automatic transmission BMW 528i 1997 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 604 of 1002

Downloaded from www.Manualslib.com manuals search engine

pearshift Linkage

~UTOMATIC TRANSMISSION

GEARSHIFT

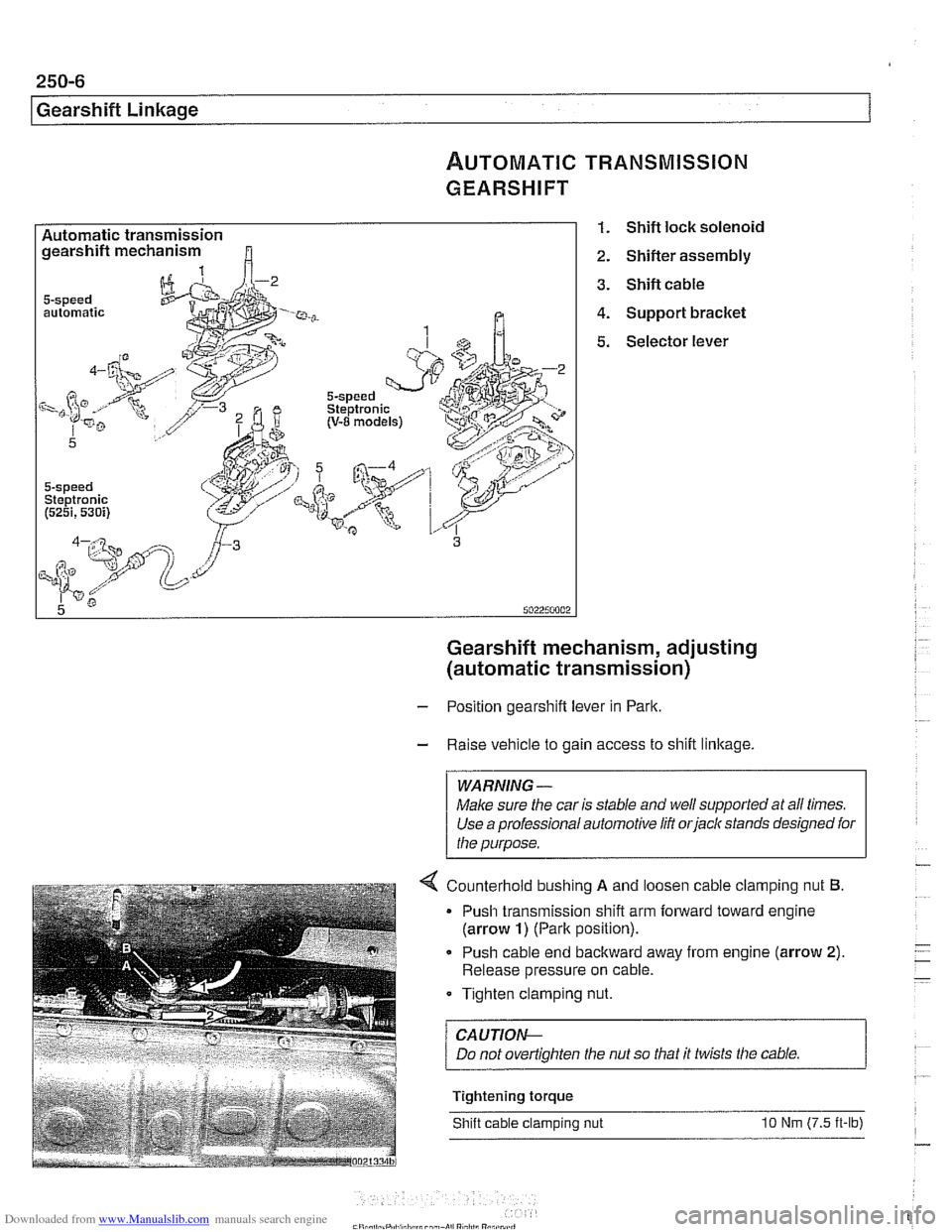

Automatic transmission gearshift mechanism

automatic

5-speed Steptronic (5251,530i)

1. Shift lock solenoid

2. Shifter assembly

3. Shift cable

4. Support bracket

5. Selector lever

Gearshift mechanism, adjusting

(automatic transmission)

- Position gearshift lever in Park.

- Raise vehicle to gain access to shift linkage.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjack stands designed for

the purpose.

4 Counterhold bushino A and loosen cable clam~ino nut 6.

Push cable end backward away from engine (arrow 2).

Release pressure on cable.

Tighten clamping nut.

/ CAUTION--

Tightening torque

Shift cable clamping nut

10 Nm (7.5 it-lb)

Page 605 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-7

Gearshift ~inka~el

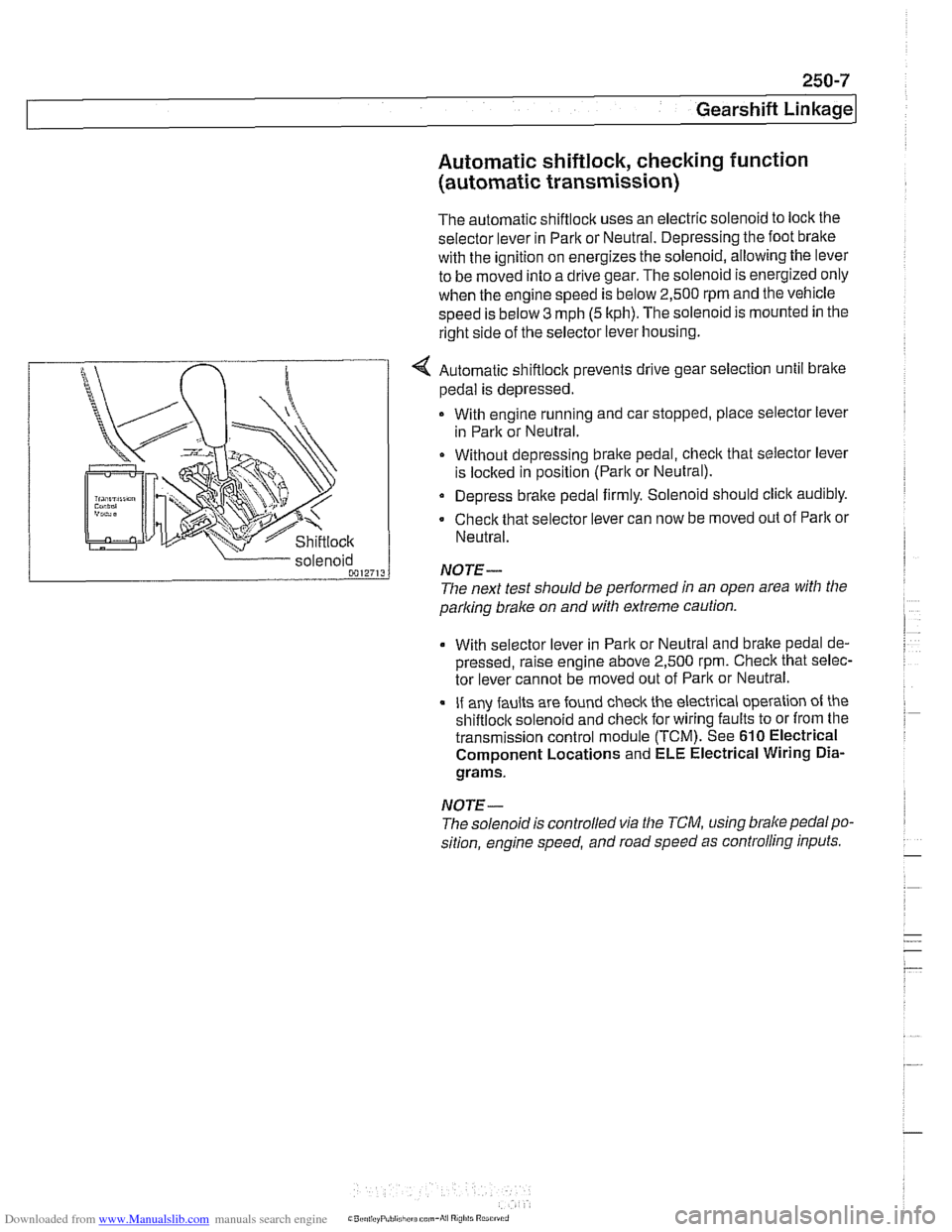

Automatic shiftlock, checking function (automatic transmission)

The automatic shiftlock uses an electric solenoid to lock the

selector lever in Park or Neutral. Depressing the foot bralte

with the ignition on energizes the solenoid, allowing the lever

to be moved into a drive gear. The solenoid is energized only

when the engine speed is below 2,500 rpm and the vehicle

speed is below

3 mph (5 kph). The solenoid is mounted in the

right side of the selector lever housing.

... nir r

Shiftlock

4 Automatic shiftlock prevents drive gear selection until brake

pedal is depressed.

With engine running and car stopped, place selector lever

in Park or Neutral.

Without depressing bralte pedal, check that selector lever

is

loclted in position (Parlt or Neutral).

Depress brake pedal firmly. Solenoid should click audibly.

Check that selector lever can now be moved out of

Parlt or

Neutral.

parking

brake on and with extreme caution.

solenoid

0012713

With selector

lever in Park or Neutral and bralte pedal de-

pressed, raise engine above 2,500

rpm. Check that selec-

tor lever cannot be moved out of Park or Neutral.

If any faults are found check the electrical operation of the

shiftloclt solenoid and checlt for wiring faults to or from the

transmission control module (TCM). See

610 Electrical

Component Locations and ELE Electrical Wiring

Dia-

grams.

NOTE-

NOTE-

The solenoidis controlled via the TCM, using brake pedalpo-

sition, engine speed, and road speed as controlling inputs.

The

next test should be performed in an open area with the

Page 606 of 1002

Downloaded from www.Manualslib.com manuals search engine

250-8

Gearshift Linkage

-;Ag Gate "",?it.,

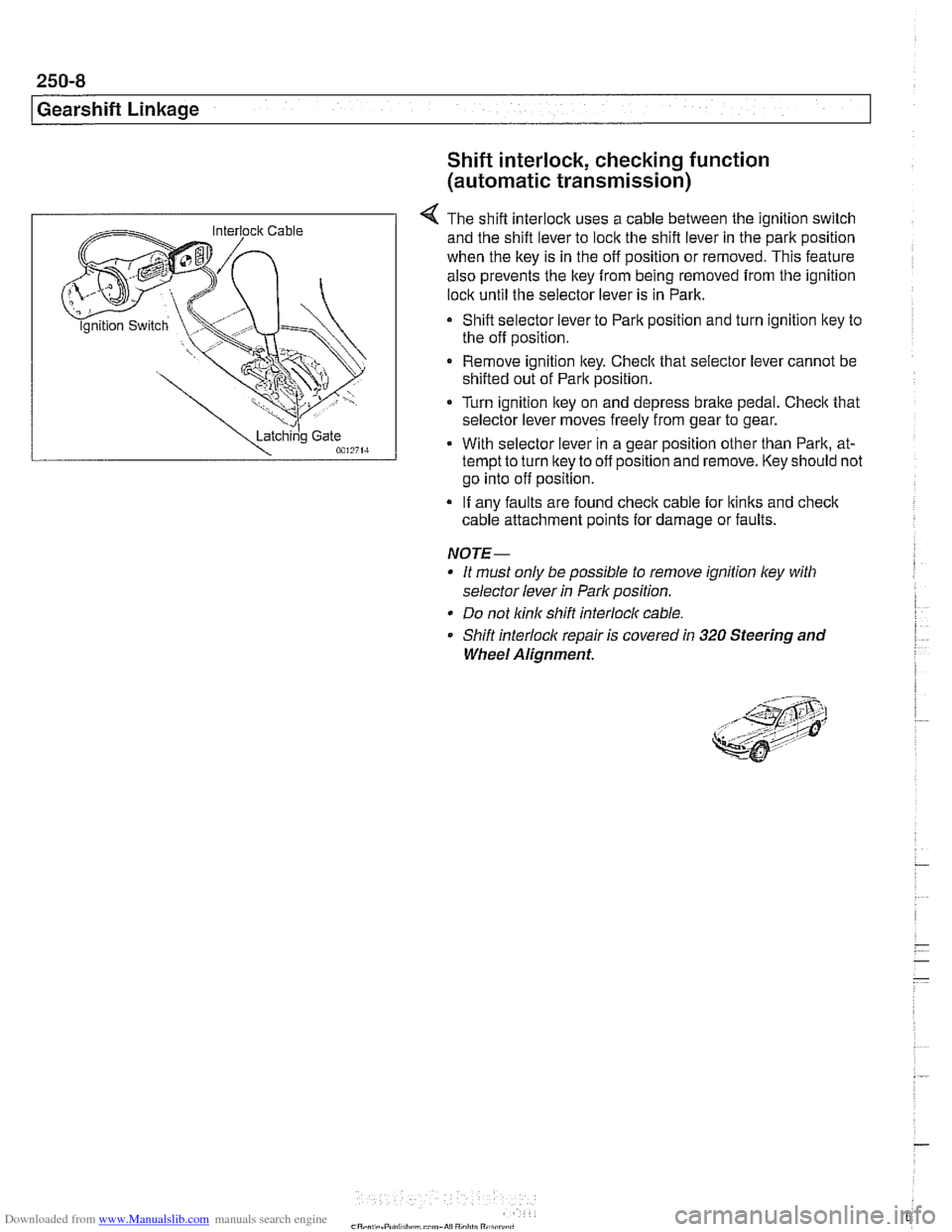

Shift interlock, checking function

(automatic transmission)

4 The shift interlock uses a cable between the ignition switch

and the shift lever to lock the shift lever in the park position

when the key is in the off position or removed. This feature

also prevents the key

from being removed from the ignition

lock until the selector lever is in Park.

Shift selector lever to Park position and turn ignition key to

the off position.

Remove ignition key. Checlc that selector lever cannot be

shifted out of Park position.

Turn ignition lkey on and depress

brake pedal. Checlc that

selector lever moves freely from gear to gear.

With selector lever in a gear position other than Park, at-

tempt to turn lkey to off position and remove. Key should not

go into off position.

If any faults are found check cable for lkinks and

check

cable attachment points for damage or faults.

NOTE-

* It must only be possible to remove ignition ley with

selector lever

in Park position.

* Do not link shift interlocl( cable.

Shift interlock repair is covered

in 320 Steering and

Wheel Alignment.

Page 631 of 1002

Downloaded from www.Manualslib.com manuals search engine

Suspension, Steering and Brakes - General

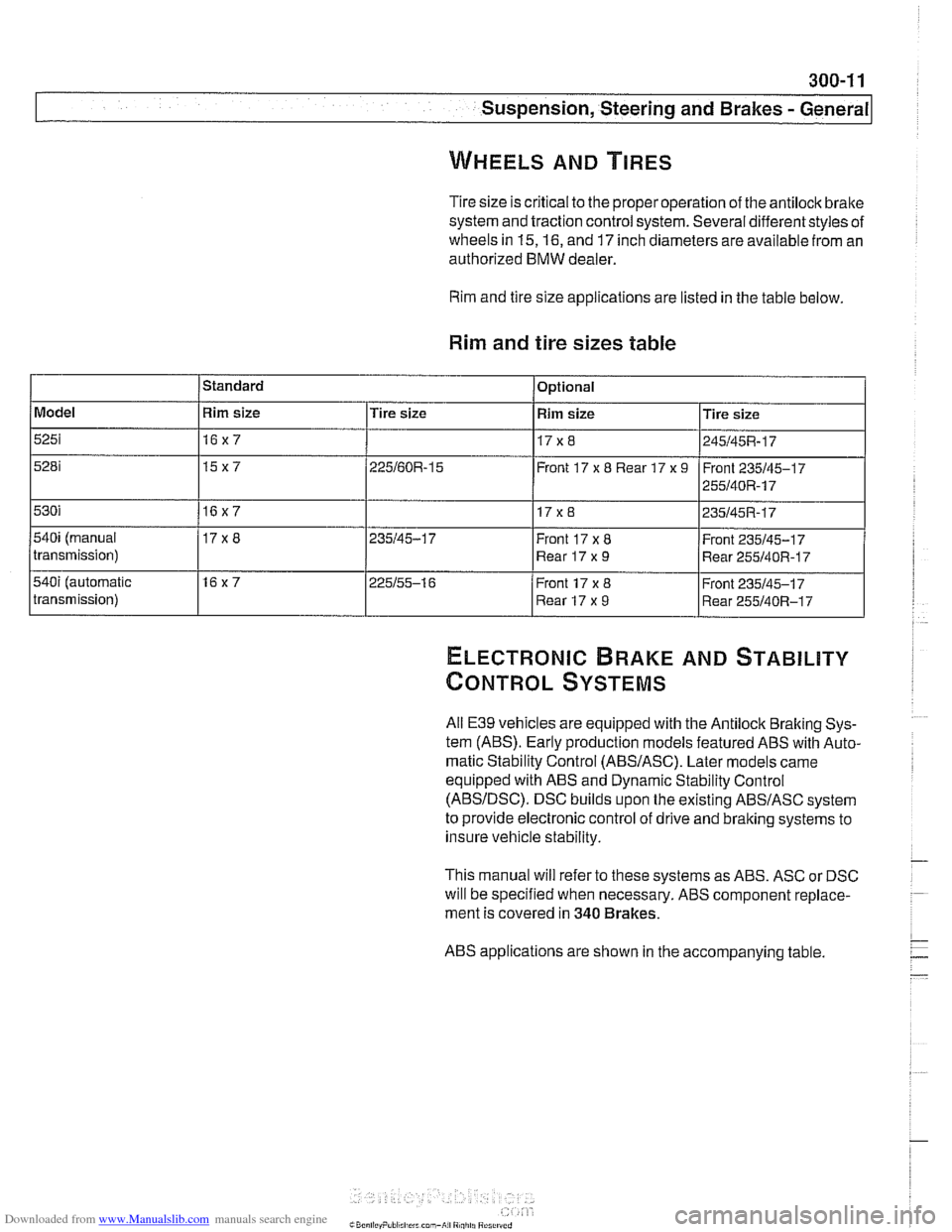

WHEELS AND TIRES

Tire size is critical to the properoperation of the antilock brake

system and traction control system. Several differentstyles of

wheels in

15,16, and 17 inch diameters are available from an

authorized BMW dealer.

Rim and tire size applications are listed in the table below.

Rim and tire sizes table

ELECTRONIC BRAKE AND STABILITY

CONTROL SYSTEMS

Model

5251

5281

530i

540i (manual

transmission)

540i (automatic

transmission)

All

E39 vehicles are equipped with the Antilock Braking Sys-

tem

(ABS). Early production models featured ABS with Auto-

matic Stability

control (ABSIASC). Later models came

equipped with ABS and Dynamic Stability Control

(ABSIDSC). DSC builds upon the existing ABSIASC system

to provide electronic control of drive and braking systems to

insure vehicle stability.

This manual will refer to these systems as ABS. ASC or DSC

will be specified when necessary. ABS component replace-

ment is covered in

340 Brakes.

Standard

ABS applications are shown in the accompanying table

Rim size

16x7

15x7

16x7

17x8

16x7 Optional

Tire size

225160R-15

235145-1 7

225155-1 6

Rim size

17x8

Front 17

x 8 Rear 17 x 9

17 x 8

Front 17x8

Rear 17x9

Front 17 x 8

Rear 17 x 9 Tire

size

245145R-17

Front 235145-1 7

255140R-17

235145R-17

Front 235145-1 7

Rear

255140R-17

Front 235145-17

Rear 255140R-17

Page 659 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 320 Steering and Wheel Alignment

General ........................... .32 0.2

Special tools

........................ .32 0.2

Steering system

..................... .32 0.4

Steering system variations

............. .32 0.5

Steering system warnings and cautions

... .32 0.6

Steering Wheel .................... .32 0.7

Steering wheel. removal and installation

.. .32 0.7

Steering Column ................. .32 0.1 0

Steering column components .......... .32 0.10

Steering column trim, removing

and replacing

...................... .32 0.10

lgnition switch ring antenna (EWS).

removing and installing

............... .32 0.1 1

lgnition lock cylinder.

removing and installing

............... .32 0-1 1

Steering column lock. removing

and installing

....................... .32 0.12

lgnition

interloclc cable. removing and installing

(models with automatic transmission)

... .32 0.13

Interlock cable. adjusting

(models with automatic transmission)

... .32 0.14

Steering column. removing and installing

. .32 0.14

Steering column adjustment motors.

removing and installing

............... .32 0.16

Power Steering Pump ............. .32 0.17

Power steering pump. removing

and installing

....................... .32 0.1 7

Power steering system.

bleeding and filling

.................. .32 0.18

Rack and Pinion Steering

(6-cylinder models)

............... 320-19

Rack and pinion steering components

(6-cylinder models)

.................. 320-1 9

Steering rack. removing and installing

.... 320-19

Steering

rack boot. replacing ........... 320-22

Tie rod (outer). replacing

.............. 320-22

Tie rod (inner). replacing

.............. 320-23

Steering Gearbox (V-8 models) .... 320-24

Steering gearbox system components

. .

(V-8 models) ....................... 320-24

Steering gearbox, removing and installing 320-25

Pitman arm. removing and installing ..... 320-28

Pitman arm. adjusting ................ 320-29

Steering idler arm. removing

and installing

....................... 320-30

Idler arm bushing. replacing ........... 320-31

Center tie rod. replacing

.............. 320-32

Wheel Alignment .................. 320-33

Camber

........................... 320-33

Caster

............................ 320-33

Front toe and toe difference angle

....... 320-34

Reartoe ........................... 320-34

Preparing for alignment

............... 320-35

Alignment specifications tables

......... 320-35

Page 670 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

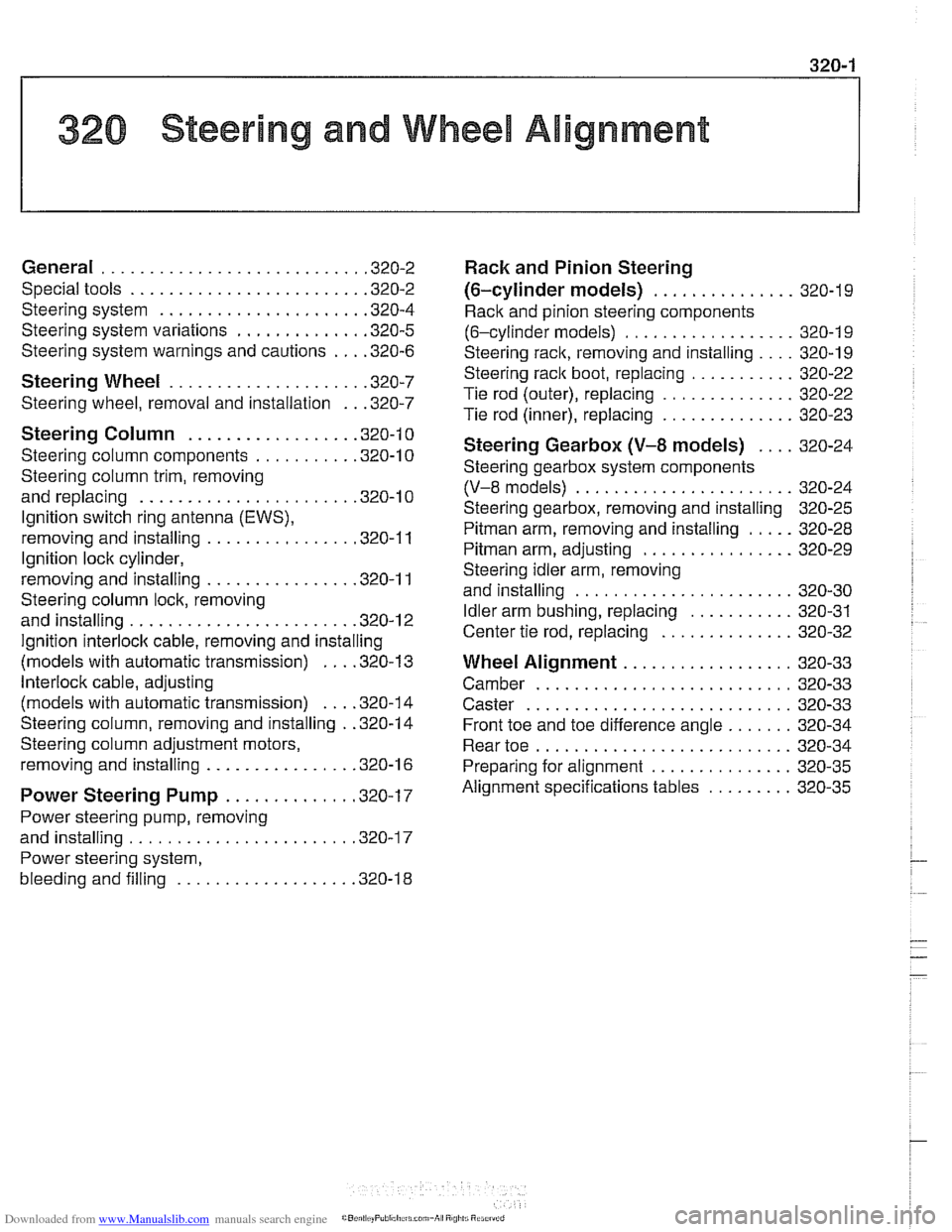

With ignition key in ON position (60" from LOCKED):

- Disconnect ring antenna harness connector.

Insert

BMW special tool 32 3 110 or a thin piece of stiff wire

into opening (arrow) in lock cylinder.

Turn tool forward (clockwise) approximately 90" and re-

move lock cylinder.

* Reinstallation is reverse of removal.

NOTE-

Using the valet ley during this procedure will provide better

access to lock opening.

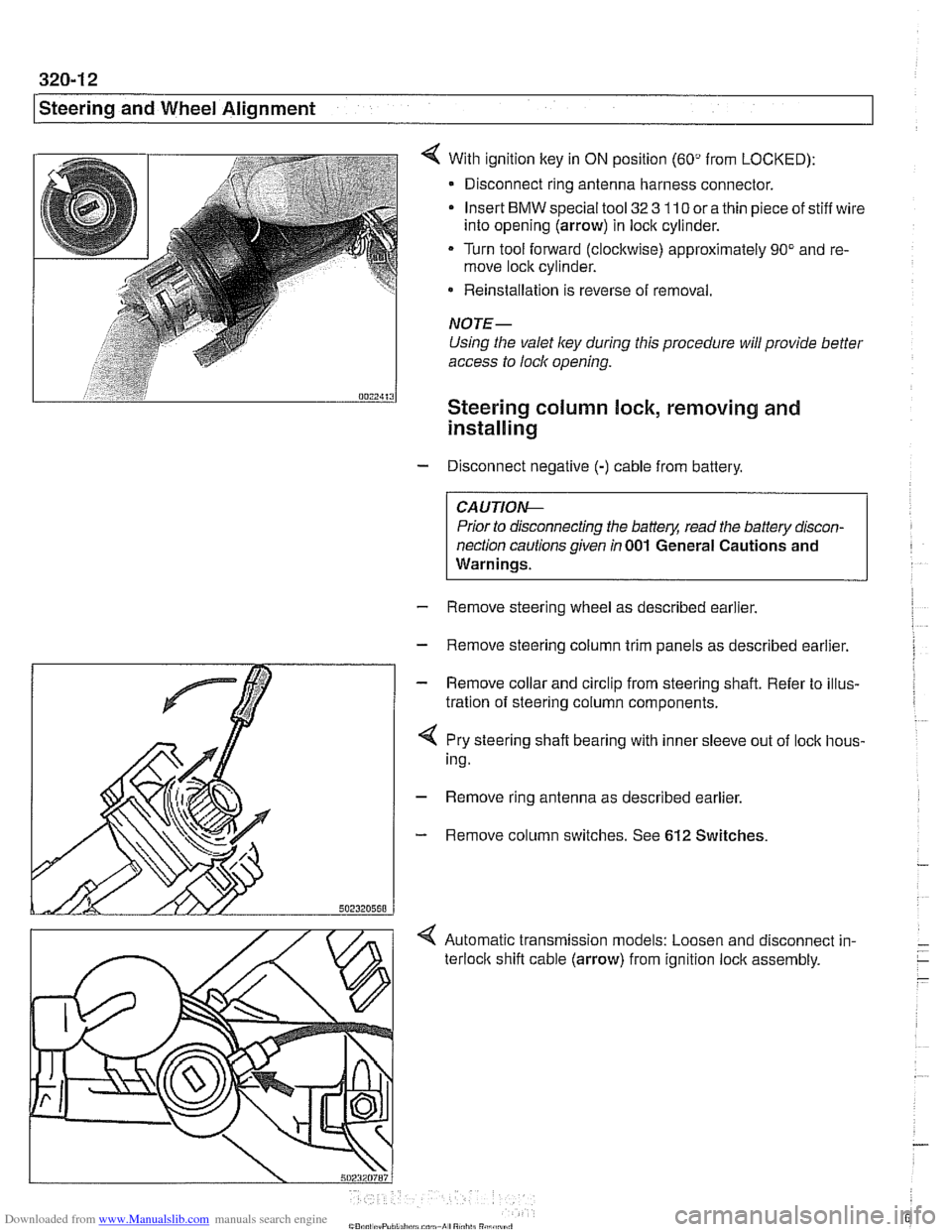

Steering column lock, removing and

installing

- Disconnect negative (-) cable from battery.

CAUTIO&

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

- Remove steering wheel as described earlier.

- Remove steering column trim panels as described earlier.

- Remove collar and circlip from steering shaft. Refer to illus-

tration of steering column components.

4 Pry steering shaft bearing with inner sleeve out of lock hous-

ing.

- Remove ring antenna as described earlier.

- Remove column switches. See 612 Switches.

< Automatic transmission models: Loosen and disconnect in-

terloclc shift cable (arrow) from ignition lock assembly.

Page 671 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

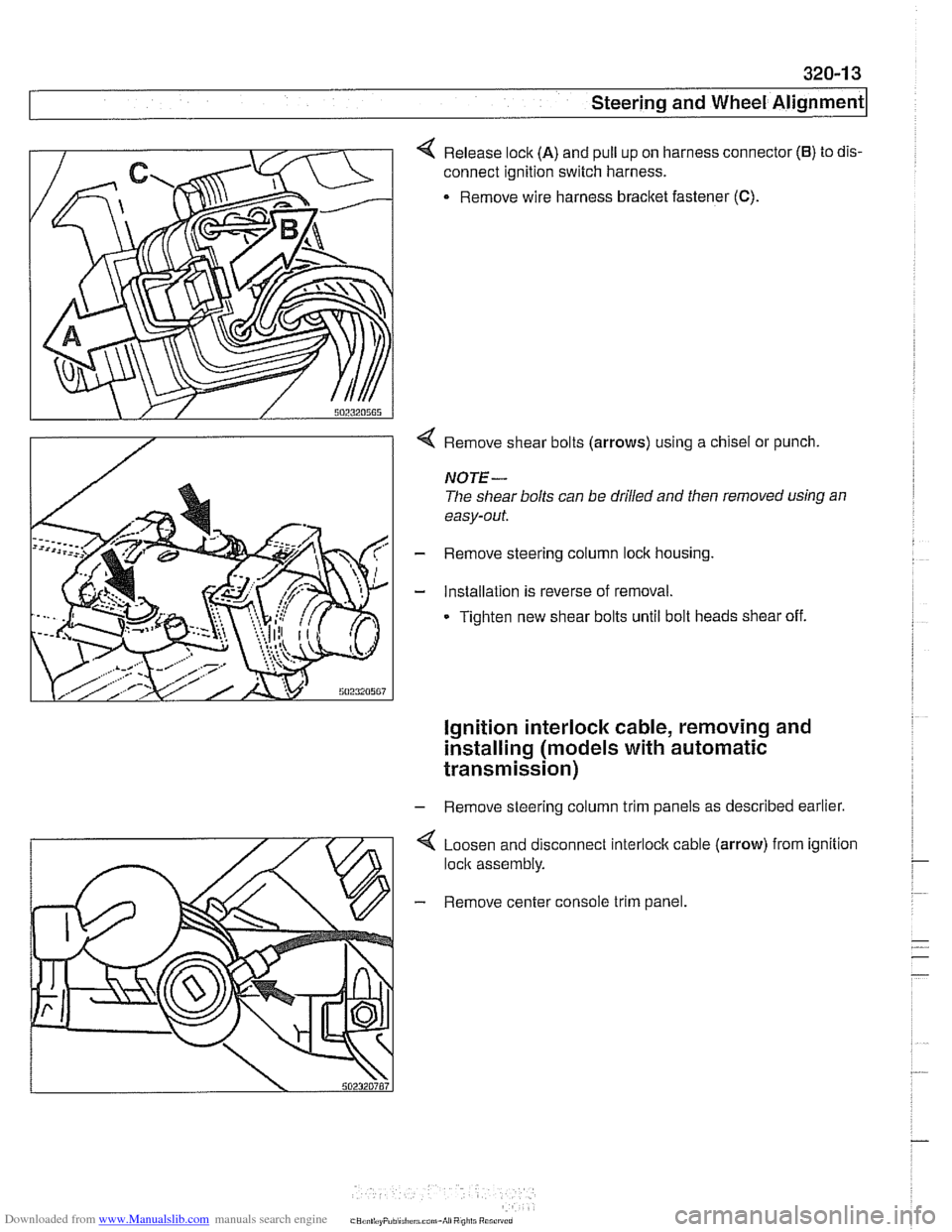

4 Release lock (A) and pull up on harness connector (6) to dis-

connect ignition switch harness.

. Remove wire harness bracket fastener (C).

4 Remove shear bolts (arrows) using a chisel or punch.

NOTE-

The shear bolts can be drilled and then removed using an

easy-out.

- Remove steering column lock housing.

- Installation is reverse of removal.

Tighten new shear bolts until bolt heads shear off.

ignition interlock cable, removing and

installing (models

with automatic

transmission)

- Remove steering column trim panels as described earlier.

4 Loosen and disconnect interlock cable (arrow) from ignition

lock assembly.

- Remove center console trim panel.

Page 672 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-1 4

Steering and Wheel Alignment

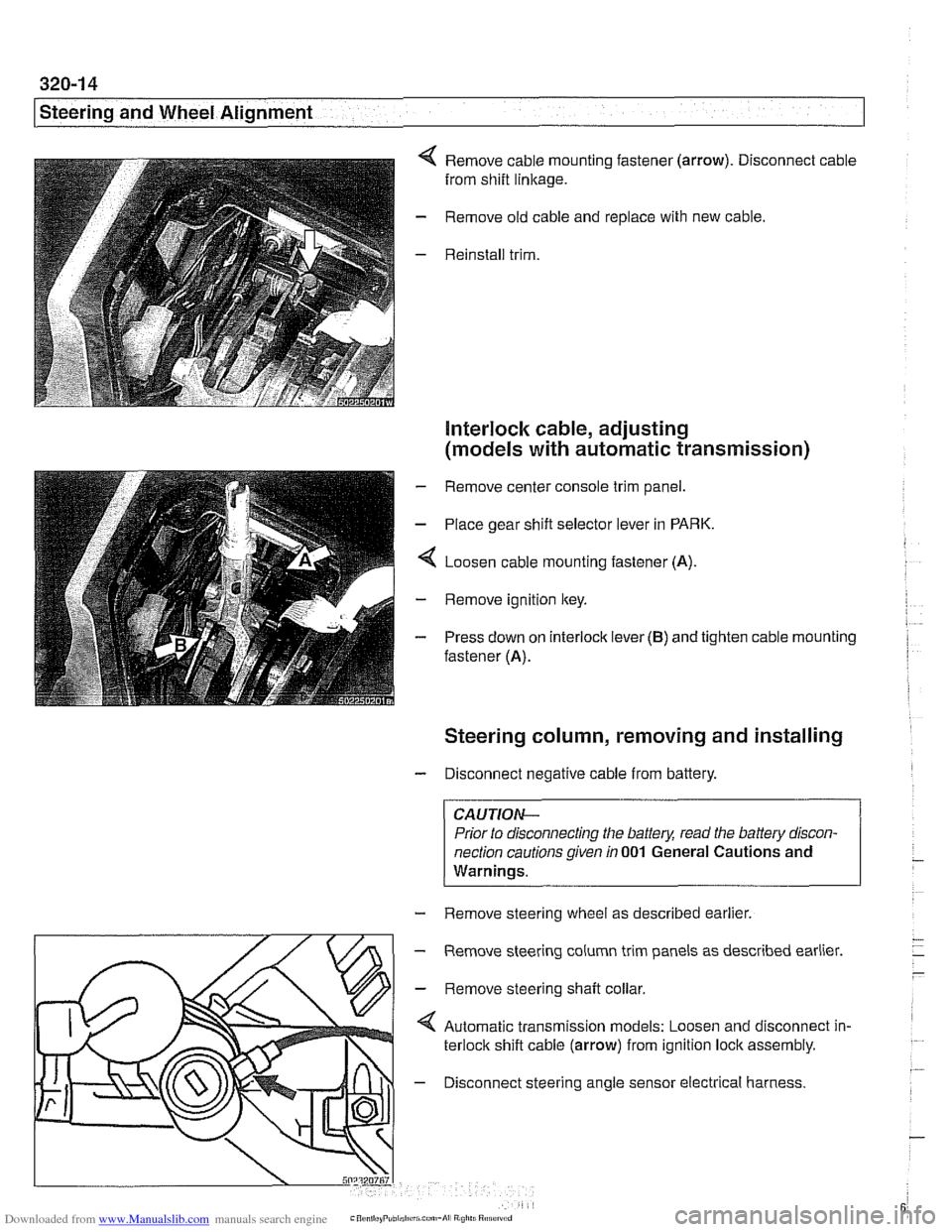

Remove cable mounting fastener (arrow). Disconnect cable

from shift

linkage.

Remove old cable and replace with new cable.

Reinstall trim.

Interlock cable, adjusting

(models with automatic transmission)

- Remove center console trim panel.

- Place gear shift selector lever in PARK.

4 Loosen cable mounting fastener (A).

- Remove ignition key.

- Press down on interlock lever (B) and tighten cable mounting

fastener (A).

Steering column, removing and installing

- Disconnect negative cable from battery.

CAUTIOI\C

Prior to disconnecting the battea read the battery discon-

nection cautions given

in 001 General Cautions and

Warninqs.

- Remove steering wheel as described earlier.

m

- Remove steering column trim panels as described earlier.

' \L/>I - Remove steerinq shaft collar

Automatic transmission models: Loosen and disconnect in-

terlock shift cable (arrow) from ignition lock assembly.

4 - Disconnect steering angle sensor electrical harness.

Page 881 of 1002

Downloaded from www.Manualslib.com manuals search engine

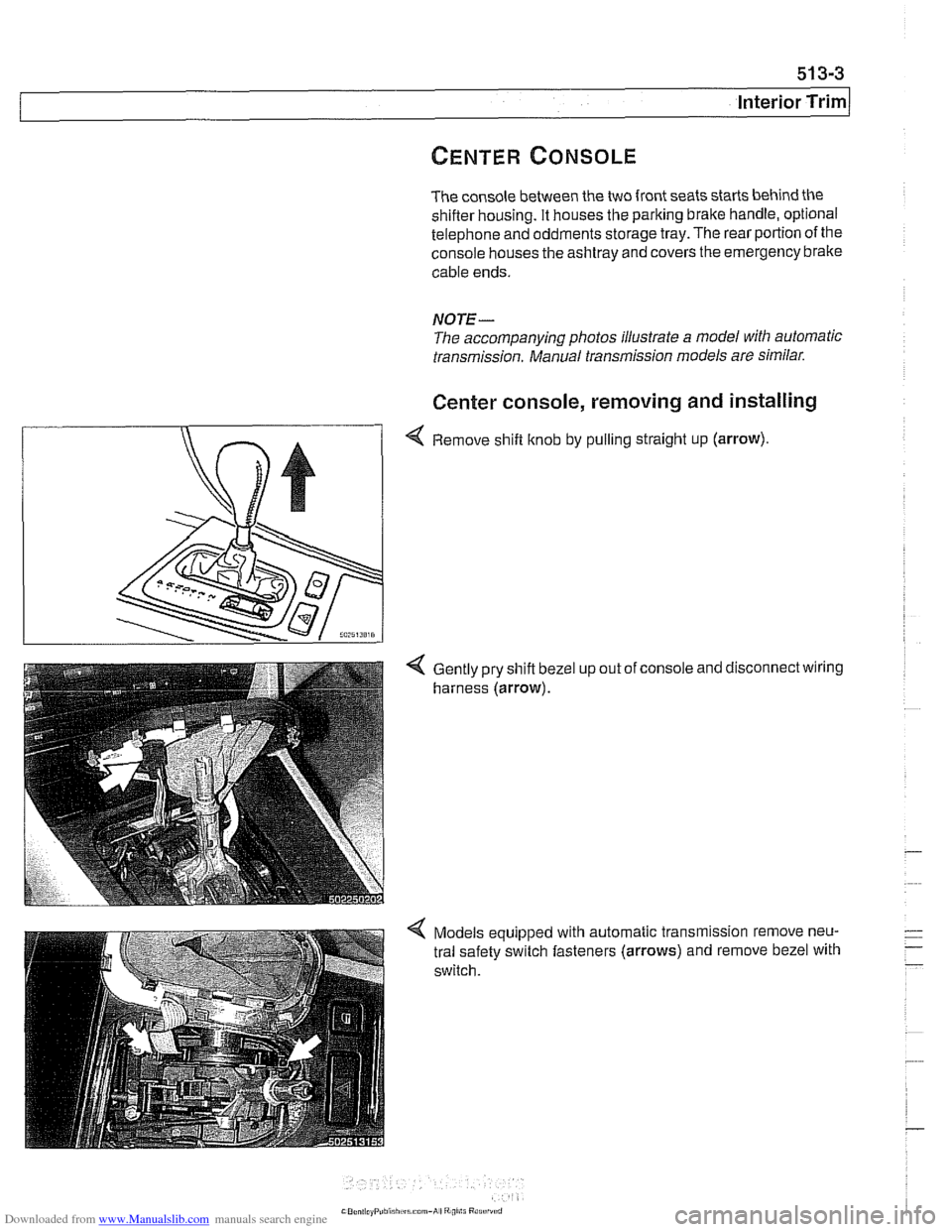

513-3

Interior ~rirnl

The console between the two front seats starts behind the shifler housing. It houses the parking brake handle, optional

telephone and oddments storage tray. The rear portion of the

console houses the ashtray and covers the emergency brake

cable ends.

NOTE-

The accompanying photos illustrate a model with automatic

transmission. Manual transmission models are similar.

Center console, removing and installing

4 Remove shift knob by pulling straight up (arrow).

Gently pry shift bezel

harness (arrow). up

out of console and disconnect wiring

Models equipped with automatic transmission remove neu-

tral safety switch fasteners (arrows) and remove bezel with

switch.

Page 916 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anii-Theft

- If the starter engages, the following EWS inputs are function-

ing normally:

Ignition key

Code function

Transmission range switch or clutch position switch

Engine speed sensor

NO JE -

If a vehicle key is lost or stolen, the electronic authorization

for that key

can be cancelled using the BMW scan and di-

agnostic tools

DISplus, GTl or MoDiC.

Force applied to a ley can damage the electronic circuitry

in the key A damaged ley will not start the engine. In that

case, a new key should be purchased and initialized

by an

authorized BMW dealer.

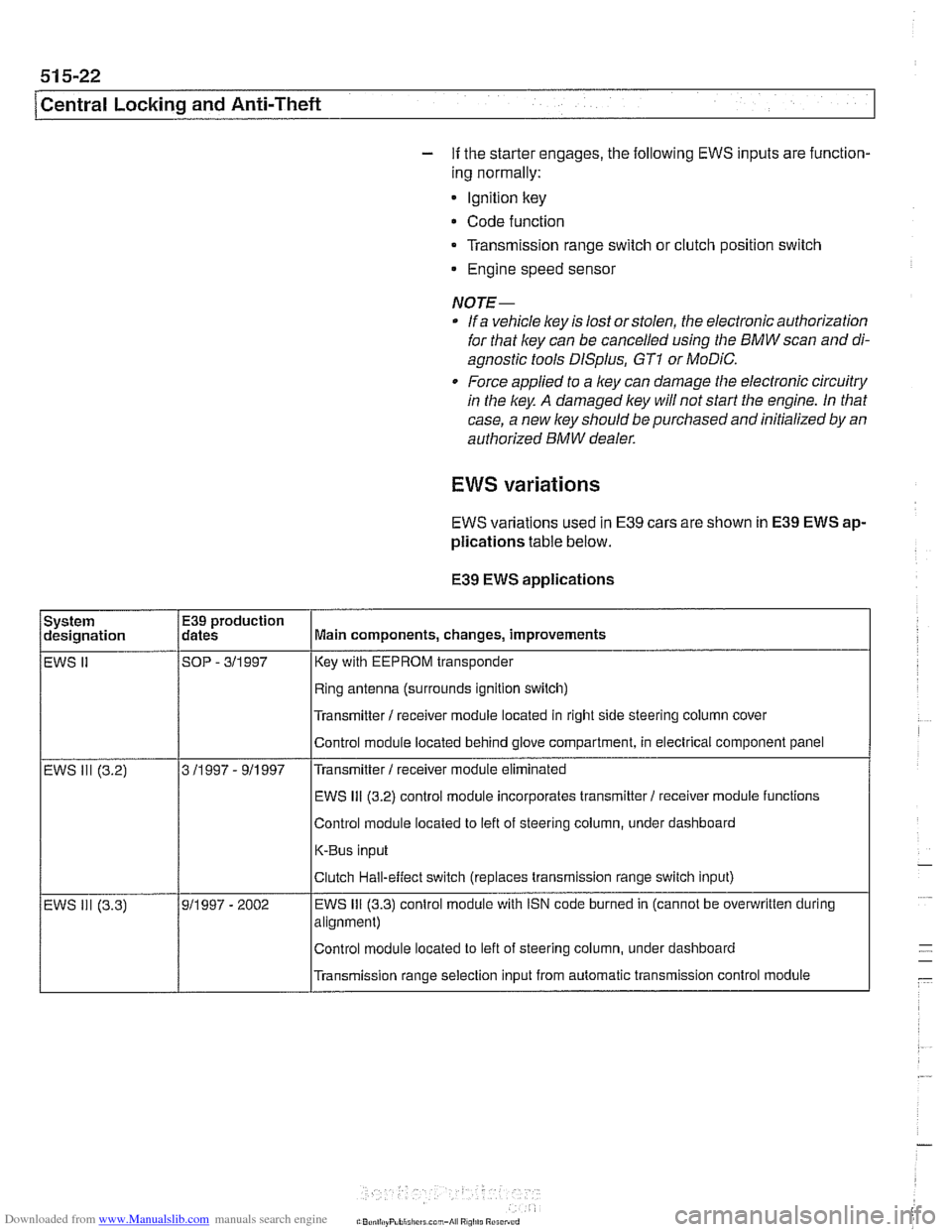

EWS variations

EWS variations used in E39 cars are shown in E39 EWS ap-

plications

table below.

E39

EWS applications

I I Ifling antenna (surrounds ignition switch) I

System

designation

EWS

II

I I l~ransmitter I receiver module located in right side steering column cover I

E39 production

dates

SOP

- 311 997

I I IEWS 111 (3.2) control module incorporates transmitter1 receiver moduie functions /

Main components, changes, improvements

Key with EEPROM transponder

Control moduie located behind glove compartment, in electrical component panel

Control module located to left of steering column, under dashboard

K-Bus input

Transmitter

I receiver module eliminated

EWS 111 (3.2)

Transmission range selection input from automatic transmission control module

3

11997 - 911997

- EWS ill (3.3) Clutch

Hall-effect switch (replaces transmission range switch input)

911997 - 2002 EWS 111 (3.3) control

module with iSN code burned in (cannot be overwritten during

alignment)

Control module located to left of steering column, under dashboard