Electric BMW 528i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 464 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-74

I Fuel Injection

Evaporative system pressure leak

diagnosis, overview

The M62 TU engine is equipped wlth an evaporative fuel sys-

tem pressure leak diagnosis system. The main component of

this system is the leakdiagnosis pump (LDP). The function of

the LDP is to pressurize the fuel tank and the evaporative

emission system for the purpose of detecting leaks.

This system iscapable of detecting a

lealcas small as0.5 mm.

The LDP, located in the left rear wheel housing, contains the

following:

Vacuum chamber. Pneumatic pump chamber

DME activated vacuum solenoid

Reed switch (provides switched voltage

feedback signal to

DME).

The vacuum supply line is in the wiring harness from the en-

gine compartment and runs down the driver's side of the vehi-

cle.

The canister vent valve is

~ntegrated into the LDP, which IS

electrically controlled by the ECM. The canister vent valve is

opened to provide fresh air entry into the fuel system only dur-

ing purge operation.

- Purge operation characteristics:

Off idle through full throttle: purge valve opened by pulse

width modulated (PWM) control of the ECM. PWM duty cy-

cle varies by engine operating conditions

(e.g. warm idle,

purge valve opened slightly; cold

idleldecel with engine

temp

< 67" C. purge valve always closed).

Page 465 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-75

Fuel Injection

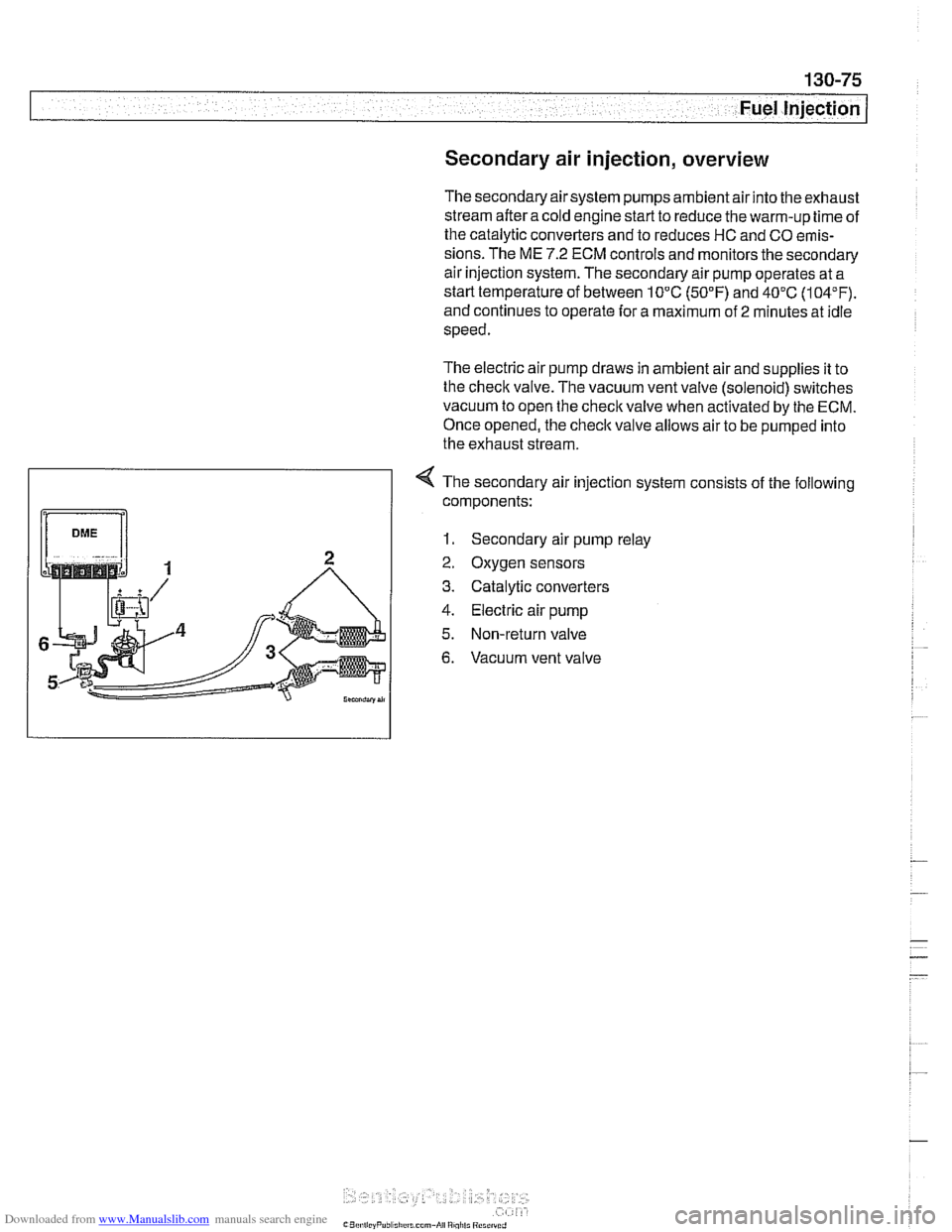

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afteracoid engine start to reduce the warm-up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ME

7.2 ECM controls and monitors the secondary

air injection system. The secondary air pump operates at a

starttemperature of between 10°C

(50°F) and 40°C (104°F).

and continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the

checlc valve. The vacuum vent valve (solenoid) switches

vacuum to open the

checlc valve when activated by the ECM.

Once opened, the checlc

valve allows air to be pumped into

the exhaust stream.

4 The secondary air injection system consists of the following

components:

1. Secondary air pump relay

2. Oxygen sensors

3. Catalytic converters

4. Electric air pump

5. Non-return valve

6. Vacuum vent valve

Page 467 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lnjection

I 1- I

4 /output l~em~erature signal. E-box fan I E-box fan

Connector

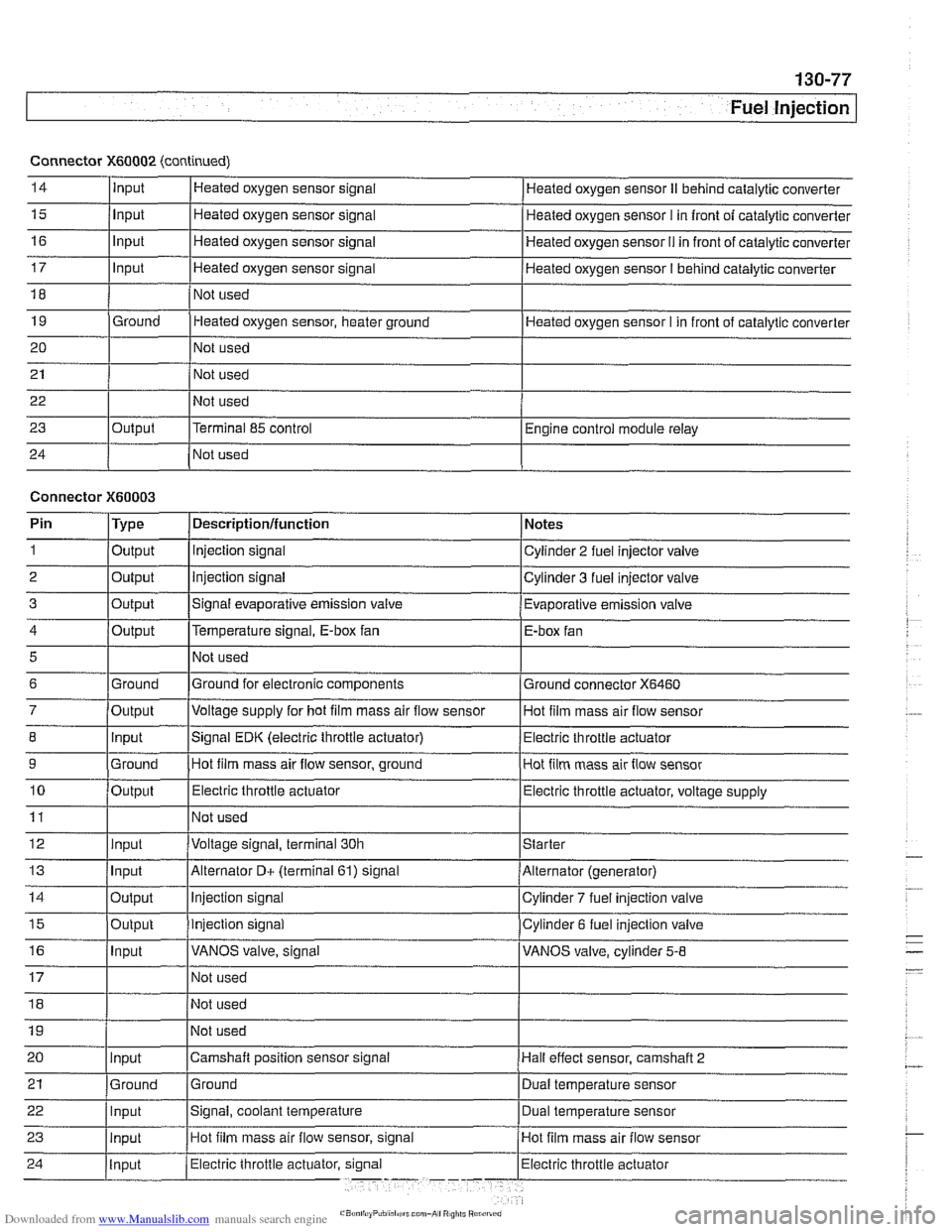

X60002 (continued)

14

15

16

17

18

19

20

21

22

23

24

5

6

7

8

9

10

11

12

13

14

15

16

Input

Input

Input

Input

Ground

Output Heated

oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Heated oxygen sensor signal

Not used

Heated oxygen sensor, heater ground

Not used

Not used

Not used

Terminal 85 control

Not used Heated oxygen sensor

II behind catalytic converter

Heated oxygen sensor

I in front of catalytic converter

Heated oxygen sensor

I1 in front of catalytic converter

Heated oxygen sensor

I behind catalytic converter

Heated oxygen sensor I in front of catalytic converter

Engine control module relay

Connector

X60003

Ground

Output Input

Ground

Output

Input

Input

Output

Output

Input

Pin 1

2

3

Not used

Ground for electronic components

Voltage supply for hot

film mass air flow sensor

Signal EDK (electric throttle actuator) Hot film mass air flow sensor, ground

Electric throttle actuator

Not used

Voltage signal, terminal 30h

Alternator

D+ (terminal 61) signal

Injection signal

Injection signal

VANOS valve, signal

Type

Output

Output

Output

Ground connector

X6460

Hot film mass air flow sensor

Electric throttle actuator

Hot film mass air flow sensor

Electric throttle actuator, voltage supply

Starter

Alternator (generator)

Cylinder

7 fuel injection valve

Cylinder 6 fuel injection valve

VANOS valve, cylinder

5-8

Descriptionlfunction

Injection signal

Injection signal

Signal evaporative emission valve Notes

Cylinder 2 fuel injector valve

Cylinder 3 fuel injector valve

Evaporative emission valve

Page 468 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

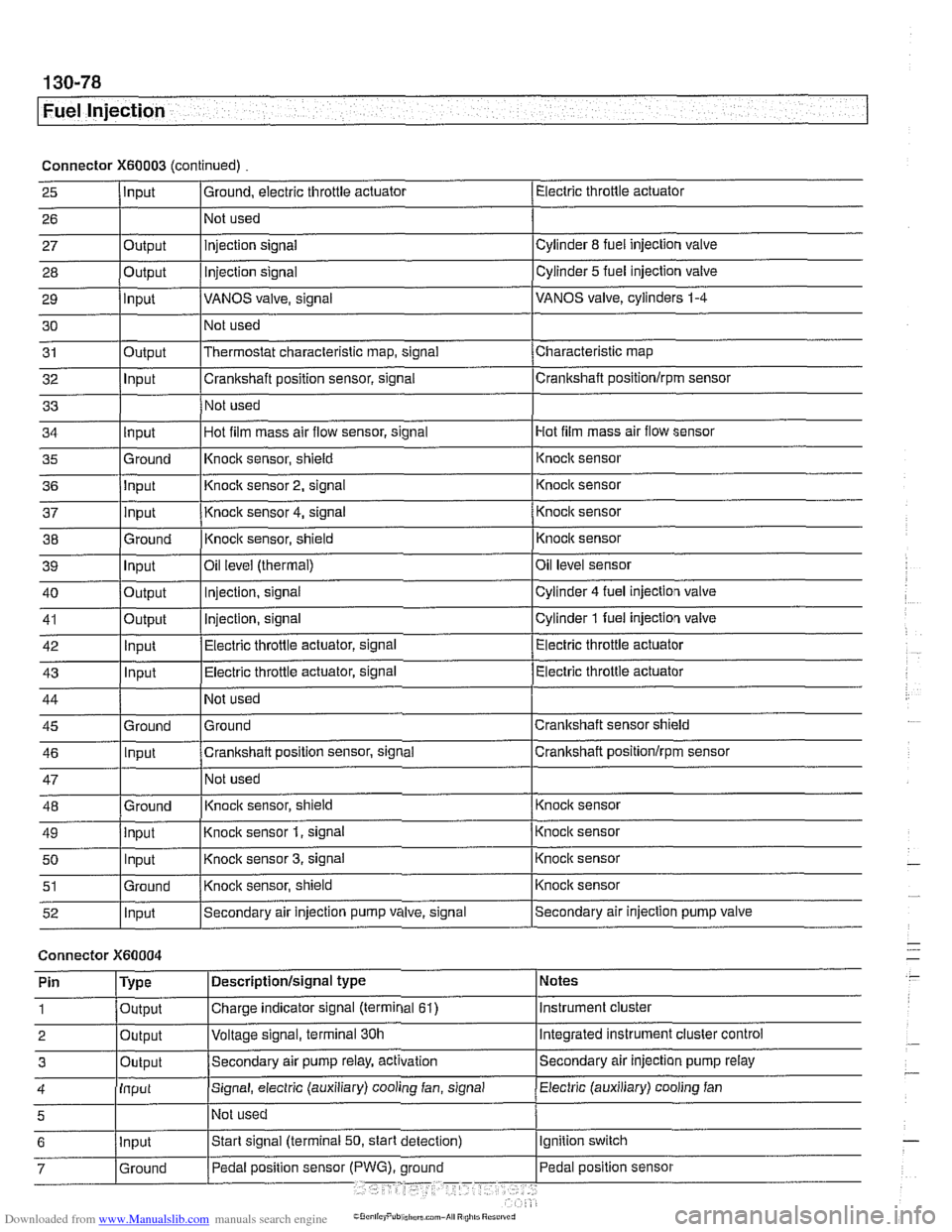

Connector X60003 (continued) Electric throttle actuator

25

- 27 28

29

30

31

32

33

I I I

36 jlnput I Knoclc sensor 2, signal 1 Knock sensor

I I I

Input

26

Output

Output

input

Output

Input

I ' I . I

43 1 ln~ut I Electric throttle actuator, signal (Electric throttle actuator

Ground, electric throttle actuator

1 Not

used

Hot film mass air flow sensor

34

- 37

38

39

40

41

42

injection signal

Injection

signal

VANOS valve, signal

Not used

Thermostat characteristic map, signal

Crankshaft position sensor, signal

Not used

35 l~round I~nock sensor, shield 1 ~nock sensor

Cylinder

8 fuel injection valve

Cylinder

5 fuel injection valve

VANOS valve, cylinders

1-4

Characteristic map

Crankshaft positionlrpm sensor

input

input

Ground

Input

Output

Output

Innut

Hot film mass air flow sensor, signal

I

44

45 46

47

48

49

50

51

52

Connector )(GO004

Knock sensor 4, signal

Knock sensor, shield

Oil

level (thermal)

Injection, signal

Injection, signal

Electric throttle actuator, signal

Not used

Ground

Crankshaft position sensor, signal

Not used

Knoclc sensor, shield

Knock sensor

1, signal

Knock sensor

3, signal

Knock sensor, shield

Secondary air injection pump valve, signal

'

Ground

Input

Ground

input Input

Ground

Input

I' I ... I . ~

Knock sensor

Knocic sensor

Oil level sensor

Cylinder

4 fuel injection valve

Cylinder

1 fuel injection valve

Electric throttle actuator

Crankshaft sensor shield

Crankshaft

positionlrprn sensor

Knock sensor

Knock sensor

Knock sensor

Knock sensor

Secondary air injection pump valve

Notes

Instrument cluster

Integrated instrument cluster control

Secondary air injection pump

relay

Pin

1

2

3

Electric (auxiliary) cooling fan 4

Type

Output

Output

Outout

Descriptionlsignal type

Charge indicator signal (terminal

61)

Voltage signal, terminal 30h

Secondam air pump relay, activation

Input

5

Signal, electric (auxiliary) cooling fan, signal

I~ot used

Page 471 of 1002

Downloaded from www.Manualslib.com manuals search engine

160 Fuel Tank and Fuel Pump

General ........................... .I6 0.2

Special tools ........................ .I6 0.2

Fuel pump ......................... .I6 0.3

Fuel tank evaporative control system ..... .I6 0.3

Evaporative system troubleshooting ..... .I6 0.4

Warnings and cautions ................ .I6 0.5

Fuel System Troubleshooting ...... .I6 0.6

Fuel pump fuse and relay .............. .I6 0.6

Operating fuel pump for tests ........... .I6 0.6

Fuel pump electrical circuit, testing ...... .I6 0.7

Fuel pump power consumption, testing ... .I6 0.9

Fuel pressure gauge, installing

(6-cylinder models)

................. .I6 0.1 0

Fuel pressure gauge, installing

(V-8 models) ....................... .I6 0.1 1

Fuel delivery, testing ................ .I6 0.12

Fuel Pump and Fuel Level Sender . . 160-15

Fuel level sender (right side) and

fuel pump. removing and installing

...... 160-15

Fuel level sender (left side).

removing and installing

............... 160-17

Siphon pump. removing and installing .... 160-1 9

Fuel Tank and Fuel Lines .......... 160-20

Fuel tank. draining ................... 160-20

Fuel tank. removing and installing ....... 160-21

Fuel expansion tank. removing

and installing

....................... 160-23

Activated carbon canister I fuel tank

leak detection unit

(LDP or DMTL).

removing and installing ............... 160-24

Running losses (312-way) valve.

removing and installing

............... 160-24

Page 473 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

Fuel pump

The electric fuel pump is mounted in the fuel tank in tandem

with the right side fuel level sender. The fuel pump delivers

pressurized fuel to the fuel injection system.

A pressure regu-

lator maintains system pressure. The quantity of fuel supplied

exceeds demand, so excess fuel returns to the fuel tank via a

return line. See

130 Fuel Injection for more information.

NOTE-

Fuel pump removal procedures are given under Fuel level

sender (right side) and fuel pump, removing and install-

ing.

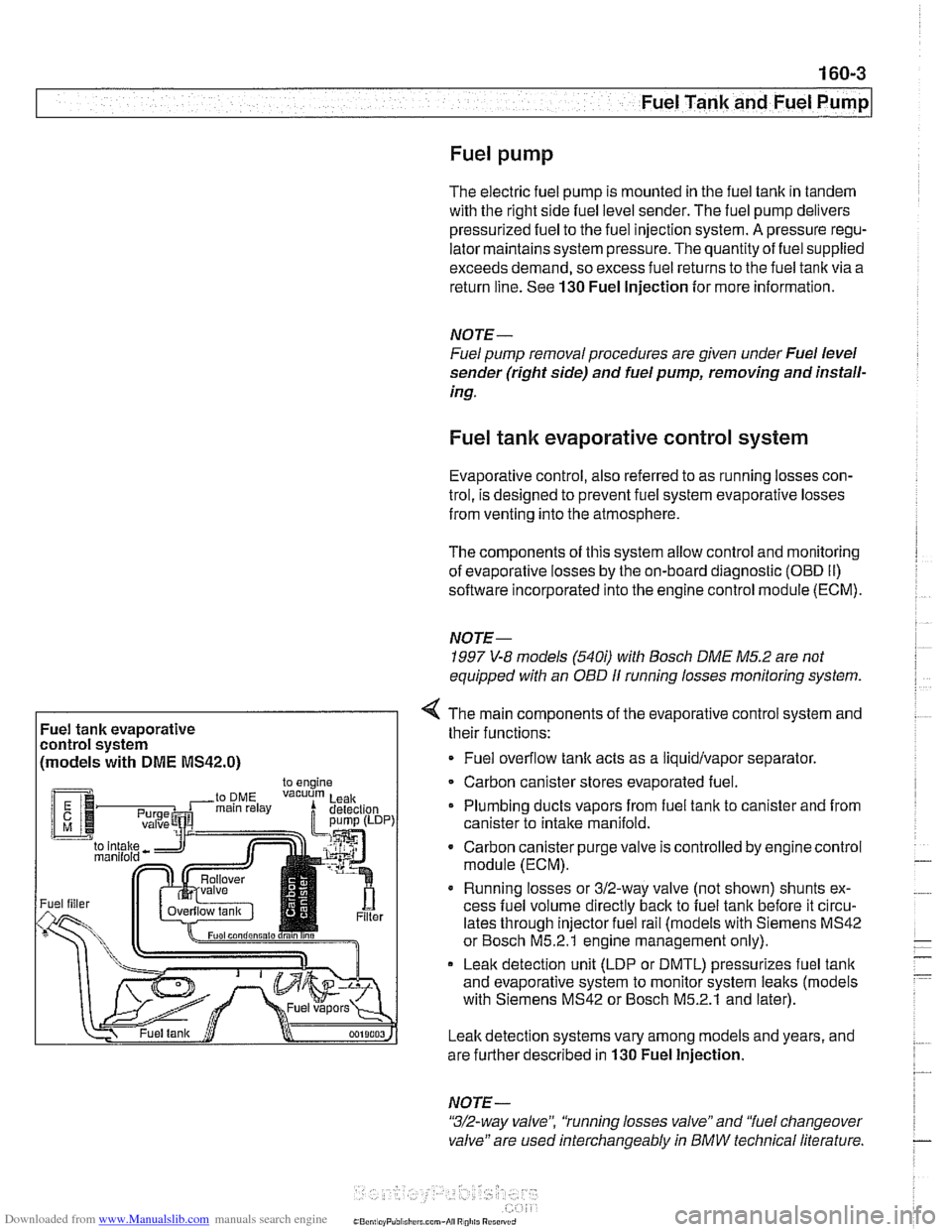

Fuel tank evaporative control system

Evaporative control, also referred to as running losses con-

trol, is designed to prevent fuel system evaporative losses

from venting into the atmosphere.

The components of this system allow control and monitoring

of evaporative losses by the on-board diagnostic

(OED II)

software incorporated into the engine control module (ECM).

NOTE-

1997 V-8 models (540i) with Bosch DME M5.2 are not

equipped with an

OBD I1 running losses monitoring system.

Fuel tank evaporative

control system

(models with

DME MS42.0)

4 The main components of the evaporative control system and

their functions:

Fuel overflow

tank acts as a liquidlvapor separator

Carbon canister stores evaporated fuel.

Plumbing ducts vapors from fuel tank to canister and from

canister to intake

manifold.

- Carbon canister purge valve is controlled by enginecontrol

module (ECM).

Running losses or 312-way valve (not shown) shunts ex-

cess fuel volume directly

back to fuel tank before it circu-

lates through injector fuel rail (models with Siemens MS42

or Bosch M5.2.1 engine management only).

Leak detection unit (LDP or DMTL) pressurizes fuel

tank

and evaporative system to monitor system leaks (models

with Siemens MS42 or Bosch M5.2.1 and later).

Leak detection systems vary among models and years, and

are further described in

130 Fuel Injection.

NOTE -

"3/2-way valve", 'tunning losses valve" and "fuel changeover

valve" are used interchangeably

in BMW technical literature.

Page 475 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

Warnings and cautions

Observe the following warnings and cautions when servicing

the fuel system.

WARNING-

* The fuel system is designed to retain pressure even when

the ignition is off. When working with the fuelsystem, loos-

en the fuel lines slowly to allow residual

fuel pressure to

dissipate. Avoid spraying fuel. Use shop rags to capture

leaking fuel.

Before beginning any work on the fuel system, place a

fire extinguisher in the vicinity of the work area.

Fuel is highly flammable. When working around fuel, do

not disconnect any wires that could cause electrical

sparks. Do not smoke or worknearheaters or other fire

hazards.

* Always unscrew the fuel tank cap to release pressure

in the

tanlc before working on the tank or lines.

When disconnecting a fuel hose, wrap shop rag around

end of hose to prevent spray of fuel under pressure.

Do not use a work light with an incandescent bulb near

any fuel. Fuel may spray on the hot bulb causing a fire.

0 Make sure the worlc area is properly ventilated.

CAUTION-

- Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions an4

Warnings.

Before

making any electrical tests with the ignition

turned on, disable the ignition system as described in

120 Ignition System. Be sure the battery is discon-

nected when replacing components.

To prevent damage to the ignition system or other DME

components, including the engine control module

(ECM), always connect and disconnect wires and test

equipment with the ignition off.

Cleanliness is essential when

worl~ing with the fuel sys-

tem. Thoroughly clean the fuel line unions before dis-

connecting any of the lines.

Use only clean tools. Keep removed parts clean and

sealed or covered with a clean, lint-free cloth, especial-

ly if completion of the repair is delayed.

Do not move the car while the fuel system is open.

Avoid using high pressure compressed air to blow out

lines and components. High pressure can rupture inter-

nal seals and gaskets.

Always replace seals, O-rings and hose clamps.

Page 476 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-- -

/ Fuel Tank and Fuel Pump - .. -. -- 1

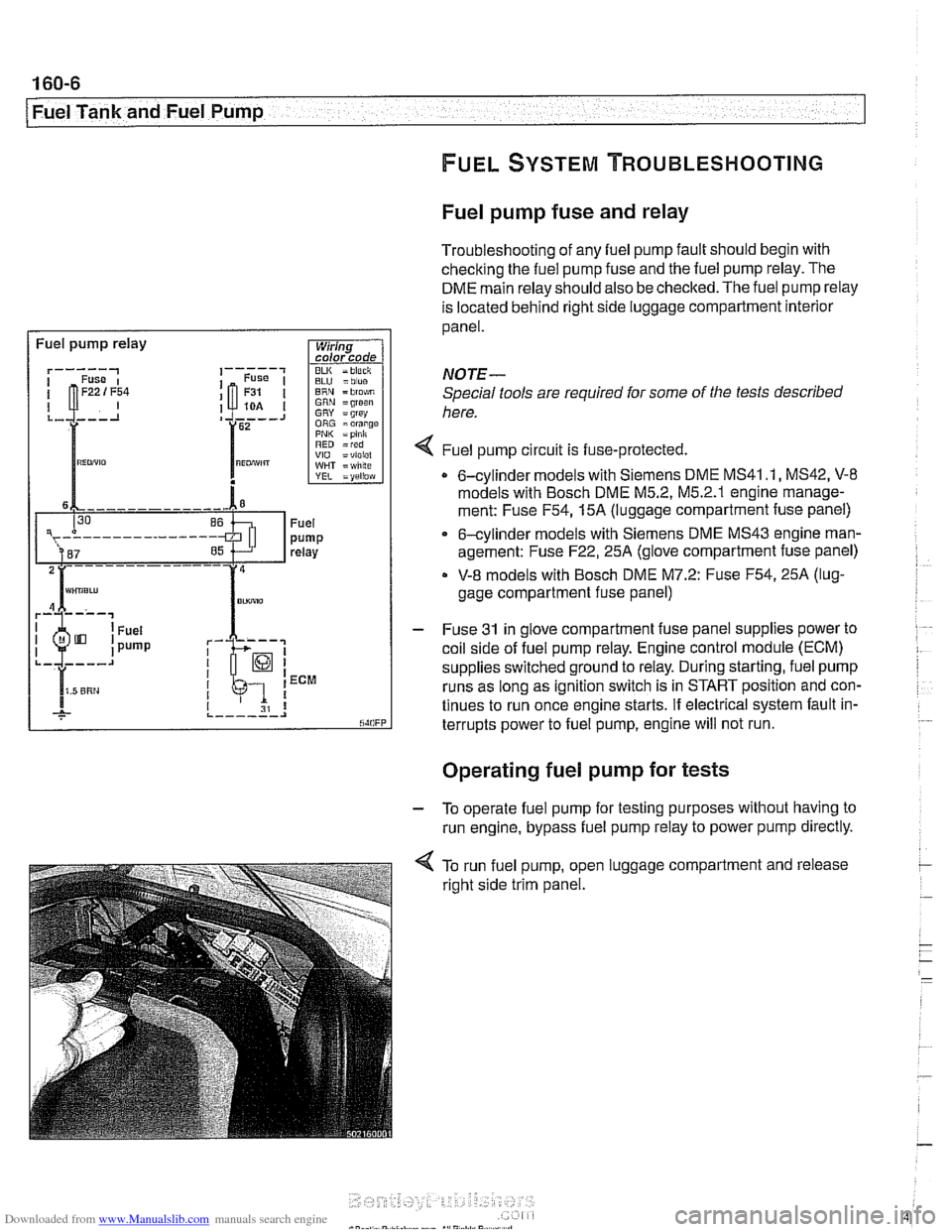

Fuel pump fuse and relay

Troubleshooting of any fuel pump fault should begin with

checking the fuel pump fuse and the fuel pump relay. The

DME main relay should also be checked. The fuel pump relay

is located behind right side luggage compartment interior

panel.

I Fuel pump relay

BLU =blue ERN = blo$,m GRN =groan GRY = grsy ORG =orange PNI< =pink RED =red VIO =violel WHT = wlilte

rk-; I I 1 ECM

I I I 31 8 ,._--___.I

NOTE-

Special tools are required for some of the tests described

here.

4 Fuel pump circu~t is fuse-protected.

0 6-cylinder models with Siemens DME MS41 .I, MS42, V-8

models with Bosch DME M5.2, M5.2.1 englne manage-

ment: Fuse

F54,15A (luggage compartment fuse panel)

6-cylinder models with Siemens DME MS43 engine man-

agement: Fuse

F22,25A (glove compartment fuse panel)

V-8 models with Bosch DME M7.2: Fuse F54,25A (lug-

gage compartment fuse panel)

- Fuse 31 in glove compartment fuse panel supplies power to

coil side of fuel pump relay. Engine control module (ECM)

supplies switched ground to relay. During starting, fuel pump

runs as long as ignition switch is in START position and con-

tinues to run once engine starts. If electrical system fault in-

terrupts power to fuel pump, engine will not run.

. .

Operating fuel pump for tests

- To operate fuel pump for testing purposes without having to

run engine, bypass fuel pump relay to power pump directly.

< To run fuel pump, open luggage compartment and release

right side trim panel.

Page 477 of 1002

![BMW 528i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi BMW 528i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi](/img/1/2822/w960_2822-476.png)

Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket terminal

2 (whitelblue wire) with a fused jumper wire.

After completing tests, remove jumper harness.

CA

UTIOG

Relay locations may vary Use care when identifying relays

and making electrical checks at

the fuse/relay panel. See

610 Electrical Component Locations for additional re-

lay information.

The fuel pump relay has a 1.5

md red/violet wire at

terminal

6 in the relay socket. Terminal2 has a 2.5md

white/blue wire. See ELE Electrical Wiring Diagrams

for additional wiring information.

NOTE-

* The fuel pump will run as soon as the jumper wire Is at-

tached.

The jumper wire should be 1.5

md (14 ga.) and include

an in-line fuse holder with a 15A fuse. To avoid

fuse/relay

panel damage from repeated connecting and disconnect-

ing, also include a toggle switch in the jumper harness.

- If pump does not run with jumper installed, fault could be in

fuel pump, fuses

F31 or F22 1 F54, or wiring to pump. Check

pump, fuses and its wiring as described below.

Fuel pump electrical circuit, testing

- The test given below assumes that the fuel pump relay circuit

is functioning correctly as described earlier. Access to the

pump is from below the rear seat bottom cushion.

- Remove rear seat lower cushion by lifting front edge off left

and right catches.

Page 479 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Fuel Tank and Fuel purnpl

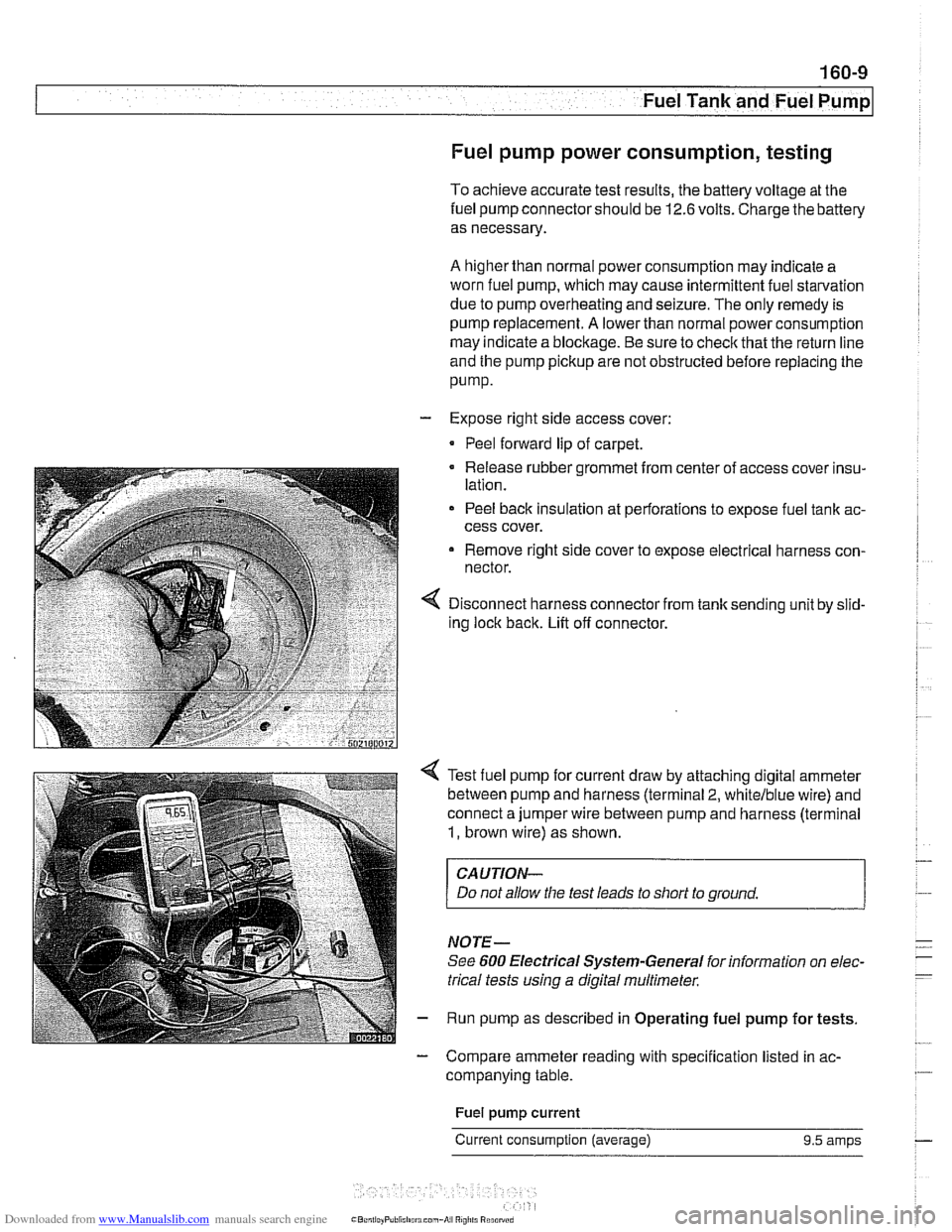

Fuel pump power consumption, testing

To achieve accurate test results, the battery voltage at the

fuel pump connector should be

12.6 volts. Charge the battery

as necessary.

A higher than normal power consumption may indicate a

worn fuel pump, which may cause intermittent fuel starvation

due to pump overheating and seizure. The only remedy is

pump replacement.

A lower than normal power consumption

may indicate a blockage. Be sure to check that the return line

and the pump pickup are not obstructed before replacing the

pump.

- Expose right side access cover:

Peel forward lip of carpet.

Release rubber grommet from center of access cover insu-

lation.

Peel back insulation at perforations to expose fuel tank ac-

cess cover.

Remove right side cover to expose electrical harness con-

nector.

Disconnect harness connector from tank sending unit by slid-

ing lock back. Lift off connector.

Test fuel pump for current draw by attaching digital ammeter

between pump and harness (terminal

2, whitelblue wire) and

connect a jumper wire between pump and harness (terminal

1, brown wire) as shown.

CAUTION-

Do not allow the test leads to short to ground.

NOTE-

See 600 Electrical Systern-General for information on elec-

trical tests

using a digital multirneter.

Run pump as described in Operating fuel pump for tests.

- Compare ammeter reading with specification listed in ac-

companying table.

Fuel

pump current

Current consumption (average) 9.5 amps