Transmission BMW 528i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 707 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 1

Rear Suspension

Coil spring, removing and installing

Raise car and remove rear wheels.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect

bralte fluid hose. See

340 Brakes.

- Remove exhaust system. See 180 Exhaust System.

- Disconnect driveshafl from final drive. See 260 Driveshaft.

- Detach parking bralte cables from mounting bracltets on sub-

frame.

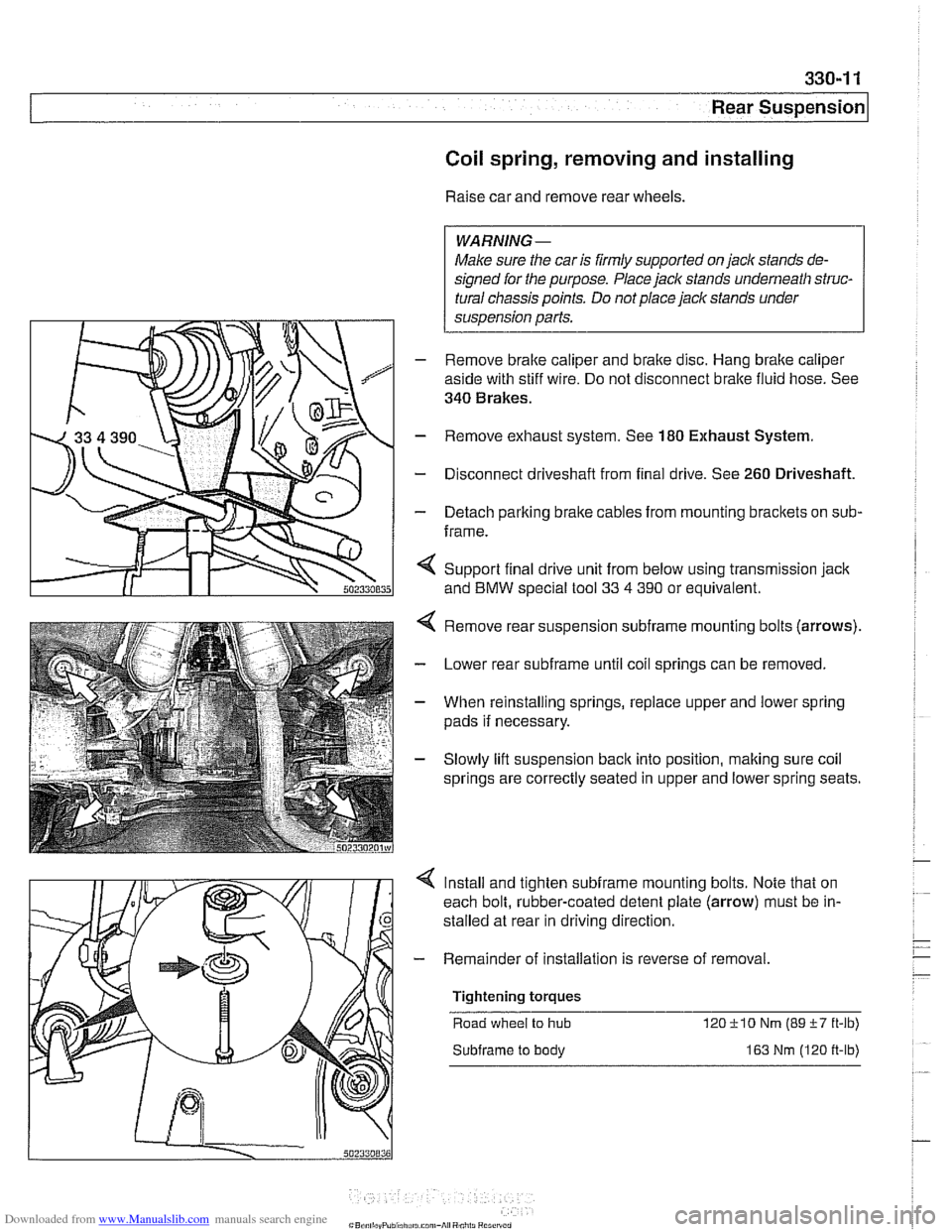

< Support final drive unit from below using transmission jack

and

BMW special tool 33 4 390 or equivalent.

Remove rear suspension

subframe mounting bolts (arrows).

Lower rear

subframe until coil springs can be removed.

When reinstalling springs, replace upper and lower spring

pads if necessary.

Slowly lift suspension

back into position, making sure coil

springs are correctly seated in upper and lower spring seats.

Install and tighten

subframe mounting bolts. Note that on

each bolt, rubber-coated detent plate (arrow) must be in-

stalled at rear in driving direction

- Remainder of installation is reverse of removal

Tightening torques Road wheel

to hub 12OilO Nm (89i-7 ft-lb)

Subframe to body 163 Nm (120 ft-lb)

Page 723 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-27

Rear ~uspensionl

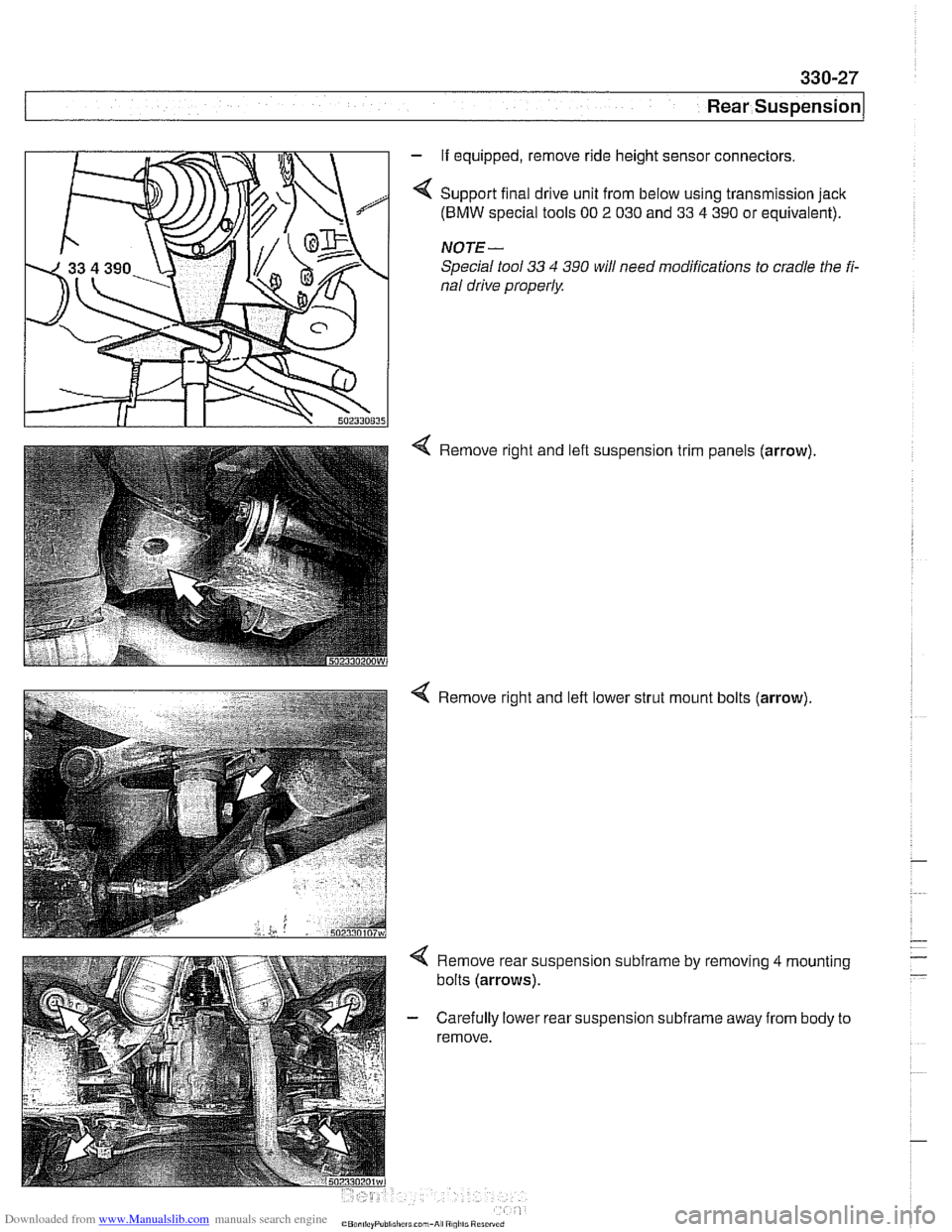

- If equipped, remove ride height sensor connectors.

Support final drive unit from below using transmission jack

(BMW special tools 00

2 030 and 33 4 390 or equivalent).

NOTE-

Special tool 33 4 390 will need modifications to cradle the ii-

nal drive properly.

4 Remove right and left suspension trim panels (arrow)

4 Remove right and left lower strut mount bolts (arrow)

Remove rear suspension

subframe by removing 4 mounting

bolts (arrows).

Carefully lower rear suspension

subframe away from body to

remove.

Page 725 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

- Remove exhaust system. See 180 Exhaust System.

- Detach driveshaft from differential. See 260 Driveshaft.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect brake fluid hose. See

340 Brakes.

- Remove left and right ABS sensors from wheel bearing car-

riers.

Disconnect parking brake cable from brake shoe expander.

See 340 Brakes.

Remove heat shield from above driveshaft

If equipped, remove ride height sensor connectors

CAUTION-

Models with air springs: Disable air supply pump by discon-

necting electrical plug before performing any repairs. Pump is

locatedbeneath a coverunder

thespare tire in the floorof the

carqo compartment.

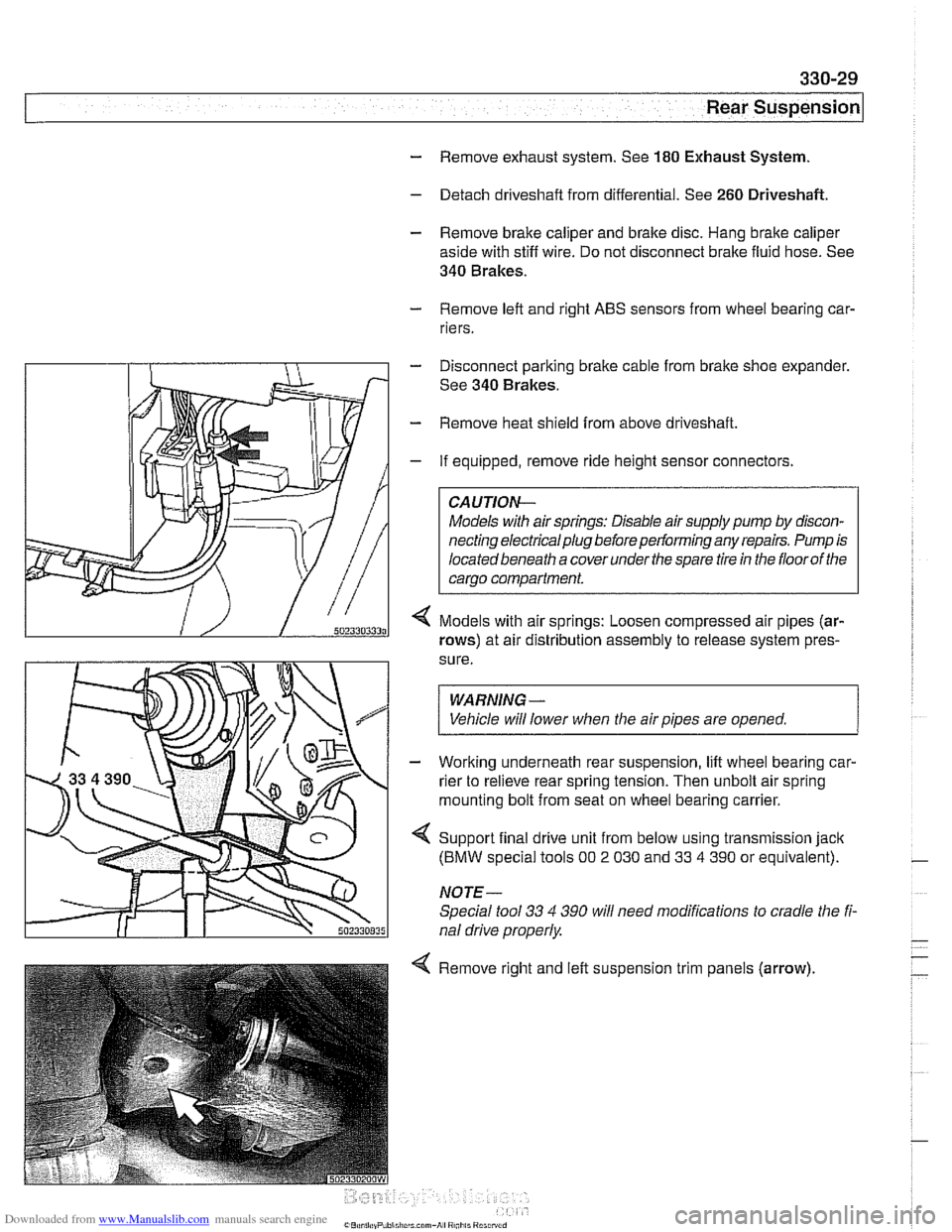

Models with air springs: Loosen compressed air pipes (ar-

rows) at air distribution assembly to release system pres-

sure.

WARNING -

Vehicle will lower when the air pipes are opened. 1

- Working underneath rear suspension, lift wheel bearing car-

rier to relieve rear spring tension. Then unbolt air spring

mounting bolt from seat on wheel bearing carrier.

4 Support final drive unit from below using transmission jack

(BMW special tools 00 2 030 and 33 4 390 or equivalent).

NOTE-

Special tool 33 4 390 will need modifications to cradle the fi-

nal drive properly

4 Remove right and left suspension trim panels (arrow),

Page 881 of 1002

Downloaded from www.Manualslib.com manuals search engine

513-3

Interior ~rirnl

The console between the two front seats starts behind the shifler housing. It houses the parking brake handle, optional

telephone and oddments storage tray. The rear portion of the

console houses the ashtray and covers the emergency brake

cable ends.

NOTE-

The accompanying photos illustrate a model with automatic

transmission. Manual transmission models are similar.

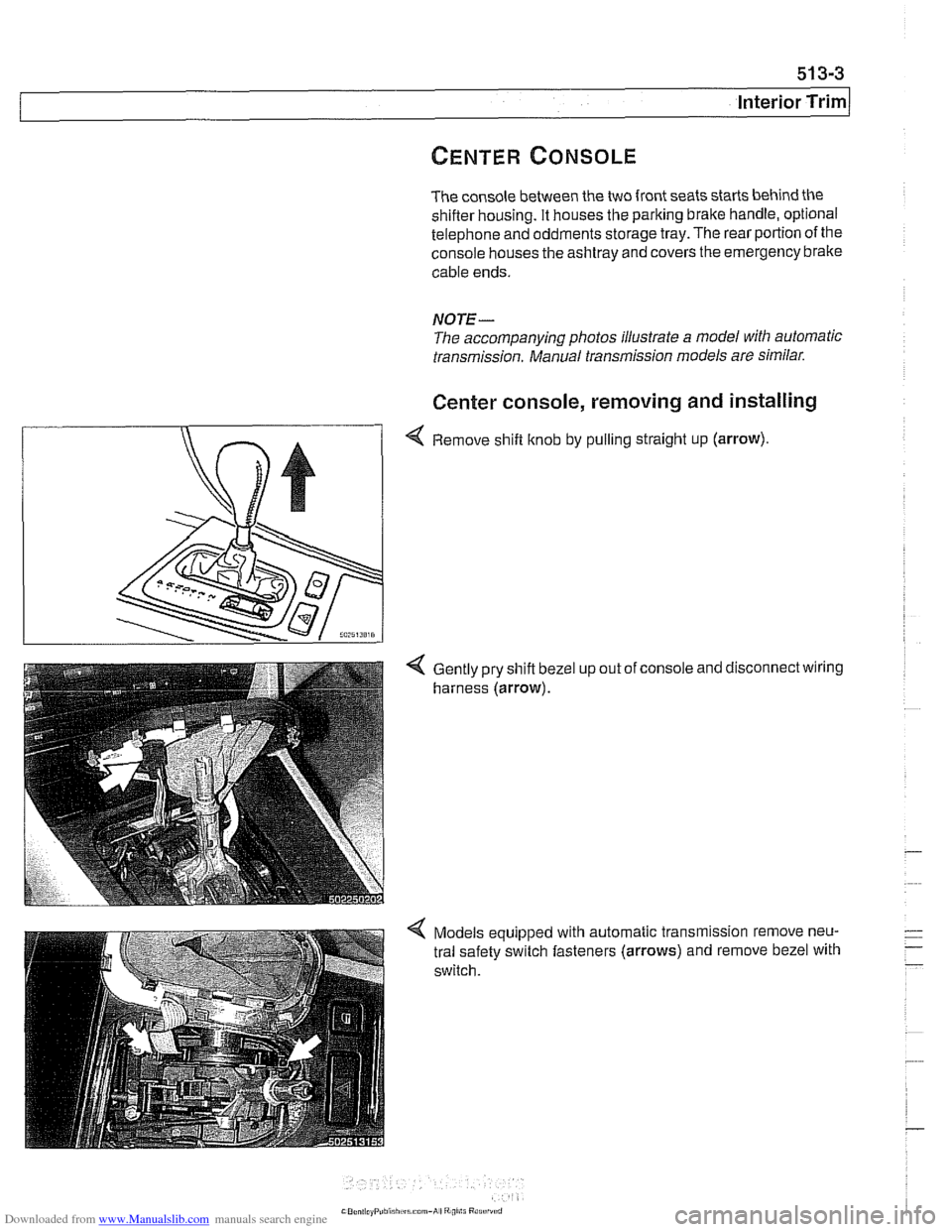

Center console, removing and installing

4 Remove shift knob by pulling straight up (arrow).

Gently pry shift bezel

harness (arrow). up

out of console and disconnect wiring

Models equipped with automatic transmission remove neu-

tral safety switch fasteners (arrows) and remove bezel with

switch.

Page 916 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anii-Theft

- If the starter engages, the following EWS inputs are function-

ing normally:

Ignition key

Code function

Transmission range switch or clutch position switch

Engine speed sensor

NO JE -

If a vehicle key is lost or stolen, the electronic authorization

for that key

can be cancelled using the BMW scan and di-

agnostic tools

DISplus, GTl or MoDiC.

Force applied to a ley can damage the electronic circuitry

in the key A damaged ley will not start the engine. In that

case, a new key should be purchased and initialized

by an

authorized BMW dealer.

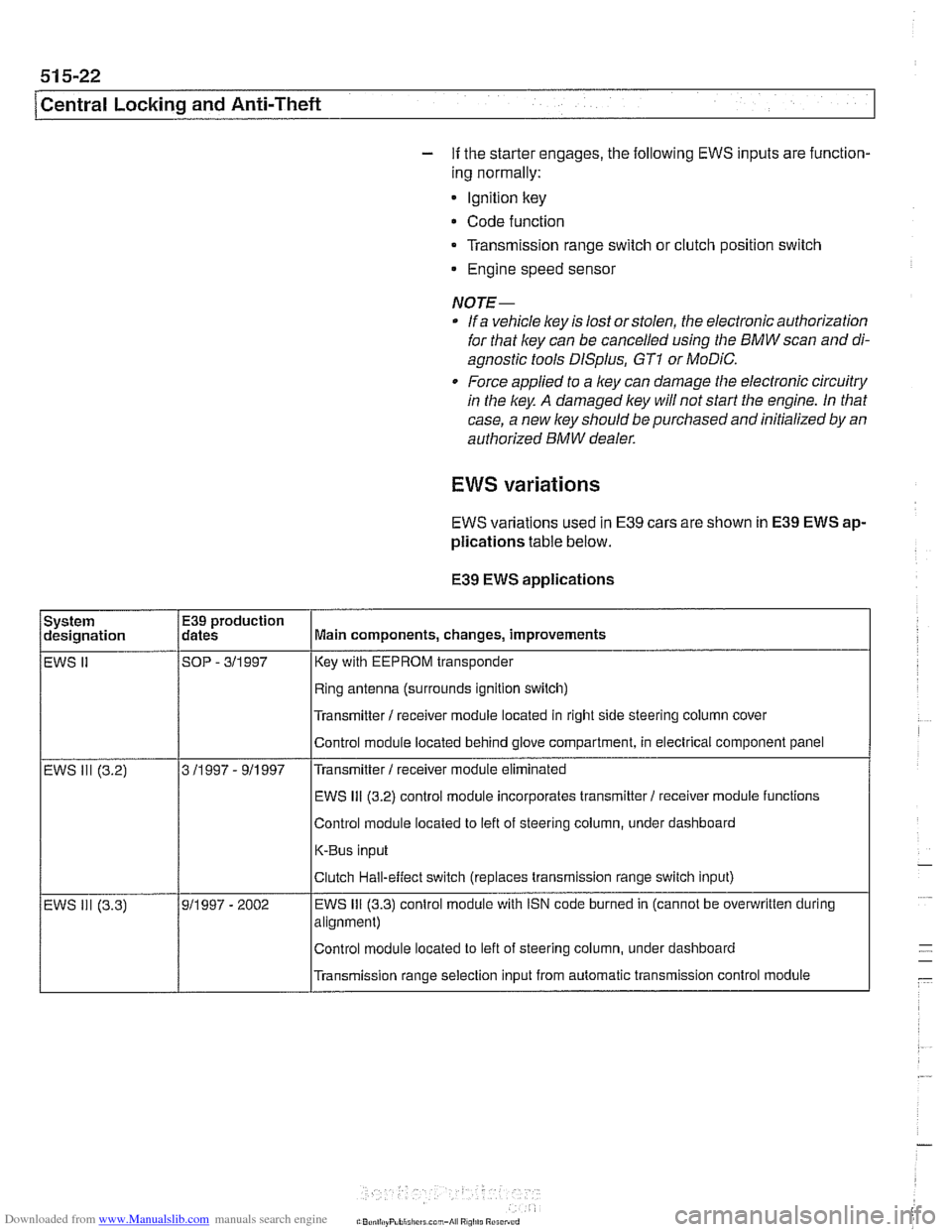

EWS variations

EWS variations used in E39 cars are shown in E39 EWS ap-

plications

table below.

E39

EWS applications

I I Ifling antenna (surrounds ignition switch) I

System

designation

EWS

II

I I l~ransmitter I receiver module located in right side steering column cover I

E39 production

dates

SOP

- 311 997

I I IEWS 111 (3.2) control module incorporates transmitter1 receiver moduie functions /

Main components, changes, improvements

Key with EEPROM transponder

Control moduie located behind glove compartment, in electrical component panel

Control module located to left of steering column, under dashboard

K-Bus input

Transmitter

I receiver module eliminated

EWS 111 (3.2)

Transmission range selection input from automatic transmission control module

3

11997 - 911997

- EWS ill (3.3) Clutch

Hall-effect switch (replaces transmission range switch input)

911997 - 2002 EWS 111 (3.3) control

module with iSN code burned in (cannot be overwritten during

alignment)

Control module located to left of steering column, under dashboard

Page 922 of 1002

Downloaded from www.Manualslib.com manuals search engine

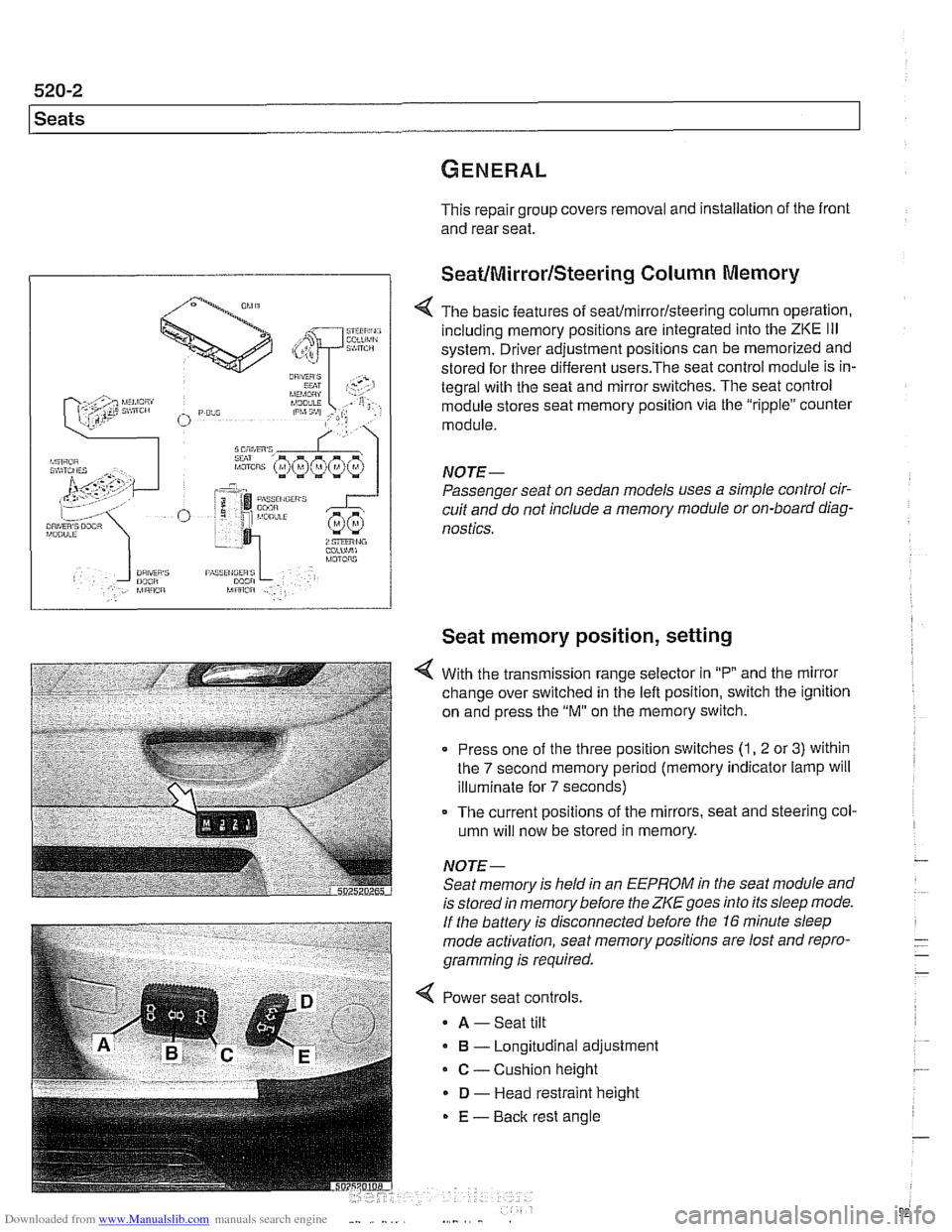

l Seats

This repair group covers removal and installation of the front

and rear seat.

SeatIMirrorlSteering Column Memory

< The basic features of seaffmirrorlsteering column operation,

including memory positions are integrated into the

ZKE Ill

system. Driver adjustment positions can be memorized and

stored for three different

users.The seat control module is in-

tegral with the seat and mirror switches. The seat control

module stores seat memory position via the "ripple" counter

module.

NOTE-

Passenger seat on sedan models uses a simple control cir-

cuit and do not include a memory module or on-board diag-

nostics.

Seat memory position, setting

With the transmission range selector in "P and the mirror

change over switched in the left position, switch the ignition

on and press the

"M" on the memory switch.

Press one of the three position switches

(1, 2 or 3) within

the

7 second memory period (memory indicator lamp will

illuminate for

7 seconds)

- The current positions of the mirrors, seat and steering col-

umn will now be stored in memory.

NOTE- Seat memory is held in an

EEPROM in the seat module and

is stored in memory before the

ZKE goes into its sleep mode.

If the battery is disconnected before the 16 minute sleep

mode activation, seat memorypositions are lost and repro-

gramming is required.

< Power seat controls.

A -Seat tilt

B - Longitudinal adjustment

C - Cushion height

D - Head restraint height

E - Back rest angle

Page 961 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD On-Board Diagnostics

I I

General ........................... OBD-1 Diaqnostic Trouble Codes (DTCs) . . OBD-9

On-Board Diagnostics (OBD I!) ..... OBD-I

Malfunction Indicator Light (MIL)

........ OBD-2

Scan tools and scan tool display.

........ OBD-3

Diagnostic monitors

.................. OED-4

Drive cycle

......................... OED-6

Readiness codes

.................... OBD-6

Diagnostic trouble codes

(DTCs) ........ OBD-7

-

Automatic transmission diagnostic

trouble codes

....................... OBD-9

Engine diagnostic trouble

codes: M52 engine.

................. OED-13

Engine diagnostic trouble

codes: M54 engine.

................. OBD-17

Engine diagnostic trouble

codes: M62 engine.

................. OBD-24

This chapter outlines the fundamentals and equipment

requirements of On-Board Diagnostics

I1 (OBD 11) standards

as they apply to BMW vehicles. Also covered here is a listing

of BMW and OBD

I1 diagnostic trouble codes (DTCs).

ON-BOARD DIAGNOSTICS (QBD !I)

OBD II standards were developed by the SAE (Society of

Automotive Engineers) and CARB (California Air Resources

Board).

OED I1 is the second generation of on-board self-

diagnostic equipment requirements. These standards were

originally mandated for California vehicles. Since

1996 they

have been applied

toall passengervehicles sold in the United

States.

On-board diagnostic capabilities are incorporated into the

hardware and soflwareof the enginecontrol module

(ECM) to

monitor virtually every component that can affect vehicle

emissions. The

OED I1 system works to ensure that

emissions remain as clean as possible over the life of the

vehicle.

Each emission-influencing component is checked by a

diagnostic routine (called a monitor) to verify that it is

functioning properly.

If a problem or malfunction is detected,

the

diagnostic executive built into the OBD I1 system

illuminates a malfunction indicator light (MIL) on the

instrument panel.

The OBD

I1 system also stores diagnostic trouble codes

(DTCs) about the detected malfunction in the ECM so that a

repair technician can accurately find and fix the problem.

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

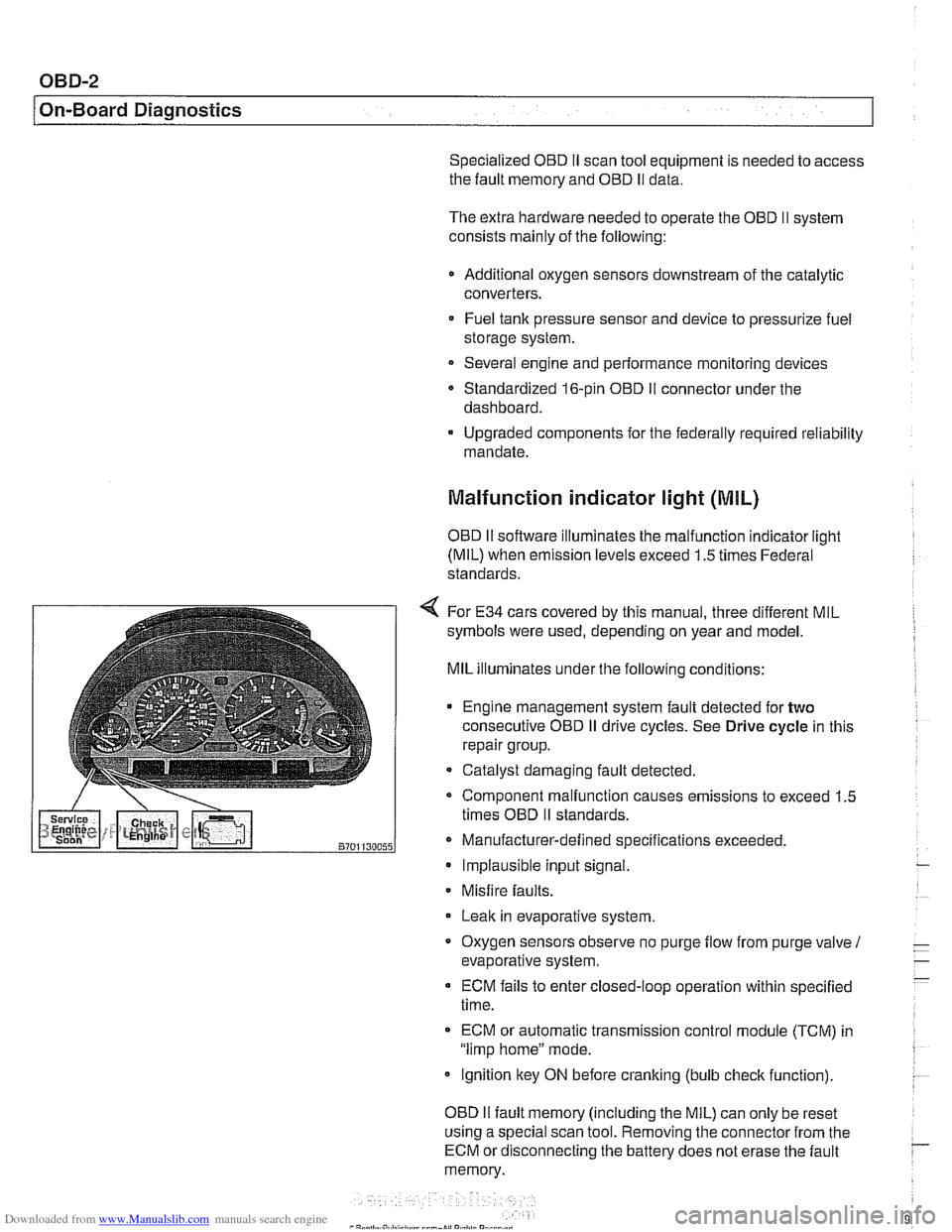

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 968 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-8

I On-Board Diagnostics

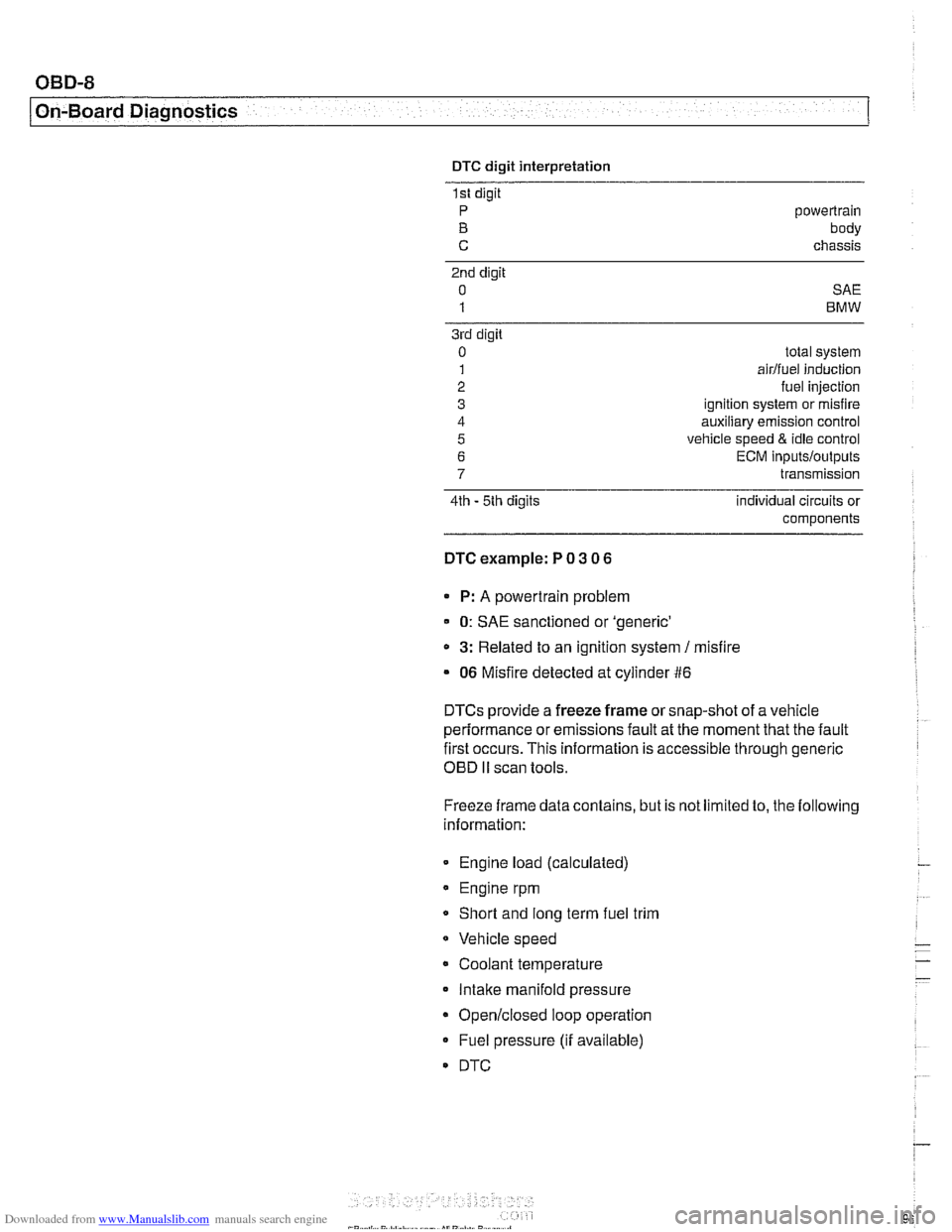

DTC digit interpretation

1st digit

P powertrain

B body

C chassis

2nd digit

0 SAE

1 BMW

3rd digit

0

1

2

3

4

5

6

7

4th - 5th digits total

system

airlfuei induction

fuel injection

ignition system or misfire

auxiliary emission control

vehicle speed

& idle control

ECM

inputs/outputs

transmission

individual circuits or

components

DTC example: P 0 3 0 6

P: A powertrain problem

0: SAE sanctioned or 'generic'

a 3: Related to an ignition system / misfire

06 Misfire detected at cylinder #6

DTCs provide a freeze frame or snap-shot of a vehicle

performance or emissions fault at the moment that the fault

first occurs. This information is accessible through generic

OED I1 scan tools.

Freeze frame data contains, but is not limited to, the following

information:

Engine load (calculated)

Engine rpm

Short and

long term fuel trim

Vehicle speed

Coolant temperature Intake manifold pressure

Open/closed loop operation

Fuel pressure (if available)

DTC

Page 969 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

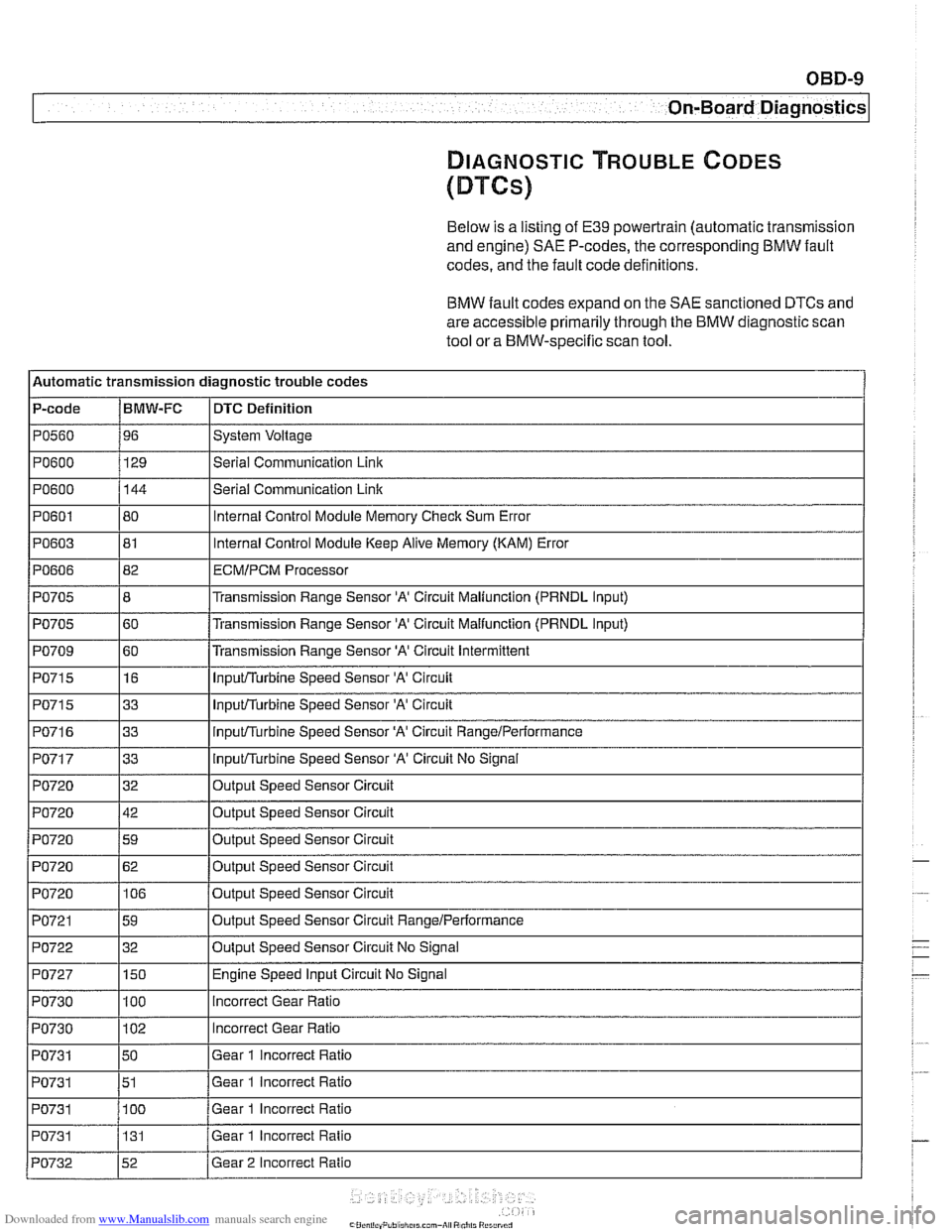

DIAGNOSTIC TROUBLE CODES

(DTCs)

Below is a listing of E39 powertrain (automatic transmission

and engine)

SAE P-codes, the corresponding BMW fault

codes, and the fault code definitions.

BMW fault codes expand on the SAE sanctioned DTCs and

are accessible primarily through the BMW diagnostic scan

tool or a BMW-specific scan tool.

l~utomatic transmission diagnostic trouble codes

P-code

IBMW-FC I DTC Definition

Ip0560 196 ISystem Voltage I

IPO~OO I129 l~eriai Communication Link I

1~0715 116 I InpuVTurbine Speed Sensor 'A' Circuit I

PO600

PO601

PO603

PO606

PO705

PO705

PO709

144

80

81

82

8

60

60

PO71 5

PO71 6

PO717

PO720

PO720

PO720

I I

PO721 159 loutput Speed Sensor Circuit RangeIPerformance I

Serial Communication Link

Internal Control Module Memory Check Sum Error

Internal Control Module Keep Alive Memory (KAM) Error

ECMIPCM Processor

Transmission Range Sensor 'A' Circuit Maliunction (PRNDL Input)

Transmission Range Sensor

'A' Circuit Malfunction (PRNDL input)

Transmission Range Sensor

'A' Circuit Intermittent

I I'

1~0722 132 IOutput Speed Sensor Circuit No Signal I

33

33

33

32

42

59

PO720

I I

PO727 1150 I Engine Speed Input Circuit No Signal

InpuVTurbine Speed Sensor 'A' Circuit

inpuVTurbine Speed Sensor 'A' Circuit RangeiPerformance

InpuVTurbine Speed Sensor 'A' Circuit No Signal

Output Speed Sensor Circuit

Output Speed Sensor Circuit

Out~ut Speed Sensor Circuit

PO720 1106 /output Speed Sensor Circuit

62

Output Speed Sensor Circuit

PO730

PO730

PO731

PO731

PO731 I I

100

102

50

51

100

PO731

incorrect Gear Ratio

Incorrect Gear Ratio

Gear 1 incorrect Ratio

Gear 1 incorrect Ratio

Gear 1 Incorrect Ratio

PO732 152 /Gear 2 Incorrect Ratio

131

Gear

1 Incorrect Ratio