air filter BMW 528i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 315 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

Camshaft timing, checking and adjusting

(M62 engine)

WARNING -

Allow engine to cool before beginning this procedure. 1

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTIOI\C

Prior to disconnecting battery cable, read the battery discon-

nection cautions given

in 001 General Cautions and

Warninss.

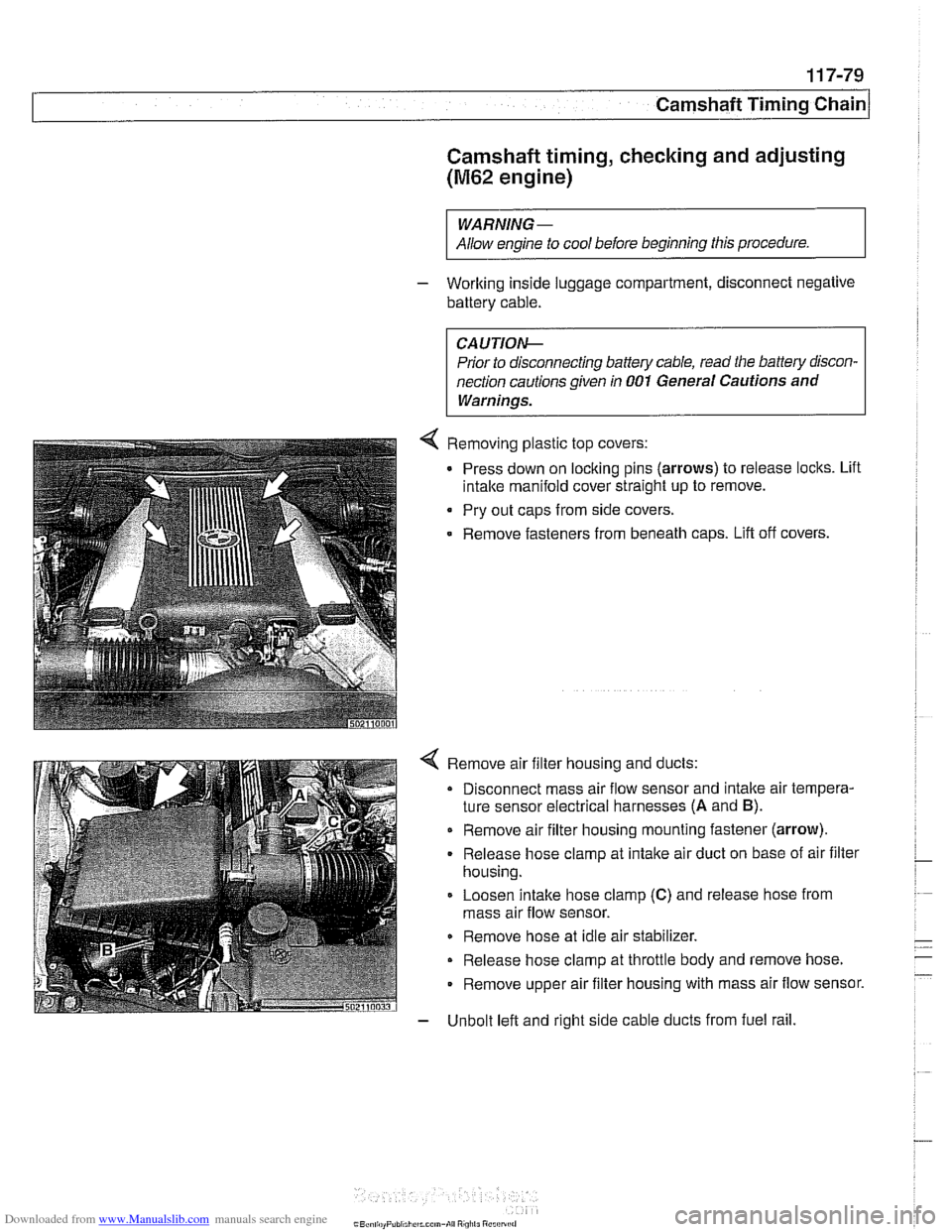

4 Removing plastic top covers:

Press down on locking pins (arrows) to release locks. Lift

intake manifold cover straight up to remove.

Pry out caps from side covers.

Remove fasteners from beneath

caDs. Lift off covers.

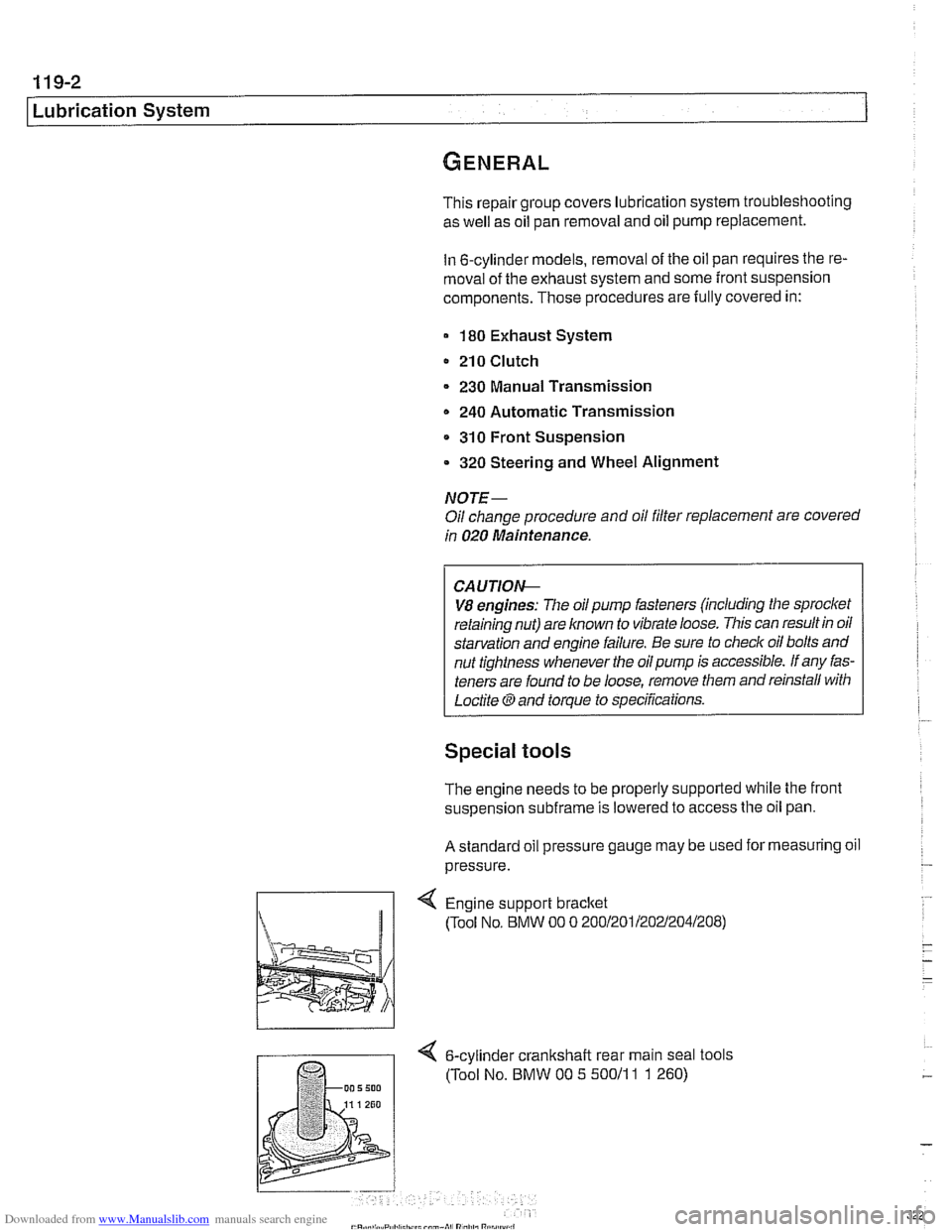

4 Remove air filter housing and ducts:

Disconnect mass air flow sensor and intake air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow).

Release hose clamp at intake air duct on base of air filter

housing.

Loosen intake hose clamp

(C) and release hose from

mass air flow sensor.

Remove hose at idle air stabilizer.

Release hose clamp at throttle body and remove hose.

Remove upper air filter housing with mass air flow sensor.

- Unbolt left and right side cable ducts from fuel rail.

Page 322 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-2

Lubrication System

This repair group covers lubrication system troubleshooting

as well as oil pan removal and oil pump replacement.

In 6-cylinder models, removal of the oil pan requires the re-

moval of the exhaust system and some front suspension

components. Those procedures are fully covered in:

180 Exhaust System

210 Clutch

230 Manual Transmission

0 240 Automatic Transmission

310 Front Suspension

320 Steering and Wheel Alignment

NOTE-

Oil change procedure and oil filter replacement are covered

in

020 Maintenance.

CAUTIOG

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to check oil bolts and

nut tightness whenever the

oilpump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

Band torque to specifications.

Special tools

The engine needs to be properly supported while the front

suspension

subframe is lowered to access the oil pan.

A standard oil pressure gauge may be used for measuring oil

pressure.

Engine support bracket

(Tool No, BMW 00 0 20012011202~2041208)

4 6-cylinder crankshalt rear main seal tools

(Tool No. BMW 00 5 50011

1 1 260)

Page 325 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

L

- --

- - -. - -- Lubrication ~~stern

- Remove pressure gauge and reinstall pressure switch with

new sealing washer.

Tightening torque

Oil pressure switch to oil filter housing 27 Nm (20 ft-lb)

If testing shows low oil pressure, one or more of the following

conditions may be indicated:

Worn or faulty oil pump or faulty pump pressure relief valve

Worn or damaged engine bearings

Severe engine wear

Any of these conditions indicate the need for major repairs.

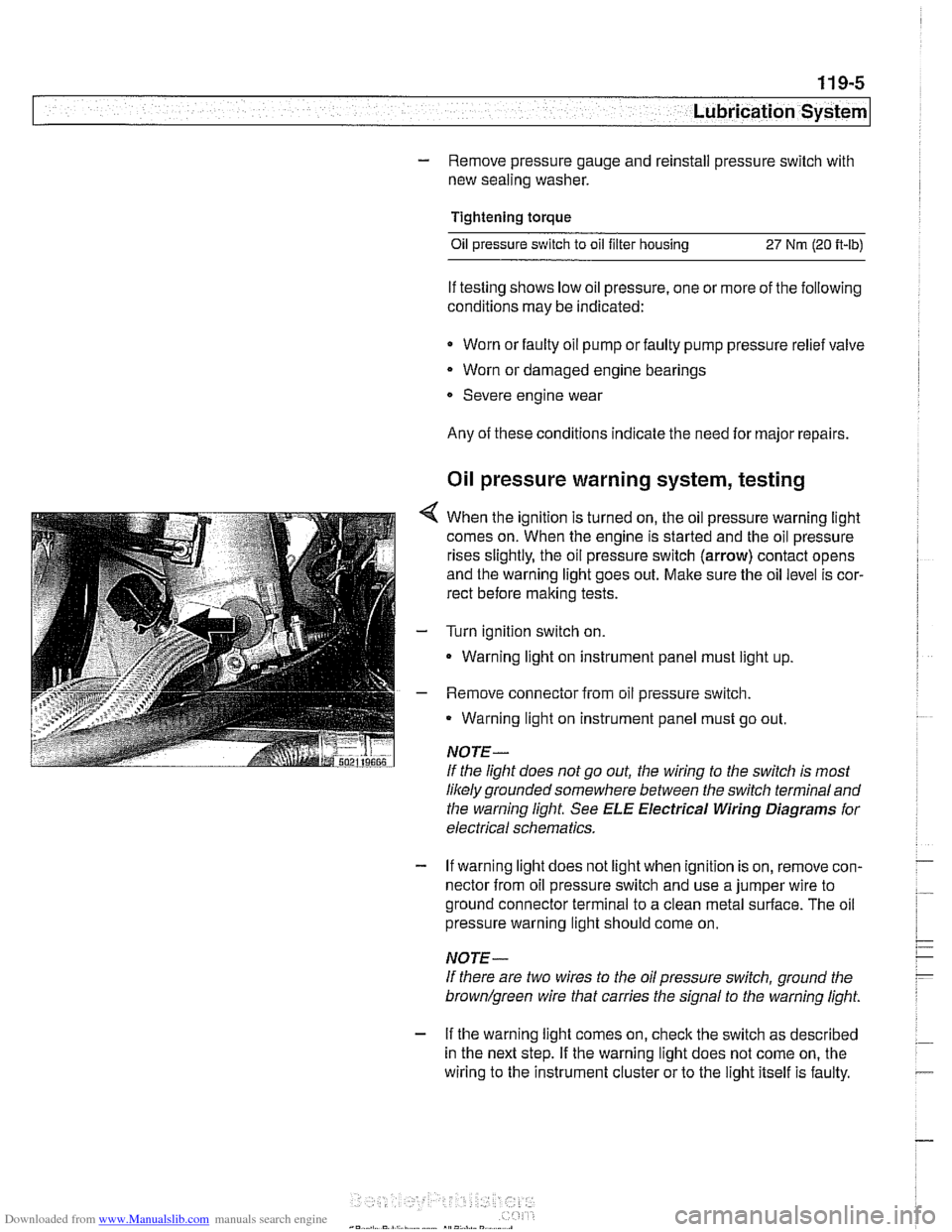

Oil pressure warning system, testing

4 When the ignition is turned on, the oil pressure warning light

comes on. When the engine is started and the oil pressure

rises slightly, the oil pressure switch (arrow) contact opens

and the warning light goes out. Make sure the oil level is cor-

rect before making tests.

- Turn ignition switch on.

- Warning light on instrument panel must light up

- Remove connector from oil pressure switch.

Warning light on instrument panel must go out.

NOTE-

If the light does not go out, the wiring to the switch is most

likely grounded somewhere between the switch terminaland

the warning light See

ELE Electrical Wiring Diagrams for

electrical schematics.

- If warning light does not light when ignition is on, remove con-

nector from oil pressure switch and use a jumper wire to

ground connector terminal to a clean metal surface. The oil

pressure warning light should come on.

NOTE-

If there are two wires to the oil pressure switch, ground the

brown/green wire that carries the signal to the warning light.

- If the warning light comes on, check the switch as described

in the next step. If the warning light does not come on, the

wiring to the instrument cluster or to the light itself is faulty.

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

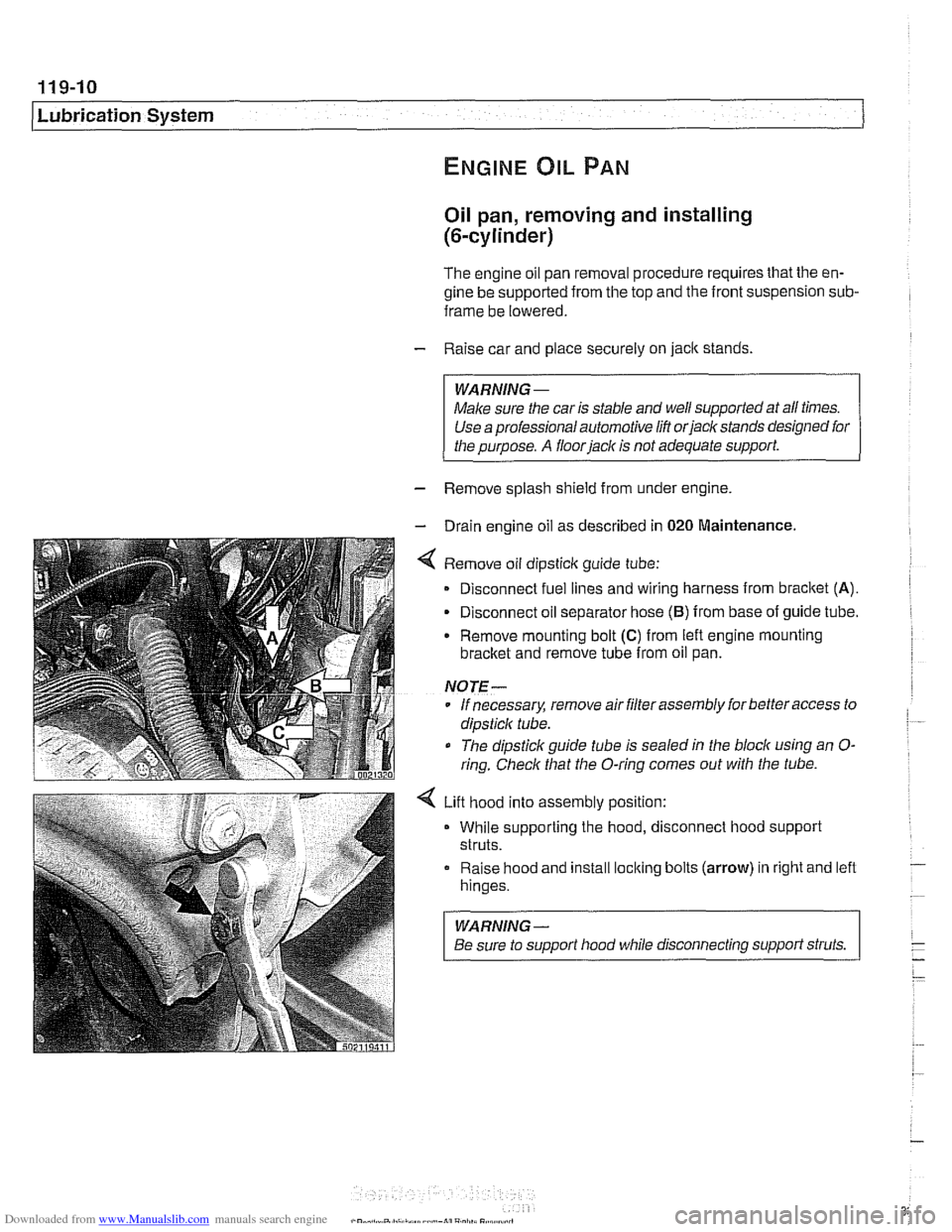

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.

Page 335 of 1002

Downloaded from www.Manualslib.com manuals search engine

... . . Lubrication sy=

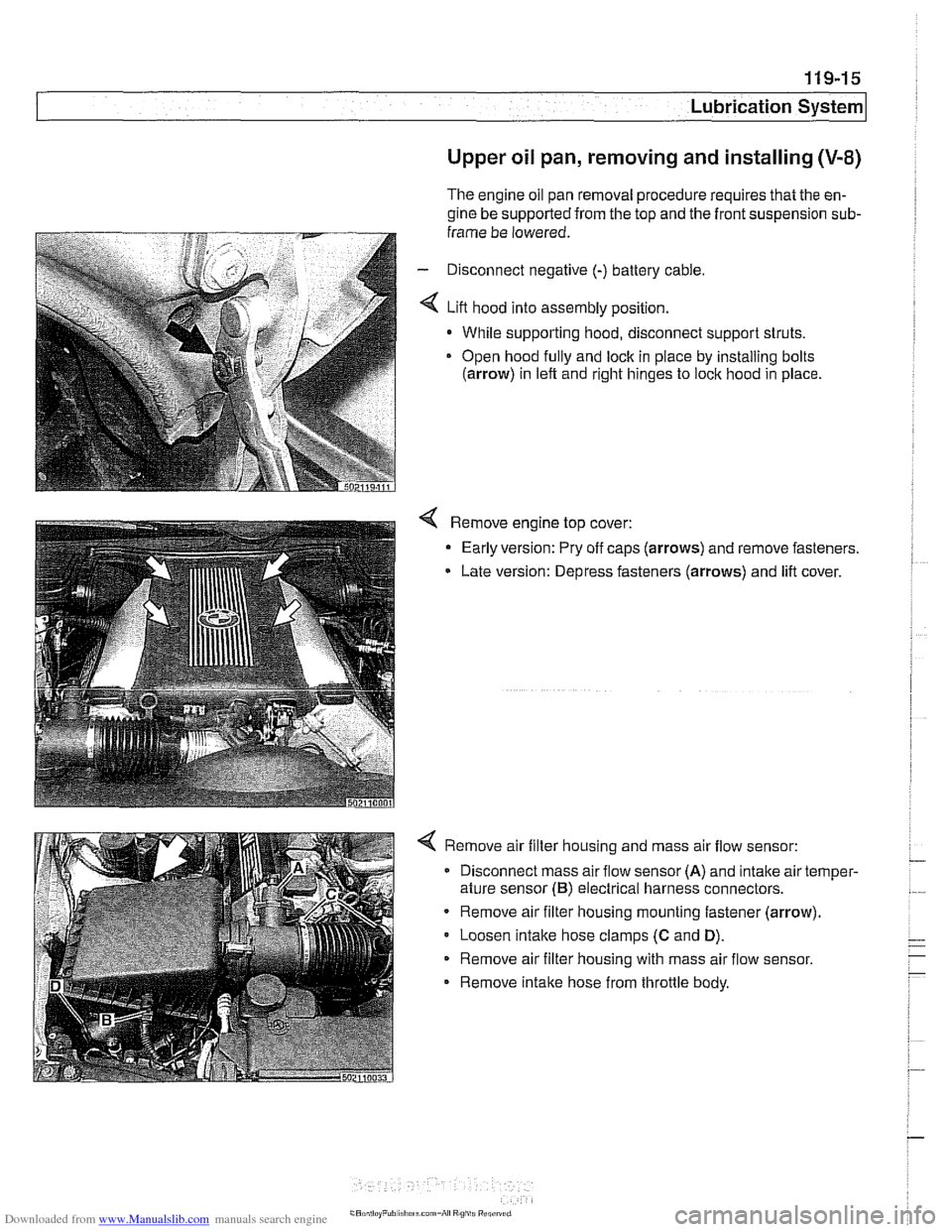

Upper oil pan, removing and installing (V-8)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Disconnect negative (-) battery cable

4 Lift hood into assembly position.

- While supporting hood, disconnect support struts.

Open hood

fully and lock in piace by installing bolts

(arrow) in left and right hinges to lock hood in place

4 Remove engine top cover:

- Early version: Pry off caps (arrows) and remove fasteners.

Late version: Depress fasteners (arrows) and lift cover.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor

(A) and intake air temper-

ature sensor

(B) electrical harness connectors.

Remove air filter housing mounting fastener (arrow)

Loosen

intake hose clamps (C and D).

Remove air filter housing with mass air flow sensor.

Remove intake hose from throttle body.

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

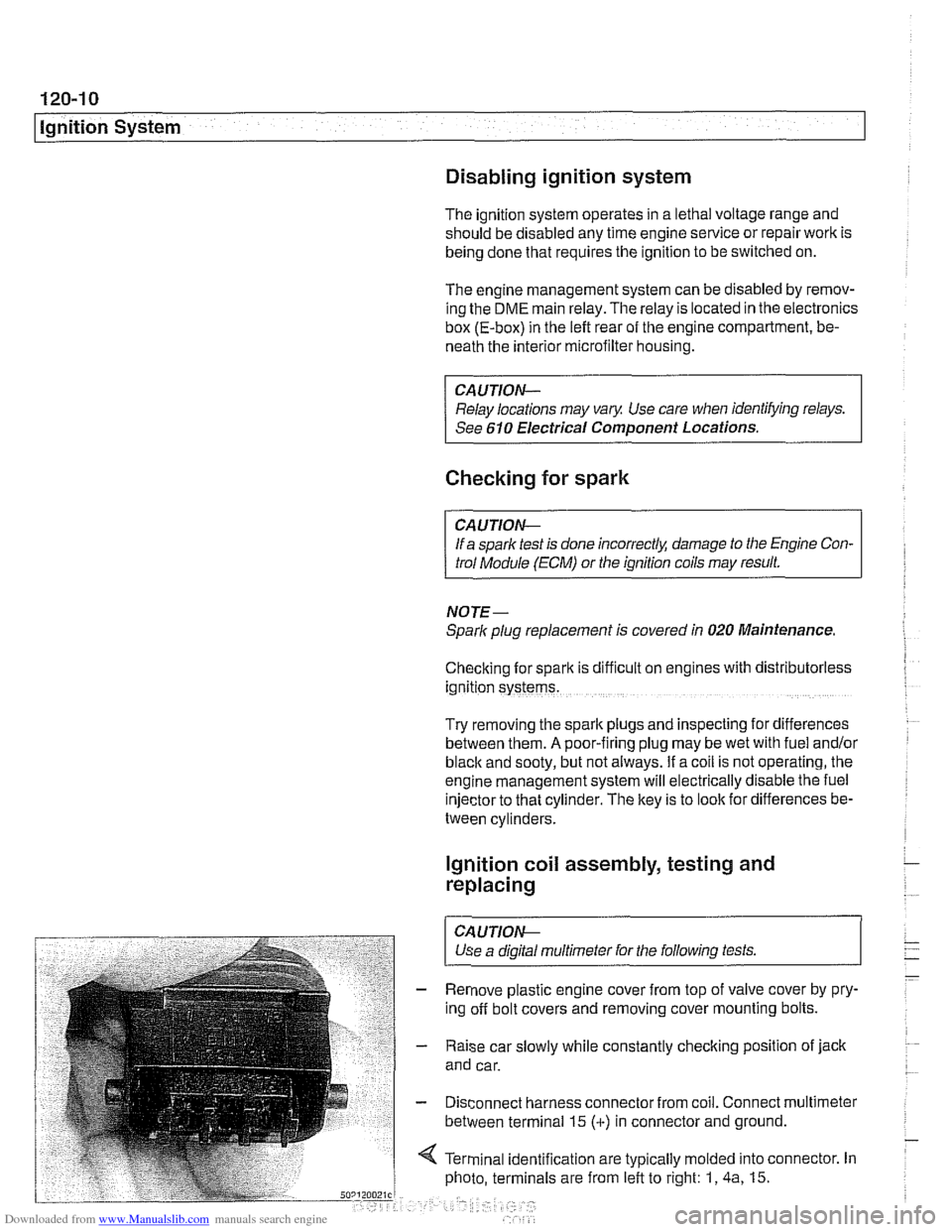

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.

Page 362 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Ignition System

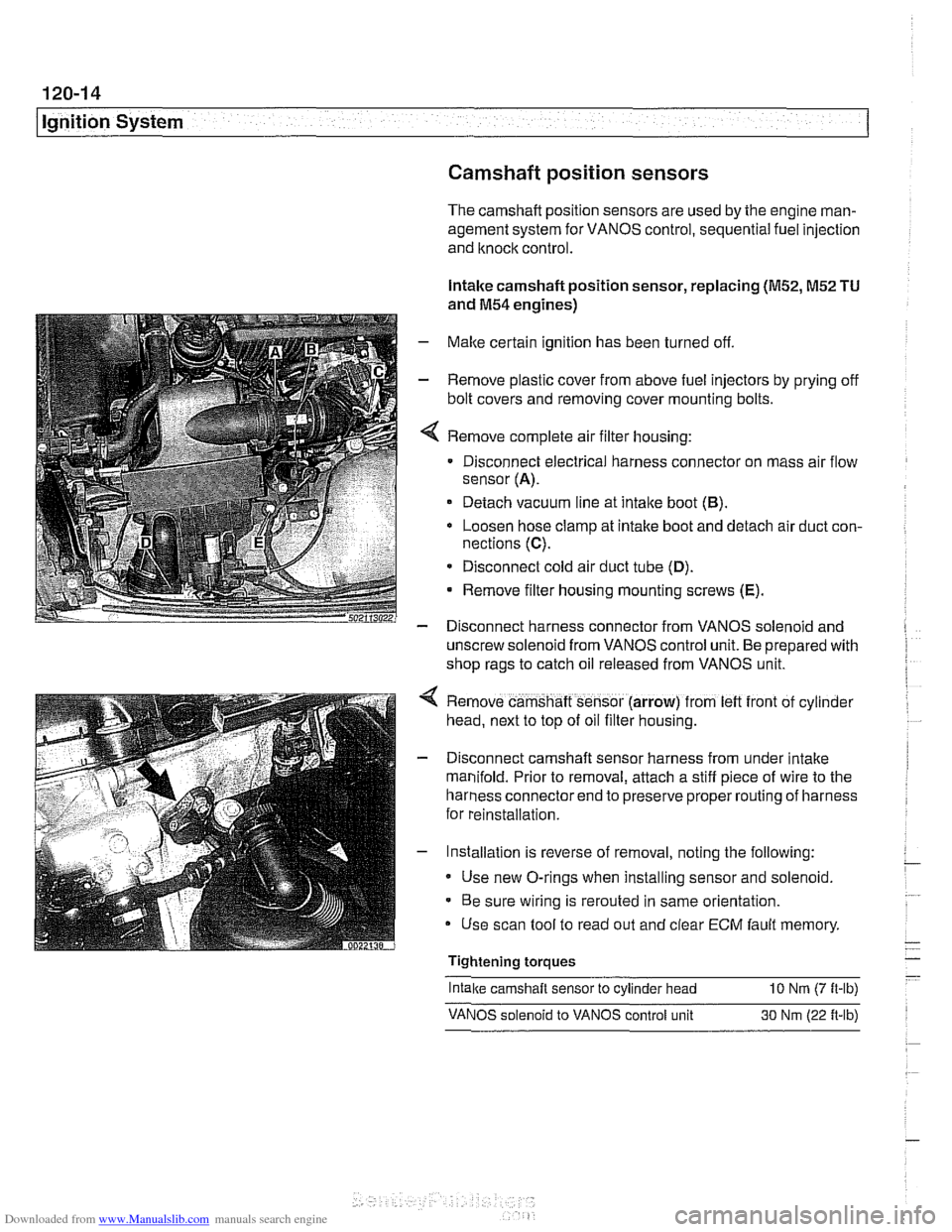

Camshaft position sensors

The camshaft position sensors are used by the englne man-

agement system for VANOS control, sequential fuel injection

and knock control.

Intake camshaft position sensor, replacing

(M52,M52 TU

and M54 engines)

- Make certain ignition has been turned off.

- Remove plastic cover from above fuel injectors by prying off

bolt covers and removing cover mounting bolts.

Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Detach vacuum line at intake boot (B).

Loosen hose clamp at intake boot and detach air duct con-

nections

(C).

* Disconnect cold air duct tube (D).

Remove filter housing mounting screws (E).

- Disconnect harness connector from VANOS solenoid and

unscrew solenoid from VANOS control unit. Be prepared with

shop rags to catch oil released from VANOS unit.

Remove camshaft sensor (arrow) from

left front of cyl~nder

head, next to top of oil filter housing.

Disconnect camshaft sensor harness from under intake

manifold. Prior to removal, attach a stiff piece of wire to the

harness connector end to preserve proper routing of harness

for reinstallation.

Installation is reverse of removal, noting the following:

Use new O-rings when installing sensor and solenoid.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear

ECM fault memory

Tightening torques

-

Intake camshaft sensor to cylinder head 10 Nrn (7 ft-lb)

VANOS solenoid to VANOS control unit 30 Nm (22 ft-lb)

Page 363 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-15

Ignition system1

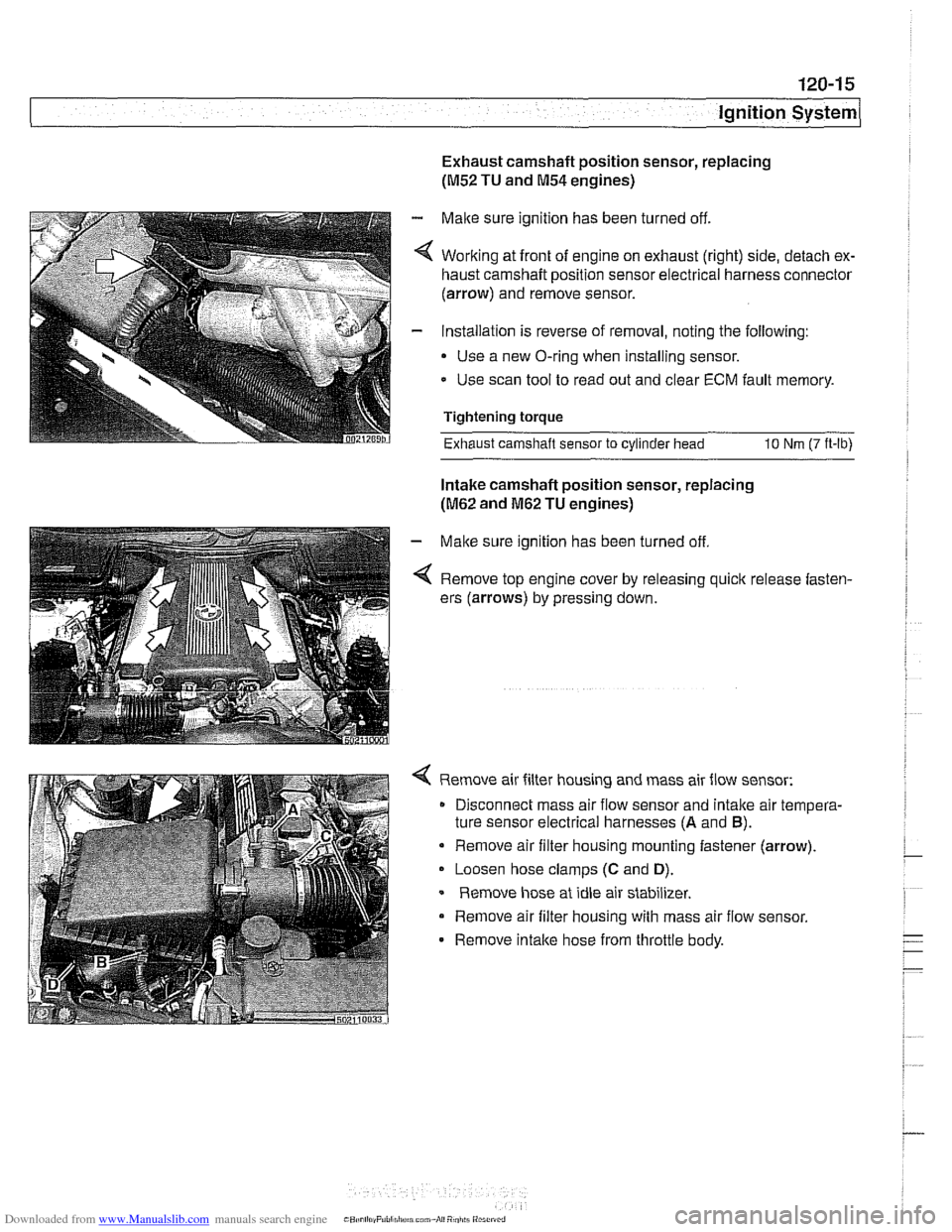

Exhaust camshaft position sensor, replacing

(M52 TU and M54 engines)

- Make sure ignition has been turned off.

4 Working at front of engine on exhaust (right) side, detach ex-

haust camshaft position sensor electrical harness connector

(arrow) and remove sensor.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

- Use scan tool to read out and clear ECM fault memory.

Tightening torque

Exhaust camshaft sensor

to cylinder head 10 Nm (7 ft-lb)

Intake camshaft position sensor, replacing

(M62 and M62 TU engines)

- Make sure ignition has been turned off

4 Remove top engine cover by releasing quick release fasten-

ers (arrows) by pressing down.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor and

intalte air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow).

Loosen hose clamps

(C and D).

Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

- Remove intalte hose from throttle body.

Page 379 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

Charging system quick-check

Use a digital multimeter to measure voltage across the bat-

tery terminals with key off and then again with engine running.

Battery voltage should be about 12.6 volts with key off and be-

tween 13.5 and 14.5 volts with engine running.

NOTE-

The regulated voltage (engine running) should be between

13.2 and 14.5, depending on temperature andoperating con-

ditions.

If the voltage is higher than 14.8, the voltage regula-

tor or

mulitfunction controller is most likely faulty

Check for clean and tight battery cables. Check ground cable

running from negative

(-) battery terminal to chassis and

ground cable running from engine to chassis. Check alterna-

tor drive belt condition and tension.

Charging system, checking

CAUTIOI\C

* Do not disconnect the battery while the engine is running.

Damage to the alternator and/or engine electronic systems

may result.

Only use a digital multimeter when testing charging

system components.

--7

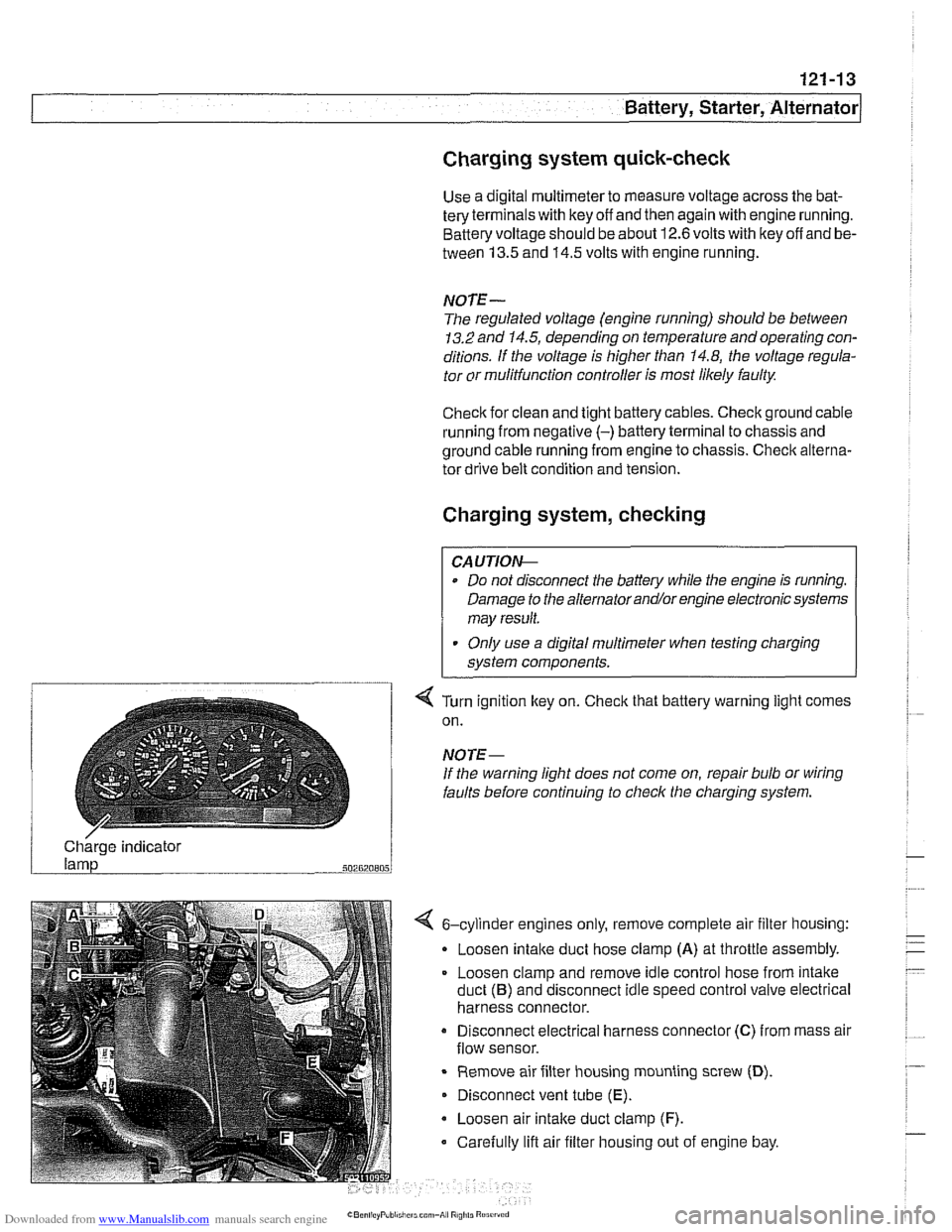

4 Turn ignition key on. Check that battery warning light comes

on.

NOTE-

If the warning light does not come on, repair bulb or wiring

faults before continuing to checlc the charging system.

/ Charge indicator

502820805

4 6-cylinder engines only, remove complete air filter housing:

Loosen

intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw

(D).

Disconnect vent tube (E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Page 381 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

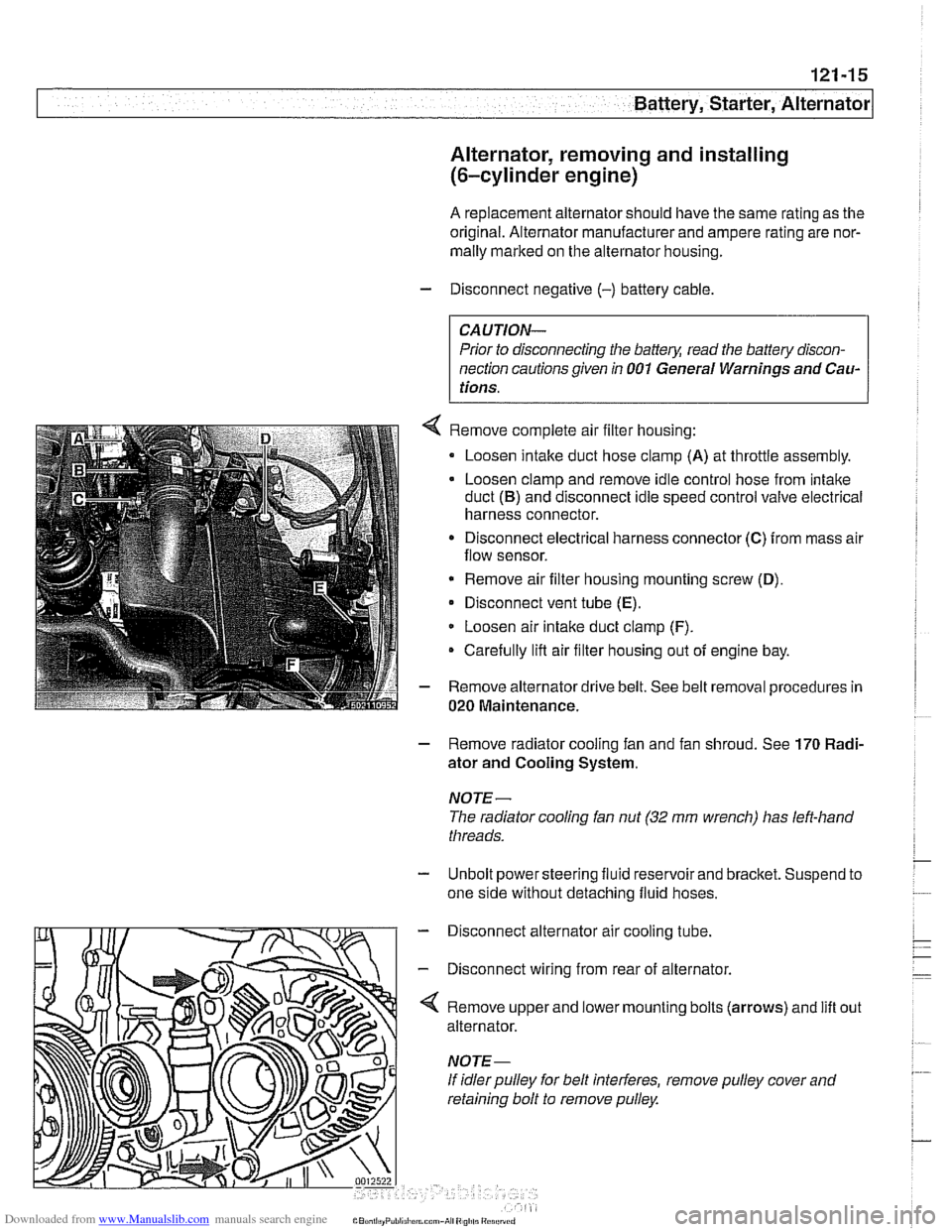

Alternator, removing and installing

(6-cylinder engine)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

I tions.

Remove complete air filter housing:

Loosen intake duct hose clamp

(A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

* Remove air filter housing mounting screw (D),

Disconnect vent tube (E).

Loosen air intake duct clamp (F).

Carefully lifl air filter housing out of engine bay.

Remove alternator drive belt. See belt removal procedures in

020 Maintenance.

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

- Unbolt power steering fluid reservoir and bracket. Suspend to

one side without detaching fluid hoses.

- Disconnect alternator air cooling tube.

- Disconnect wiring from rear of alternator.

'4 Remove upper and lower mounting bolts (arrows) and lift

alternator.

If idler pulley for belt interferes, remove pulley cover and

retaining bolt to remove pulley. out