Idle BMW 528i 1999 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 528i, Model: BMW 528i 1999 E39Pages: 1002

Page 429 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

Fuel Injection

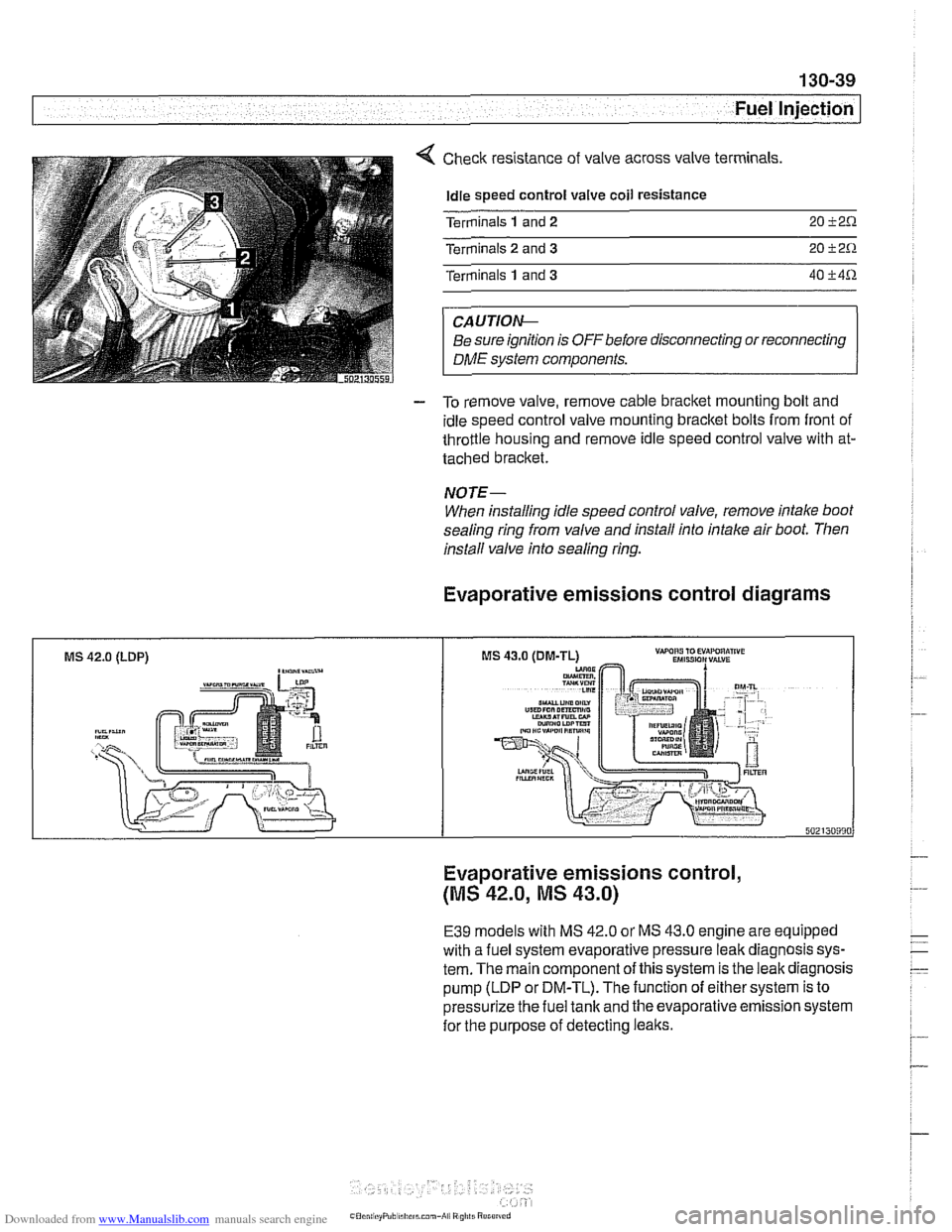

Check resistance of valve across valve terminals

Idle speed control valve coil resistance

Terminals

1 and 2 20 i2.0.

Terminals 2 and 3 20 i2.0.

Terminals 1 and 3 40 i4.0.

CAUTIOIG

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

- To remove valve, remove cable bracket mounting bolt and

idle speed control valve mounting bracket bolts from front of

throttle housing and remove idle speed control valve with at-

tached bracket.

NOTE-

When installing idle speed control valve, remove intake boot

sealing ring from valve and install into intake air boot. Then

install valve info sealing

ring.

Evaporative emissions control diagrams

MS 42.0 (LDP) ,-a"-

Evaporative emissions control,

(MS 42.0, MS 43.0)

E39 models with MS 42.0 or MS 43.0 engine are equipped

with a fuel system evaporative pressure leak diagnosis sys-

tem. The main component of this system is the leak diagnosis

pump (LDP or DM-TL). The function of either system is to

pressurize the fuel tank and the evaporative emission system

for the purpose of detecting leaks.

Page 434 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

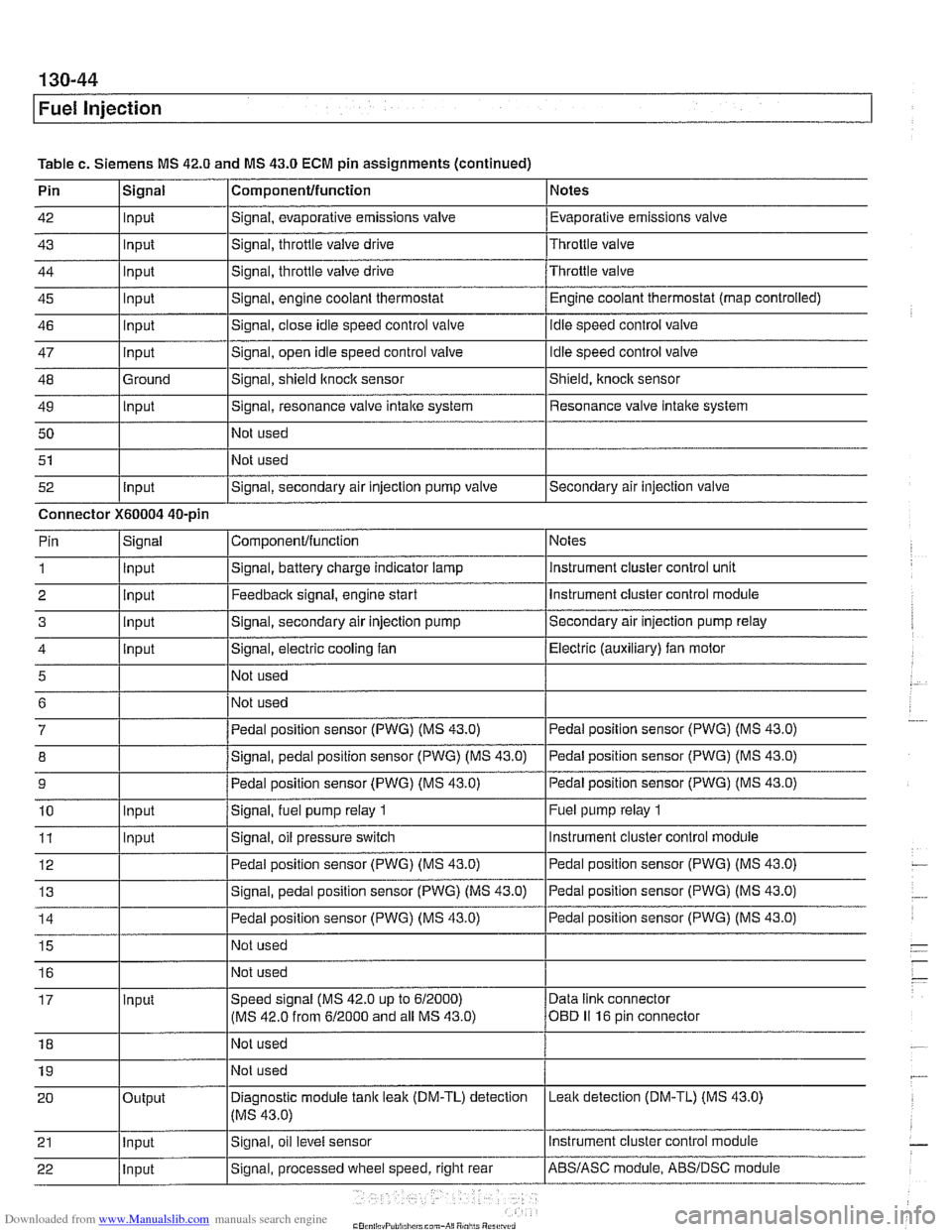

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments (continued)

Pin

42

43

44

45

46

47

48

49 50

51

52 Componentlfunction

Signal, evaporative emissions valve

Signal, throttle

valve drive

Signal, throttle valve drive

Signal, engine coolant thermostat

Signal, close idle speed control valve

Signal, open idle speed control valve

Signal, shield

ltnock sensor

Signal, resonance valve

intake system

Not used

Not used

Signal, secondary air injection pump valve

Signal

Input

Input

Input

Input

input

Input

Ground

Input

Input

Notes

Evaporative emissions valve

Throttle valve

Throttle valve Engine coolant thermostat (map controlled)

idle speed control valve

Idle speed control valve

Shield,

knock sensor

Resonance valve intake system

Secondary air injection valve

Connector

X60004 40-pin Notes

instrument cluster control unit

Instrument cluster control module

Secondary air injection pump relay

Electric (auxiliary) fan motor

Pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Fuel pump relay

1

Instrument cluster control module

ComponenVfunction

Signal, battery charge indicator lamp

Feedback signal, engine start

Signal, secondary air injection pump

Signal, electric cooling fan

Not used

Not used

Pedal position sensor (PWG) (MS 43.0)

Signal, pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Signal,

fuel pump relay 1

Signal, oil pressure switch

Pin

1

2 3

4

5

6

7

8

9

10

11 Signal

Input

Input

input

input

Input

Input

Page 437 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

M5.2 system features

The Bosch M5.2 system used on 1997 540i models uses an

88-pin control unit. The

M5.2 system has the following func-

tions and capabilities:

Fully sequential cylinder-individual fuel injection.

Integrated adaptive knock control.

Oxygen sensor fuel mixture control.

0 Self-diagnosis and emergency operation characteristics.

CAN-Bus link.

0 OED II functions (misfire detection, catalytic converter

monitoring, oxygen sensor monitor, and fuel tank ventila-

tion system).

Electronic vehicle immobilization via EWS.

One-touch starter function.

Control of characteristic map thermostat.

M5.2.1 system features

The Bosch M5.2.1 system is used on 1998 540i models. The

M5.2.1 control module utilizes the SKE (standard shell con-

struction housing) with 5 connectors and a combined total of

134 pins.

The M5.2.1 systefn has

tile following functions or capabilities:

Separate power supply relay for ignition coils. Leak diagnosis pump (LDP) control and feedback

rnonitor-

ing for evaporative system leak testing.

Fuel evaporative system providing ORVR (on-board refuel-

ing vapor recovery) compliancy.

Batterylalternator charge logic (idle speed varied with the

battery state of charge).

CAN-Bus communications with the instrument cluster

EWS

Ill "rolling code" ISN interface.

More sensitive ignition

knock sensors.

Pulse width modulated (P-W-M) Heating and

AIC (IHKA)

status signal.

Running loss (312-way) solenoid valve.

Page 439 of 1002

Downloaded from www.Manualslib.com manuals search engine

- Fuel Injection

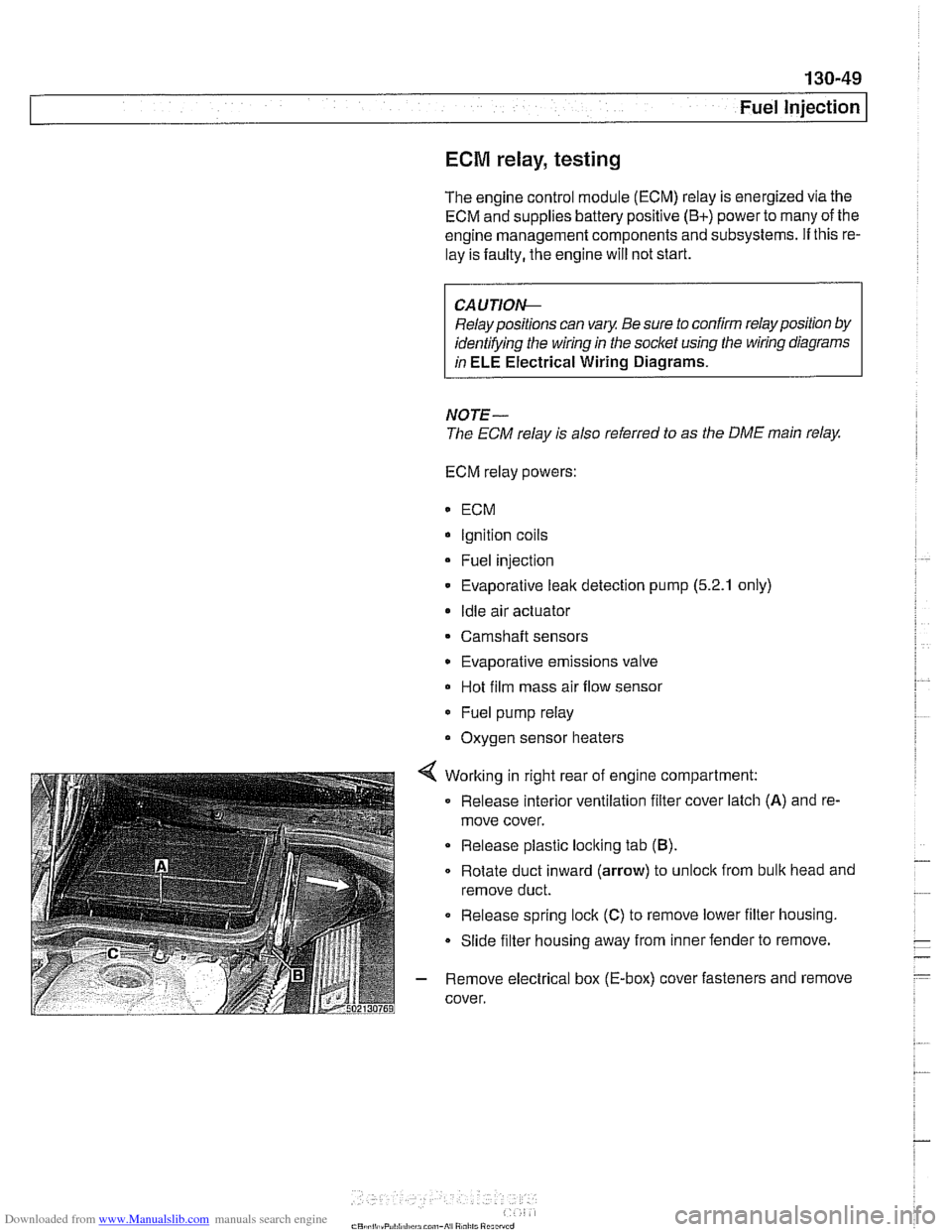

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine

management components and subsystems. If this re-

lay is faulty, the engine will not start.

CAUTIOI\C

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring

in the socket using the wiring diagrams

in ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.

ECM relay powers:

* ECM

Ignition coils

Fuel injection

Evaporative leak detection pump

(5.2.1 only)

Idle air actuator

Camshaft sensors Evaporative emissions valve

Hot film mass air flow sensor

Fuel pump relay

Oxygen sensor heaters

4 Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unloclc from bulk head and

remove duct.

0 Release spring lock (C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

Page 441 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-51

Fuel Injection

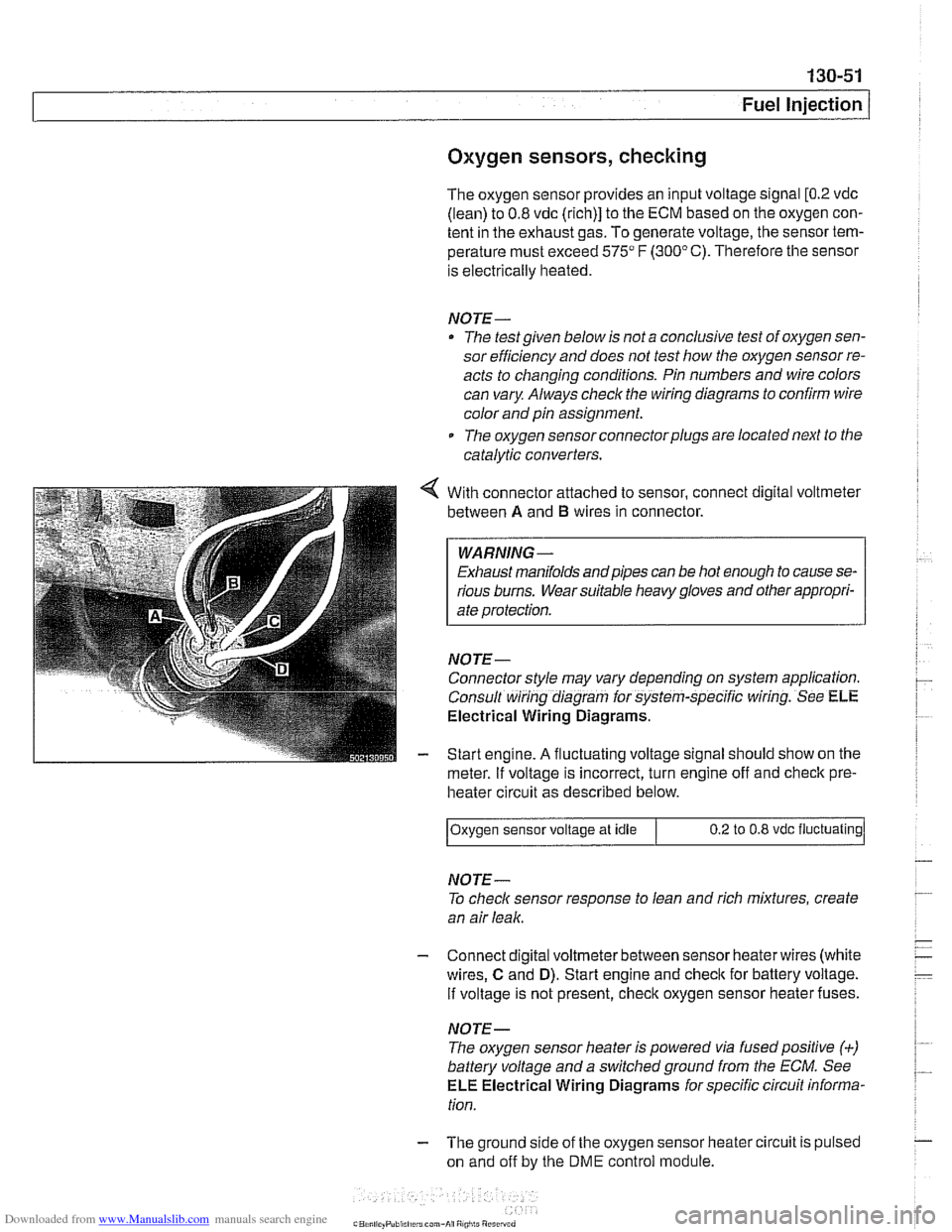

Oxygen sensors, checking

The oxygen sensor provides an input voltage signal [0.2 vdc

(lean) to 0.8 vdc (rich)] to the

ECM based on the oxygen con-

tent in the exhaust gas. To generate voltage, the sensor tem-

perature must exceed 575"

F (300" C). Therefore the sensor

is electrically heated.

NO JE -

The test given below is not a conclusive test of oxygen sen-

sor efficiency and does not test how the oxygen sensor re-

acts to changing conditions. Pin numbers and wire colors

can vary Always check the wiring diagrams to confirm wire

color and pin assignment.

0 The oxygen sensorconnectorplugs are locatednext to the

catalytic converters.

With connector attached to sensor, connect digital voltmeter

between

A and B wires in connector.

WARNING -

Exhaust manifolds andpipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

NOJE-

Connector style may vary depending on system application.

Consult wiring diagram for system-specific wiring. See

ELE

Electrical Wiring Diagrams.

Start engine.

A fluctuating voltage signal should show on the

meter.

If voltage is incorrect, turn engine off and check pre-

heater circuit as described below.

NOJE-

To check sensor response to lean and rich mixtures, create

an air leak.

Oxygen sensor

voltage at idle

- Connect digital voltmeterbetween sensor heaterwires (white

wires,

C and D). Start engine and check for battery voltage.

If voltage is not present, check oxygen sensor heater fuses.

0.2 to 0.8 vdc fluctuating

NOJE-

The oxygen sensor heater is powered via fusedpositive (+)

battery voltage and a switchedground from the ECM. See

ELE Electrical Wiring Diagrams for specific circuit informa-

tion.

- The ground side of the oxygen sensor heater circuit is pulsed

on and off by the

DME control module.

Page 444 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-54

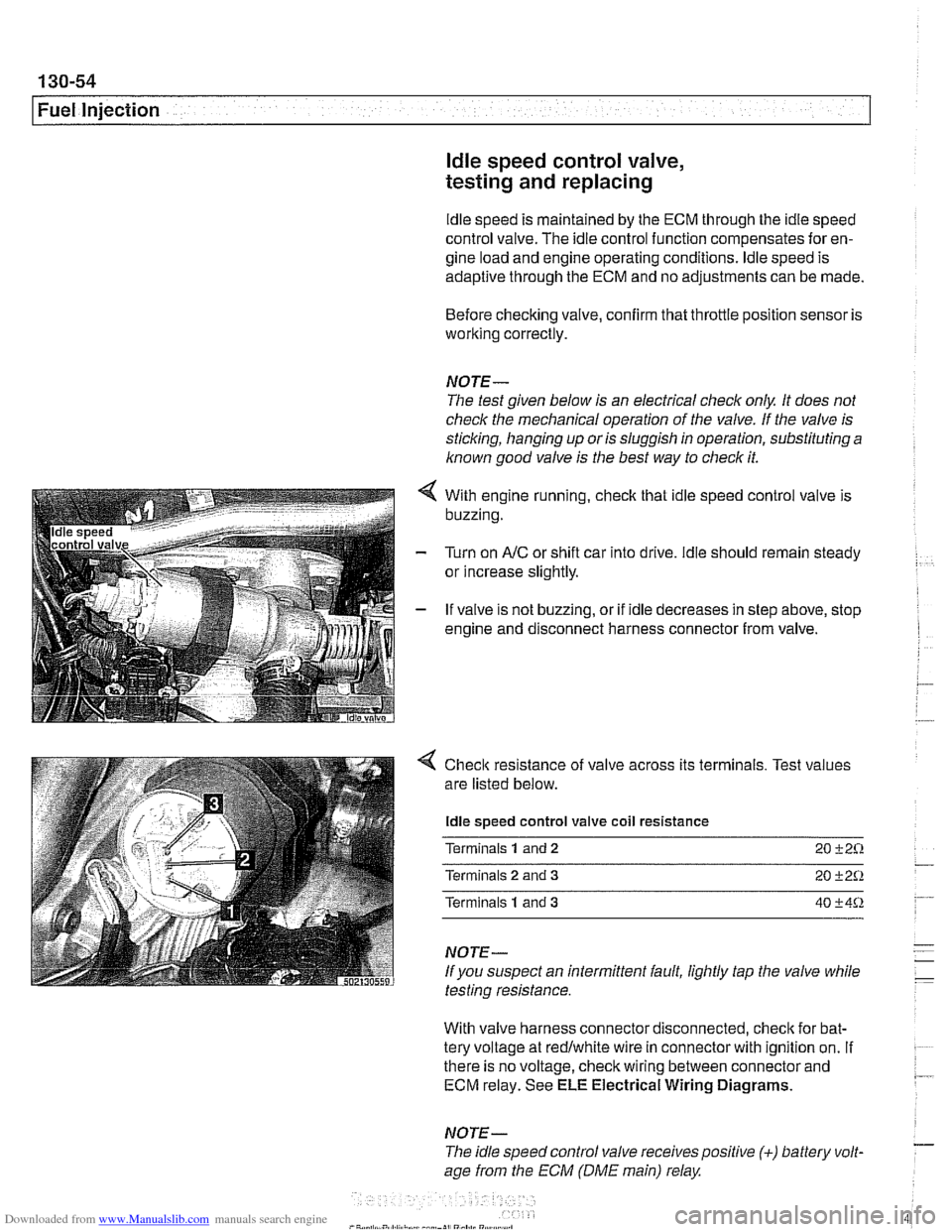

I Fuel Injection ldle speed control valve,

testing and replacing

ldle speed is maintained by the ECM through the idle speed

control valve. The idle control function compensates for en-

gine load and engine operating conditions. ldle speed is

adaptive through the ECM and no adjustments can be made.

Before checking valve, confirm that throttle position sensor is

working correctly.

NOTE-

The test given below is an electrical check only. It does not

check the mechanical operation of the valve. If the valve is

sticking, hanging up or is sluggish in operation, substituting a

Inown good valve is the best way to check it.

With engine running, check that idle speed control valve is

buzzing.

Turn on

AIC or shift car into drive. ldle should remain steady

or increase slightly.

If valve is not buzzing, or if idle decreases in step above, stop

engine and disconnect harness connector from valve.

4 Check resistance of valve across its terminals. Test values

are listed below.

ldle speed control valve coil resistance

Terminals

1 and 2 20 +2%

Terminals 2 and 3 20 +2Q

Terminals 1 and 3 40 +4%

NOTE-

If you suspect an intermittent fault, lightly tap the valve while

testing resistance.

With valve harness connector disconnected, check for bat-

tery voltage at redlwhite wire in connector with ignition on.

If . ~~ ~~

there is no voltage, check wiring between connector and 7 ECM relay. See ELE Electrical Wiring Diagrams.

NOTE- - The idle speed control valve receivespositive (+) battery volt-

age from the ECM (DME main) relay

Page 445 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If voltage is present as described above, check wiring be-

tween ECM and valve. If no wiring faults are found, check

ECM signal to valve.

- When replacing idle speed control valve, clean and inspect

all sealing areas.

. Inspect sealing ring in throttle body and replace if neces-

sary.

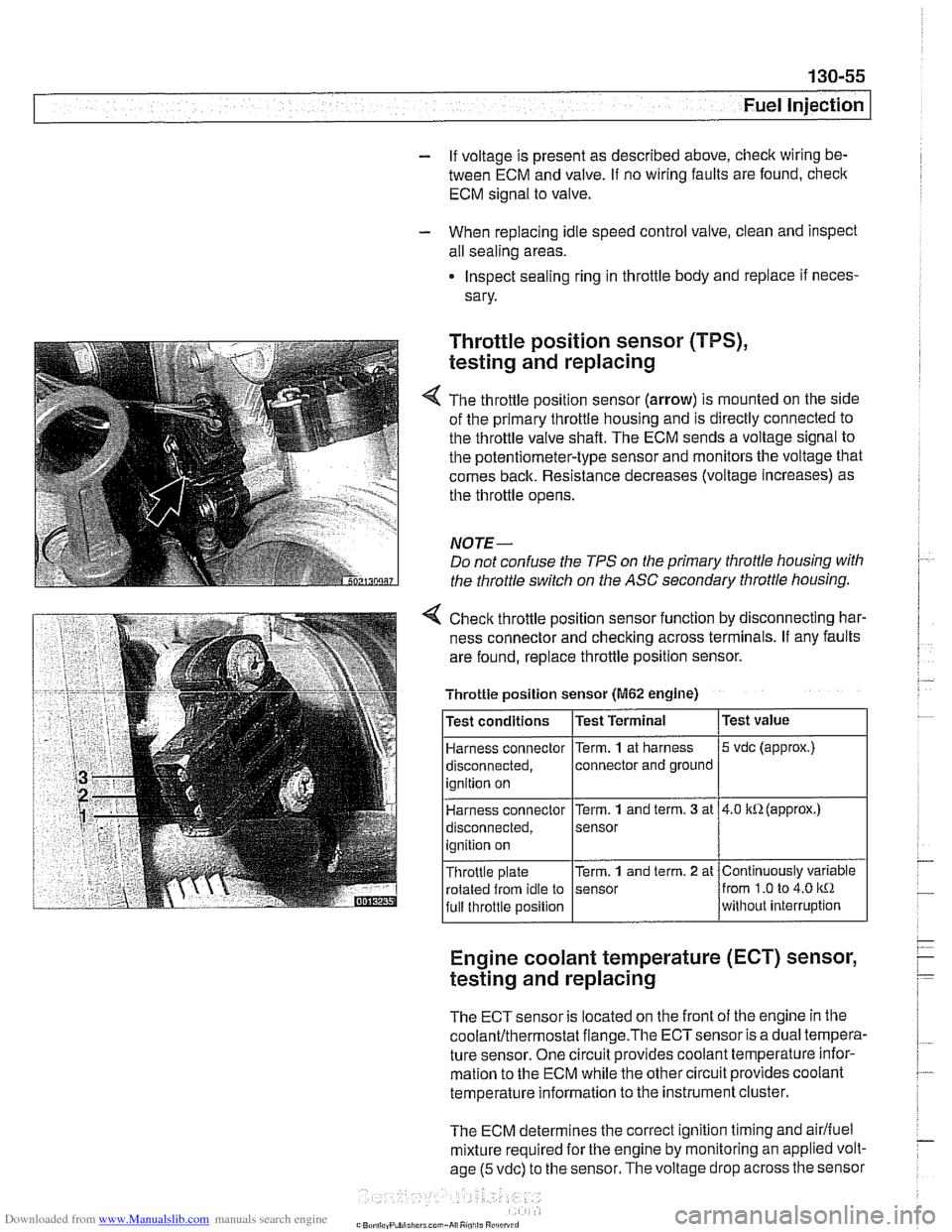

Throttle position sensor (TPS),

testing and replacing

The throttle position sensor (arrow) is mounted on the side

of the primary throttle housing and is directly connected to

the throttle valve shaft. The ECM sends a voltage signal to

the potentiometer-type sensor and monitors the voltage that

comes back. Resistance decreases (voltage increases) as

the throttle opens.

NOTE-

Do not confuse the TPS on the primary throttle housing with

the throttle switch on the

ASC secondary throttle housing.

4 Check throttle position sensor function by disconnecting har-

ness connector and checking across terminals. If any faults

are found, replace throttle position sensor.

Engine coolant temperature (ECT) sensor,

testing and replacing

Throttle position sensor (M62 engine)

The ECT sensor is located on the front of the engine in the

coolanVthermostat flange.The ECTsensor is a dual tempera-

ture sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

Test

value

5 vdc (approx.)

4.0 kR(approx.)

Continuously variable

from

1.0 to 4.0 kR

without interruption

Test

conditions

Harness connector

disconnected, ignition on

Harness connector

disconnected,

ignition on

Throttle plate rotated from idle to

full throttle position Test Terminal

Term.

1 at

harness

connector and ground

Term.

1 and term. 3 at

sensor

Term.

1 and term. 2 at

sensor

Page 447 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Intake air temperature

([AT) sensor,

testing and replacing

Disconnect harness connector from intake air temperature

sensor

(A) at air filter housing.

Turn ignition on. Using a digital voltmeter, check for

5 volts

between supply voltage wire in connector and ground.

If volt-

age is not present, test ECM

inputs/outputs as described lat-

er.

With harness connector disconnected, test resistance across

sensor terminals. If any faults are found, replace IAT sensor.

IAT test resistance

0 lV *lac (50" i-2°F) 7-1 1.6 k.0.

020' kl°C (68' 322°F) 2.1-2.9 it.0.

080" ?lac (176" i-2°F) 0.27-0.40 itn

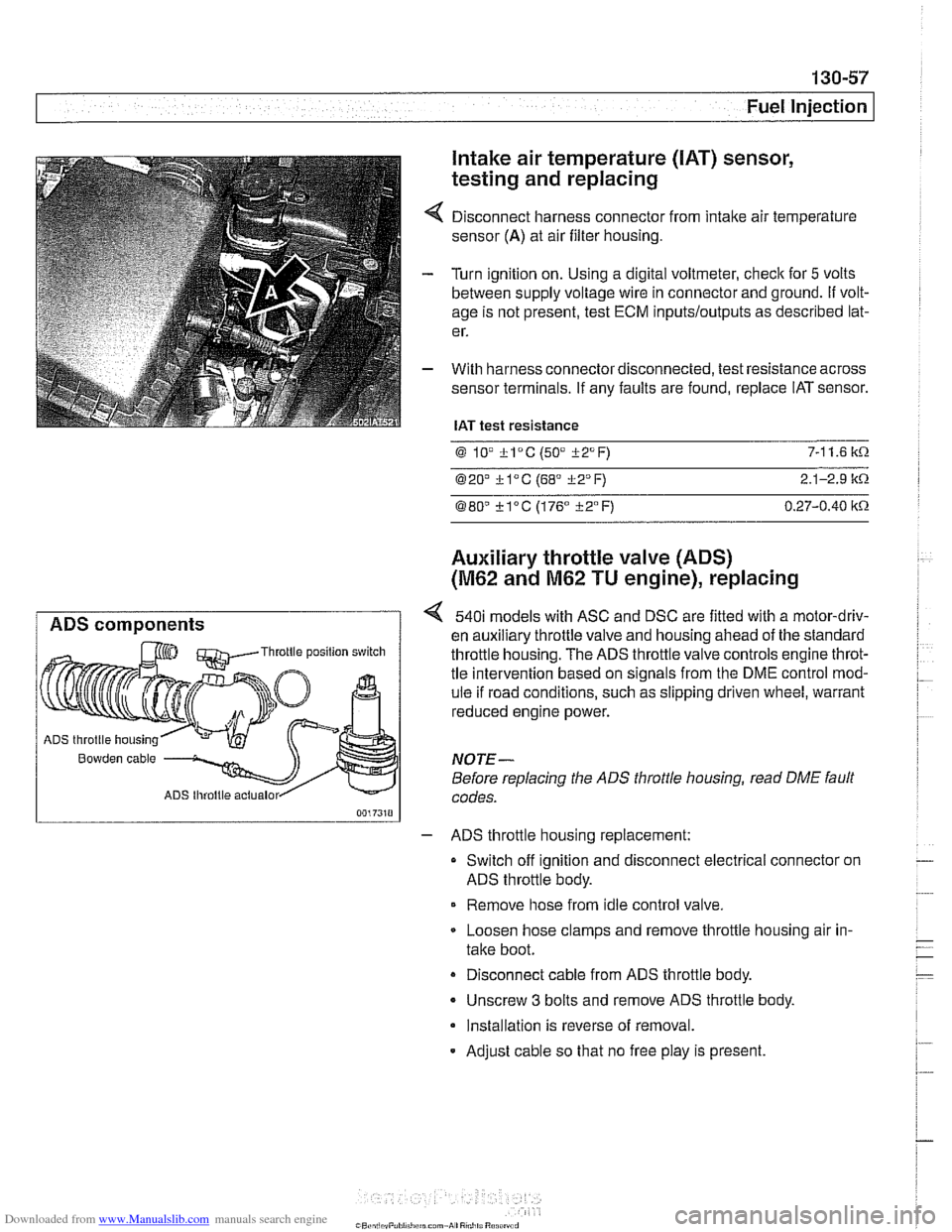

Auxiliary throttle valve (ADS)

(M62 and M62 TU engine), replacing

ADS components 540i models with ASC and DSC are fitted with a motor-driv-

en auxiliary throttle valve and housing ahead of the standard Throttle position switch throttle housing. The ADS throttle valve controls engine throt-

tle intervention based on signals from the DME control mod-

ule if road conditions, such as slipping driven wheel, warrant

reduced engine power.

ADS throttle housing

Bowden cable NOTE-

Before replacing the ADS throttle housing, read DME fault

ADS lhroltle actualor codes.

- ADS throttle housing replacement:

Switch off ignition and disconnect electrical connector on

ADS throttle body.

Remove hose from idle control valve.

Loosen hose clamps and remove throttle housing air in-

take boot.

Disconnect cable from ADS throttle body.

- Unscrew 3 bolts and remove ADS throttle body.

Installation is reverse of removal.

- Adjust cable so that no free play is present.

Page 448 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection Evaporative fuel system pressure leak

diagnosis, overview

(M5.2.1 only)

1998 540i models are equipped with an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leak diagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting

leaks. This sys-

tem is capable of detecting a leak as small as 0.5 mm.

The LDP, located in the left rear wheel housing, is a unitized

component that contains the following:

Vacuum chamber. Pneumatic pump chamber.

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

ECM).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is integrated into the LDP, which is

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C, purge valve always closed).

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

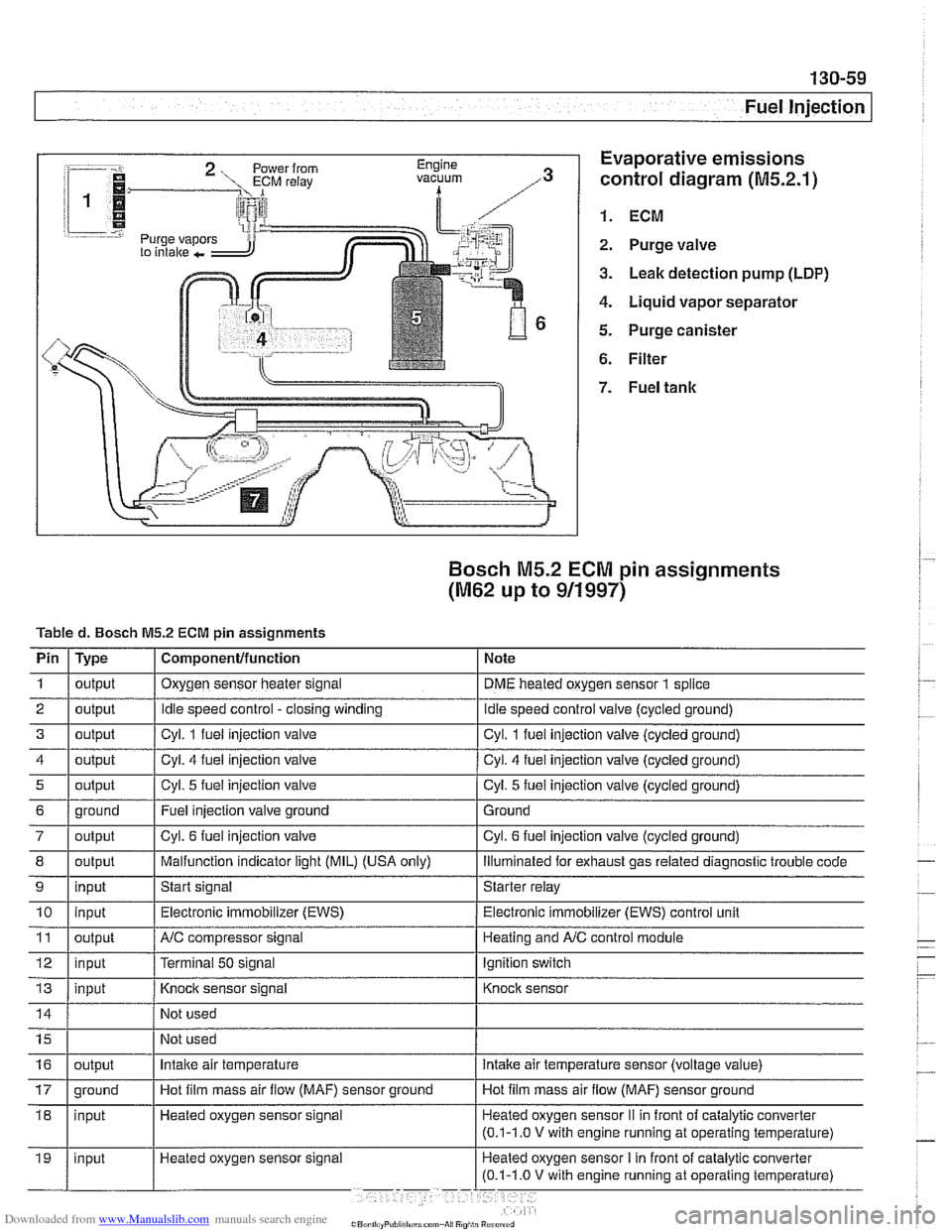

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)