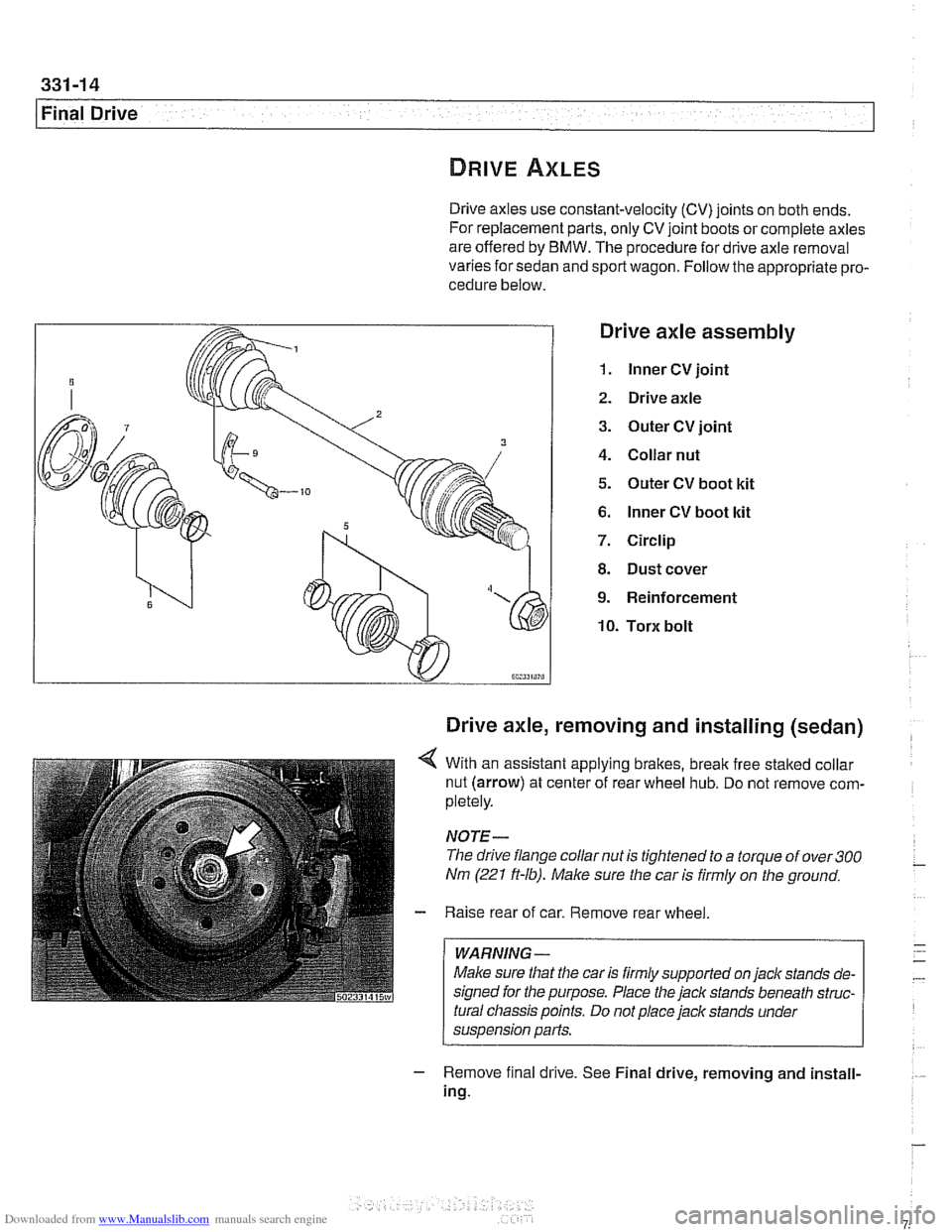

Final Drive

Drive axles use constant-velocity (CV) joints on both ends.

For replacement parts, only CV joint boots or complete axles

are offered by BMW. The procedure for drive axle removal

varies for sedan and sport wagon. Follow the appropriate pro-

cedure below.

Drive axle assembly

1. lnner CV joint

2. Drive axle

3. Outer CV joint

4. Collar nut

5. Outer CV boot kit

6. lnner CV boot kit

7. Circlip

8. Dust cover

9. Reinforcement

10. Torx bolt

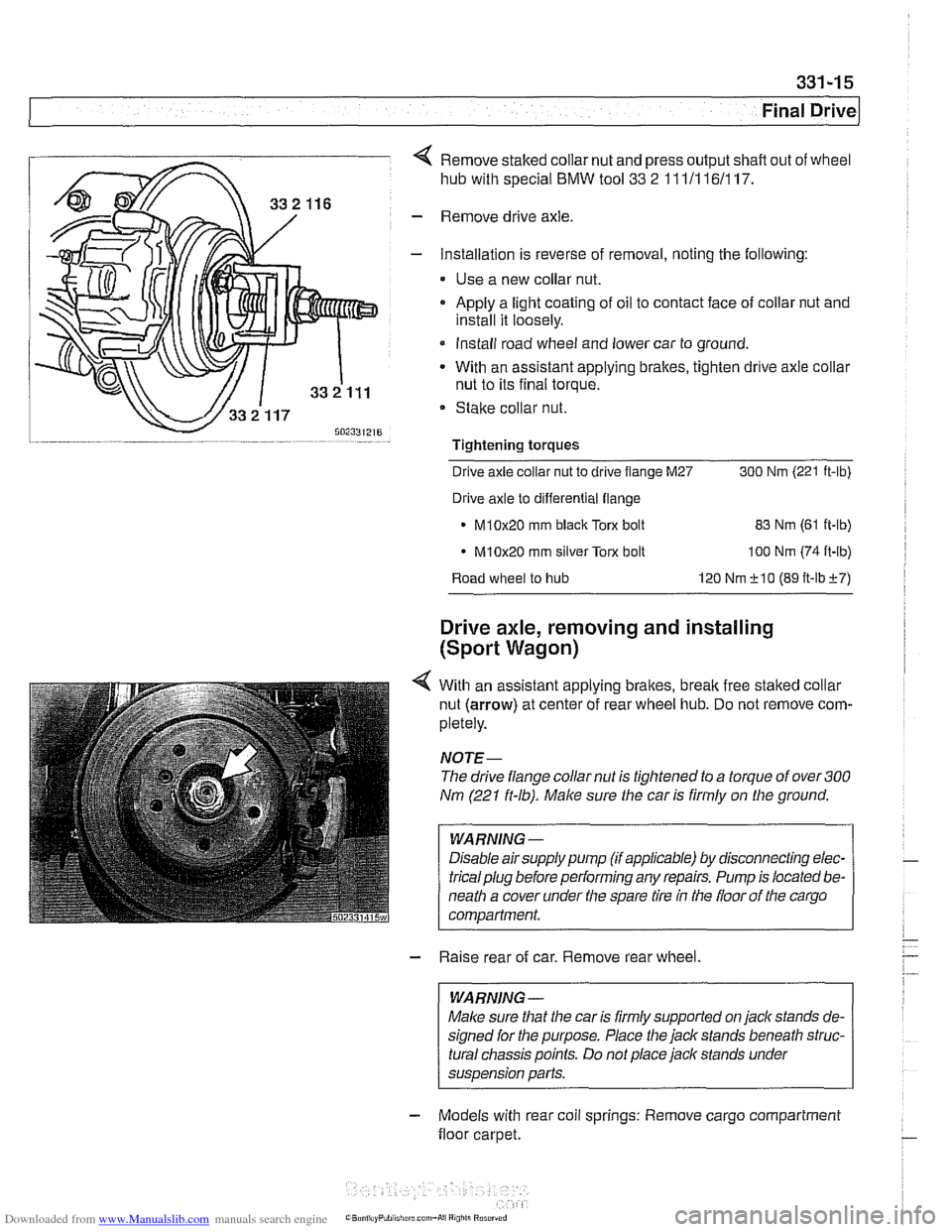

Drive axle, removing and installing (sedan)

4 With an assistant applying brakes, break free staked collar

nut (arrow) at center of rear wheel hub. Do not remove com-

pletely.

NOTE-

The drive flange collar nut is tightened to a torque of over 300

Nm (221 ft-lb). Male sure the car is firmly on the ground.

- Raise rear of car. Remove rear wheel

WARNING -

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the

jack stands beneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove f~nal drrve. See Final drive, removing and install-

ing.

Page 759 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final ~rivel

4 Remove staked collar nut and press output shafl out of wheel

hub with special

BMW tool 33 2 111/116/117.

- Remove drive axle.

- Installation is reverse of removal, noting the following:

Use a new collar nut.

a Apply a light coating of oil to contact face of collar nut and

install it loosely.

* Install road wheel and lower car to ground.

- With an assistant applying brakes, tighten drive axle collar

nut to its final torque.

Stake collar nut.

Tightening torques

-

Drive axle collar nut to drive flange M27 300 Nrn (221 ft-lb)

Drive axle to differential flange

* M10x20 rnm black Torx bolt

83 Nrn (61 ft-lb)

M10x20 rnrn silver Torx bolt

100 Nrn (74 ft-lb)

Road wheel to hub 120 Nrn f 10 (89 ft-lbf7)

Drive axle, removing and installing

(Sport Wagon)

4 With an assistant applying brakes, brealc free staked collar

nut (arrow) at center of rear wheel hub. Do not remove com-

pletely.

NOJE-

The drive flange collar nut is tightened to a torque of over 300

Nm (221 ft-lb). Make sure the car is firmly on the ground.

WARNING -

Disable airsupply pump (if applicable) by disconnecting elec-

tricalplug before performing any repairs. Pump is located be-

neath a cover under the spare tire

in the floor of the cargo

compartment.

- Raise rear of car. Remove rear wheel.

WARNING -

Malce sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Models with rear coil springs: Remove cargo compartment

floor carpet.