electrical BMW 528i 2000 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 528i, Model: BMW 528i 2000 E39Pages: 1002

Page 147 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

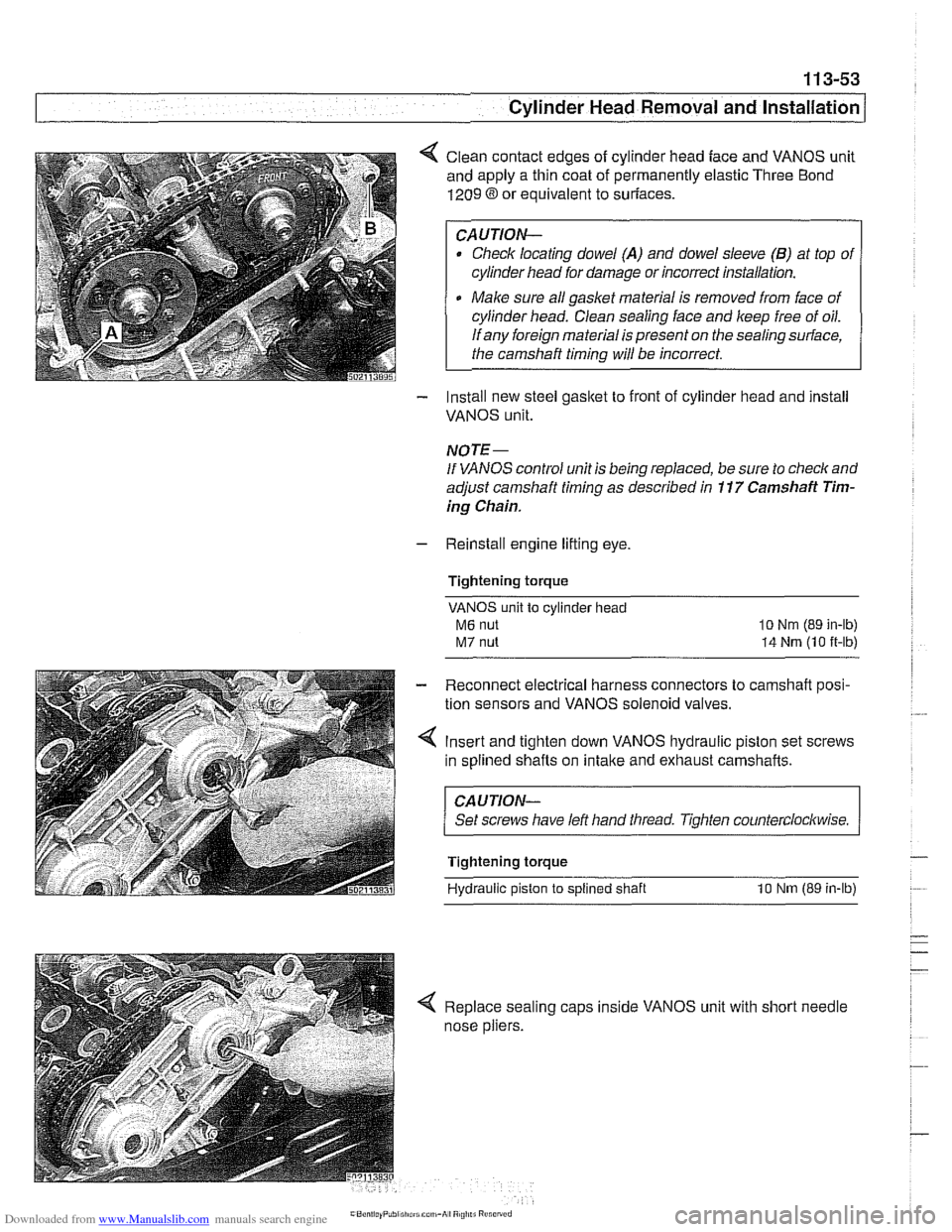

< Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of permanently elastic Three Bond

1209 8 or equivalent to suriaces.

CAUTION-

Check locating dowel (A) and dowel sleeve (B) at top of

cylinder head for damage or incorrect installation.

Make sure all gasket material is removed from face of

cylinder head. Clean sealing face and keep free of oil.

If any foreign material is present on the sealing surface,

the camshaft timing will be incorrect.

- Install new steel gasket to front of cylinder head and install

VANOS unit.

NOTE -

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in

11 7 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

Tightening torque

VANOS unit to cylinder head

M6 nut

M7 nut

lo Nm (89 in-lb)

14 Nrn (10 it-lb)

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and VANOS solenoid valves.

4 Insert and tighten down VANOS hydraulic piston set screws

in splined shafts on

intake and exhaust camshafts.

CAUJION-

Set screws have left hand tliread. Tighten counterclockwise.

Tightening torque

Hydraulic piston

to splined shaft 10 Nm (89 in-lb)

< Replace sealing caps inside VANOS unit with short needle

nose pliers.

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

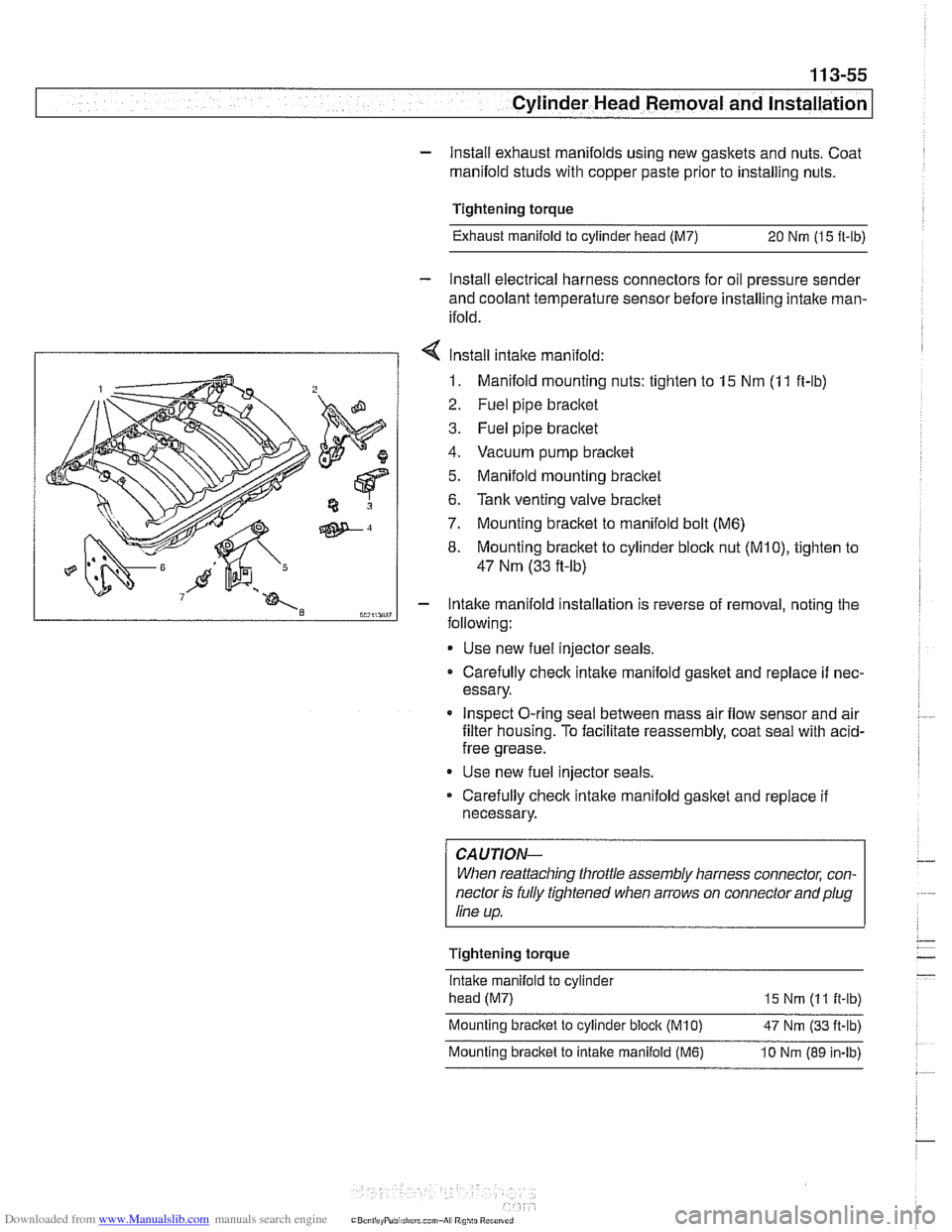

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)

Page 151 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

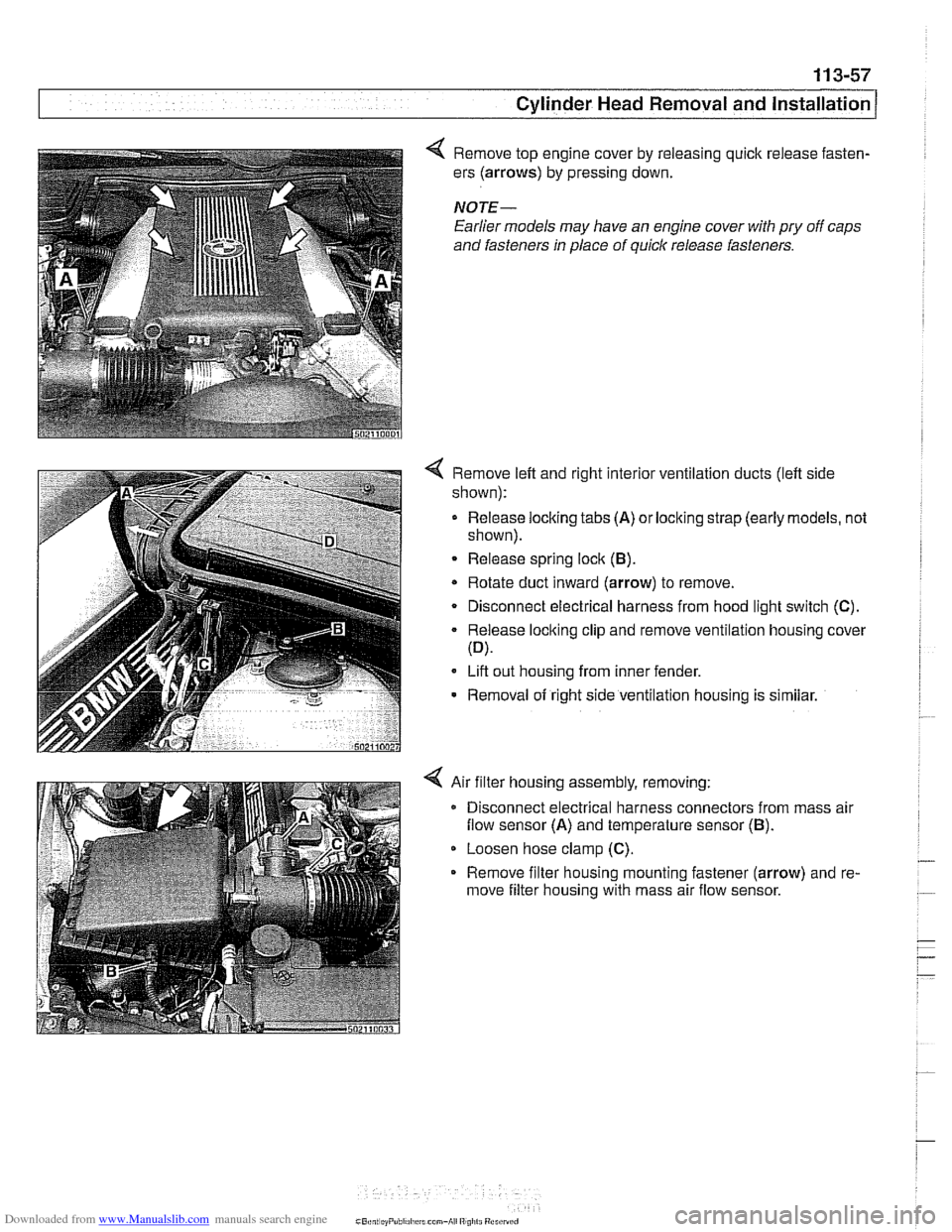

4 Remove top engine cover by releasing quick release fasten-

ers (arrows) by pressing down.

NOTE-

Earlier models may have an engine cover with pry off caps

and fasteners

In place of quick release fasteners.

4 Remove left and right interior ventilation ducts (left side

shown):

- Release locking tabs (A) or locking strap (early models, not

shown).

Release spring lock (B).

* Rotate duct inward (arrow) to remove.

Disconnect electrical harness from hood light switch (C).

Release locking clip and remove ventilation housing cover

(D).

Lift out housing from inner fender.

- Removal of right side ventilation housing is similar.

4 Air filter housing assembly, removing:

Disconnect electrical harness connectors from mass air

flow sensor (A) and temperature sensor (B).

Loosen hose clamp (C).

Remove filter housing mounting fastener (arrow) and re-

move filter housing with mass air flow sensor.

Page 153 of 1002

Downloaded from www.Manualslib.com manuals search engine

- .-

.. Cylinder Head Removal and Installation I -

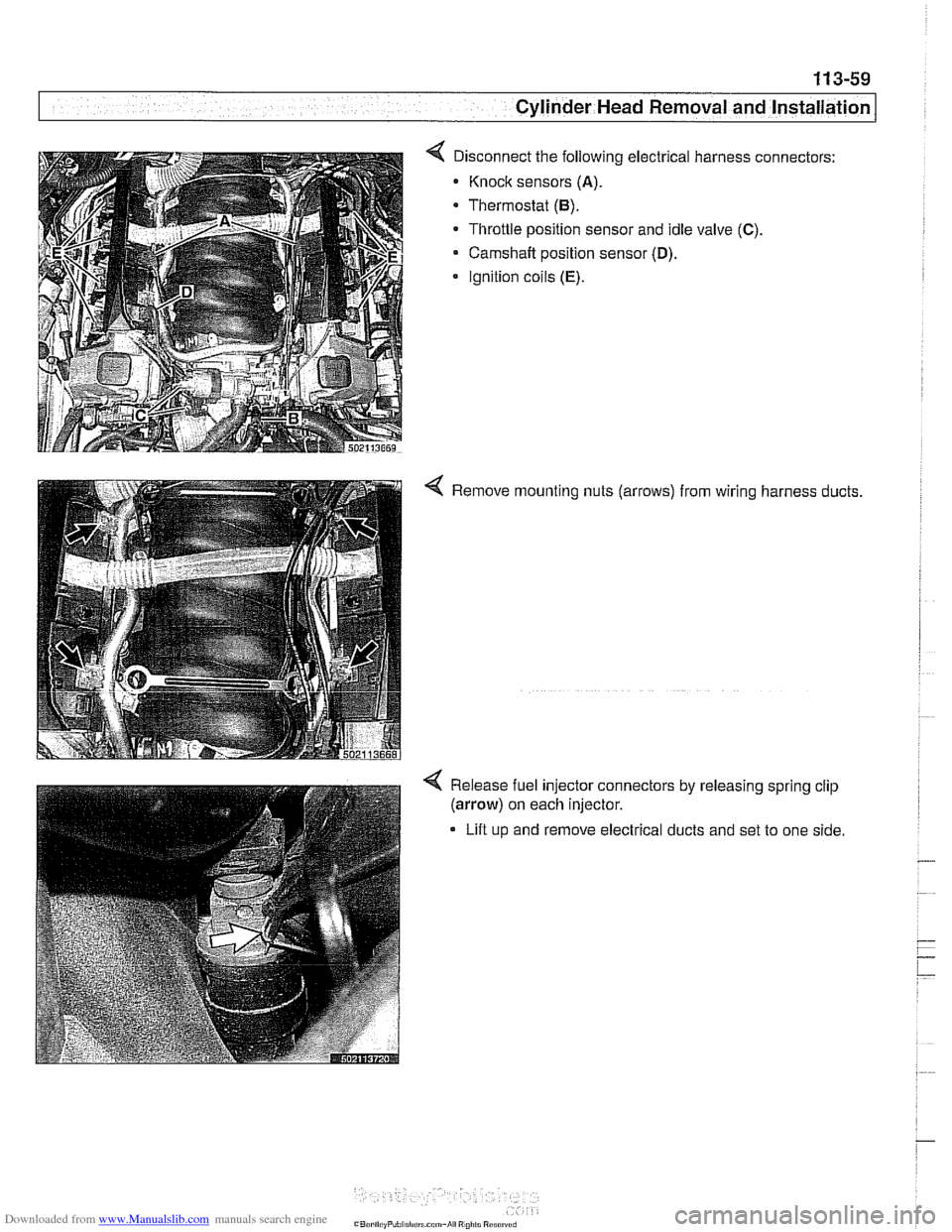

< Disconnect the following electrical harness connectors:

Knock sensors

(A).

Thermostat (6).

Throttle position sensor and idle valve (C).

Camshaft position sensor (D).

Ignition coils (E).

< Remove mounting nuts (arrows) from wiring harness ducts.

4 Release fuel injector connectors by releasing spring clip

(arrow) on each injector.

Lift up and remove electrical ducts and set to one side

Page 166 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Cylinder Head Removal and Installation

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new gaskets when mounting intake

manifold. Tighten

nuts finger tight first, then torque to specification in stages

working diagonally from center out.

Be sure to reinstall ignition coil ground straps at cylinders

no.

3 and no. 7. See 120 Ignition System.

Reinstall cooling fan and shroud. See

170 Radiator and

Cooling System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

CA UTIOG

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening torques

Camshaft sprocket to camshaft 15

Nm (11 H-lb)

Coolant manifold to cylinder head 10 Nm (7.5 H-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mounts to subirame 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

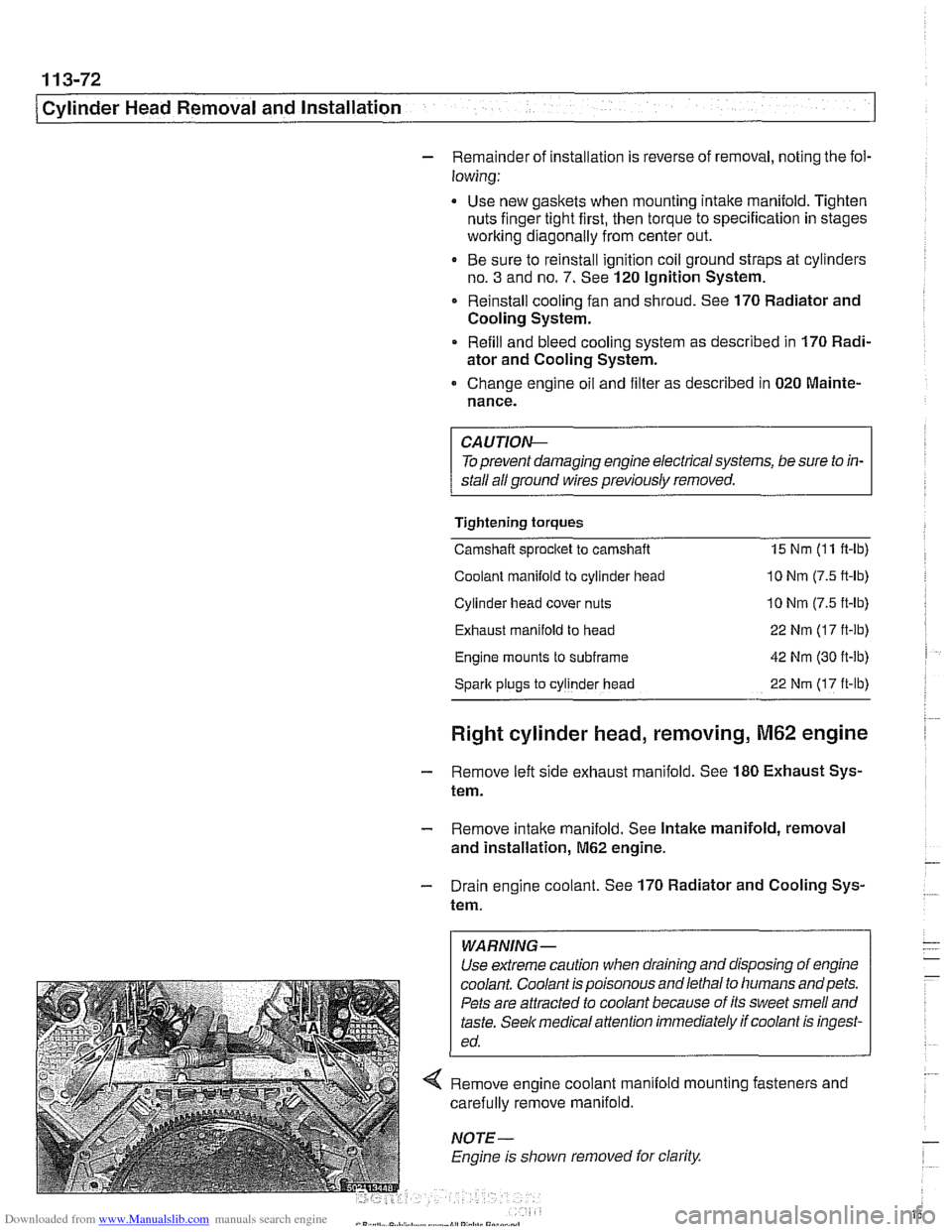

Right cylinder head, removing, M62 engine

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Remove intake manifold. See Intake manifold, removal

and installation,

M62 engine.

- Drain engine coolant. See 170 Radiator and Cooling Sys-

tem.

WARNING-

Use extreme caution when draining and disposing of engine

coolant.

Coolanl is poisonous andlellial lo liumans andpels.

Pets are

altracled to coolant because of 11s sfieet smell and

fasle. Seelc medcal anenfion immed~alely if coolant is ingesl-

. .-

< Remove engine coolant manlold mo~nlng fasreners and

carei~lly remove manifo d.

. I

NOTE

Engine 8s slioivn removed lor clarify

Page 176 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-82

1 Cylinder Head Removal and Installation

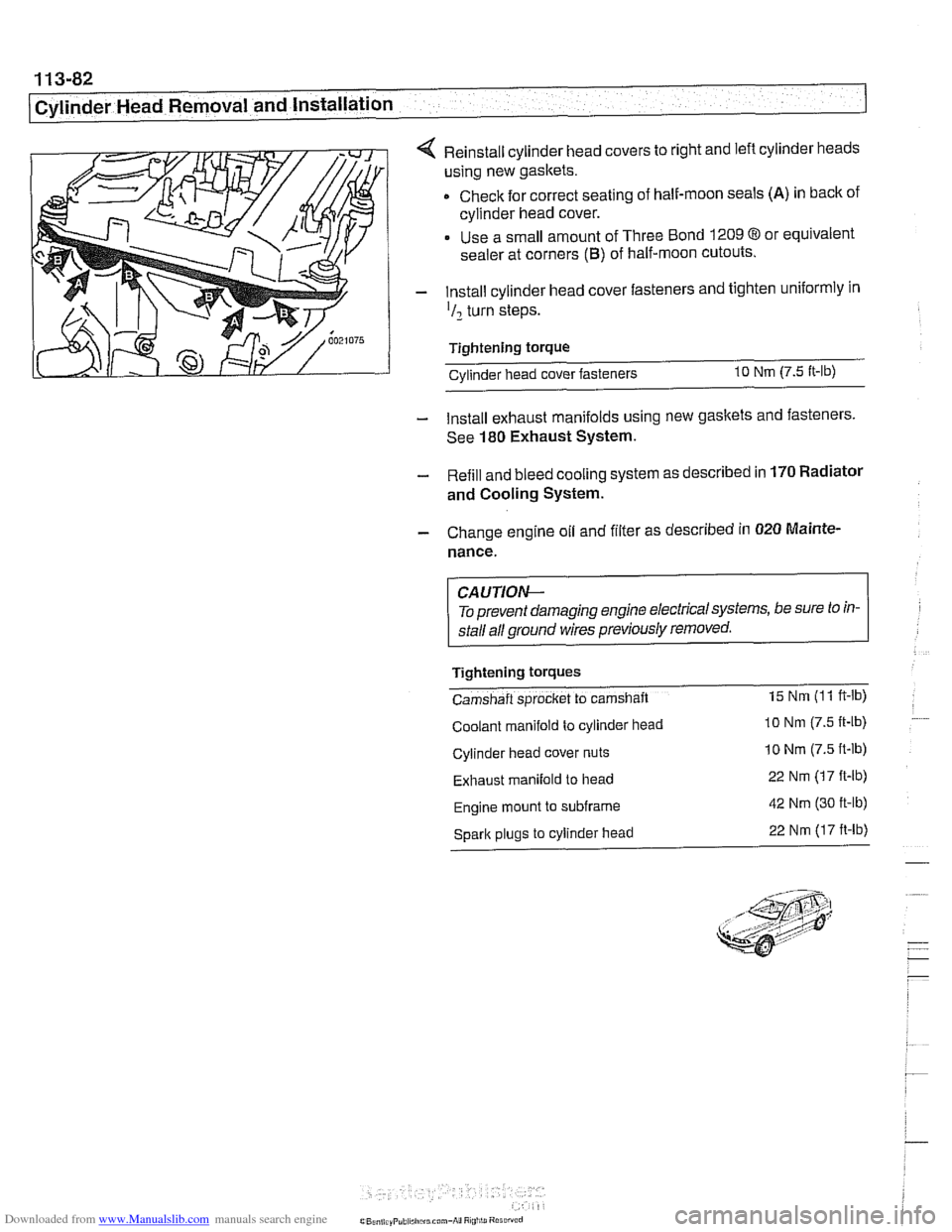

4 Reinstall cylinder head covers to right and left cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealer at corners

(B) of half-moon cutouts.

- Install cylinder head cover fasteners and tighten uniformly in

'I2 turn steps.

Tightening torque Cvlinder head cover fasteners

10 Nm (7.5 It-lb)

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.

- Refill and bleed cooling system as described in 170 Radiator

and Cooling System.

- Change engine oil and filter as described in 020 Mainte.

nance.

CA UTIOW-

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening

tOrqUeS

Camshaft sprocket to camshaft 15 Nm (1 1 ft-lb)

Coolant manifold to cylinder head lo Nm (7.5 It-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mount to subframe 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Page 185 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-9

Cvlinder Head and valvetrain1

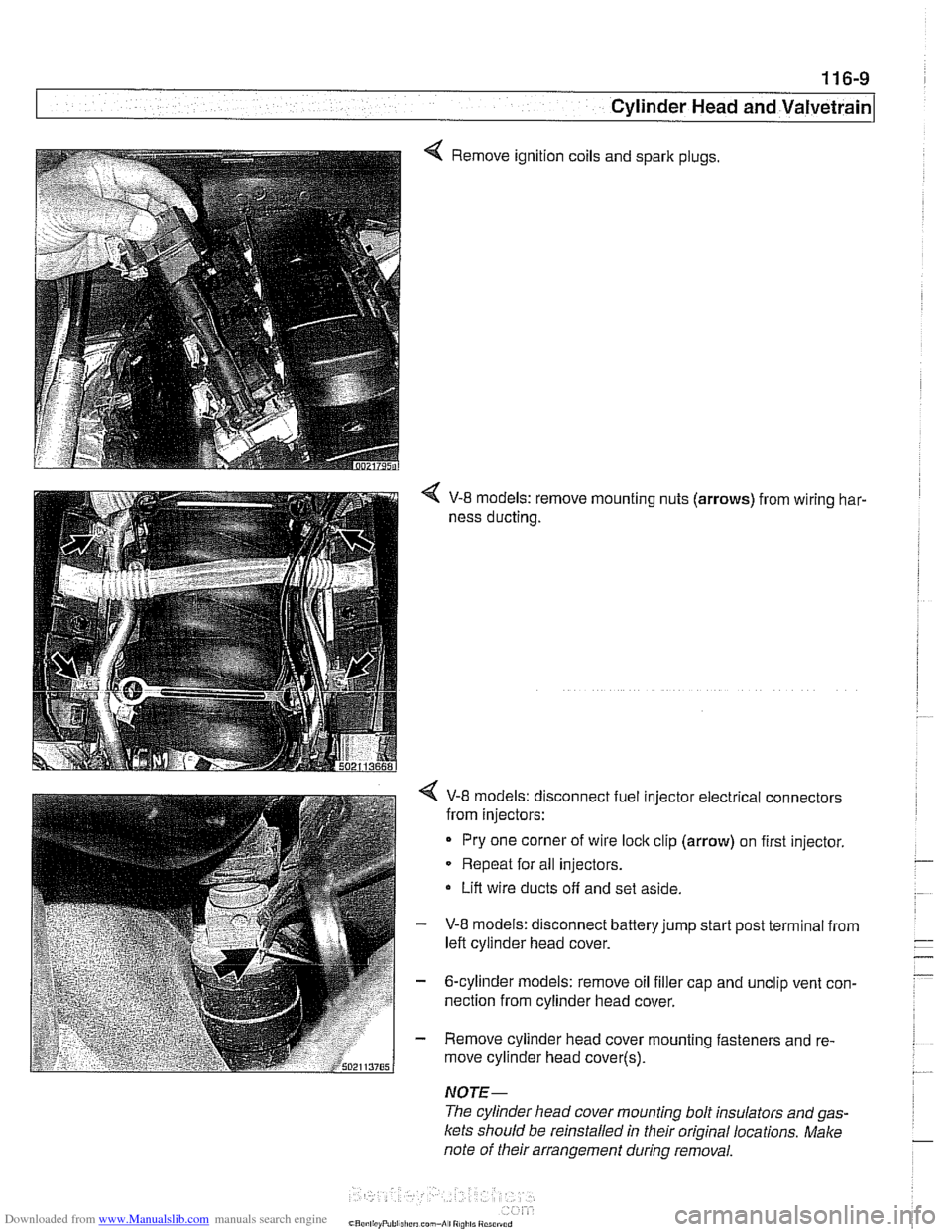

4 Remove ignition coils and spark plugs.

V-8 models: remove mounting nuts (arrows) from wiring har-

ness ducting.

< V-8 models: disconnect fuel injector electrical connectors

from injectors:

Pry one corner of wire

loclc clip (arrow) on first injector.

Repeat for all injectors.

Lift wire ducts off and set aside.

- V-8 models: disconnect battery jump start post terminal from

left cylinder head cover.

- 6-cylinder models: remove oil filler cap and unclip vent con-

nection from cylinder head cover.

- Remove cylinder head cover mounting fasteners and re-

move cylinder head cover(~).

NOTE-

The cylinder head cover mounting bolt insulators and gas-

Icets should be reinstalled in their original locations. Make

note of their arrangement

during removal.

Page 213 of 1002

![BMW 528i 2000 E39 Service Manual Downloaded from www.Manualslib.com manuals search engine

-

. - - -- Cylinder Head and valvetrain]

Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft BMW 528i 2000 E39 Service Manual Downloaded from www.Manualslib.com manuals search engine

-

. - - -- Cylinder Head and valvetrain]

Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft](/img/1/2822/w960_2822-212.png)

Downloaded from www.Manualslib.com manuals search engine

-

. - - -- Cylinder Head and valvetrain]

Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft lobes (arrows) face each other.

- Lock crankshaft in TDC position with BMW special tool

11 2 300.

4 Place BMW special tool set 11 3 240 over camshafts and

measure clearances.

NOTE-

@ If the exhaust side of the tool (A) is not flush with the head,

camshaft timing is incorrect. Reset camshaft timing as de-

scribed in 11

7 Camshaft Timing Chain.

Due to flexible sprocket design, VANOS unit tolerances

and play in the VANOS splines, when the camshaft timing

is set correctly, the intake side of special tool set

11 3 240

(B) may be up to 1 mm (0.04 in.) above the suiface of the

cylinder head. This is normal. Reassemble engine. Other-

wise, reset camshaft timing as describedin 1

l?Camshaft

Timing Chain.

- Remove BMW special tool 11 6 150 from front of cylinder

head.

4 Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of Three Bond

12090 or equivalent

sealing compound to surfaces.

CAUTION-

Male sure all gasket material is removed from face of cyl-

inder head. Clean sealing face and keep free of oil.

Check locating dowel

(A) and dowel sleeve (B) at top

of cylinder head for damage or incorrect installation.

- Using a new steel gasket, install VANOS unit to front of cyi-

inder head. See 117 Camshaft Timing Chain.

NOTE-

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in 117 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and

VANOS solenoid valves.

Page 215 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

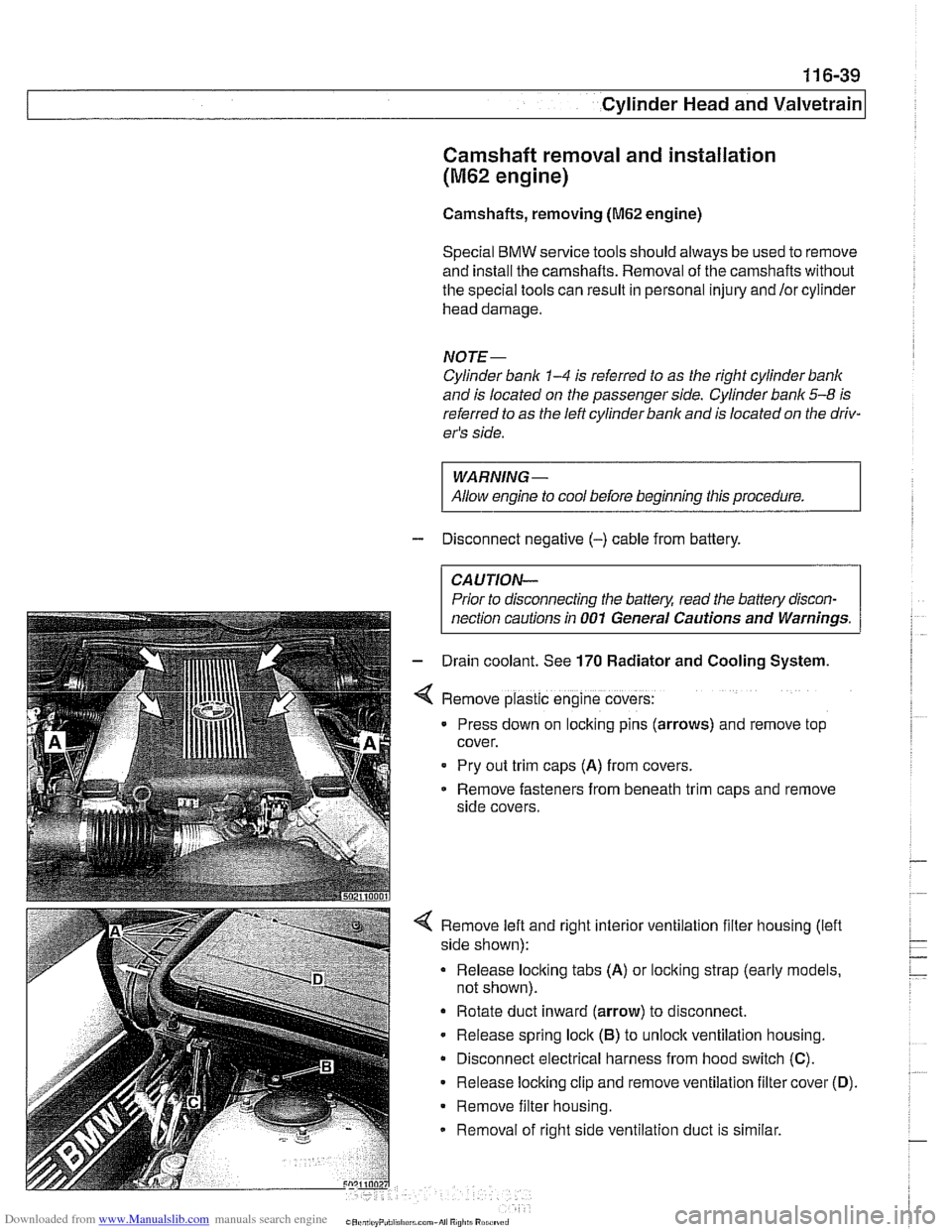

Camshaft removal and installation

(M62 engine)

Camshafts, removing (M62 engine)

Special

BMW service tools should always be used to remove

and install the camshafts. Removal of the camshafts without

the special tools can result in personal injury and lor cylinder

head damage.

NOTE-

Cylinder bank 1-4 is referred to as the right cylinder bank

and is located on the passenger side. Cylinder bank 5-8 is

referred to as the left cylinder bank and is located on the driv-

er's side.

WARNING-

Allow enqine to cool before beqinninq this procedure. 1

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions

in 001 General Cautions and Warnings.

- Dra~n coolant. See 170 Radiator and Cooling System.

Remove plastic engine covers:

Press down on locking pins (arrows) and remove top

cover.

Pry out

trlm caps (A) from covers.

Remove fasteners from beneath

trlm caps and remove

side covers.

4 Remove left and right interior ventilation filter housing (lefl

side shown):

Release locking tabs

(A) or locking strap (early models,

not shown).

Rotate duct inward (arrow) to disconnect.

- Release spring lock (6) to unloclc ventilation housing.

Disconnect electrical harness from hood switch

(C).

Release locking clip and remove ventilation filter cover (0).

Remove filter housing.

Removal of right side ventilation duct is similar.

Page 216 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. .

Cylinder Head and Valvetrain -- v . -- --- --

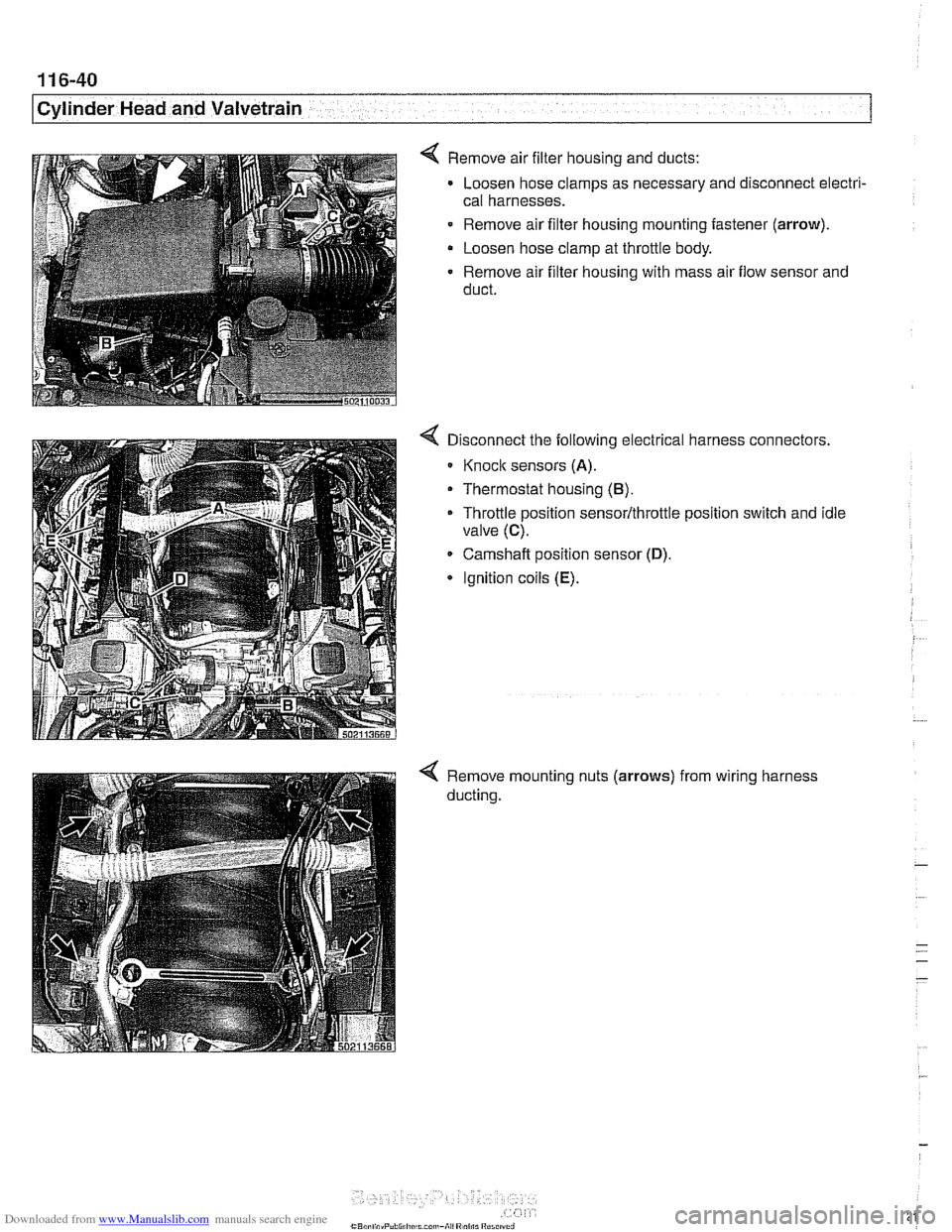

4 Remove air filter housing and ducts:

Loosen hose clamps as necessary and disconnect electri-

cal harnesses.

- Remove air filter housing mounting fastener (arrow).

Loosen hose clamp at throttle body.

Remove air filter housing with mass air flow sensor and

duct.

Disconnect the following electrical harness connectors.

Knoclc sensors (A).

Thermostat housing (B).

Throttle position sensor/throttle position switch and idle

valve

(C).

Camshaft position sensor (D).

* Ignition coils (E).

Remove mounting nuts (arrows)

ducting. from

wiring harness