start electrical BMW 528i 1999 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 439 of 1002

Downloaded from www.Manualslib.com manuals search engine

- Fuel Injection

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine

management components and subsystems. If this re-

lay is faulty, the engine will not start.

CAUTIOI\C

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring

in the socket using the wiring diagrams

in ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.

ECM relay powers:

* ECM

Ignition coils

Fuel injection

Evaporative leak detection pump

(5.2.1 only)

Idle air actuator

Camshaft sensors Evaporative emissions valve

Hot film mass air flow sensor

Fuel pump relay

Oxygen sensor heaters

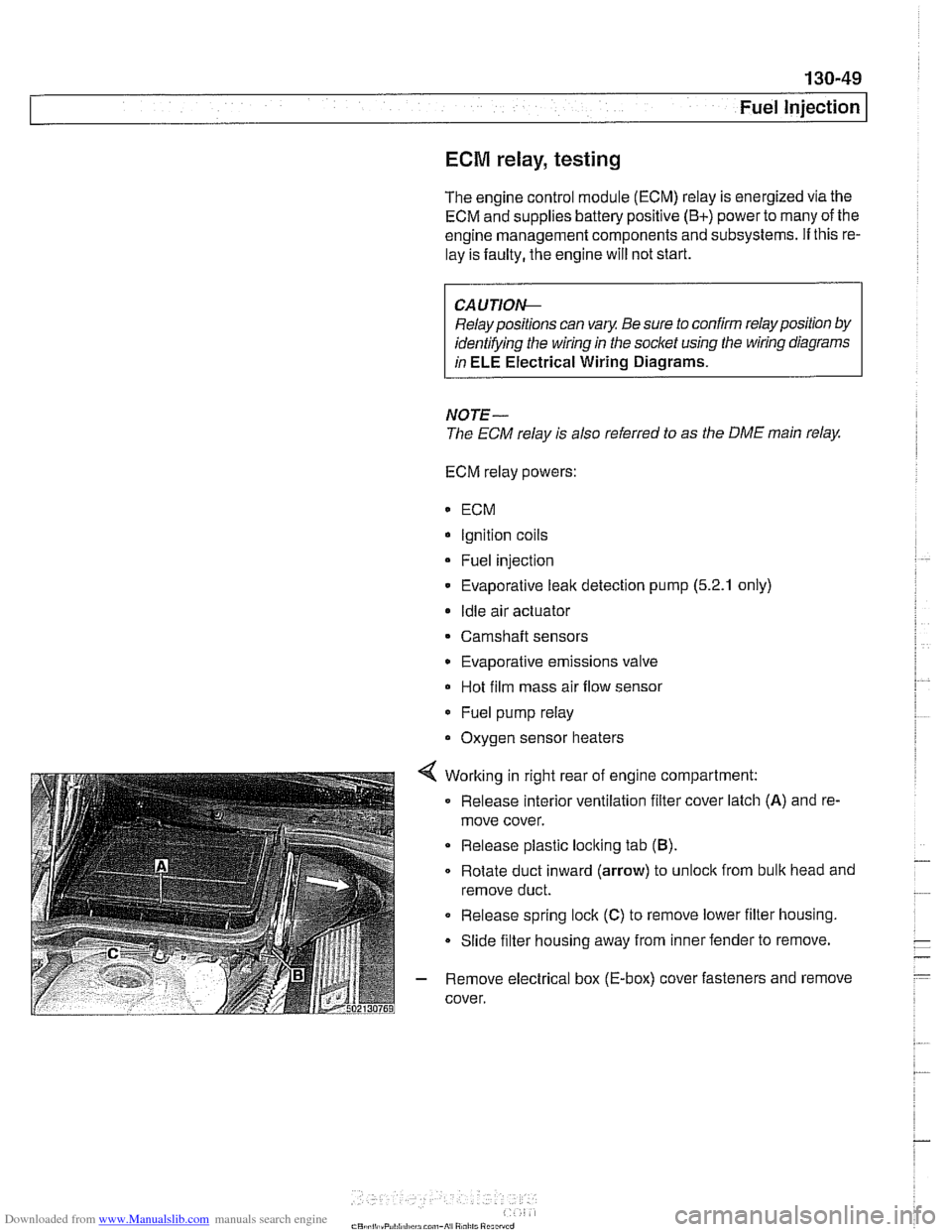

4 Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unloclc from bulk head and

remove duct.

0 Release spring lock (C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

Page 441 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-51

Fuel Injection

Oxygen sensors, checking

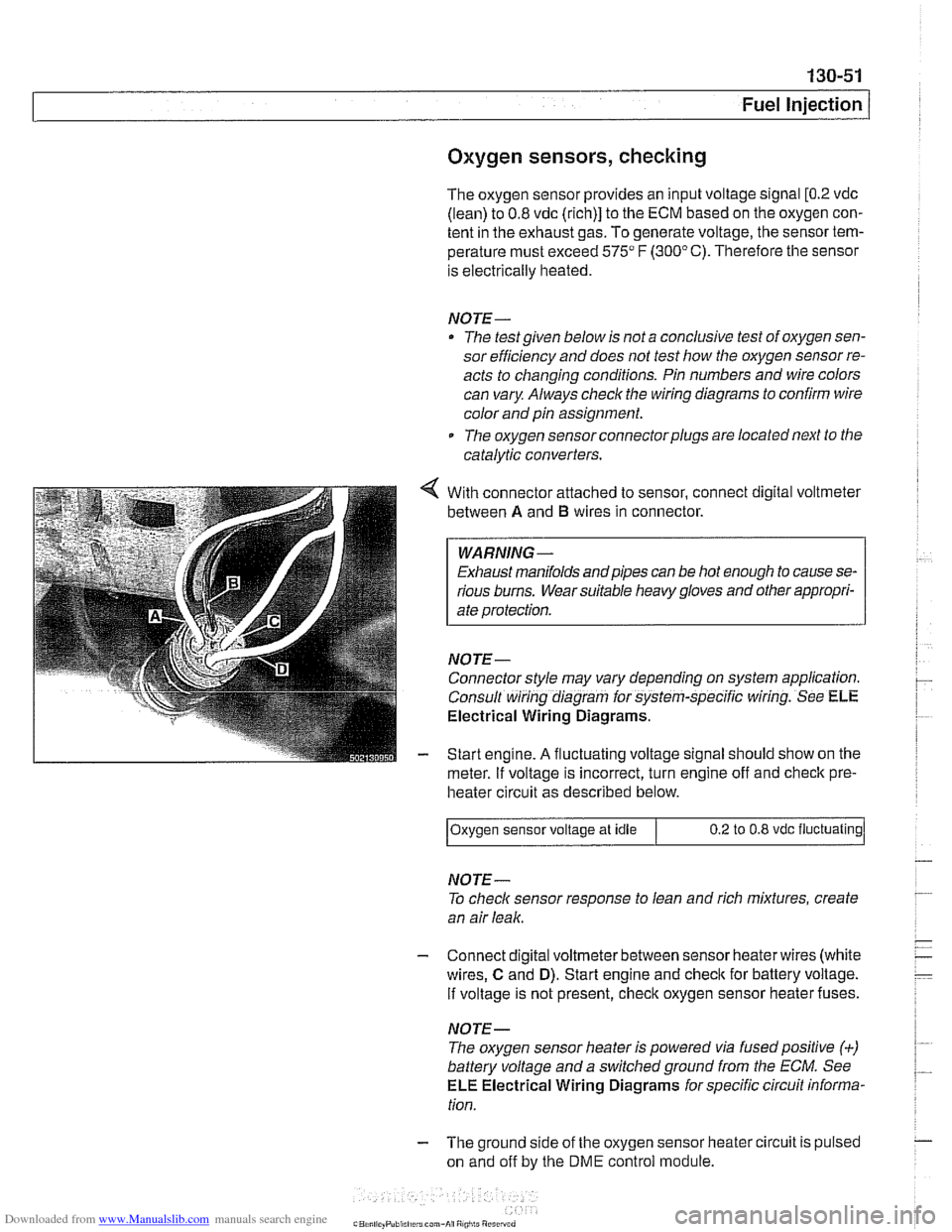

The oxygen sensor provides an input voltage signal [0.2 vdc

(lean) to 0.8 vdc (rich)] to the

ECM based on the oxygen con-

tent in the exhaust gas. To generate voltage, the sensor tem-

perature must exceed 575"

F (300" C). Therefore the sensor

is electrically heated.

NO JE -

The test given below is not a conclusive test of oxygen sen-

sor efficiency and does not test how the oxygen sensor re-

acts to changing conditions. Pin numbers and wire colors

can vary Always check the wiring diagrams to confirm wire

color and pin assignment.

0 The oxygen sensorconnectorplugs are locatednext to the

catalytic converters.

With connector attached to sensor, connect digital voltmeter

between

A and B wires in connector.

WARNING -

Exhaust manifolds andpipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

NOJE-

Connector style may vary depending on system application.

Consult wiring diagram for system-specific wiring. See

ELE

Electrical Wiring Diagrams.

Start engine.

A fluctuating voltage signal should show on the

meter.

If voltage is incorrect, turn engine off and check pre-

heater circuit as described below.

NOJE-

To check sensor response to lean and rich mixtures, create

an air leak.

Oxygen sensor

voltage at idle

- Connect digital voltmeterbetween sensor heaterwires (white

wires,

C and D). Start engine and check for battery voltage.

If voltage is not present, check oxygen sensor heater fuses.

0.2 to 0.8 vdc fluctuating

NOJE-

The oxygen sensor heater is powered via fusedpositive (+)

battery voltage and a switchedground from the ECM. See

ELE Electrical Wiring Diagrams for specific circuit informa-

tion.

- The ground side of the oxygen sensor heater circuit is pulsed

on and off by the

DME control module.

Page 443 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

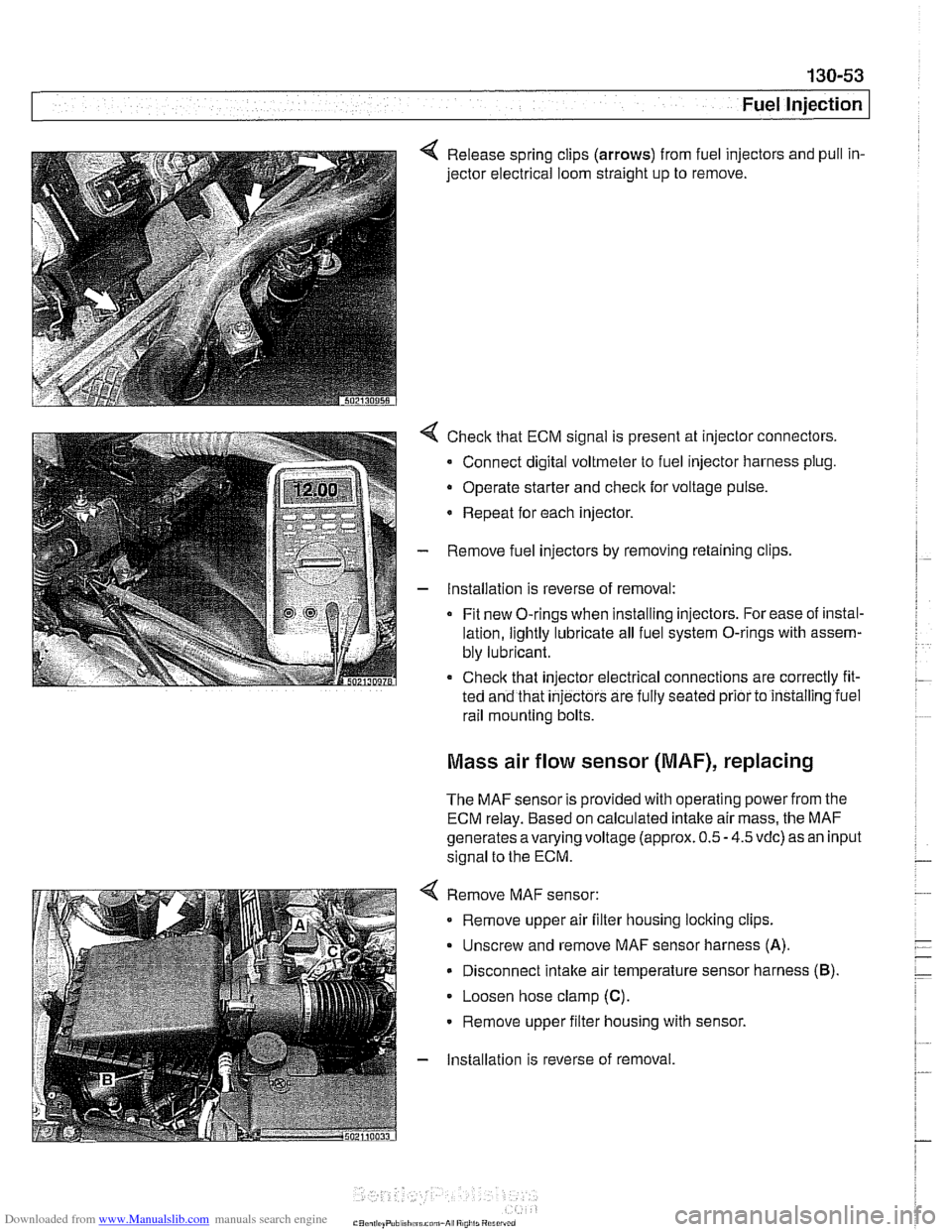

4 Release spring clips (arrows) from fuel injectors and pull in-

jector electrical loom straight up to remove.

4 Check that ECM signal is present at injector connectors.

- Connect digital voltmeter to fuel injector harness plug.

Operate starter and

check for voltage pulse.

* Repeat for each injector.

- Remove fuel injectors by removing retaining clips

- Installation is reverse of removal:

Fit new O-rings when installing injectors. For ease of instal-

lation, lightly lubricate all fuel system O-rings with assem-

bly lubricant.

Check that injector electrical connections are correctly fit-

ted and that

injectors are fully seated prior to installing iuel

rail mounting bolts.

Mass air flow sensor (MAF), replacing

The MAF sensor is provided with operating power from the

ECM relay. Based on calculated intake air mass, the MAF

generates

avarying voltage (approx. 0.5 - 4.5 vdc) as an input

signal to the ECM.

4 Remove MAF sensor:

Remove upper air filter housing locking clips.

Unscrew and remove MAF sensor harness

(A).

Disconnect intake air temperature sensor harness (B).

Loosen hose clamp (C).

Remove upper filter housing with sensor.

- Installation is reverse of removal

Page 457 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-67

Fuel Injection /

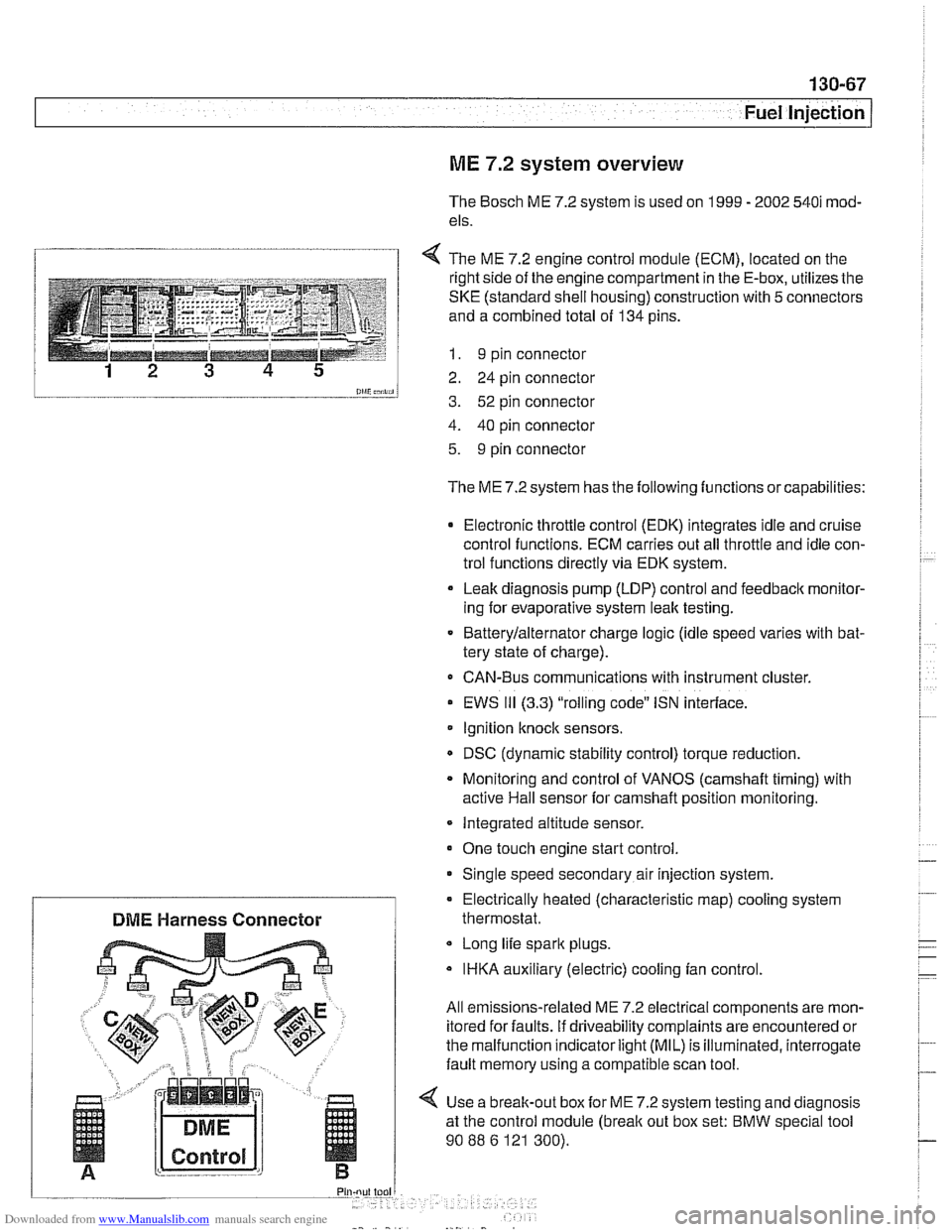

ME 7.2 system overview

The Bosch ME 7.2 system is used on 1999 - 2002 540i mod-

els.

1 4 The ME 7.2 enaine control module (ECM). located on the

l and a combined total of 134 pins.

--__-- 1 I. 9 pin connector

12 3 4 5 2 24 pin connector

0lliC;nii, 3. 52 pin connector

4. 40 pin connector

5. 9 pin connector

The ME 7.2 system has the following functions or capabilities:

Electronic throttle control (EDK) integrates idle and cruise

control functions. ECM carries out all throttle and idle con-

trol functions directly via EDK system.

Leak diagnosis pump

(LDP) control and feedback monitor-

ing for evaporative system leak testing.

Batterylalternator charge logic (idle speed varies with bat-

tery state of charge).

CAN-Bus communications with instrument cluster.

EWS

111 (3.3) "rolling code" ISN interface.

Ignition

knock sensors.

DSC (dynamic stability control) torque reduction.

Monitoring and control of VANOS

(camshaft timing) with

active Hail sensor for camshaft position monitoring.

Integrated altitude sensor.

One touch engine start control

Single speed secondary air injection system.

Long life spark plugs.

IHKA auxiliary (electric) cooling fan control.

All emissions-related ME 7.2 electrical components are mon-

itored for faults. if driveability complaints are encountered or

the malfunction indicator

light (MIL) is illuminated, interrogate

fault memory using a compatible scan tool.

4 Use a break-out box for ME 7.2 system testing and diagnosis

at the control module

(break out box set: BMW special tool

90

88 6 121 300).

Electrically heated (characteristic

map) cooling system

DME Harness Connector thermostat.

Page 476 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-- -

/ Fuel Tank and Fuel Pump - .. -. -- 1

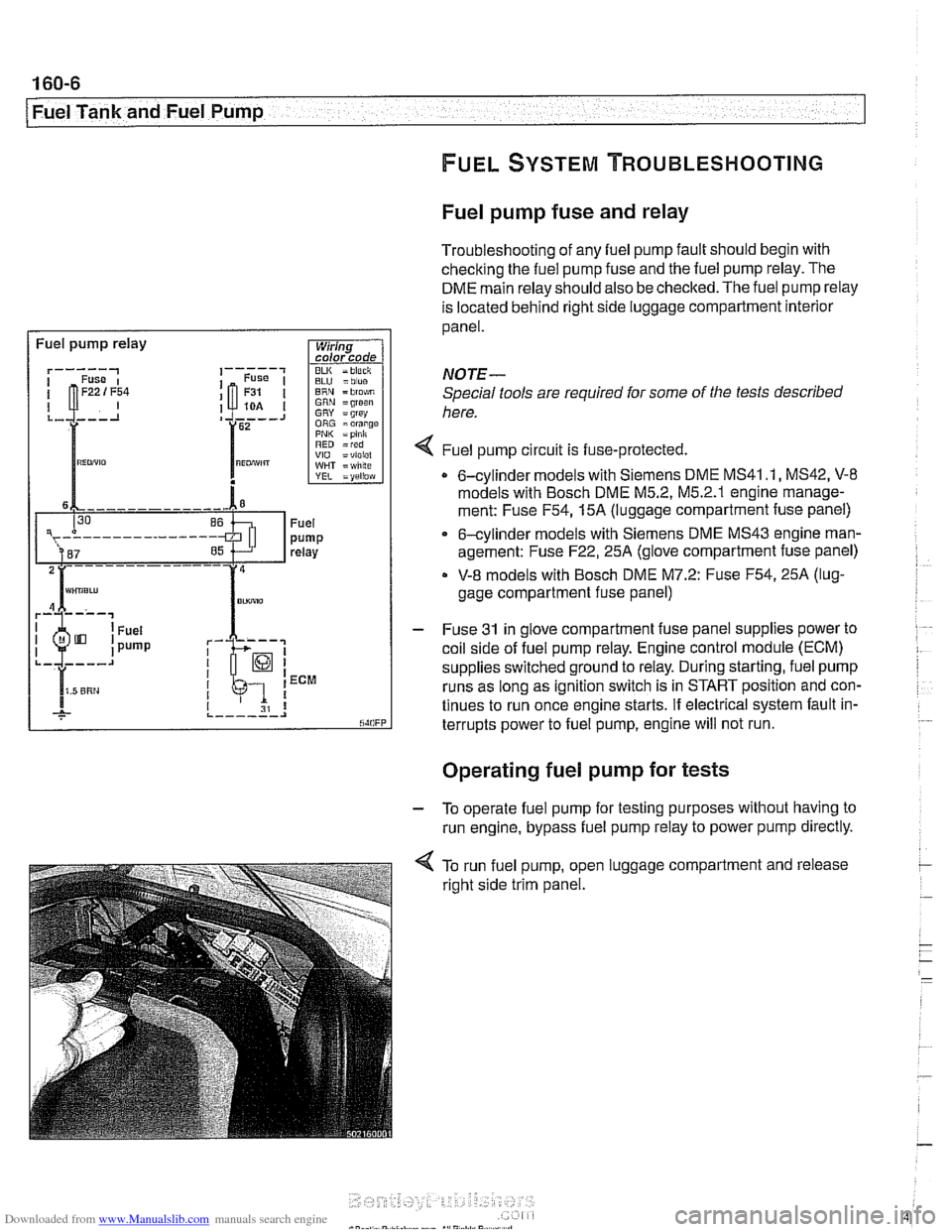

Fuel pump fuse and relay

Troubleshooting of any fuel pump fault should begin with

checking the fuel pump fuse and the fuel pump relay. The

DME main relay should also be checked. The fuel pump relay

is located behind right side luggage compartment interior

panel.

I Fuel pump relay

BLU =blue ERN = blo$,m GRN =groan GRY = grsy ORG =orange PNI< =pink RED =red VIO =violel WHT = wlilte

rk-; I I 1 ECM

I I I 31 8 ,._--___.I

NOTE-

Special tools are required for some of the tests described

here.

4 Fuel pump circu~t is fuse-protected.

0 6-cylinder models with Siemens DME MS41 .I, MS42, V-8

models with Bosch DME M5.2, M5.2.1 englne manage-

ment: Fuse

F54,15A (luggage compartment fuse panel)

6-cylinder models with Siemens DME MS43 engine man-

agement: Fuse

F22,25A (glove compartment fuse panel)

V-8 models with Bosch DME M7.2: Fuse F54,25A (lug-

gage compartment fuse panel)

- Fuse 31 in glove compartment fuse panel supplies power to

coil side of fuel pump relay. Engine control module (ECM)

supplies switched ground to relay. During starting, fuel pump

runs as long as ignition switch is in START position and con-

tinues to run once engine starts. If electrical system fault in-

terrupts power to fuel pump, engine will not run.

. .

Operating fuel pump for tests

- To operate fuel pump for testing purposes without having to

run engine, bypass fuel pump relay to power pump directly.

< To run fuel pump, open luggage compartment and release

right side trim panel.

Page 487 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- .

Fuel Tank and Fuel Pump

- To reinstall:

Use new sealing ring at tank collar.

* Align tab of sending unit with matching recess in opening

of tank.

Be sure that fuel line connections point in same direction

as they came out.

Reconnect harness connector and hose.

Fill tank and check for leaks by running engine.

Install access cover and its mounting fasteners.

CAUTIOI\C

After finishing repairs but before starting engine, be sure

there is at least

5 liters (1.5 gallons) of fuel in the tank. The

NOTE-

It is common practice to replace the fuel filter when the fuel

pump

unit is replaced. See 020 Maintenance.

Tightening torque

Tank collar locking ring to tank 35 Nm (26 lb-ft)

Fuel level sender (left side),

removing and installing

The procedure for removing and replacing the left side fuel

level sender is

simllar to that used for the r~ght side. There is

no fuel pump on the left side.

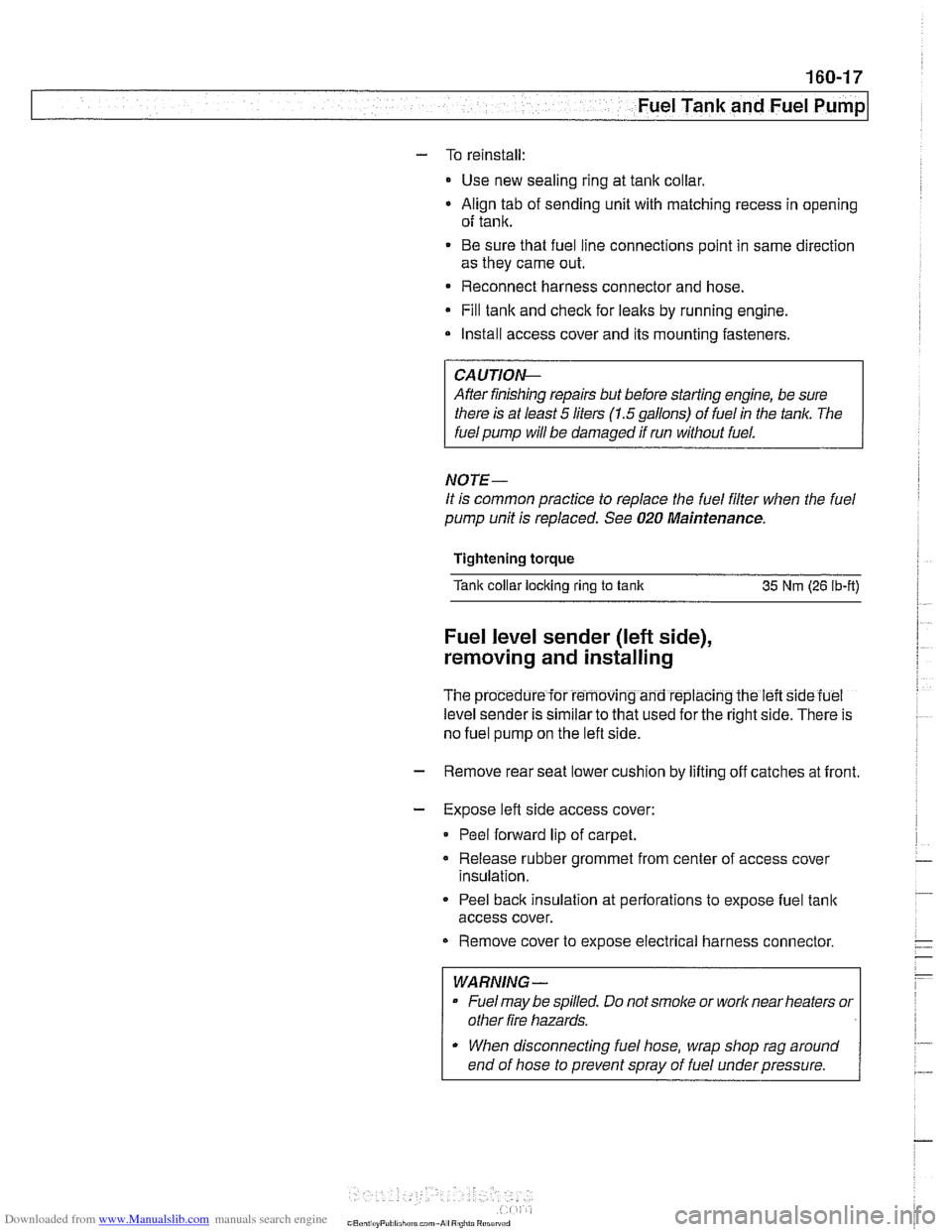

- Remove rear seat lower cushion by lifting off catches at front.

- Expose left side access cover:

- Peel forward lip of carpet.

Release rubber grommet from center of access cover

insulation.

Peel back insulation at

perforations to expose fuel tank

access cover.

Remove cover to expose electrical harness connector.

WARNING-

Fuel may be spilled. Do not smoke or work near heaters or

other fire hazards.

When disconnecting fuel hose, wrap shop rag around

end of hose to prevent spray of fuel under pressure.

Page 488 of 1002

Downloaded from www.Manualslib.com manuals search engine

/ ~uel Tank and Fuel Pump

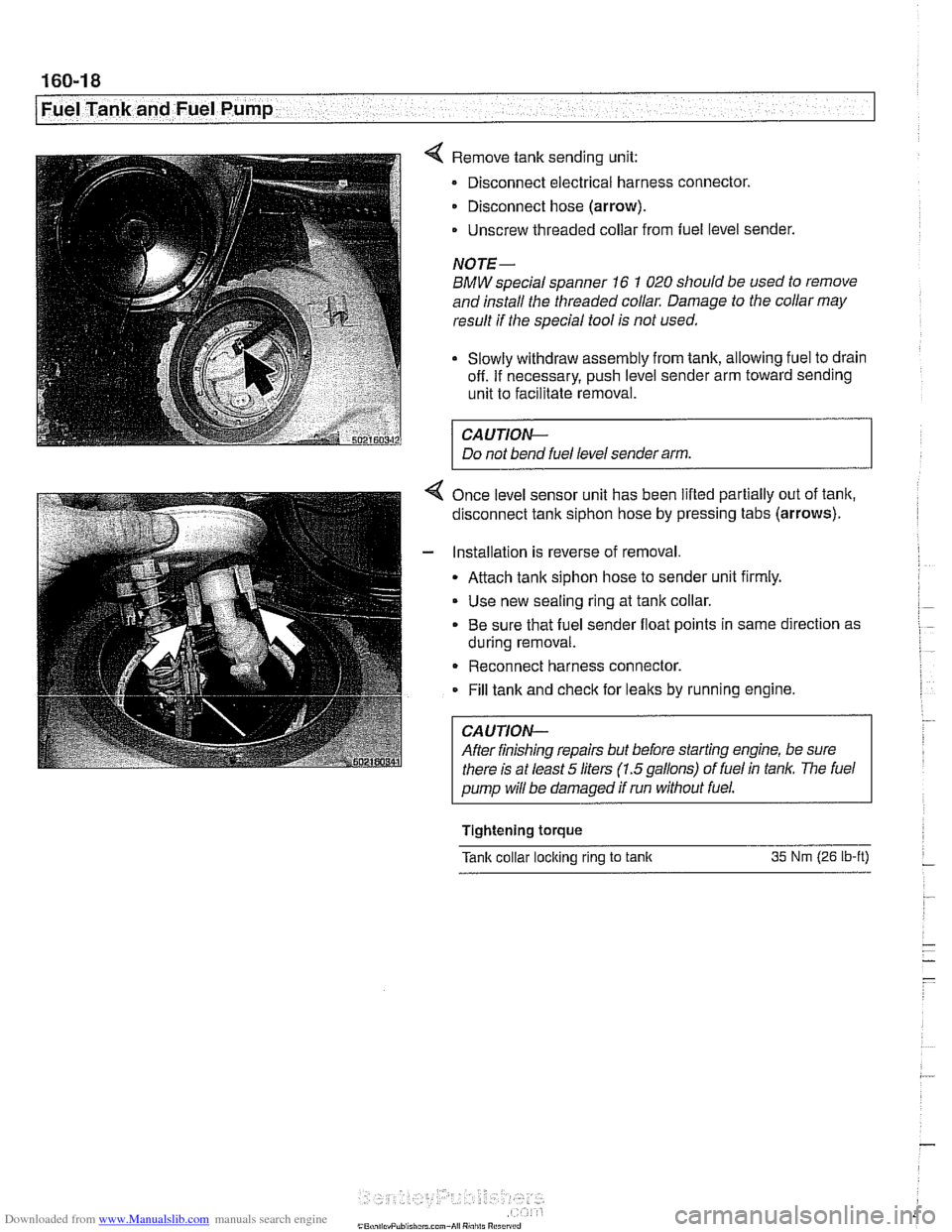

4 Remove tank sending unit:

Disconnect electrical harness connector.

Disconnect hose (arrow).

- Unscrew threaded collar from fuel level sender.

NOTE-

BMW special spanner 16 1 020 should be used to remove

and install the threaded collar. Damage to the collar may

result if the special tool is not used.

Slowly withdraw assembly from tank, allowing fuel to drain

off. If necessary, push level sender arm toward sending

unit to facilitate removal.

CA UTIOW-

Do not bend fuel level sender arm.

4 Once level sensor unit has been lifted partially out of tank,

disconnect tank siphon hose by pressing tabs (arrows).

- Installation is reverse of removal

Attach tank siphon hose to sender unit firmly.

Use new sealing ring at tank collar.

. Be sure that fuel sender float points in same direction as

during removal.

- Reconnect harness connector.

Fill tank and

check for leaks by running engine.

CAUTION-

After finishing repairs but before starting engine, be sure

there is at least

5 liters (1.5gallons) of fuel in tan/(. The fuel

pump will be damaged if run without fuel.

Tightening

torque

Tank collar loclting rlng to tanlt 35 Nm (26 lb-ft) -

Page 492 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-22

Fuel Tank and Fuel Pump

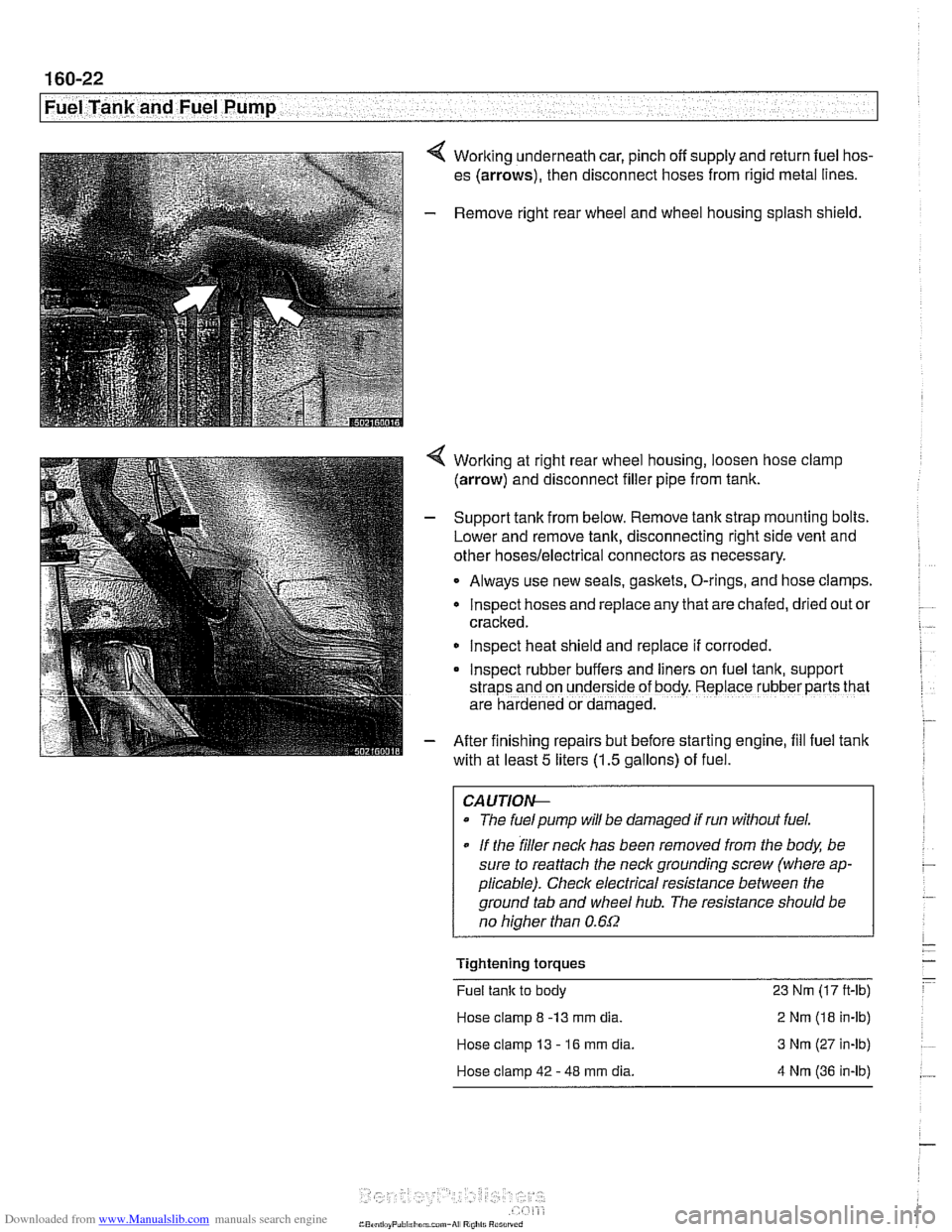

4 Working underneath car, pinch off supply and return fuel hos-

es (arrows), then disconnect hoses from rigid metal lines.

- Remove right rear wheel and wheel housing splash shield.

4 Worlting at right rear wheel housing, loosen hose clamp

(arrow) and disconnect filler pipe from tank.

- Support tank from below. Remove tank strap mounting bolts.

Lower and remove tank, disconnecting right side vent and

other

hoses/electrical connectors as necessary.

Always use new seals, gaskets, O-rings, and hose clamps.

lnspect hoses and replace any that are chafed,

dr~ed out or

cracked.

lnspect heat shield and replace if corroded.

Inspect rubber buffers and

hers on fuel tank, support

straps and on underside of body. Replace rubber parts that

are hardened or damaged.

- After finishing repairs but before starting engine, fill fuel tank

with at least

5 liters (1.5 gallons) of fuel.

CAUTlOI+

The fuelpump will be damaged if run without fuel.

* If the filler neck has been removed from the body, be

sure to reattach the

neck grounding screw (where ap-

plicable). Check electrical resistance between the

ground tab and wheel

hub. The resistance should be

no

hiaher than 0.6f2

Tightening torques

Fuel tank to body 23 Nm (17 ft-lb)

Hose clamp

8 -13 mm dia. 2 Nm (18 in-lb)

Hose clamp 13

- 16 mm dia. 3 Nm (27 in-lb)

Hose clamp 42

- 48 mm dia. 4 Nm (36 in-lb)

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

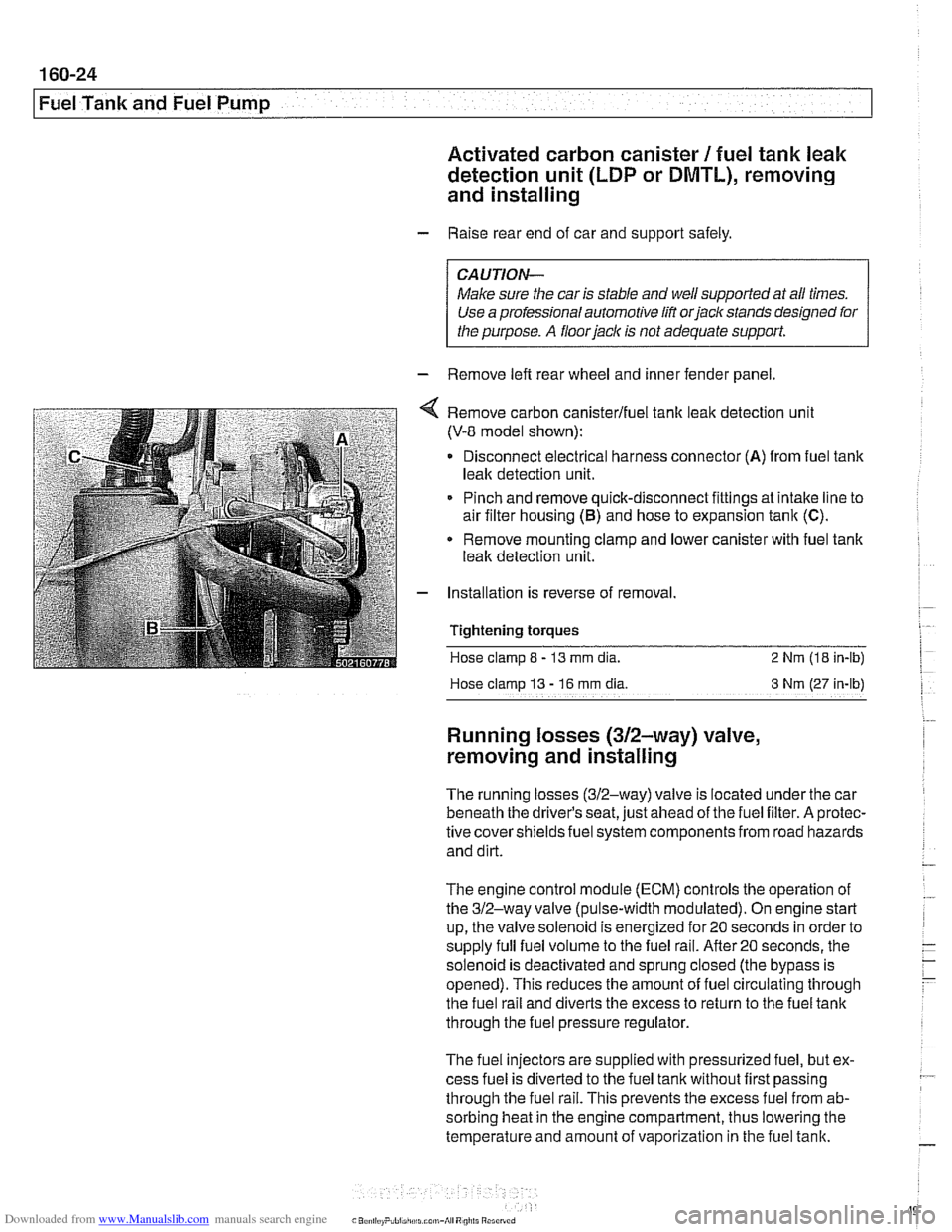

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 770 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-8

1 Brakes

Brake bleeding is usually done for one of two reasons: either

to replace old brake fluid as part of routine maintenance or to

expel trapped air in the system that resulted

from opening the

brake hydraulic system during repairs.

Read the

Warnings listed below before beginning the bleed-

ing procedure an on any

E39 car. If air enters the ACS or DSC

hydraulic unit, the factory BMW Service Tester MUST be

used in conjunction with a bralte pressure bleeder before the

vehicle is driven.

The BMW

ServiceTester (DISpluslGT1iMoDiC) must be

used to bleed the braltes if:

Any hydraulic brake system components are replaced, in-

cluding bralte lines.

Air has enter the

ABSIASC or ABSlDSC hydraulic unit.

WARNING -

* The ASC and DSC systems use electronic controls and a

sophisticated hydraulic unit Once air enters the hydraulic

unit, it is very difficult to remove using traditional methods.

For this reason, pressure

brake bleeding should be done

in conjunction with the BMW

Sewice Tester (DIS-

plus/GTl/MoDiC). The tester electrically cycles the hy-

draulic unit solenoids in the hydraulic unit while

pressurized brake fluid is forced through the system.

When flushing the brake fluid from the system, use ex-

treme care to not let the

brale fluid reservoir run dry If

air enters the hydraulic unit, the BMW Service Tester

MUST be used to bleed the brale system before the

vehicle is driven.

Always use new brake fluid from an unopened container. It is

important to bleed the entire system when any part of the hy-

draulic system has been opened. Be sure to have the special

equipment needed before beginning the job.

When bleeding the

braltes, start atthe wheel farthest from the

master cylinder and progress in the following order:

right rear brake

left rear brake

* right front brake

left front brake