Car engin BMW 528i 1997 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 82 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

-6val and Installation -

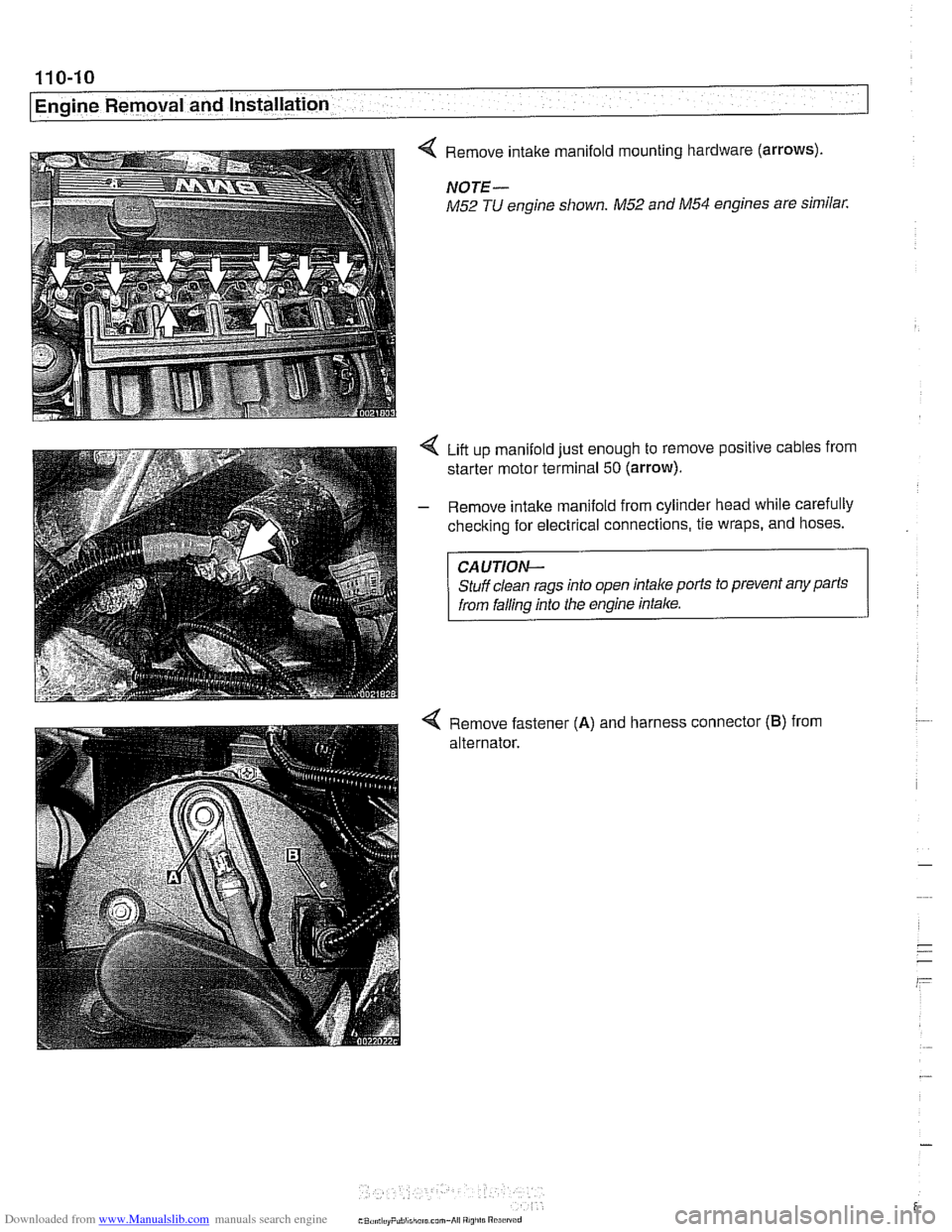

< Remove intake manifold mounting hardware (arrows).

NOTE-

M52 TU engine shown. M52 and M54 engines are similar.

Liit up manifold just enough to remove positive cables from

starter motor terminal

50 (arrow).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections, tie wraps, and hoses.

CAUTION-

Stuff clean rags into open intake ports to prevent any parts

from falling into the engine intake.

4 Remove fastener (A) and harness connector (B) from

alternator.

Page 84 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-12

Engine Removal and Installation

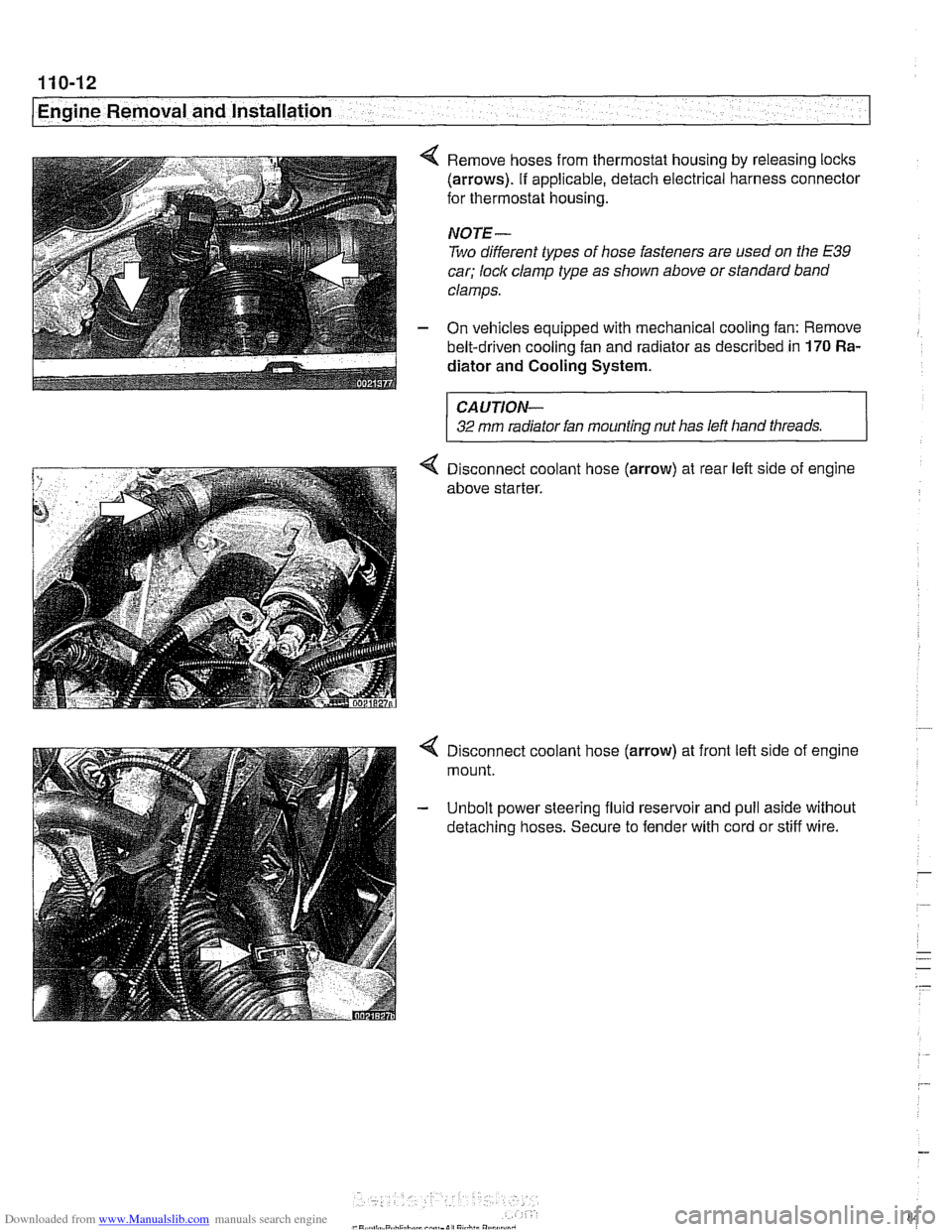

4 Remove hoses from thermostat housing by releasing locks

(arrows). If applicable, detach electrical harness connector

for thermostat housing.

NOTE-

Two different types of hose fasteners are used on the E39

car; lock clamp type as shown above or standard band

clamps.

- On vehicles equipped with mechanical cooling fan: Remove

belt-driven cooling fan and radiator as described in

170 Ra-

diator and Cooling

System.

CAUTION-

32 mm radiator fan mounting nut has left hand threads.

4 Disconnect coolant hose (arrow) at rear left side of engine

above starter.

4 Disconnect coolant hose (arrow) at front left side of engine

mount.

- Unbolt power steering fluid reservoir and pull aside without

detaching hoses. Secure to fender with cord or stiff wire.

Page 85 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and Installation

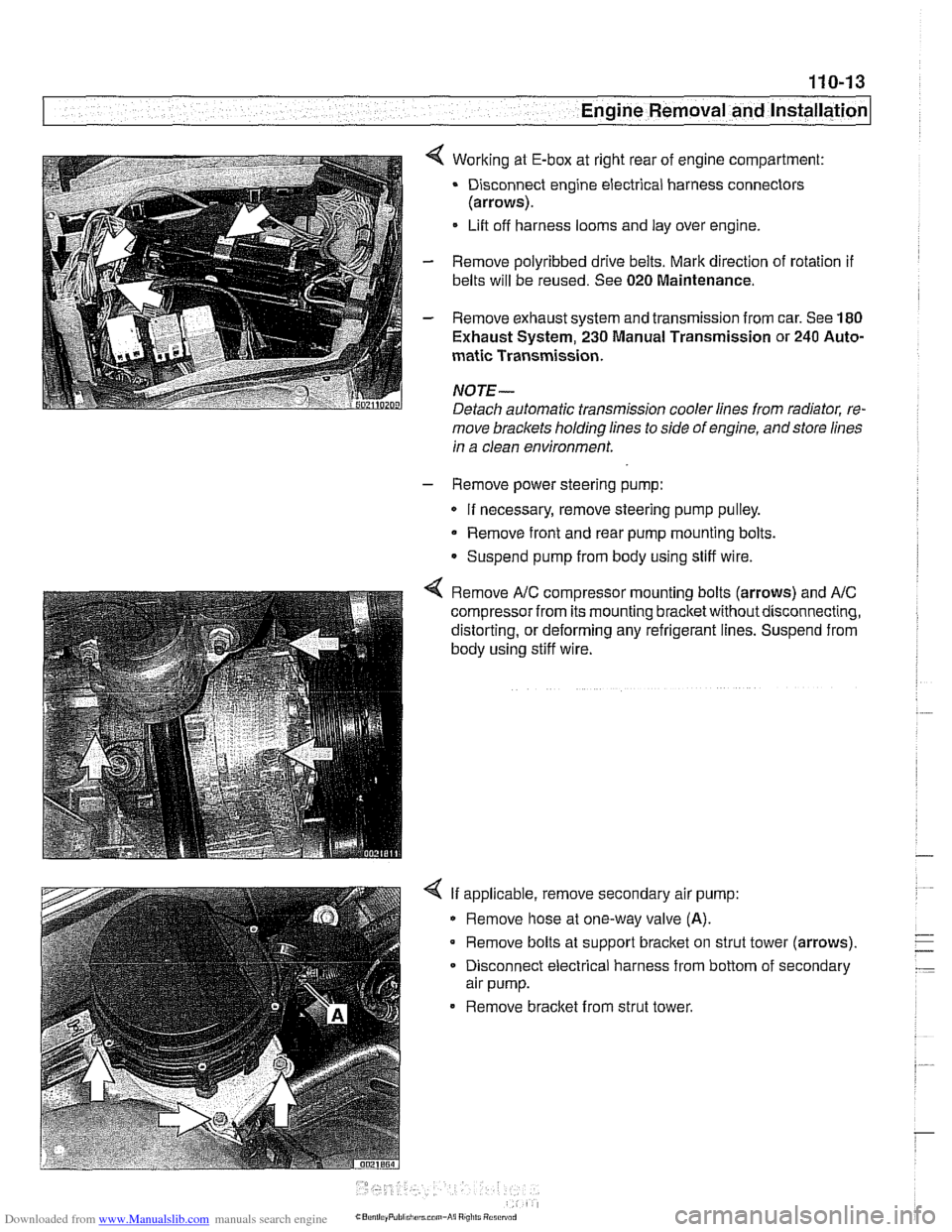

4 Working at E-box at right rear of engine compartment:

Disconnect engine electrical harness connectors

(arrows).

Lift off harness looms and lay over engine.

- Remove polyribbed drive belts. Mark direction of rotation if

belts will be reused. See 020 Maintenance.

- Remove exhaust system and transmission from car. See 180

Exhaust System, 230 Manual Transmission or 240 Auto-

matic Transmission.

NOJE-

Detach automatic transmission cooler lines from radiator, re-

move brackets holding lines to side of engine, andstore lines

in a clean environment.

- Remove power steering pump:

If necessary, remove steering pump pulley.

Remove front and rear pump mounting bolts.

Suspend pump from body using stiff wire.

4 Remove A/C compressor mounting bolts (arrows) and AIC

compressor from its mounting bracketwithoutdisconnecting,

distorting, or deforming any refrigerant lines. Suspend from

body using stiff wire.

4 If applicable, remove secondary air pump:

Remove hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

- Disconnect electrical harness from bottom of secondary

air pump.

Remove bracket from strut tower.

Page 86 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-14

I Engine Removal and Installation

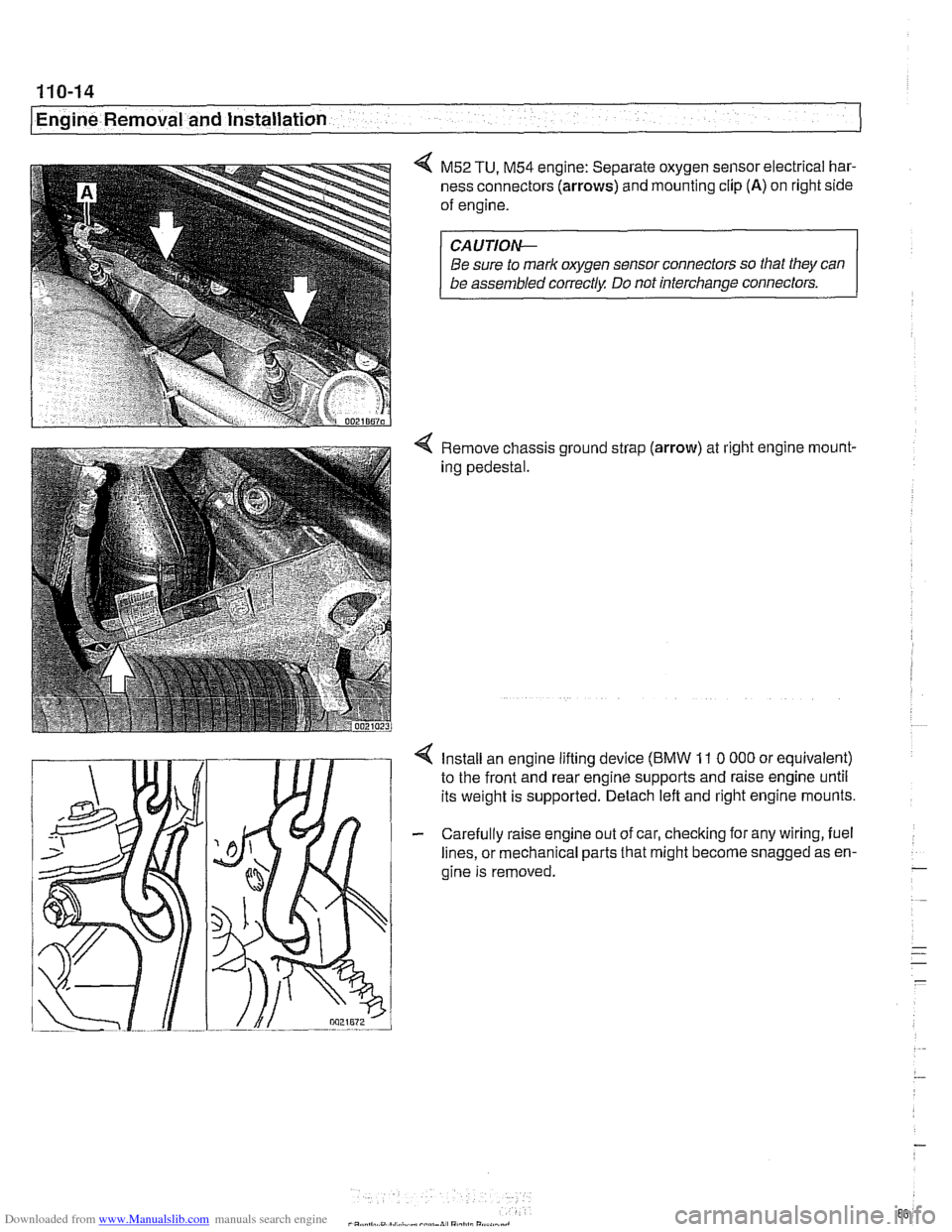

4 M52 TU, M54 engine: Separate oxygen sensor electrical har-

ness connectors

(arrows) and mounting clip (A) on right side

of engine.

CA UTIOW

Be sure to mark oxygen sensor connectors so that they can

be assembled correctly Do not interchange connectors.

4 Remove chassis ground strap (arrow) at right engine rnount-

ing pedestal.

4 Install an engine lifting device (BMW 11 0 000 or equivalent)

to the front and rear engine supports and raise engine until

its weight is supported. Detach left and right engine mounts.

- Carefully raise engine out of car, checking for any wiring, fuel

lines, or mechanical parts that might become snagged as en-

gine is removed.

-

. ..

- .- -

-

Page 91 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-19

Engine Removal and Installation

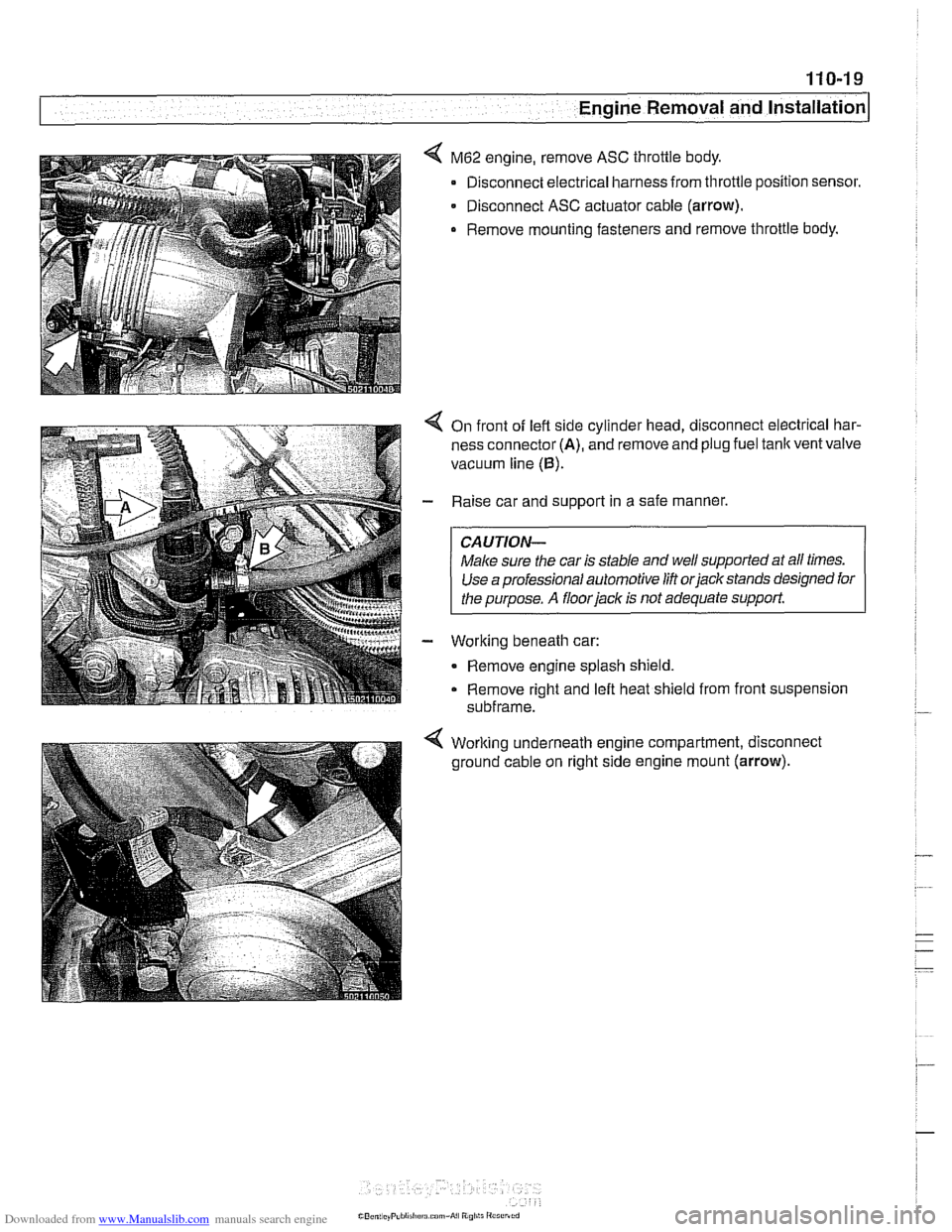

M62 engine, remove ASC throttle body.

Disconnect electrical harness from throttle position sensor.

- Disconnect ASC actuator cable (arrow).

. Remove mounting fasteners and remove throttle body.

On front of left side cylinder head, disconnect electrical har-

ness connector

(A), and remove and plug fuel tank vent valve

vacuum line

(0).

Raise car and support in a safe manner.

CAUTION-

Male sure the car is stable and well supported at aN times.

Use a professional automotive

lifi orjackstands designed for

I the ouroose. A floor jack is not adequate support.

Working beneath car:

- Remove engine splash shield.

Remove right and left heat shield from front suspension

subframe.

Working underneath engine compartment, disconnect

ground cable on right side engine mount

(arrow).

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

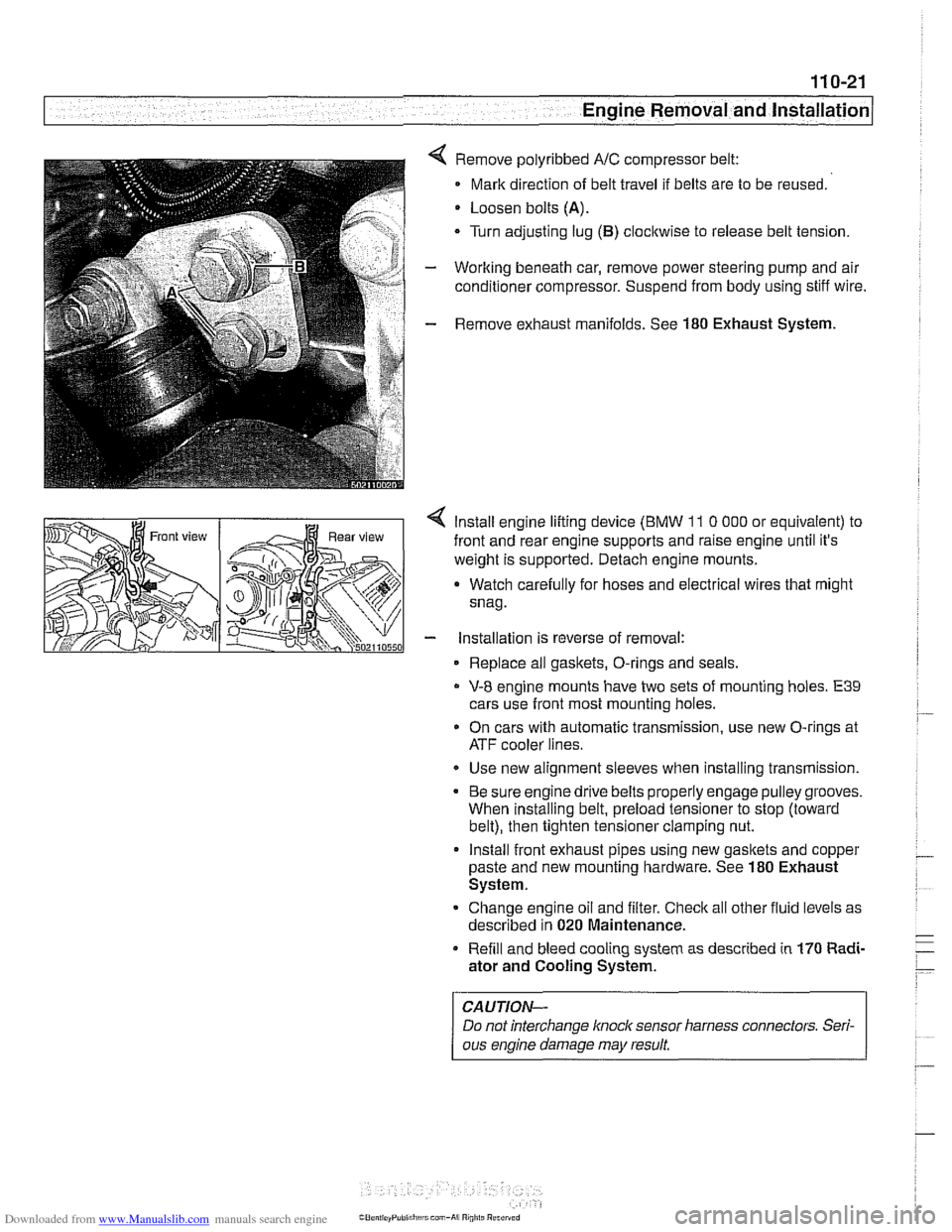

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

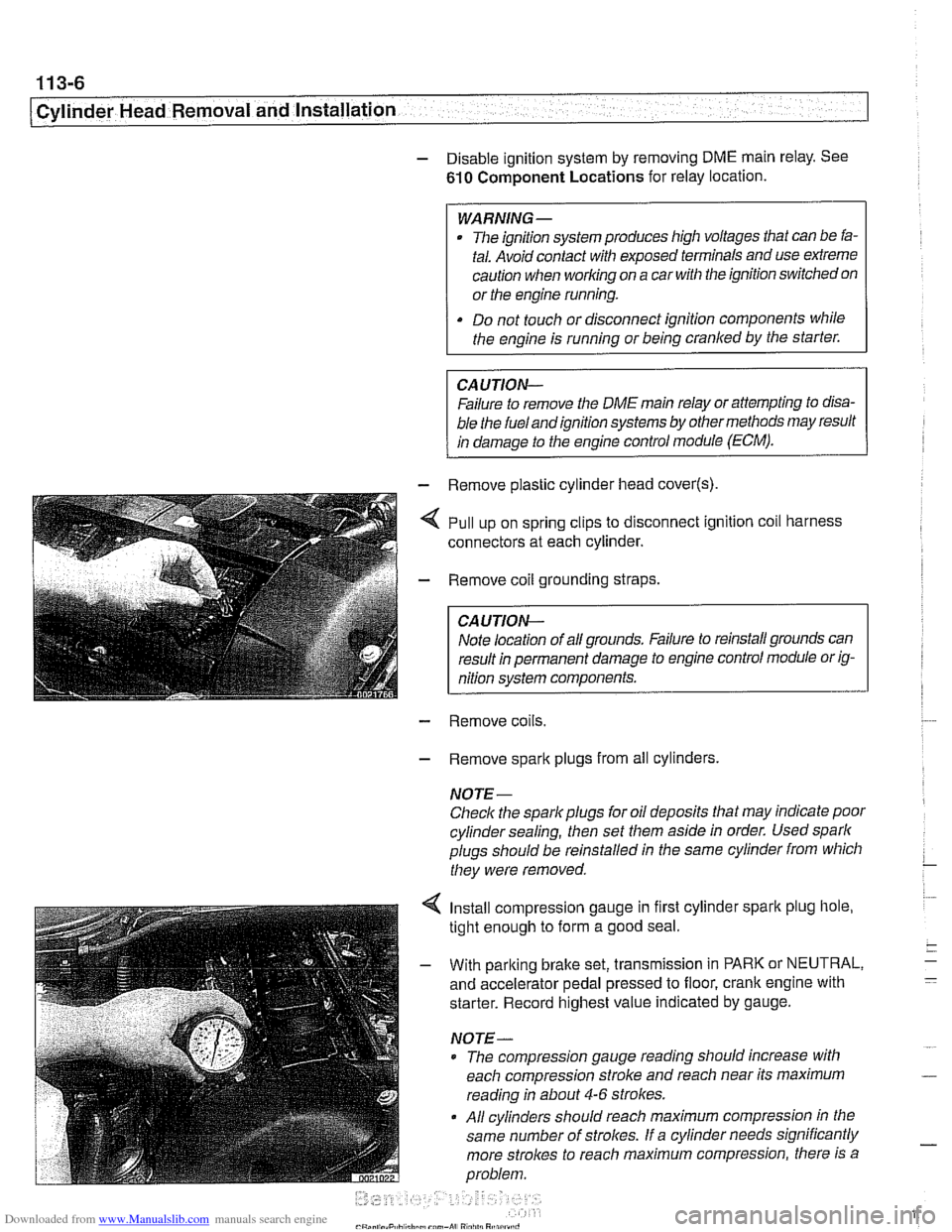

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 103 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-9

Cylinder Head Removal and Installation

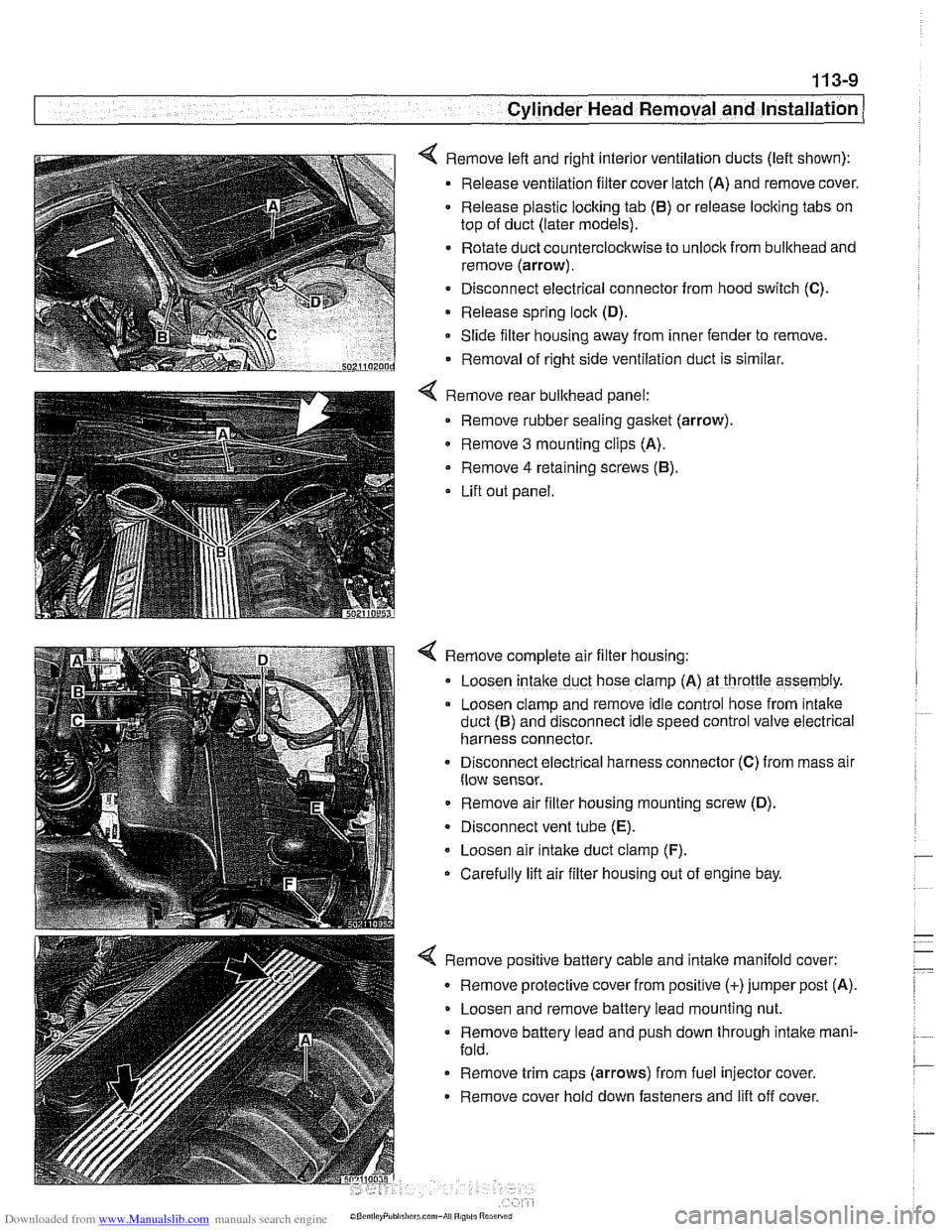

< Remove left and right interior ventilation ducts (left shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic locking tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclockwise to unlock from bulkhead and

remove (arrow).

Disconnect electrical connector from hood switch

(C).

Release spring lock (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel: Remove rubber sealing

gasket (arrow).

0 Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift out panel.

< Remove complete air filter housing:

Loosen

intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from

~ntake

duct (6) and disconnect Idle speed control valve electr~cal

harness connector.

Disconnect

electr~cal harness connector (C) from mass alr

flow sensor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

4 Remove positive battery cable and intake manifold cover:

Remove protective cover from positive (+)jumper post (A).

Loosen and remove battery lead mounting nut.

Remove battery lead and push down through intake mani-

fold.

Remove trim caps (arrows) from fuel injector cover.

Remove cover hold down fasteners and lift off cover.

Page 105 of 1002

Downloaded from www.Manualslib.com manuals search engine

..

Cylinder Head Removal and Installation 1

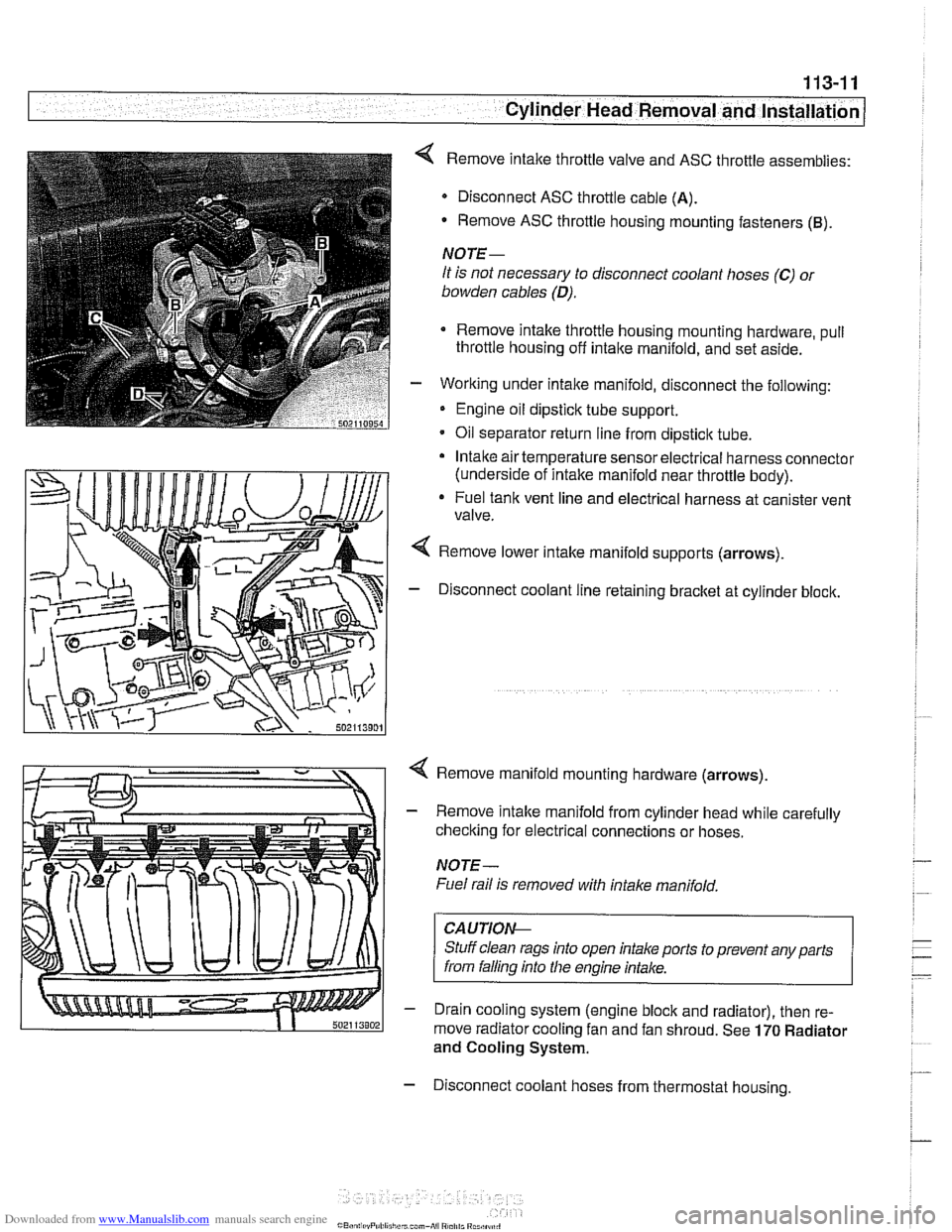

< Remove intake throttle valve and ASC throttle assemblies:

Disconnect ASC throttle cable

(A).

- Remove ASC throttle housing mounting fasteners (B).

NOTE-

It is not necessary to disconnect coolant hoses (C) 01

bowden cables (D).

Remove intake throttle housing mounting hardware, pull

throttle housing off

intake manifold, and set aside.

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Intake air temperature sensor electrical harness connector

(underside of intake manifold near throttle body).

* Fuel tank vent line and electrical harness at canister vent

valve.

Remove lower intake manifold supports (arrows).

- Disconnect coolant line retaining bracket at cylinder block.

4 Remove manifold mounting hardware (arrows).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections or hoses.

NOTE-

Fuel rail is removed with intake manifold,

CAUTIOI\C

Stuff clean rags into open intake ports to prevent any parts

from falling into

Nie engine intake.

- Drain cooling system (engine block and radiator), then re-

move radiator cooling fan and fan shroud. See

170 Radiator

and Cooling System.

- Disconnect coolant hoses from thermostat housing.

Page 109 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation / -

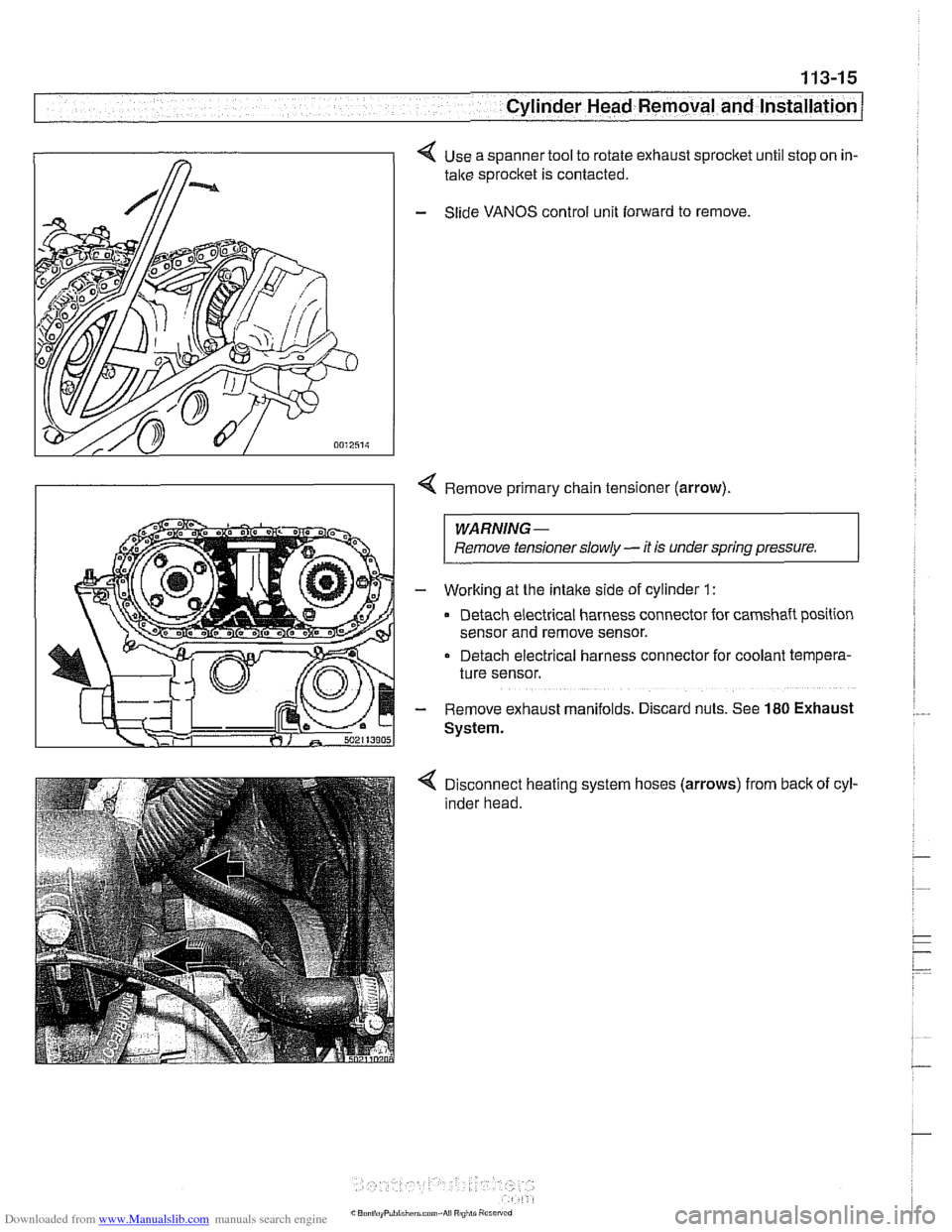

< Use a spanner tool to rotate exhaust sprocket until stop on in-

take sprocket is contacted.

- Slide VANOS control unit forward to remove

Remove primary chain tensioner (arrow)

WARNING -

Remove tensioner slowly - it is under spring pressure. I

- Working at the intake side of cylinder 1 :

Detach electrical harness connector for camshaft position

sensor and remove sensor.

Detach electrical harness connector for coolant tempera-

ture sensor.

- Remove exhaust manifolds. D~scard nuts. See 180 Exhaust

System.

Disconnect heating system hoses (arrows) from back of cyl-

inder head.