OBD port BMW 530i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 13 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

0 GENERAL, MAINTENANCE covers general vehicle infor-

mation

(010 General) as well as the recommended mainte-

nance schedules and service procedures to perform BMW

scheduled maintenance

work (020 Maintenance).

The next seven sections

(1 through 7) are repair based and

organized by three digit repair groups. Most major sections

begin with a GENERAL repair group,

e.g. 100 Engine-Gen-

eral. These "00 (double zero) groups contain descriptive the-

ory of operation and system troubleshooting information. The

remainder of the repair groups within a section contain the

service and repair information. The last two sections contain

detailed electrical wiring schematics and OBD

II scan tool and

diagnostic information.

Warnings, cautions and notes

Throughout this manual are many passages with the head-

ings WARNING, CAUTION, or NOTE. These very important

headings have different meanings.

WARNING-

The text under this heading warns of unsafe practices that

are very

likely to cause injury, either by direct threat to the per-

son(~) performing the work

orby increasedrisl( of accident or

mechanical failure while

drivinq.

CAUTION-

A CAUTION calls attention to importantprecautions to be ob-

senfed during the repair work that will help prevent acciden-

tally damaging the car or its parts.

NOTE-

A NOTE contains helpful information, tips that will help in do-

ing a betterjob and completing it more easily.

Please read every WARNING, CAUTION, AND NOTE in

001

General Warnings and Cautions and as they appear in re-

pair procedures. They are very important. Read them before

you begin any maintenance or repair job.

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

Crankshaftspeedsensor

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

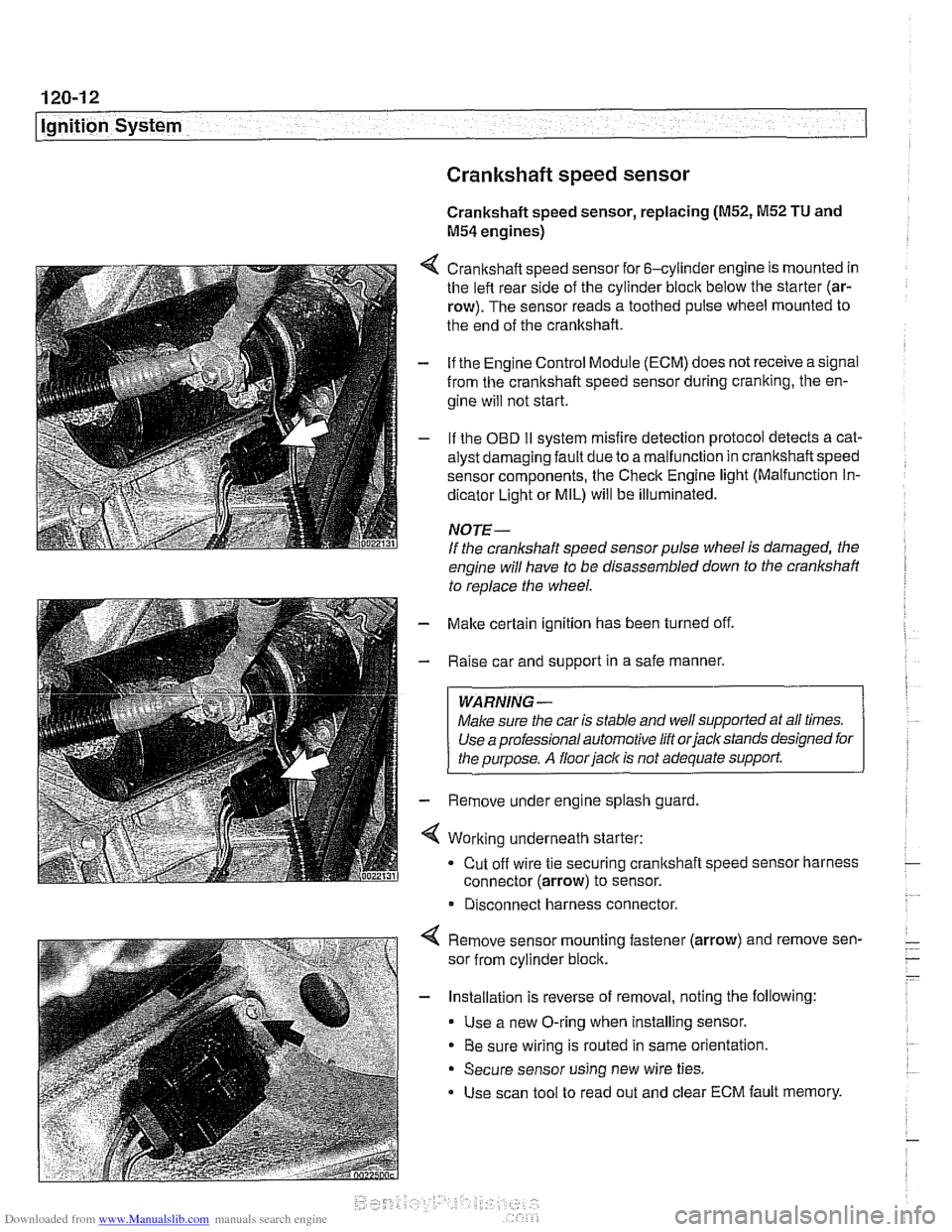

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 495 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-25

Fuel Tank and Fuel pump1

The 312-way valve is also activated briefly if an engine misfire

is detected. This provides full fuel flow through the fuel rail to

determine if the misfire was caused by a lean fuel condition.

The valve is monitored by the ECM forfaults.

- Using BMW or compatible scan tool, read out fault memory.

See

OBD On-Board Diagnostics.

- Turn off ignition.

- Raise car and support safely.

CA UTIOW

Male sure the car is stable and well suppodedat all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Worlting under car beneath driver's seat, remove protective

panel from fuel filter and 312-way valve.

- Clamp off fuel lines at 312-way valve.

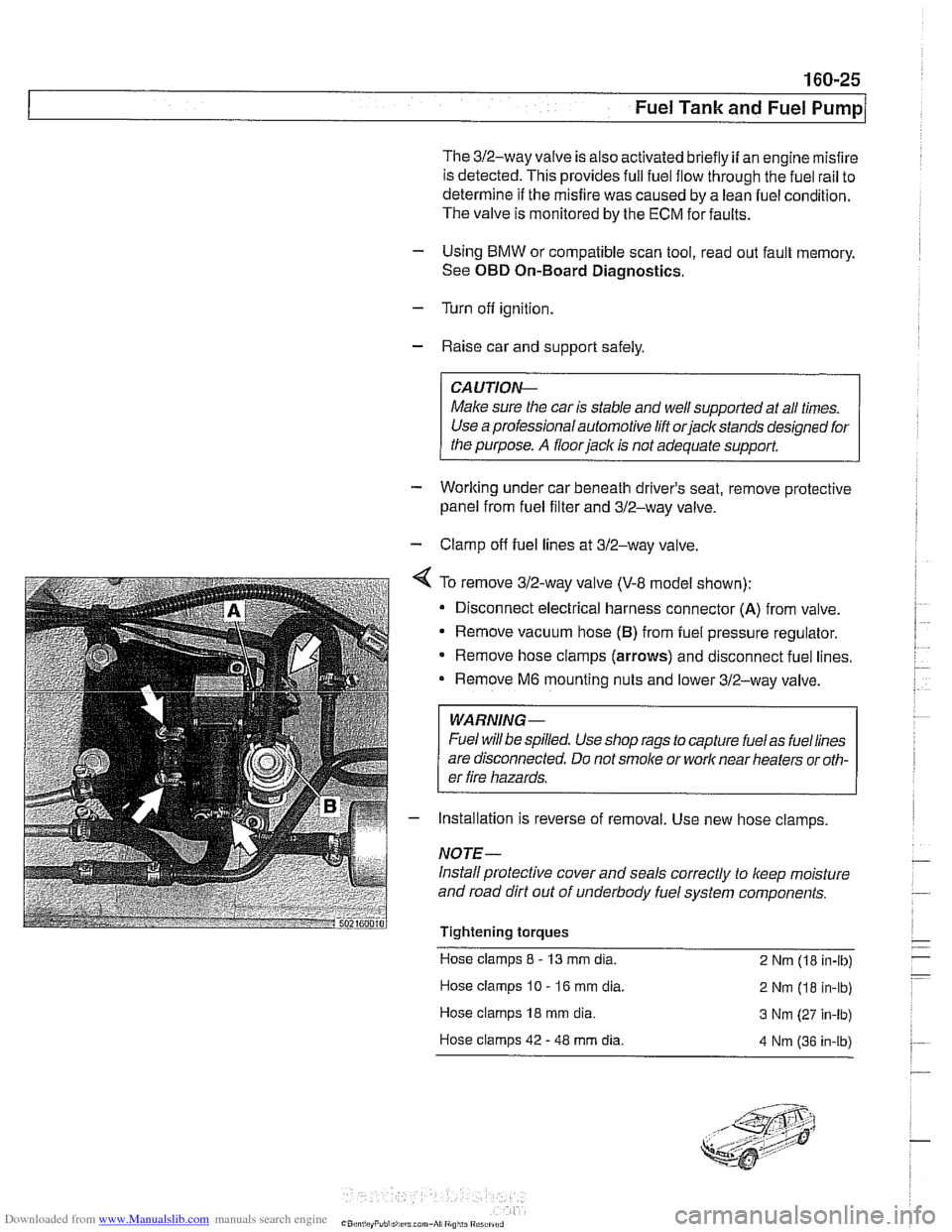

4 To remove 312-way valve (V-8 model shown):

Disconnect electrical harness connector

(A) from valve.

Remove vacuum hose

(B) from fuel pressure regulator.

* Remove hose clamps (arrows) and disconnect fuel lines.

Remove

M6 mounting nuts and lower 312-way valve.

WARNING-

Fuel will be spilled. Use shop rags to capture fuelas fuellines

are disconnected. Do not

smoke or work near heaters or oth-

er fire hazards.

- Installation is reverse of removal. Use new hose clamps

NOTE-

Install protective cover and seals correctly to keep moisture

and road dirt out of underbody fuel system components.

Tightening torques Hose clamps

8 - 13 mm dia.

2 Nm (18 in-lb)

Hose clamps

10 - 16 mm dia.

2 Nm (18 in-lb)

Hose clamps

18 mm dia. 3 Nm (27 in-lb)

Hose clamps 42

- 48 mm dia. 4 Nm 136 in-ib)

Page 506 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 0

I Radiator and Cooling System

Combustion chamber leak test

- If you suspect that combustion chamber pressure is leaking

into the cooling system past the cylinder head gasket, use an

exhaust gas analyzer to test the vapors rising from the cool-

ant at the expansion tank.

CAUTIO&

Use an extension tube above the reservoir neclc to main-

tain distance between the top of the coolant and the gas

analyzer

nozzle. The gas analyzer is easily damaged if it is

allowed to inhale liquid coolant.

* While running engine to checlc for causes of overheat-

ing, observe coolant temperature carefully in order to

avoid engine damage.

Thermostat

If the engine overheats or runs too cool and no other cooling

system tests indicate trouble, the thermostat may be faulty.

In

V-8 models and 6-cvlinder models nroduced afler 911 998

(M52TU or M54 eng'ne), rheelecrricaily heated rhermostal IS

mon tored by [he OBD II diagnostlc software The fault may ic

in the DME software or hardware, or it may lie in the wiring to

the thermostat. See

OED On-Board Diagnostics.

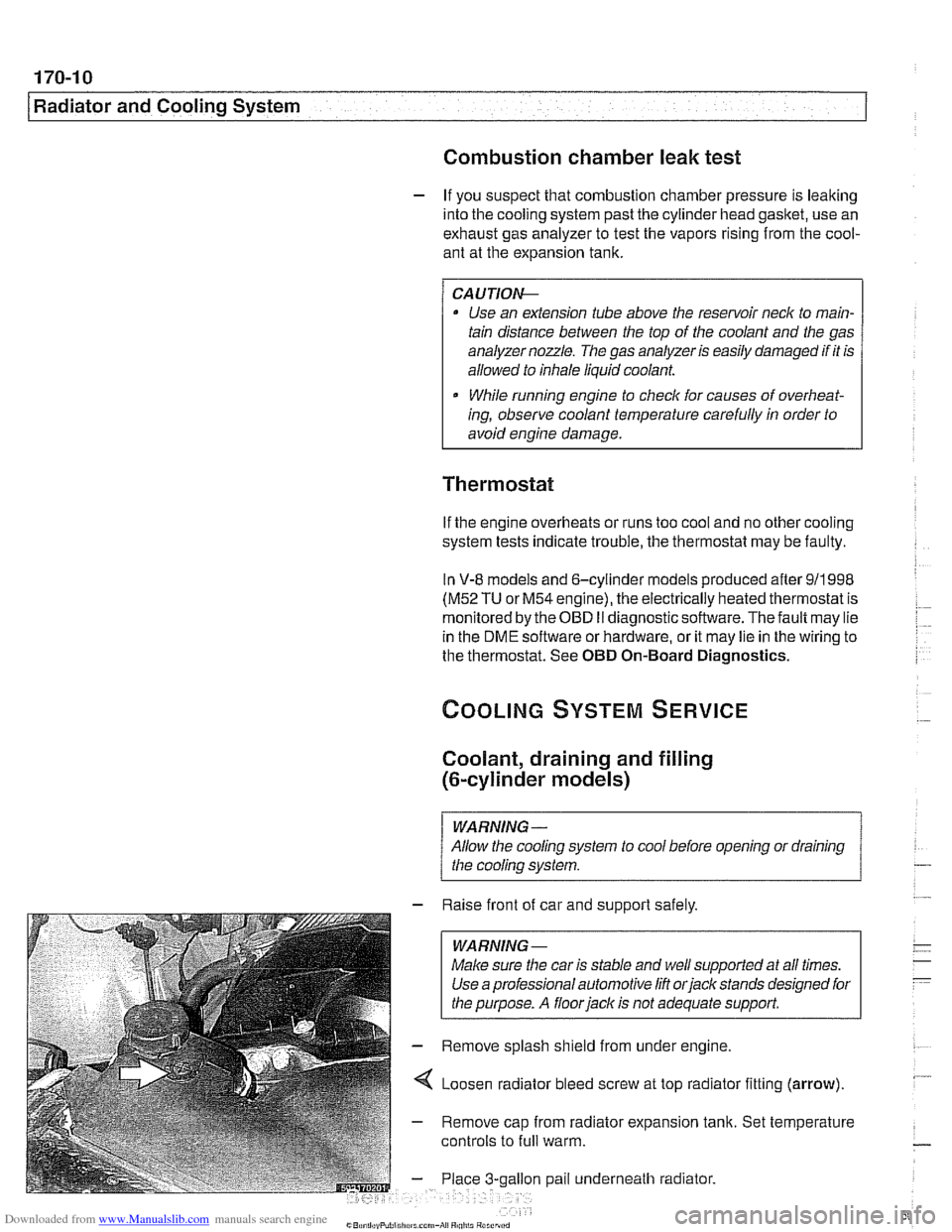

Coolant, draining and filling

(6-cylinder models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floor jack is not adequate support.

- Remove splash shield from under engine.

4 Loosen radiator bleed screw at top radiator fitting (arrow).

- Remove cap from radiator expansion tank. Set temperature

controls to

full warm.

gallon pail underneath radiator.

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.

Page 994 of 1002

Downloaded from www.Manualslib.com manuals search engine

4 INDEX

Door window anti-trap

512-4 convenience openinglclosing 512.4

regulator and motor 512-1 1

service

512-5 switches 512-3

see also Switches

Double

VANOS see VANOS

Drive

axle

CV joint 331-15 CV joint boot 331-15

rernovinglinstalling 331-14

Drive belt

see Maintenance

Driveabiiity troubleshooting

100-4

Driveaway protection

see EWS (eiectronic immobilization)

Driveshaft aligning

260-7

center bearing, replacing 260-12 CV joint, replacing 260-14

itex-disc, replacing 260-1 1

iront centering guide, replacing 260-13

rernovinglinstailing 260-6

lroubleshooting 260-3

U-joint 260-3

DSC

see Braires

DTC (diagnostic trouble code)

OBD-8

DWA

see Anti-theft alarm

ECM (engine control module)

see 130 under appropriate

iuei

injection system

ECT (engine coolant temperature)

sensor see 130 under appropriate

iuei

injection system

EDK adaptation

130-69

MS 43.0 130-35

EHC see Electronic iieigiit control (EHC)

Electric cooling fan

see Cooling system, cooling

fan

see also Cooiing system, eiectric fan

Electrical switches

see Switches

Electrical system abbreviations

600-14 bus System 600-4

component location table 610-3

components

photos

610-36

Sport Wagon 610-81 engine 121-2

troubleshooting 600-15

voltage and polarily 600-5 wire color codes 600-12

wiring diagrams 600-12

Electrical wiring diagrams

ELE-1

Eiectricaliy heated thermostat

(characteristic map)

170-4

Eiectronic height control (EHC)

300-8, 330-44

Eiectronic immobilization

see EWS (electronic immobilization)

Eiectronics box

(E-box)

610-37

Emergencies

010-18

Emergency brake see

BraBes, parking brake Engine

see also Cylinder head and valvetrain

applications

100-2

compression, testing 113-5

cooling see Cooiing system

crankshaft front oil seai

see Crankshaft oil seals

cyiinder leak-down test 113-8

diagnostic testing 113-1

drive belts

see Maintenance

driveability troubleshooting

100-4

engine management systems 100-2

see also Ignition

see also Fuel injection

fuel supply

130-6

ground connections 100-5

see also 61 0 identilying ieatures 100-3

lubrication svstem

see

~ubricetion system

mount

on-board diagnostics

OBD-I

oxygensensor

see Fuel injection

see also Exhaust system

Dreventive maintenance

see Maintenance

removal/installation

Engine control module (ECM)

see 130 under appropriate iuel

injection system

Engine cooiant temperature (ECT)

sensor see 130 under appropriate iuel

injection

system

Engine cooling fan

see Cooiing system, electric fan

Engine hood

41

0-6 raising to service position 410-6

Engine troubleshooting

see Engine, driveability troubleshooting

EVa~oratiVe control svstem

160-3 see also 130 under aDDroDriate iuel

injection system

Evaporator see

NC

Evaporator temperature sensor see

NC