catalytic BMW 530i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 531 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Exhaust System

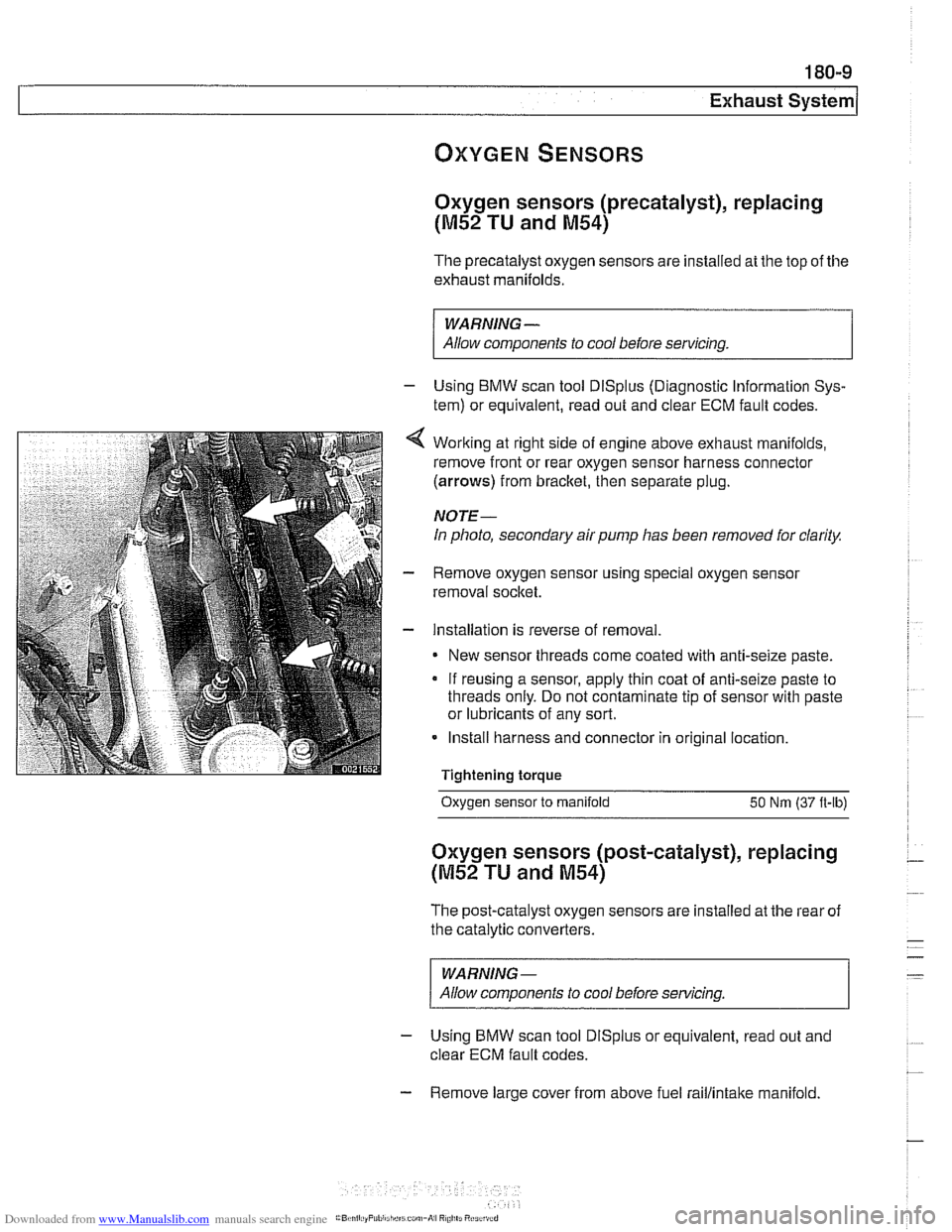

Oxygen sensors (precatalyst), replacing

(M52 TU and M54)

The precatalyst oxygen sensors are installed at the top of the

exhaust manifolds.

WARNING-

Allow components to cool before servicing.

- Using BMW scan tool DlSplus (Diagnostic Information Sys-

tem) or equivalent, read out and clear ECM fault codes.

Working at right side of engine above exhaust manifolds,

remove front or rear oxygen sensor harness connector

(arrows) from bracket, then separate plug.

NOTE-

In photo, secondary air pump has been removed for clarity.

Remove oxygen sensor using special oxygen sensor

removal socket.

Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing a sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

- -.

Oxygen sensor to manifold 50 Nm (37 ft-lb)

Oxygen sensors (post-catalyst), replacing

(M52 TU and M54)

The post-catalyst oxygen sensors are installed at the rear of

the catalytic converters.

WARNING-

Allow components to cool before servicing

- Using BMW scan tool DlSplus or equivalent, read out and

clear ECM fault codes.

- Remove large cover from above fuel raillintake manifold.

Page 532 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust System

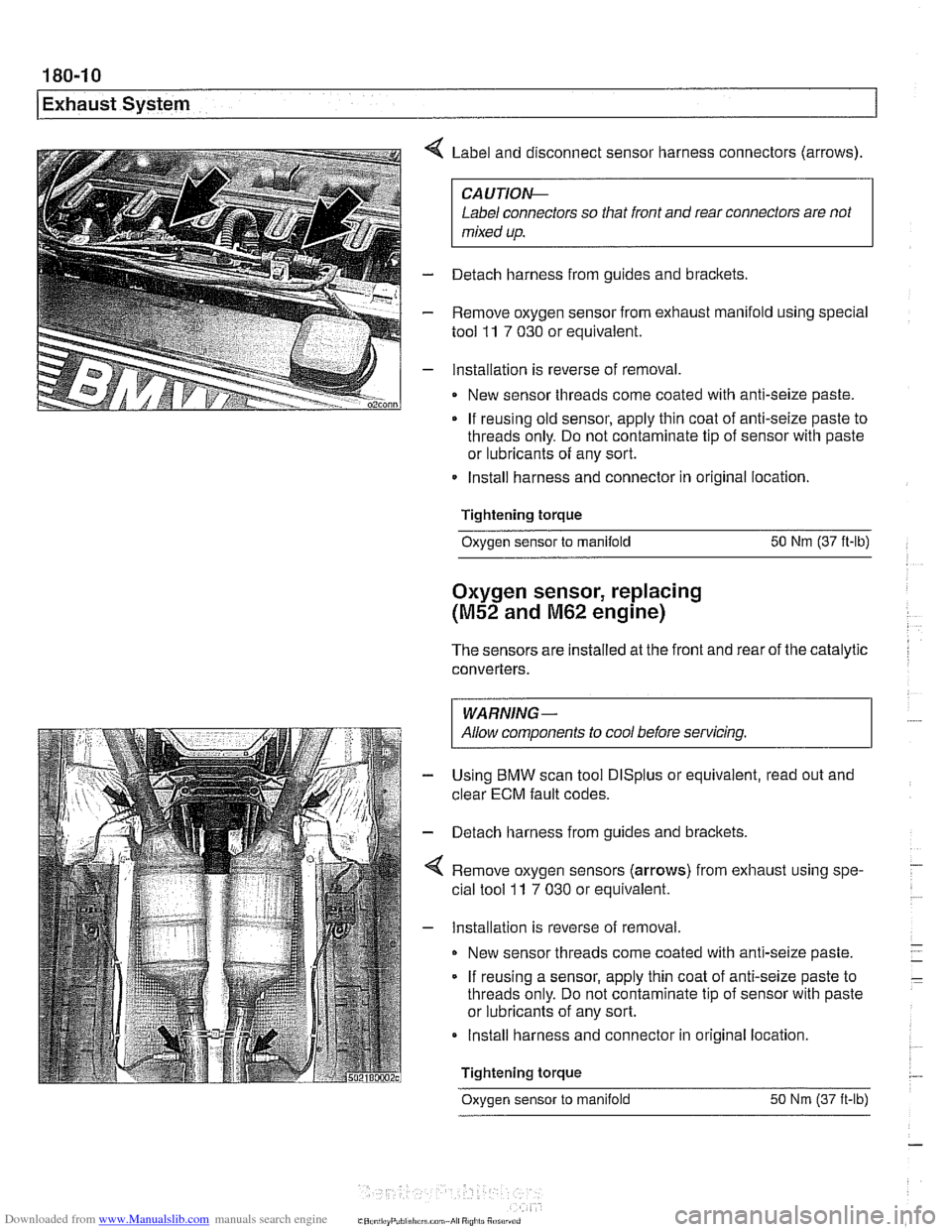

Label and disconnect sensor harness connectors (arrows).

CAUTlOI\C

Label connectors so that front and rear connectors are not

mixed up.

- Detach harness from guides and brackets.

- Remove oxygen sensor from exhaust manifold using special

tool

11 7 030 or equivalent.

- Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing old sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

Oxygen sensor to manifold 50 Nm (37 ft-lb)

Oxygen sensor, replacing

(M52 and M62 engine)

The sensors are installed at the front and rear of the catalytic

converters.

I WARNING- I

I Allow components to cool before servicing. I

Using BMW scan tool DlSplus or equivalent, read out and

clear

ECM fault codes.

Detach harness from guides and brackets.

Remove oxygen sensors (arrows) from exhaust using spe-

cial tool

ll 7 030 or equivalent.

Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing a sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

Oxvaen sensor to manifold 50 Nm (37 it-lb)

Page 533 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust System

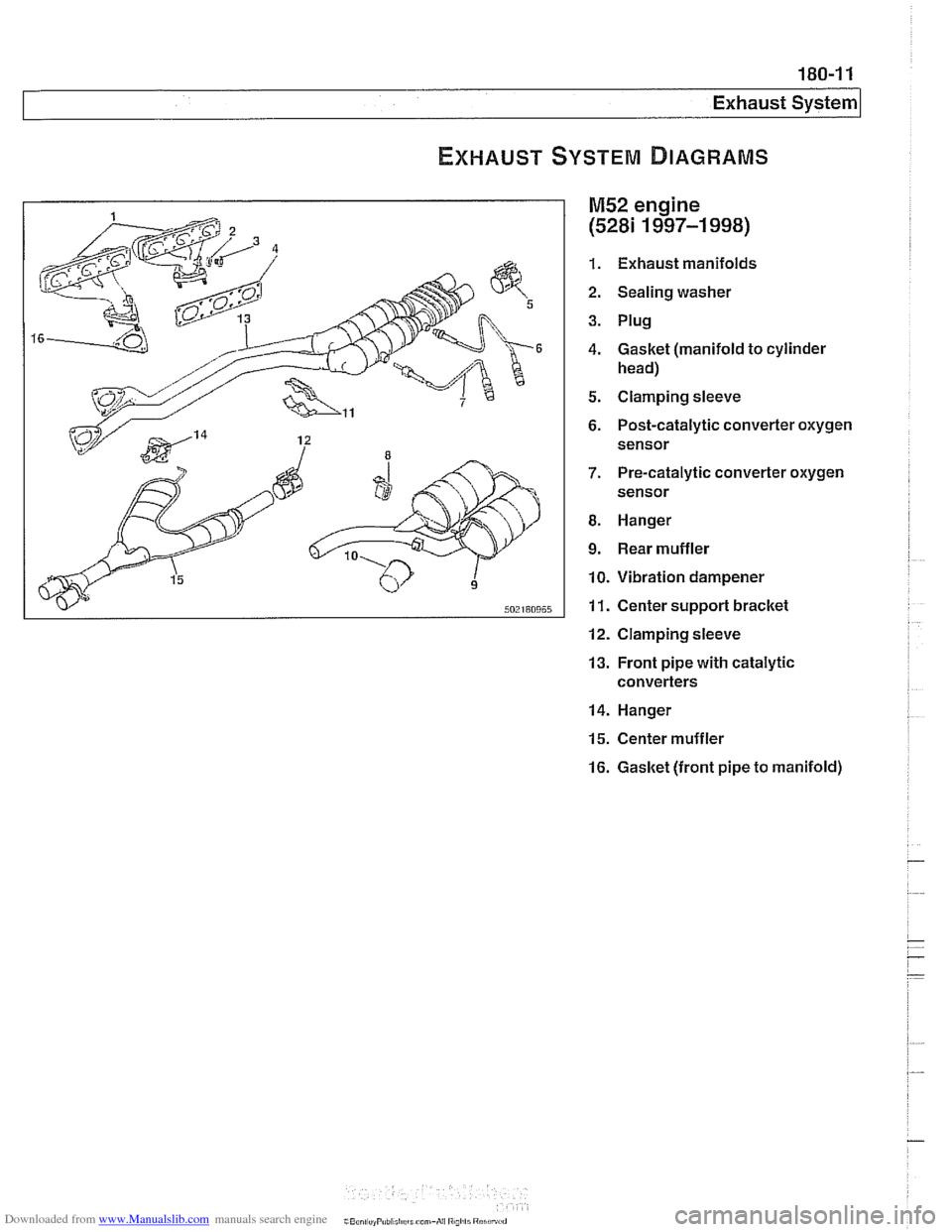

M52 engine

(5281 1997-1 998)

1. Exhaust manifolds

2. Sealing washer

3. Plug

4. Gasket (manifold to cylinder

head)

5. Clamping sleeve

6. Post-catalytic converter oxygen sensor

7. Pre-catalytic converter oxygen

sensor

8. Hanger

9. Rear muffler

10. Vibration dampener

11. Center support bracket

12. Clamping sleeve

13. Front pipe with catalytic

converters

14. Hanger

15. Center muffler

16. Gasket (front pipe to manifold)

Page 534 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exhaust System

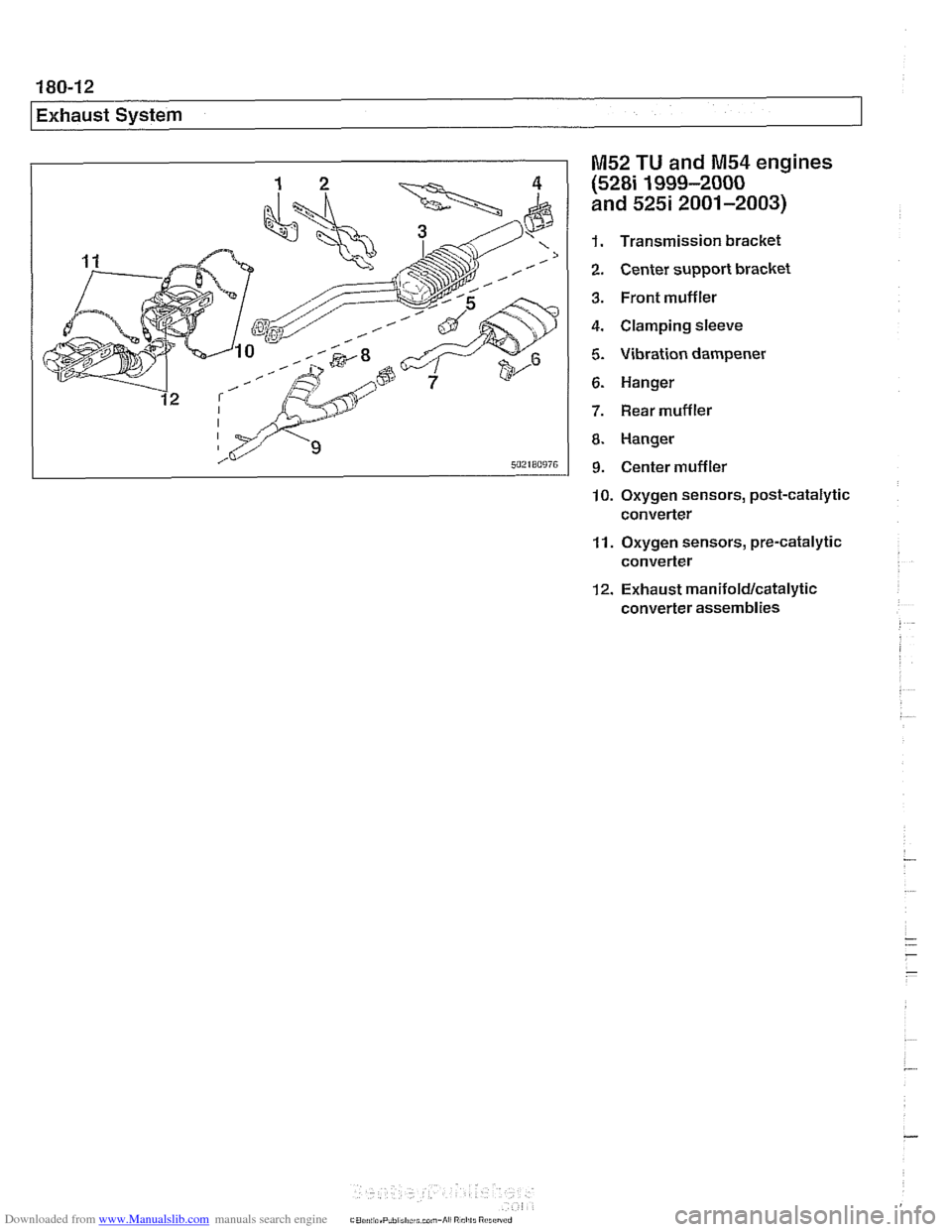

M52 TU and M54 engines

(528i 1999-2000

and 525i 2001-2003)

1. Transmission bracket

2. Center support bracket

3. Front muffler

4. Clamping sleeve

5. Vibration dampener

6. Hanger

7. Rear muffler

8. Hanger

9. Center muffler

10. Oxygen sensors, post-catalytic

converter

11. Oxygen sensors, pre-catalytic

converter

12. Exhaust manifoldlcatalytic

converter assemblies

Page 535 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust systeml

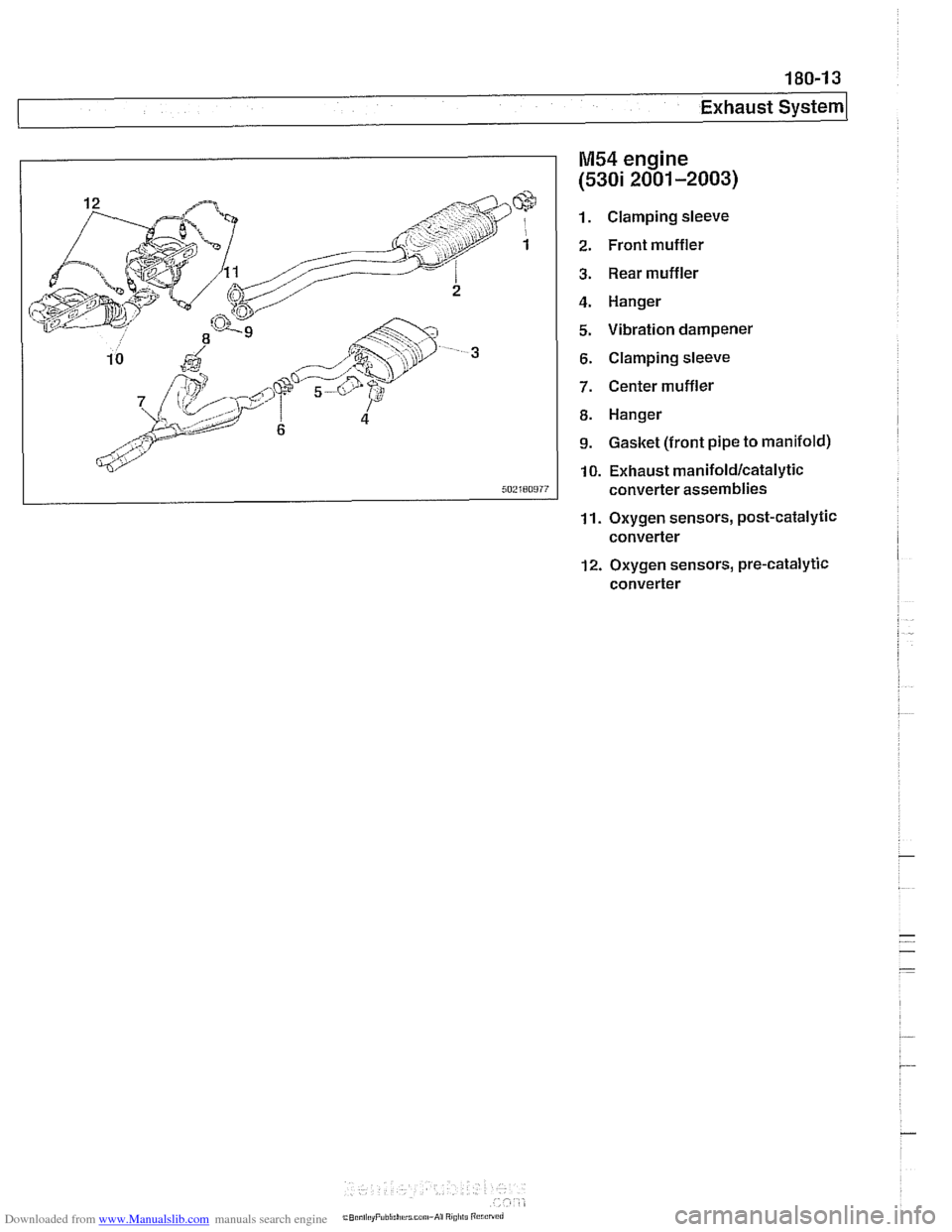

M54 engine

(5301 2001-2003)

Clamping sleeve

Front muffler Rear muffler

Hanger

Vibration dampener

Clamping sleeve

Center muffler

Hanger

Gasket (front pipe to manifold)

10. Exhaust

manifold/catalytic

converter assemblies

11. Oxygen sensors, post-catalytic converter

12. Oxygen sensors, pre-catalytic converter

Page 536 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exhaust System

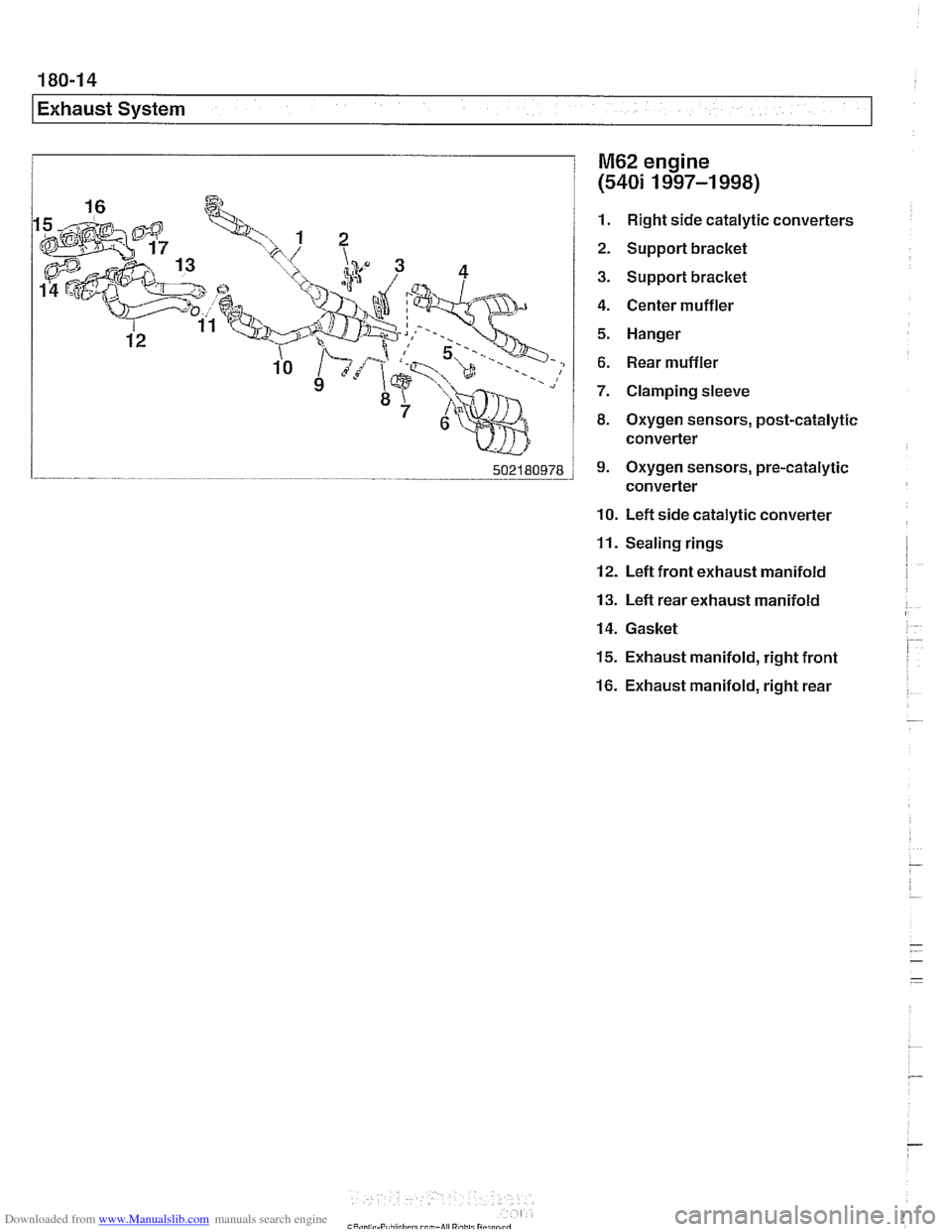

M62 engine

(540i 1997-1 998)

1. Right side catalytic converters

2. Support bracket

3. Support bracket

4. Center muffler

5. Hanger

6. Rear muffler

7. Clamping sleeve

8. Oxygen sensors, post-catalytic

converter

9. Oxygen sensors, pre-catalytic

converter

10. Left side catalytic converter

11. Sealing rings

12. Left front exhaust manifold

13. Left rear exhaust manifold

14. Gasket

15. Exhaust manifold, right front

16. Exhaust manifold, right rear

Page 537 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust systeml

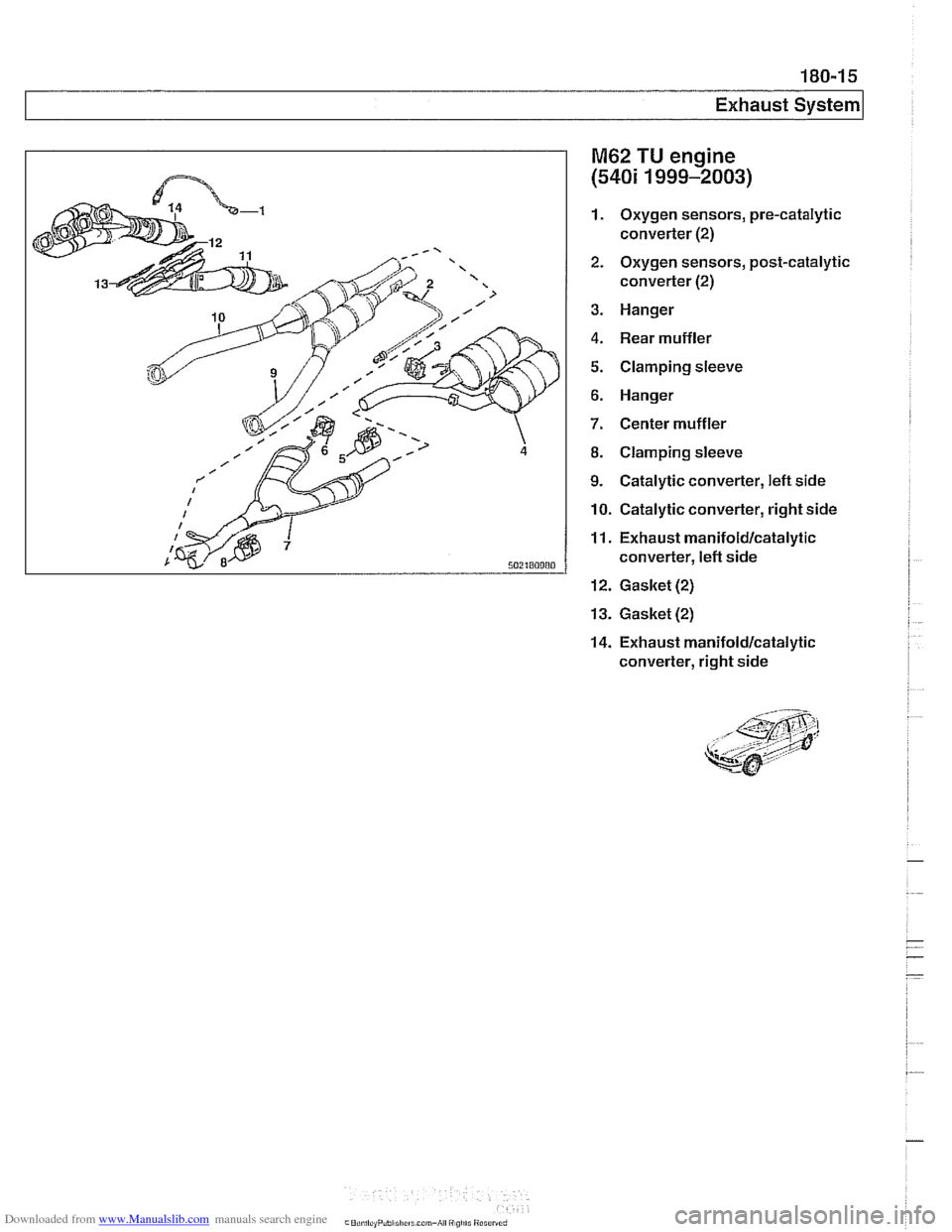

M62 TU engine

(540i 1999-2003)

1. Oxygen sensors, pre-catalytic

converter

(2)

2.

Oxygen sensors, post-catalytic

converter

(2)

3.

Hanger

4. Rear muffler

5. Clamping sleeve

6. Hanger

7. Center muffler

8. Clamping sleeve

9. Catalytic converter, left side

10. Catalytic converter, right side

11. Exhaust manifoldlcatalytic

converter,

left side

12. Gasket (2)

13.

Gasket (2)

14.

Exhaust manifoldlcatalytic

converter, right side

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

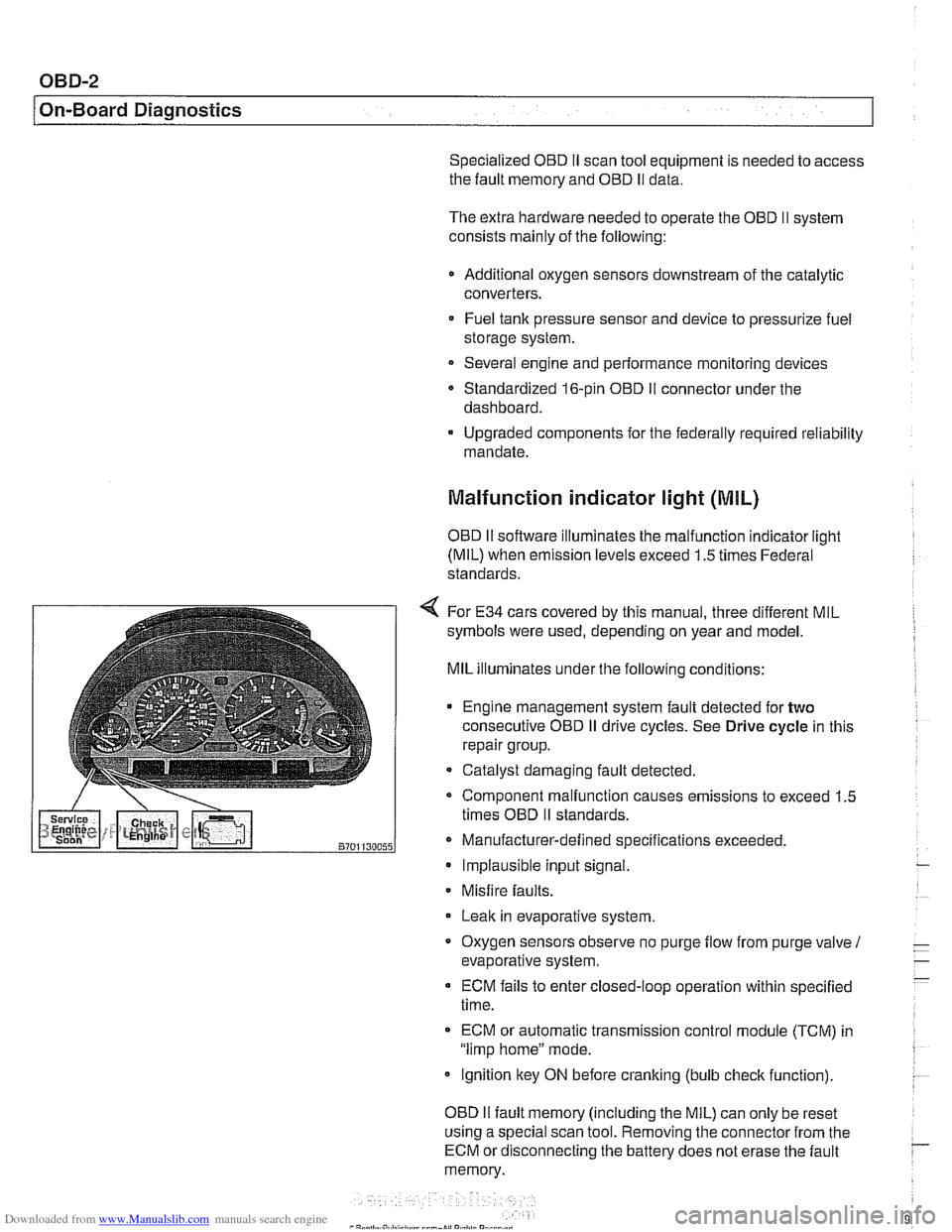

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 965 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

Catalyst monitoring. Thisstrategy monitors the outputofthe

precatalyst and post-catalyst oxygen sensors, comparing the

oxygen content going into the catalytic converter to the

oxygen leaving the converter.

The diagnostic executive

lknows that most of the oxygen

should be used up during the oxidation phase. If it detects

higherthan programmed values, afault is set and the MIL

illuminates.

Misfire detection. This strategy monitors crankshaft speed

fluctuations and determines if an enoine misfire occurs bv

monitoring variations in speed between each crankshaft

sensortrigger point. This strategy is so finely tuned that it can

determine the severity of the misfire.

The system determines

if a misfire is occurring, as well as

other pertinent misfire

information such as:

Specific

cylinder(s)

Severity of the misfire event

Emissions relevant or catalyst damaging

Misfire detection is an on-going monitoring process that is

only disabled under certain limited conditions.

Secondary air injection monitoring. Secondary air

injection is used to reduce HC and CO emissions during

engine warm up. Immediately following a cold engine start

(-1 0" to 40°C), fresh air (and therefore oxygen) is pumped

directly into the exhaust

manifold. By injecting additional

oxygen into the exhaust manifold, catalyst warm-up time is

reduced.

Secondary air system components are:

Electric air injection pump

* Electric pump relay

* Non-return valve

Vacuum

I vent valve

- Stainless steel air injection pipes

Vacuum reservoir

The secondary air system is monitored via the use

of the pre-

catalyst oxygen sensors. Once the air pump is active and air

is injected into the system, the signal at the oxygen sensor

reflects a lean condition. If the oxygen sensor signal does not

change, a fault is set and the faulty

bank(s) identified. If after

completing the next cold startafault is again present, the MIL

illuminates.

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.