ECT BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 743 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-47

Rear suspension/

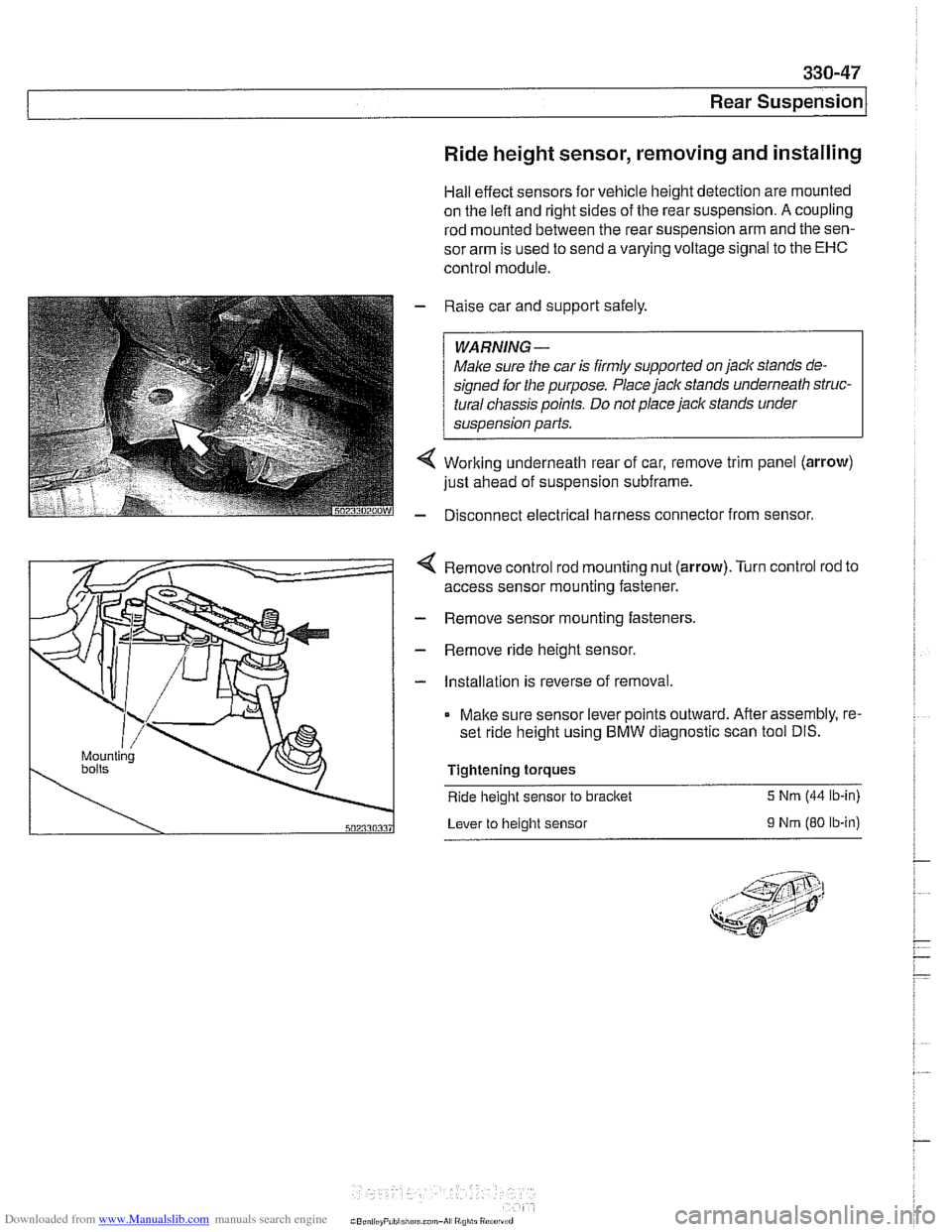

Ride height sensor, removing and installing

Hall effect sensors for vehicle height detection are mounted

on the

left and right sides of the rear suspension. A coupling

rod mounted between the rear suspension arm and the sen-

sor arm is used to send a varying voltage signal to the

EHC

control module.

Raise car and support safely.

WARNING-

Male sure the car is firmly supported on jaclc stands de-

signed

for the purpose. Place jaclc stands underneath struc-

tural chassis points. Do not place jaclc stands under

sus~ension Darts.

Working underneath rear of car, remove trim panel (arrow)

just ahead of suspension subframe.

Disconnect electrical harness connector from sensor.

4 Remove control rod mounting nut (arrow).Turn control rod to

access sensor mounting fastener.

- Remove sensor mounting fasteners.

- Remove ride height sensor.

- Installation is reverse of removal.

Make sure sensor lever points outward. After assembly, re-

set ride height using BMW diagnostic scan tool DIS.

Tightening torques

Ride

height sensor to bracket 5 Nrn (44 lb-in)

Lever to height sensor

9 Nrn (80 ib-in)

Page 748 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-4

Final Drive

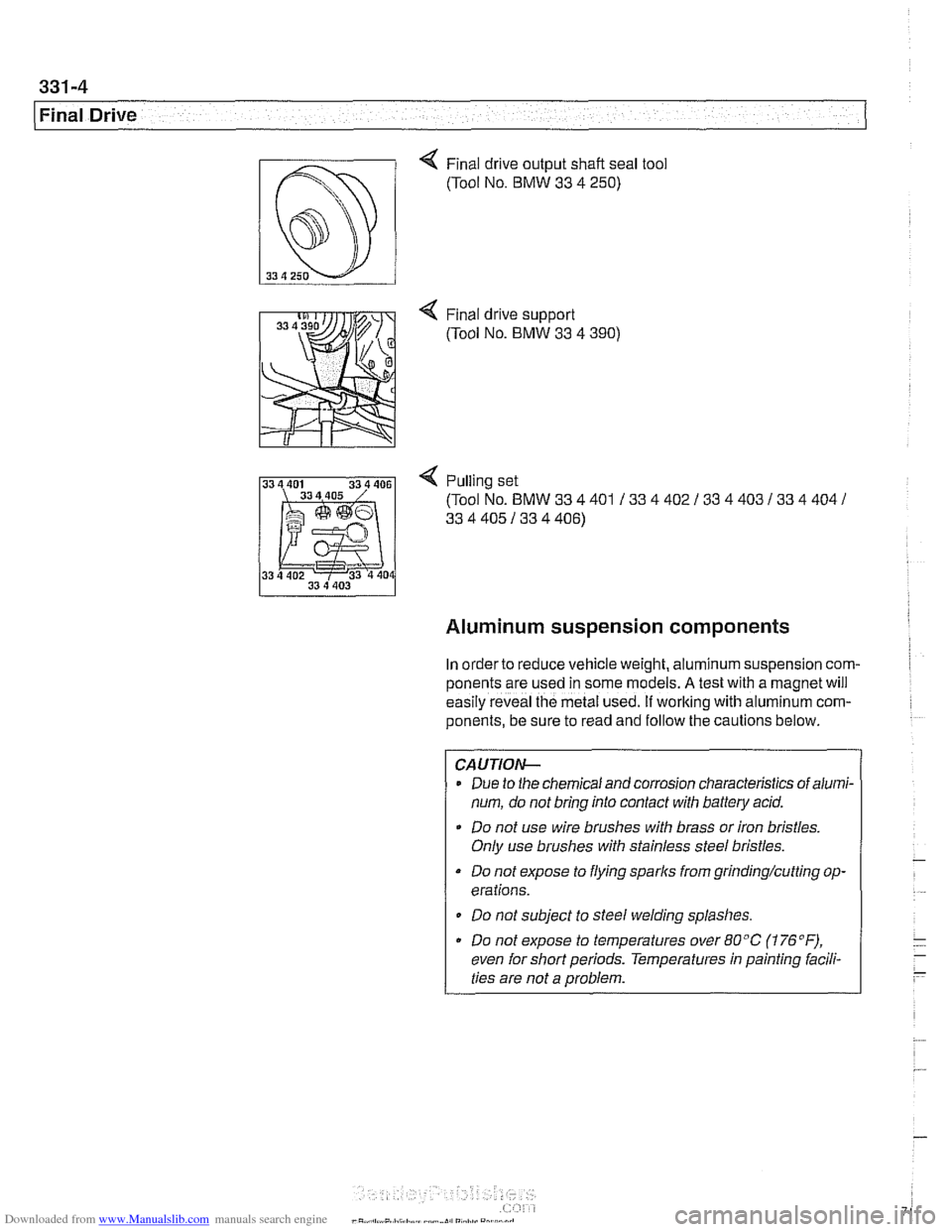

4 Final drive output shaft seal tool

(Tool No.

BMW 33 4 250)

4 Pulling set

(Tool No.

BMW 33 4 401 / 33 4 402 / 33 4 403 133 4 404 /

33 4 405 / 33 4 406)

Aluminum suspension components

In order to reduce vehicle weight, aluminum suspension com-

ponents are

~sed in some models. A tesl wlh a magnet wi.1

eas'ly reveal lhe metal Lseo. If working with a umin~m com-

ponents, be sure to read and follow the cautions below.

CAUTIOI\C

Due to the chemical and corrosion characteristics of alumi-

num, do not bring into contact with battery acid.

Do not use wire brushes with brass or iron bristles.

Only use brushes with stainless steel bristles.

Do not expose to flying sparks from grinding/cutting op-

erations.

Do not subject to steel welding splashes.

Do not expose to temperatures over

80°C (176"F),

even for short periods. Temperatures in painting facili-

ties are not a problem.

Page 749 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

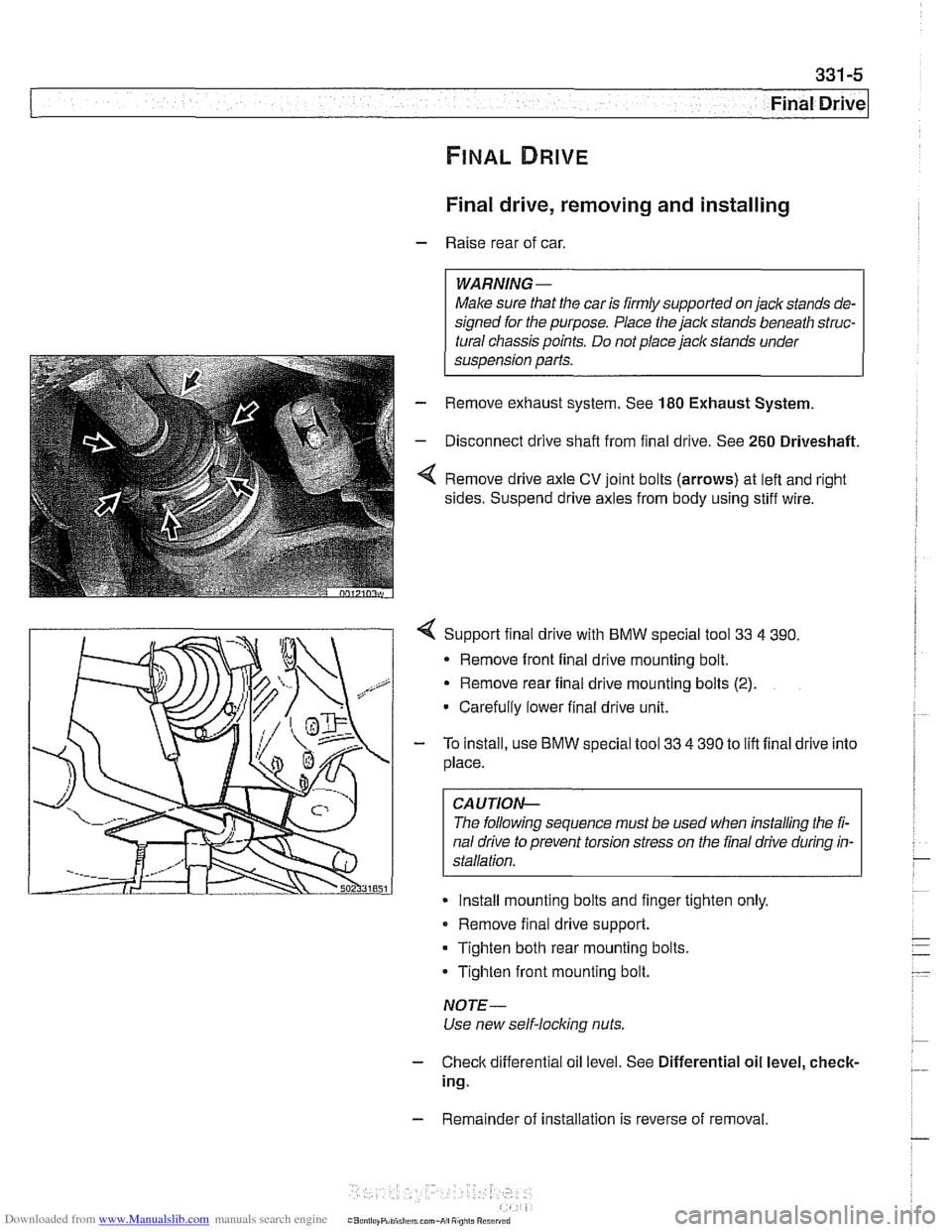

Final drive, removing and installing

- Raise rear of car.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jaclc stands beneath struc-

tural chassis

~oints. Do not i lace iaclc stands under

( suspension barfs.

Remove exhaust system. See 180 Exhaust System.

Disconnect drive shaft from final drive. See

260 Driveshaft.

Remove drive axle CV joint bolts (arrows) at left and right

sides. Suspend drive axles from body using stiff wire.

4 Support final drive with BMW special tool 33 4 390.

* Remove front final drive mounting bolt.

Remove rear final drive mounting bolts

(2).

Carefully lower final drive unit.

- To install, use BMW special tool 33 4 390 to lift final drive into

place.

CA UTIOP&

The following sequence must be used when installing the fi-

nal drive to prevent torsion stress on the final drive during in-

Install mounting bolts and finger tighten only.

Remove final drive support.

Tighten both rear mounting bolts.

Tighten front mounting bolt.

NOTE-

Use new self-locking nuts.

- Check differential oil level. See Differential oil level, check-

ing.

- Remainder of installation is reverse of removal.

Page 750 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final Drive

Tightening torques

F~nal drive to rear axle carrier 105 Nm (77 it-lb)

Driveshaft CV joint to final drive flange

- MlO (Torx bolt) 70

Nm (51 ft-lb)

- M8 (compression nut) 32 Nm (24

ft-lb)

Drive axle to final drive

ilange

Torx bolts (M10) 83 Nm (61 ft-lb)

Torx bolt with

rlbbed teeth (M10) 64 Nm (47 ft-lb)

Torx bolt

wlth ribbed teeth (MI0 sliver) 80 Nm (59 ft-lb)

Torx

bolt with ribbed teeth (M10 black) 100 Nm (74 ft-lb)

* Torx bolt with ribbed teeth (M12) 135 Nm (100 ft-lb)

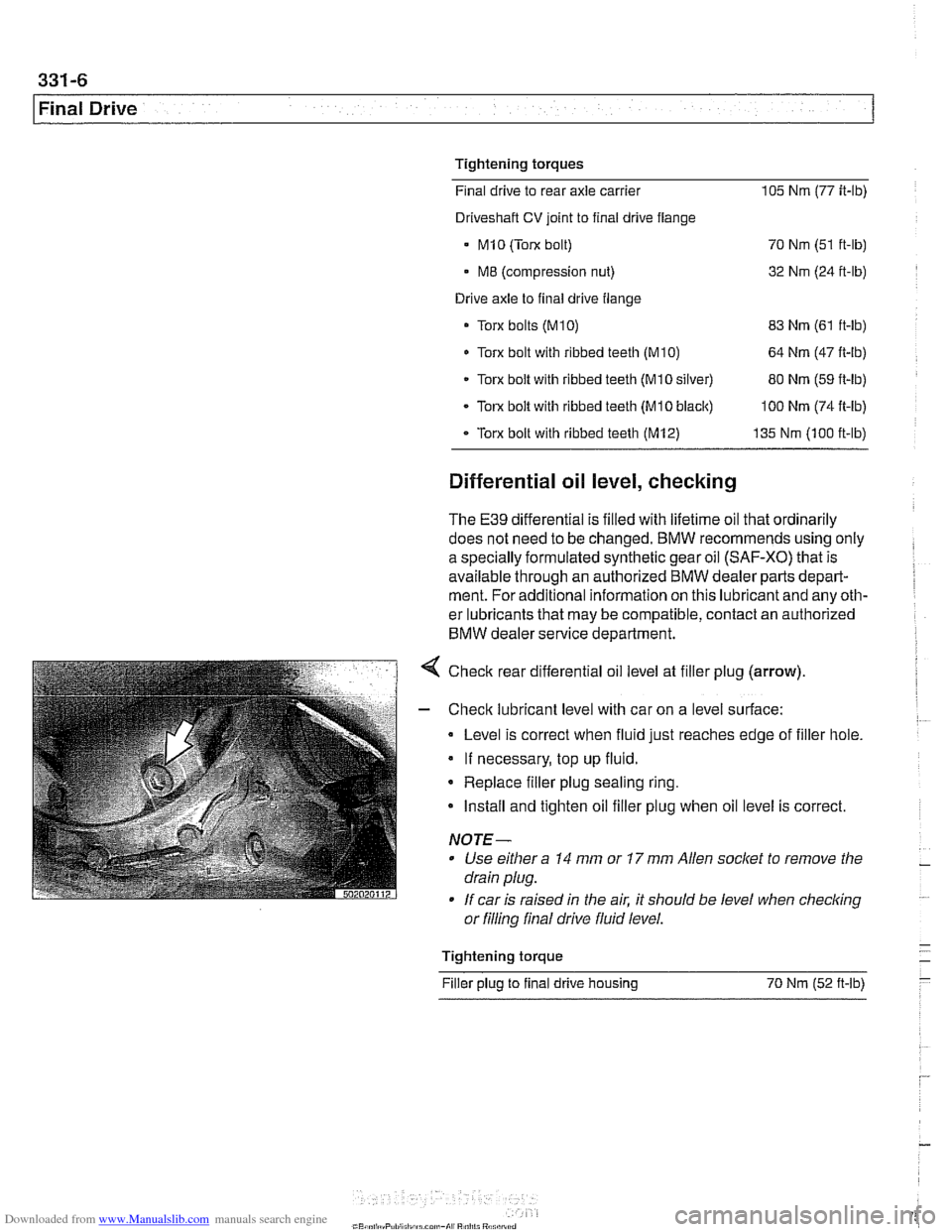

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed. BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized BMW dealer parts depart-

ment. For additional information on this lubricant and any oth-

er lubricants that may be compatible, contact an authorized

BMW dealer service department.

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

* Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If car is raised in the air. it should be level when

checkino " or filling final drive fluid level.

- Tightening torque -

Filler plug to final drive housing 70 Nm (52

ft-lb) -

Page 759 of 1002

Downloaded from www.Manualslib.com manuals search engine

Final ~rivel

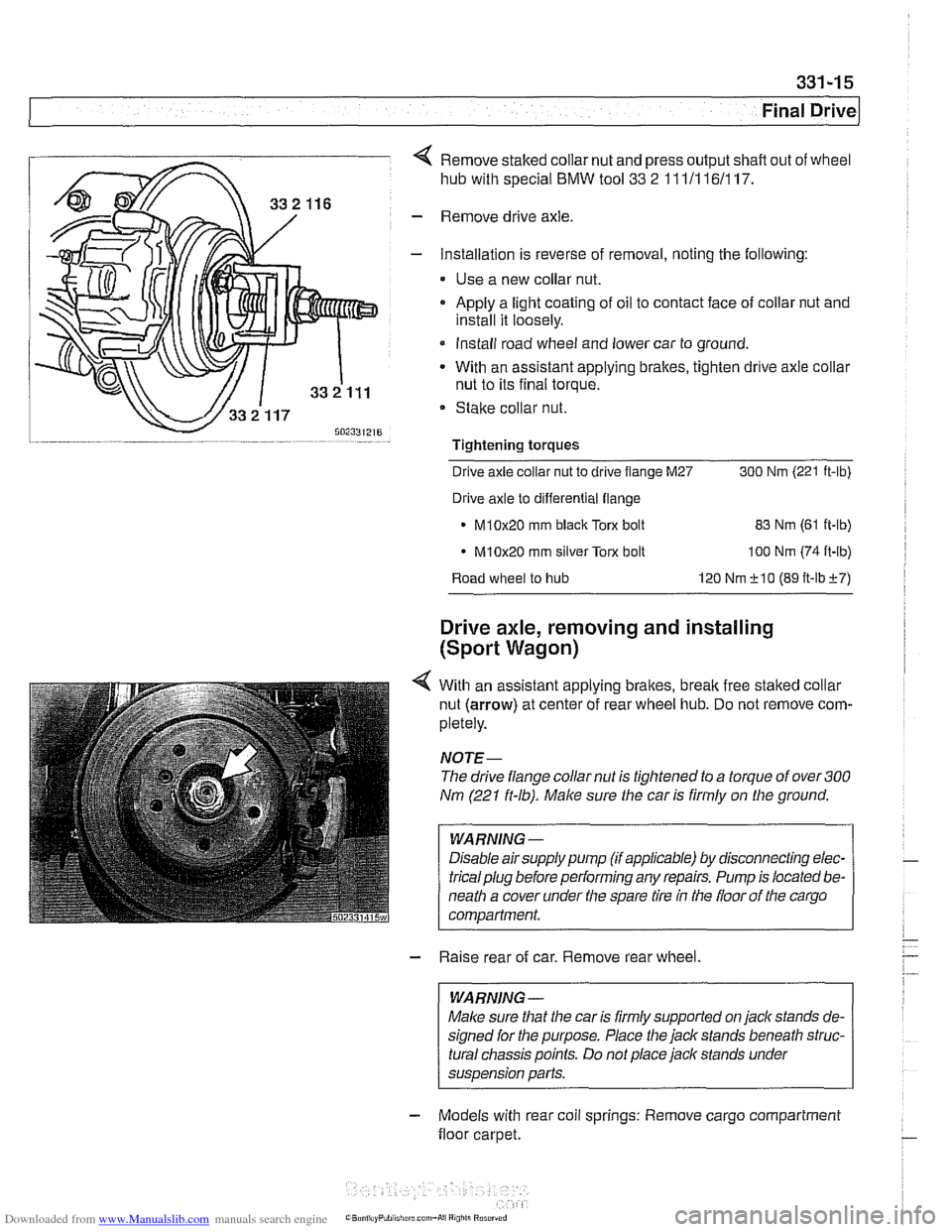

4 Remove staked collar nut and press output shafl out of wheel

hub with special

BMW tool 33 2 111/116/117.

- Remove drive axle.

- Installation is reverse of removal, noting the following:

Use a new collar nut.

a Apply a light coating of oil to contact face of collar nut and

install it loosely.

* Install road wheel and lower car to ground.

- With an assistant applying brakes, tighten drive axle collar

nut to its final torque.

Stake collar nut.

Tightening torques

-

Drive axle collar nut to drive flange M27 300 Nrn (221 ft-lb)

Drive axle to differential flange

* M10x20 rnm black Torx bolt

83 Nrn (61 ft-lb)

M10x20 rnrn silver Torx bolt

100 Nrn (74 ft-lb)

Road wheel to hub 120 Nrn f 10 (89 ft-lbf7)

Drive axle, removing and installing

(Sport Wagon)

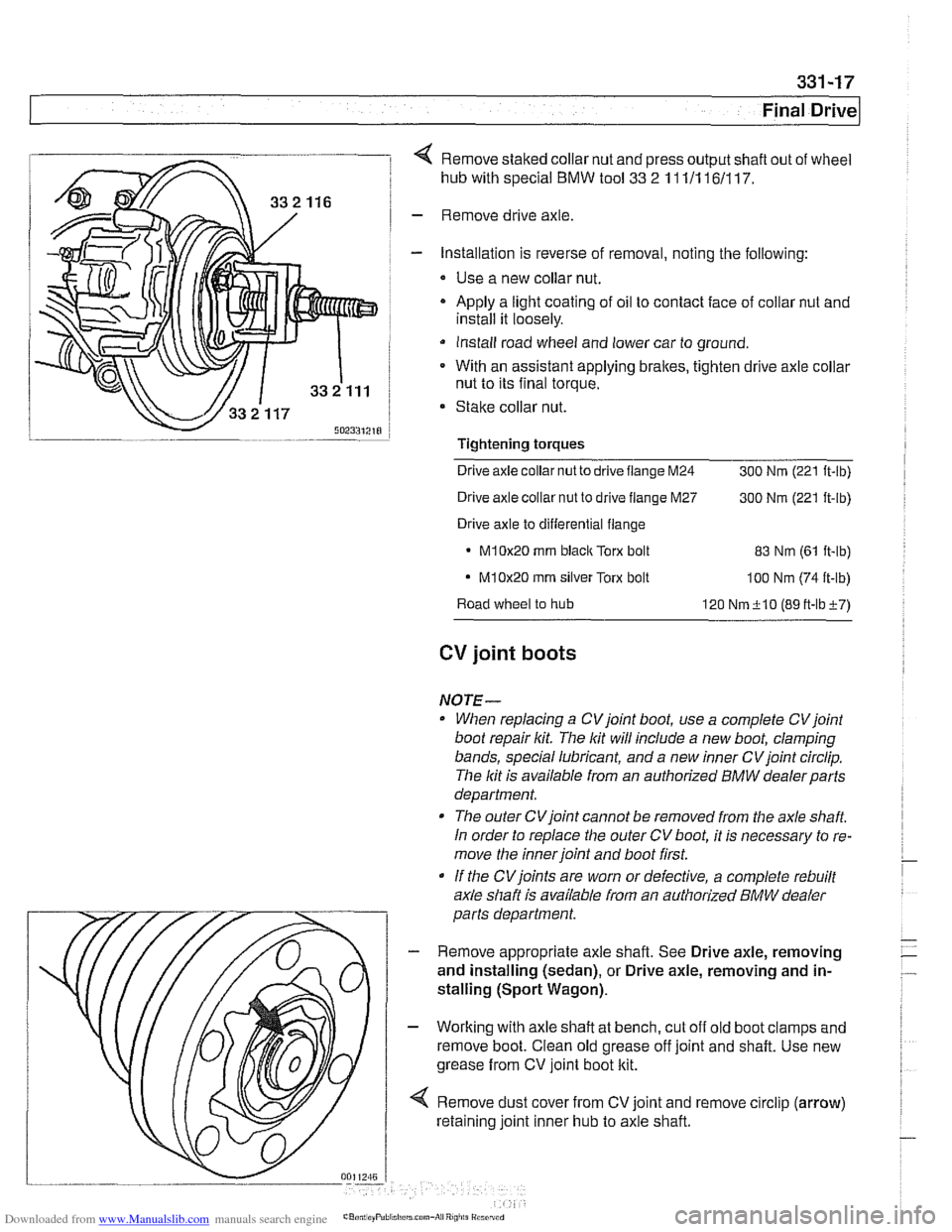

4 With an assistant applying brakes, brealc free staked collar

nut (arrow) at center of rear wheel hub. Do not remove com-

pletely.

NOJE-

The drive flange collar nut is tightened to a torque of over 300

Nm (221 ft-lb). Make sure the car is firmly on the ground.

WARNING -

Disable airsupply pump (if applicable) by disconnecting elec-

tricalplug before performing any repairs. Pump is located be-

neath a cover under the spare tire

in the floor of the cargo

compartment.

- Raise rear of car. Remove rear wheel.

WARNING -

Malce sure that the car is firmly supported on jack stands de-

signed for the purpose. Place the jack stands beneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Models with rear coil springs: Remove cargo compartment

floor carpet.

Page 761 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-17

Final ~rivel

4 Remove staked collar nut and press output shaft out of wheel

hub with special

BMW tool 33 2 11 111 161117.

- Remove drive axle

- Installation is reverse of removal, noting the following:

* Use a new collar nut.

- Apply a light coating of oil to contact face of collar nut and

install it loosely.

Install road wheel and lower car to ground.

* With an assistant applying brakes, tighten drive axle collar

nut to its final torque.

Stake collar nut.

Tightening

torques

Drive axle collar nut to drive flange M24

300 Nrn (221 ft-lb)

Drive axle collar nut to drive flange M27

300 Nrn (221 ft-lb)

Drive axle to differential flange

M10x20 rnrn blaclc Torx bolt 83 Nrn (61 it-lb)

- M10x20 rnrn silver Torx bolt loo Nrn (74 ft-lb)

Road wheel to hub

120 Nrn+lO (89tt-lbi-7)

CV joint boots

NOTE-

When replacing a CVjoint boot, use a complete CVjoint

boot repair kit. The lit will include a new boot, clamping

bands, special lubricant, and a new inner CV joint circlip.

The lit is available from an authorized

BMW dealerparts

department.

The outer CVjoint cannot be removed from the axle

shaft

In order to replace the outer CV boot, it is necessary to re-

move the inner joint and boot first.

If the

CVjoints are worn or defective, a complete rebuilt

axle shaft is available from an authorized

BMW dealer

parts department.

- Remove appropriate axle shaft. See Drive axle, removing

and installing (sedan), or Drive axle, removing and in-

stalling (Sport Wagon).

- Working with axle shaft at bench, cut off old boot clamps and

remove boot. Clean old grease off joint and shaft. Use new

grease from CV joint boot kit.

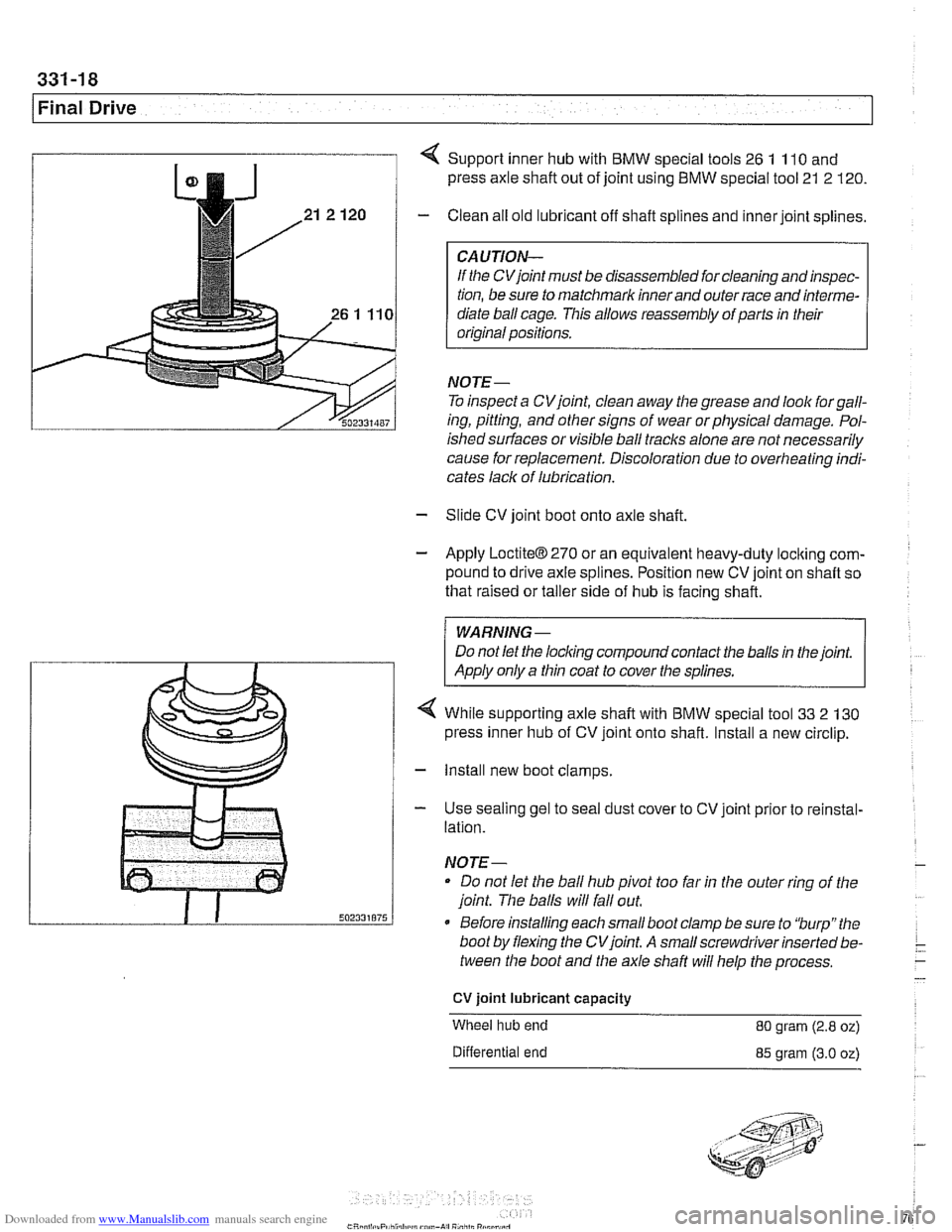

4 Remove dust cover from CV joint and remove circlip (arrow)

retaining joint inner hub to axle shaft.

Page 762 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Final Drive

4 Support inner hub with BMW special tools 26 1 110 and

press axle shaft out of joint using BMW special tool 21 2 120.

- Clean all old lubricant off shaft splines and inner joint splines.

If the CVjoint must be disassembled for cleaning and inspec-

tion, be sure to matchmark inner and outer race and interme-

diate ball cage. This allows reassembly

ofparfs in their

original positions.

NOTE-

To inspect a CVjoint, clean away the grease and loolc forgall-

ing, pitting, and other signs of wear orphysical damage. Pol-

ishedsurfaces or visible ball traclts alone are not necessarily

cause forreplacement. Discoloration due to overheating indi-

cates

laclt of lubrication.

- Slide CV joint boot onto axle shaft

- Apply LoctiteO270 or an equivalent heavy-duty loclting corn-

pound to drive axle splines. Position new CV joint on shaft so

that raised or taller side of hub is facing shaft.

WARNING-

Do not let the locking compound contact the balls in the joint.

Apply only a thin coat to cover the splines.

While supporting axle shaft with BMW special tool

33 2 130

press inner hub of CV joint onto shaft. Install a new circlip.

- Install new boot clamps.

- Use sealing gel to seal dust cover to CV joint prior to reinstal-

lation.

NOTE-

* Do not let the ball hub pivot too far in the outer ring of the

joint.

Tlie balls will fa1 out.

Before installing each small boot clamp be sure to

'burp"the

boot by flexing the CVjoint. A small screwdriver inserted be-

tween the boot and the axle shafl will help the process.

CV joint lubricant capacity

Wheel hub end

80 gram (2.8 oz)

Differential end

85 gram (3.0 oz)

Page 763 of 1002

Downloaded from www.Manualslib.com manuals search engine

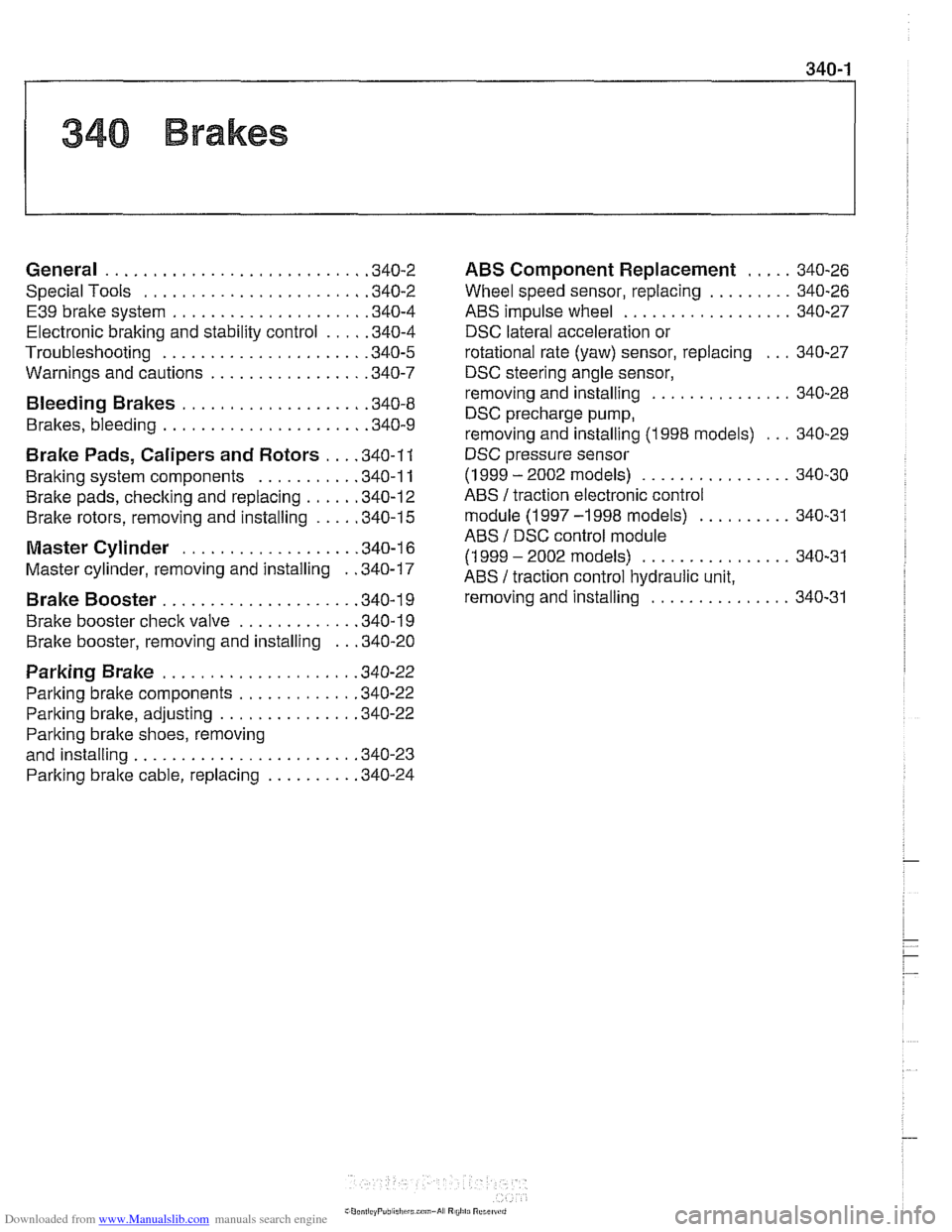

General ........................... .34 0.2

Special Tools

....................... .34 0.2

E39 brake system

.................... .34 0.4

Electronic braking and stability control

.... .34 0.4

Troubleshooting

..................... .34 0.5

Warnings and cautions

................ .34 0.7

Bleeding Brakes ................... .34 0.8

Brakes, bleeding

..................... .34 0.9

Brake Pads, Calipers and Rotors ... .34 0.1 1

Braking system components .......... .34 0.11

Brake pads,

checking and replacing ..... .34 0.12

Brake rotors, removing and installing

.... .34 0.15

Master Cylinder .................. .34 0.16

Master cylinder, removing and installing

. .34 0.17

Brake Booster .................... .349 0.1

Brake booster check valve

............ .34 0.19

Brake booster, removing and installing

.. .34 0.20

Parking Brake .................... .34 0.22

Parking brake components

............ .34 0.22

Parking

brake, adjusting .............. .34 0.22

Parking bralte shoes, removing

and installing

....................... .34 0.23

Parking

brake cable, replacing ......... .34 0.24

ABS Component Replacement ..... 340-26

Wheel speed sensor. replacing

......... 340-26

ABS impulse wheel

.................. 340-27

DSC lateral acceleration or

rotational rate (yaw) sensor. replacing

... 340-27

DSC steering angle sensor.

removing and installing

............... 340-28

DSC precharge pump.

removing and installing (1998 models)

... 340-29

DSC pressure sensor

(1 999 - 2002 models) ................ 340-30

ABS /traction electronic control

module

(1 997 -1 998 models) .......... 340-31

ABS

/ DSC control module

(1 999

- 2002 models) ................ 340-31

ABS

/ traction control hydraulic unit.

removing and installing

............... 340-31

Page 766 of 1002

Downloaded from www.Manualslib.com manuals search engine

E39 brake system

BMW E39 models are equipped with vacuum power-assisted

four-wheel disc brakes with an integral

Antilock Brake System

(ABS). Single-piston calipers act on vented front and rear ro-

tors. A brake pad wear sensor for each axle indicates when

brake pads need replacement. The dual drum-type parking

brake system is integrated with the rear brake rotors.

Electronic braking and stability control

E39 models were introduced with Automatic Stability Control,

a computer controlled traction control system that uses the

AB5 system in conjunction with engine management controls

to control wheel spin during take-off and maintain vehicle sta-

bility while braking.

Added in the

1998 model year was Dynamic Stability Control

(DSC). This system implements wheel speed modulation

throughout all stages of driving. For example, DSC is able to

reduce understeer by applying differing amounts of braking

force to each wheel, or it can override the engine manage-

ment system during hard cornering.

A summary of distinguishing characteristics of the various

systems is shown in the table

E39 electronic braking and

stability control systems.

For ABS, ASC and DSC system and component descriptions,

see

300 Suspension, Steering and Brakes-General.

WARNING-

A car with electronic stability control is still subject to normal

physical laws. Avoid excessive speeds for the road conditions

encountered.

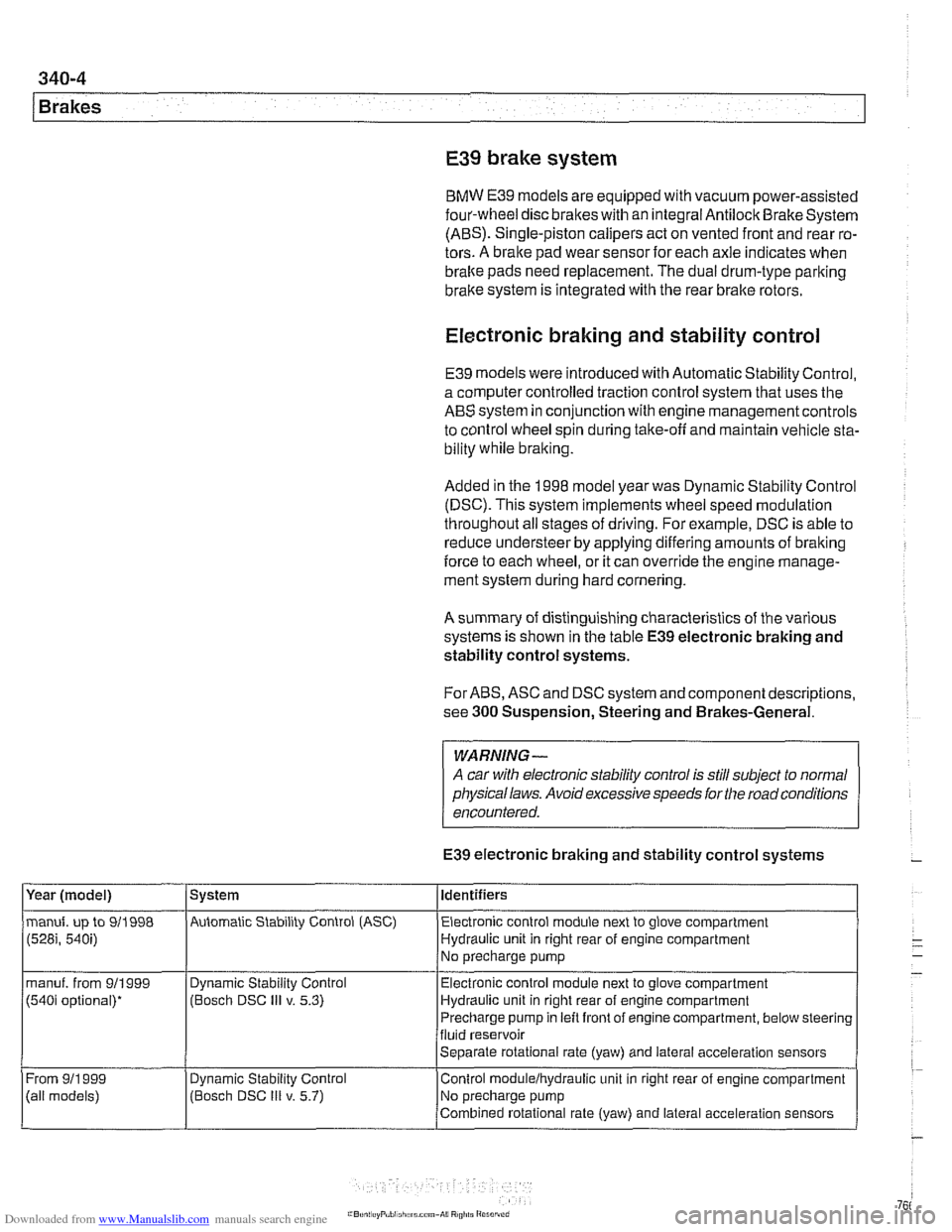

E39 electronic braking and stability control systems

Year (model)

manuf. up to 911998

(528i, 540i)

manuf. from 911999

(540i optional)*

From

911 999

(ail models) System

Automatic Stability Control (ASC) Identifiers

Electronic control module next to glove compartment

Hydraulic unit in right rear of engine compartment

No precharge pump

Dynamic Stability Control

(Bosch DSC

Ill v. 5.3)

Dynamic

Stabil~ty Control

(Bosch DSC

Ill v. 5.7) Electronic

control module next to glove compartment

Hydraulic unit in right rear of engine compartment

Precharge pump in left front of engine compartment, below steering

fluid reservoir

Separate rotational rate (yaw) and lateral acceleration sensors

Control

modulelhydraulic unit in right rear of engine compartment

No precharge pump

Combined rotational rate (yaw) and lateral acceleration sensors

Page 767 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Troubleshooting

Brake performance is mainly affected by three things:

Q Level and condition of brake fluid

Ability of bralte system to create and maintain pressure

Condition of friction components

Air in bralte fluid will

make the brake pedal feel spongy during

braking

orwill increase the bralte pedal force required to stop.

Fluid contaminated by moisture or dirt can corrode the sys-

tem. lnspect the brake fluid inside the reservoir. If it is dirty or

murky, or is more then two years old, replace fluid.

To

check the function of the master cylinder hold the bralte

pedal down hard with the engine running. If the pedal slowly

falls to the floor, either the master cylinder is leaking internal-

ly, or fluid is leaking externally.

lnspect the rotors for glazing, discoloration and scoring.

Steering wheel vibration while braking at speed is often

caused by warped rotors, but can also be caused by worn

suspension components.

When troubleshooting, keep in mind that tire inflation, wear

and temperature can all have an affect on braking. See

300

Suspension, Steering and Brakes-General for additional

suspension and brake system troubleshooting.

The table Brake system troubleshooting lists symptoms of

brake problems, probable causes, and suggested corrective

actions. Unless noted otherwise, relevant repairs are de-

scribed later in this repair group.