electrical BMW 528i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 499 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

L- -

--

-. - - - Radiator and Cooling sYstelll/ --

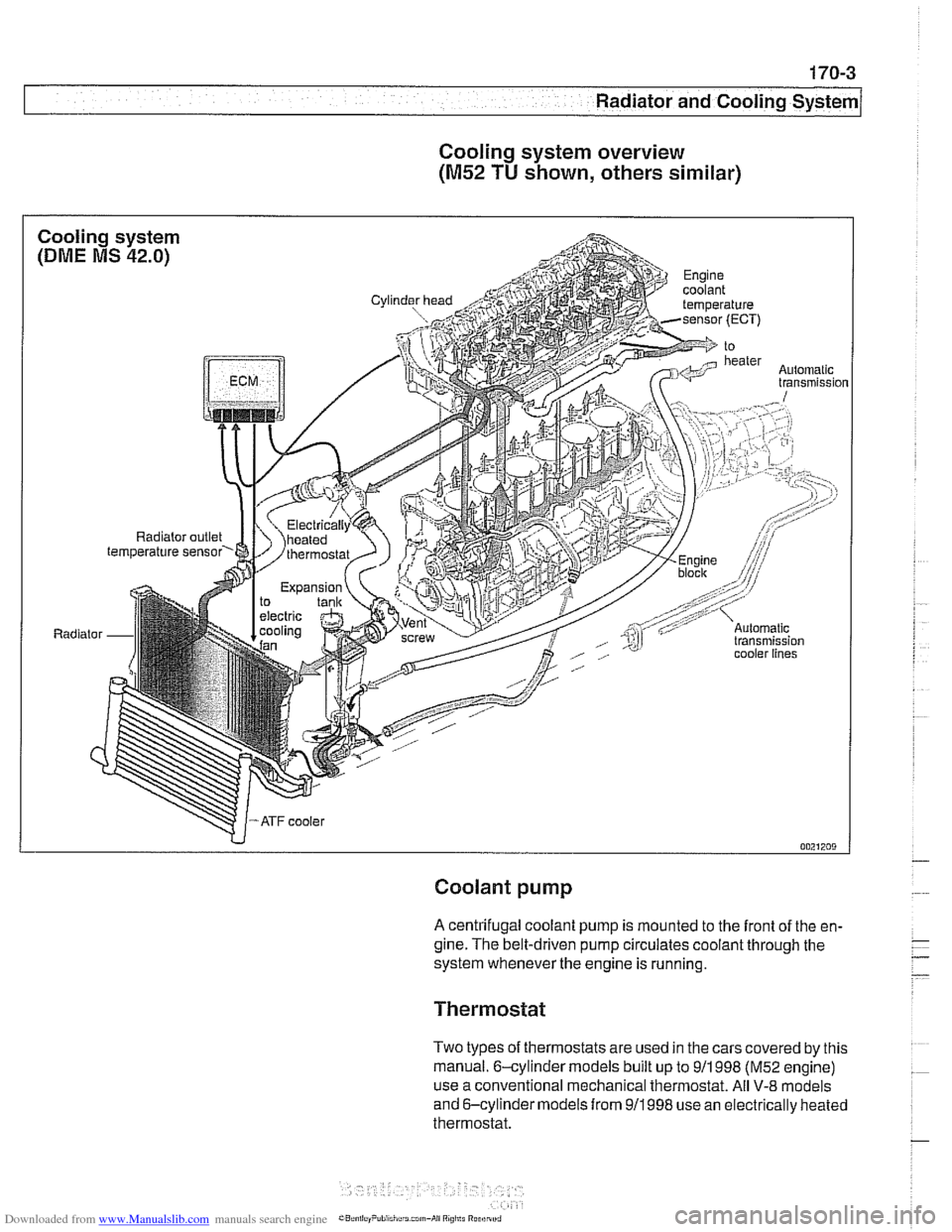

Cooling system overview

(M52 TU shown, others similar)

Coolant pump

A centrifugal coolant pump is mounted to the front of the en-

gine. The belt-driven pump circulates coolant through the

system whenever the engine is running.

Thermostat

Two types of thermostats are used in the cars covered by this

manual. 6-cylinder models built up to

911 998 (M52 engine)

use a conventional mechanical thermostat. All

V-8 models

and 6-cylinder models from

911998 use an electrically heated

thermostat.

Page 500 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Radiator and Cooling System

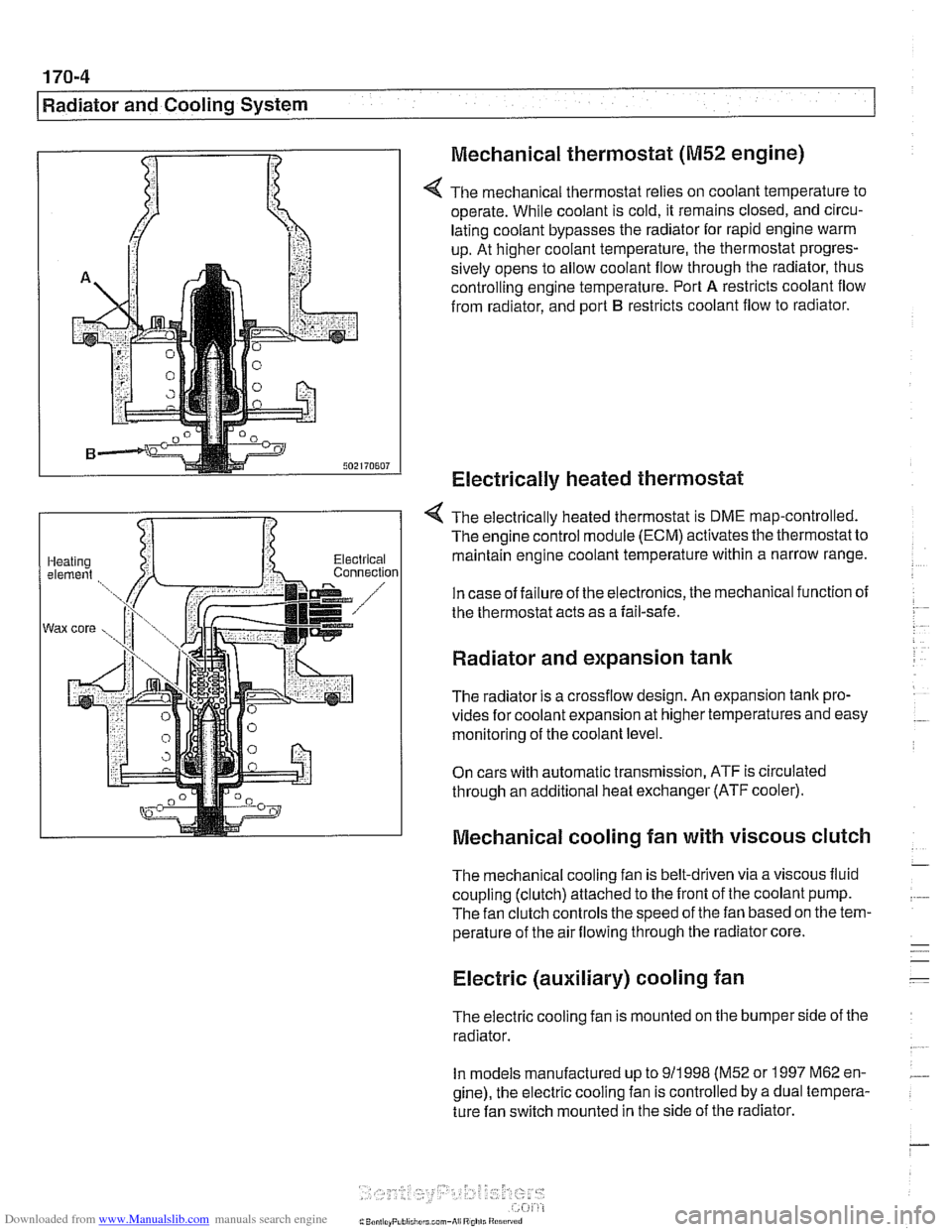

Mechanical thermostat

(M52 engine)

4 The mechanical thermostat relies on coolant temperature to

operate. While coolant is cold, it remains closed, and circu-

lating coolant bypasses the radiator for rapid engine warm

up. At higher coolant temperature, the thermostat progres-

sively opens to allow coolant flow through the radiator, thus

controlling engine temperature. Port

A restricts coolant flow

from radiator, and port

B restricts coolant flow to radiator.

Electrically heated thermostat

4 The electrically heated thermostat is DME map-controlled.

The engine control module (ECM) activates the thermostat to

maintain engine coolant temperature within a narrow range.

In case of failure of the electronics, the mechanical function of

the thermostat acts as a fail-safe.

Radiator and expansion tank

The radiator is a crossflow design. An expansion tank pro-

vides for coolant expansion at higher temperatures and easy

monitoring of the coolant level.

On cars with automatic transmission, ATF is circulated

through an additional heat exchanger (ATF cooler).

Mechanical cooling fan with viscous clutch

The mechanical cooling fan is belt-driven via a viscous fluid

coupling (clutch) attached to the front of the coolant pump.

The fan clutch controls the speed of the fan based on the tem-

perature of the air flowing through the radiator core.

Electric (auxiliary) cooling fan

The electric cooling fan is mounted on the bumper side of the

radiator.

In models manufactured up to

911 998 (M52 or 1997 M62 en-

gine), the electric cooling fan is controlled by a dual tempera-

ture fan switch mounted in the side of the radiator.

Page 504 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-8

I Radiator and Cooling System

Common cooling system faults can be grouped into one of 4

categories:

Cooling system

lealts

Poor coolant circulation

Radiator cooling fan faults

Electrical/electronic faults

Cooling system inspection

- Check that coolant pump drive belt tensioner is functioning

properly and that belt tension is correct. Belt tensioner sys-

tems for the different models are shown in

020 Maintenance.

- Check condition of coolant pump drive belt.

- Checlc coolant hoses for cracks or softness. Checlc clamps

for looseness. Check coolant level and check for evidence of

coolant

lealts from engine.

- Check that radiator fins are not blocked with dirt or debris.

Clean radiator using low-pressure water or compressed air.

Blow outward, from engine side out.

- To check coolant pump:

Remove mechanical cooling fan. See Mechanical

(vis.

cous clutch) cooling fan, removing and installing.

Remove drive belt from coolant pump pulley. See

020

Maintenance.

Firmly grasp opposite sides of pulley and check for play in

all directions.

Spin pulley and check that shaft runs smoothly without

play.

NOTE-

The coolant provides lubrication for the pump shaft, so an oc-

casional drop of coolant

lealing from the pump is acceptable.

If coolant drips steadily from the vent hole, replace the pump.

- At normal engine operating temperature, cooling system is

pressurized. This raises boiling point of coolant.

Leaks may

prevent system from becoming pressurized. If visual evi-

dence is inconclusive, pressure test cooling system as de-

scribed later to help pinpoint hard-to-find leaks.

- If cooling system is full of coolant and holds pressure:

- Use an appropriate scan tool to interrogate engine control

module (ECM) for radiator fan or DME control circuit faults.

Checlc for loose or worn drive belt.

0 Test for failed thermostat or coolant pump impeller. Some

pumps may be fitted with plastic impellers.

Page 511 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling System

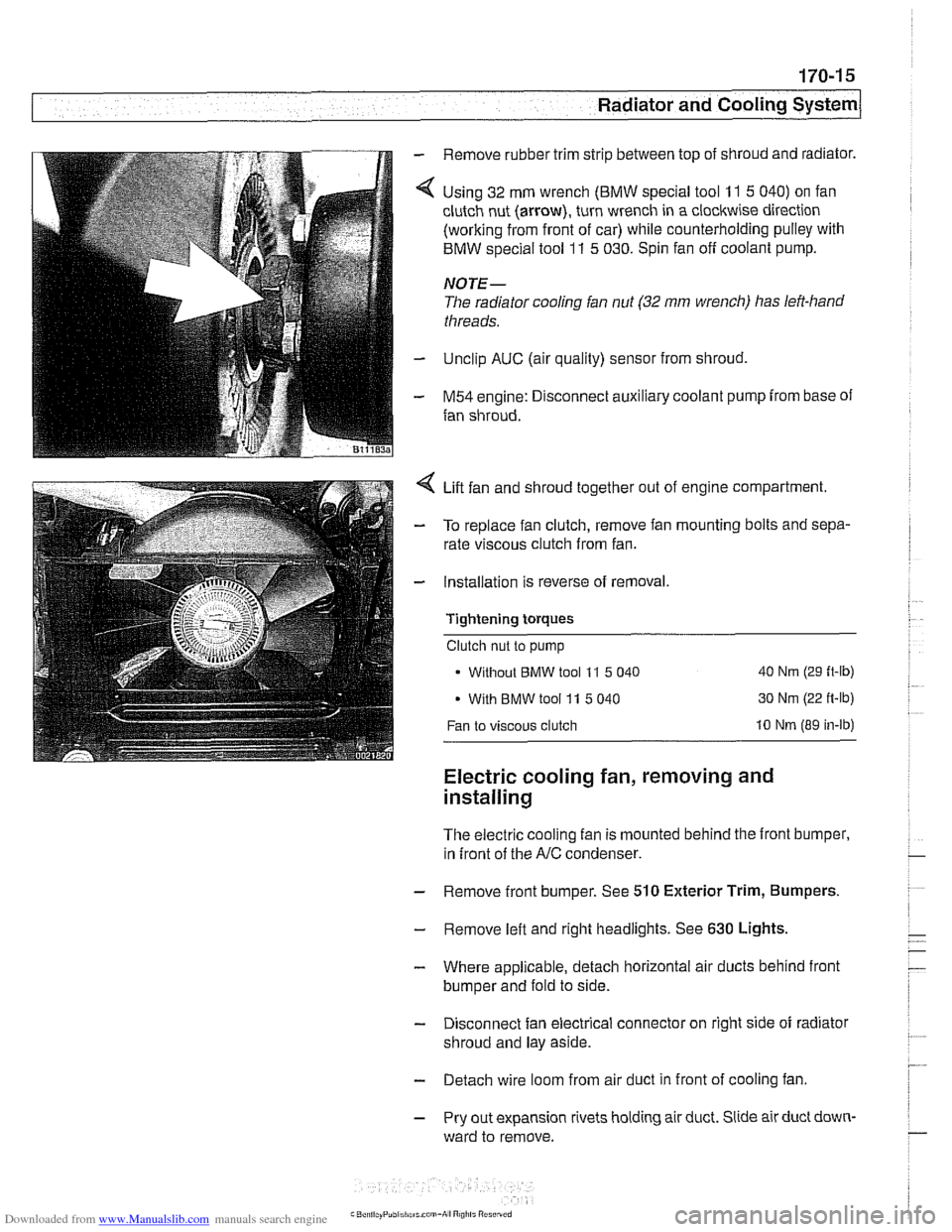

Remove rubber trim strip between top of shroud and radiator.

Using 32 mm wrench

(BMW special tool 11 5 040) on fan

clutch nut (arrow), turn wrench in a clockwise direction

(working from front of car) while counterholding pulley with

BMW special tool

11 5 030. Spin fan off coolant pump.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

Unclip AUC (air quality) sensor from shroud,

M54 engine: Disconnect auxiliary coolant pump from base of

fan shroud.

Lift fan and shroud together out of engine compartment.

To replace fan clutch, remove fan mounting bolts and sepa-

rate viscous clutch from fan.

Installation is reverse of removal.

Tightening

torques

Clutch nut to pump

Without

BMW tool 11 5 040 40 Nm (29 ft-lb)

With BMW tool 11 5 040 30 Nm

(22 ft-lb)

Fan to viscous clutch 10 Nm (89 in-lb)

Electric cooling fan, removing and

installing

The electric cooling fan is mounted behind the front bumper,

in front of the

A/C condenser.

- Remove front bumper. See 510 Exterior Trim, Bumpers.

- Remove left and right headlights. See 630 Lights,

- Where applicable, detach horizontal air ducts behind front

bumper and fold to side.

- Disconnect fan electrical connector on right side of radiator

shroud and lay aside.

- Detach wire loom from air duct in front of cooling fan

- Pry out expansion rivets holding air duct. Slide air duct down-

ward to remove.

Page 513 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling systeml

Tightening torques

Block drain plug to block 25 Nm

(18

it-lb)

Coolant hose clamp (32 - 48 2.

5 Nm (22 in-lb)

mm hose diameter)

Radiator drain plug to radiator

2-3Nm(l8-27in-lb)

Thermostat housing to cylinder

head 10 Nm (89 in-lb)

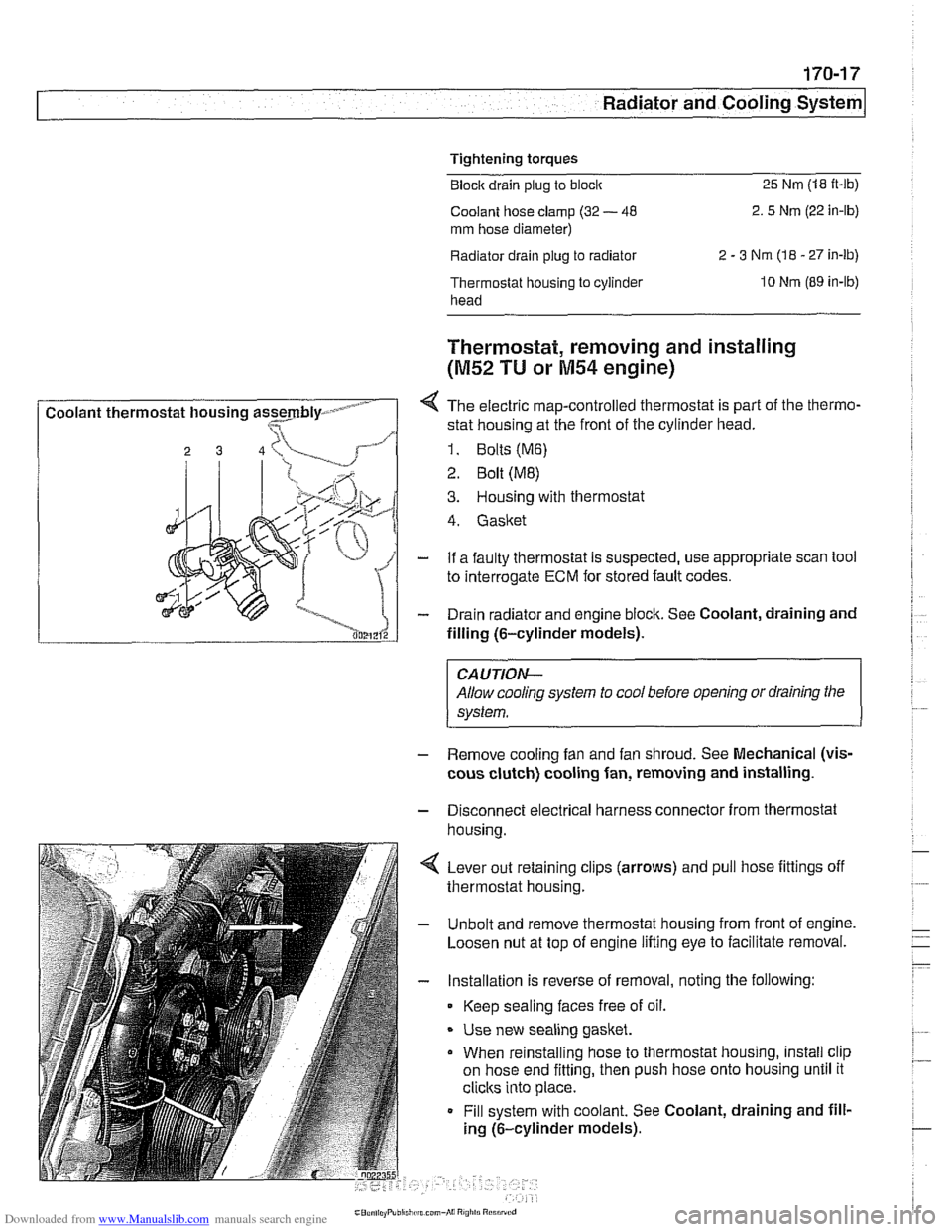

I Coolant thermostat housing assmbly- - I

Thermostat, removing and installing

(M52 TU or M54 engine)

4 The electric map-controlled thermostat is part of the thermo-

stat housing at the front of the cylinder head.

1. Bolts (M6)

2 Bolt (ME)

3. Housing with thermostat

4. Gasket

- If a faulty thermostat is suspected, use appropriate scan tool

to interrogate

ECM for stored fault codes.

- Drain radiator and engine block. See Coolant, draining and

filling (6-cylinder models).

CAUTION-

Allow cooling system to cool before opening or draining the

system.

- Remove cooling fan and fan shroud. See Mechanical (vis-

cous clutch) cooling fan, removing and installing.

- Disconnect electrical harness connector from thermostat

housina.

4 Lever out retaining clips (arrows) and pull hose fittings off

thermostat housing.

- Unbolt and remove thermostat housing from front of engine.

Loosen nut at top of engine lifting eye to facilitate removal.

- Installation is reverse of removal, noting the following:

Keep sealing faces free of oil.

* Use new sealing gasket.

When reinstalling hose to thermostat housing, install clip

on hose end fitting, then push hose onto housing until it

clicks into place.

Fill system with coolant. See Coolant, draining and fill-

ing (6-cylinder models).

Page 514 of 1002

Downloaded from www.Manualslib.com manuals search engine

Tightening torques Block drain plug to block

25 Nm (18 ft-lb)

Radiator drain plug to radiator 2 - 3 Nm (18 - 27 in-lb)

Thermostat housing to

cylinder head 10 Nm (89 in-lb)

Thermostat, removing and installing

(V-8 models)

The electrically-heated thermostat is an integral parl of the

thermostat housing. The operation of the thermostat is moni-

tored by the engine control module (ECM).

- If a faulty thermostat is suspected, use appropriate scan tool

to interrogate ECM for stored fault codes.

- Drain radiator and engine block. See Coolant, draining and

filling

(V-8 models).

WARNING -

Allow cooling system to cool before opening or draining the

system.

- Disconnect mass air flow (MAF) sensor electrical harness

connector. Remove air intake duct together with MAF sensor.

- Remove mechanical cooltng fan and fan shroud. See Me-

chanical (viscous clutch) cooling fan, removing and

in-

stalling.

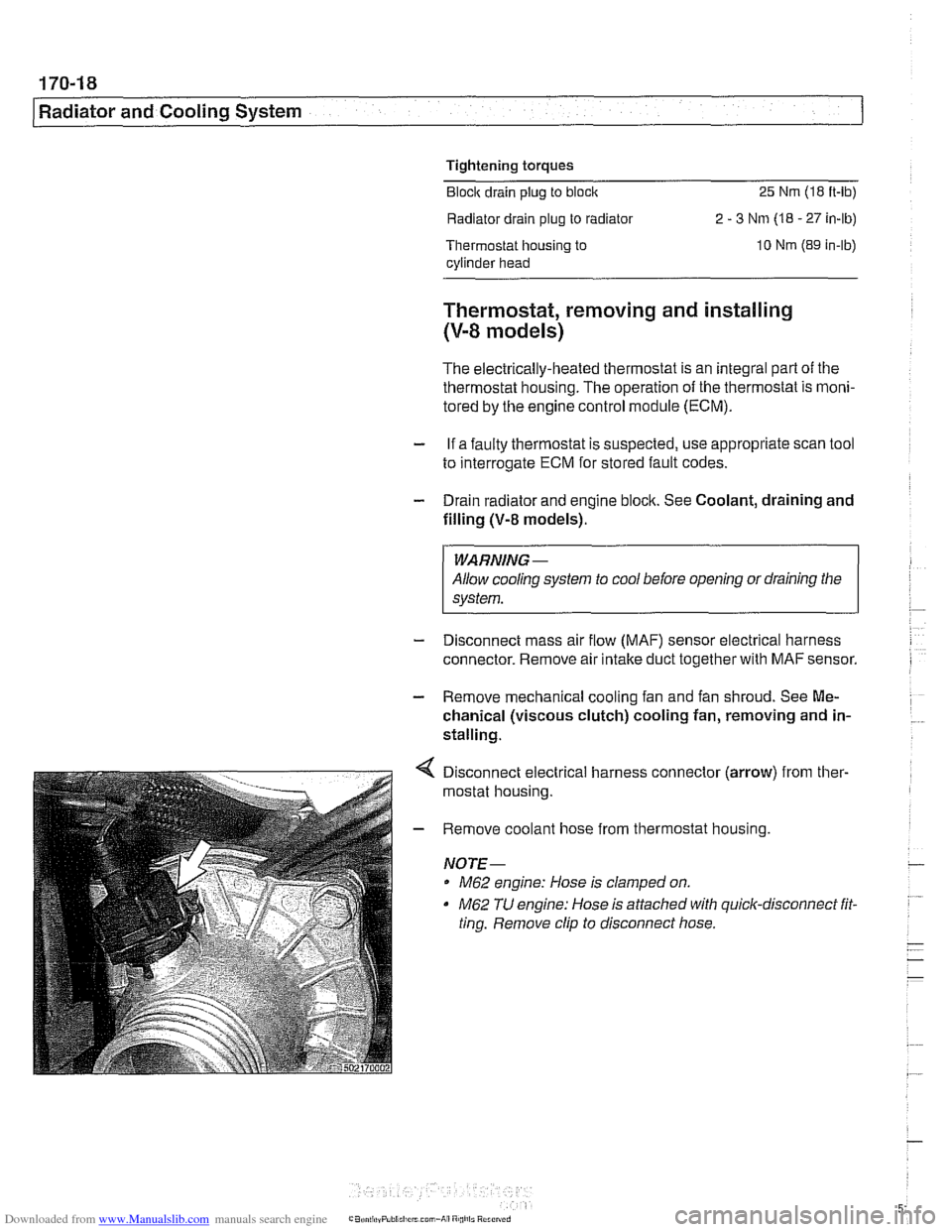

Disconnect electrical harness connector (arrow) from ther-

mostat housing.

Remove coolant hose from thermostat housing.

NOTE-

M62 engine: Hose is clamped on.

M62 TU engine: Hose is attached with quick-disconnect fit.

ting. Remove clip to disconnect hose.

Page 516 of 1002

Downloaded from www.Manualslib.com manuals search engine

.," --

Radiator and Cooling System --- 1

insert two M6 screws (arrows) in tapped bores and tighten

uniformly until pump is free from timing chain cover (thermo-

stat and hoses have been removed for purposes of visual

clarity).

Installation is reverse of removal, noting the following:

Be sure to replace sealing O-ring and gaskets.

Coat O-ring with water-based lubricant during installation.

Refill with coolant. See Coolant, draining and filling

(6-

cylinder models).

Tightening torques

-

Coolant pump to timing chain 10 Nm (89 in-lb)

cover

Coolant pump pulley to coolant

10 Nm (89 in-lb

pump

Engine block drain plug to block 25 Nm (1 8 It-lb)

Radiator drain plug to radiator 2 - 3 Nm (I8 - 27 in-lb)

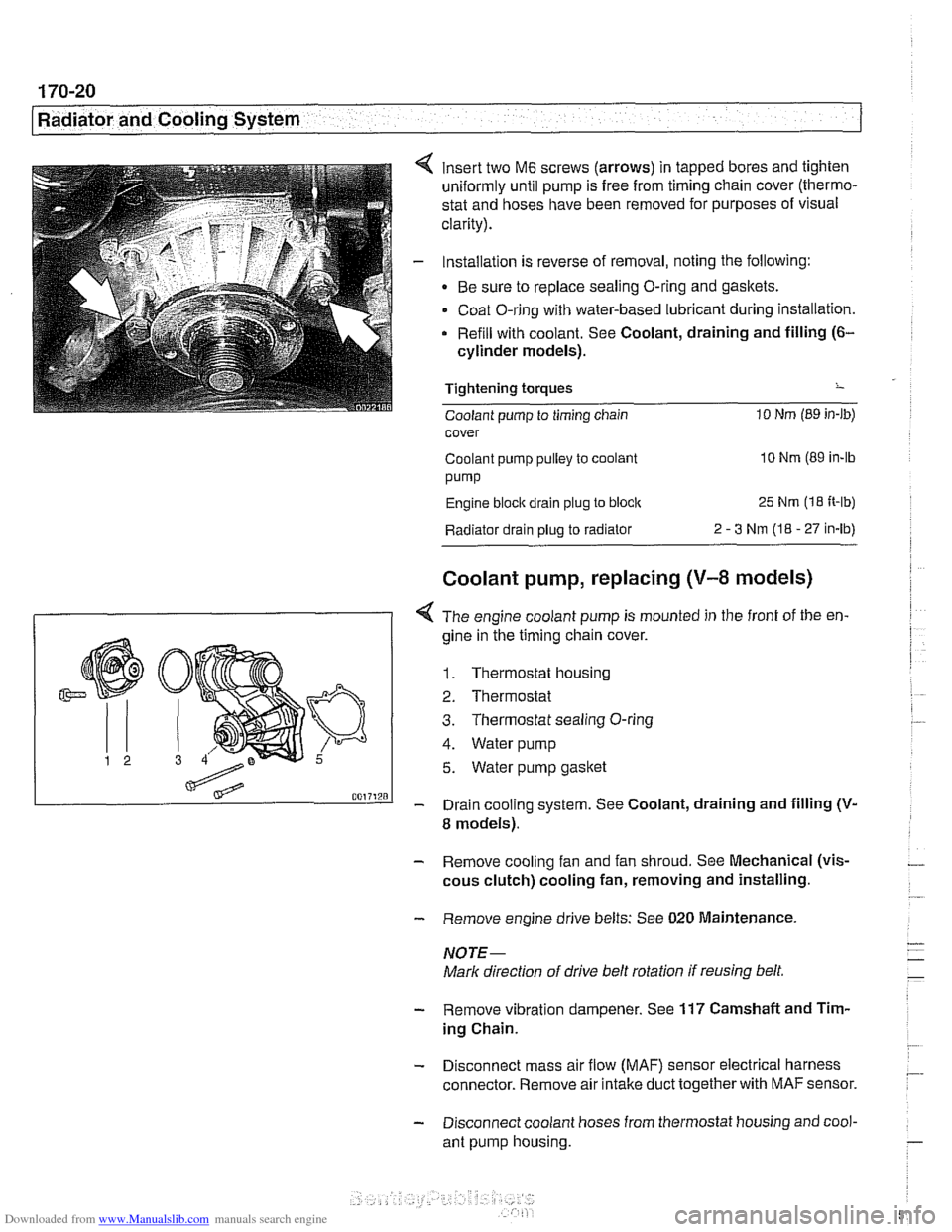

Coolant pump, replacing (V-8 models)

I 1 < The engine coolant pump is mounted in the front of the en-

gine in ;he timing chain cover.

1. Thermostat housing

2. Thermostat

3. Thermostat sealing O-ring

4. Water pump

5. Water pump gasket

- Drain cooling system. See Coolant, draining and filling (V-

8 models).

- Remove cooling fan and fan shroud. See Mechanical (vis-

cous clutch) cooling fan, removing and installing.

- Remove engine drive belts: See 020 Maintenance.

NOTE-

Mark direction of drive belt rotation if reusing belt,

- Remove vibration dampener. See 117 Camshaft and Tim-

ing Chain.

- Disconnect mass air flow (MAF) sensor electrical harness

connector. Remove air intake duct together with

MAF sensor.

- Disconnect coolant hoses from thermostat housing and cool-

ant pump housing.

Page 518 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. - --

Radiator and Cooling System

Tightening torques

Coolant pump to timing chain 10

Nm (89 in-lb)

cover

Coolant pump

pulley to coolant

pump

10 Nm (89 in-lb

Engine

blocic drain plug to block 25 Nm (18 ft-lb)

Radiator drain plug to radiator

2-3Nm(18-27in-lb)

Thermostat cover to coolant

pump assembly 10 Nm (89 in-lb)

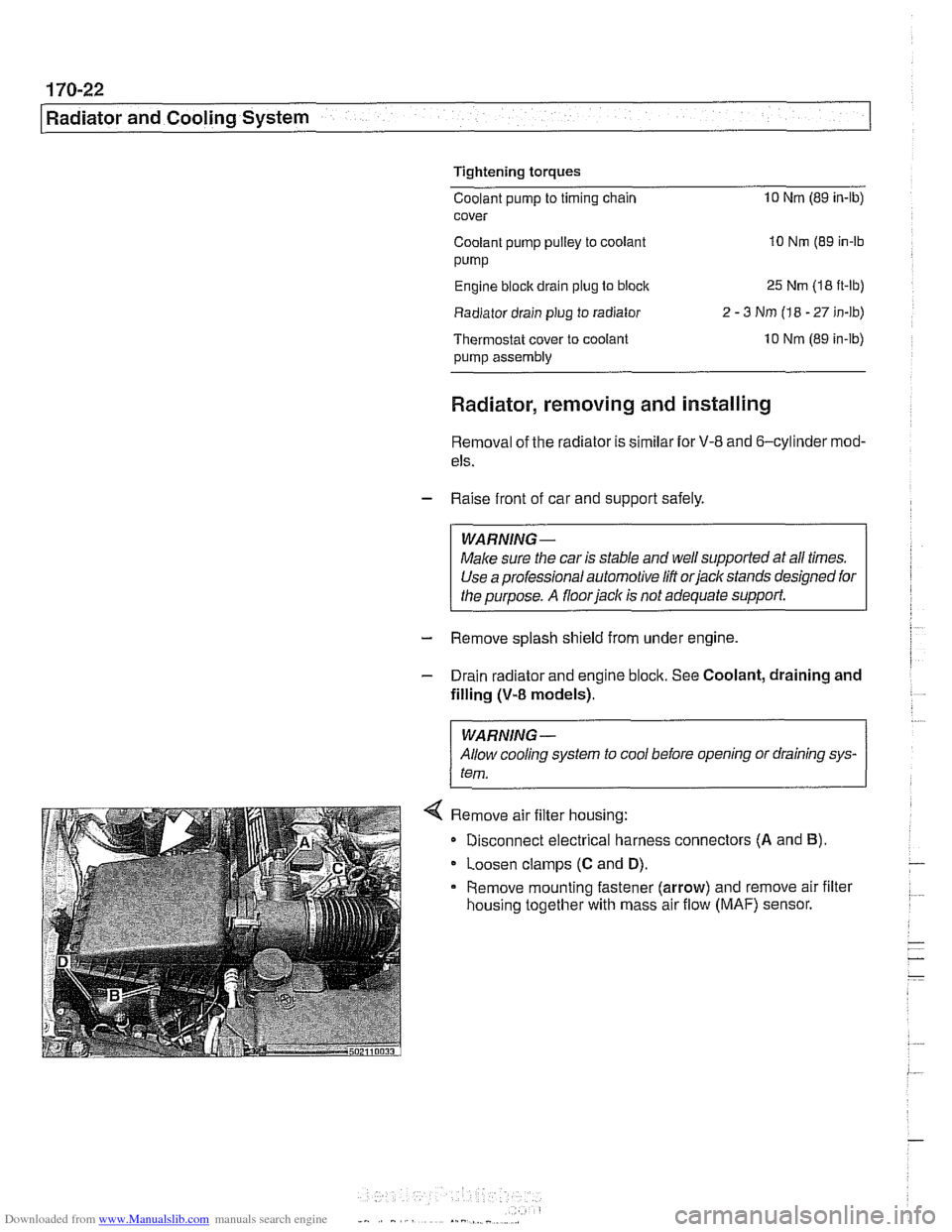

Radiator, removing and installing

Removal of the radiator is similar for V-8 and 6-cylinder mod-

els.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at aN times.

Use a professional automotive liff

orjaclc stands designed for

- Remove splash shield from under engine.

- Drain radiator and engine block. See Coolant, draining and

filling

(V-8 models).

WARNING -

Allow cooling system to cool before opening or draining sys-

tem.

< Remove air filter housing:

Disconnect electrical harness connectors

(A and B).

Loosen clamps (C and D).

Remove mounting fastener (arrow) and remove air filter

housing together with mass air flow

(MAF) sensor.

Page 519 of 1002

Downloaded from www.Manualslib.com manuals search engine

. --

Radiator and Cooling system/

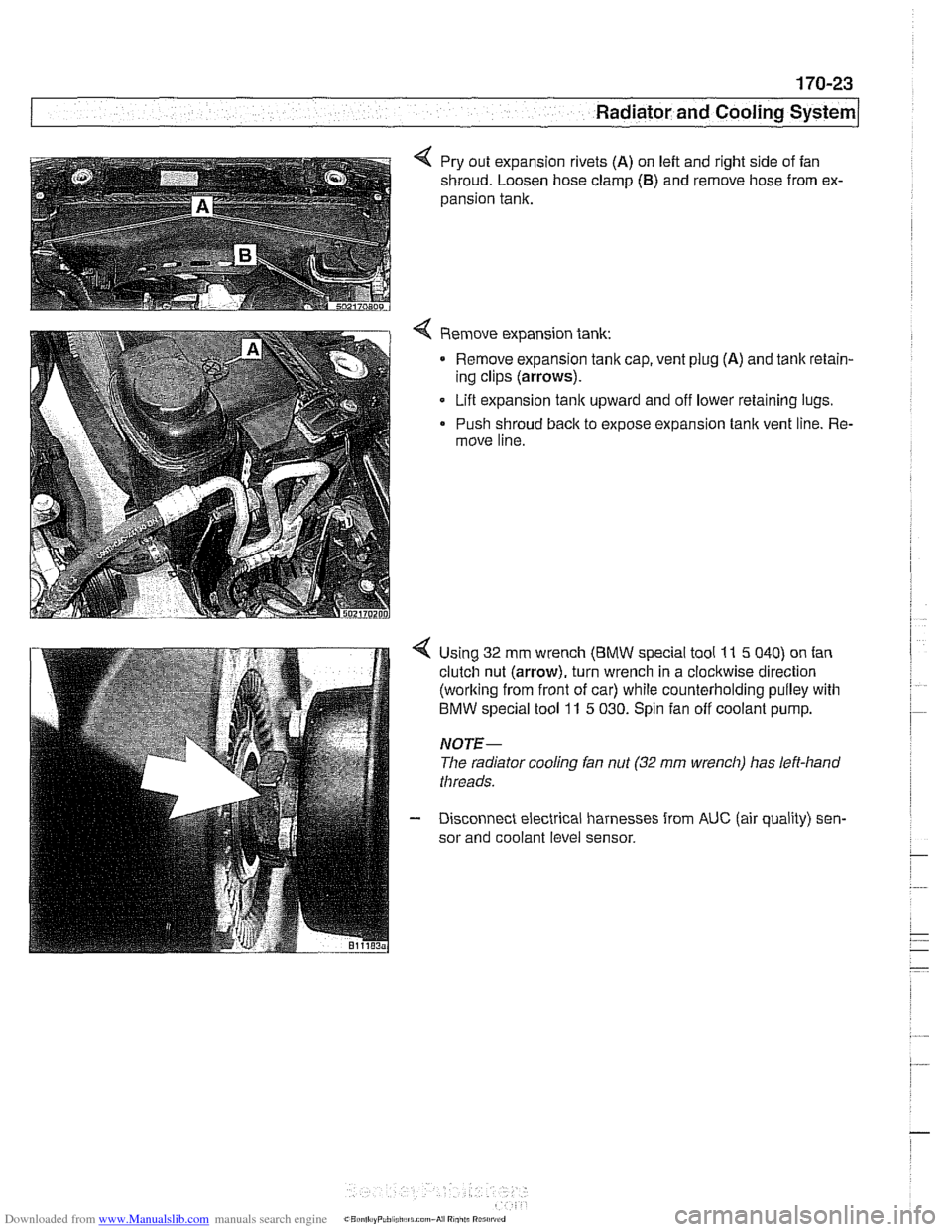

4 Pry out expansion rivets (A) on left and right side of fan

shroud. Loosen hose clamp

(6) and remove hose from ex-

pansion tank.

Remove expansion tank: Remove expansion tanlc cap, vent plug

(A) and tank retain-

ing clips (arrows).

Lift expansion

tanlc upward and off lower retaining lugs.

Push shroud back to expose expansion tank vent line. Re-

move line.

Using 32 mm wrench

(BMW special tool 11 5 040) on fan

clutch nut (arrow), turn wrench in a clockwise direction

(working from front of car) while counterholding pulley with

BMW special tool 11 5 030. Spin fan off coolant pump.

NOTE-

The radiator cooling fan nut (32 mrn wrench) has left-hand

threads.

Disconnect electrical harnesses from

AUC (air quality) sen-

sor and coolant level sensor.

Page 546 of 1002

Downloaded from www.Manualslib.com manuals search engine

Tool for bleeding clutch hydraulics (Tool No. 21 5 030)

21 5 030 I

The clutch is hydraulically actuated by the master and slave

cylinders. With the self-adjusting clutch

(SAC), clutch disc

wear is automatically taken up through the self-adjusting

pressure plate springs, making pedal feel consistent through-

out the life of the clutch.

A soft or spongy feel to the clutch pedal, long pedal free-play,

or grinding noises

from the gears while shifting can all indi-

cate problems with the clutch hydraulics. In these circum-

stances it is best to

star? with a clutch fluid flush, followed, if

necessary, by replacement of the hydraulic parts.

NOTE-

The clutch hydraulic system shares the fluid reservoir and flu-

id with the brake hydraulic system.

Clutch hydraulic system,

bleeding and flushing

If the clutchlbralte fluid is murky or muddy, or has not been

changed within the last two years, flush the system and

change the fluid. Flushing the old fluid from the clutch lines is

done using a bralte system pressure bleeder.

- Remove brake fluid reservoir cap. Using a clean syringe, re-

move brake fluid from reservoir. Refill reservoir with clean

DOT

4 bralte fluid.

Worlting inside engine compartment, remove left

interiorven-

tilation filter housing:

Release 3 plastic taps

(A) on duct. Earlier models use a

single release latch.

Rotate duct inward to remove.

Disconnect electrical harness to hood position switch.

Remove filter housing cover.

Release spring lock

(B) on interior ventilation housing and

remove housing.