jump start BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 7 of 1002

Downloaded from www.Manualslib.com manuals search engine

001 General Warnings and Cautions

PLEASE READ THESE WARNINGS AND CAUTIONS

BEFORE PROCEEDING

WITH MAINTENANCE AND REPAIR WORK.

WARNINGS-

See also CAUTIONS

- Some repairs may be beyond your capability. If you lack the skills, - Catch draining fuel, oil, or brake fluid in suitable containers. Do

tools and equipment, or a suitable workplace for any procedure

not use

foodor beverage containers that might mislead someone

described in this manual, we suggest you leave such repairs to

into

drinking from them. Store flammable fluids away from fire

an authorized BMW dealer service department or other qualified

hazards. Wipe up spills at once, but do not store the oily rags,

shop. which can ignite and burn spontaneously.

. Do not reuse any fasteners that are worn or deformed. Many fas- Always observe good worRshop practices. Wear qoqqles when

teners are designed to be used only once and become

unreliable you operate machine tools or work with battery acid:kloves or

and mav fail when used a second time. This includes, but is not other

~rotective clothino should be worn whenever the iob re-

limited io, nuts, bolts, washers, self-locking nuts or bolts, clrclips yires' working with harmful substances.

and cotter pins. Always replace these fasteners with new parts.

Greases, lubricants and other automotive chemicals contain toxic

. Never work under a lifted car unless it is solidly supported on

substances, many of which are absorbed directly through the

stands

desiqned for the purpose. Do not supeort a car on cinder

skin. Read the manufacturer's instructions and warninos careful-

blochs, hollow tiles orotherbrops that may drurnbie undercontin-

uous toad. Never work under a car that is supported solely by a

iack. Never work under the car

while the enqine is runninq. - -

If you aregoing to work underacaron the ground, makesure that

the ground is level. Block the wheels to

keep the car from rolling.

Disconnect the battery negative

(-) terminal to prevent others

from starting the car while you are under it.

- Never run the engine unless the work area is well ventilated. Car-

bon monoxide kills.

Rings, bracelets and other jewelry should be removed so that

they cannot cause electrical shorts, get caught in running ma-

chinery, or be crushed by heavy parts.

- Tie long hair behind your head. Do not wear a necktie, a scarf.

loose clothing, or a necklace when you work near machine tools

or running engines. if your hair, clothing, or jewelry were to get

caught in the machinery, severe injury could result.

DO not attempt to

work on your car if you do not feel well. You in-

crease the

danger of injuryto yourseliand others if you are tired,

uDset or have taken medication or anv other substance that mav

keep you from being fully alert.

Illuminate your work area adequately but safely. Use a portable

iy. Use hand and eye protection. Avoid direct skin conGct.

Disconnect the battery negative (-) terminal whenever you work

on the fuel system

orthe electrical system. Do not smokeorwork

near heaters or other fire hazards. Keep an approved fire extin-

guisher handy.

. Friction materials (such as brake pads or shoes or clutch discs)

contain asbestos fibers or other friction materials. Do not create

dust by grinding, sanding, or by cleaning with compressed air.

Avoid breathing dust. Breathing any

friclion material dust can

lead to serious diseases and may result in death.

Batteries

giveoff explosive hydrogen gas during charging. Keep

sparks, lighted matches and open flame away from the top of the

battery. If hydrogen gas escaping from the cap vents is ignited, it

will ignite gas trapped in the cells and cause the battery to ex-

plode.

Connect and disconnect battery cables, jumper cables or a bat-

tery charger only wilh the ignition switched off. Do not disconnect

the battery while the engine is running.

Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

. . safety lighiforworking lnsideor under the car. Make sure the bulb - Do not allow battery charging vollage to exceed 16.5 volts. If the

is enclosed bv a wire caoe. The hot filament of an accidentallv

batten! beoins ~roducina oas or boilino violentiv, reduce the

broken bulb can ignite spilled

fuel, vapors or oil. , - - - charglng rate. ~oostlng a sutfaled battery at a igh charging rate

can cause an

explosion.

-

Continued on next page

Page 11 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1

010 General

General ........................... .01 0.2

How to Use this Manual ............ .01 0.2

Warnings. cautions and notes ........... .0l 0.3

Getting Started .................... .0i 0.5

Safety ............................. .O1 0.5

Lifting the car ........................ .O1 0.5

Raising car ......................... .O1 0.5

Working under car .................... .O1 0.6

Advice for the Beginner ............ .O1 0.7

Planning ahead ...................... .O1 0.7

Workshop practices ................... .O1 0.7

Non-reusable fasteners ................ .O1 0.7

Tightening fasteners .................. .O1 0.8

Gaskets and seals .................... .O1 0.9

Electrical testing .................... .O1 0.10

Wire repairs ........................ .O1 0.10

Buying Parts ..................... .01 0.11

Genuine BMW parts ................. .O1 0.11

Non-returnable parts ................. .O1 0.11

Information you need to know .......... .0l 0.12

Service ........................... 01 0-1 3

TOOIS ............................. 010-13

Basic tool requirements ............... 01 0-1 4

Jack stands ......................... 01 0-1 6

Oil change equipment ................. 01 0-1 6

Torque wrench ...................... 01 0-17

Digital multimeter .................... 010-17

BMW special tools ................... 01 0-1 8

Emergencies ...................... 01 0-1 8

Changing a tire ...................... 01 0-1 8

Jump starting ....................... 01 0-1 9

Indicator and warning lights ............ 01 0-1 9

Towing ............................ 010-20

Spare parts kit ...................... 010-21

Page 29 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Cars with discharged or dead batteries can be jump-started

using the good battery from another car. See owner's manual

for proper instruction on jump starting. When jump-starling

the engine, always note the following warnings.

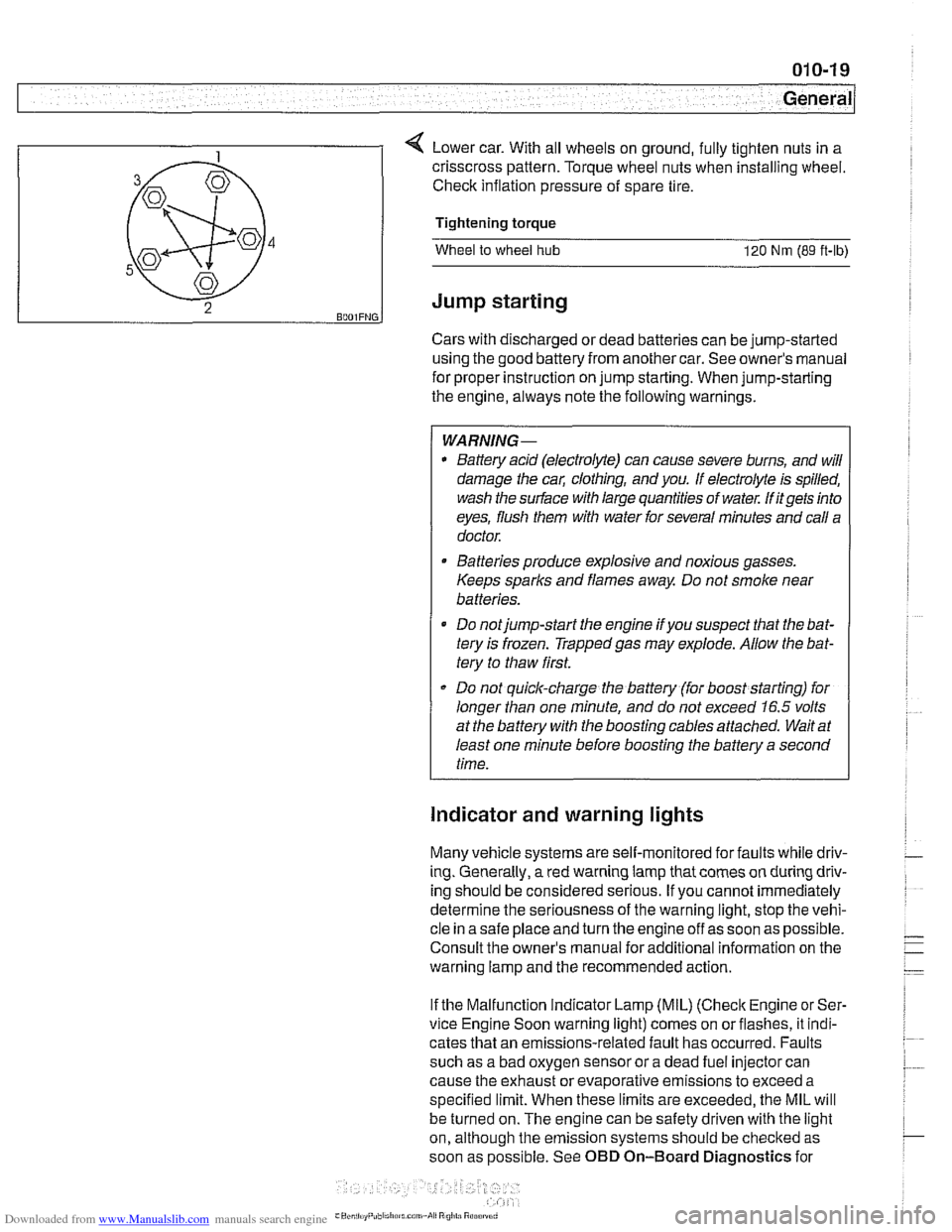

4 Lower car. With all wheels on ground, fully tighten nuts in a

WARNING-

* Battery acid (electrolyte) can cause severe burns, and will

damage the

cal; clothing, and you. If electrolyte is spilled,

wash the surface with large quantities of water.

M itgets into

eyes, flush them with water for several minutes and call a

doctor.

B4

5

43

2 BOOIFNG.

Batteries produce explosive and noxious gasses.

Keeps sparks and flames away. Do not smoke near

batteries.

Do notjump-start the engine

ifyou suspect that the bat-

tery is frozen. Trappedgas may explode. Allow the bat-

tery to thaw first.

Do not quick-charge the battery (for boost starting) for

longer than one minute, and do not exceed

16.5 volts

at the battery with the boosting cables attached. Wait at

least one minute before boosting the battery a second

time.

crisscross pattern.

Torque wheel nuts when installing wheel.

Check inflation pressure of spare tire.

Tightening torque

Wheel to wheel hub 120 Nm (89 ft-ib)

Jump starting

Indicator and warning lights

Many vehicle systems are self-monitored for faults while driv-

ing. Generally,

a red warning lamp that comes on during driv-

ing should be considered serious. If you cannot immediately

determine the seriousness of the warning light, stop the vehi-

cle in a safe place and turn the engine off as soon as possible.

Consult the owner's manual for additional information on the

warning lamp and the recommended action.

If the Malfunction Indicator Lamp (MIL)

(Check Engine or Ser-

vice Engine Soon warning light) comes on orflashes, it indi-

cates that an emissions-related fault has occurred. Faults

such as a bad oxygen sensor or a dead fuel injector can

cause the exhaust or evaporative emissions to exceed a

specified limit. When these limits are exceeded, the MIL will

be turned on. The engine can be safety driven with the light

on, although the emission systems should be

checked as

soon as possible. See OBD On-Board Diagnostics for

Page 77 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and lnstallationl

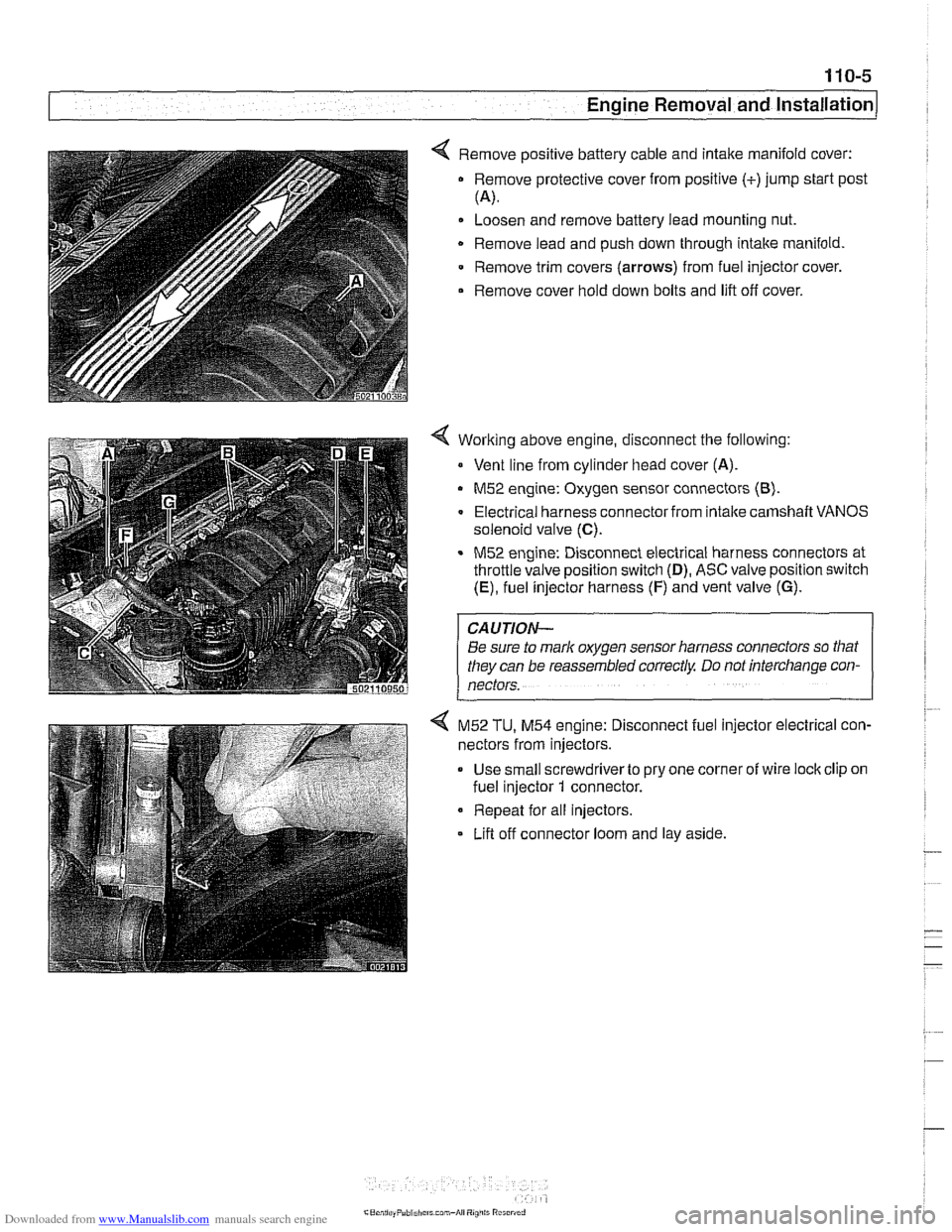

< Remove positive battery cable and intake manifold cover:

Remove protective cover from positive (+)jump start post

(4.

Loosen and remove battery lead mounting nut.

Remove lead and push down through intake manifold

Remove trim covers

(arrows) from fuel injector cover.

Remove cover hold down bolts and lift off cover.

Working above engine, disconnect the following:

Vent line from cylinder head cover (A).

M52 engine: Oxygen sensor connectors (8).

Electrical harness connector from intalte camshaft VANOS

solenoid valve

(C).

M52 engine: Disconnect electrical harness connectors at

throttle valve position switch

(D), ASC valve position switch

(E), fuel injector harness (F) and vent valve (G).

CAUTION-

Be sure to mark oxygen sensor harness connectors so that

they can be reassembled correctly Do not interchange con-

nectors.

4 M52 TU, M54 engine: Disconnect fuel injector electrical con-

nectors from injectors.

Use small screwdriverto pry one corner of wire lock clip on

fuel injector

1 connector.

Repeat for all injectors.

Lifl off connector loom and lay aside.

Page 152 of 1002

Downloaded from www.Manualslib.com manuals search engine

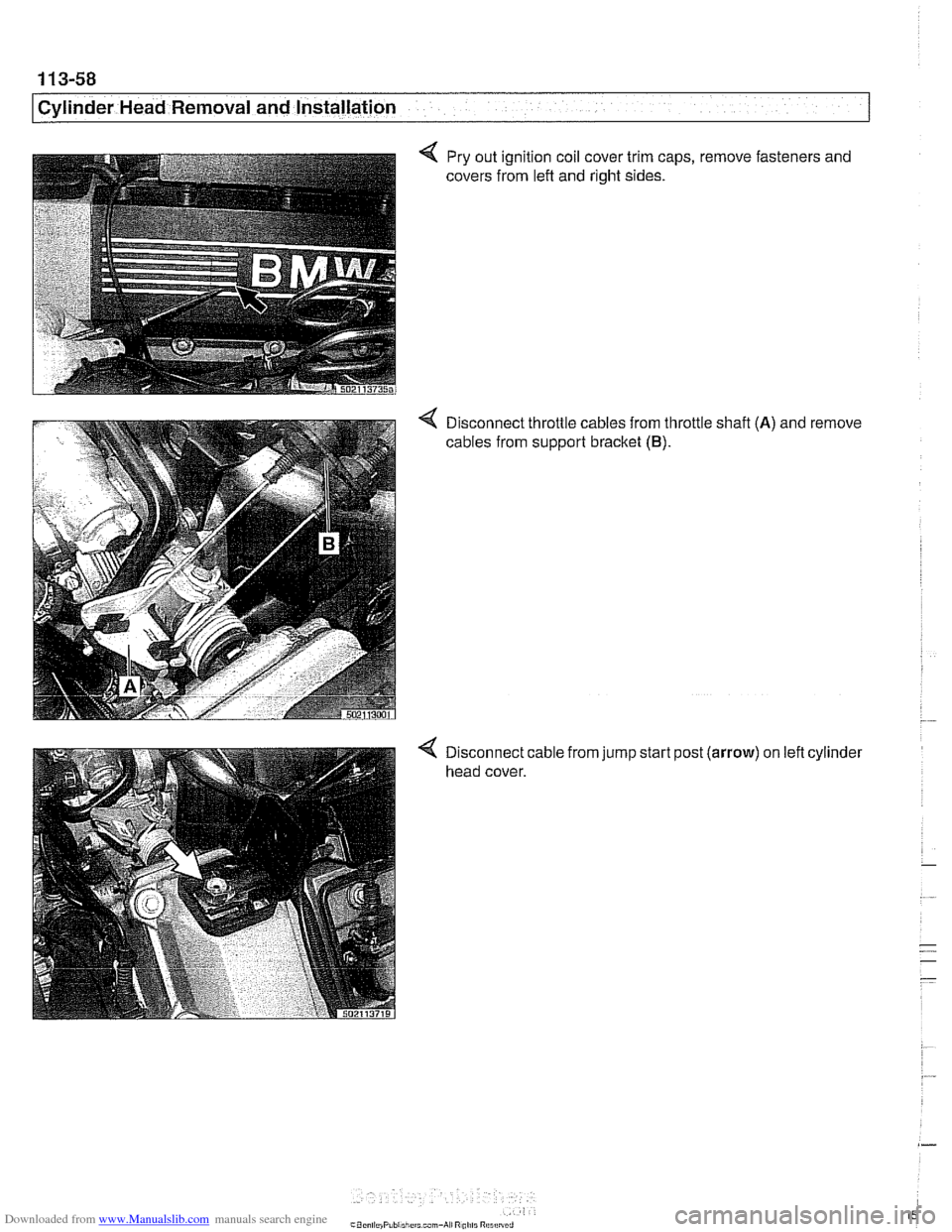

Cylinder Head Removal and Installation

Pry out ignition coil cover trim caps,

covers from lefl and right sides. remove fasteners

and

< Disconnect throttle cables from throttle shafl (A) and remove

cables from support bracket

(B).

< Disconnect cable from jump start post (arrow) on left cylinder

head cover.

Page 185 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-9

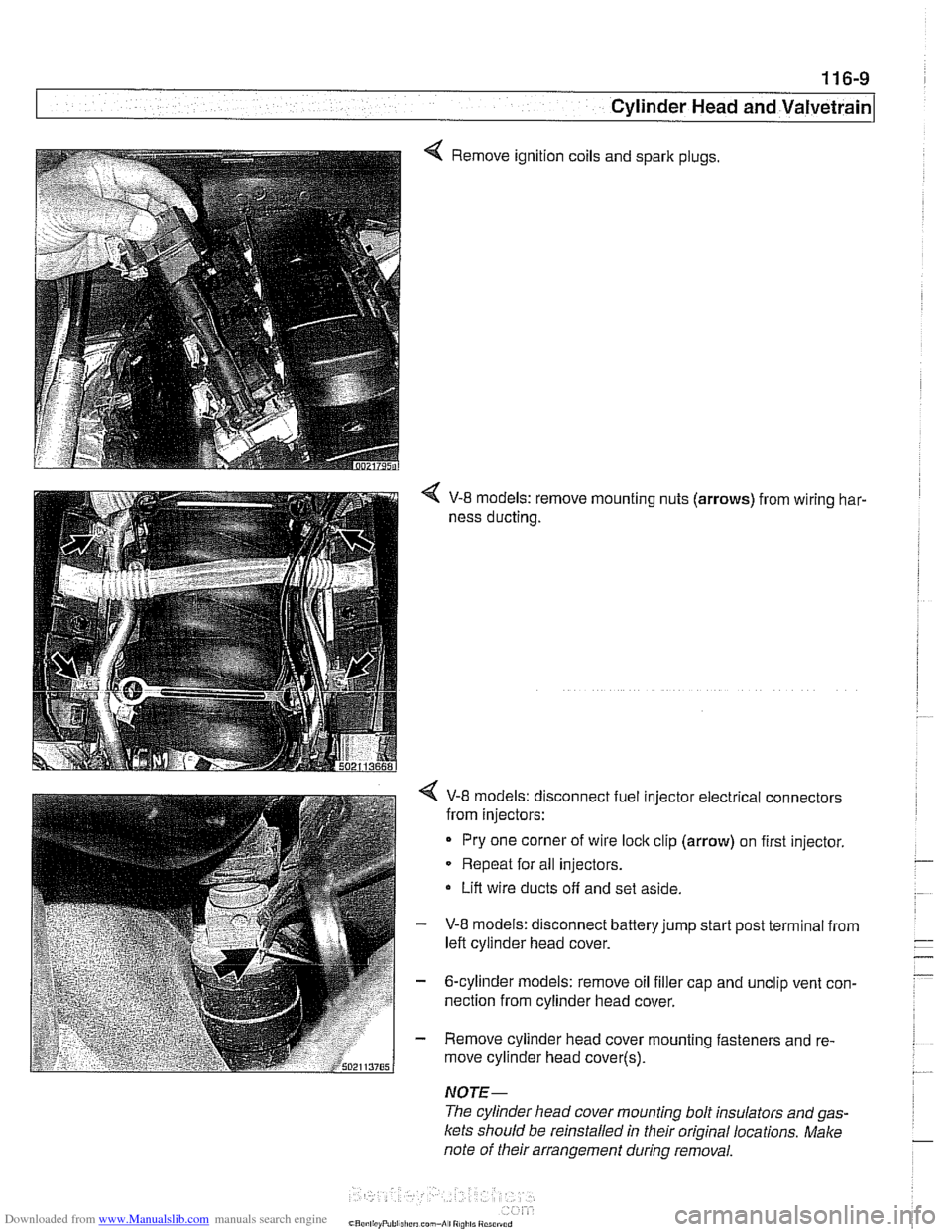

Cvlinder Head and valvetrain1

4 Remove ignition coils and spark plugs.

V-8 models: remove mounting nuts (arrows) from wiring har-

ness ducting.

< V-8 models: disconnect fuel injector electrical connectors

from injectors:

Pry one corner of wire

loclc clip (arrow) on first injector.

Repeat for all injectors.

Lift wire ducts off and set aside.

- V-8 models: disconnect battery jump start post terminal from

left cylinder head cover.

- 6-cylinder models: remove oil filler cap and unclip vent con-

nection from cylinder head cover.

- Remove cylinder head cover mounting fasteners and re-

move cylinder head cover(~).

NOTE-

The cylinder head cover mounting bolt insulators and gas-

Icets should be reinstalled in their original locations. Make

note of their arrangement

during removal.

Page 325 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

L

- --

- - -. - -- Lubrication ~~stern

- Remove pressure gauge and reinstall pressure switch with

new sealing washer.

Tightening torque

Oil pressure switch to oil filter housing 27 Nm (20 ft-lb)

If testing shows low oil pressure, one or more of the following

conditions may be indicated:

Worn or faulty oil pump or faulty pump pressure relief valve

Worn or damaged engine bearings

Severe engine wear

Any of these conditions indicate the need for major repairs.

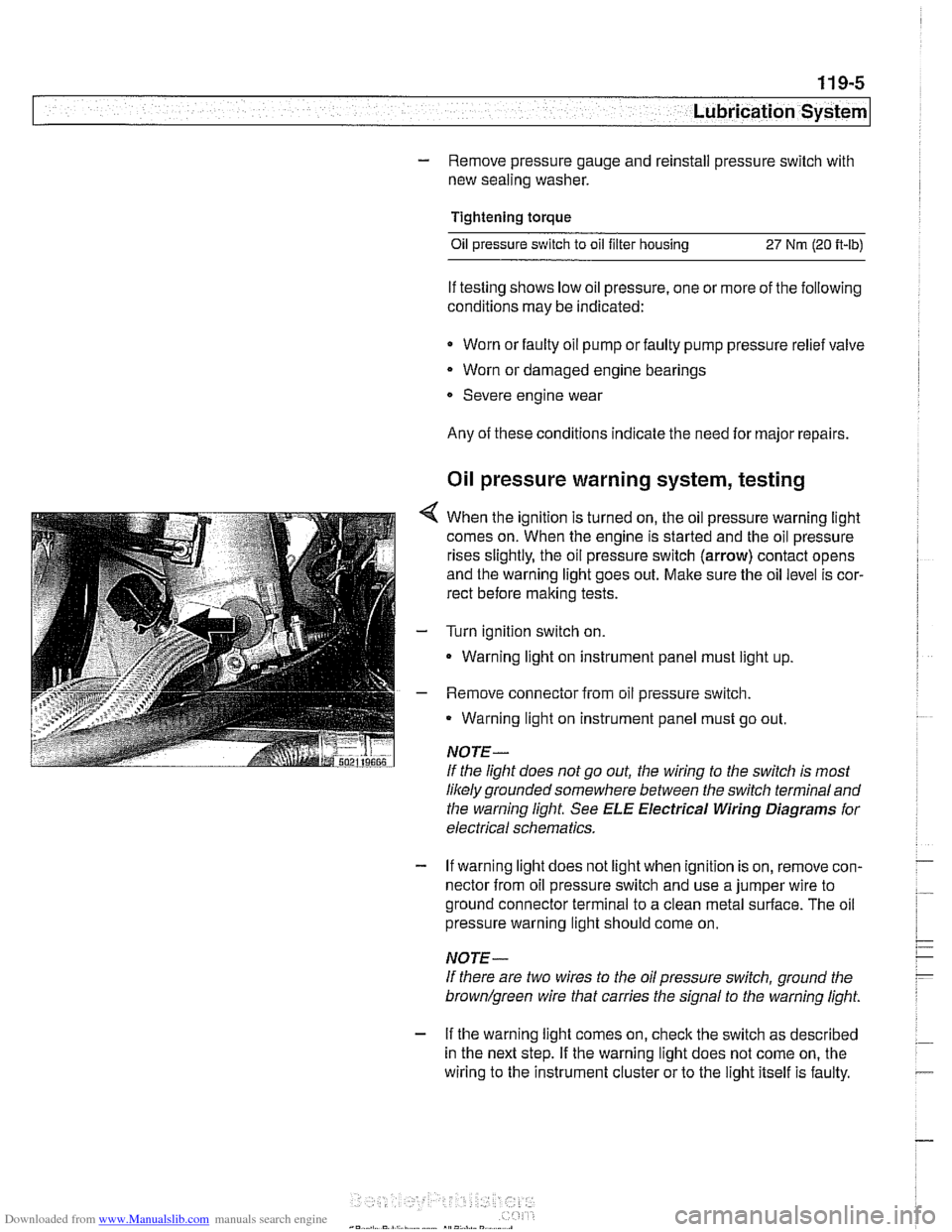

Oil pressure warning system, testing

4 When the ignition is turned on, the oil pressure warning light

comes on. When the engine is started and the oil pressure

rises slightly, the oil pressure switch (arrow) contact opens

and the warning light goes out. Make sure the oil level is cor-

rect before making tests.

- Turn ignition switch on.

- Warning light on instrument panel must light up

- Remove connector from oil pressure switch.

Warning light on instrument panel must go out.

NOTE-

If the light does not go out, the wiring to the switch is most

likely grounded somewhere between the switch terminaland

the warning light See

ELE Electrical Wiring Diagrams for

electrical schematics.

- If warning light does not light when ignition is on, remove con-

nector from oil pressure switch and use a jumper wire to

ground connector terminal to a clean metal surface. The oil

pressure warning light should come on.

NOTE-

If there are two wires to the oil pressure switch, ground the

brown/green wire that carries the signal to the warning light.

- If the warning light comes on, check the switch as described

in the next step. If the warning light does not come on, the

wiring to the instrument cluster or to the light itself is faulty.

Page 359 of 1002

Downloaded from www.Manualslib.com manuals search engine

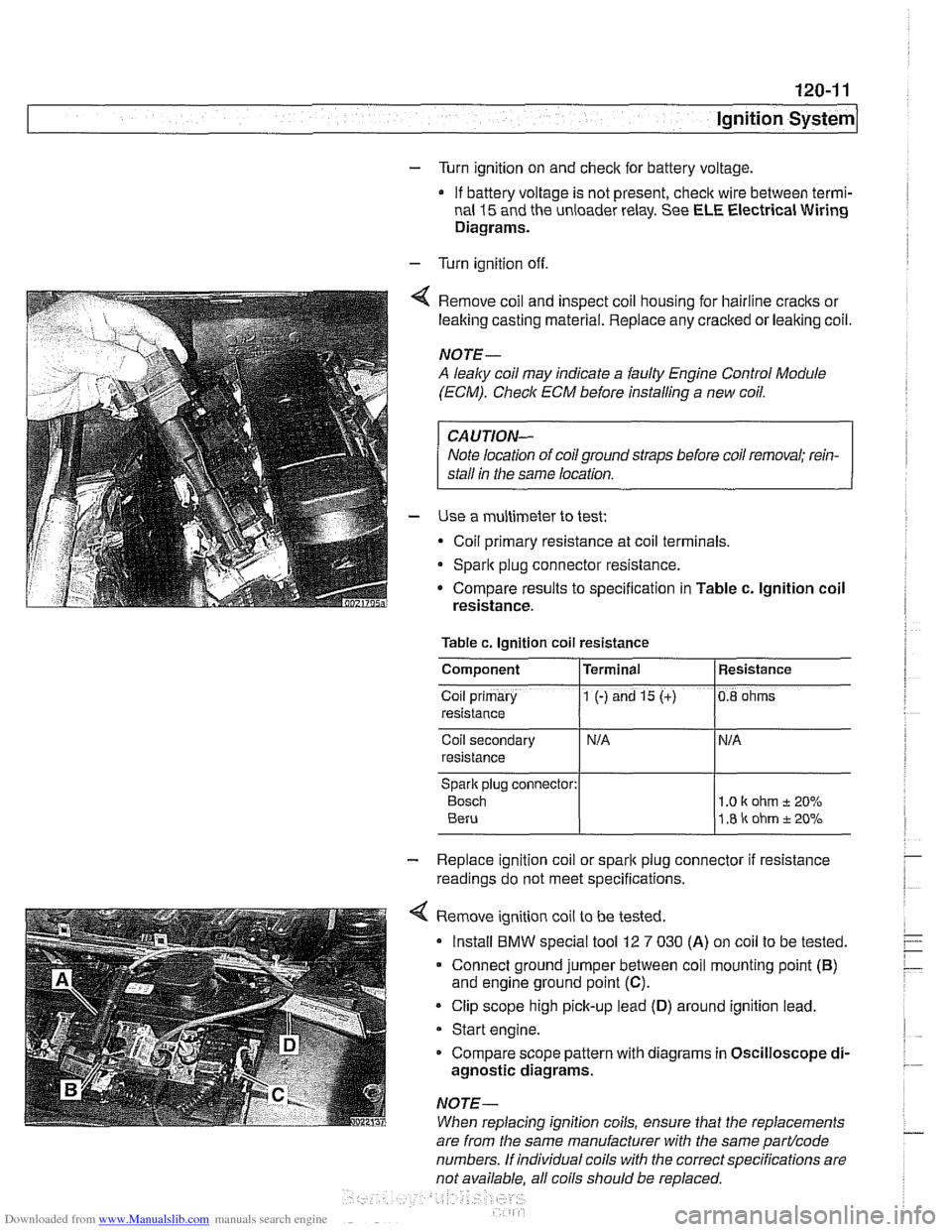

Ignition System

- Turn ignition on and check for battery voltage,

If battery voltage is not present,

checlt wire between termi-

nal

15 and the unloader relay. See ELE Electrical Wiring

Diagrams.

- Turn ignition off.

Remove coil and inspect coil housing for hairline

cracks or

leaking casting material. Replace any

cracked or leaking coil.

NOTE-

A leaky coil may indicate a faulty Engine Control Module

(ECM). Check ECM before installing a new coil.

CAUTION-

Note location of coilground straps before coil removal; rein-

stall in the same location.

Use a multimeter to test:

Coil primary resistance at coil terminals.

Sparlt plug connector resistance.

* Compare results to specification in Table c. lgnition coil

resistance.

Table c. Ignition coil resistance

Coil secondary

resistance

Spark plug connector:

Bosch 1 .O I( ohm t 20%

1.8 ir ohm t 20%

Component

Co~l prlmary

resistance

- Replace ignition coil or sparlt plug connector if resistance

readings do not meet specifications.

4 Remove ignition coil to be tested.

Install

BMW special tool 12 7 030 (A) on coil to be tested.

Connect ground jumper between coil mounting point

(B)

and engine ground point (C).

Clip scope high pick-up lead (D) around ignition lead.

Start engine.

Compare scope pattern with diagrams in Oscilloscope

di-

agnostic diagrams.

NOTE-

When replacing ignition coils, ensure that the replacements

Terminal

1 (-) and 15 (+)

are

from the same manufacturer with the same partlcode

numbers. If individual coils with the correct specifications are

not available. all coils should be

re~laced.

Resistance

0.8 ohms

Page 380 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

/Battery, Starter, Alternator -- - -. - --I

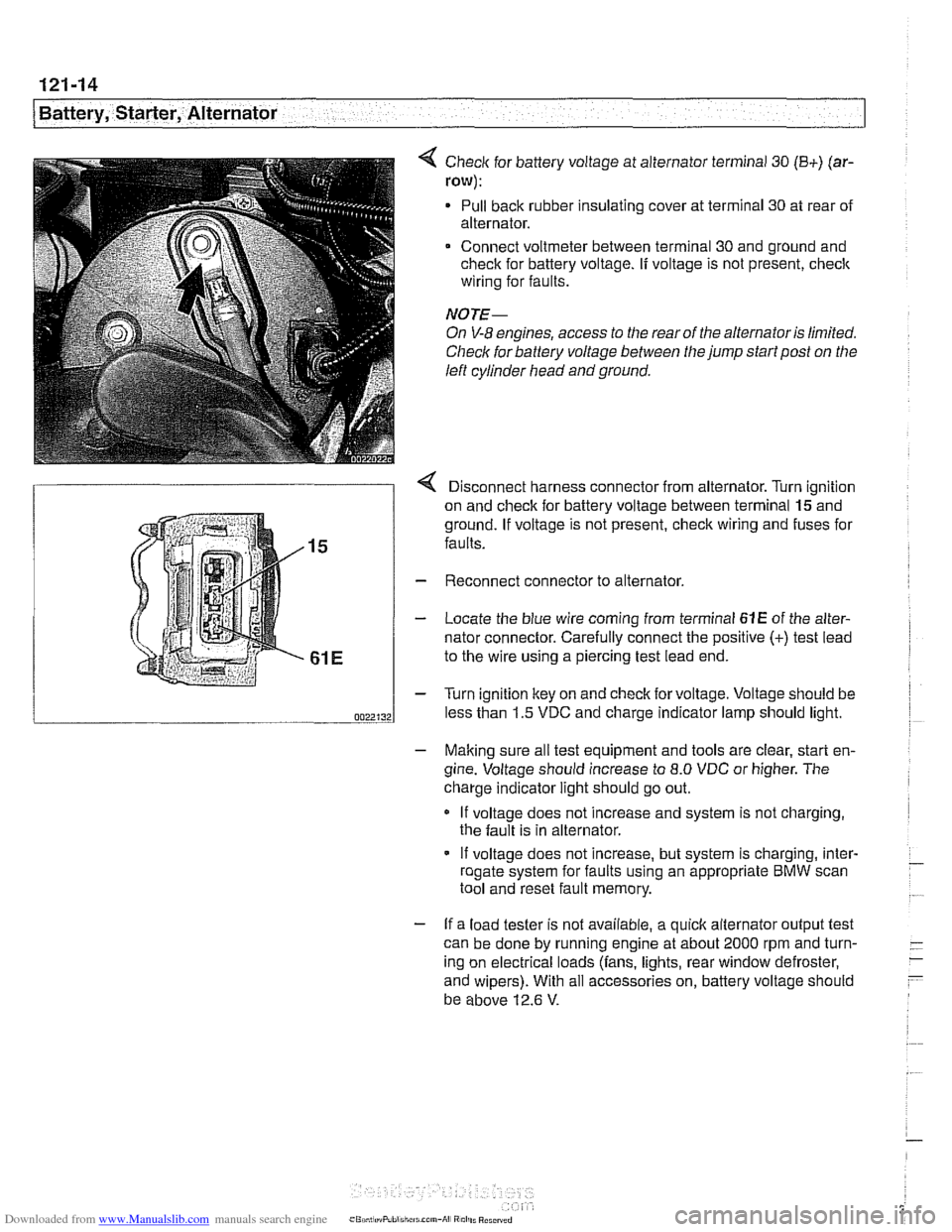

< Check for battery voltage at alternator terminal 30 (B+) (ar-

row):

Pull back rubber insulating cover at terminal 30 at rear of

alternator.

Connect voltmeter between terminal 30 and ground and

check for battery voltage.

If voltage is not present, check

wiring for faults.

NOTE-

On V-8 engines, access to the rear of the alternator is limited.

Check for battery voltage between the jump start post on the

left cylinder head and ground.

r Disconnect harness connector from alternator. Turn ianition

on and check for battery voltage between terminal

lgand

ground. If voltage is not present, check wiring and fuses for

faults.

Reconnect connector to alternator.

Locate the blue wire coming from terminal

61E of the alter-

nator connector. Carefully connect the positive

(+) test lead

to the wire using a piercing test lead end.

Turn ignition key on and check for voltage. Voltage should be

less than 1.5 VDC and charge indicator lamp should light.

- Making sure all test equipment and tools are clear, start en-

gine. Voltage should increase to

8.0 VDC or higher. The

charge indicator light should go out.

If voltage does not increase and system is not charging,

the fault is in alternator.

- If voltage does not increase, but system is charging, inter- - roaate svstem for faults usina an appropriate BMW scan - .. . tool and'reset fault memory.

- If a load tester is not available, a quick alternator output test

can be done by running engine at about 2000 rpm and turn-

- -

ing on electrical loads (fans, lights, rear window defroster, -

- and wipers). With all accessories on, battery voltage should

be above 12.6

V.

Page 382 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-16

Battery, Starter, Alternator

- installation is reverse of removal.

Tightening torques Belt tensloner to engine block

M8 (8.8 grade) 22

Nm (16 ft-ib)

Fan clutch to coolant pump

with BMW special tool 11

5 040 30 Nm (22

ft-lb)

without BMW special tool

11 5 040 40 Nm

(29 ft-ib)

Pulley to alternator 70

Nm (44 ft-lb)

Terminal 30

(B+) wire to alternator (M8) 13 Nm (10 ft-ib)

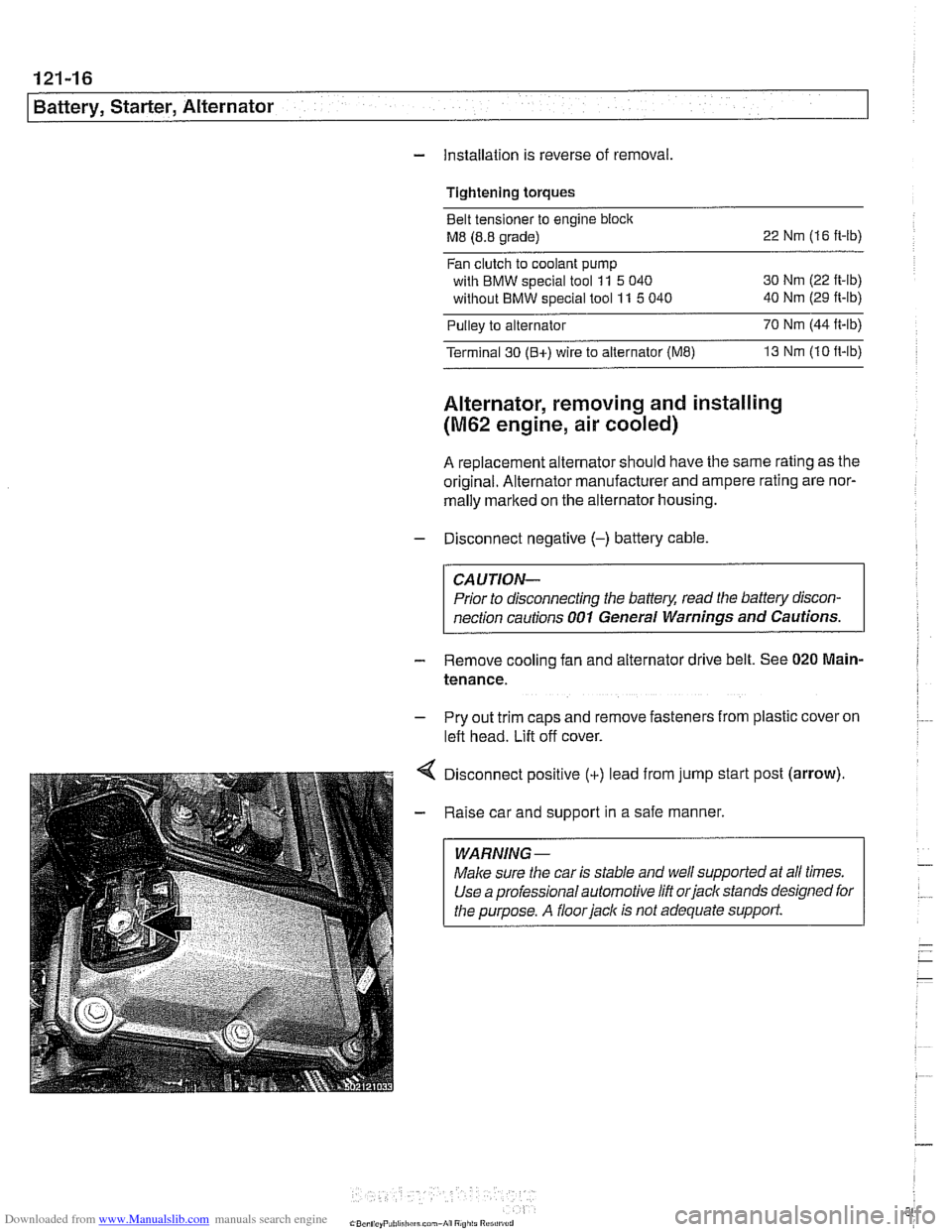

Alternator, removing and installing

(M62 engine, air cooled)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally

marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions

001 General Warnings and Cautions.

- Remove cooling fan and alternator drive belt. See 020 Main-

tenance.

- Pry out trim caps and remove fasteners from plastic cover on

left head. Lift off cover.

Disconnect positive

(+) lead from jump start post (arrow).

Raise car and support in a safe manner.

WARNING-

Make sure the car is stable and well supported at aN times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support.