BMW 530i 2000 E39 Workshop Manual

Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 361 of 1002

Downloaded from www.Manualslib.com manuals search engine

ignition System

Crankshaft speed sensor, replacing (M62 and M62TU

engines)

The crankshaft speed sensor reads a toothed pulse wheel

mounted on the flywheel.

If the Engine Control Module(ECM)

does not receive an impulse signal from the crankshaft speed

sensor during

cranking, the engine will not start. If the OBD II

system misfire detection protocol detects a catalyst damag-

ing fault due to a malfunction in the crankshaft speed sensor

components, the Check Engine light (Malfunction

Indicator

Light or MIL) will be Illuminated.

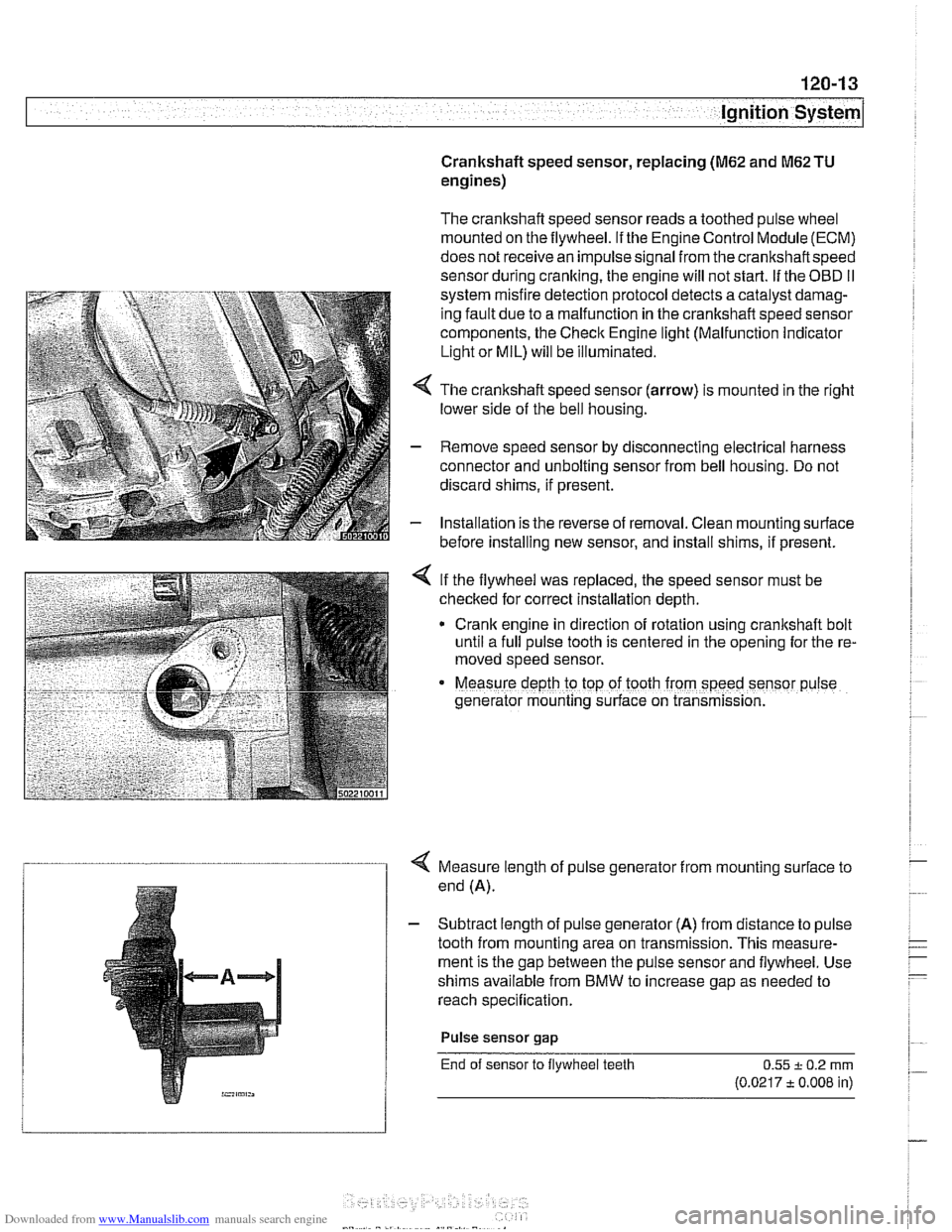

4 The crankshaft speed sensor (arrow) is mounted in the right

lower side of the bell housing.

- Remove speed sensor by disconnecting electrical harness

connector and unbolting sensor from bell housing. Do not

discard shims, if present.

- Installation is the reverse of removal. Clean mounting surface

before installing new sensor, and install shims, if present.

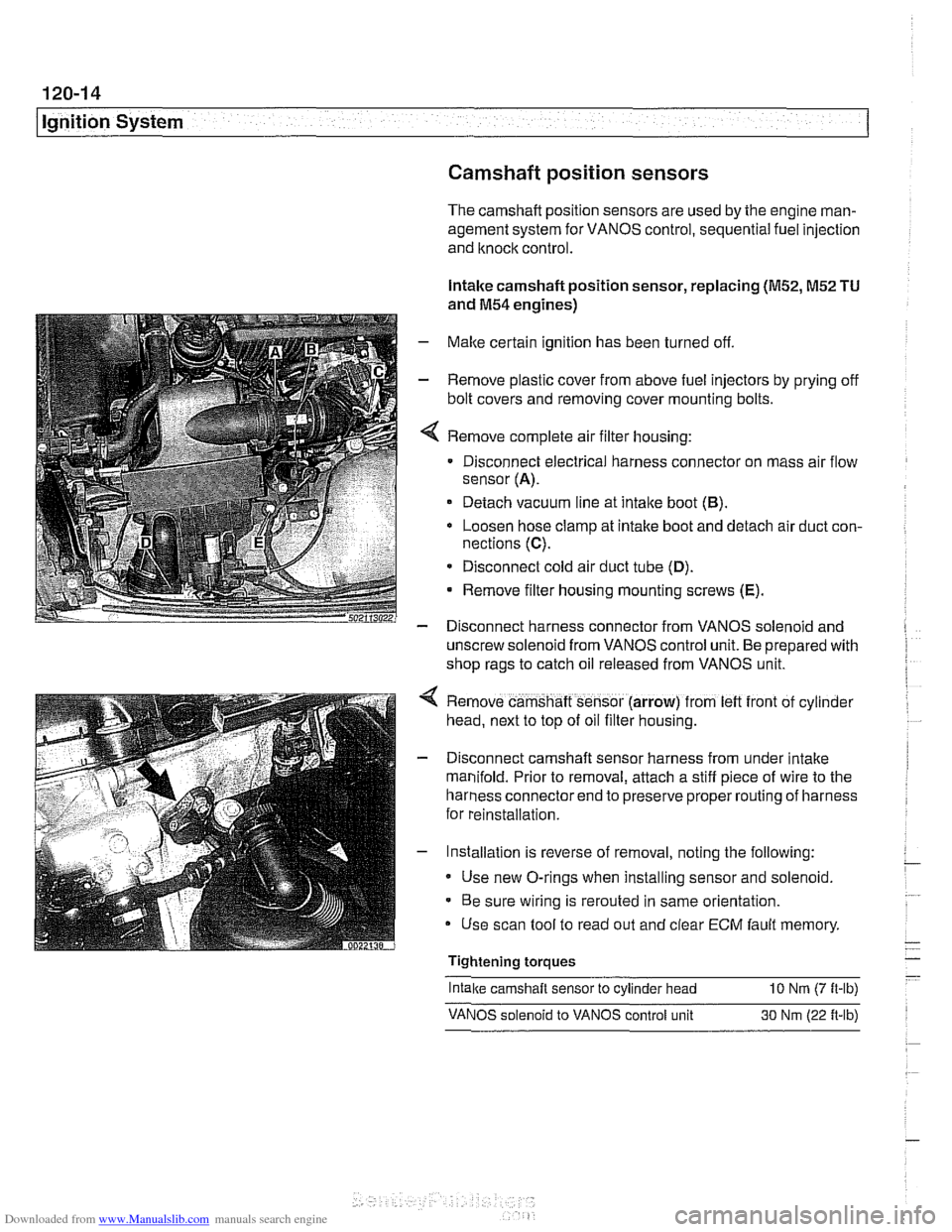

< If the flywheel was replaced, the speed sensor must be

checked for correct installation depth.

* Crank engine in direction of rotation using crankshaft bolt

until a full pulse tooth is centered in the opening for the re-

moved speed sensor.

Measure depth ro top of tooth from speed sensor p~lse

generator mounting s~rface on transmission.

4 Measure length of pulse generator from mounting surface to

end (A).

- Subtract length of pulse generator (A) from distance to pulse

tooth from mounting area on transmission. This measure-

ment is the gap between the pulse sensor and flywheel. Use

shims available from BMW to increase gap as needed to

reach specification.

Pulse sensor

gap

End of sensor to flywheel teeth 0.55 + 0.2 rnrn

(0.0217 t 0.008 in)

Page 362 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Ignition System

Camshaft position sensors

The camshaft position sensors are used by the englne man-

agement system for VANOS control, sequential fuel injection

and knock control.

Intake camshaft position sensor, replacing

(M52,M52 TU

and M54 engines)

- Make certain ignition has been turned off.

- Remove plastic cover from above fuel injectors by prying off

bolt covers and removing cover mounting bolts.

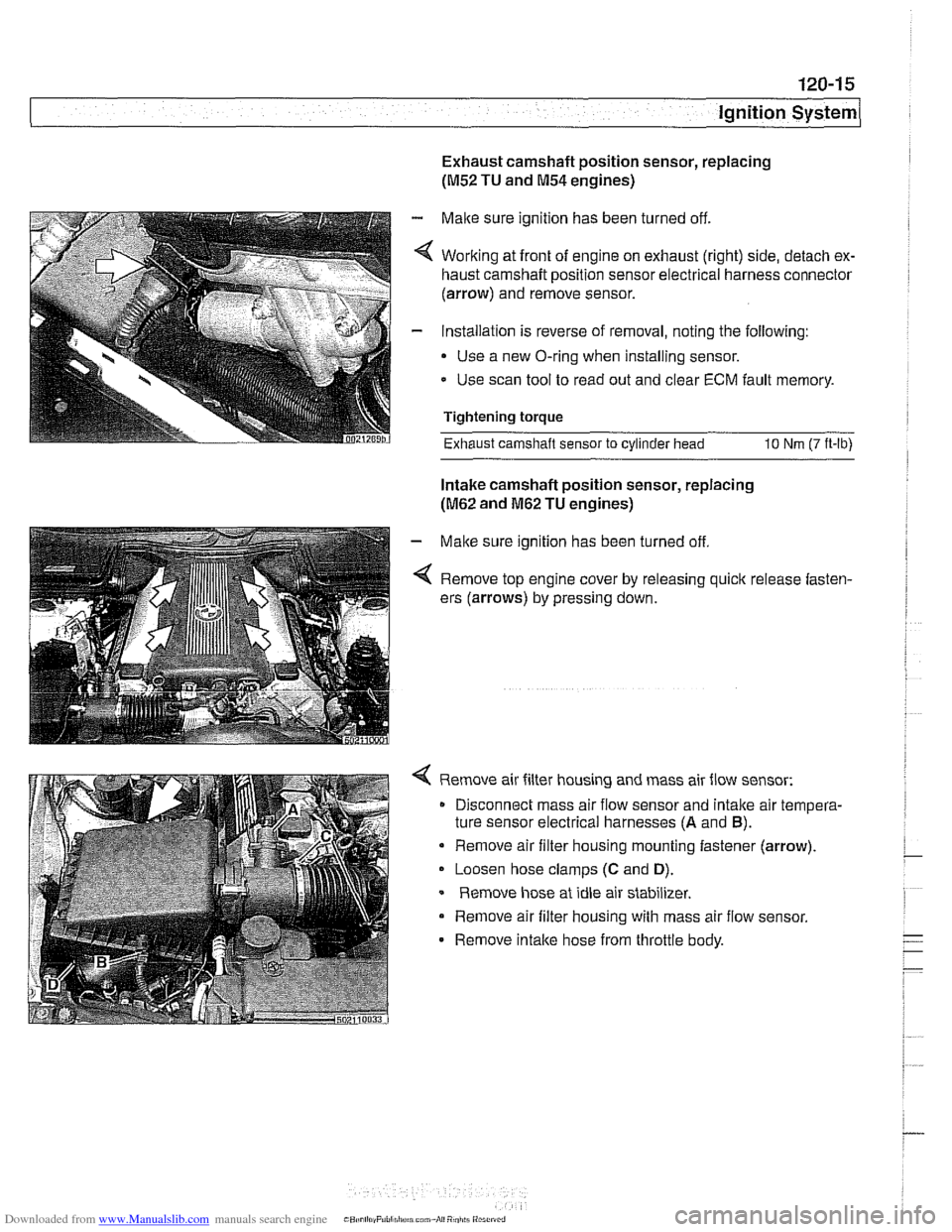

Remove complete air filter housing:

Disconnect electrical harness connector on mass air flow

sensor

(A).

Detach vacuum line at intake boot (B).

Loosen hose clamp at intake boot and detach air duct con-

nections

(C).

* Disconnect cold air duct tube (D).

Remove filter housing mounting screws (E).

- Disconnect harness connector from VANOS solenoid and

unscrew solenoid from VANOS control unit. Be prepared with

shop rags to catch oil released from VANOS unit.

Remove camshaft sensor (arrow) from

left front of cyl~nder

head, next to top of oil filter housing.

Disconnect camshaft sensor harness from under intake

manifold. Prior to removal, attach a stiff piece of wire to the

harness connector end to preserve proper routing of harness

for reinstallation.

Installation is reverse of removal, noting the following:

Use new O-rings when installing sensor and solenoid.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear

ECM fault memory

Tightening torques

-

Intake camshaft sensor to cylinder head 10 Nrn (7 ft-lb)

VANOS solenoid to VANOS control unit 30 Nm (22 ft-lb)

Page 363 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-15

Ignition system1

Exhaust camshaft position sensor, replacing

(M52 TU and M54 engines)

- Make sure ignition has been turned off.

4 Working at front of engine on exhaust (right) side, detach ex-

haust camshaft position sensor electrical harness connector

(arrow) and remove sensor.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

- Use scan tool to read out and clear ECM fault memory.

Tightening torque

Exhaust camshaft sensor

to cylinder head 10 Nm (7 ft-lb)

Intake camshaft position sensor, replacing

(M62 and M62 TU engines)

- Make sure ignition has been turned off

4 Remove top engine cover by releasing quick release fasten-

ers (arrows) by pressing down.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor and

intalte air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow).

Loosen hose clamps

(C and D).

Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

- Remove intalte hose from throttle body.

Page 364 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 6

Ignition System

Remove camshaft sensor (arrow) from front of right cylinder

head.

Disconnect camshaft sensor harness from cable duct above

right cylinder head.

Installation is reverse of removal, noting the following:

Use new O-ring when installing sensor.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear ECM fault memory.

Tightening torque Intake camshaft sensor to timing chain 5 Nm

(3.5 ft-lb)

cover

Knock sensors

Knock sensors, replacing (M52, M52 TU and M54

engines)

The knock sensors are bolted to the left side of the cylinder

block under the intake manifold.

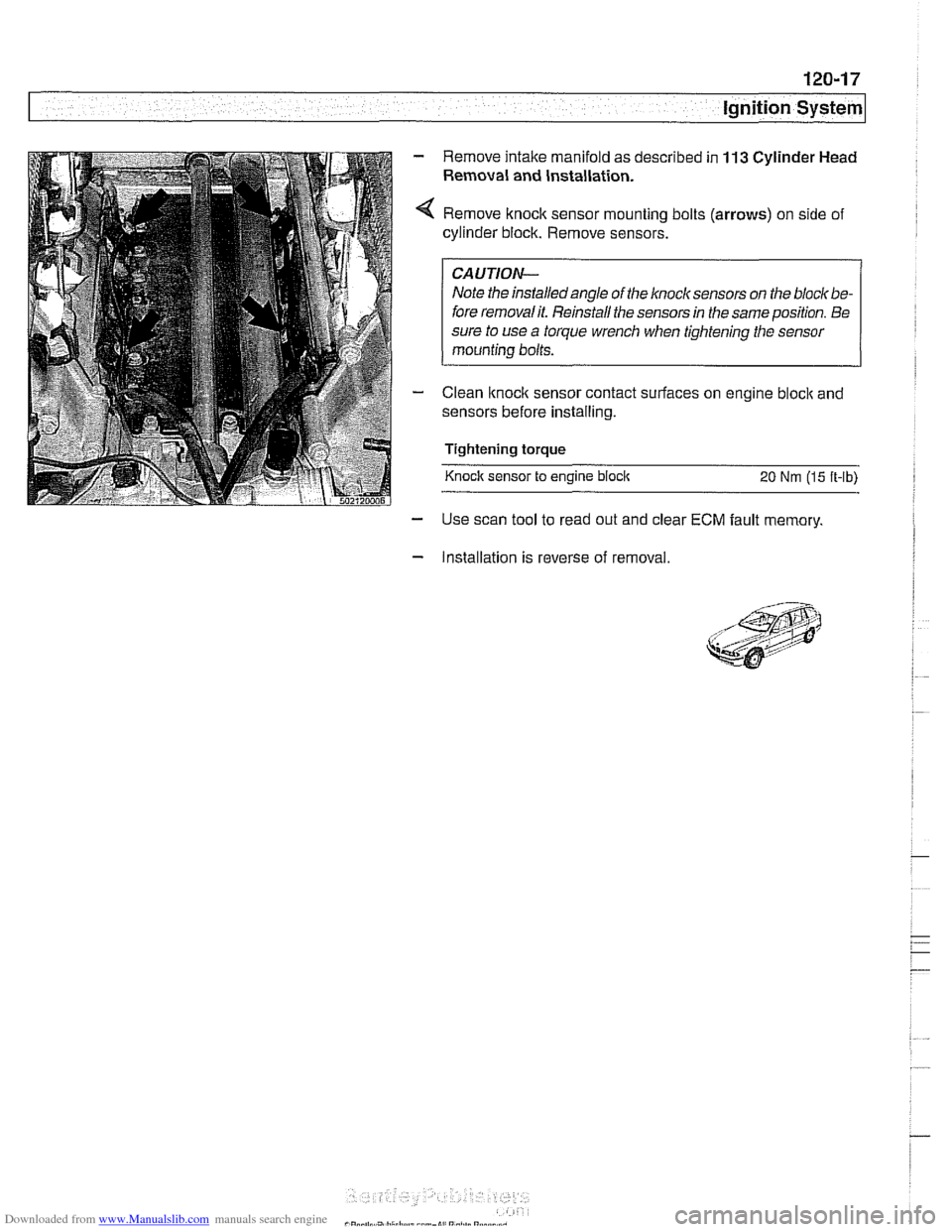

- Remove intalte manifold as described in 113 Cylinder Head

Removal and Installation.

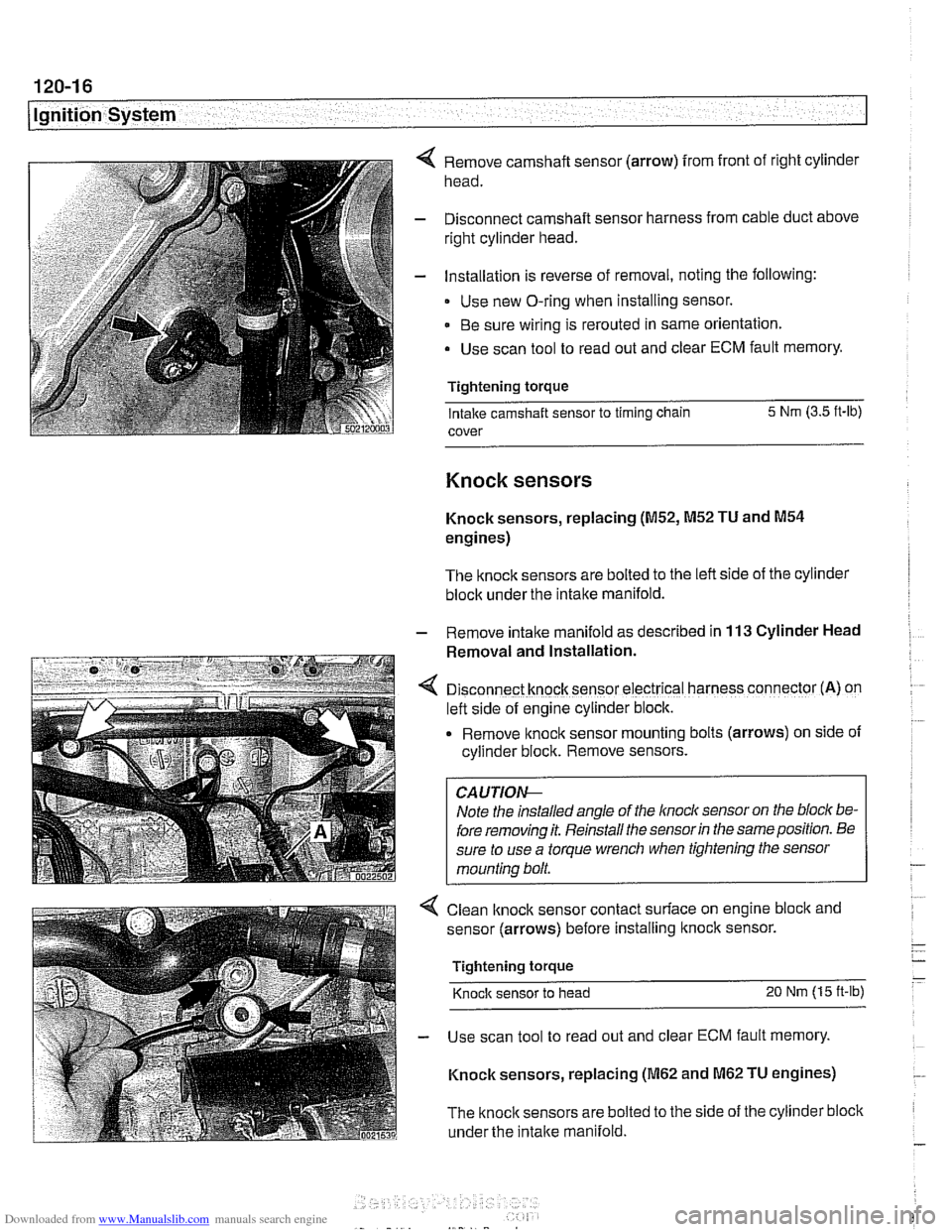

D~sconnect knock sensor electrical harness connector (A) on

left side of engine cylinder block.

Remove knock sensor

mount~ng bolts (arrows) on side of

cyllnder block. Remove sensors.

Note the installed angle of the

lnocl~ sensor on the bloc/( be-

fore removing it. Reinstall the sensor

in the same position. Be

sure to use a torque wrench when tightening the sensor

mounting bolt.

< Clean lknock sensor contact surface on engine bloclc and

sensor (arrows) before installing

ltnock sensor.

Tightening torque

Knock sensor to head 20 Nm (15 ft-lb)

- Use scan tool to read out and clear ECM fault memory.

Knock sensors, replacing

(M62 and M62 TU engines)

The

knock sensors are bolted to the side of the cylinder block

under the

intake manifold.

Page 365 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

Remove intake manifold as described in 113 Cylinder Head

Remaval and Installation.

Remove knock sensor mounting bolts (arrows) on side of

cylinder block. Remove sensors.

I CAUTION- I

Note the installedangle of the knock sensors on the bloclt be-

fore removalit. Reinstall the sensors in the same position. Be

sure to use

a torque wrench when tightening the sensor

mounting bolts.

Clean

lknoclc sensor contact surfaces on engine bloclc and

sensors before installing.

Tightening torque

Knock sensor to engine

bloclc 20 Nm (15 ft-lb)

- Use scan tool to read out and clear ECM fault memory.

- Installation is reverse of removal.

Page 366 of 1002

Downloaded from www.Manualslib.com manuals search engine

Page 367 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-1

121 Battery. Starter. Alternator

General ........................... .I2 1.2

Special tools ........................ .I2 1.2

Engine electrical system ............... .I2 1.2

Battery Safety Terminal ............... .I2 1.3

Warnings and cautions ................. 121 -4

Battery ............................ 121-5

Battery testing ...................... .I2 1.5

Hydrometer testing ................... .I2 1.5

Battery open-circuit voltage test ......... .I2 1.6

Battery load voltage test ................ 121 -6

Closed-circuit current measurement ..... .I2 1.7

Battery charging ...................... 121 -9

Battery safety terminal, replacing ......... 121-9

Alternator (generator) ............. .I2 1.10

Alternator. basic .................... .I2 1.11

Alternator with multi-function

control (MFR)

...................... .I2 1.11

Water-cooled alternator ............... 121 -12

Charging System Troubleshooting . 121-12

Charging system quick-check .......... 121-13

Charging system. checking ............ 121-13

Alternator. removing and installing

(6-cylinder engine)

.................. 121 -1 5

Alternator. removing and installing

(M62 engine. air cooled)

.............. 121-16

Alternator. removing and installing

(M62 TU engine. water cooled) ......... 121-1 8

Starter ........................... 121 -1 9

Starter troubleshooting ............... 121 -1 9

Starter. removing and installing

(6-cylinder engine)

.................. 121-20

Starter. removing and installing

(V-8 engine)

........................ 121 -21

Solenoid switch. removing and installing . . 121-23

Page 368 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Battery, Starter, Alternator

This section covers the battery, alternator, starter and associ-

ated components of the electrical system.

Troubleshooting information

forthese components isfound in

Table a. Battery, alternator and starter troubleshooting.

For additional electrical troubleshooting information, see

600 Electrical System-General.

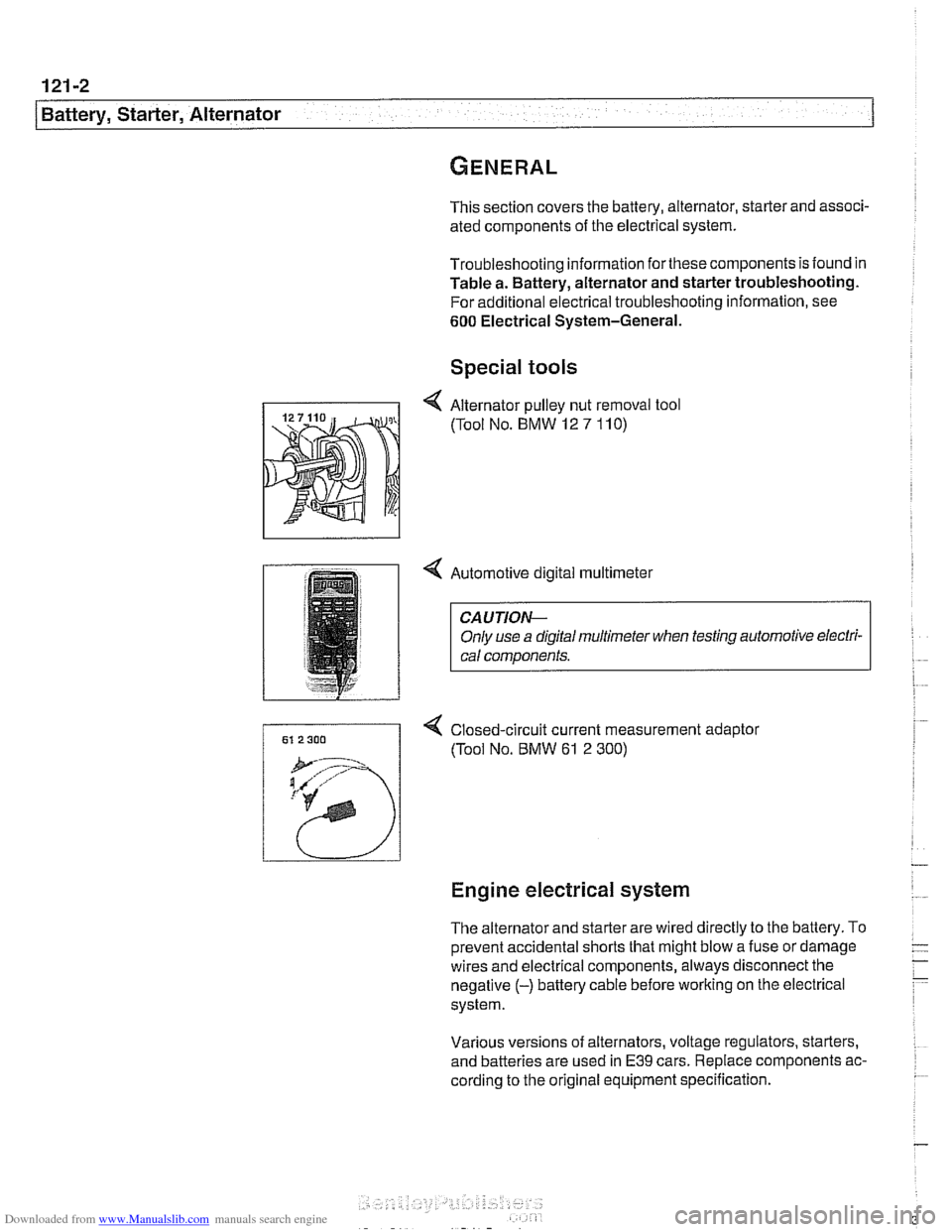

Special tools

4 Automotive digital multimeter

CAUTION-

Only use a digital multirneter when testing automotive electri- I) cal components.

4 Closed-circuit current measurement adaptor

(Tool No.

BMW 61 2 300)

Engine electrical system

The alternator and starter are wired directly to the battery. To

prevent accidental shorts that might blow a fuse or damage

wires and electrical components, always disconnect the

negative

(-) battery cable before working on the electrical

system.

Various versions of alternators, voltage regulators, starters,

and batteries are used in

E39 cars. Replace components ac-

cording to the original equipment specification.

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

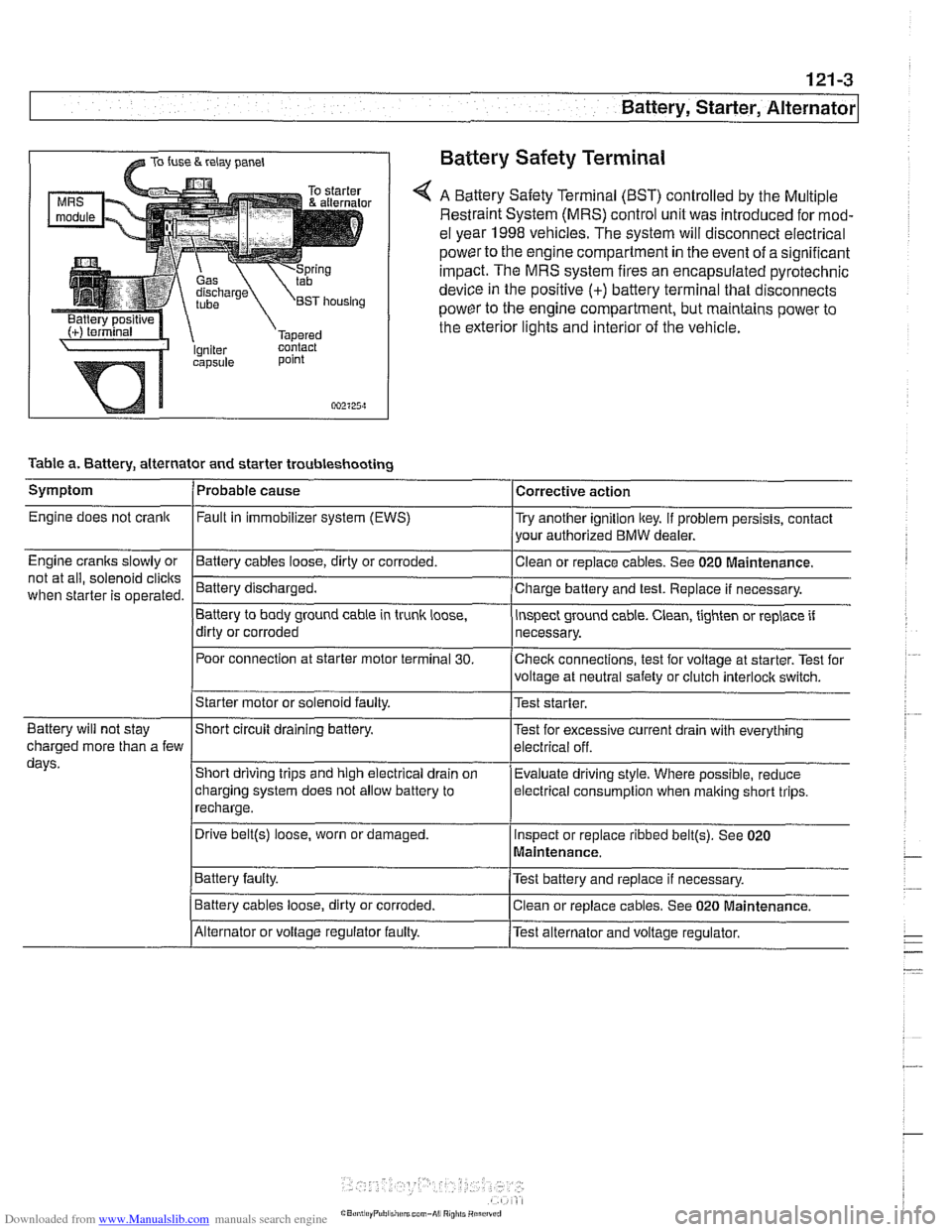

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.

Page 370 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-. .

Battery, Starter, Alternator

Warnings and cautions

WARNING -

Wear goggles, rubber gloves, and a rubber apron when

working around the battery or battery acid (electrolyte).

Battery acid contains sulfuric acid and can cause skin

irritation and burning.

If acid is spilled on your skin or

clothing, flush the area at once with large quantities of

water. If electrolyte gets into your eyes, flush them with

large quantities of clean water for several minutes and

call a physician.

Batteries that are being charged or are fully charged

give off explosive hydrogen gas. Keep sparks and open

flames away. Do not

smoke.

CA UTIOI\C

Only use a digital multimeter when testing automotive elec-

trical components.

. If a repair procedure specifies disconnecting the bat-

tery, follow the instruction for safety reasons.

Prior to disconnecting the battery, read the battery dis-

connection cautions in

001 General Cautions and

Warnings.

Models with MS43 engine management: Allow at least

3 minutes to elapse after turning ignition ley to OFFpo-

sition before disconnecting battery. This willallow sum-

cient tinie to complete the DMJL (fuel tank pressure)

test

* Disconnecting the battery cables may erase fault codes

stored in ECM memory.

Always disconnect the negative

(-) battery cable first

and reconnect it last. Cover the battery post with an in-

sulating material whenever the cable is removed.

Do not disconnect battery, alternator or starter wires

while the engine is running.

0 Never reverse the battery cables. Even a momentary

wrong connection can damage the alternator or other

electrical components.

Do not depend on the color of insulation to tell battery

positive and negative cables apart. Label cables before

removing.

The slide-tilt sunroof may fail to function properly

after

disconnecting and reconnecting the battery. Reinitial-

ize sunroof as described in 540 Sunroof.