Idle BMW 528i 1999 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 659 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 320 Steering and Wheel Alignment

General ........................... .32 0.2

Special tools

........................ .32 0.2

Steering system

..................... .32 0.4

Steering system variations

............. .32 0.5

Steering system warnings and cautions

... .32 0.6

Steering Wheel .................... .32 0.7

Steering wheel. removal and installation

.. .32 0.7

Steering Column ................. .32 0.1 0

Steering column components .......... .32 0.10

Steering column trim, removing

and replacing

...................... .32 0.10

lgnition switch ring antenna (EWS).

removing and installing

............... .32 0.1 1

lgnition lock cylinder.

removing and installing

............... .32 0-1 1

Steering column lock. removing

and installing

....................... .32 0.12

lgnition

interloclc cable. removing and installing

(models with automatic transmission)

... .32 0.13

Interlock cable. adjusting

(models with automatic transmission)

... .32 0.14

Steering column. removing and installing

. .32 0.14

Steering column adjustment motors.

removing and installing

............... .32 0.16

Power Steering Pump ............. .32 0.17

Power steering pump. removing

and installing

....................... .32 0.1 7

Power steering system.

bleeding and filling

.................. .32 0.18

Rack and Pinion Steering

(6-cylinder models)

............... 320-19

Rack and pinion steering components

(6-cylinder models)

.................. 320-1 9

Steering rack. removing and installing

.... 320-19

Steering

rack boot. replacing ........... 320-22

Tie rod (outer). replacing

.............. 320-22

Tie rod (inner). replacing

.............. 320-23

Steering Gearbox (V-8 models) .... 320-24

Steering gearbox system components

. .

(V-8 models) ....................... 320-24

Steering gearbox, removing and installing 320-25

Pitman arm. removing and installing ..... 320-28

Pitman arm. adjusting ................ 320-29

Steering idler arm. removing

and installing

....................... 320-30

Idler arm bushing. replacing ........... 320-31

Center tie rod. replacing

.............. 320-32

Wheel Alignment .................. 320-33

Camber

........................... 320-33

Caster

............................ 320-33

Front toe and toe difference angle

....... 320-34

Reartoe ........................... 320-34

Preparing for alignment

............... 320-35

Alignment specifications tables

......... 320-35

Page 663 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

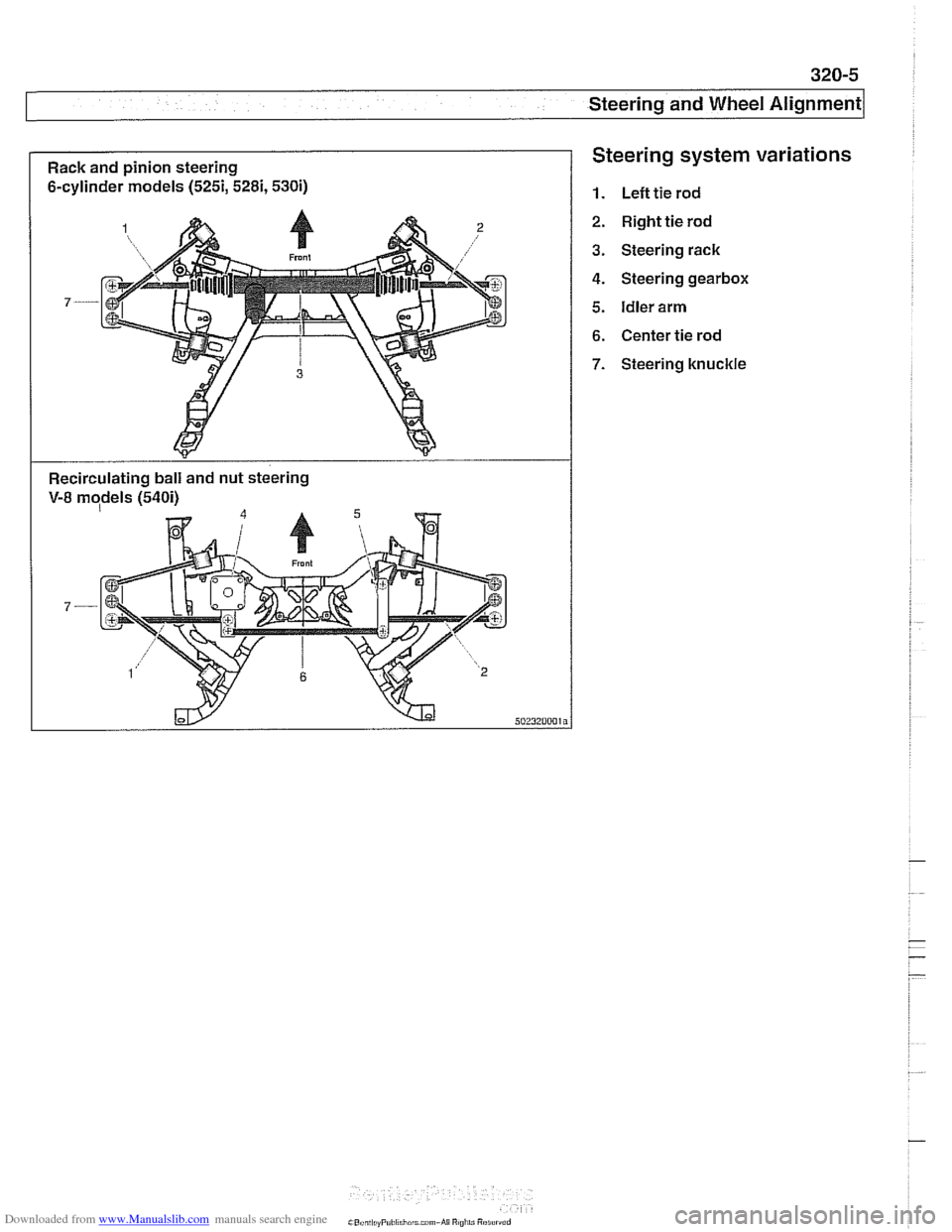

I Rack and r in ion steering 1 Steering system variations

I 6-~~linder'rnodels (525i,>28i, 530i) / 1. Left tie rod

2. Right tie rod

3. Steering rack

4. Steering gearbox

5. idler arm

6. Center tie rod

7. Steering knuckle

Recirculating ball and nut steering

r V-8 models 154Oib

Page 688 of 1002

Downloaded from www.Manualslib.com manuals search engine

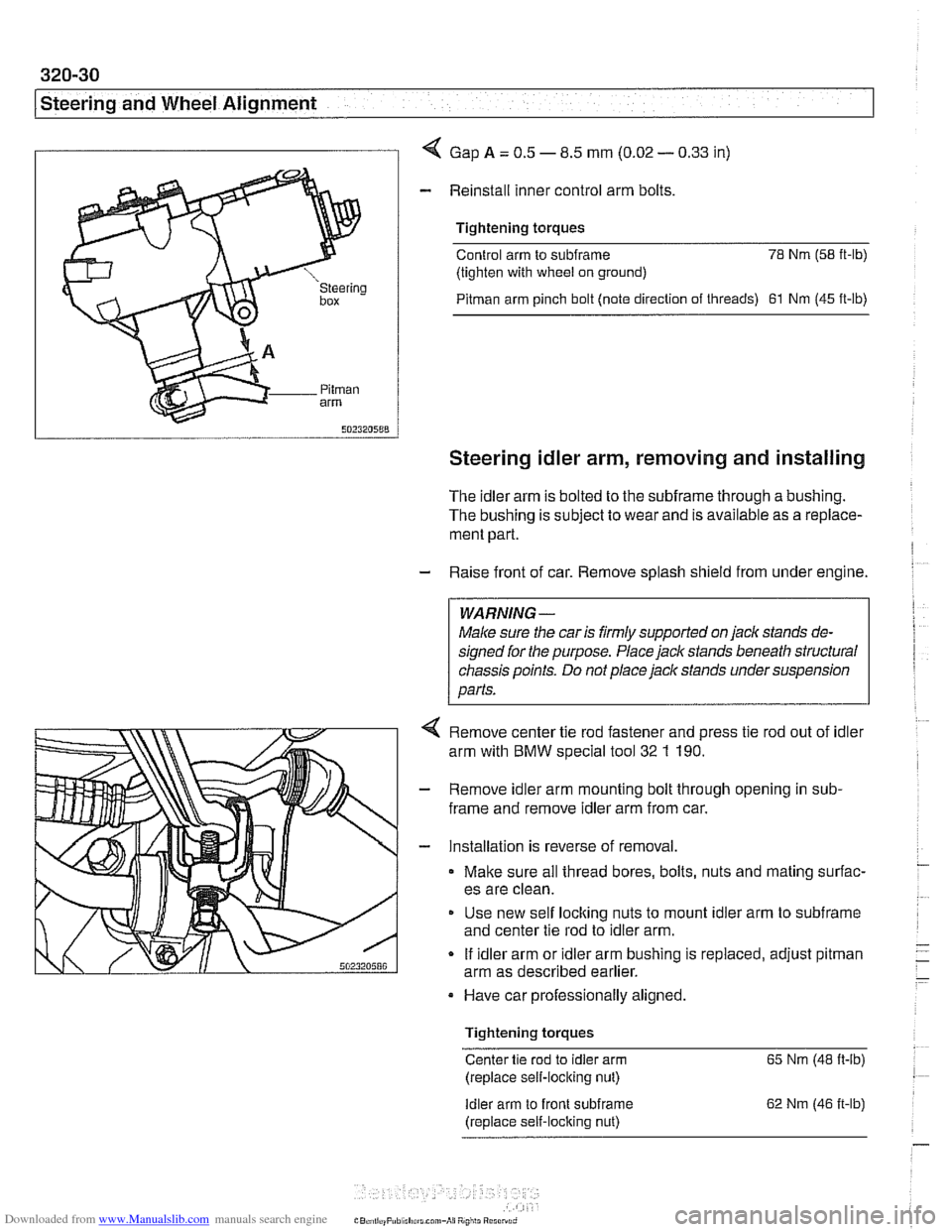

I Steering and Wheel Alignment

I I 4 Gap A = 0.5 - 8.5 mm (0.02 - 0.33 in)

- Reinstall inner control arm bolts

Tightening torques

Control arm to

subframe 78 Nm (58 it-lb)

(tighten with wheel on ground)

Pitman arm pinch bolt (note direction of threads) 61 Nm (45 ft-lb)

Steering idler arm, removing and installing

The idler arm is bolted to the subframe through a bushing.

The bushing is subject to wear and is available as a replace-

ment part.

- Raise front of car. Remove splash shield from under engine.

WARNING -

Male sure the car is firmly supported on jaclc stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

4 Remove center tie rod fastener and press tie rod out of idler

arm with

BMW special tool 32 1 190.

- Remove idler arm mounting bolt through opening in sub-

frame and remove idler arm from car.

- Installation is reverse of removal.

Make sure all thread bores, bolts, nuts and mating surfac-

es are clean.

Use new self

loclting nuts to mount idler arm to subframe

and center tie rod to idler arm.

If idler arm or idler arm bushing is replaced, adjust

pitman

arm as described earlier.

Have car professionally aligned.

Tightening torques

Center tie rod to idler arm 65 Nm (48 ft-ib)

(replace self-locking nut)

Idler arm to front subirame

(replace self-locking nut) 62

Nm (46 it-lb)

Page 689 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-31

Steering and Wheel ~li~nrnentl

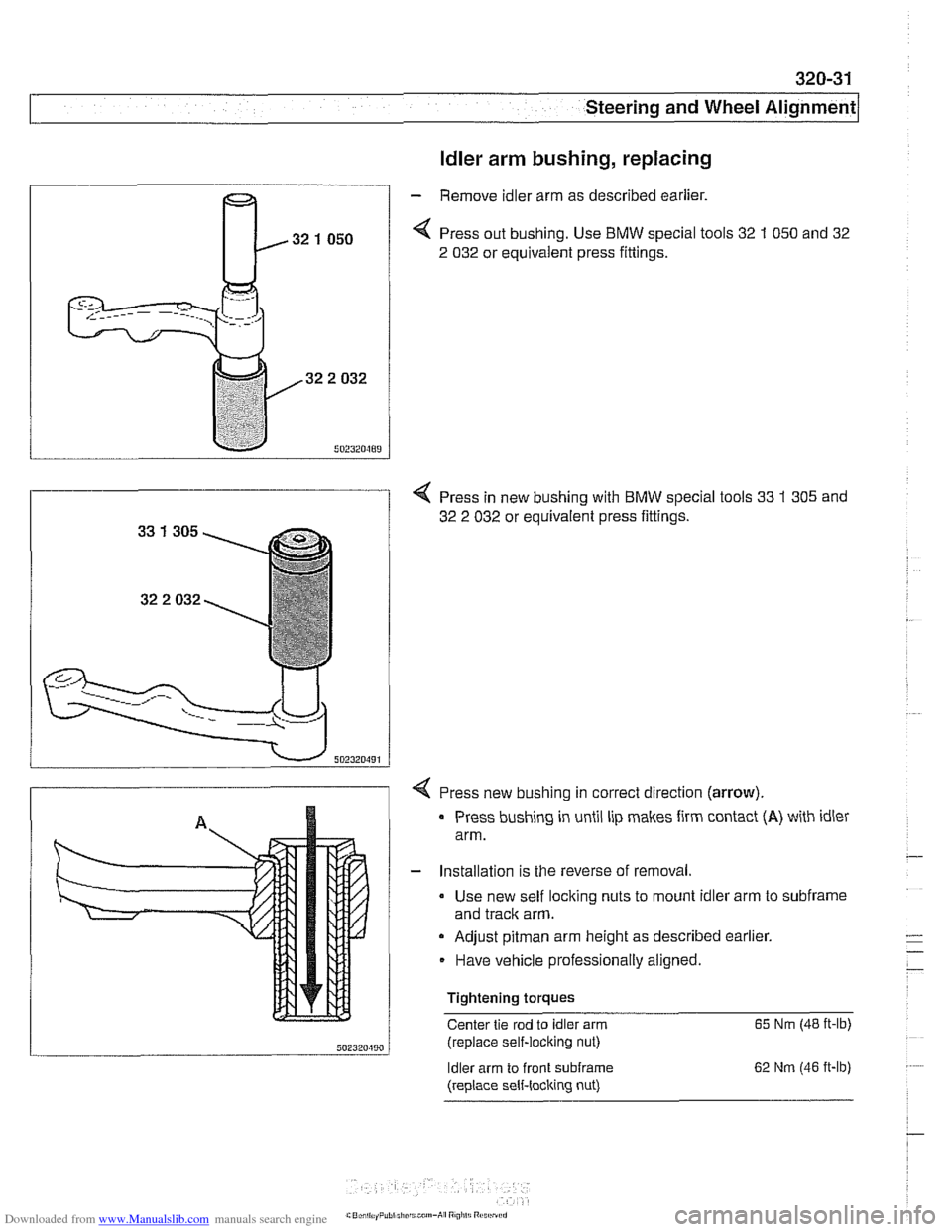

ldler arm bushing, replacing

- Remove idler arm as described earlier.

< Press out bushing. Use BMW special tools 32 1 050 and 32

2 032 or equivalent press fittings.

4 Press in new bushing with BMW special tools 33 1 305 and

32 2 032 or equivalent press fittings.

4 Press new bushing in correct direction (arrow).

u ..... "A",

Press bushing in until lip makes firm contact (A) with idler

arm.

I

Installation is the reverse of removal

Use new self locking nuts to mount idler arm to

subframe

and traclc arm.

a Adjust pitman arm height as described earlier.

Have vehicle professionally aligned.

Tightening torques Center tie rod to idler arm

65 Nm (48 ft-lb)

;nl?mmn / (replace self-locking nut)

ldler arm to front

subframe

(replace sell-locking nut) 62

Nm (46 ft-lb)

Page 690 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-32

Steering and Wheel Alignment

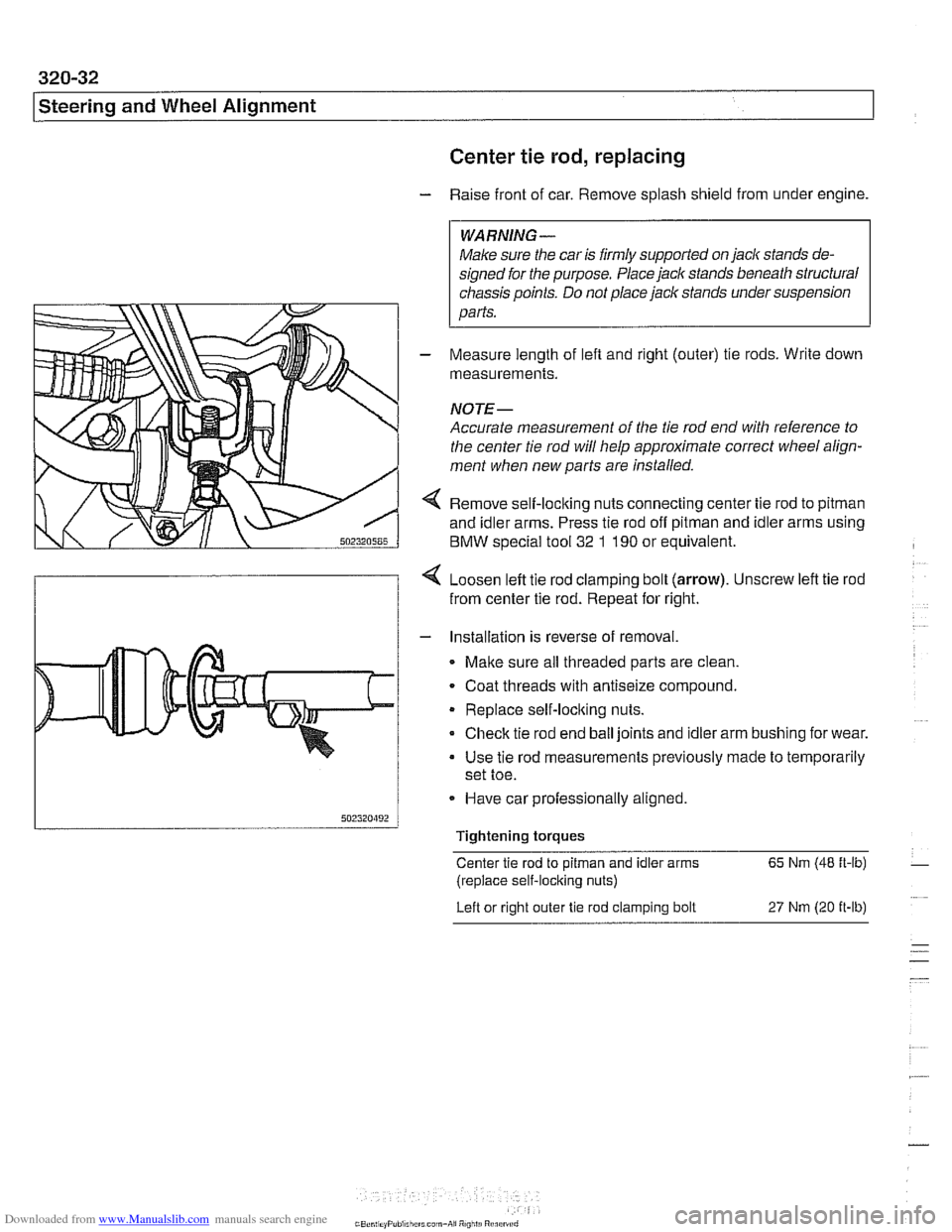

Center tie

rod, replacing

- Raise front of car. Remove splash shield from under engine.

WARNING-

Make sure tlie car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

cliassis points. Do not place jack stands under suspension

parts.

- Measure length of left and right (outer) tie rods. Write down

measurements.

NOTE-

Accurate measurement of the tie rod end with reference to

the center tie rod will help approximate correct wheel align-

ment when new parts are installed.

4 Remove self-loclting nuts connecting center tie rod to pitman

and idler arms. Press tie rod off pitman and idler arms using

BMW special tool

32 1 190 or equivalent.

4 Loosen left tie rod clamping bolt (arrow). Unscrew left tie rod

from center tie rod. Repeat for right.

- Installation is reverse of removal.

Malte sure all threaded parts are clean.

. Coat threads with antiseize compound.

Replace self-loclting nuts.

Check tie rod end ball joints and idler arm bushing for wear.

Use tie rod measurements previously made to temporarily

set toe.

- Have car professionally aligned.

Tightening torques

Center tie rod to

pitman and idler arms 65 Nm (48 ft-lb)

(replace self-locking nuts)

Left or right outer

tie rod clamping bolt 27 Nm (20 it-lb)

Page 968 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-8

I On-Board Diagnostics

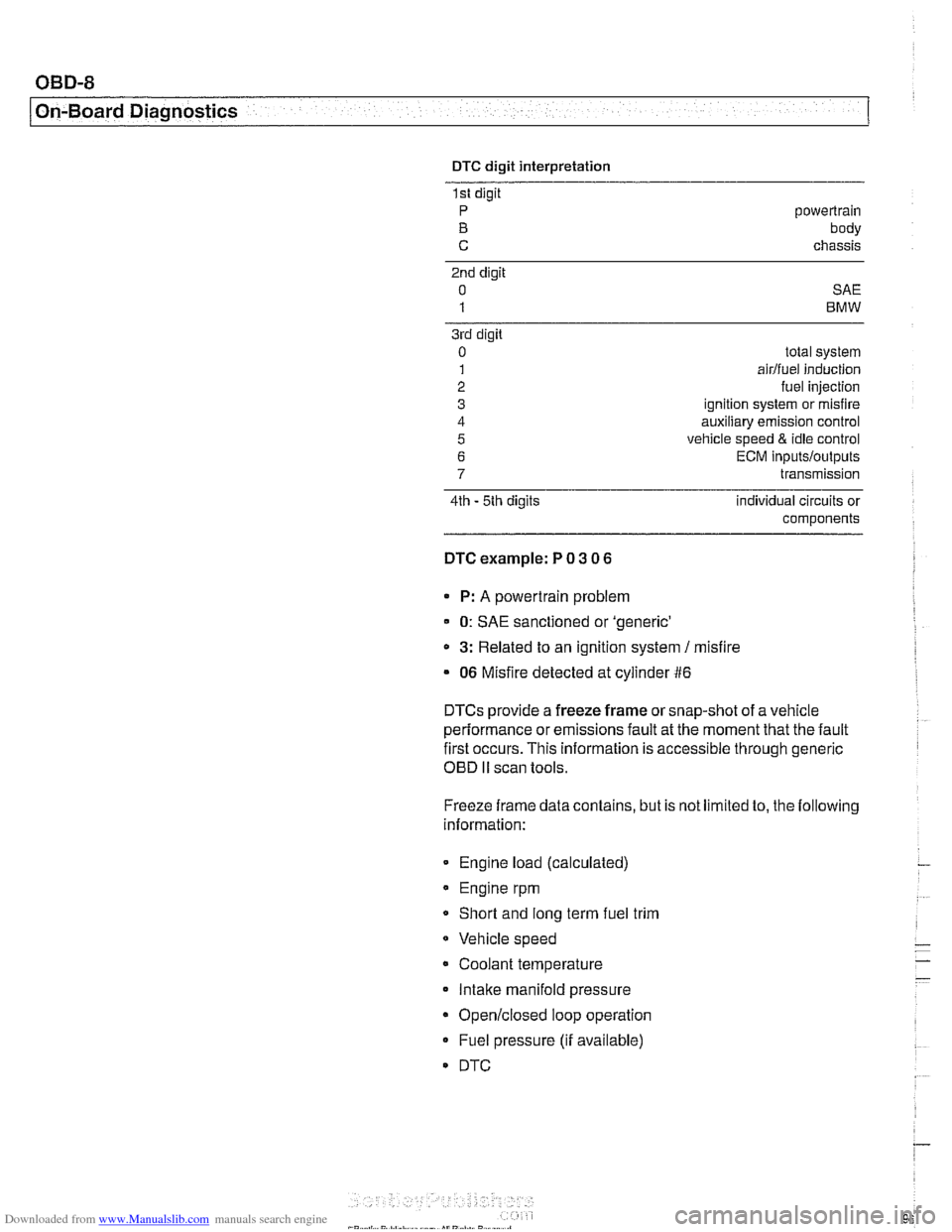

DTC digit interpretation

1st digit

P powertrain

B body

C chassis

2nd digit

0 SAE

1 BMW

3rd digit

0

1

2

3

4

5

6

7

4th - 5th digits total

system

airlfuei induction

fuel injection

ignition system or misfire

auxiliary emission control

vehicle speed

& idle control

ECM

inputs/outputs

transmission

individual circuits or

components

DTC example: P 0 3 0 6

P: A powertrain problem

0: SAE sanctioned or 'generic'

a 3: Related to an ignition system / misfire

06 Misfire detected at cylinder #6

DTCs provide a freeze frame or snap-shot of a vehicle

performance or emissions fault at the moment that the fault

first occurs. This information is accessible through generic

OED I1 scan tools.

Freeze frame data contains, but is not limited to, the following

information:

Engine load (calculated)

Engine rpm

Short and

long term fuel trim

Vehicle speed

Coolant temperature Intake manifold pressure

Open/closed loop operation

Fuel pressure (if available)

DTC

Page 975 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-15

On-Board ~iagnosticsl

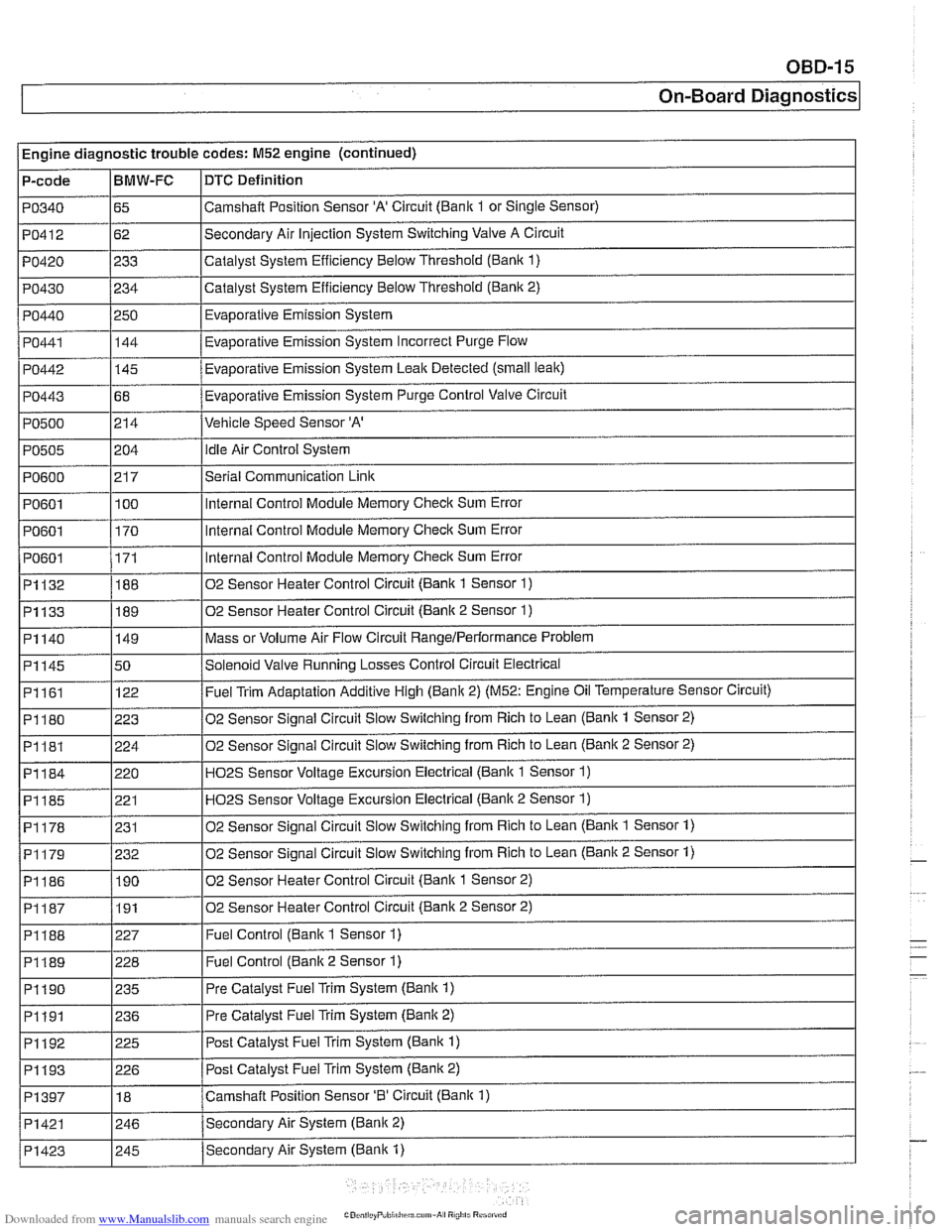

Engine diagnostic trouble codes: M52 engine (continued)

P-code

PO340

PO412

PO420

PO430

PO440

PO441

PO442

PO443

PO500

PO505

PO600

PO601

PO601

I PO601

~1132

~1133

BMW-FC

65

62

233

234

250 144

-

145

68

214

i I

DTC Definition

Camshalt Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Secondary Air Injection System Switching Valve A Circuit

Catalyst System Efficiency Below Threshold

(Bank 1)

Catalyst System Efficiency Below Threshold (Bank 2)

Evaporative Emission System

Eva~orative Emission Svstem Incorrect Purge Flow .

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Vehicle Speed Sensor 'A'

204

21 7

100

170

171

188

189

PI161

PI180

PI181

PI184

PI185

PI178

02 Sensor Heater Control Circuit (Bank 2 Sensor 2) I

idle Air Control System

Serial Communication

Link

Internal Control Module Memory Check Sum Error

Internal Control Module Memory

Check Sum Error

Internal Control Module Memory

Check Sum Error

02 Sensor Heater Control Circuit (Bank 1 Sensor

1)

02 Sensor Heater Control Circuit (Bank 2 Sensor 1)

Mass or Volume Air Flow Circuit RangeIPerlormance Problem PI140

I

I I

P1188 1227 I Fuel Control (Bank 1 Sensor 1)

PI145 150 /Solenoid Valve Running Losses Control Circuit Electrical

149

122

223

224

220 221

231

I I

P1189 1228 I Fuel Control (Banlc 2 Sensor 1)

Fuel Trim Adaptation Additive High (Bank 2) (M52: Engine Oil Temperature Sensor Circuit)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 1 Sensor 2)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 2 Sensor 2)

H02S Sensor Voltage Excursion Electrical (Banlc 1 Sensor 1)

HO2S Sensor Voltage Excursion Electrical (Banlc 2 Sensor 1)

02 Sensor Sianai Circuit Slow Switchina from Rich to Lean (Bank 1 Sensor 1)

02 Sensor Signal Circuit Slow Switching from Rich to Lean (Bank 2 Sensor 1) PI179

I I

PI190 1235 I Pre Catalyst Fuel Trim System (Banlc 1)

PI186 1190 102 Sensor Heater Control Circuit (Banlc 1 Sensor 2)

232

I I

PI191 1236 I Pre

Catalyst Fuel Trim System (Banlc 2)

PI192

. . -- - i Pi193 1226 I Post Catalvst Fuel Trim Svstem (Bank 2)

225

PI397

I I

Post Catalyst Fuel Trim System (Bank 1)

PI421 1246 /Secondarv Air System (Bank 2)

18

Secondary Air System (Bank

1) PI423

Camshaft Position Sensor '0' Circuit (Bank 1)

I 245

Page 976 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

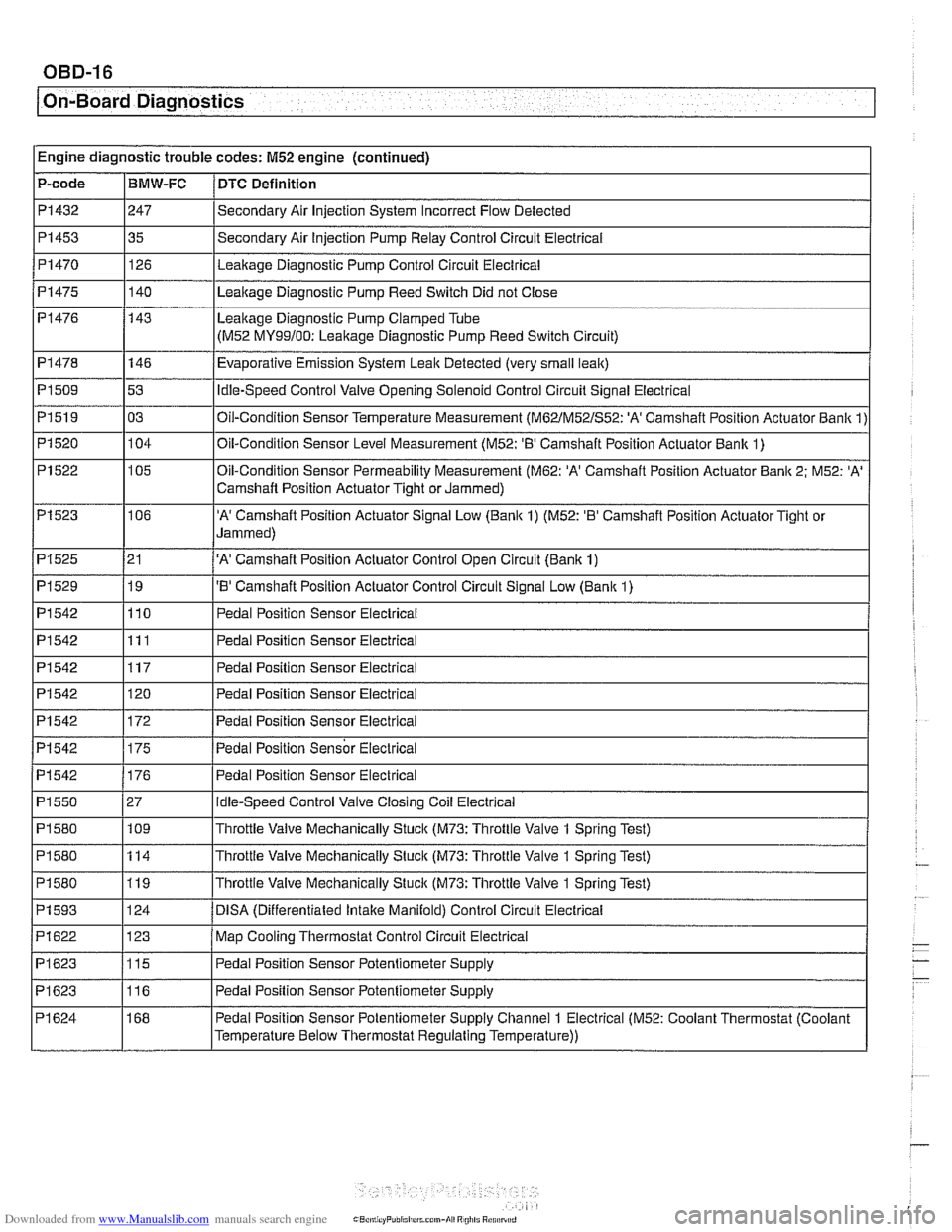

On-Board Diagnostics - - --- - -- - -

PI542

PI550

PI580

PI 580

PI 580

PI 593

PI622

PI623

PI623

PI 624 176

27 109

114

119

124

123

115

116

168 Pedal Position Sensor Electrical

Idle-Speed

Control Valve Closing Coil Electrical

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

Throttle Valve Mechanically Stuck

(M73: Throttle Valve 1 Spring Test)

DlSA (Differentiated lntalte Manifold) Control Circuit Electrical

Map Cooling Thermostat Control Circuit Electrical

Pedal Position Sensor Potentiometer Supply

Pedal Position Sensor Potentiometer Supply

Pedal Position Sensor Potentiometer Supply Channel

1 Electrical (M52: Coolant Thermostat (Coolant

Temperature Below Thermostat Regulating Temperature))

Page 980 of 1002

Downloaded from www.Manualslib.com manuals search engine

I On-Board Diagnostics

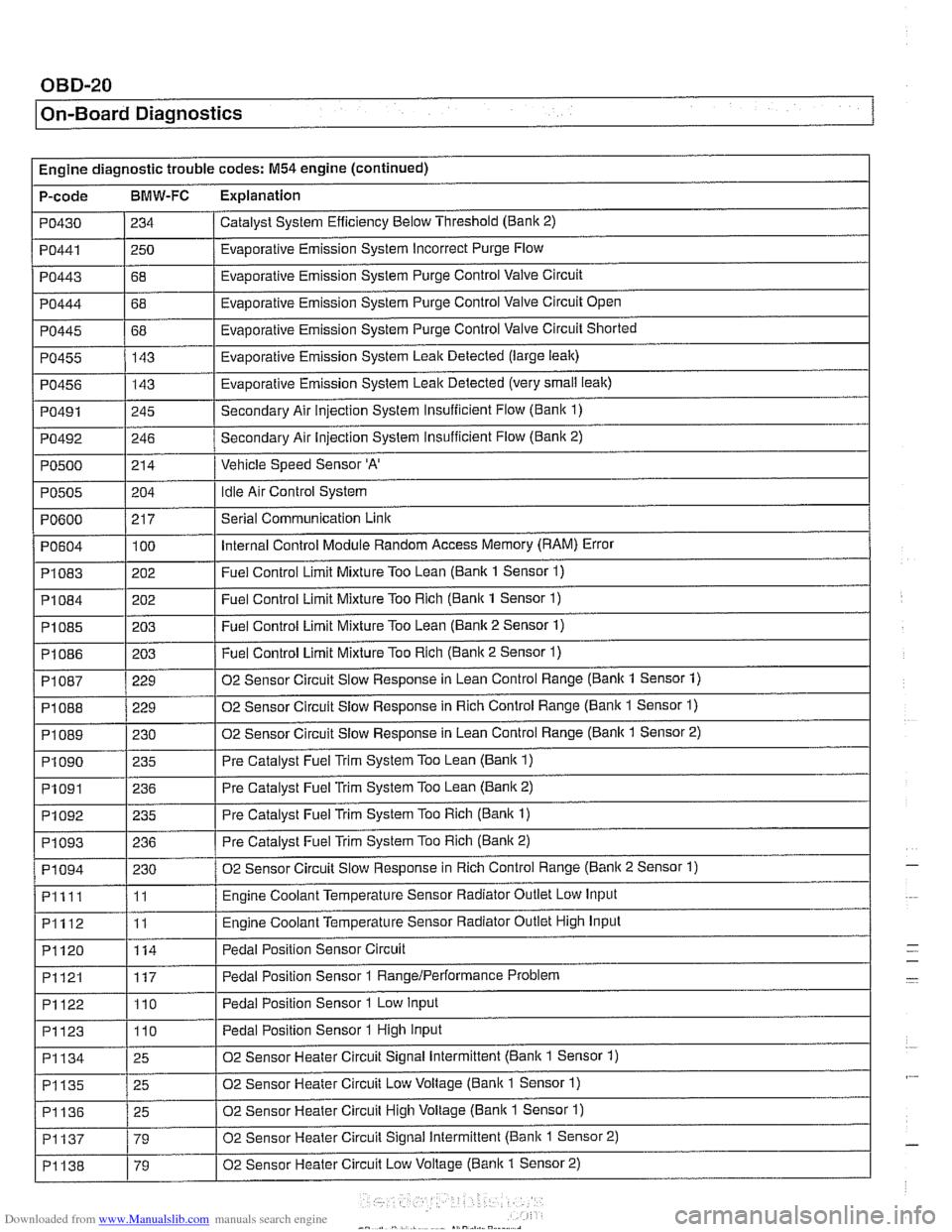

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

Catalyst System Efficiency Below Threshold (Bank 2)

PO430

PO443

PO444

PO445

PO455

PO456

PO491

PO492

PO500

PO441 1250 / Evaporative Emission System Incorrect Purge Flow

234

I I

68

68

68 143

143

245

246

214

PO604

PI083

PI084

PI085

PI086

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purge Control Valve Circuit Open

Evaporative Emission System Purge Control Valve Circuit Shorted

Evaporative Emission System Leak Detected (large leak)

Evaporative Emission System Leak Detected (very

small leak)

Secondary Air injection System Insufficient Flow (Bani( 1)

Secondary Air Injection System insufficient Flow

(Banic 2)

Vehicle Speed Sensor

'A'

Idle Air Control System PO505

.

PI 087

PI 088

PI089

PI090

PO600 / 217 I Serial Communication Link

204

100

202

202

203

203

PI091

PI092

PI093

PI094

Pllll

PI112

PI120

Internal Control Module Random Access Memory (RAM) Error

Fuel Control Limit Mixture Too Lean (Bank 1 Sensor

1)

Fuel Control Limit Mixture Too Rich (Bank 1 Sensor 1)

Fuel Control Limit Mixture Too Lean (Bank 2 Sensor 1)

Fuel Control Limit Mixture Too Rich (Banic 2 Sensor 1) ~ ~

229

229

230 235

PI121

PI122

PI123

02 Sensor Circuit Slow Response in Lean Control Range (Bank 1 Sensor 1)

02 Sensor Circuit Slow Response in Rich Control Range (Bank 1 Sensor

1)

02 Sensor Circuit Slow Response in Lean Control Range (Banlc 1 Sensor 2)

Pre Catalyst Fuel Trim System Too Lean

(Bank 1)

236

235

236

230

11

11

114

PI134

PI135

PI136

PI137

PI138

Pre Catalyst Fuel Trim System Too Lean (Banic 2)

Pre Catalyst Fuel Trim System Too Rich

(Bank 1)

Pre Catalyst Fuel Trim System Too Rich (Bank 2)

02 Sensor Circuit Slow Response in Rich Control Range (Banic 2 Sensor 1)

Engine Coolant Temperature Sensor Radiator Outlet Low Input

Engine Coolant Temperature Sensor Radiator Outlet High Input

Pedal Position Sensor Circuit

117

110

110

25

25

25

79

79 Pedal Position Sensor 1

RangeIPerformance Problem

Pedal Position Sensor 1 Low Input

Pedal Position Sensor 1 High Input

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 1)

02 Sensor Heater Circuit Low Voltage (Bank 1 Sensor

1)

02 Sensor Heater Circuit High Voltage (Bank 1 Sensor 1)

02 Sensor Heater Circuit Signal Intermittent (Bank 1 Sensor 2)

02 Sensor Heater Circuit Low Voltage

(Banic 1 Sensor 2)

-

-

Page 987 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

I I

PO340 1113 I Camshaft Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

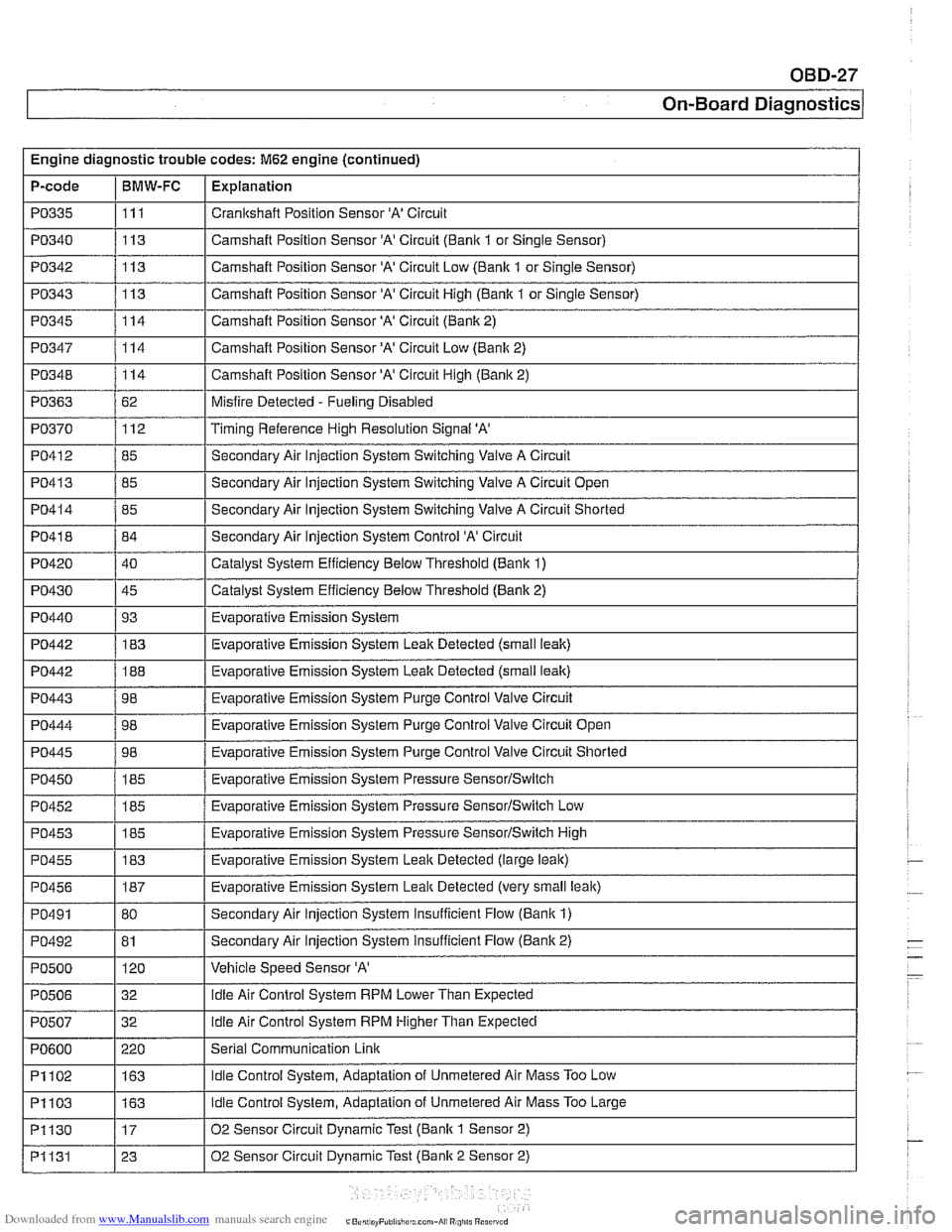

Engine

diagnostic trouble codes:

M62 engine (continued)

P-code

PO342

PO343

PO345

PO347

PO348

PO363

PO370

PO41 2

PO335 I111 I Crankshaft Position Sensor 'A' Circuit

BMW-FC

I I -

I I -

PO445 1 98 1 Evaporative Emission System Purge Control Valve Circuit Shorted

Explanation

113

113

114

114

114

62 112

85

PO41 3

PO41 8

PO420

PO430

PO440

PO442

PO442

PO443

PO444

Camshaft Position Sensor 'A' Circuit Low (Bank 1 or Single Sensor)

Camshaft Position Sensor

'A' Circuit High (Bank 1 or Single Sensor)

Camshaft Position Sensor

'A' Circuit (Bank 2)

Camshaft Position

Sensor'A' Circuit Low (Bank 2)

Camshaft Position Sensor 'A' Circuit High

(Banic 2)

Misfire Detected

- Fueling Disabled

Timing Reference High Resolution Signal

'A'

Secondary Air lniection System Switchinq Valve A Circuit

PO41 4 / 85 I Secondary Air Injection System Switching Valve A Circuit Shorted

85

84

40

45 93 183

188

98

98

PO450

PO452

PO453

PO455

PO456

PO491

PO492

PO500

PO506

I I

PI102 1163 I Idle Control System, Adaptation of Unmetered Air Mass Too Low

Secondary

Air Injection System Switching Valve A Circuit Open

Secondary Air Injection System Control

'A' Circuit

Catalyst System Efficiency Below Threshold (Bank 1)

Catalyst System Efficiency

Below Threshold (Bank 2)

Evaporative Emission System

Evaporative Emission System Leak Detected (small

leak)

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Evaporative Emission System Purqe Control Valve Circuit Open

I

I

185

185

185

183

187

80

81 120

32

PO507

Evaporative Emission System Pressure SensorISwitch

Evaporative Emission System Pressure SensorISwitch Low

Evaporative Emission System Pressure

SensorISwitch High

Evaporative Emission System

Leaic Detected (large leak)

Evaporative Emission System

Leal$ Detected (very small leak)

Secondary Air Injection System Insufficient Flow (Bank

1)

Secondary Air Injection System insufficient Flow (Bank 2)

Vehicle Speed Sensor

'A'

idle Air Control System RPM Lower Than Expected

PI103

PI130

PI131

PO600 1 220 I Serial Communication Link

32

idle Air

Control System RPM Higher Than Expected

163

17

23

Idle Control System, Adaptation of Unmetered Air Mass Too Large

02 Sensor Circuit Dynamic Test (Bank

1 Sensor 2)

02 Sensor Circuit Dynamic Test (Bank 2 Sensor 2)