BMW 530i 2000 E39 Workshop Manual

Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 381 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

Alternator, removing and installing

(6-cylinder engine)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

I tions.

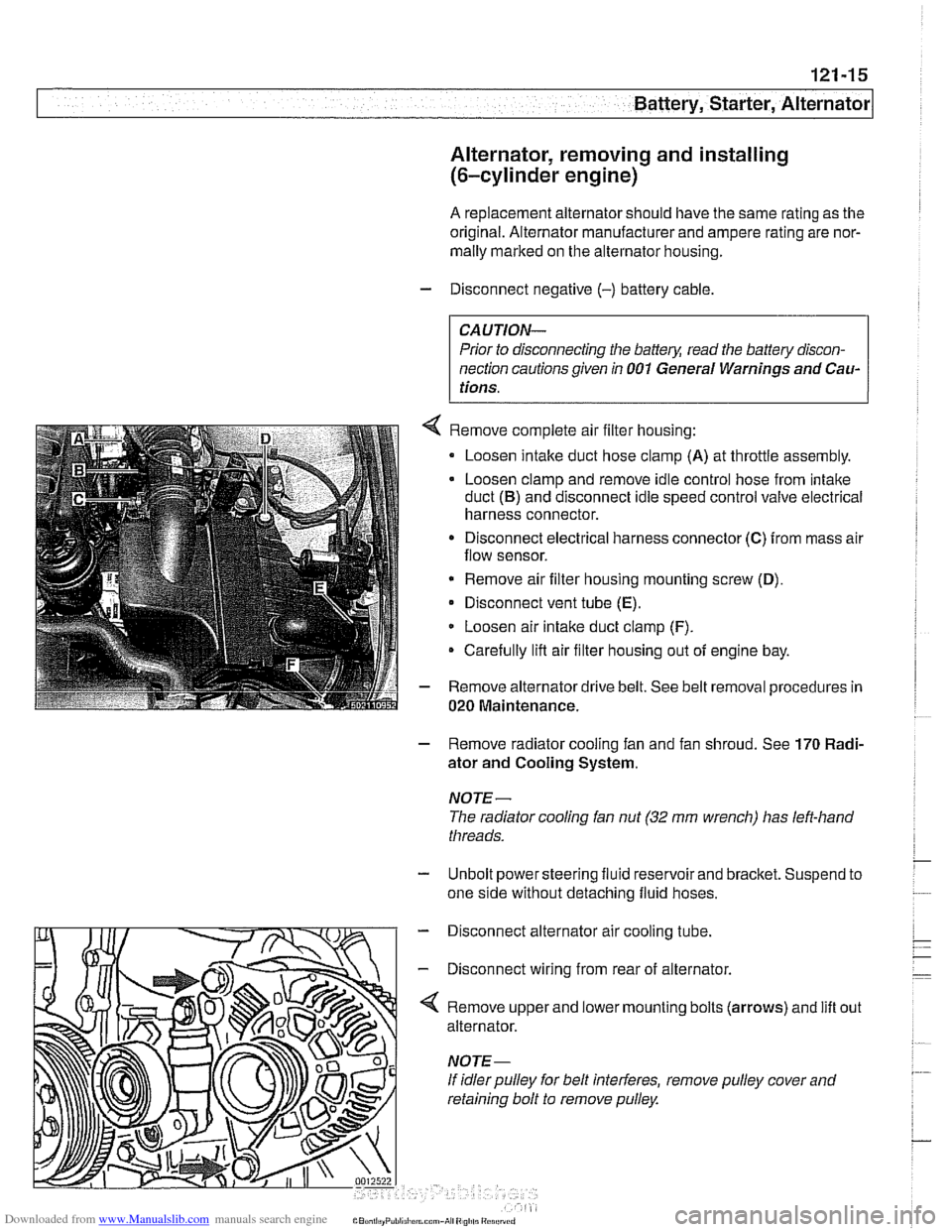

Remove complete air filter housing:

Loosen intake duct hose clamp

(A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

* Remove air filter housing mounting screw (D),

Disconnect vent tube (E).

Loosen air intake duct clamp (F).

Carefully lifl air filter housing out of engine bay.

Remove alternator drive belt. See belt removal procedures in

020 Maintenance.

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

NOTE-

The radiator cooling fan nut (32 mm wrench) has left-hand

threads.

- Unbolt power steering fluid reservoir and bracket. Suspend to

one side without detaching fluid hoses.

- Disconnect alternator air cooling tube.

- Disconnect wiring from rear of alternator.

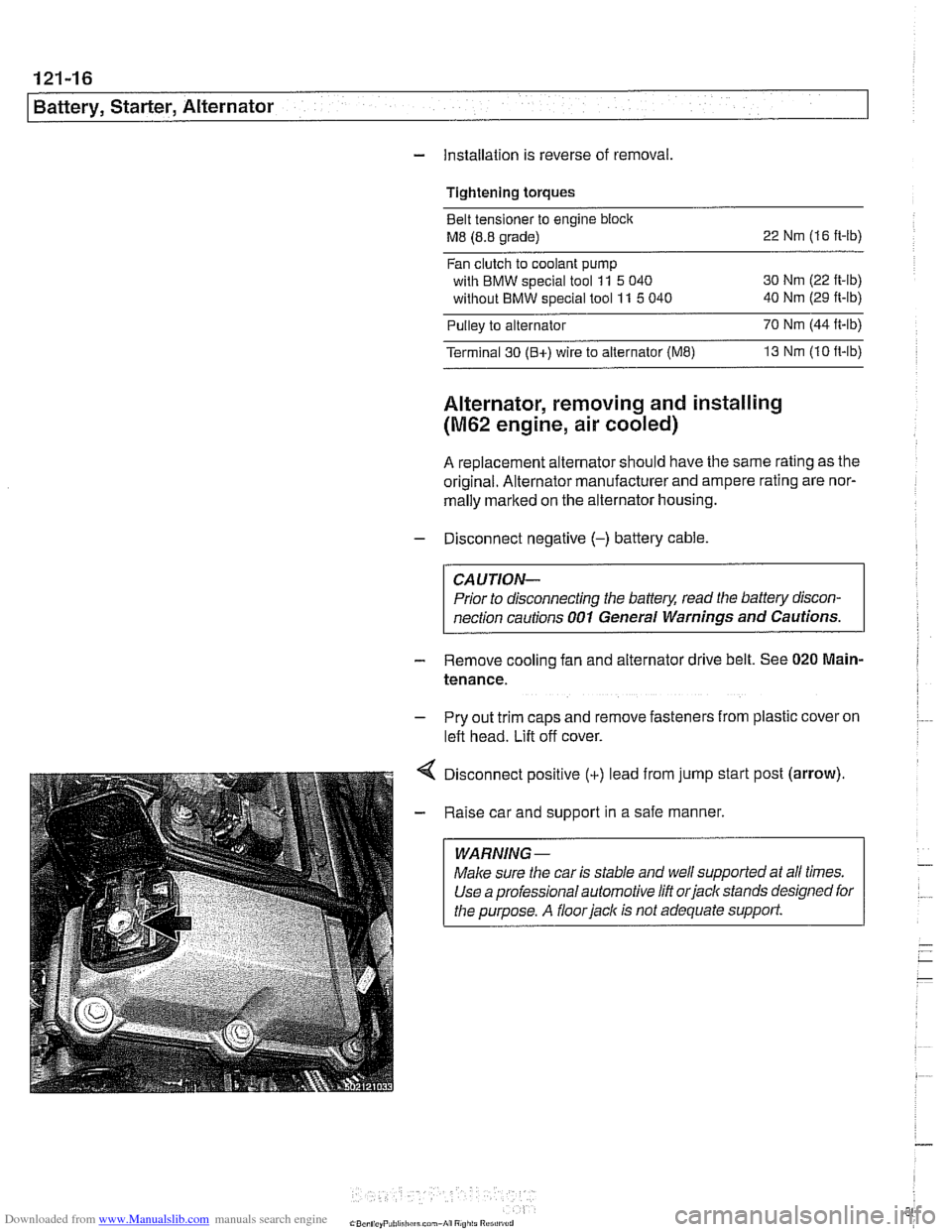

'4 Remove upper and lower mounting bolts (arrows) and lift

alternator.

If idler pulley for belt interferes, remove pulley cover and

retaining bolt to remove pulley. out

Page 382 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-16

Battery, Starter, Alternator

- installation is reverse of removal.

Tightening torques Belt tensloner to engine block

M8 (8.8 grade) 22

Nm (16 ft-ib)

Fan clutch to coolant pump

with BMW special tool 11

5 040 30 Nm (22

ft-lb)

without BMW special tool

11 5 040 40 Nm

(29 ft-ib)

Pulley to alternator 70

Nm (44 ft-lb)

Terminal 30

(B+) wire to alternator (M8) 13 Nm (10 ft-ib)

Alternator, removing and installing

(M62 engine, air cooled)

A replacement alternator should have the same rating as the

original. Alternator manufacturer and ampere rating are nor-

mally

marked on the alternator housing.

- Disconnect negative (-) battery cable.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions

001 General Warnings and Cautions.

- Remove cooling fan and alternator drive belt. See 020 Main-

tenance.

- Pry out trim caps and remove fasteners from plastic cover on

left head. Lift off cover.

Disconnect positive

(+) lead from jump start post (arrow).

Raise car and support in a safe manner.

WARNING-

Make sure the car is stable and well supported at aN times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floorjack is not adequate support.

Page 383 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-17

Bauery, Starter, Alternator

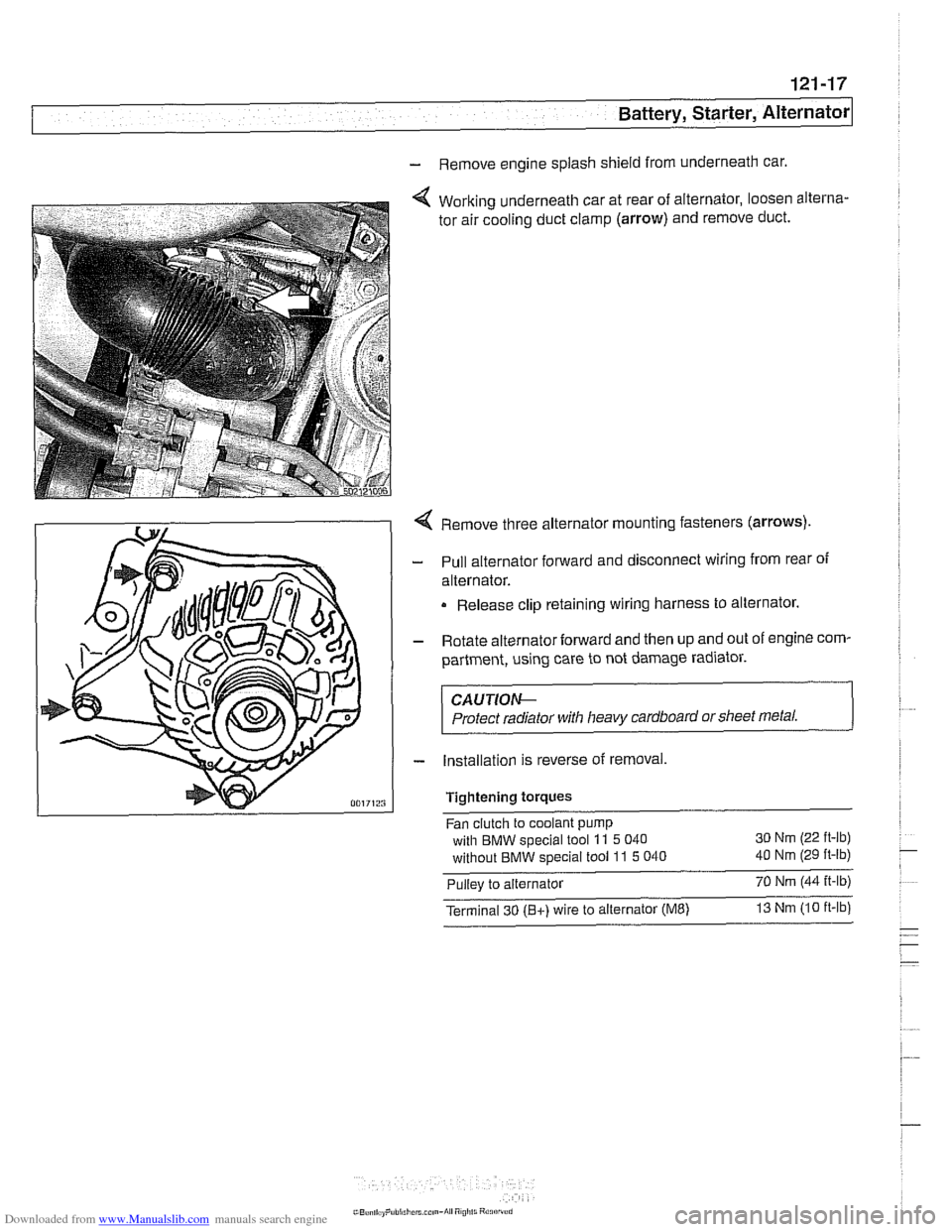

- Remove engine splash shield from underneath car.

Working underneath car at rear of alternator, loosen alterna-

tor air cooling duct clamp

(arrow) and remove duct.

Remove three alternator mounting fasteners

(arrows)

Pull alternator forward and disconnect wiring from rear of

alternator.

Release clip retaining wiring harness to alternator.

Rotate alternator forward and then up and out of engine com-

partment, using care to not damage radiator.

CAUTIOe

Protect radiator with heavy cardboard or sheet metal.

Installation is reverse of removal,

Tightening

torques

Fan clutch to coolant pump

with BMW special tool

11 5 040 30

Nm (22 ft-lb)

without BMW special tool 11 5 040 40 Nm (29 ft-lb)

Pullev to alternator 70 Nm 144 it-lb) -,

Terminal 30 (Bt) wire to alternator (ME) 13 Nm 110 ft-lb

Page 384 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-18

I Battery, Starter, Alternator

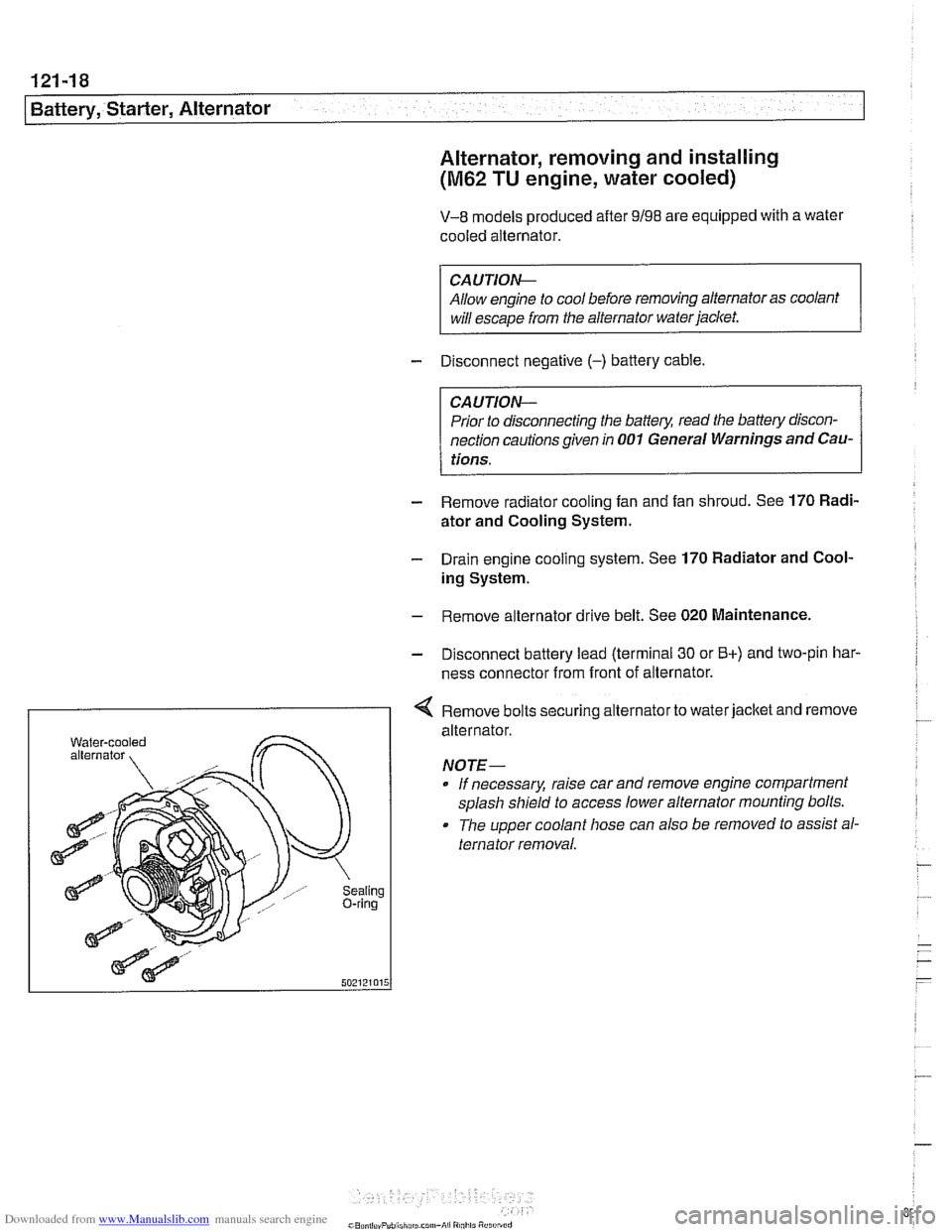

Alternator, removing and installing

(M62 TU engine, water cooled)

V-8 models produced after 9/98 are equipped with a water

cooled alternator.

CAUTION-

Allow engine to cool before removing alternator as coolant

will

escape from the alternator water jacket.

- Disconnect negative (-) battery cable

CAUTION- Prior to disconnecting the

battew read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

- Remove radiator cooling fan and fan shroud. See 170 Radi-

ator and Cooling System.

- Drain engine cooling system. See 170 Radiator and Cool-

ing System.

- Remove alternator drive belt. See 020 Maintenance.

- Disconnect battery lead (terminal 30 or B+) and two-pin har-

ness connector from front of alternator.

I < Remove bolts securing alternator to water jacket and remove

aling ring

alternator.

NOTE- If necessary, raise car and remove engine compartment

splash shield to access lower alternator mounting bolts.

The upper coolant hose can also

be removed to assist al-

ternator removal.

Page 385 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, Alternator

- Installation is reverse of removal, noting the following:

Replace alternator rubber sealing O-ring.

* Fill and bleed cooling system as described in 170 Radiator

and Cooling System.

Tightening torques

Fan clutch to coolant pump

with

BMW special tool 11 5 040 30 Nm (22 ft-lb)

without

BMW special tool 11 5 040 40 Nm (29 ft-lb)

Terminal 30 (Bc) wire to alternator (ME) 13 Nm (10 ft-lb)

STARTER

Starter troubleshooting

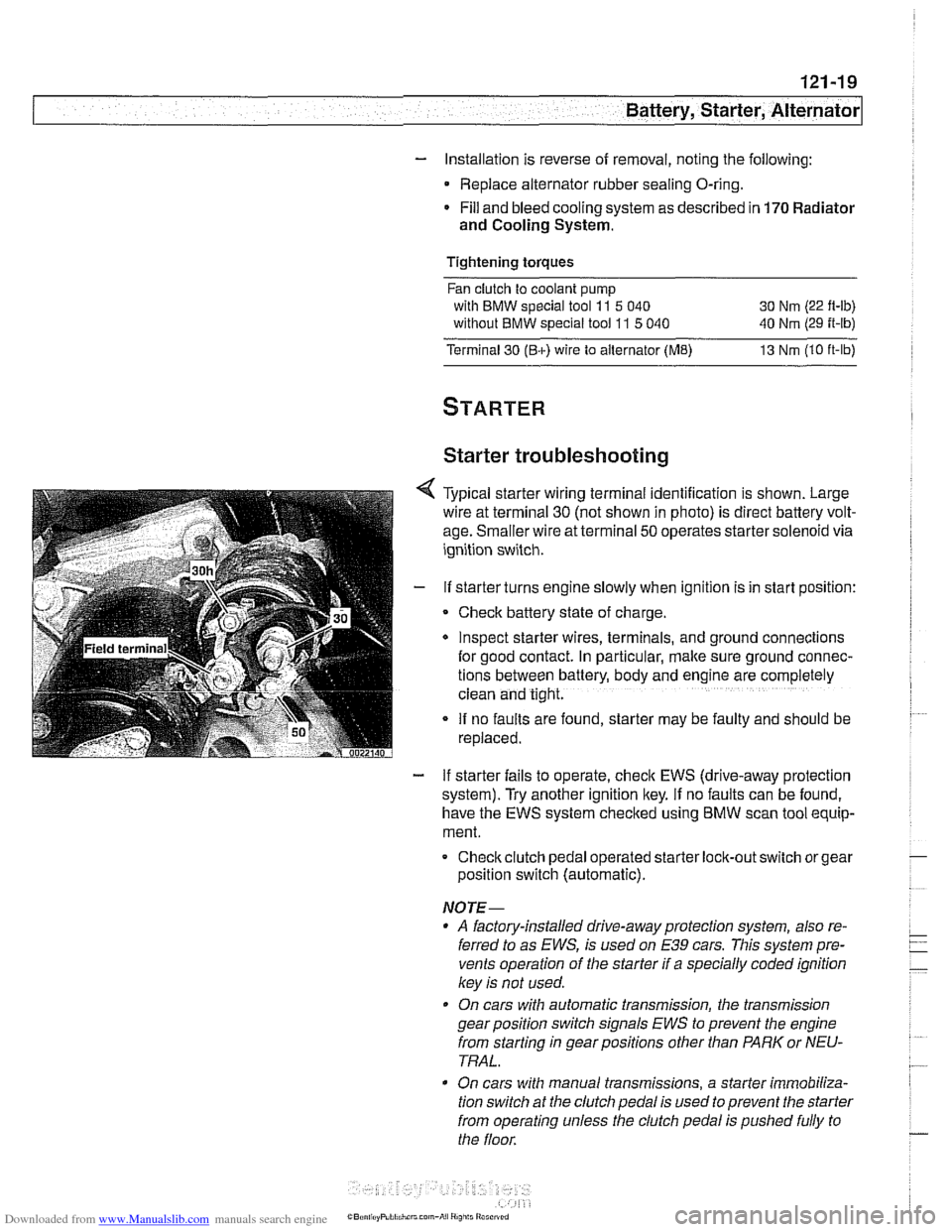

Typical starter wiring terminal identification is shown. Large

wire at terminal

30 (not shown in photo) is direct battery volt-

age. Smaller wire at terminal

50 operates starter solenoid via

ignition switch.

If starter turns engine slowly when ignition is in start position:

Check battery state of charge.

Inspect starter wires, terminals, and ground

connectlons

for good contact. In particular, make sure ground connec-

tions between battery, body and

englne are completely

clean and tight.

If no faults are found, starter may be faulty and should be

replaced.

- If starter fails to operate, check EWS (drive-away protection

system). Try another ignition key.

If no faults can be found,

have the EWS system checked using

BMW scan tool equip-

ment.

Checkclutch pedal operated

starter lock-out switch or gear

position switch (automatic).

NOTE-

* A factory-installed drive-away protection system, also re-

ferred to as

EWS, is used on E39 cars. This system pre-

vents operation of the starter if a specially coded ignition

key is not used.

On cars with automatic transmission, the transmission

gear position switch signals

EWS to prevent the engine

from starting in gear positions other than PARK or NEU-

TRAL.

On cars with manual transmissions, a starter immobiliza-

tion switch

at the clutch pedal is used to prevent the starter

from operating unless the clutch pedal is pushed fully to

the floor.

Page 386 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Battery, Starter, Alternator

- Check for battery voltage at terminal 50 of starter motor with

key in start position. If voltage is not present, check wiring be-

tween ignition switch and starter terminal. Check the EWS

system and other inputs that disrupt terminal

56 to the start-

er. See ELE Electrical

Wiring Diagrams. If voltage is

present and no other visible wiring faults can be found, prob-

lem is most likely in starter motor.

Starter, removing and installing

(6-cylinder engine)

The starter is removed from below. Access to starter bolts is

difficult. Be sure to have the proper tools on hand before pro-

ceeding.

NOTE-

Access to the starter wiring is very limited. Forbetteraccess,

it may be necessary to remove the intake manifold.

- Disconnect negative (-) battery cable.

CAUTIOI\C

Prior to disconnecting the battern read the baltery discon-

nection cautions

in OOlGeneral Cautions and Warnings.

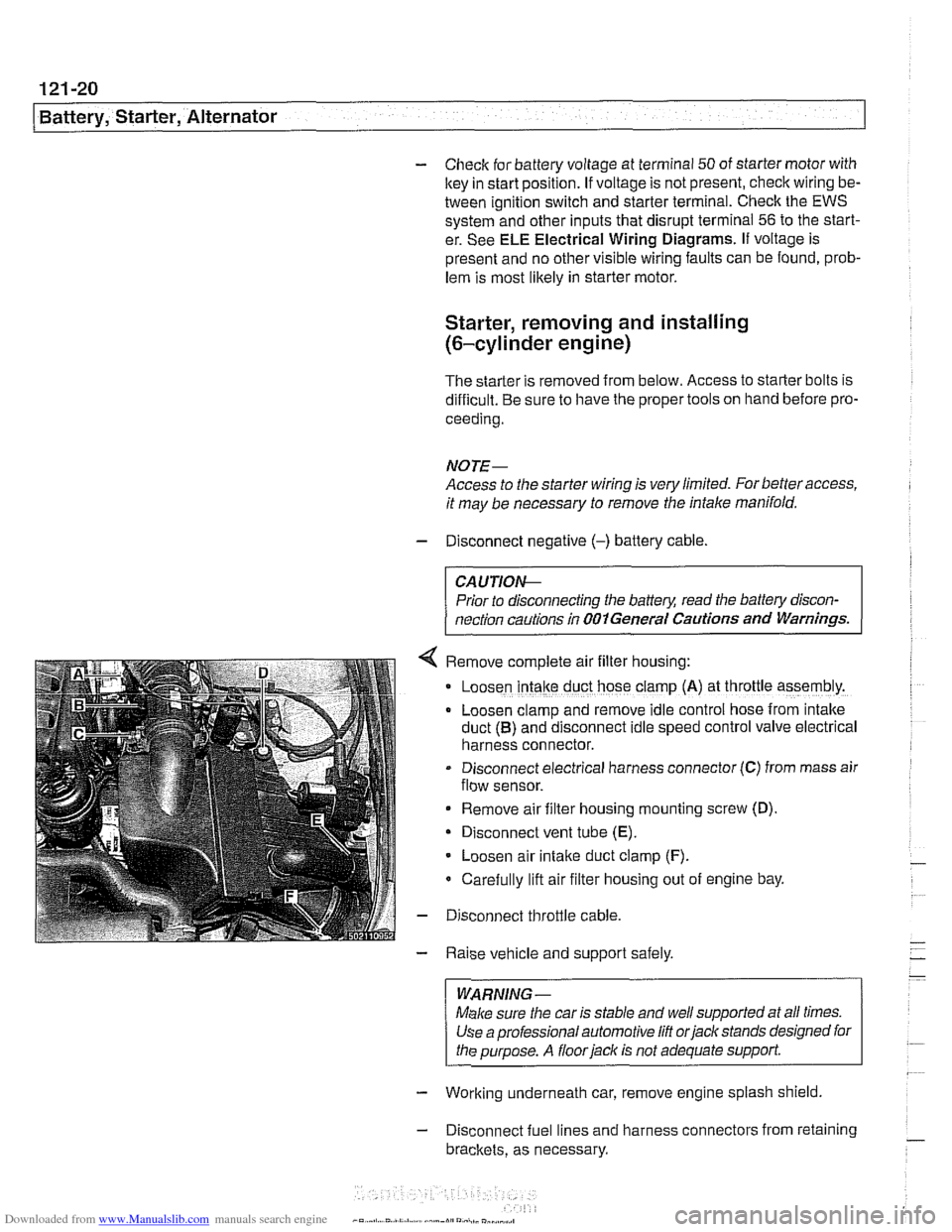

Remove complete air filter hous~ng:

Loosen intake duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control hose from intake

duct

(B) and disconnect idle speed control valve electrical

harness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw (D)

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Disconnect throttle cable.

Raise vehicle and support safely.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjack stands designed for

the purpose. A

floorjaclc is not adequate support

- Working underneath car, remove engine splash shield

- Disconnect fuel lines and harness connectors from retaining

brackets, as necessary.

Page 387 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

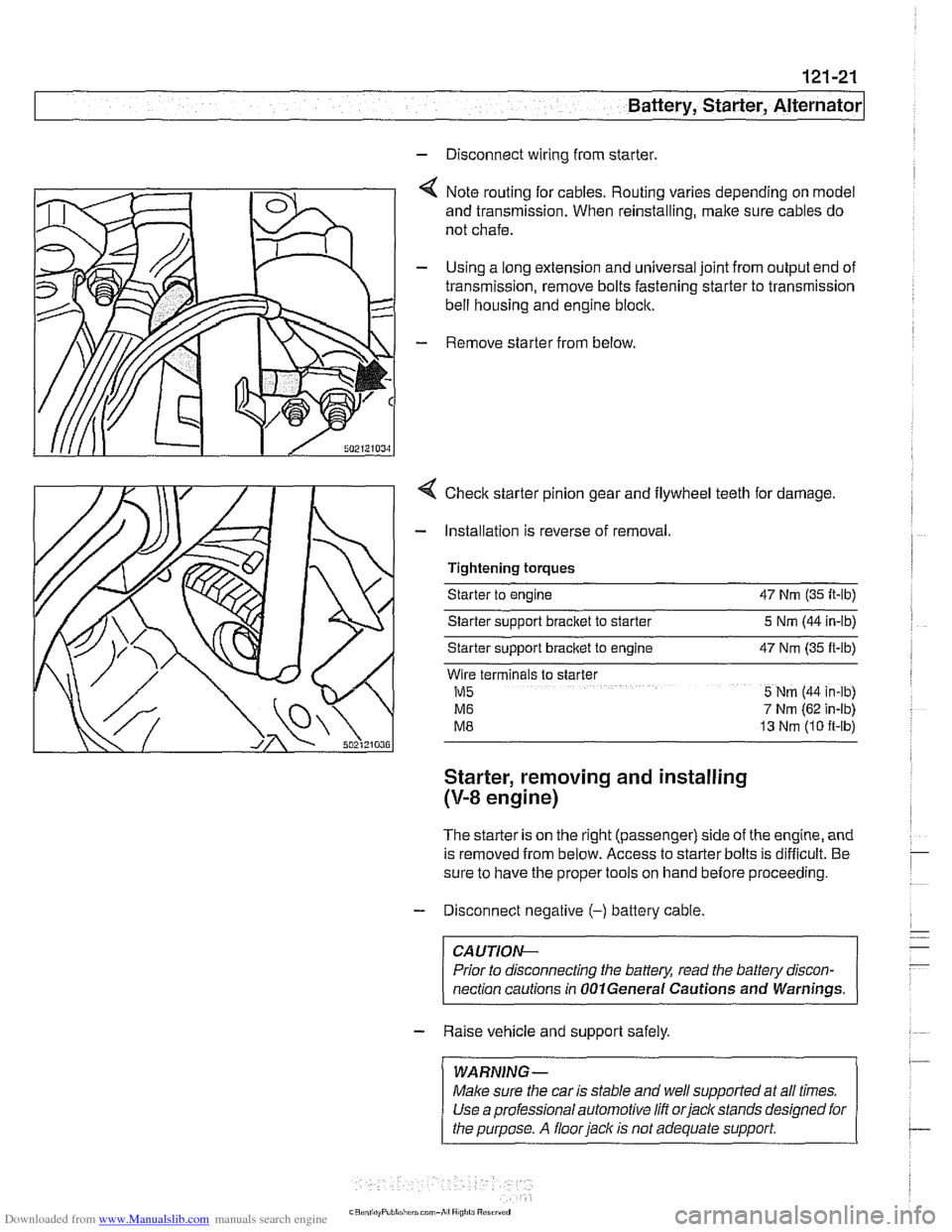

- Disconnect wiring from starter.

4 Note routing for cables. Routing varies depending on model

and transmission. When reinstalling, make sure cables do

not chafe.

- Using a long extension and universal joint from output end of

transmission, remove bolts fastening starter to transmission

bell housing and engine block.

- Remove starter from below

4 Checlc starter pinion gear and flywheel teeth for damage.

- Installation is reverse of removal.

Tightening torques

Starter to engine 47 Nrn (35 It-lb)

Starter sipport bracket to starter 5 Nrn (44 in-lb)

Starter support

bracket to engine 47 Nrn (35 ft-lb)

Wlre terminals to slarter

M5 5 Nrn (44 in-lb)

M6 7 Nrn (62 in-lb)

M8 13 Nrn (10 ft-lb)

Starter, removing and installing

(V-8 engine)

The starter is on the right (passenger) side of the engine, and

is removed from below. Access to starter bolts is difficult. Be

sure to have the proper tools on hand before proceeding.

- Disconnect negative (-) battery cable

CA UTIOW-

Prior to disconnecting the battery, read the battev discon-

nection cautions in

OOlGeneral Cautions and Warnings. -

- Raise vehicle and support safely.

/ WARNING- 1 ~ ~~ ~~ ~~~ ~

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

I the purpose. A floor jack is not adequate support I

Page 388 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Battery, Starter, Alternator

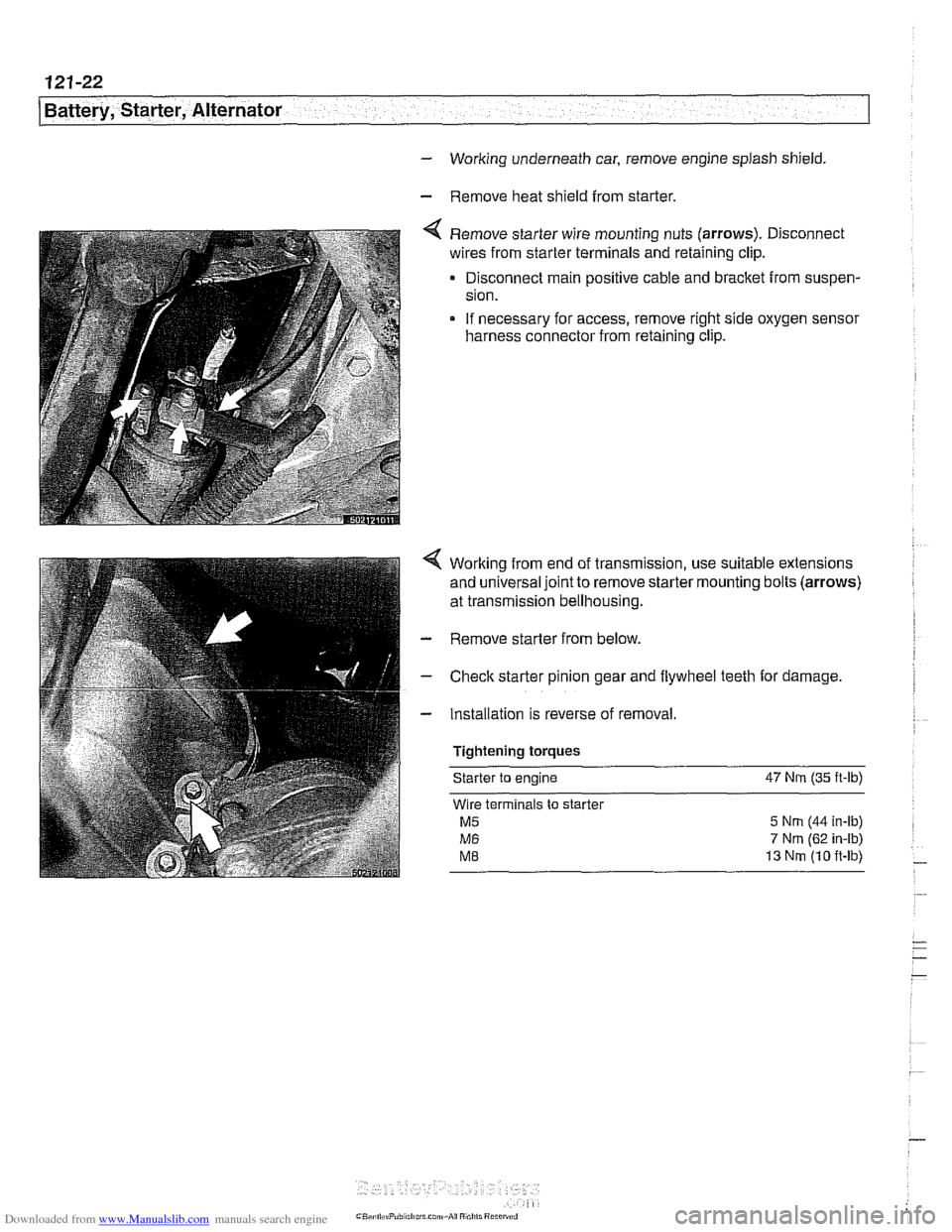

- Working underneath car, remove engine splash shield.

- Remove heat shield from starter.

Remove starter wire mounting nuts (arrows). Disconnect

wires from starter terminals and retaining clip.

Disconnect main positive cable and bracket from suspen-

sion.

If necessary for access, remove right side oxygen sensor

harness connector from retaining clip.

Working from end of transmission, use suitable extensions

and universal joint to remove starter mounting bolts (arrows)

at transmission bellhousing.

- Remove starter from below.

- Check starter pinion gear and flywheel teeth for damage.

- Installation is reverse of removal

Tightening torques Starter

to engine 47 Nrn (35

ft-lb)

Wire terminals to starter

M5 5 Nrn (44 in-ib)

M6 7 Nm (62 in-ib)

ME 13 Nrn (10 ft-lb)

Page 389 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-23

Battery, Starter, ~lternatorl

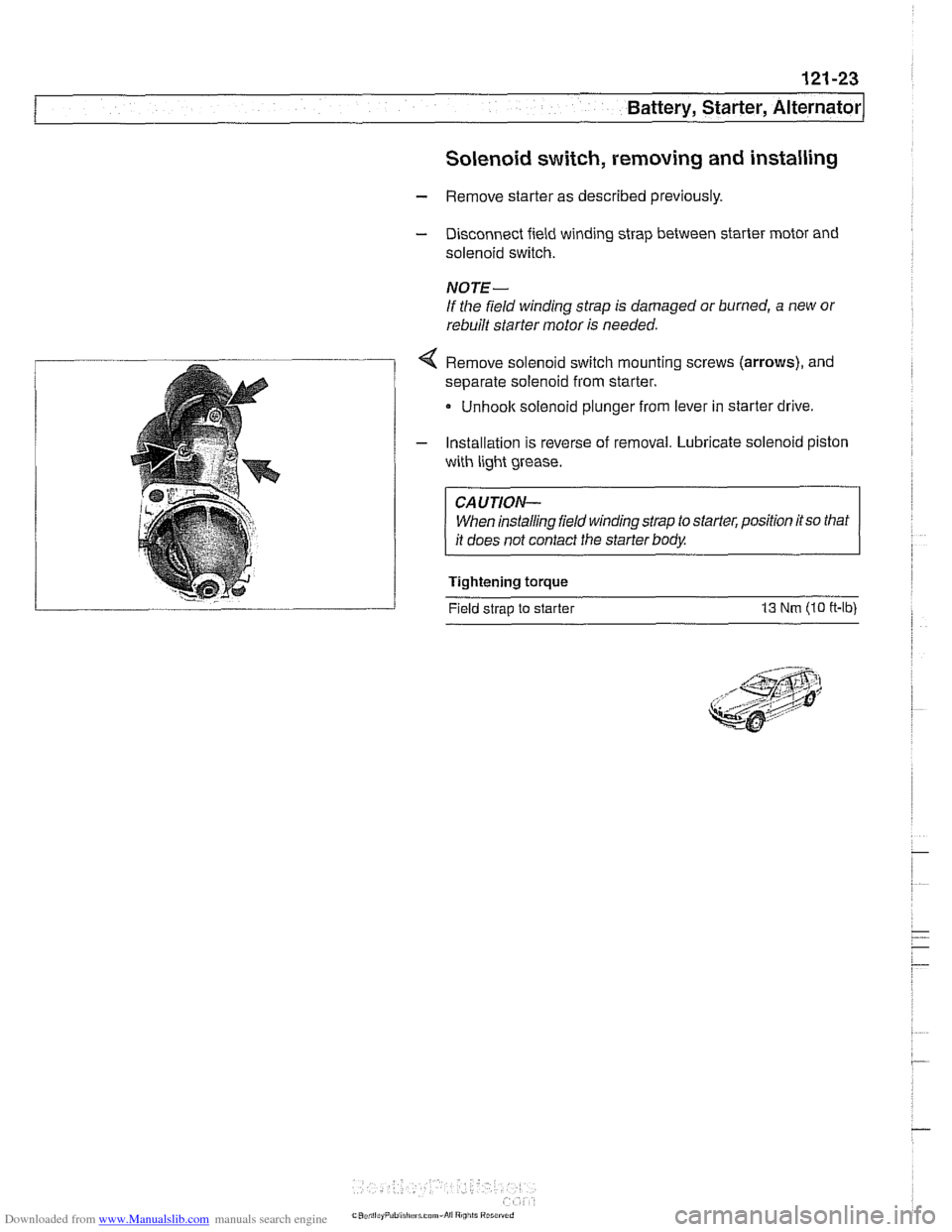

Solenoid switch, removing and installing

- Remove starter as described previously.

- Disconnect field winding strap between starter motor and

solenoid switch.

NOTE-

If the field winding strap is damaged or burned, a new or

rebuilt starter motor is needed.

< Remove solenoid switch mounting screws (arrows), and

separate solenoid from starter.

Unhoolc solenoid plunger from lever in starter drive

- Installation is reverse of removal. Lubricate solenoid piston

with light grease.

CAUTION- When installing field winding strap to starter, position

itso that

it does not contact the starter body.

Tightening torque

Field strap to starter

13 Nm (10 ff-lb)

Page 390 of 1002

Downloaded from www.Manualslib.com manuals search engine