Ecu BMW 530i 2000 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 804 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-1 0

Body-General

Seats

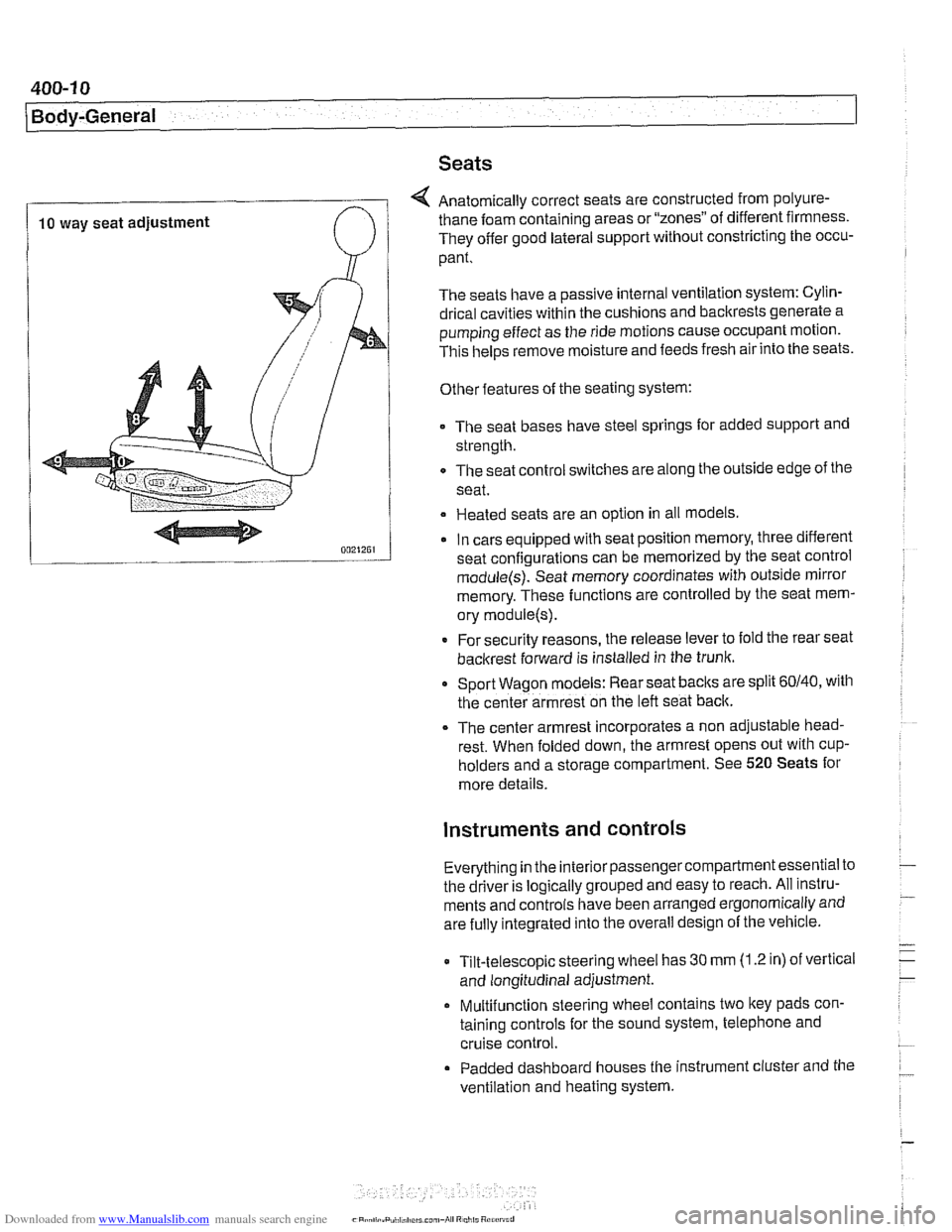

4 Anatomically correct seats are constructed from polyure-

10 way seat adjustment thane foam

containing areas or "zones" of different firmness.

They offer good lateral support without constricting the occu-

pant.

The seats have a passive internal ventilation system: Cylin-

drical cavities within the cushions and backrests generate a

pumping effect as the ride motions cause occupant motion.

This

helps remove moisture and feeds fresh air into the seats.

Other features of the seating system:

The seat bases have steel springs for added support and

strength.

The seat control switches are along the outside edge of

the

seat.

Heated seats are an option in all models

In cars equipped with seat position memory, three different

seat confiaurations can be memorized by the seat control

module(s): Seat memory coordinates with outside mirror

memory. These functions are controlled by the seat mem-

ory

module(s).

* For security reasons, the release lever to fold the rear seat

backrest forward is installed in the trunk.

Sport Wagon models: Rear seat

baclts are split 60140, with

the center armrest on the left seat back.

The center armrest incorporates a non adjustable head-

rest. When folded down, the armrest opens out with

cup-

holders and a storage compartment. See 520 Seats for

more details.

instruments and controls

Everything in the interior passengercompartment essential to

the driver is logically grouped and easy to reach. All instru-

ments and controls have been arranged ergonomically and

are fully integrated into the overall design of the vehicle.

Tilt-telescopic steering wheel has

30 mm (1.2 in) of vertical

and longitudinal adjustment.

Multifunction steering wheel contains two

ltey pads con-

taining controls for the sound system, telephone and

cruise control.

Padded dashboard houses the instrument cluster and the

ventilation and heating system.

Page 810 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-4

Fenders, Engine Hood

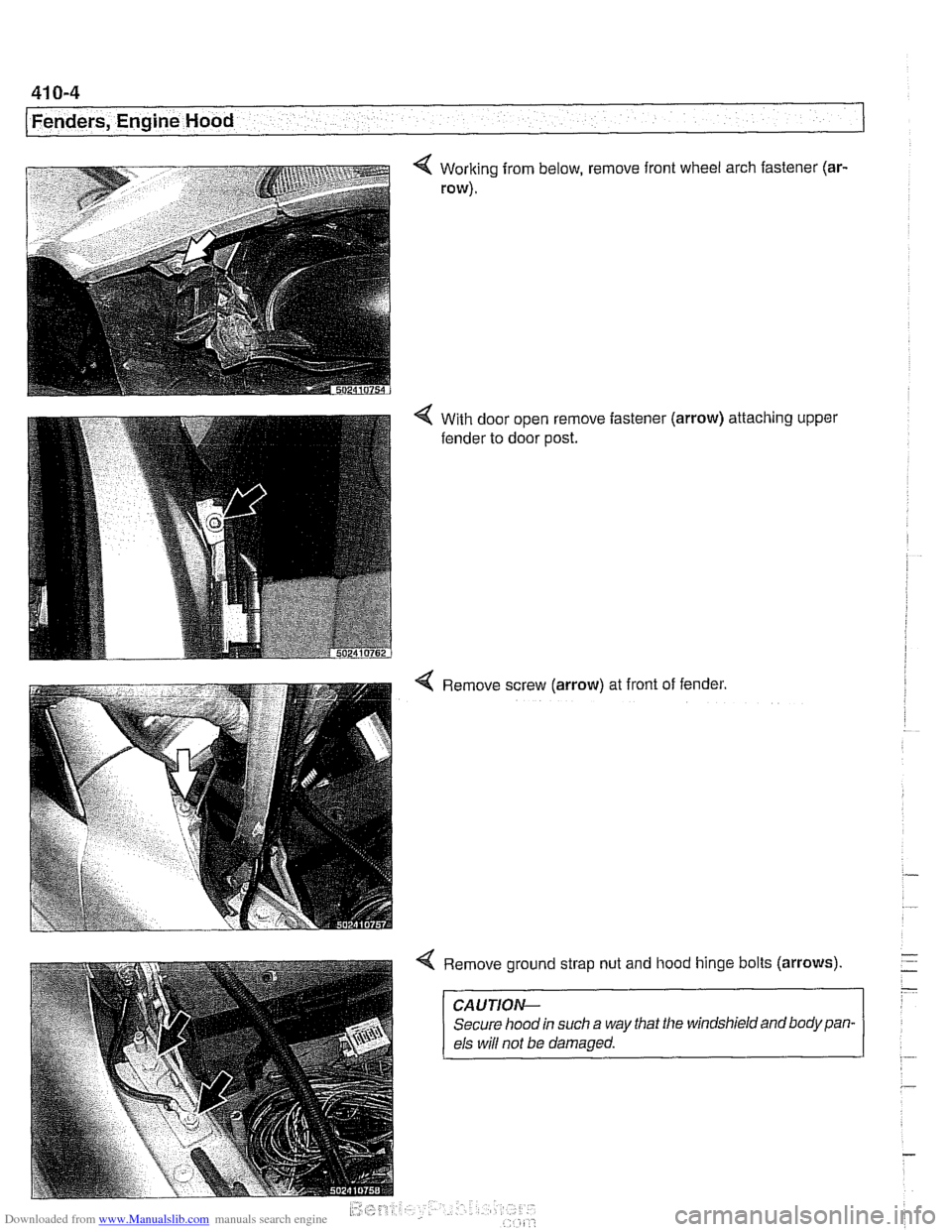

Working from below, remove front wheel arch fastener (ar-

row).

With door open remove fastener

fender to door post. (arrow) attaching upper

Remove screw

(arrow) at front of fender.

Remove ground strap nut and hood hinge bolts

(arrows)

CAUTION-

Secure hood in such a way that the windshield and body pan-

els

wiN not be damaged.

Page 864 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exterior Trim, Bumpers 1

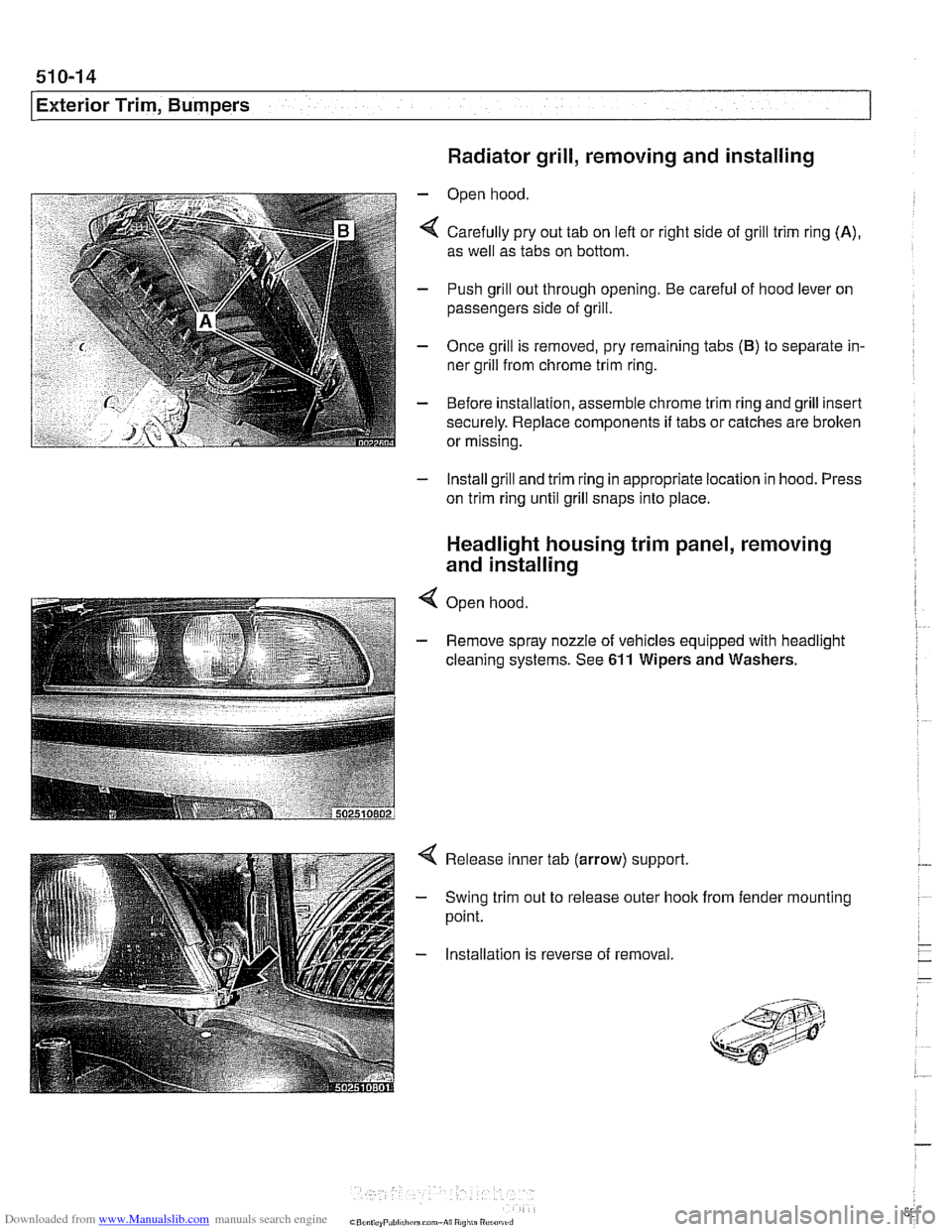

Radiator grill, removing and installing

- Open hood

4 Carefully pry out tab on lefl or right side of grill trim ring (A),

as well as tabs on bottom.

- Push grill out through opening. Be careful of hood lever on

passengers side of grill.

- Once grill is removed, pry remaining tabs (B) to separate in-

ner grill from chrome trim ring.

- Before installation, assemble chrome trim ring and grill insert

securely. Replace components

if tabs or catches are brolten

or missing.

- Install grill and trim ring in appropriate location in hood. Press

on trim ring until grill snaps into place.

Headlight housing trim panel, removing

and installing

4 Open hood

- Remove spray nozzle of vehicles equipped with headlight

cleaning systems. See

611 Wipers and Washers.

Release inner tab (arrow) support.

Swing trim out to release outer hook

point. from fender mounting

Installation is reverse of removal

Page 905 of 1002

Downloaded from www.Manualslib.com manuals search engine

515-11

Central Lockinq and ~nti-l heft/

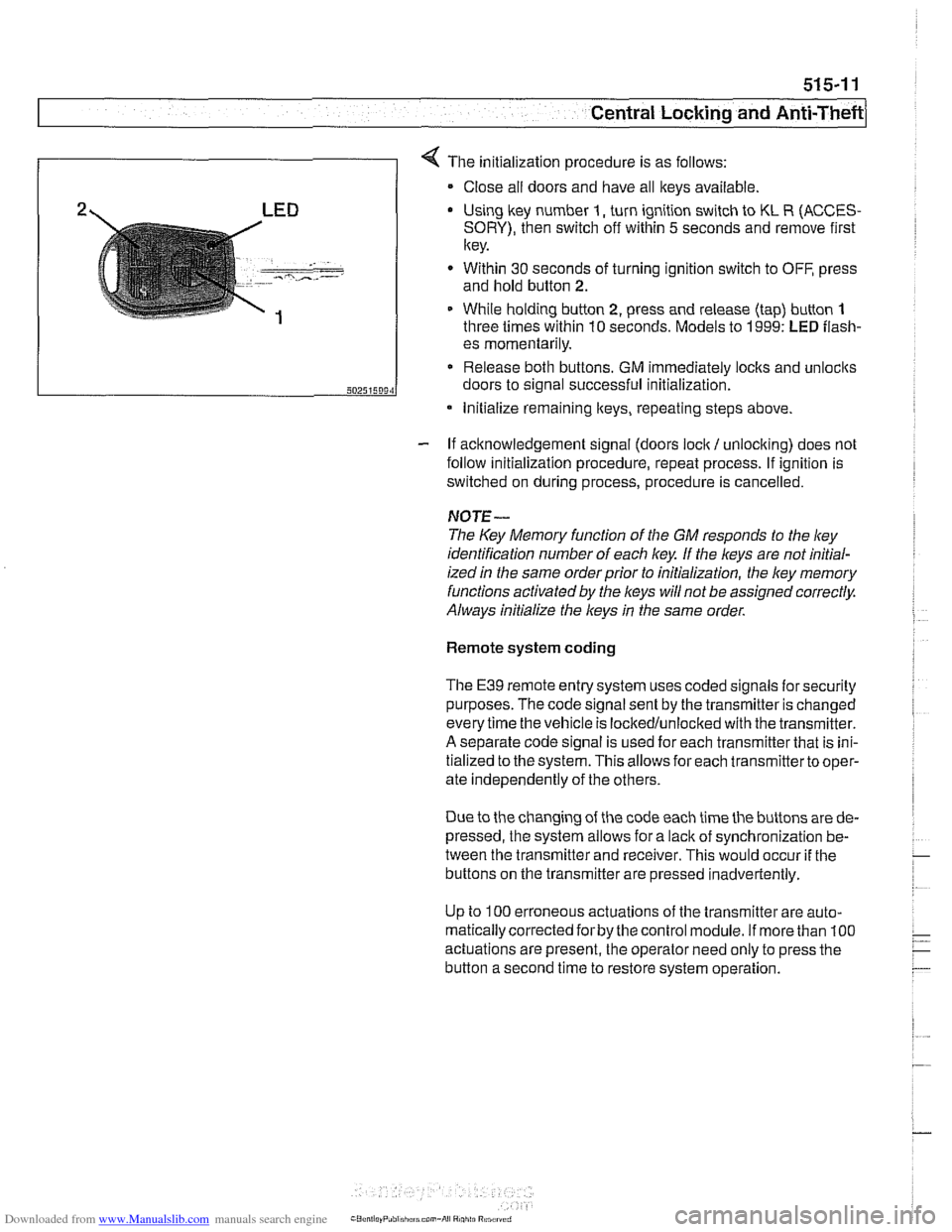

4 The initialization procedure is as follows:

Close ail doors and have all keys available

2 LED Using lkey number I, turn ignition switch to KL R (ACCES-

SORY), then switch off within 5 seconds and remove first

key.

. - -- , ..-.---- - Within 30 seconds of turning ignition switch to OFF, press

and hold button

2.

1 While holding button 2, press and release (tap) button 1

three times within 10 seconds. Models to 1999: LED flash-

- If acknowledgement signal (doors lock / unlocking) does not

follow initialization procedure, repeat process. If ignition is

switched on during process, procedure is cancelled.

50251509‘1

NOTE-

The Key Memory function of the GM responds to the ley

identification number of each key If the keys are not initial-

ized

in the same orderprior to initialization, the ley memory

functions activated by the

l(eys will not be assigned correctly.

Always initialize the keys

in the same order.

es momentarily.

Release both buttons. GM immediately locks and unlocits

doors to signal successful initialization.

Remote system coding

* Initialize remaining lteys, repeating steps above.

The E39 remote entry system uses coded signals for security

purposes. The code signal sent by the transmitter is changed

every time the vehicle is lockedlunlocked with the transmitter.

A separate code signal is used for each transmitter that is ini-

tialized to the system. This allows for each transmitterto oper-

ate independently of the others.

Due to the changing of the code each time the buttons are de-

pressed, the system allows for a

lacit of synchronization be-

tween the transmitter and receiver. This would occur

if the

buttons on the transmitter are pressed inadvertently.

Up to

100 erroneous actuations of the transmitter are auto-

matically corrected

forby the control module. If more than 100

actuations are present, the operator need only to press the

button a second time to restore system operation.

Page 961 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD On-Board Diagnostics

I I

General ........................... OBD-1 Diaqnostic Trouble Codes (DTCs) . . OBD-9

On-Board Diagnostics (OBD I!) ..... OBD-I

Malfunction Indicator Light (MIL)

........ OBD-2

Scan tools and scan tool display.

........ OBD-3

Diagnostic monitors

.................. OED-4

Drive cycle

......................... OED-6

Readiness codes

.................... OBD-6

Diagnostic trouble codes

(DTCs) ........ OBD-7

-

Automatic transmission diagnostic

trouble codes

....................... OBD-9

Engine diagnostic trouble

codes: M52 engine.

................. OED-13

Engine diagnostic trouble

codes: M54 engine.

................. OBD-17

Engine diagnostic trouble

codes: M62 engine.

................. OBD-24

This chapter outlines the fundamentals and equipment

requirements of On-Board Diagnostics

I1 (OBD 11) standards

as they apply to BMW vehicles. Also covered here is a listing

of BMW and OBD

I1 diagnostic trouble codes (DTCs).

ON-BOARD DIAGNOSTICS (QBD !I)

OBD II standards were developed by the SAE (Society of

Automotive Engineers) and CARB (California Air Resources

Board).

OED I1 is the second generation of on-board self-

diagnostic equipment requirements. These standards were

originally mandated for California vehicles. Since

1996 they

have been applied

toall passengervehicles sold in the United

States.

On-board diagnostic capabilities are incorporated into the

hardware and soflwareof the enginecontrol module

(ECM) to

monitor virtually every component that can affect vehicle

emissions. The

OED I1 system works to ensure that

emissions remain as clean as possible over the life of the

vehicle.

Each emission-influencing component is checked by a

diagnostic routine (called a monitor) to verify that it is

functioning properly.

If a problem or malfunction is detected,

the

diagnostic executive built into the OBD I1 system

illuminates a malfunction indicator light (MIL) on the

instrument panel.

The OBD

I1 system also stores diagnostic trouble codes

(DTCs) about the detected malfunction in the ECM so that a

repair technician can accurately find and fix the problem.

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

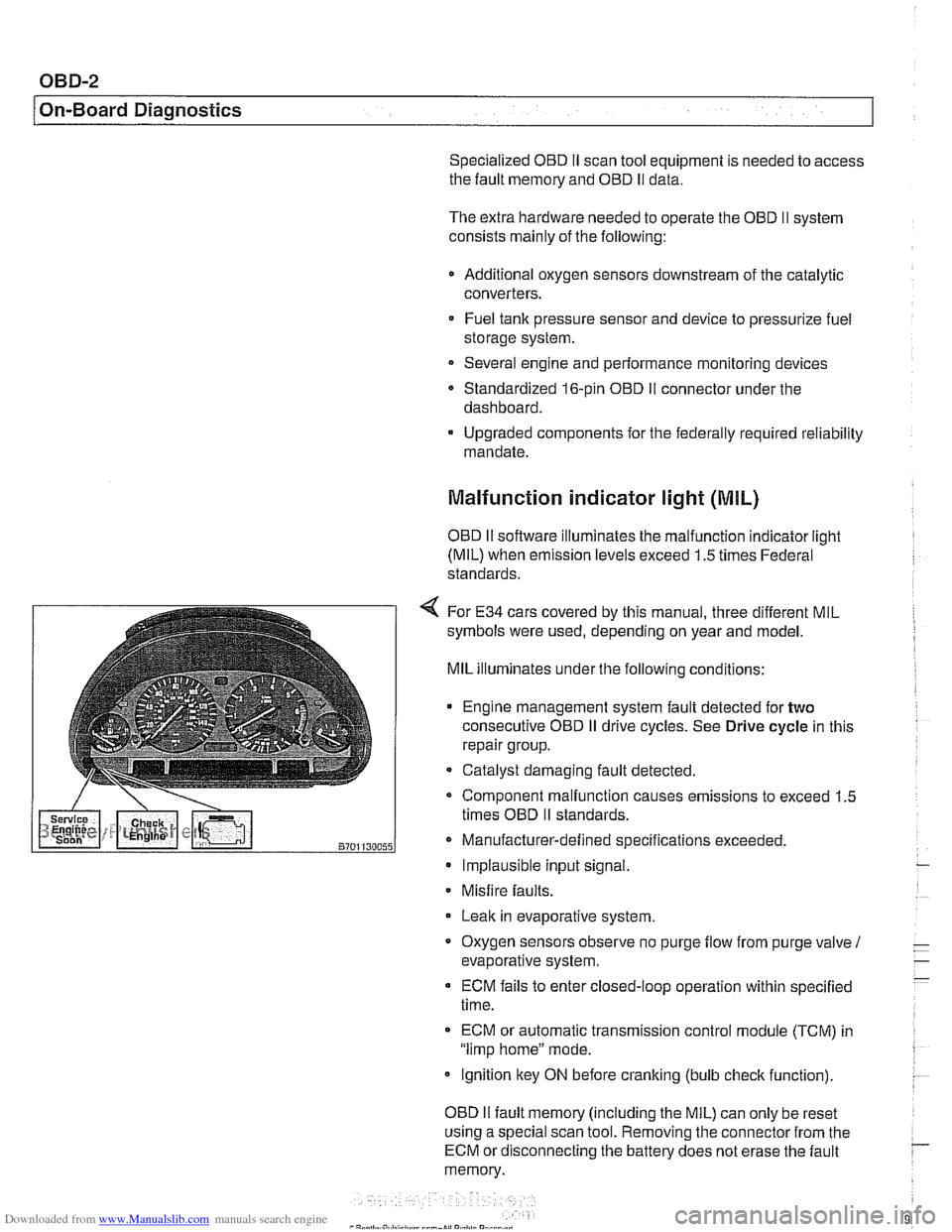

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 963 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-3

On-Board

~iactnosticsl

Additional MIL information:

A fault code is stored within the ECM upon the first

occurrence of a fault in the system being checlted.

Two complete consecutive drive cycles with the iault

present illuminate the MIL. The exception to the two-fault

requirement is a catalyst-damaging fault, which illuminates

the MIL immediately.

If the second drive cycle was not complete and the fault

was not checked, the ECM counts the third drive cycle as

the next consecutive drive cycle. The MIL illuminates

if the

system is checked and the fault is still present.

Once the MIL is illuminated, it remains illuminated until the

vehicle completes three consecutive drive cycles without

detecting a fault.

0 An existing fault code is cleared from memory

automatically when the vehicle completes

40 consecutive

drive cycles without the fault being detected.

In order to automatically clear a catalyst-damaging fault from

memory, the condition underwhich the fault occurred must be

evaluated for 80 consecutive drive cycles without the fault

reoccurring.

A generic scan tool connected to the BMW data link

connector (DLC) or OBD

I1 plug can display diagnostic trouble

codes (DTCs), along with the conditions associated with the

illumination of the MIL. Using a more advanced or

BMW-

dedicated scan tool, additional proprietary information is

normally available.

Scan tool and scan tool display

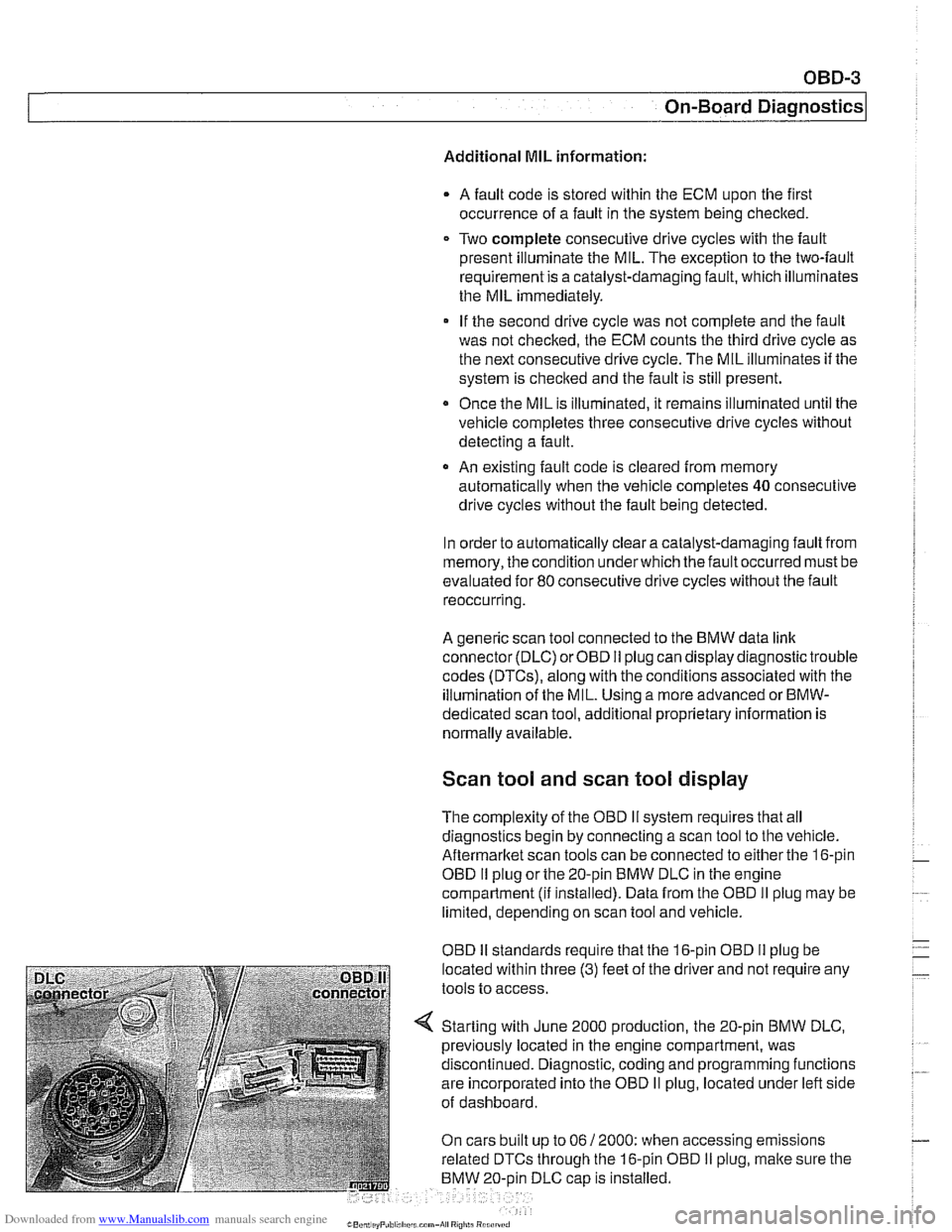

The complexity of the OBD I1 system requires that all

diagnostics begin by connecting a scan tool to the vehicle.

Aftermarltet scan tools can be connected to either the 16-pin

OBD

I1 plug or the 20-pin BMW DLC in the engine

compartment

(ii installed). Data from the OBD II plug may be

limited, depending on scan tool and vehicle.

OBD

I1 standards reouire that the 16-oin OBD I1 oluo be

located within three

(3) feet of the driier and not're&ire any

tools to access.

Starting with June 2000 production, the 20-pin BMW DLC,

previously located in the engine compartment, was

discontinued. Diagnostic, coding and programming functions

are incorporated into the OBD

II plug, located under left side

of dashboard.

On cars built up to 06

/ 2000: when accessing emissions

related DTCs through the 16-pin OBD

I1 plug, malte sure the

BMW 20-oin DLC

caD is installed.

Page 965 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

Catalyst monitoring. Thisstrategy monitors the outputofthe

precatalyst and post-catalyst oxygen sensors, comparing the

oxygen content going into the catalytic converter to the

oxygen leaving the converter.

The diagnostic executive

lknows that most of the oxygen

should be used up during the oxidation phase. If it detects

higherthan programmed values, afault is set and the MIL

illuminates.

Misfire detection. This strategy monitors crankshaft speed

fluctuations and determines if an enoine misfire occurs bv

monitoring variations in speed between each crankshaft

sensortrigger point. This strategy is so finely tuned that it can

determine the severity of the misfire.

The system determines

if a misfire is occurring, as well as

other pertinent misfire

information such as:

Specific

cylinder(s)

Severity of the misfire event

Emissions relevant or catalyst damaging

Misfire detection is an on-going monitoring process that is

only disabled under certain limited conditions.

Secondary air injection monitoring. Secondary air

injection is used to reduce HC and CO emissions during

engine warm up. Immediately following a cold engine start

(-1 0" to 40°C), fresh air (and therefore oxygen) is pumped

directly into the exhaust

manifold. By injecting additional

oxygen into the exhaust manifold, catalyst warm-up time is

reduced.

Secondary air system components are:

Electric air injection pump

* Electric pump relay

* Non-return valve

Vacuum

I vent valve

- Stainless steel air injection pipes

Vacuum reservoir

The secondary air system is monitored via the use

of the pre-

catalyst oxygen sensors. Once the air pump is active and air

is injected into the system, the signal at the oxygen sensor

reflects a lean condition. If the oxygen sensor signal does not

change, a fault is set and the faulty

bank(s) identified. If after

completing the next cold startafault is again present, the MIL

illuminates.

Page 992 of 1002

Downloaded from www.Manualslib.com manuals search engine

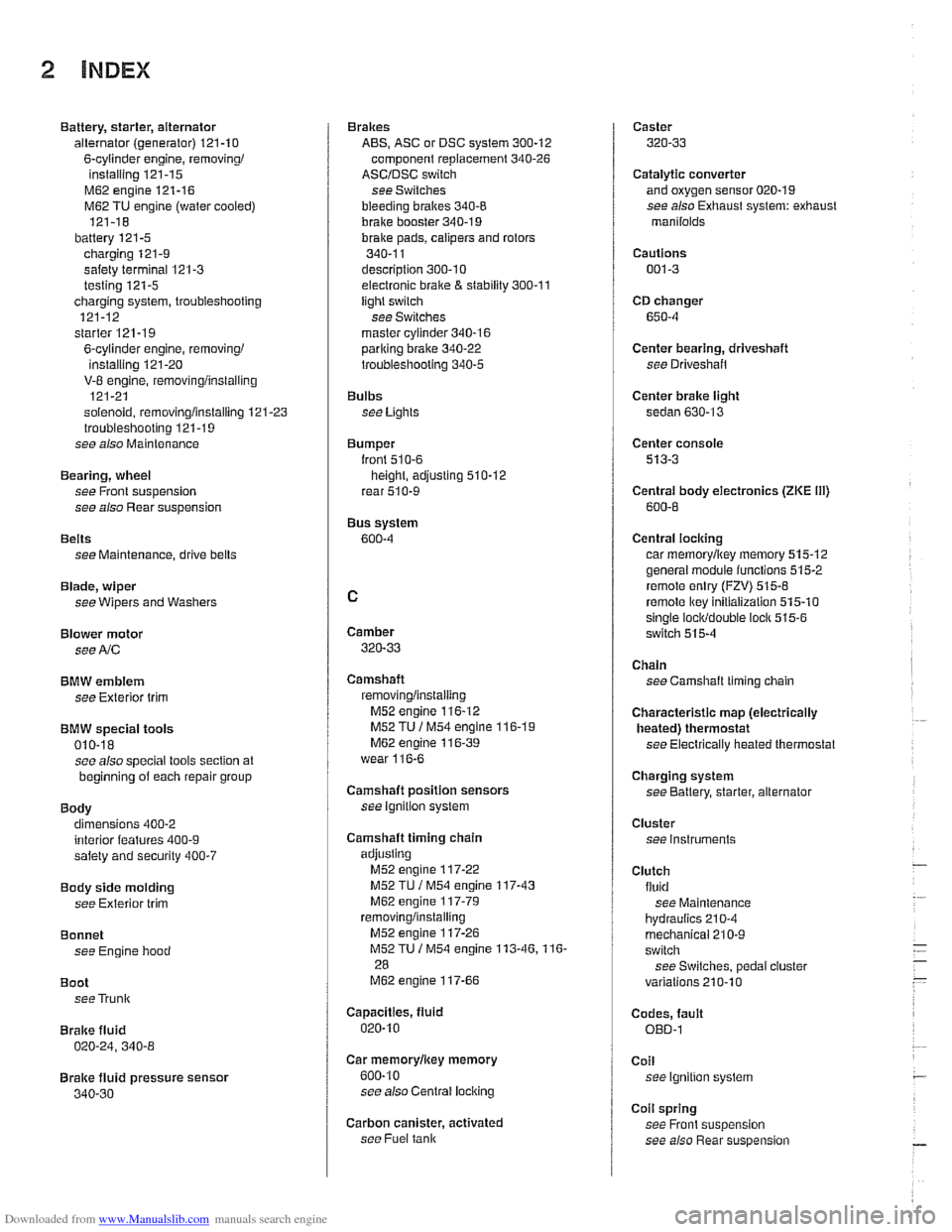

2 INDEX

Battery, starter, alternator

alternator (generator)

121-10

6-cylinder engine, removingi

installing 121-15

M62 engine 121-16

M62 TU engine (water cooled)

121-18

battery

121-5 charging 121-9

safety terminal 121-3

testing 121-5 charging system, troubleshooting

121-12

starter

121-1 9

6-cylinder engine, removingi instaliinq 121-20 . V-8 engine, rernovinglinsialiing

121-21

solenoid, removinglinstalling

121-23 troubleshooting 121-19

see also Maintenance

Bearing, wheel

see Front suspension

see also Rear suspension

Belts see Maintenance, drive belts

Blade, wiper

see Wipers and Washers

Blower motor see

A/C

BMW emblem

see Exterior trim

BMW special tools 010-18 see also special tools section at

beginning

of each repair group

Body dimensions 400-2

interior features

400-9 salety and security 400-7

Body side molding

see Exterior trim

Bonnet see Engine hood

Boot see Trunk

Brake fluid

020-24, 340-8

Brake fluid pressure sensor

340-30

Brakes

ABS, ASC or DSC system

300-12

component replacement 340-26

ASCIDSC switch

see Switches

bleeding

bralces 340-8

brake booster 340-1 9 bralce Dads. caiioers and rotors ,., 340-1 1

descriotion 300-10

e~ectrdnic brake & stability 300-11

light switch

see Switches

master cylinder

340-16 pariking brake 340-22

troubleshooting 340-5

Bulbs see Lights

Bumper

lront 510-6 height, adjusting 510-12

rear 510-9

Bus system

600-4

Camber

320-33

Camshaft

removingiinslaiiing

M52 engine 116-12

M52 TU

/ M54 engine 116-1 9 M62 engine 11 6-39

wear

116-6

Camshaft position sensors

see ignition system

Camshaft timing chain

adjusting M52 engine

117-22

M52 TU I M54 engine 117-43

M62 engine 117-79 removinglinstalling

M52 engine 117-26

M52TU 1 M54 engine 113-46.116-

28

M62 engine 117-66

Capacities, fluid

020.10

Car rnemorvlicev memorv . . 600-10

see also Centrai

lociking

Carbon canister, activated

see Fuel

tank

Caster

320-33

Catalytic converter and oxygen sensor 020-19

see also Exhaust system: exhaust

manilolds

Cautions

001-3

CD changer

650-4

Center bearing, driveshaft

see Driveshait

Center brake light

sedan

630-13

Center console

513-3

Centrai body electronics (ZKE 111)

600-6

Central locking

car memoryiey memory 515.12 general module iunctions 515-2

remote entry (FZV) 515-8

remote lkey initialization 515-10 single lociddouble ioclk 515-6

switch 515-4

Chain

see Camshaft liming chain

Characteristic map (electrically heated) thermostat

see Electrically heated thermostat

Charging system

see Battery, starter, alternator

Cluster see instruments

Clutch fluid see Maintenance

hydraulics

210-4

mechanical 210-9

switch

see Switches, pedal ciuster

variations

210.10

Codes, fault OED-1

Coil

see Ignition system

Coil spring

see Front suspension

see also Rear

suspe nsion