BMW 530i 2001 E39 Repair Manual

Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

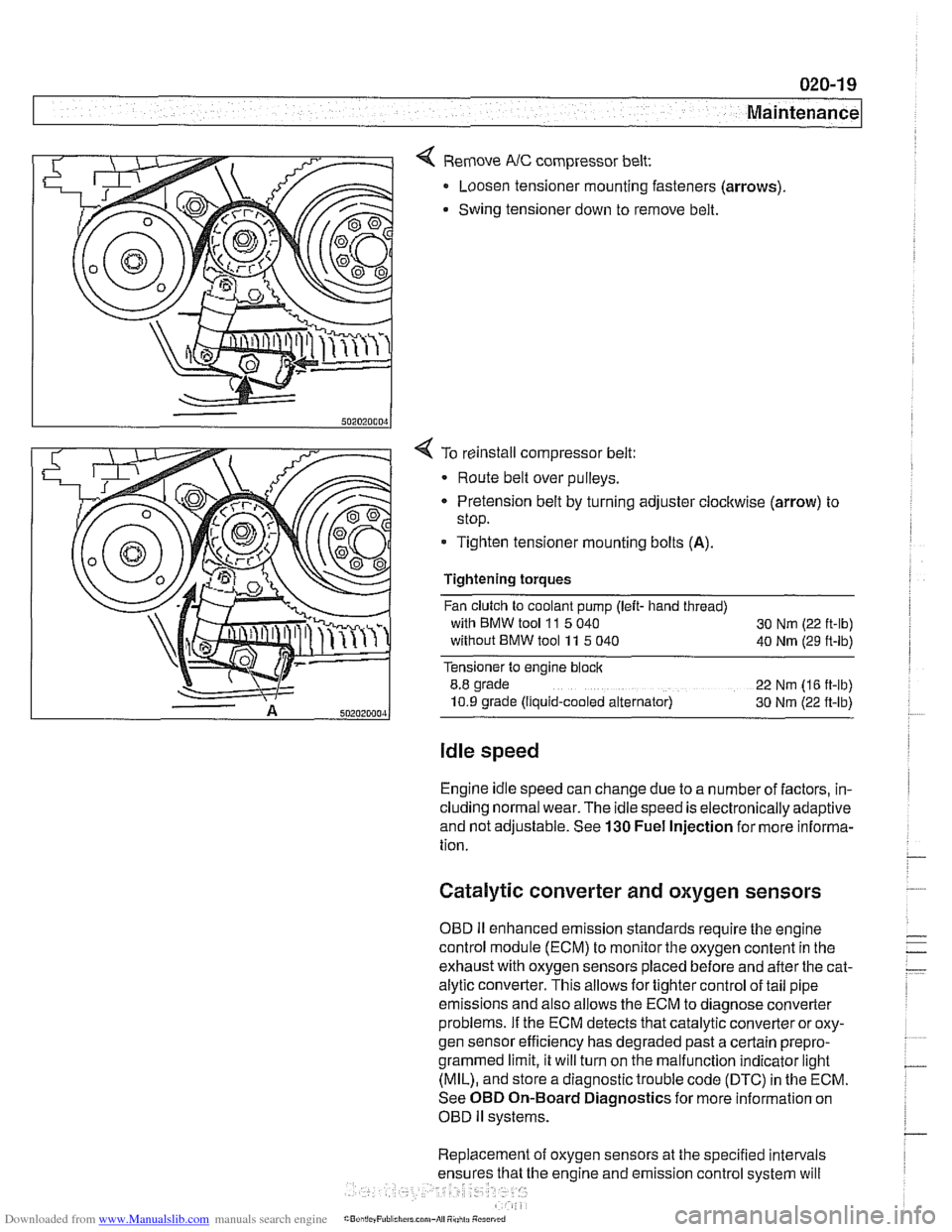

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 52 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

continue to operate as designed. Extending the replacement

interval may void the emission control warranty coverage.

See

180 Exhaust System for information on replacing the

oxygen sensors.

Tightening torque

Oxvoen sensor to exhaust

manifold 50 Nrn (37 ft-lb)

NOTE-

A special soclet for replacing the oxygen sensor is available

from most automotive parts stores. The soclet has

a groove

cut down one side to allow the sensor to be installed without

damaging the wire harness.

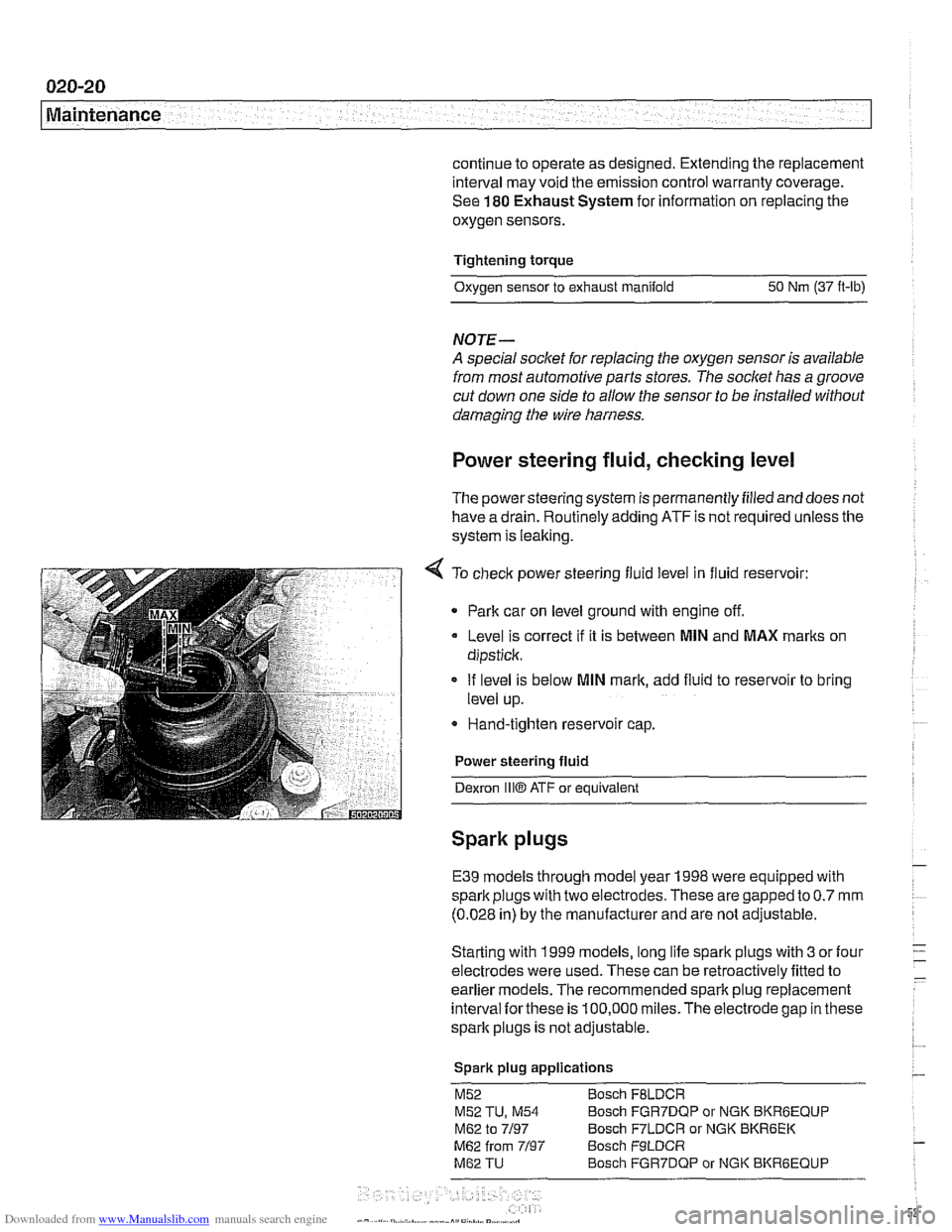

Power steering fluid, checking level

The power steering system is permanently filled and does not

have a drain. Routinely adding ATF is not required unless the

system is leaking.

4 To check power steering fluid level in fluid reservoir:

Park car on level ground with engine off.

Level is correct

if it is between MlN and MAX marks on

dipstick.

If level is below

MlN mark, add fluid to reservoir to bring

level up.

* Hand-tighten reservoir cap.

Power steering fluid

Dexron

1iiO ATF or equivalent

Spark plugs

E39 models through model year 1998 were equipped with

spark plugs with two electrodes. These are gapped to

0.7 mm

(0.028 in) by the manufacturer and are not adjustable.

Starting with 1999 models, long life spark plugs with

3 or four

electrodes were used. These can be retroactively fitted to

earlier

models. The recommended spark plug replacement

interval

forthese is 100,000 miles.The electrode gap in these

spark plugs is not adjustable.

Spark plug applications

M52 Bosch FBLDCR

M52 TU, M54 Bosch FGR7DQP or NGK BKRBEQUP

M62 to 7/97 Bosch F7LDCR or NGK BKR6EK

M62 from 7/97 Bosch F9LDCR

M62 TU Bosch FGR7DQP or NGK BKRGEQUP

Page 53 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-21

Maintenance

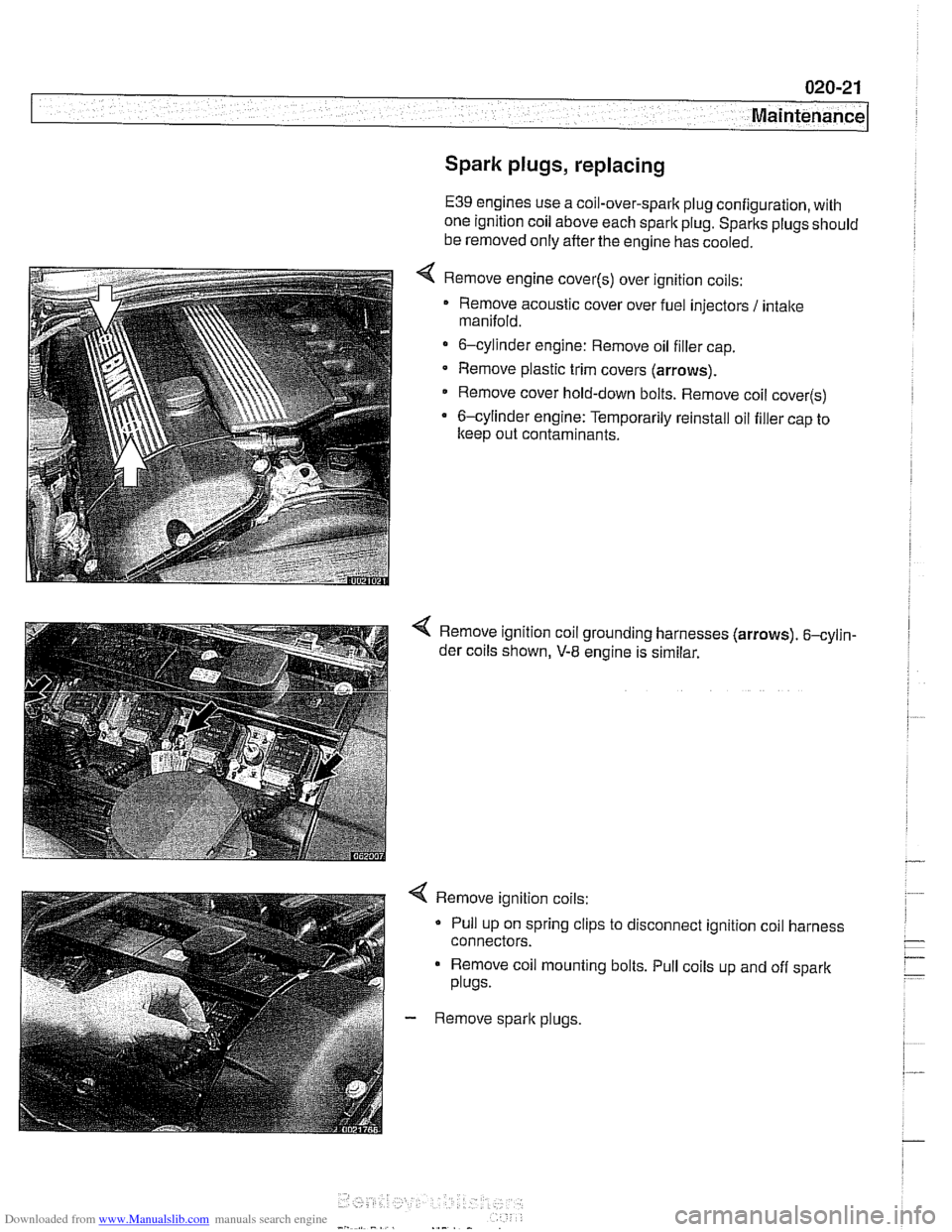

Spark plugs, replacing

E39 engines use a coil-over-spark plug configuration, with

one ignition coil above each spark plug. Sparks plugs should

be removed only after the engine has cooled.

Remove engine

cover(s) over ignition coils:

Remove acoustic cover over fuel injectors

I intake

manifold.

6-cylinder engine: Remove oil filler cap.

Remove plastic trim covers (arrows).

Remove cover hold-down bolts. Remove coil

cover(s)

6-cylinder engine: Temporarily reinstall oil filler cap to

keep out contaminants.

Remove ignition coil grounding harnesses (arrows). 6-cylin-

der coils shown,

V-8 engine is similar.

< Remove ignition coils:

Pull up on spring clips to disconnect ignition coil harness

connectors.

Remove coil mounting bolts. Pull coils up and off spark

plugs.

- Remove spark plugs.

Page 54 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-22 Maintenance

1

- Installation is reverse of removal, bearing in mind the

following:

Lightly lubricate new

spark plug threads with

copper-based anti-seize compound.

Thread plugs into cylinder head by hand to prevent

cross-threading.

. Be sure to reinstall and tighten coil grounds.

Tightening torque Spark plug

to cylinder head 25 Nm (18 It-lb)

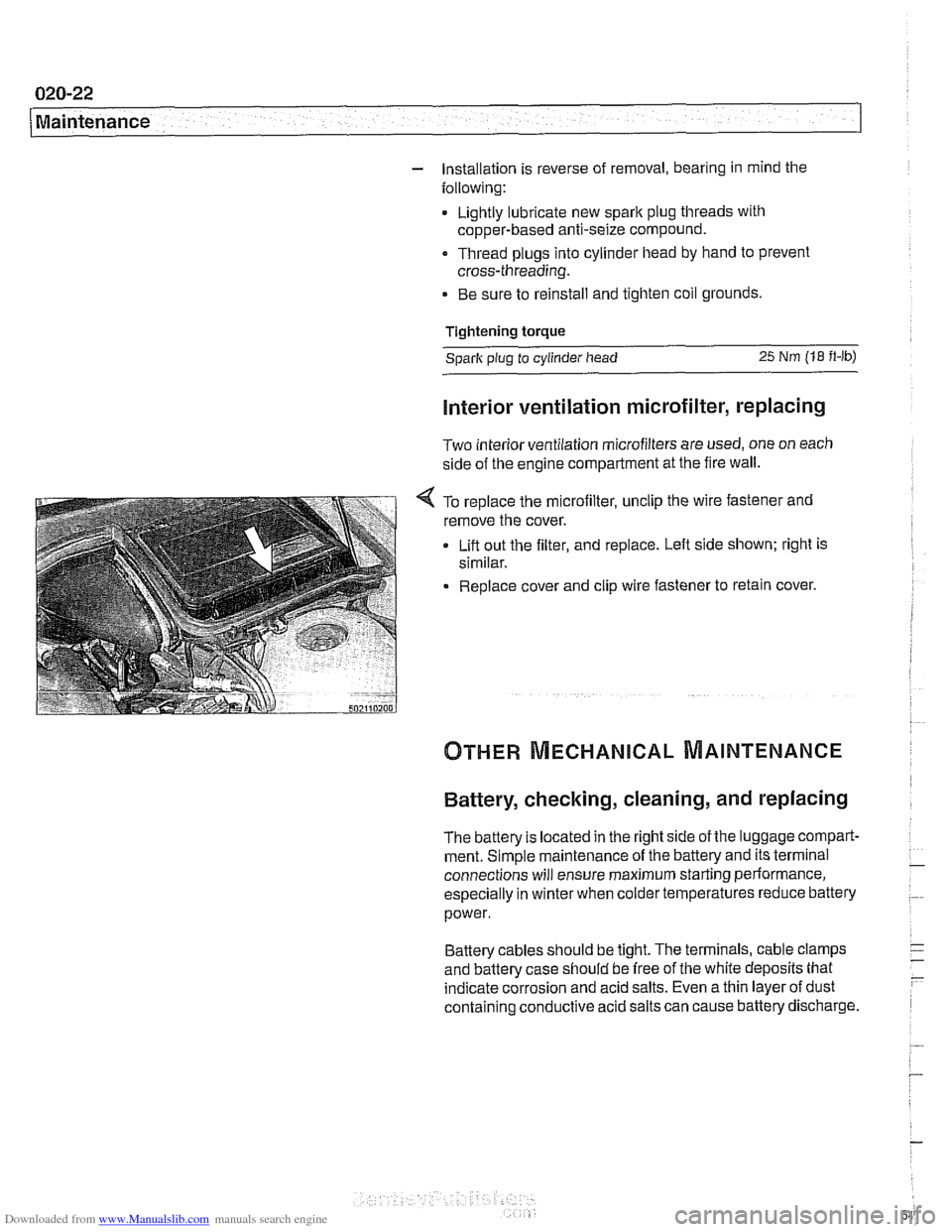

Interior ventilation microfilter, replacing

Two interior ventilation microfilters are used, one on each

side of the engine compartment at the fire wall.

< To replace the microfilter, unclip the wire fastener and

remove the cover.

Lift out the filter, and replace. Left side shown; right is

similar.

Replace cover and clip wire fastener to retain cover.

Battery, checking, cleaning, and replacing

The battery Is located in the right side of the luggage compart-

ment. Simple maintenance of the battery and its terminal

connections will ensure maximum starting periormance,

especially in winter when colder temperatures reduce battery

power.

Battery cables should be tight. The terminals, cable clamps

and battery case should be free of the white deposits that

indicate corrosion and acid salts. Even a thin layer of dust

containing conductive acid salts can cause battery discharge.

Page 55 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

- To remove battery corrosion:

Disconnect battery cables. Disconnect negative (-)cable

first.

* Remove battery from trunk

Clean terminal posts and cable clamps with a wire brush.

Clean main chassis ground terminal next to battery.

Corrosion can be washed away with a

baking soda and

water solution that will neutralize acid.

Reinstall battery and reconnect cable clamps, positive

(+)

cable first.

Lightly coat outside of terminals, hold down screws, and

clamps with petroleum jelly, grease, or a commercial

battery terminal corrosion inhibitor.

WARNING

-

Battery acid is extremely dangerous. Take care to keep it

from contacting eyes, skin, or clothing. Wear eye protection.

Extinguish all

smolihg materials and do not work near any

oaen flames.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

NOTE-

The original equipment battery in E39 models is mainte-

nance free. The original electrolyte will normally last the

entire service life of the battery under moderate climate con-

ditions.

Battery electrolyte should be maintained at the correct level

just above the battery plates and theirseparators. The correct

level is approximately

5 mm ('14 in.) above the top of battery

plates or to the top of the indicator

marks (if applicable). The

battery plates and the indicator marks can be seen once the

fillercaps are removed.

if theelectrolyte level is low, replenish

it by adding distilled water only.

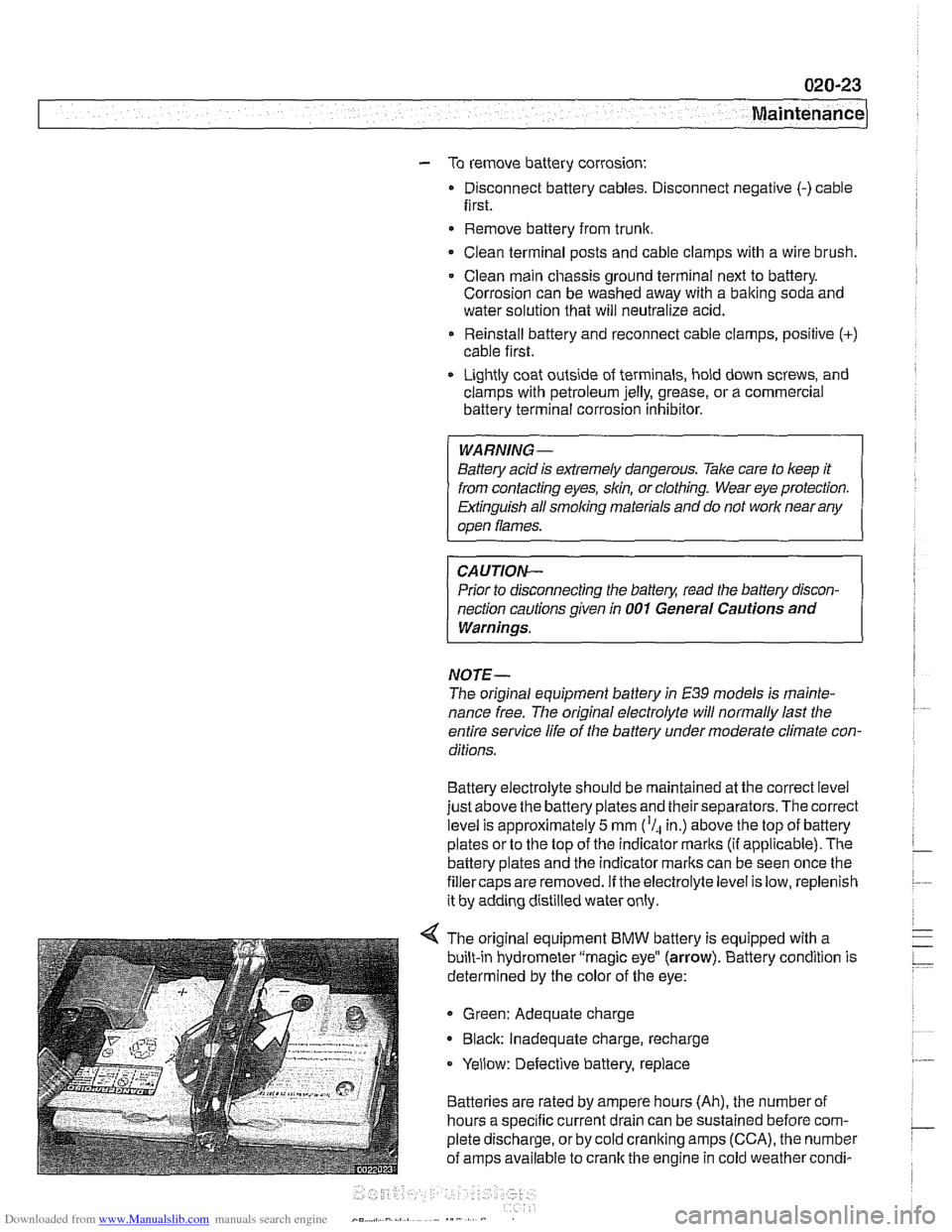

4 The original equipment BMW battery is equipped with a

built-in hydrometer "magic eye"

(arrow). Battery condition is

determined by the color of the eye:

Green: Adequate charge

* Black: Inadequate charge, recharge

Yellow: Defective battery, replace

Batteries are rated by ampere hours (Ah), the number of

hours a specific current drain can be sustained before com-

plete discharge, or by cold cranking amps (CCA), the number

of amps available to crank the engine in cold weather

condi-

Page 56 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-24

Maintenance

tions. In general, replacement batteries should always be

rated equal or higher than the original battery.

The battery is held in place by a single hand screw and plate.

A secure battery hold-down is important in order to prevent

vibrations and road shoclt from damaging the battery.

CAUTION-

Prior to disconnecting the baitem read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

NOTE-

Always disconnect the negative (-) cable first, and connect

it last. While changing the battery, clean away any corro-

sion in or around the battery tray

More battery and charging system information is in 121

Battery, Alternator, Starter.

Brake fluid, replacing

Brake fluid absorbs moisture easily, and moisture in the fluid

affects bralte performance and reliability. This is why

BMW

strictly recommends replacing the bralte fluid every two

years. When replacing or adding bralte fluid, use only new

fluid from previously unopened containers. Do not use brake

fluid that has been bled from the system, even

if it is brand

new. Use only DOT

4 brake fluid.

NOTE-

See 340 Brakes for brake fluid flushing procedures.

Brake pad 1 rotor wear, checking

Disc brakes are fitted at all four wheels. Although the brakes

are equipped with a brake pad warning system, the system

only monitors one wheel per axle. Pad thickness should be

checked whenever wheels are off or brake

worlt is being

done.

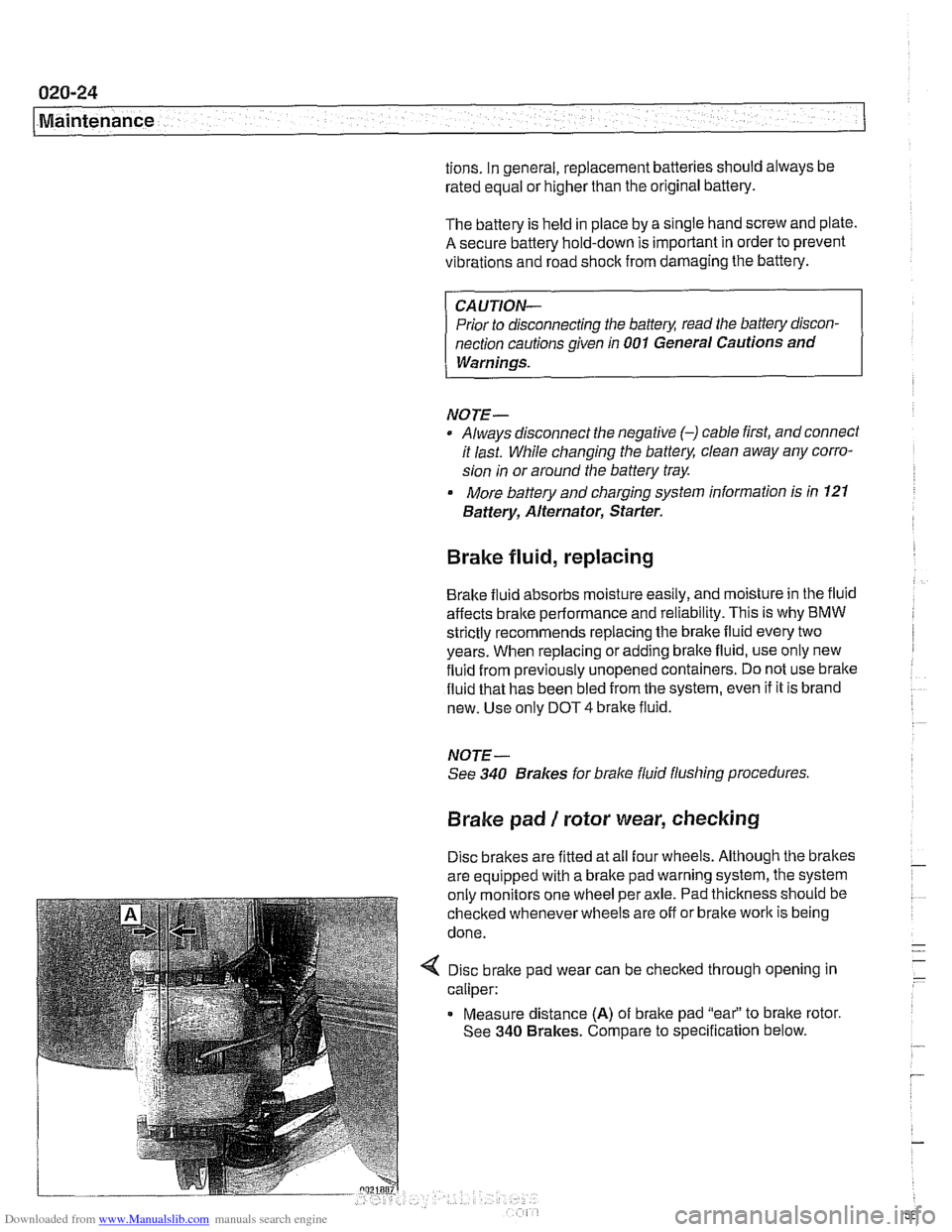

4 Disc brake pad wear can be checked through opening in

caliper:

Measure distance

(A) of brake pad "eai' to bralte rotor.

See

340 Brakes. Compare to specification below.

Page 57 of 1002

Downloaded from www.Manualslib.com manuals search engine

7 Maintenance

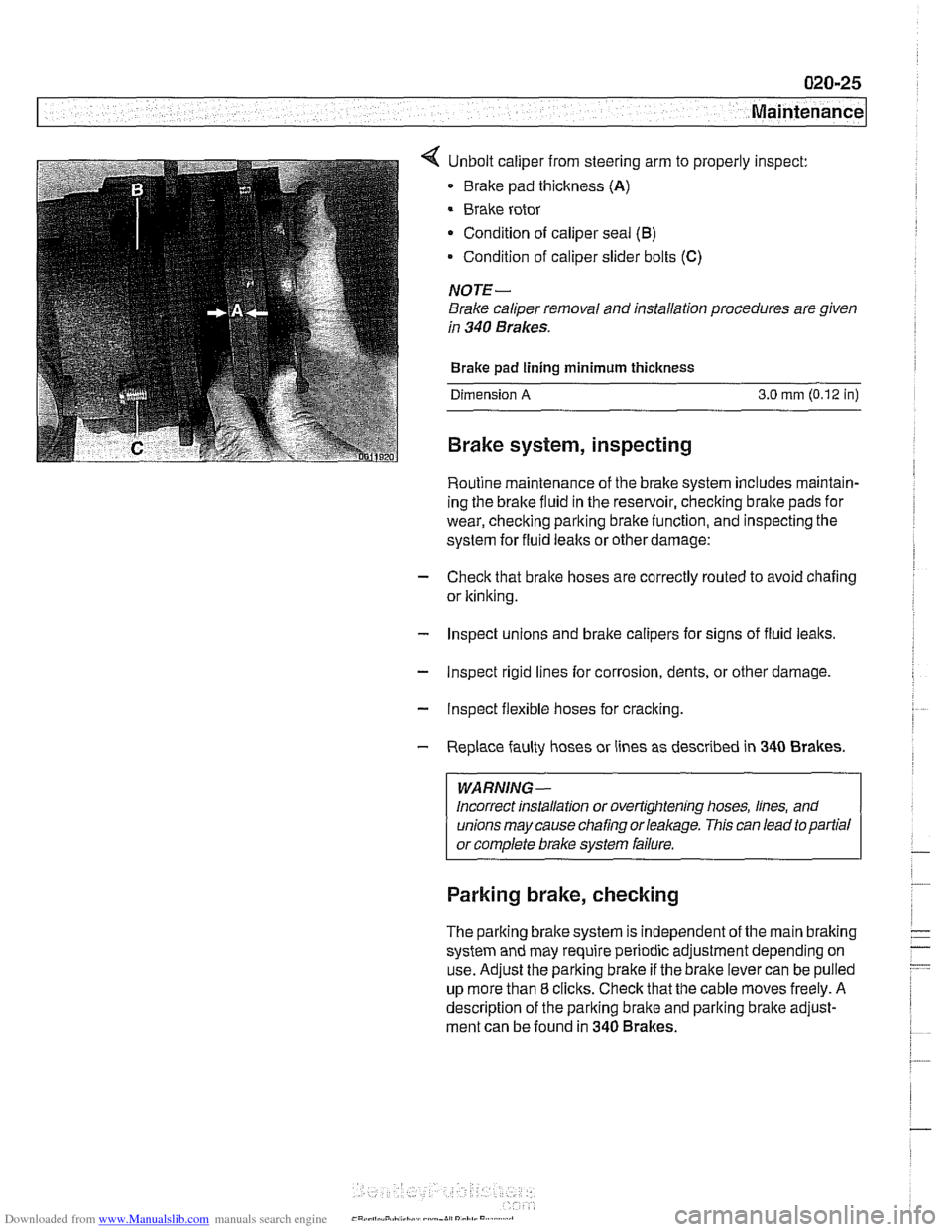

< Unbolt caliper from steering arm to properly inspect:

Brake pad thickness

(A)

Brake rotor

Condition of caliper seal

(B)

Condition of caliper slider bolts (C)

NOTE-

Brake caliper removal and installation procedures are given

in

340 Brakes.

Brake pad lining minimum thickness

Dimension

A 3.0 mm (0.12 in)

Brake system, inspecting

Routine maintenance of the brake system includes maintain-

ing the brake fluid in the reservoir,

checking bralte pads for

wear, checking parking brake function, and inspecting the

system for fluid lealts or other damage:

- Check that bralte hoses are correctly routed to avoid chafing

or

Itinking.

- lnspect unions and brake calipers for signs of fluid leaks.

- lnspect rigid lines for corrosion, dents, or other damage.

- Inspect flexible hoses for cracking

- Replace faulty hoses or lines as described in 340 Brakes.

WARNING-

Incorrect installation or overtightening hoses, lines, and

unions may cause chafing

orlealage. This can lead to partial

Parking brake, checking

The parking brake system is independent of the main braking

system and may require periodic adjustment depending on

use. Adjust the parking brake if the brake lever can be pulled

up more than

8 clicks. Check that the cable moves freely. A

description of the parking brake and

parlting bralte adjust-

ment can be found in

340 Brakes.

Page 58 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-26

Maintenance

NOTE-

The parking brake may lose some of its effectiveness if it is

not used frequently This is due to corrosion build-up on the

parking brake drum. To remove corrosion, apply the parking

brake just until it begins to grip, then pull the lever up one

more stop (click). Drive the car approximately 400 meters

(1,300

ft.) and release the brake. To recheck the adjustment

of the parking brake see

340 Brakes.

Clutch fluid, checking

In cars equipped with manual transmission and clutch, the hy-

draulic clutch and the brake system share the same reservoir

and the same bralte fluid. Clutch fluid level and brake fluid lev-

el are checked at the same time.

NOTE-

* See 340 Brakes for more information.

See

210 Clutch for information on the clutch and the

hydraulic clutch operating system.

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed.

BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized

BM\N dealer parts depart-

ment. For additional information on this lubricant and any

other lubricants that may be compatible, contact an

authorized

BMW dealer service department.

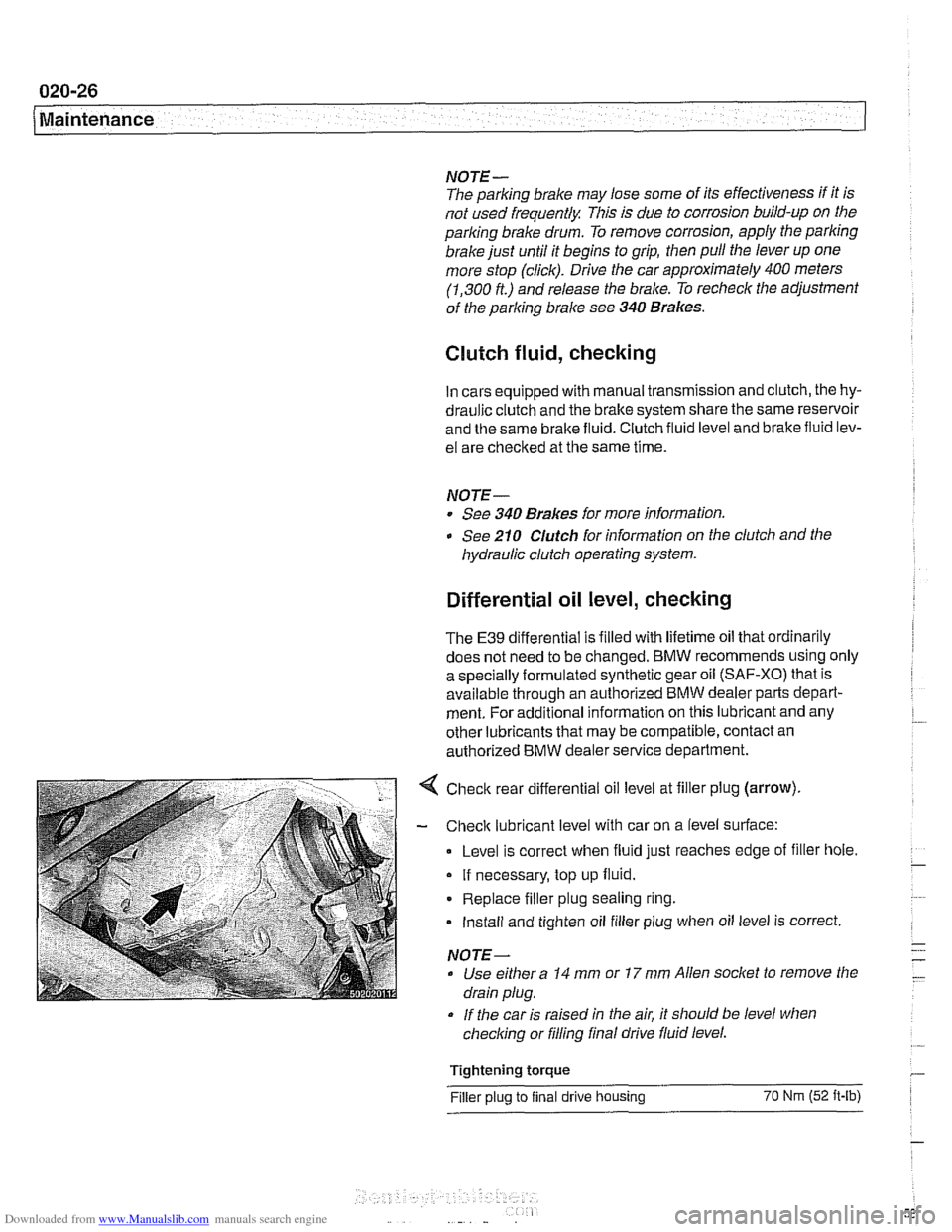

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If the car is raised in the air, it should be level when

checking or filling final drive fluid level.

Tightening torque

Filler plug to final drive housing 70 Nrn (52 it-lb)

Page 59 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-. -

Maintenance

Drive axle joint

(CV joint) boots, inspecting

CVjoint protective boots must be closely inspected forcracks

and any other damage that will allow contaminants to get into

the joint.

If the rubber boots fail, the water and dirt that enter

the joint will quickly damage it.

NOTE-

Replacement of the CVjoint boots and inspection of the

joints are described

in 331 Final Drive.

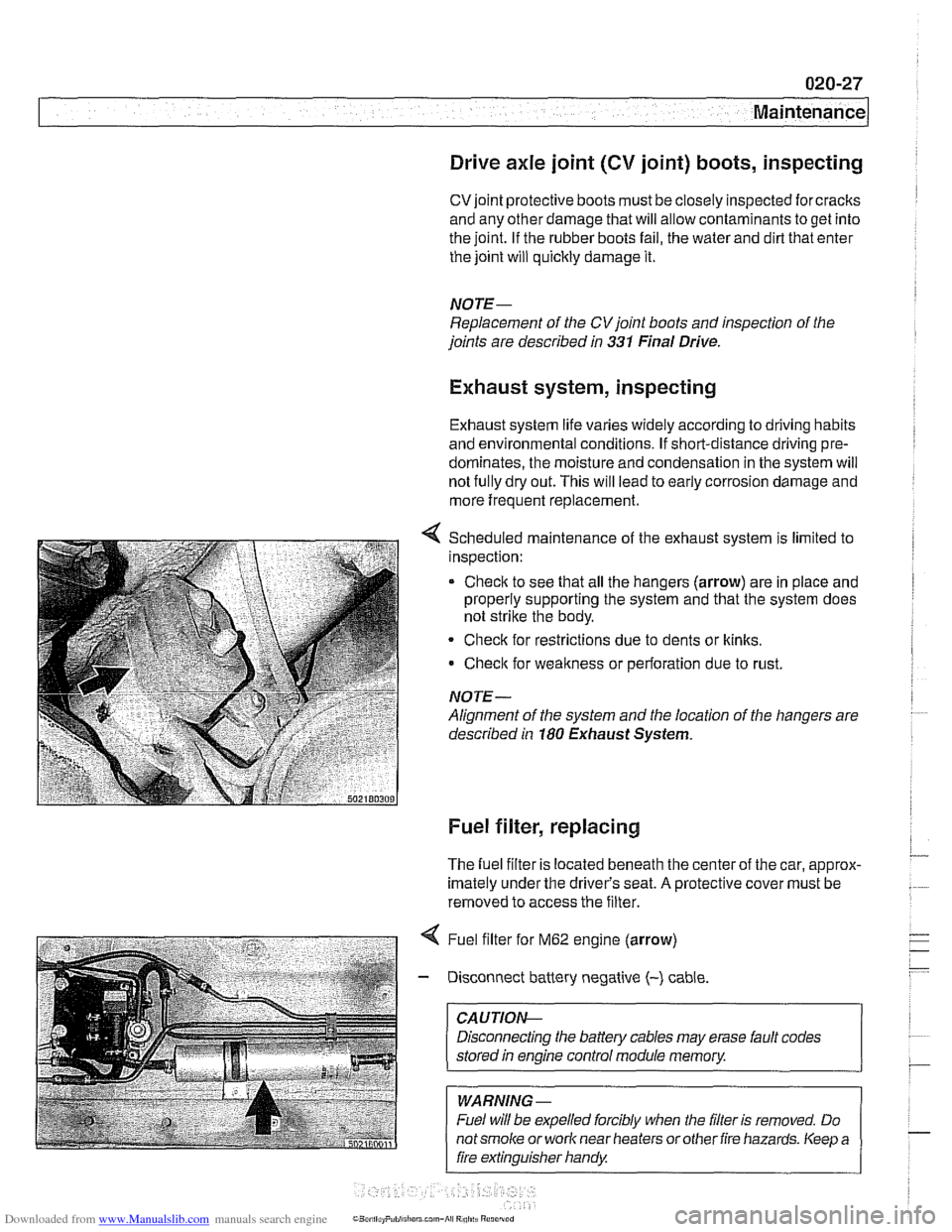

Exhaust system, inspecting

Exhaust system life varies widely according to driving habits

and environmental conditions. If short-distance driving pre-

dominates, the moisture and condensation in the system will

not fully dry out. This will lead to early corrosion damage and

more frequent replacement.

Scheduled maintenance of the exhaust system is limited to

inspection:

* Check to see that all the hangers (arrow) are in place and

properly supporting the system and that the system does

not strike the body.

Check for restrictions due to dents or

kinlts,

Check for weakness or perforation due to rust.

NOTE-

Alignment of the system and the location of the hangers are

described in

180 Exhaust System.

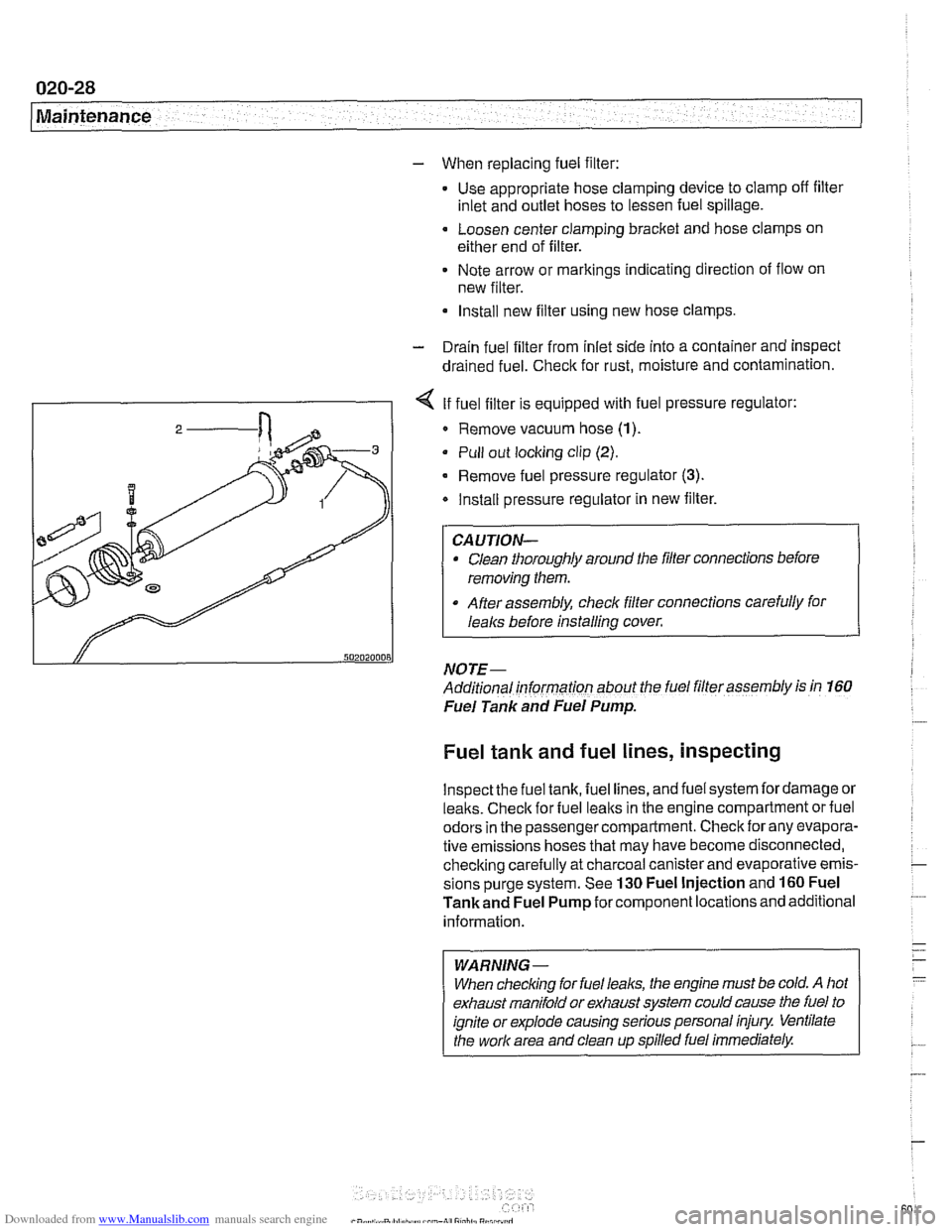

Fuel filter, replacing

The fuel filter is located beneath the center of the car, approx-

imately under the driver's seat.

A protective cover must be

removed to access the filter.

4 Fuel filter for M62 engine (arrow)

- Disconnect battery negative (-) cable

CAUTIOI\C

Disconnecting the battery cables may erase fault codes

stored

in engine control module memory.

WARNING -

Fuel will be expelled forcibly when the filter is removed. Do

notsmoke or work near heaters orother fire hazards. Keep a

fire extinguisher handy

Page 60 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-28

1 Maintenance

- When replacing fuel filter:

Use appropriate hose clamping device to clamp off filter

inlet and outlet hoses to lessen fuel spillage.

Loosen center clamping bracket and hose clamps on

either end of filter.

Note arrow or markings indicating direction of flow on

new filter.

Install new filter using new hose clamps

- Drain fuel filter from inlet side into a container and inspect

drained fuel.

Checlc for rust, moisture and contamination.

I - I < If fuel filter is equipped with fuel pressure regulator:

I 2 / Remove vacuum hose (1)

Pull out locking clip (2).

- Remove fuel pressure regulator (3).

Install pressure regulator in new filter.

Clean thoroughly around the filler connections before

removing them.

After assembly, check filter connections carefully for

I

I lealcs before installing cover.

NOTE- ~-

Additional informarion about the fuel filler assembly is in 160

Fuel Tank and Fuel Pump.

Fuel tank and fuel lines, inspecting

lnspectthe fuel tank, fuel lines, and fuel system fordamage or

lealts. Checlc for fuel lealts in the engine compartment or fuel

odors in the passenger compartment. Check for any evapora-

tive emissions hoses that may have become disconnected,

checking carefully at charcoal canister and evaporative emis-

sions purge system. See

130 Fuel Injection and 160 Fuel

Tankand Fuel Pump for component locations and additional

information.

WARNING-

When checlcing for fuel leal(s, the engine must be cold. A hot

exhaust manifold or exhaust system could cause the fuel to

ignite or explode causing serious personal injury Ventilate

the work area and clean up spilled fuel immediately.