load capacity BMW 530i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 530i, Model: BMW 530i 1997 E39Pages: 1002

Page 503 of 1002

Downloaded from www.Manualslib.com manuals search engine

Warnings and cautions

Obse~e the following warnings and cautions when worlting

on the cooling system.

WARNING -

. At normal operating temperature the cooling system is

pressurized. Allow the system to cool as long as possible

before opening (a minimum of one hour), then release the

cap slowly to allow safe release ofpressure.

a Releasing the coolant system pressure lowers the cool-

ant boilingpoint and the coolant may boil suddenly. Use

1 heavy and wear eye and face protection to

guard against scalding.

Use extreme care when draining and disposing of en-

gine coolant. Coolant is poisonous and lethal to hu-

mans andpets. Pets are attracted to coolant because

of its sweet smell and taste. Seek medical attention im-

mediately if coolant is ingested.

CAUTIOG

Avoid adding cold water to the coolant while the engine is

hot or overheated. If it is necessary to add coolant to a

hol

system, do so only with the engine running and coolanl

pump turning.

To avoid excess silicate gel precipitation in the cooling

system and loss of cooling capacity, use BMW coolant

or equivalent low silicate antifreeze.

a If oil enters the cooling system, the radiator, expansion

tank and heating circuit must be flushed with cleaning

agent. BMW recommends removal of the radiator and

expansion

tank to flush.

When

worlcing on the cooling system, cover the alter-

nator to protect it against coolant drips.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Warnings

and Cautions.

Begin the diagnosis of cooling system problems with a thor-

ough visual inspection.

If no visual faults are found, it is rec-

ommend that the engine control module (ECM) fault memory

be checked for stored diagnostic trouble codes

(DTCs) using

BMW scan tool

DlSplus or equivalent.

Page 507 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 1

Radiator and Cooling system/

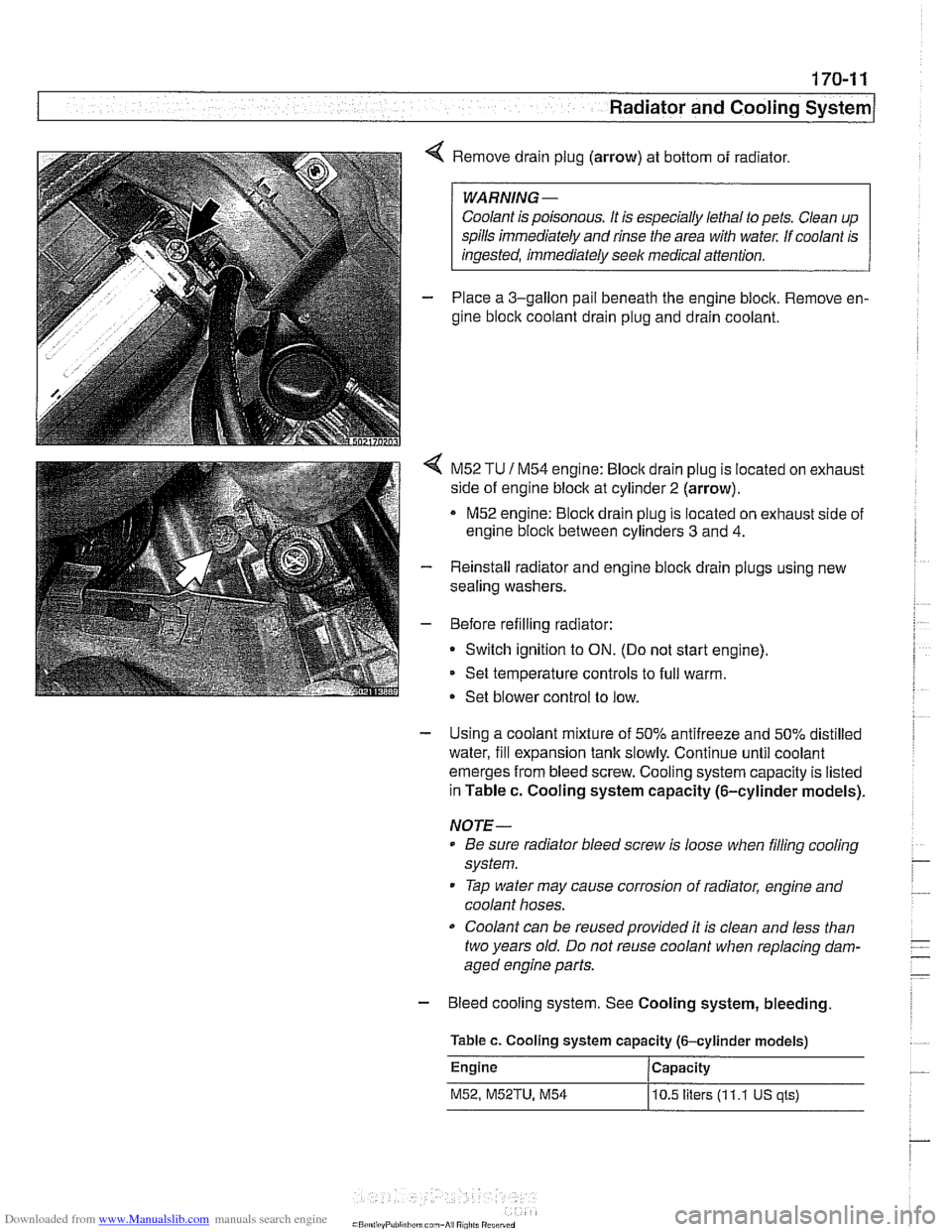

4 Remove drain plug (arrow) at bottom of radiator.

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with

wate,: If coolant is

- Place a 3-gallon pail beneath the engine block. Remove en-

gine block coolant drain plug and drain coolant.

< M52 TU 1 M54 engine: Bloclc drain plug is located on exhaust

side of engine block at cylinder

2 (arrow).

M52 engine:

Bloclc drain plug is located on exhaust side of

engine

bloclc between cylinders 3 and 4.

- Reinstall radiator and engine block drain plugs using new

sealing washers.

- Before refilling radiator:

Switch ignition to

ON. (Do not start engine).

Set temperature controls to full warm.

Set blower control to low.

- Using a coolant mixture of 50% antifreeze and 50% distilled

water, fill expansion tank slowly. Continue until coolant

emerges from bleed screw. Cooling system capacity is listed

in Table c. Cooling system capacity (6-cylinder models).

NOTE-

Be sure radiator bleed screw is loose when filling cooling

system.

Tap water may cause corrosion of radiator, engine and

coolant hoses.

Coolant can be reusedprovided it is clean and less than

two years old. Do not reuse coolant when replacing dam-

aged engine parts.

- Bleed cooling system. See Cooling system, bleeding

Table c. Cooling system capacity (6-cylinder models)

Engine Capacity

M52, M52TU, M54

10.5 liters (1 1.1 US qls)

Page 509 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 3

Radiator and Cooling ~vsteml

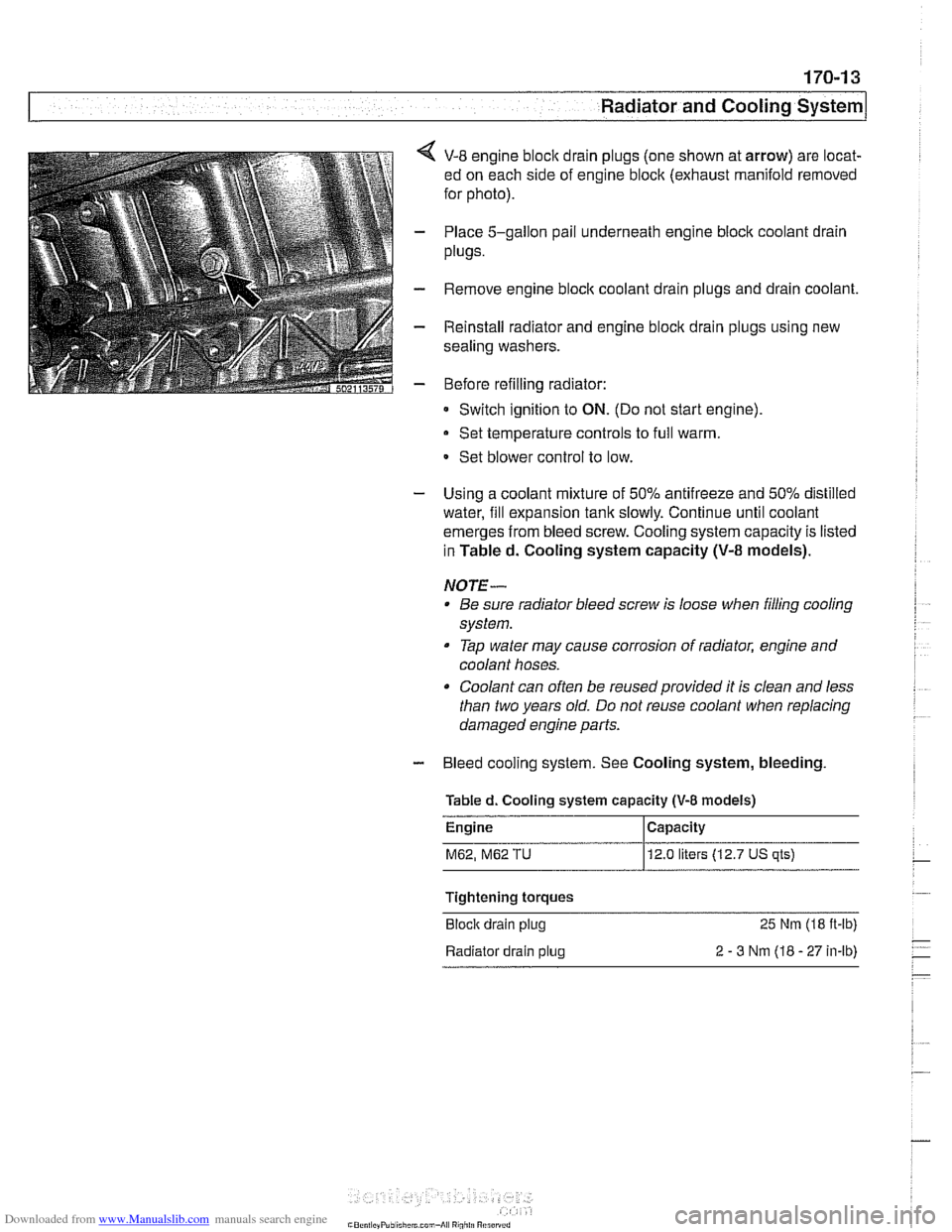

< V-8 engine bloclc drain plugs (one shown at arrow) are locat-

ed on each side of engine block (exhaust manifold removed

for photo).

- Place 5-gallon pail underneath engine block coolant drain

plugs.

- Remove engine bloclc coolant drain plugs and drain coolant.

- Reinstall radiator and engine block drain plugs using new

sealing washers.

- Before refilling radiator:

Switch ignition to

ON. (Do not start engine)

Set temperature controls to full warm.

- Set blower control to low.

- Using a coolant mixture of 50% antifreeze and 50% distilled

water, fill expansion tank slowly. Continue until coolant

emerges from bleed screw. Cooling system capacity is listed

in Tabled. Cooling system capacity

(V-8 models).

NOTE- Be sure radiator bleed screw is loose when filling cooling

system.

Tap water may cause corrosion of radiator, engine and

coolant hoses.

Coolant can often be reused provided it is clean and less

than two years old. Do not reuse coolant when replacing

damaged engine parts.

- Bleed cooling system. See Cooling system, bleeding

Tabled. Cooling system

capacity (V-8 models)

M62, M62 TU 12.0 liters (12.7 US qts)

Tightening torques

Block drain plug

25 Nm (18 ft-lb)

Radiator drain plug

2 - 3 Nm (18 - 27 in-lb)

Page 571 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-7

Manual Transmission

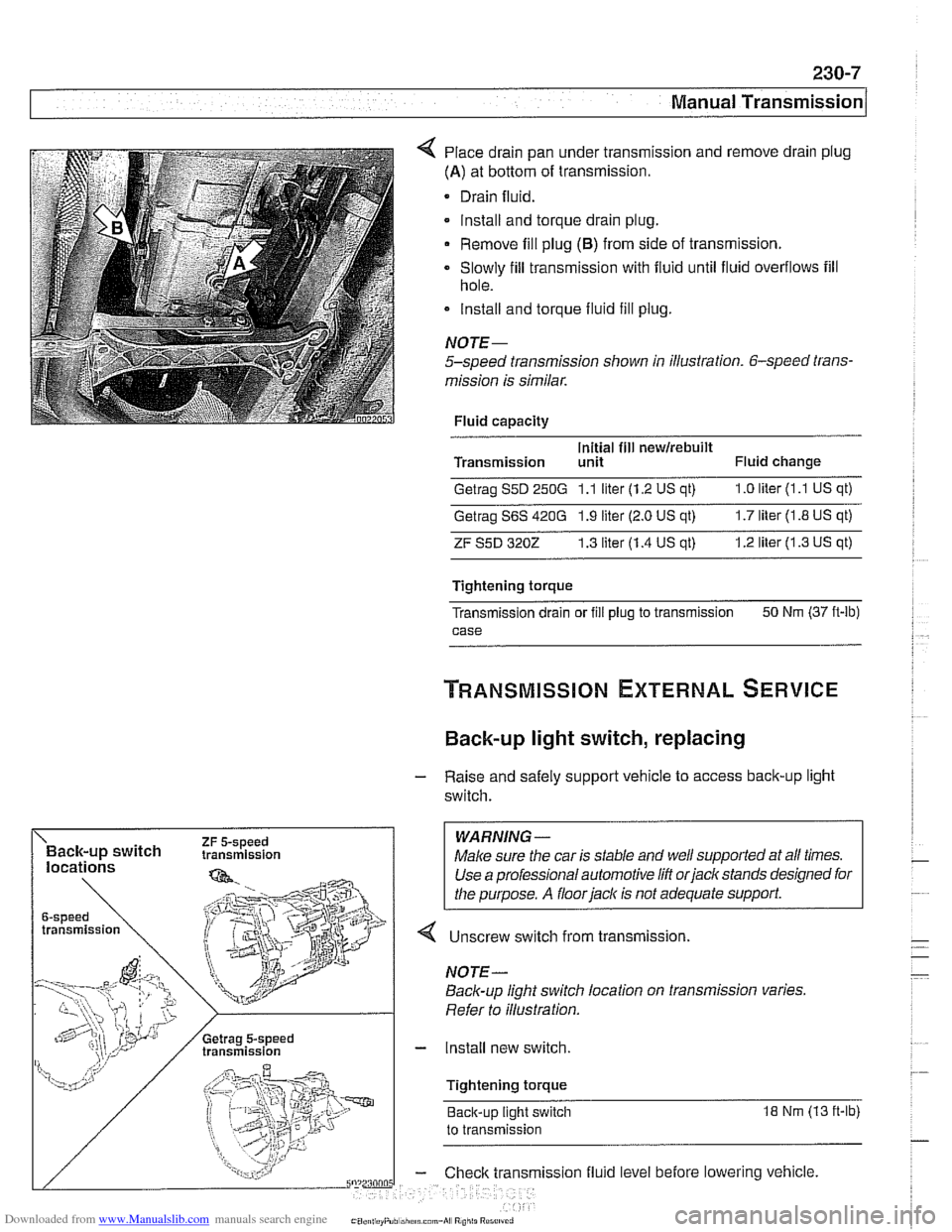

Place drain pan under transmission and remove drain plug

(A) at bottom of transmission.

Drain fluid.

lnstall and torque drain plug.

Remove fill plug

(6) from side of transmission.

Slowly fill transmission with fluid until fluid overflows fill

hole.

lnstall and torque fluid fill

plug.

NOJE-

5-speed transmission shown in illustration. 6-speed trans-

mission is similar.

Fluid capacity

Initial fill

newirebuilt Transmission unit Fluid change

Getrag S5D 250G 1.1 liter (1.2 US qt) 1.0 liter (1 .l US qt)

Getrag S6S 420G 1.9 liter (2.0 US qt) 1.7 liter (1.8 US qt)

ZF S5D 3202 1.3 liter (1.4 US at) 1.2 liter (1.3 US qt)

Tightening torque

Transmission drain or

fill plug to transmission 50

Nm (37 ft-lb)

case

Back-up light switch, replacing

- Raise and safely support vehicle to access back-up light

switch.

WARNING -

4 Unscrew switch from transmission.

Back-up light switch location on transmission varies.

Refer to illustration.

- Install new switch.

Tightening torque Back-up light switch

18 Nm (13 ft-lb)

to transmission

ission fluid level before lowering vehicle.

Page 592 of 1002

Downloaded from www.Manualslib.com manuals search engine

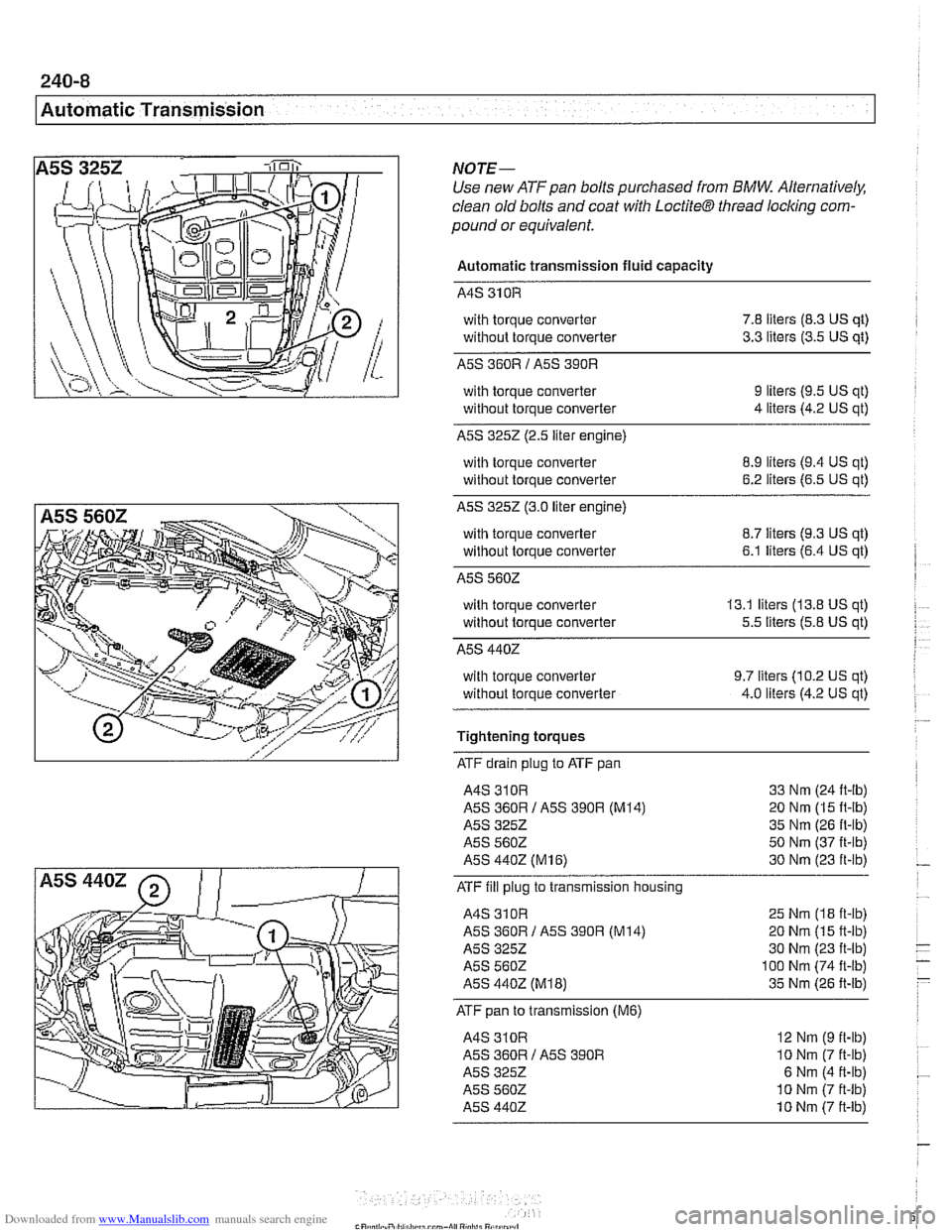

Automatic Transmission

NOTE-

Use new ATF pan bolts purchased from BMW Alternatively,

clean old bolts and coat with

LoctiteB thread locl

Automatic transmission fluid capacity

with torque converter

7.8 liters (8.3 US qt)

without torque converter

3.3 liters (3.5 US qt)

A5S 360R 1 A5S 390R

with torque converter

without torque converter 9 liters (9.5 US qt)

4 liters (4.2 US qt)

A5S 3252 (2.5 liter engine)

with torque converter

without torque converter

8.9 liters (9.4 US qt)

6.2 liters (6.5 US qt)

A5S 3252 (3.0 liter engine)

with torque converter

8.7 liters (9.3 US qt)

without torque converter

6.1 liters (6.4 US qt)

A5S 5602

with torque converter 13.1 liters (13.8 US qt)

without torque converter

5.5 liters (5.8 US qt)

A5S 4402

with torque converter

without torque converter 9.7 liters (10.2 US qt)

4.0 liters (4.2 US qt)

Tightening torques

ATF drain plug to ATF pan

A4S 310R 33 Nm (24 ft-lb)

A5S 360R I A5S 390R (M14) 20 Nm (15 It-lb)

A5S

3252 35 Nm (26 ft-lb)

A5S 560Z 50 Nm (37 ft-lb)

A5S

4402 (MI 6) 30 Nm (23 ft-lb)

ATF fill plug

to transmission housing

A4S 31 OR 25 Nm (I8 ft-lb)

A5S 360R 1 A5S 390R (M14) 20 Nm (1 5 ft-lb)

A5S 3252 30 Nm (23 ft-ib)

A5S 5602 100 Nm (74 ft-lb)

A5S 4402 (M18) 35 Nm (26 ft-lb)

ATF pan to transmission (M6)

A4S 310R

A5S

360R 1 A5S 390R

A5S 3252

A5S

5602

A5S 4402

12 Nm (9 ft-lb)

10 Nm (7 ft-ib)

6 Nm (4 ft-lb)

10 Nm (7 ft-lb)

10 Nm (7 ft-lb)

Page 762 of 1002

Downloaded from www.Manualslib.com manuals search engine

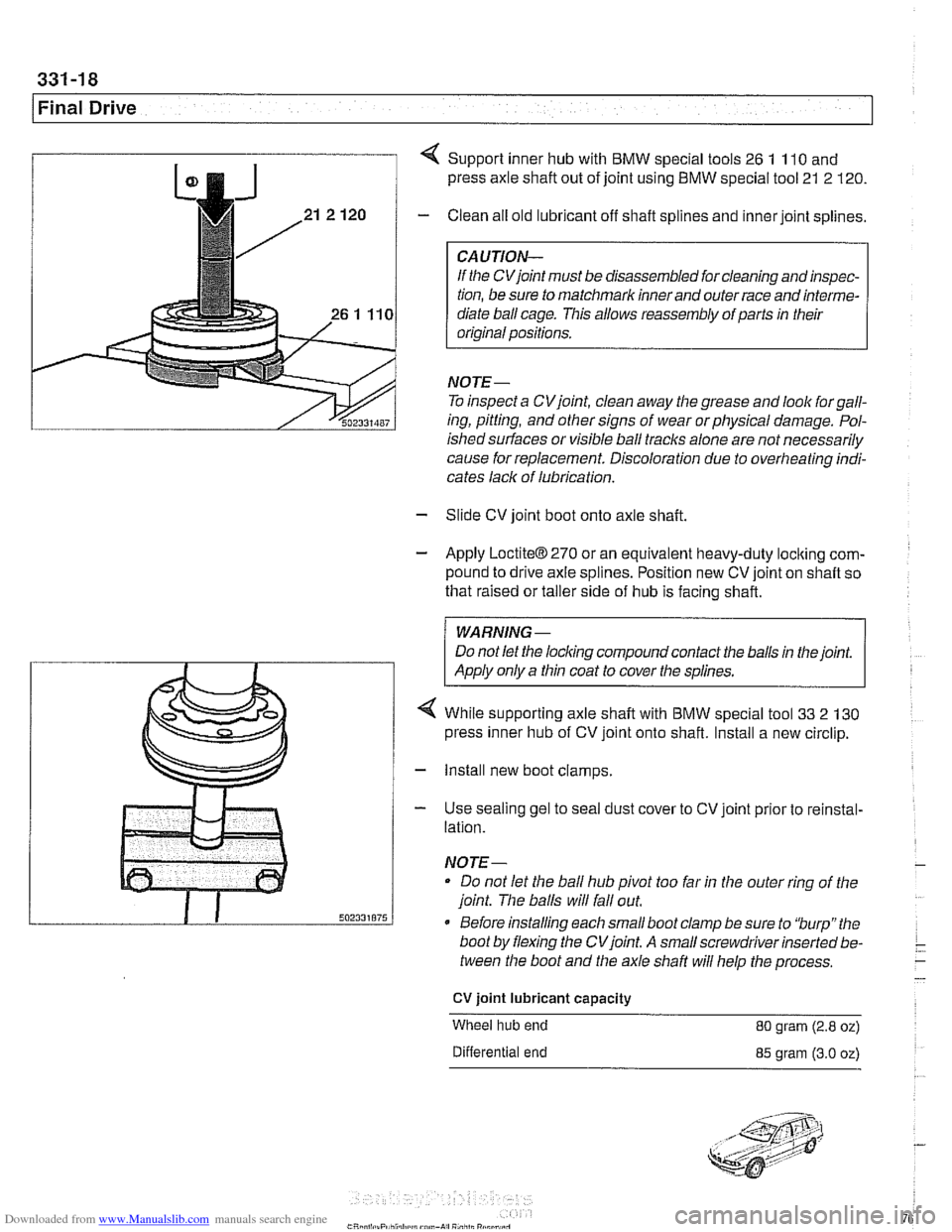

I Final Drive

4 Support inner hub with BMW special tools 26 1 110 and

press axle shaft out of joint using BMW special tool 21 2 120.

- Clean all old lubricant off shaft splines and inner joint splines.

If the CVjoint must be disassembled for cleaning and inspec-

tion, be sure to matchmark inner and outer race and interme-

diate ball cage. This allows reassembly

ofparfs in their

original positions.

NOTE-

To inspect a CVjoint, clean away the grease and loolc forgall-

ing, pitting, and other signs of wear orphysical damage. Pol-

ishedsurfaces or visible ball traclts alone are not necessarily

cause forreplacement. Discoloration due to overheating indi-

cates

laclt of lubrication.

- Slide CV joint boot onto axle shaft

- Apply LoctiteO270 or an equivalent heavy-duty loclting corn-

pound to drive axle splines. Position new CV joint on shaft so

that raised or taller side of hub is facing shaft.

WARNING-

Do not let the locking compound contact the balls in the joint.

Apply only a thin coat to cover the splines.

While supporting axle shaft with BMW special tool

33 2 130

press inner hub of CV joint onto shaft. Install a new circlip.

- Install new boot clamps.

- Use sealing gel to seal dust cover to CV joint prior to reinstal-

lation.

NOTE-

* Do not let the ball hub pivot too far in the outer ring of the

joint.

Tlie balls will fa1 out.

Before installing each small boot clamp be sure to

'burp"the

boot by flexing the CVjoint. A small screwdriver inserted be-

tween the boot and the axle shafl will help the process.

CV joint lubricant capacity

Wheel hub end

80 gram (2.8 oz)

Differential end

85 gram (3.0 oz)

Page 798 of 1002

Downloaded from www.Manualslib.com manuals search engine

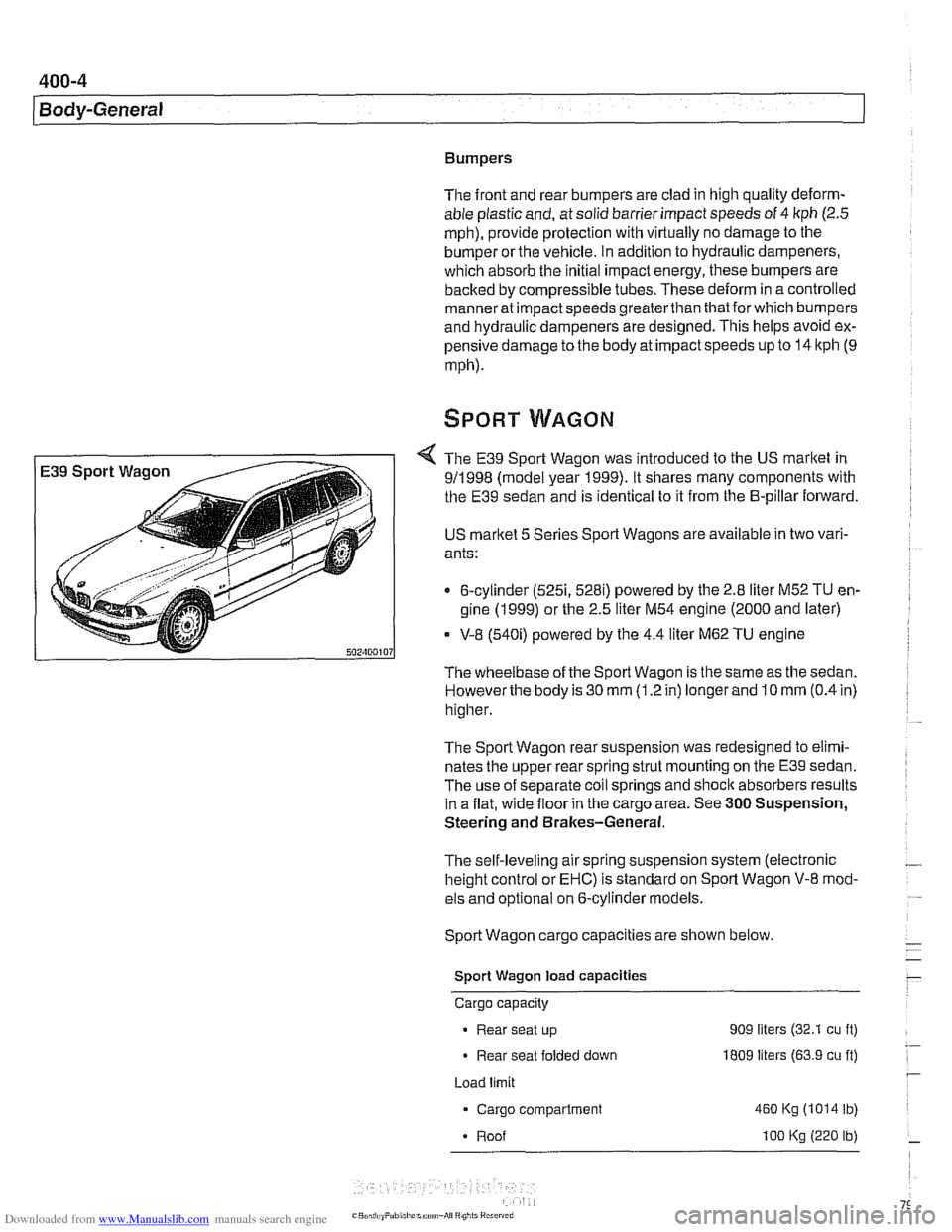

400-4

I Bodv-General

Bumpers

The front and rear bumpers are clad in high quality

deform-

able plastic and, at solid barrier impact speeds of 4 kph (2.5

mph), provide protection with virtually no damage to the

bumper

orthe vehicle. In addition to hydraulic dampeners.

which absorb the initial impact energy, these bumpers are

backed by compressible tubes. These deform in a controlled

manner at impact speeds greaterthan that

forwhich bumpers

and hydraulic dampeners are designed. This helps avoid ex-

pensive damage to the body at impact speeds up to 14 kph (9

mph).

The E39 Sport Wagon was introduced to the US market in

911 998 (model year 1999). It shares many components with

the E39 sedan and is identical to it from the B-pillar forward.

US

marltet 5 Series Sport Wagons are available in two vari-

ants:

6-cylinder

(5251, 528i) powered by the 2.8 liter M52 TU en-

gine (1 999) or the 2.5 liter M54 engine (2000 and later)

* V-8 (540i) powered by the 4.4 liter M62 TU engine

The wheelbase of the Sport Wagon is the same as the sedan.

Howeverthe body is 30

mm (1.2 in) longer and 10 mm (0.4 in)

higher.

The Sport Wagon rear suspension was redesigned to elimi-

nates the upper rear spring strut mounting on the E39 sedan.

The use of separate coil springs and

shoclc absorbers results

in a flat, wide floor in the cargo area. See

300 Suspension,

Steering and Brakes-General.

The self-leveling air spring suspension system (electronic

height control or EHC) is standard on Sport Wagon V-8 mod-

els and optional on 6-cylinder models.

Sport Wagon cargo capacities are shown below.

Sport Wagon load capacities

Cargo capacity

Rear seat up 909 liters (32.1 cu ft)

Rear seat folded down I809 liters (63.9 cu ft)

Load limit

Cargo compartment

460 Kg (1014 lb)

Roof

I00 Kg (220 lb)

Page 991 of 1002

Downloaded from www.Manualslib.com manuals search engine

INDEX 'tl

WARNING

Your common sense, good

judgemenl, and general alertness are

crucial to sale and successiul service

worlr. Belore attempting any work on

your

BMM be sure lo read 001

General Warnings and Cautions

and the

copyriglll page at the front 01

the manual. Review these warnings

and

caulions each lime you prepare

lo work on your BMW. Please also

read any warnings and cautions that

accompany

tile procedures in the

manual.

312-way valve (running losses)

see Fuel tank

Abbreviations, commonly used 600-14

ABS (antilock brake system)

see

Bral(es

A/C air distribution motors

see stepper motors (below)

blower final stage (resistor pack),

replacing

640-16

blower, removinglinslalling

640-1 5

compressor, replacing

640-24 condenser, replacing 64045

control panellmodule, removing1

installing

640-1 1

evaporakr, removinglinstalling 640-29

evaporator temperature sensor

640-12 expansion valve, removinglinstailing

640-27

IHKA/ IHKR system description 640-5

receiveridrier, replacing 640-26

stepper motors 640-1 3 ventilation microiilter, replacing

020-22. 640-17

see also Heating

Accelerator

iinlcage

see Maintenance

Activated carbon canister

see Fuel tank

ADS (auxiliary throttle valve)

130-57

Air compressor

330-44

Air conditioning

see

AIC

Air distribution (flap) motors

seeNC, stepper motors

Air filter see Maintenance

Air spring

300-6, 330-12

Airbag system (SRS)

2-stage

airbag 721-4

control module, replacing 721-7 driver airbag, removinglinstalling

721-8

iiead protection airbag 721-12 components 721-1 1

indicator

lighl721-4

passenger airbag, removinglinstalling

721-9 side-impact airbags crash sensor,

replacing

721-7

Airflow sensor see 130 under appropriate

fuel

injection system

Air pump

see 130 under appropriate fuel

injection system, secondary air

injection system

Air suspension

see Electronic height control

(EHC)

Alarm

see Anti-theft alarm

Alignment see

Wheei alignment

Aluminum suspension components

300-2

Antenna 650-6

Alternator see Battery, starter, alte rnator

Amplifier

650-4

Anti-theft alarm (DWA)

515-24 emergency disarming 515-31

Antifreeze (engine coolant)

see Maintenance

see also Cooling system

Antilock brake system (ABS) see Brakes

ASC see Brakes

ATF (automatic transmission fluid)

see Automatic transmission

see also Cooling systern

Automatic headlight adjustmenl

(LWR) see Lights

Automatic seat belt tensioner

720-4

Automatic shiftloclc

see

Gearshift

Automatic transmission

applications

200-3, 240-4

ATF 020-10, 200-4

capacity 240-8 checking 240-6

drainingifilling 240-7

heat exchanger 170-5

fluid pan and strainer 240-9 gearshift

see Gearshift

ID tag

200-3 range switch 610-6

removaliinstallation 240-10

steptronic see Gearshift

Auxiliary cooling fan

see

Coollng system, electric Ian

Auxiliary throttle valve (ADS)

130-57

Axle joint

see Drive axle

Back-up light switch

automatic transmission see Automatic transmission. range switch

- .~.~~~

manual transmission 230-8 -

- I