Ecu BMW 530i 2000 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 530i, Model: BMW 530i 2000 E39Pages: 1002

Page 594 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 0

Automatic Transmission

TRANSMISSION REMOVAL AND

INSTALLATION

Removal and installation of the transmission is best accorn-

plished on an automotive lift using a transmission jack. Use

caution and safe workshop practices when working beneath

car and lowering transmission.

Torx-head bolts are used to mount the transmission to the

bellhousing.

Besure to have appropriate tools on hand before

starting the job.

WARNING-

Be sure the vehicle is properly supported. The removal of the

transmission may upset the balance of the vehicle on a lift

CAUJION-

Tilting the engine to remove the transmission can lead to

damaae to various components due to

laclc of clearance. 1

Transmission, removing and installing

WARNING -

Allow engine and transmission to cool down before starting

work on the transmission.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warninas.

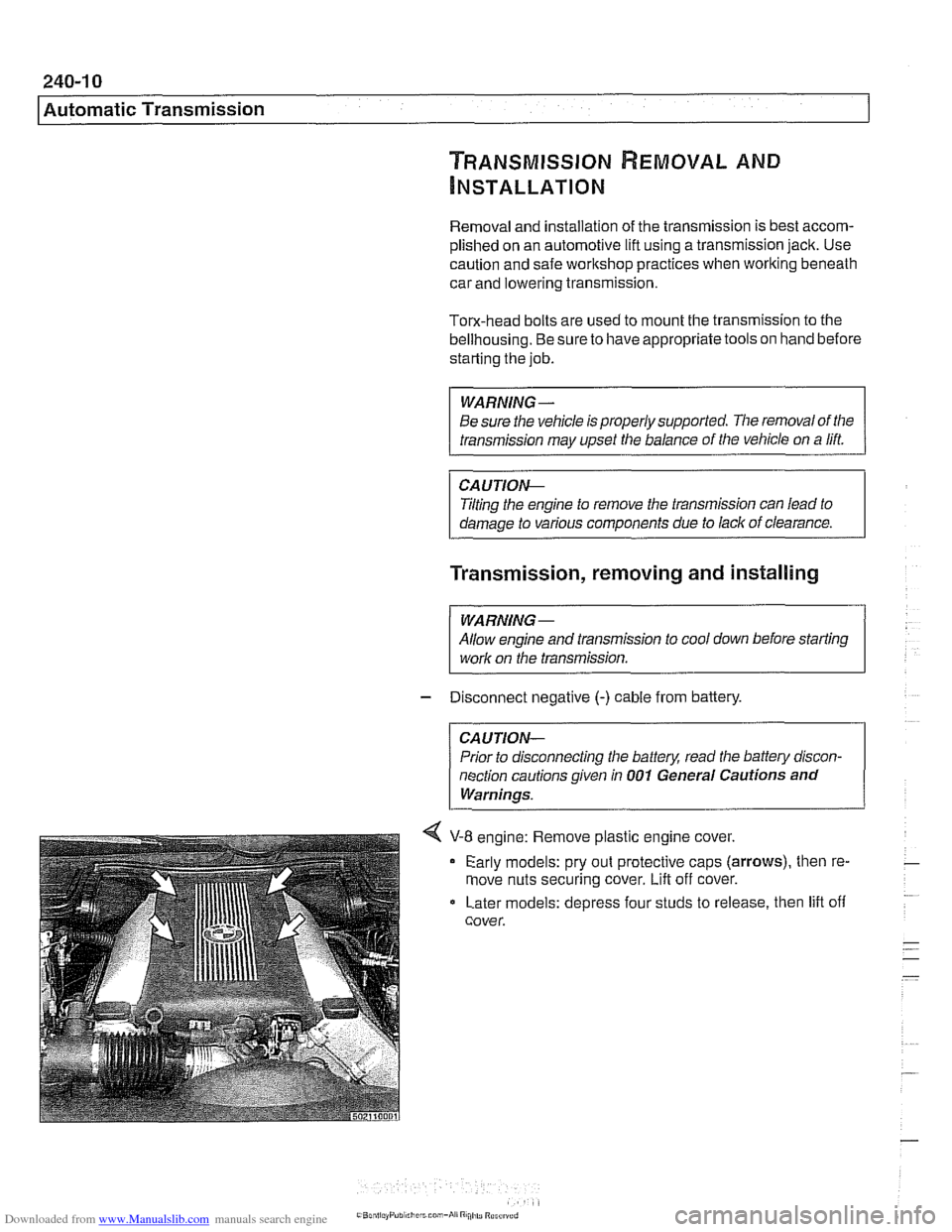

4 V-8 engine: Remove plastic engine cover.

Early models: pry out protective caps

(arrows), then re-

move nuts securing cover.

Lift off cover.

Later models: depress four studs to release, then lift off

cover.

Page 614 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.- .

/ Driveshaft Driveshaft, removing

CAUTION-

. Be sure the wheels are off the ground before removing the

driveshak Set the parl(ing brake before removing the

driveshaft.

Once the driveshaft has been removed, the vehicle can

roll regardless of whether the transmission is in gear or

not.

The driveshaft is mounted to the transmission and final

drive

with self-locliing nuts. These nuts are designed to

be used only once and should be replaced during reas-

sembly.

Remove complete exhaust system. See

180 Exhaust

System.

- Remove exhaust heat shields.

- Support transmission with transmission jack.

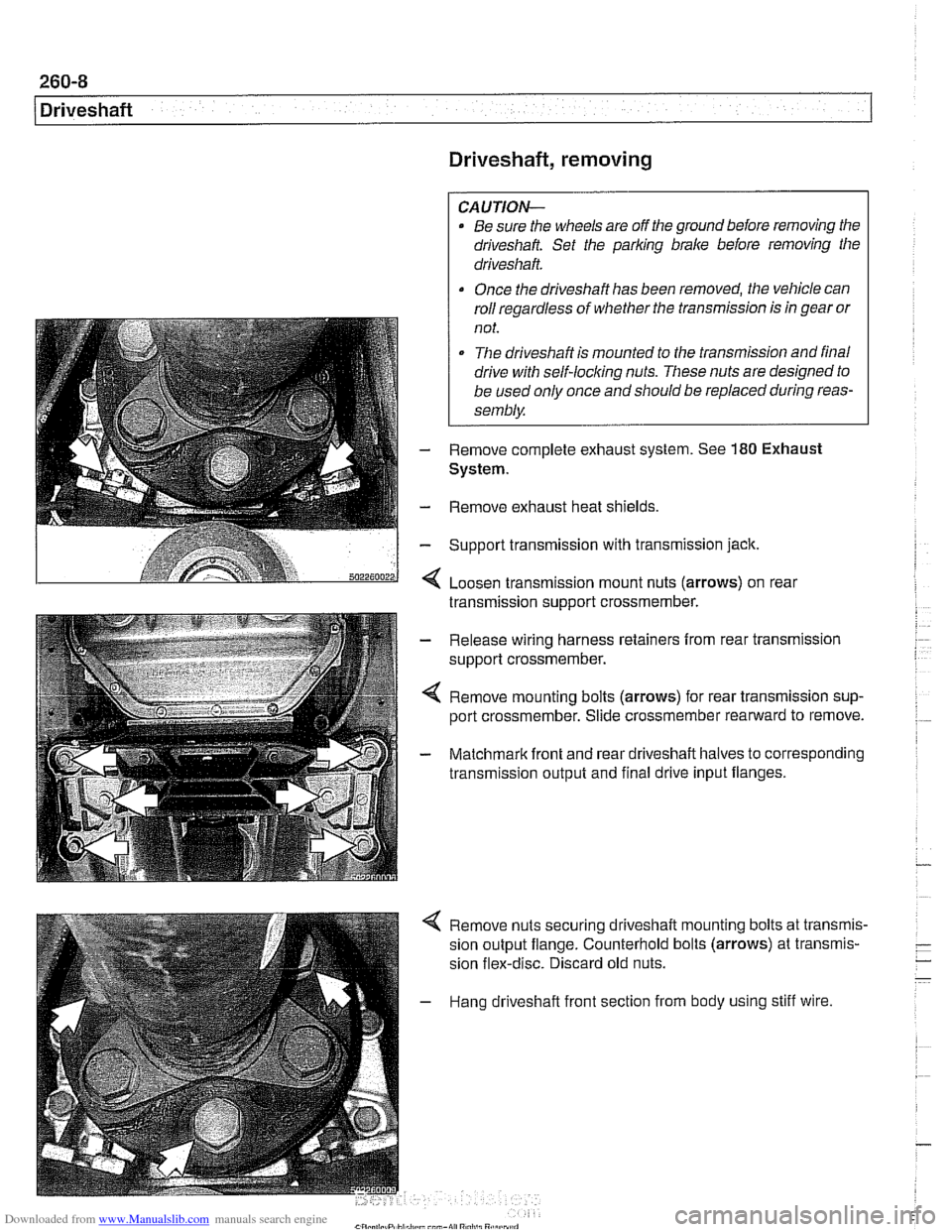

< Loosen transmission mount nuts (arrows) on real

transmission support crossmember.

- Release wiring harness retainers from rear transmission

support crossmember.

< Remove mounting bolts (arrows) for rear transmission sup-

port crossmember. Slide crossmember rearward to remove.

- Matchmark front and rear driveshaft halves to corresponding

transmission output and final drive input flanges.

4 Remove nuts securing driveshaft mounting bolts at transmis-

sion output flange. Counterhold bolts (arrows) at transmis-

sion flex-disc. Discard old nuts.

- Hang driveshaft front section from body using stiff wire.

Page 618 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 2

1 Driveshaft

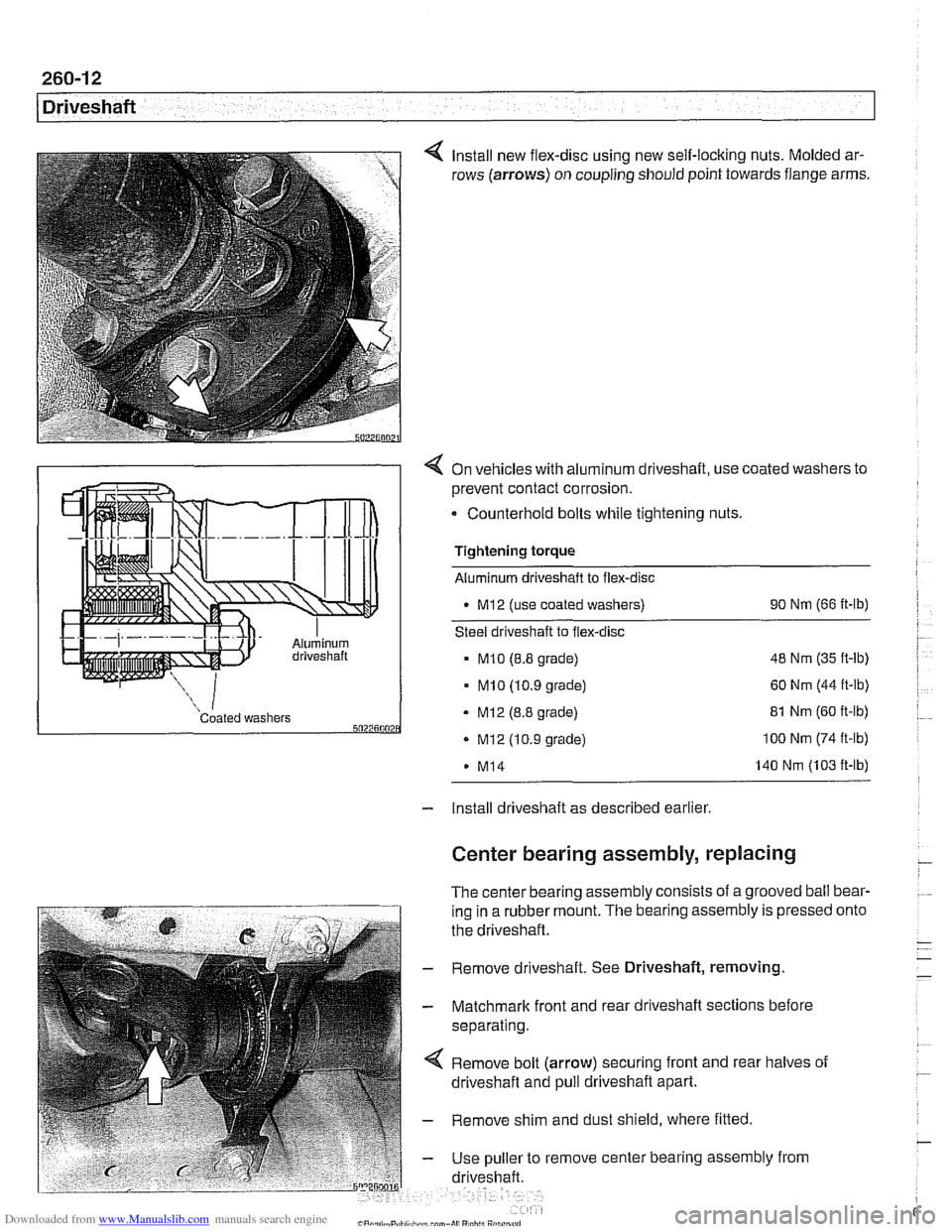

Install new flex-disc using new self-locking nuts. Molded ar-

rows (arrows) on coupling should point towards flange arms.

4 On vehicles with aluminum driveshaft, use coated washers to

prevent contact corrosion.

- Counterhold bolts while tightening nuts.

Tightening torque

Aluminum driveshaft to flex-disc

M12 (use coated washers) 90

Nm (66 ft-lb)

Steel driveshaft to flex-disc

MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

Coated washers - MI2 (8.8 grade) 5027500 . Mi2 (10.9 grade)

M14 81

Nm (60 ft-lb) 100 Nm (74 ft-lb)

140 Nm (103 ft-lb)

- Install driveshaft as described earlier

Center bearing assembly, replacing

The center bearing assembly consists of a grooved ball bear-

ing in a rubber mount. The bearing assembly is pressed

the driveshaft.

- Remove driveshaft. See Driveshaft, removing

- Matchmark front and rear driveshaft sections before

separating.

Remove bolt (arrow) securing front and rear halves of

driveshaft and pull driveshaft apart.

- Remove shim and dust shield, where fitted

- Use puller to remove center bearing assembly from

driveshaft. onto

Page 619 of 1002

Downloaded from www.Manualslib.com manuals search engine

- On installation, drive new center bearing firmly to stop.

Reassemble driveshaft using matchmarks made prior to

disassembly.

- Clean threads and install bolt securing driveshaft halves.

Use thread locking compound

LoctiteO or equivalent.

Tightening torque Driveshaft front half to rear half

(use thread locking compound) 97

Nm (72 fl-lb)

- Install driveshaft as described earlier.

Front centering guide, replacing

The front centering guide centers the driveshafl in relation to

the transmission. The guide is press-fit into a cavity in the

front of the driveshafl and slides onto the transmission output

shaft.

No specifications are given

forwear of the guide, but general-

ly the guide should fit snugly on the transmission output shafl.

NOTE-

Some driveshafts have a dust cap installed on the end of the

driveshaft, over the centering guide. The dust cap may be-

come bent or distorted when the driveshaft is removed or

in-

stalled. Damage to the dust cap should not affect the

centering guide and should not be mistaken for guide wear.

- Remove driveshafl as described earlier

- Pack cavity behind centering guide with heavy grease until

grease is flush with bottom edge of guide.

- Insert 14 mm (approximately 9/16 in.) diameter mandrel or

metal rod into guide. Strike guide with hammer to force cen-

tering guide out.

NOTE-

Tlie mandrel should fit snugly in the centering guide so that

the grease cannot escape around the sides of the mandrel.

- Remove old grease from driveshaft, lubricate new centering

guide with molybdenum disulfide grease

(MolykoteO, Long-

term8 2 or equivalent) and drive it into driveshaft.

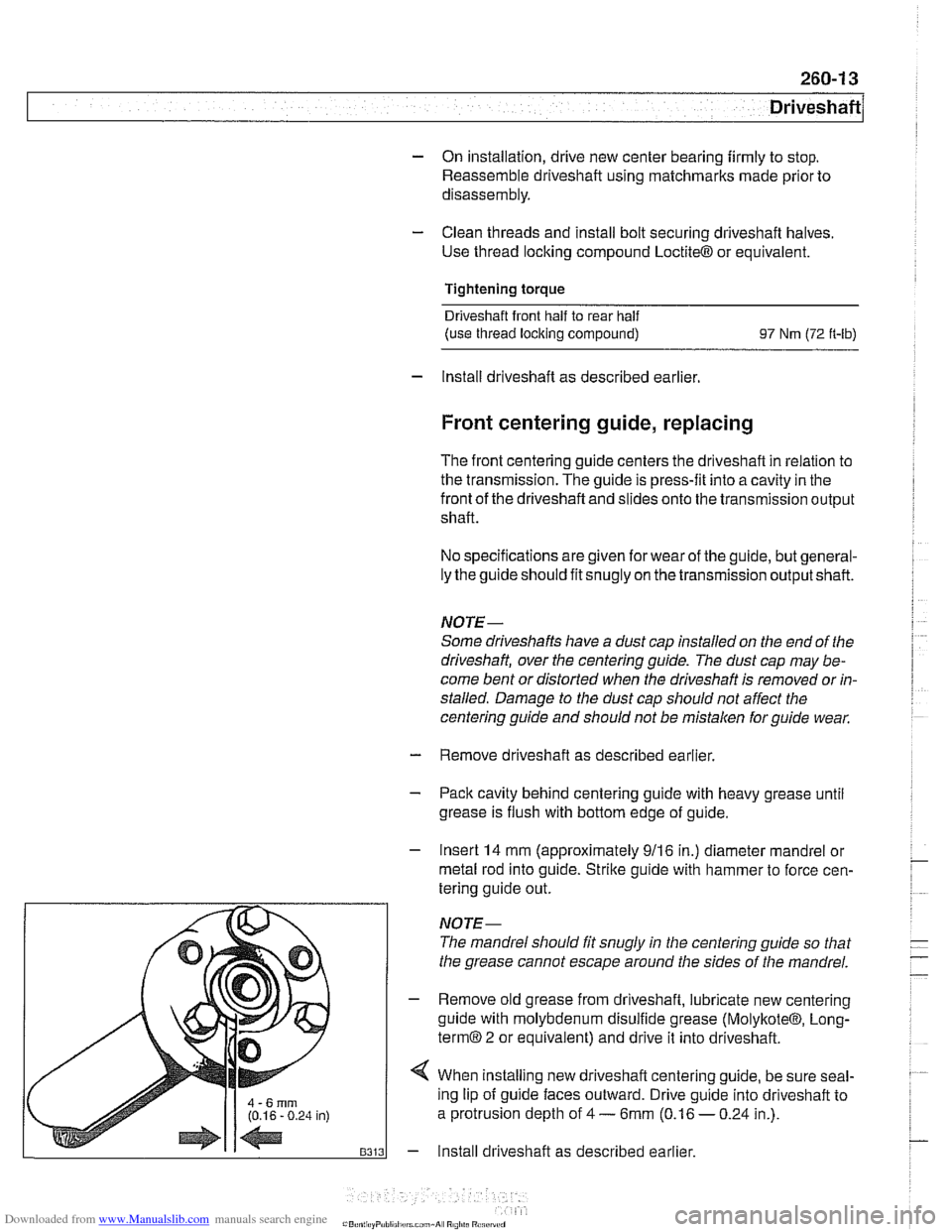

4 When installing new driveshafl centering guide, be sure seal-

ing lip of guide faces outward. Drive guide into driveshaft to

a protrusion depth of

4 - 6mm (0.16 - 0.24 in.).

- Install driveshaft as described earlier.

Page 641 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-5

Front ~uspensionl

Front strut assembly, removing and

installing

- Raise car and remove front wheel.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension

parts.

- Unbolt bralte caliper assembly, lkeeping bralte hose connect-

ed. Secure brake caliper to body with wire. Do not let it hang

from brake hose. See

340 Brakes.

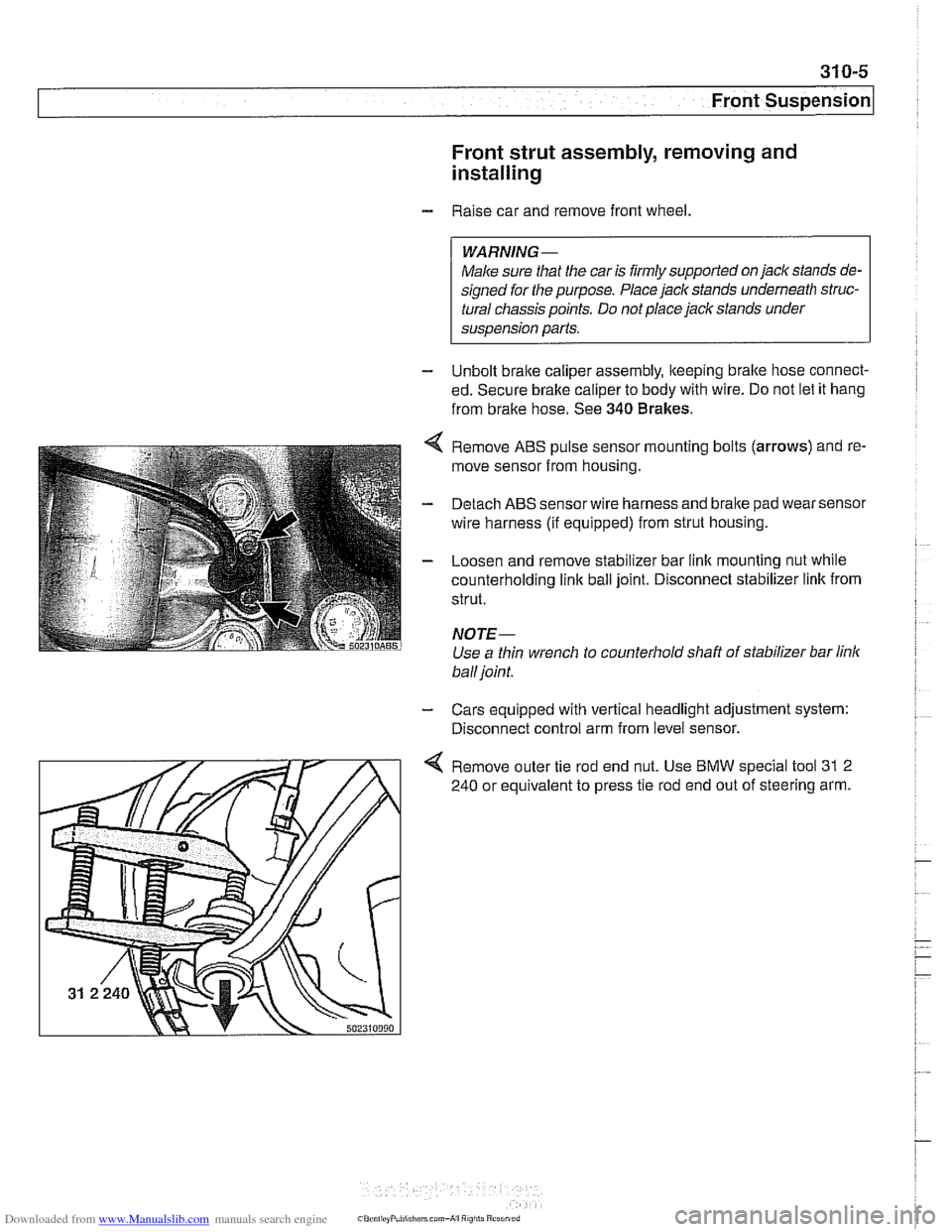

Remove ABS pulse sensor mounting bolts (arrows) and re-

move sensor from housing.

Detach ABS sensor wire harness and bralte pad wear sensor

wire harness (if equipped) from strut housing.

Loosen and remove stabilizer bar link mounting nut while

counterholding

link ball joint. Disconnect stabilizer link from

strut.

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

4 Remove outer tie rod end nut. Use BMW special tool 31 2

240 or equivalent to press tie rod end out of steering arm.

Page 779 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Master cylinder, removing and installing

CAUTlOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it properly.

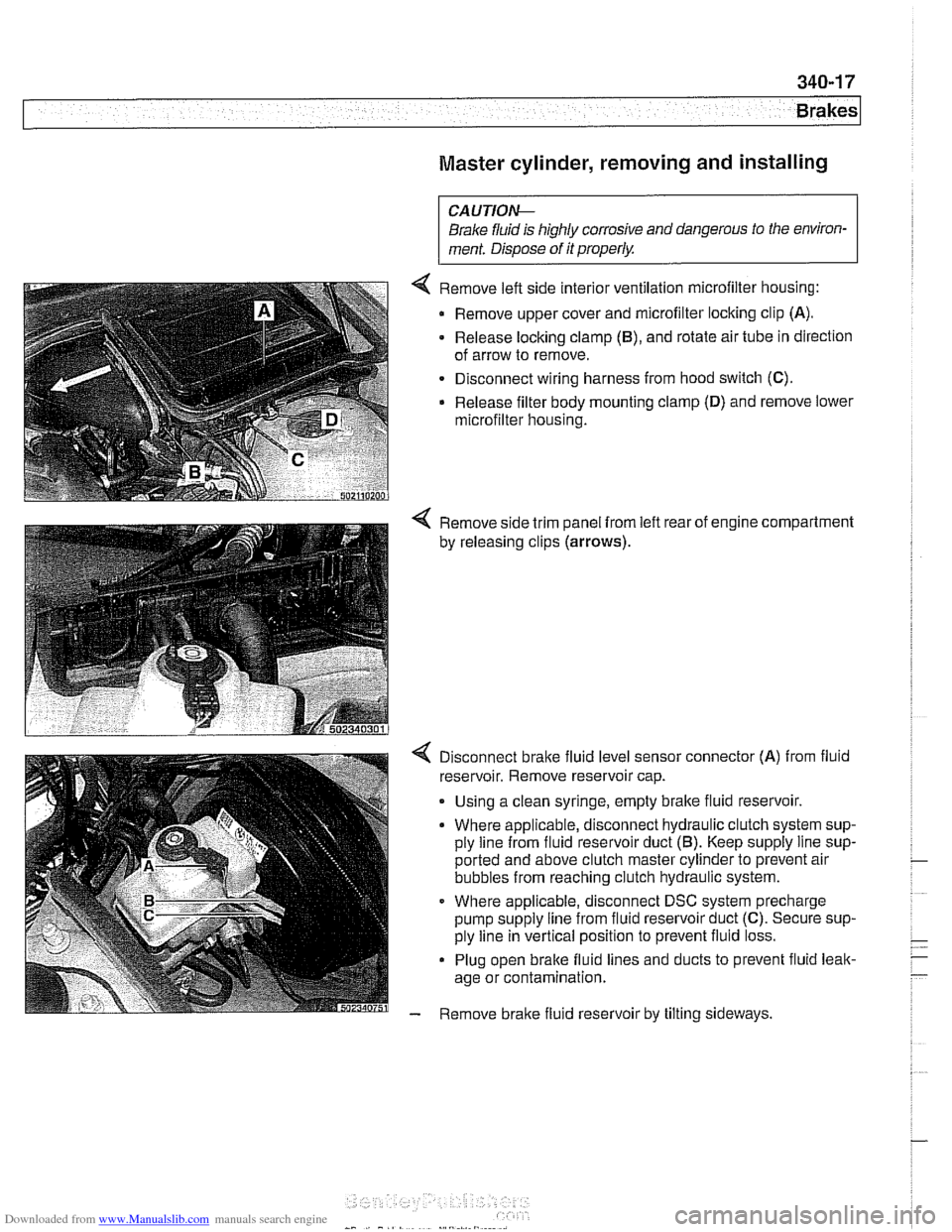

4 Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter locking clip

(A).

- Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

4 Remove side trim panel from left rear of engine compartment

by releasing clips

(arrows).

4 Disconnect bralte fluid level sensor connector (A) from fluid

reservoir. Remove reservoir cap.

. Using a clean syringe, empty bralte fluid reservoir.

Where applicable, disconnect hydraulic clutch system sup-

ply line from fluid reservoir duct

(5). Keep supply line sup-

ported and above clutch master cylinder to prevent air

bubbles from reaching clutch hydraulic system.

Where applicable, disconnect DSC system precharge

pump supply line from fluid reservoir duct

(C). Secure sup-

ply line in vertical position to prevent fluid loss.

Plug open brake fluid lines and ducts to prevent fluid leak-

age or contamination.

- Remove brake fluid reservoir by tilting sideways.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

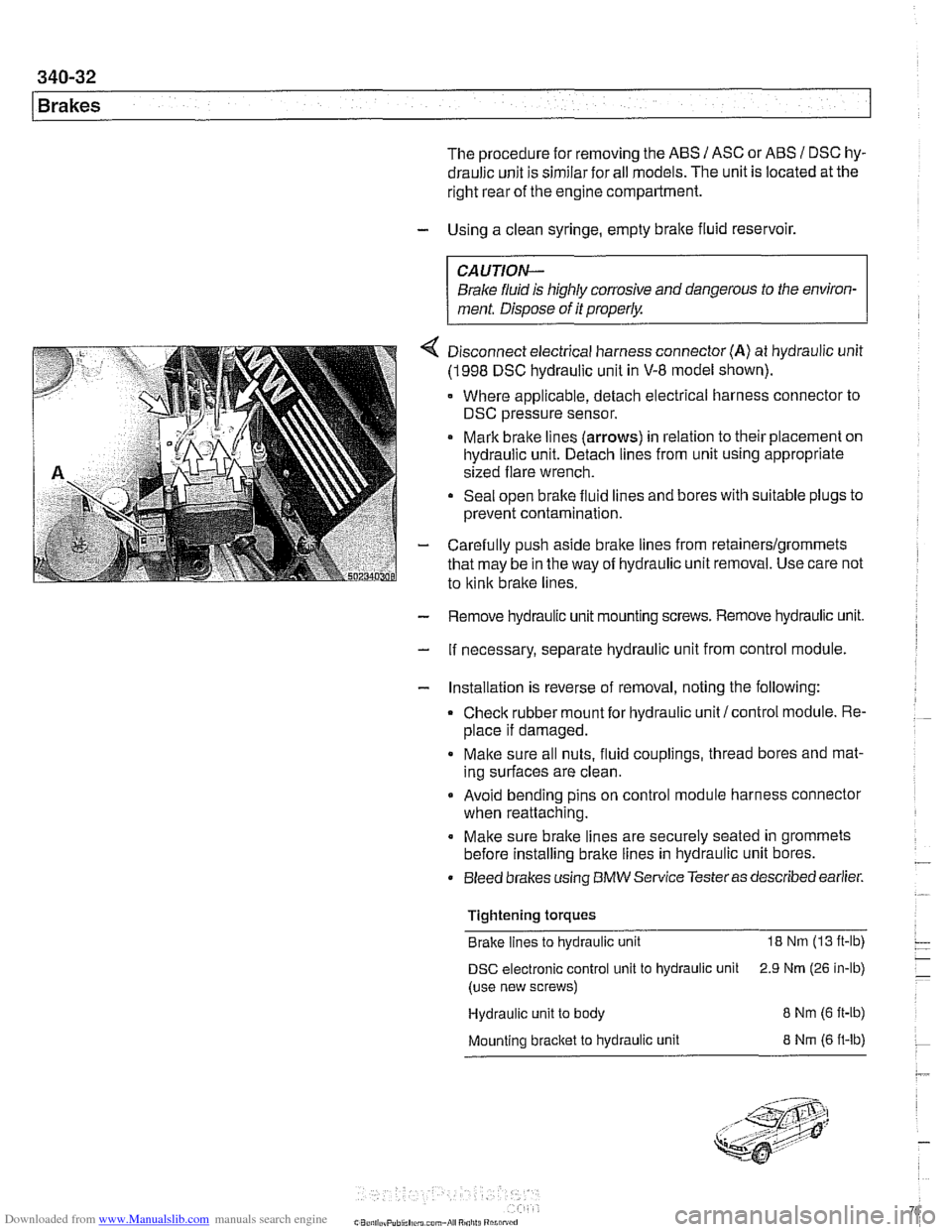

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)

Page 795 of 1002

Downloaded from www.Manualslib.com manuals search engine

400 Body-General

........................ General ........................... .40 0.2 Roof paddin~ 400-7

Body Assembly ................... .40 0.2

Body dimensions (in inches)

............ .40 0.2

Bodyshell

........................... 400-3

Exterior and aerodynamics

............. .40 0.3

Sport Wagon ...................... .40 0.4

Tailgate

............................ .40 0.5

Tailgate lock system

.................. .40 0.5

Rear wiper system ................... .40 0.6

Antenna and sound system ............ .40 0.6

Safety and Security Features ....... .40 0.7

Safety cage

......................... .40 0.7

Door locks and door handles

........... .40 0.7

.

........................... Seat belts 400-7

Airbags ............................ 400-8

Battery safety terminal (BST)

........... 400-9

Security

............................ 400-9

Interior Features ................... 400-9

............................. Seats 400-10

Instruments and controls .............. 400-10

Central body electronics

.............. 400-1 1

Heating and Air

Conditioning (IHKA)

............... 400-12

Page 801 of 1002

Downloaded from www.Manualslib.com manuals search engine

Body-General

SAFETY AND SECURITY FEATURES

A number of new or improved safety and security features are

incorporated in

E39 cars.

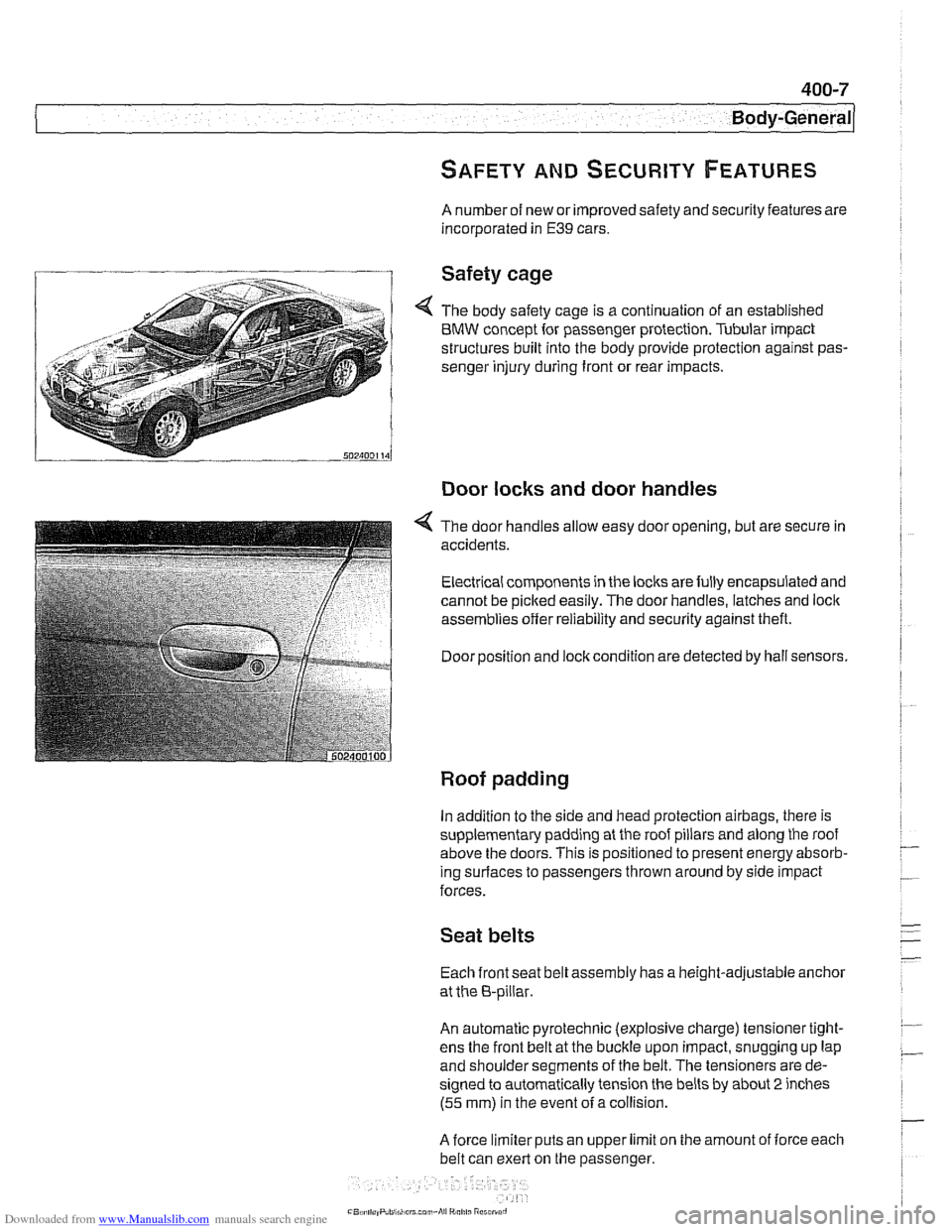

Safety cage

4 The body safety cage is a continuation of an established

BMW concept for passenger protection. Tubular impact

structures built into the body provide protection against pas-

senger injury during front or rear impacts.

Door locks and door handles

4 The door handles allow easy door opening, but are secure in

accidents.

Electrical components in the locks are fully encapsulated and

cannot be picked easily. The door handles, latches and

loclc

assemblies offer reliability and security against theft.

Door position and

loclc condition are detected by hall sensors.

Roof padding

In addition to the side and head protection airbags, there is

supplementary padding at the roof pillars and along the roof

above the doors. This is positioned to present energy absorb-

ing

surlaces to passengers thrown around by side impact

forces.

Seat belts

Each front seat belt assembly has a height-adjustable anchor

at the 8-pillar.

An automatic pyrotechnic (explosive charge) tensioner tight-

ens the front belt at the buckle upon impact, snugging up lap

and shoulder segments of the belt. The tensioners are de-

signed to automatically tension the belts by about

2 inches

(55 mm) in the event ofa collision.

A force limiter puts an upper limit on the amount of iorce each

belt can exert on the passenger.

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

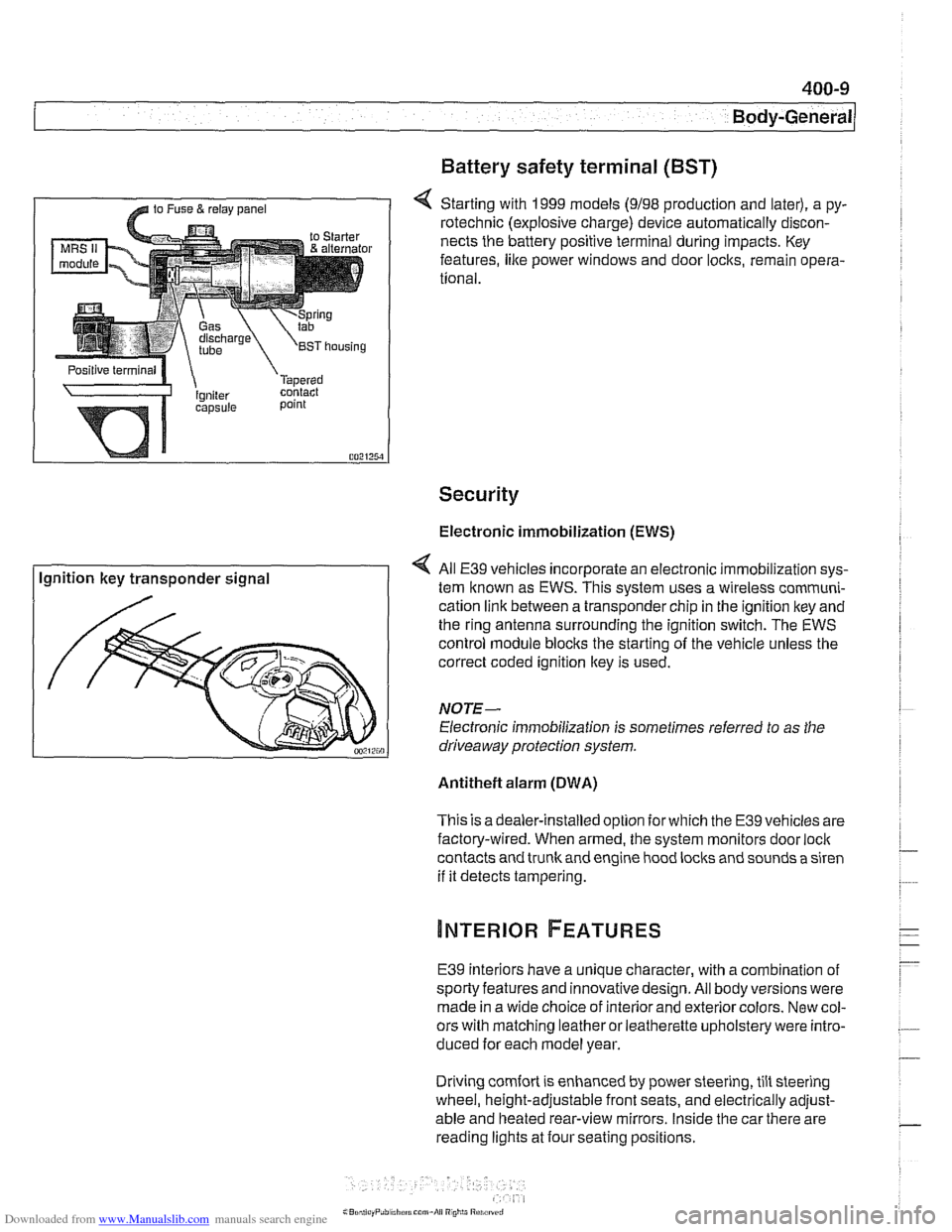

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.