jack points BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 686 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-28

[steering and Wheel Alignment

Pitman arm, removing and installing

- Raise front of car. Remove splash shield from under engine.

Male sure the car is

firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place

jaclc stands under suspension

parts.

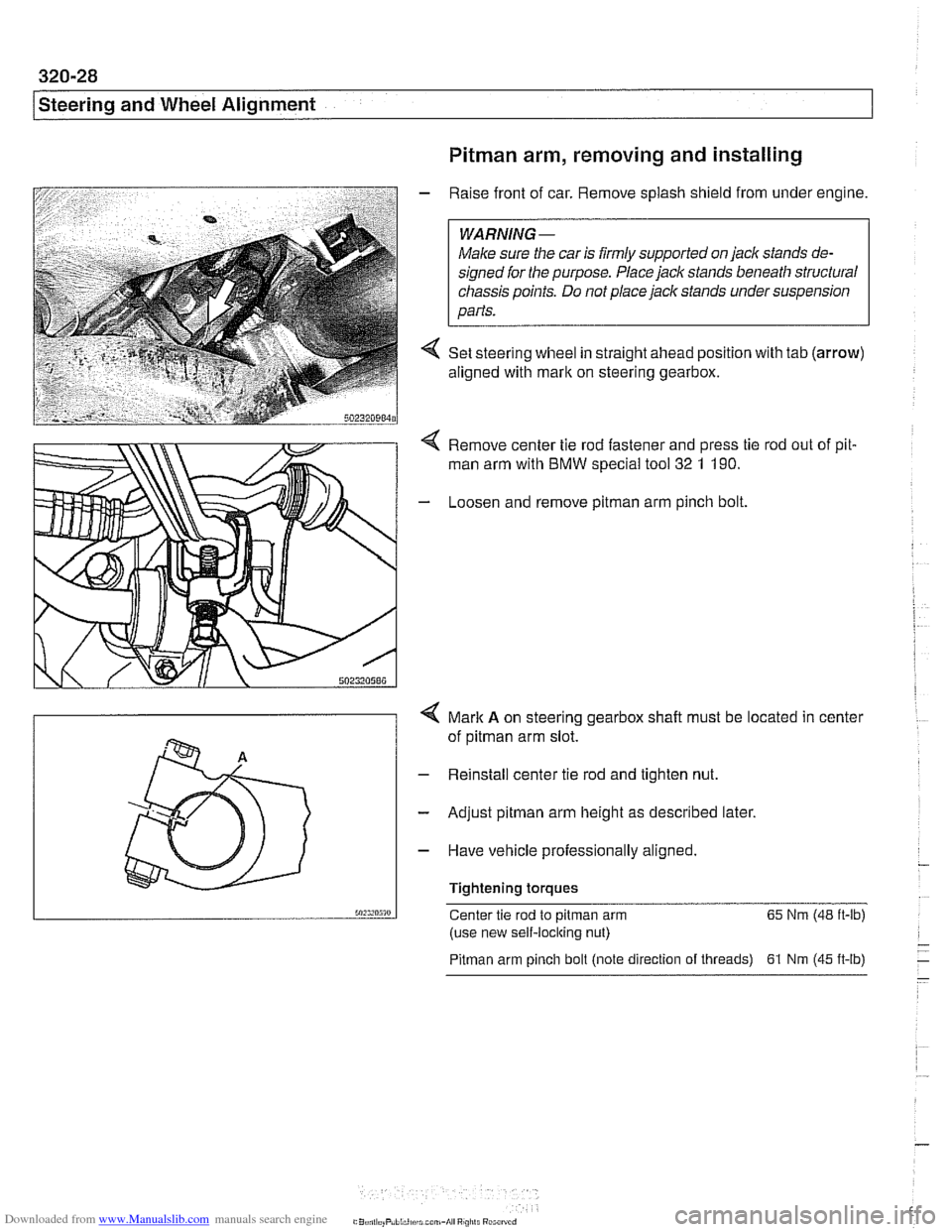

4 Set steering wheel in straight ahead position with tab (arrow)

aligned with mark on steering gearbox.

Remove center tie rod fastener and press tie rod out of pit.

man arm with BMW special

too1 32 1 190.

- Loosen and remove pitman arm pinch bolt

4 Mark A on steering gearbox shalt must be located in center

of

pitman arm slot.

- Reinstall center tie rod and tighten nut.

- Adjust pitman arm height as described later.

- Have vehicle professionally aligned.

Tightening torques

50:s,n5m Center tie rod to pitman arm 65

Nm (48 ft-lb)

(use new self-locking nut)

Pitman arm pinch bolt (note direction of threads) 61 Nrn (45 ft-lb)

Page 687 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Pitman arm, adjusting

As the vehicle suspension settles down, the toe on the left

and right wheels must remain identical for proper handling.

By adjusting the height of the

pitman arm, the left and right tie

rods are moved to the same ride level setting. This will opti-

mize straight-ahead travel on uneven road surfaces.

- Raise front of car. Remove splash shield from under engine.

WARNING-

Male sure the car is iirmly supported on jack stands de-

signed ior the purpose. Place jack stands beneath structural

chassis points. Do not place

jaclc stands under suspension

parts.

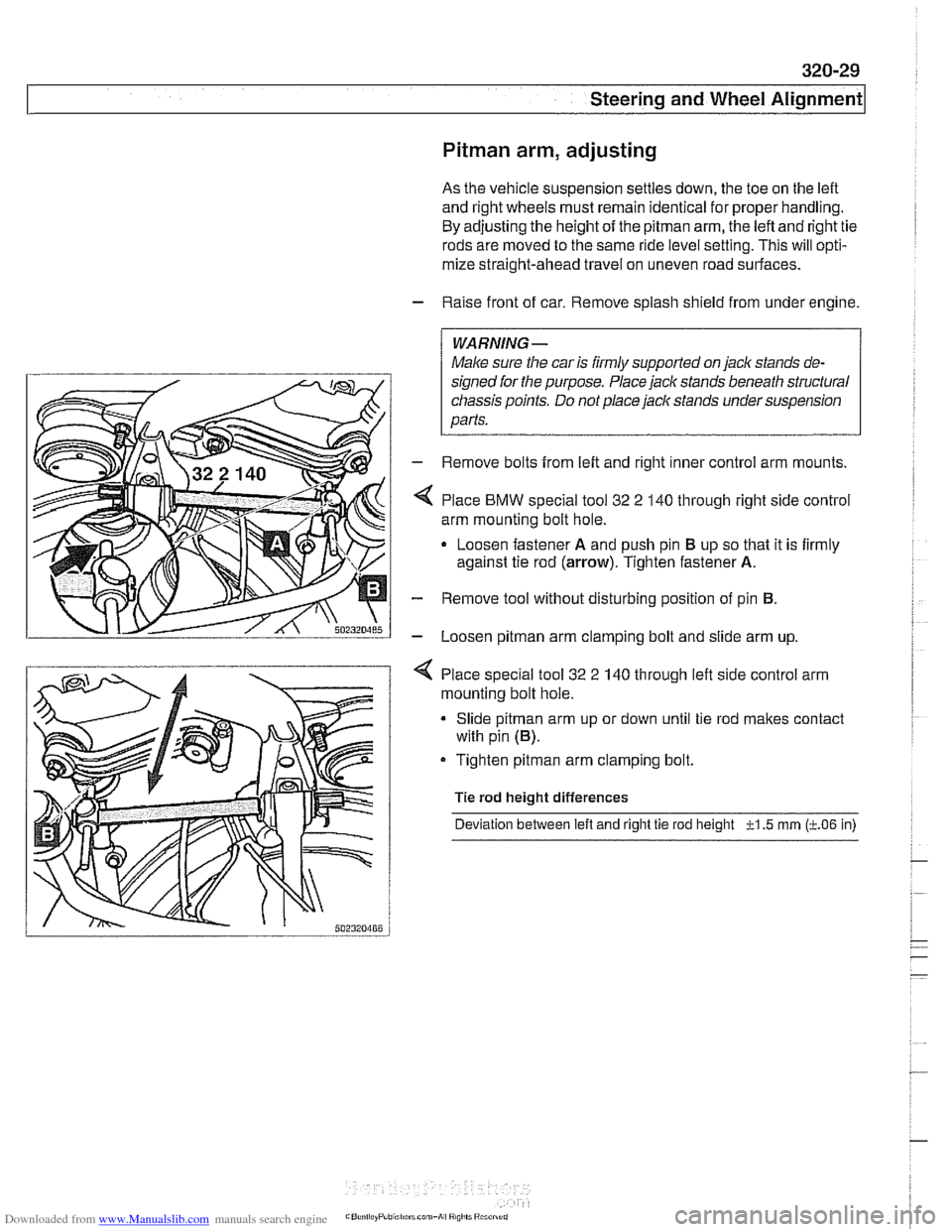

- Remove bolts from left and right inner control arm mounts.

Place

BMW special tool 32 2 140 through right side control

arm mounting bolt hole.

Loosen fastener

A and push pin El up so that it is firmly

against tie rod

(arrow). Tighten fastener A.

- Remove tool without disturbing position of pin El.

- Loosen pitman arm clamping bolt and slide arm up.

4 Place special tool 32 2 140 through left side control arm

mounting bolt hole.

Slide

pitman arm up or down until tie rod makes contact

with pin

(El).

Tighten pitman arm clamping bolt.

Tie rod height differences

Deviation between

left and right tie rod height -?-I .5 rnrn (LO6 in)

Page 688 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

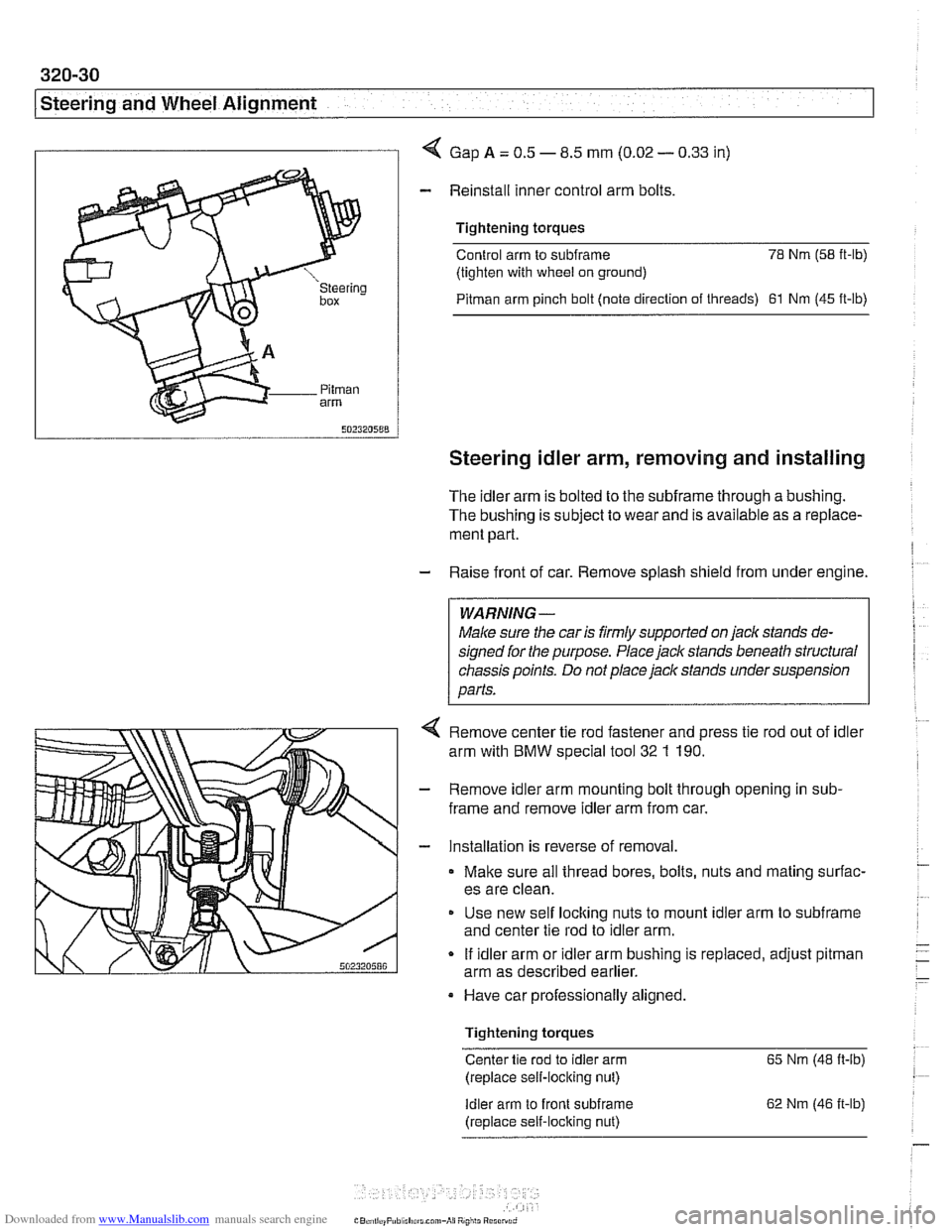

I I 4 Gap A = 0.5 - 8.5 mm (0.02 - 0.33 in)

- Reinstall inner control arm bolts

Tightening torques

Control arm to

subframe 78 Nm (58 it-lb)

(tighten with wheel on ground)

Pitman arm pinch bolt (note direction of threads) 61 Nm (45 ft-lb)

Steering idler arm, removing and installing

The idler arm is bolted to the subframe through a bushing.

The bushing is subject to wear and is available as a replace-

ment part.

- Raise front of car. Remove splash shield from under engine.

WARNING -

Male sure the car is firmly supported on jaclc stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

4 Remove center tie rod fastener and press tie rod out of idler

arm with

BMW special tool 32 1 190.

- Remove idler arm mounting bolt through opening in sub-

frame and remove idler arm from car.

- Installation is reverse of removal.

Make sure all thread bores, bolts, nuts and mating surfac-

es are clean.

Use new self

loclting nuts to mount idler arm to subframe

and center tie rod to idler arm.

If idler arm or idler arm bushing is replaced, adjust

pitman

arm as described earlier.

Have car professionally aligned.

Tightening torques

Center tie rod to idler arm 65 Nm (48 ft-ib)

(replace self-locking nut)

Idler arm to front subirame

(replace self-locking nut) 62

Nm (46 it-lb)

Page 690 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-32

Steering and Wheel Alignment

Center tie

rod, replacing

- Raise front of car. Remove splash shield from under engine.

WARNING-

Make sure tlie car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

cliassis points. Do not place jack stands under suspension

parts.

- Measure length of left and right (outer) tie rods. Write down

measurements.

NOTE-

Accurate measurement of the tie rod end with reference to

the center tie rod will help approximate correct wheel align-

ment when new parts are installed.

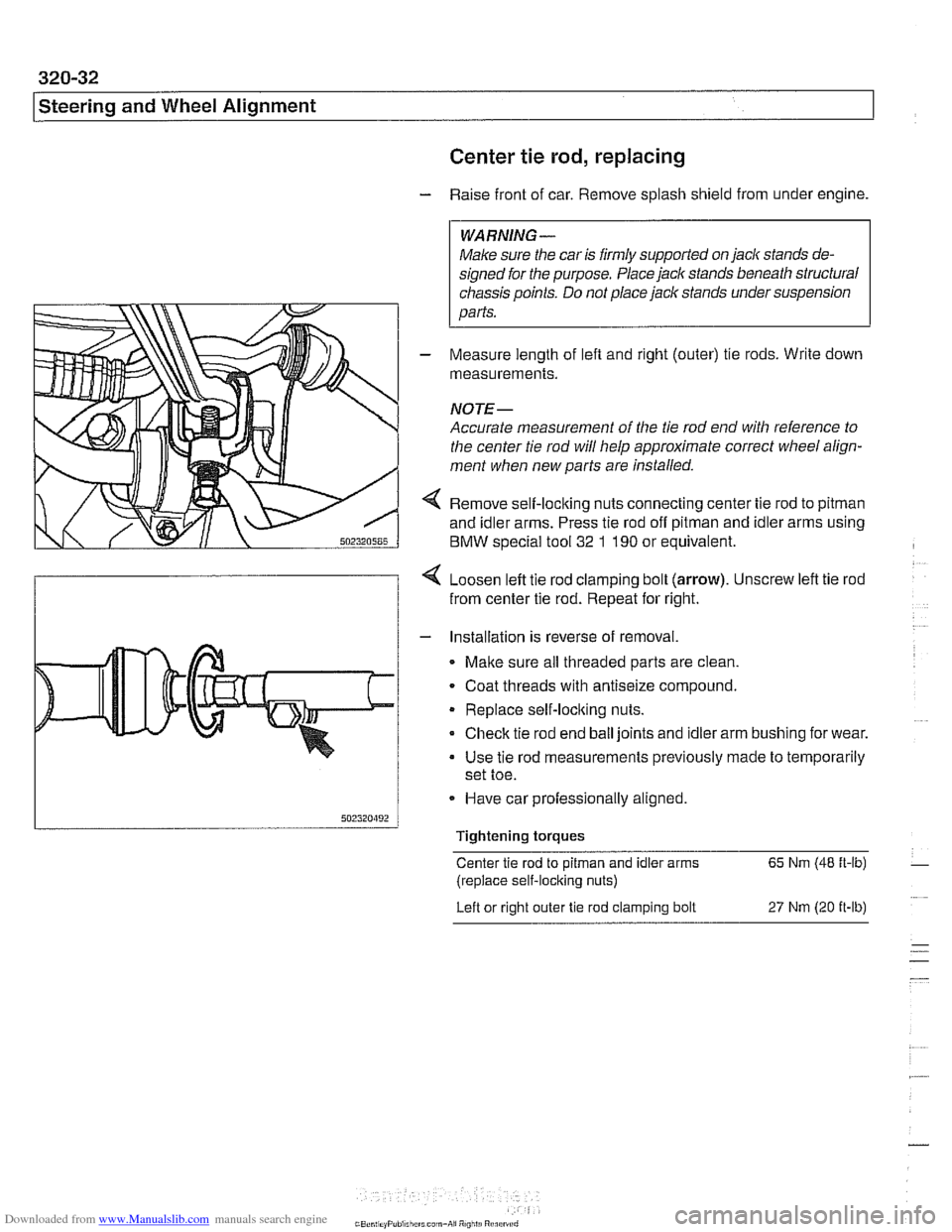

4 Remove self-loclting nuts connecting center tie rod to pitman

and idler arms. Press tie rod off pitman and idler arms using

BMW special tool

32 1 190 or equivalent.

4 Loosen left tie rod clamping bolt (arrow). Unscrew left tie rod

from center tie rod. Repeat for right.

- Installation is reverse of removal.

Malte sure all threaded parts are clean.

. Coat threads with antiseize compound.

Replace self-loclting nuts.

Check tie rod end ball joints and idler arm bushing for wear.

Use tie rod measurements previously made to temporarily

set toe.

- Have car professionally aligned.

Tightening torques

Center tie rod to

pitman and idler arms 65 Nm (48 ft-lb)

(replace self-locking nuts)

Left or right outer

tie rod clamping bolt 27 Nm (20 it-lb)

Page 701 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-5

Rear Suspension

REAR STRUTS AND SPRINGS

(SEDAN MODELS)

Rear strut assembly, removing and

installing

Replace struts and coil springs in pairs only.

- Raise car and remove rear wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove rear parcel shelf:

Remove rear seat headrests by pulling straight up.

Remove both rear roof pillar (C-pillar) trim panels.

Unbolt rear seat

belt anchors. See 720 Seat Belts.

Models with fixed rear seat: Remove rear seat backrest.

See 520 Seats.

* Models with fold-down rear seat: Remove rear seat back-

rest side sections. See 520 Seats. Fold down backrest.

* Working inside trunk, remove roller blind mounting nuts

and bolts, if applicable. Also disconnect roller blind har-

ness connector at right edge of rear seat backrest.

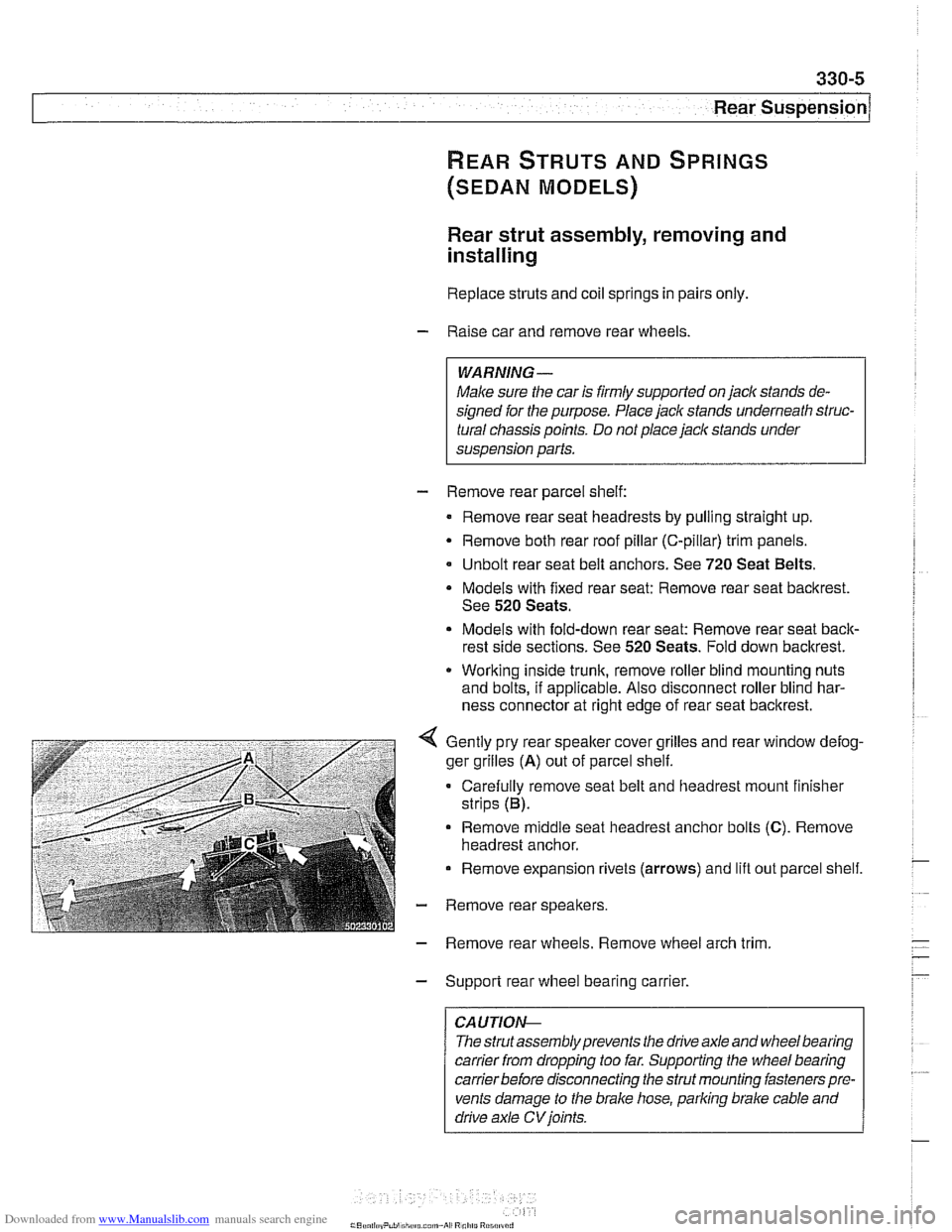

Gently pry rear speaker cover grilles and rear window defog-

ger grilles

(A) out of parcel shelf.

Carefully remove seat belt and headrest mount finisher

strips (B).

Remove

middle seat headrest anchor bolts (C). Remove

headrest anchor.

Remove expansion rivets (arrows) and lift out parcel shelf.

- Remove rear speakers.

- Remove rear wheels. Remove wheel arch trim

- Support rear wheel bearing carrier.

CAUTION-

The strutassembly prevents the drive axle and wheel bearing

carrier

from dropping too far. Supporting the wheel bearing

carrierbefore disconnecting the strut mounting fasteners pre-

vents damage to the brake hose, parking brake cable and

drive axle

CV joints.

Page 705 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

C. -- -- - -- Rear ~us~ensionl

Depending on year and model applications, the Sport Wagon

rear suspension may be equipped with:

Conventional shock absorbers and coil springs

Electronic height control (EHC) system which incorporates

air springs

NOTE-

. Suspension and EHC troubleshooting is covered in 300

Suspension, Steering and Brakes-General.

EHC system repairs, other than air spring replacement,

are covered in Electronic height control

(EHC) compo-

nent replacement.

Replace shock absorbers and springs in pairs only.

Rear shock absorber, removing and

installing

- Raise car and remove rear wheels,

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

suspension parts.

CAUTION-

If working on a vehicle with compressedairshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs. Pump is located beneath a cover

under the spare tire in the floor of the cargo compartment.

- Support swing arm from below

CAUTIOG

The shock absorber prevents the drive axle and wlieel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting fasteners prevents damage to the

brake hose,

parking

brake cable and drive axle CVjoints.

- Working in cargo compartment, remove carpet. Remove tri-

angular upper shock mount covers located beside spare tire

well.

- If applicable: Detach air supply line from shock absorber.

Plug ports and lines to keep out dirt.

Page 707 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 1

Rear Suspension

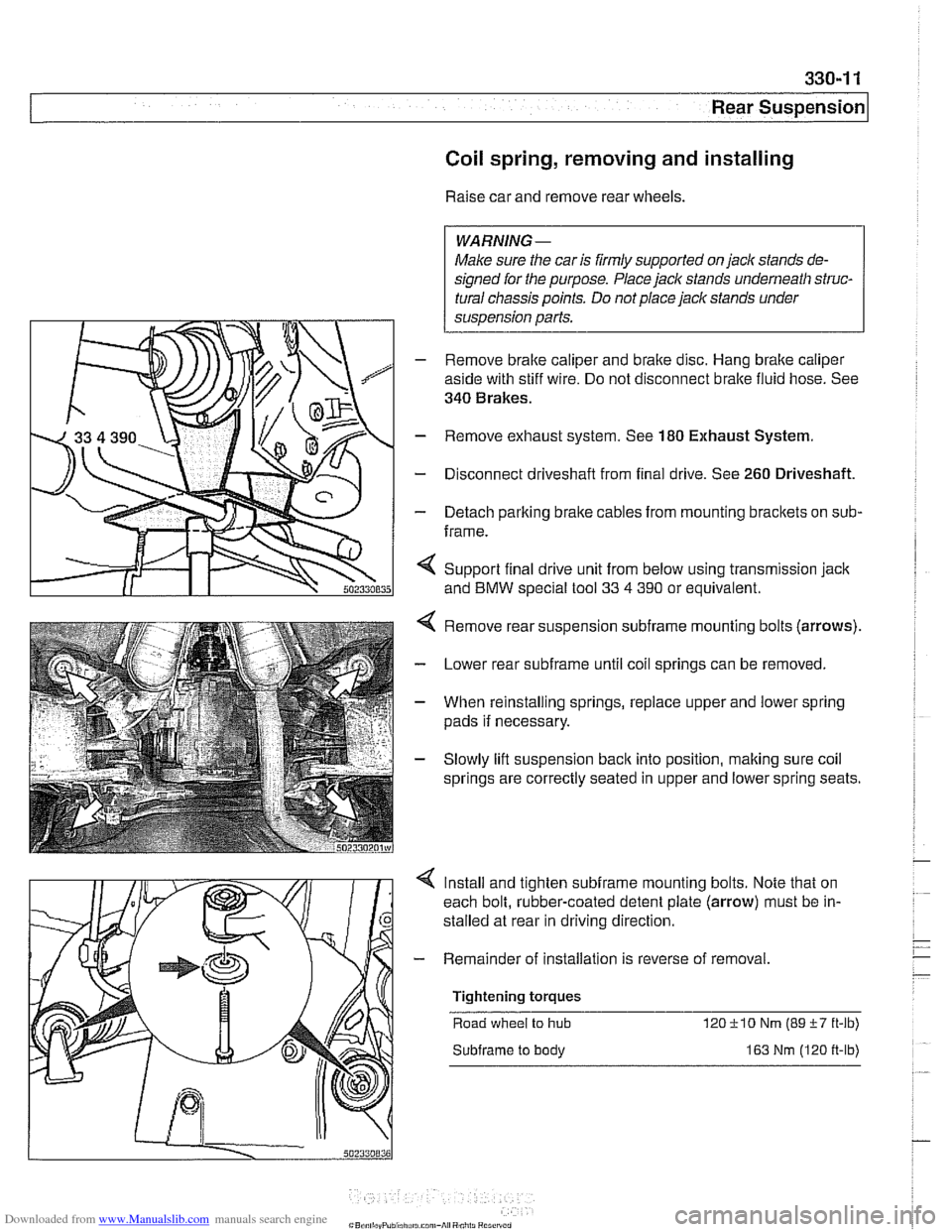

Coil spring, removing and installing

Raise car and remove rear wheels.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect

bralte fluid hose. See

340 Brakes.

- Remove exhaust system. See 180 Exhaust System.

- Disconnect driveshafl from final drive. See 260 Driveshaft.

- Detach parking bralte cables from mounting bracltets on sub-

frame.

< Support final drive unit from below using transmission jack

and

BMW special tool 33 4 390 or equivalent.

Remove rear suspension

subframe mounting bolts (arrows).

Lower rear

subframe until coil springs can be removed.

When reinstalling springs, replace upper and lower spring

pads if necessary.

Slowly lift suspension

back into position, making sure coil

springs are correctly seated in upper and lower spring seats.

Install and tighten

subframe mounting bolts. Note that on

each bolt, rubber-coated detent plate (arrow) must be in-

stalled at rear in driving direction

- Remainder of installation is reverse of removal

Tightening torques Road wheel

to hub 12OilO Nm (89i-7 ft-lb)

Subframe to body 163 Nm (120 ft-lb)

Page 708 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

Air spring, removing and installing

CAUTION-

If vehicle is driven with airspring depressurized, the airspring

will be permanently damaged and must be replaced.

An air spring is made from a flexible rubber material which

forms an airtight cavity. It is pressurized by an air supply

pump activated by an electronic control unit to provide a

vari- . . able spring rate depending on vehicle load

CAUTIOIG

Disable air supply pump by disconnecting electrical plug

before performing any repairs. Pump is located beneath a

cover under the spare tire in the floor of

the cargo compart-

ment.

When removing and installing air connections, extreme

cleanliness must be followed. Small dirt particles can

cause leakage in the system.

Remove luggage compartment floor mat.

- Working above air spring, loosen quick coupling screw con-

nection to allow

air pressure to escape.

- Once pressure has been reduced, retighten screw.

Tightening torque Quick coupling screw

to air pump 2 Nm (18 in-lb)

- Remove quick coupler. Plug openings to keep dirt out,

- Remove air spring mounting clips.

- Raise car and remove rear wheels.

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jaclc stands under

suspension parts.

- Working underneath rear suspension, lift wheel bearing car-

rier to relieve rear spring tension. Then unbolt air spring

mounting bolt from seat on wheel bearing carrier. Remove air

spring.

NOTE-

Left and right air springs are different. The left air spring is

marked with a red identification

marl. The right air spring is

marked with a blue identification mark.

Page 710 of 1002

Downloaded from www.Manualslib.com manuals search engine

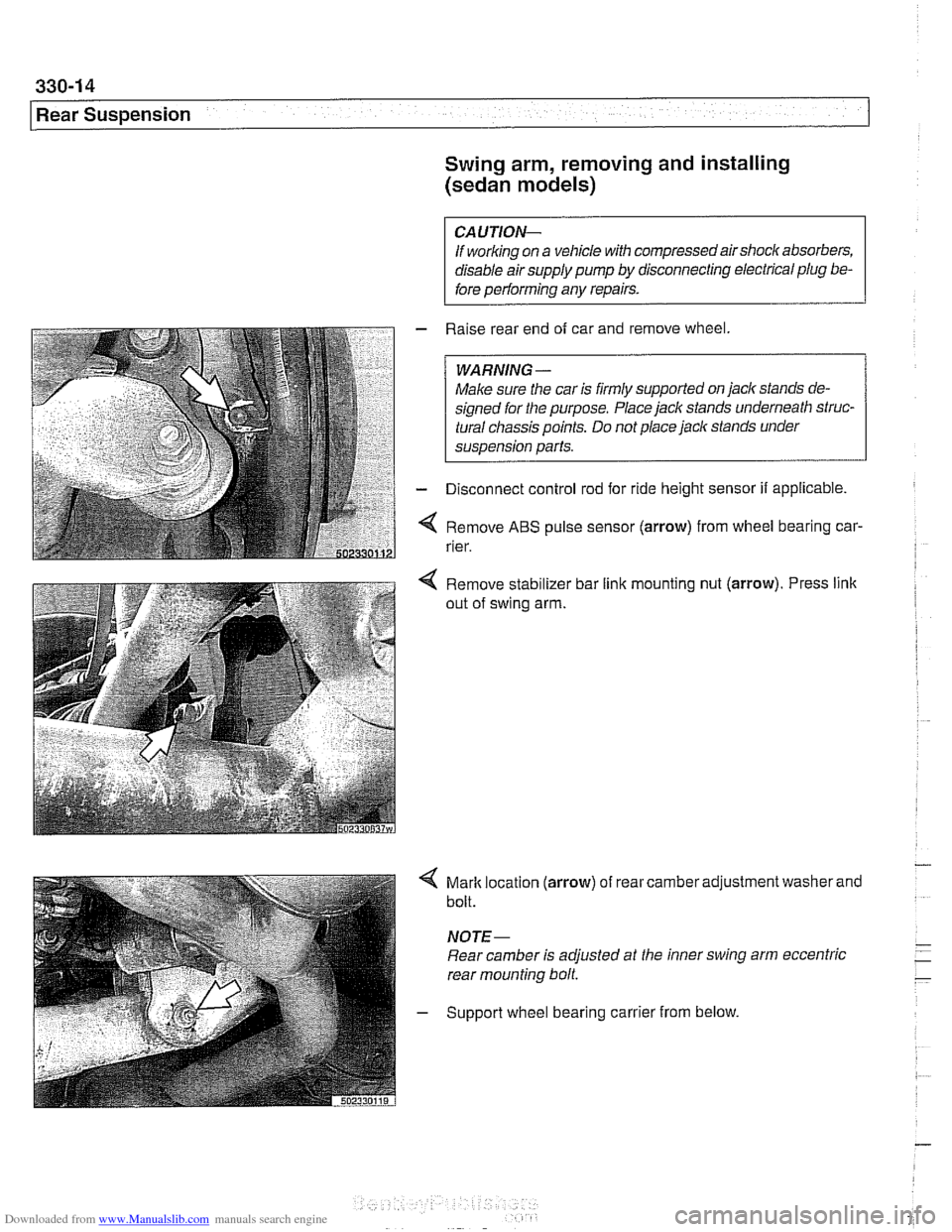

[Rear Suspension Swing arm, removing and installing

(sedan models)

CAUTION-

If working on a vehicle with compressed airshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs.

- Raise rear end of car and remove wheel

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

sus~ension Darts.

- Disconnect control rod for ride height sensor if applicable.

Remove

ABS pulse sensor (arrow) from wheel bearing car-

rier.

Remove stabilizer bar link mounting nut

(arrow). Press link

out of swing arm.

4 Mark location (arrow) of rear camber adjustment washer and

bolt.

NOTE-

Rear camber is adjusted at the inner swing arm eccentric

rear mounting bolt

- Support wheel bearing carrier from below.

Page 712 of 1002

Downloaded from www.Manualslib.com manuals search engine

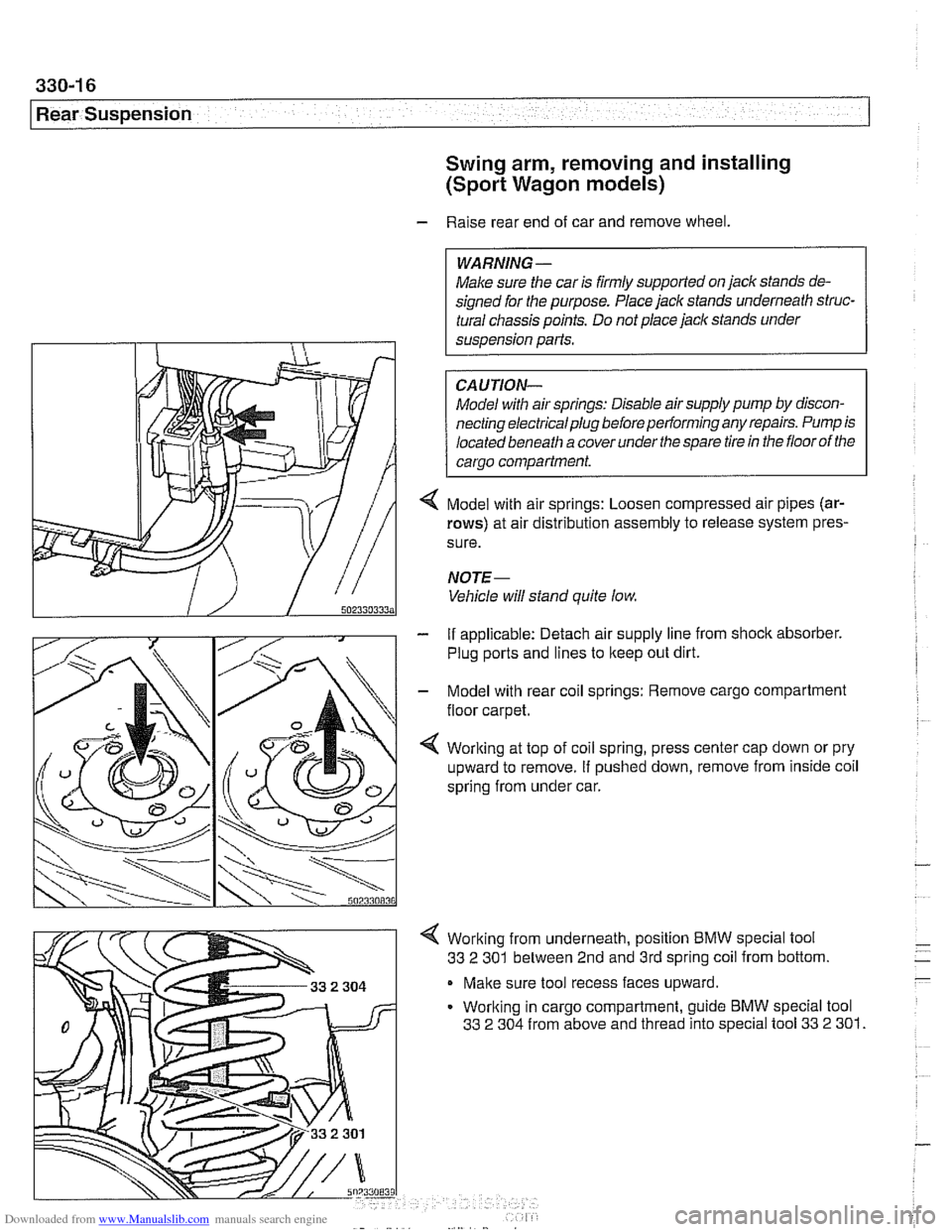

Rear Suspension Swing arm, removing and installing

(Sport Wagon models)

- Raise rear end of car and remove wheel.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

CAUJION-

Model with air springs: Disable air supply pump by discon-

necting electricalplug

beforeperforminganyrepairs. Pump is

located beneath a cover under the spare tire in the floor of the

cargo compartment.

< Model with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

sure.

NOJE-

Vehicle will stand quite low

- If applicable: Detach air supply line from shock absorber.

Plug ports and lines to

lkeep out dirt.

- Model with rear coil springs: Remove cargo compartment

floor carpet.

4 Working at top of coil spring, press center cap down or pry

upward to remove. If pushed down, remove from inside coil

spring from under car.

4 Working from underneath, position BMW special tool

33

2 301 between 2nd and 3rd spring coil from bottom.

Make sure tool recess faces upward.

Working in cargo compartment, guide BMW special tool

33

2 304 from above and thread into special tool 33 2 301.