engine cel BMW 530i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 530i, Model: BMW 530i 2001 E39Pages: 1002

Page 4 of 1002

Downloaded from www.Manualslib.com manuals search engine

Selected Boolcs and Repair Information from Bentley Publishers

MINI Cooper

MINI Cooper Service Manual: 2002-2004 Bc,illc!! Pirl~lisl!~~ ISBN 0-8376-1068-0 AlexZanardi - My Swectest Victory rllex Zmmrdi itjill! Ginrz11,cn Gns~x~ri,,i ISBN (1-8376-1249-7

BMW 3 Series IE36) Scrvire Manual: 1992-1998,318ilisliC. 323is/iC, 3?5i/is/iC, 328ilisliC, M3 Be~iili.!~ Pirl?lisliers ISBN 0-8376-0326-9

BMW

5 Series Scrvicc Manual: 1997-2002 525i, 528i. 530i. 540i, Sedan, Sport Wagon Bcrrlluy P~rlilishens ISBN 0-8376-0317-X

Porsclze Tl~c Unfair Advantage hlirrk Do,~ult,re ISBN 0-8376-0073-Iilrcj; Porsche: Excellcncc Was Expected I

Porschc 911 Enthusiast's CompanionT3' Aiirinri Slr~,tzlli~~r ISBN 0-8376-0293-9

BMW 6 Scries Enthusiasl's CompanionTh1 Jc~.li'iil!/ liV0l10li ISBN 0-8376-0193-2 Driving Tlw Skip Bizl.bul- Riicing Sclaiol ISBN 0-8376-0227-0

BMW 7 Series Servicc Manual:1988-1994, 735i,735iL, 74%. 740iL. 750iL Beritlc!/ I'irblislrens ISBN 0-8376-0328-5

A French I

Bosch 1-landbook for Automotive Elcctrics and Elcchonics Rillrcr I Bwcli, GrjilrH ISBN 0-8376-1050-8

Bosch Handbook for Diesel-Engine Managcmcnt Ril1iei.t Bosdl, ClrrbH ISBN 0-8376-1051-6

Bosch Handbook for

Gasolinc-Engine Management Robcrf Bosclr, G~ribH ISBN 0-8376-1052-4

'7

Battle for lhe Bcelle I

Jells, Golf, GTI Scrvicc Manual: 1999-2005 1.8L lurbo, 1.9LTDI diesel, PD dicscl, 2.0L ga5aline. 2.81 VRG B~.!iIlcy Pt,blislicrs ISBN 0-8376-125-9

New Bcctle ServiceManual:1998-20021.8L turbo, 1.91 TDI diesel, 2.0L gasoline Bailicy P~irirlishers ISBN 0-8376-0376-5

New Bcctle 1998-2005, New Beetle Convcrtible2003-2005 Official Factory

Rcpair Manual an CD-ROM

I~olkiatgurr ~JAriicricn ISBN 9784-8376-1265-2

Boscll Fuel Injection and Enginc Management Clml-Its 0. Pmbsi, SAE ISBN 0-8376-0300-5 Clzevrolet

Corvctlc Illustralcd Encyclopedia Torn Beifurli ISBN 0-8376-0928-3

Racc Car Aerodynamics losupli Kntz ISBN 0-8376-014>8

Road &Track Illustrated Automotive

Dictionary

Joltri Dilrkl ISBN 0-8376-11143-6

Scientific Design of Exl~aust and Intake Systems I'lrililr H. S,sillr 0-8376-0309-9 Corvette Fuel

Injection &Electronic Enginc Managcment 1982-2001: Clmrlcs 0. I1rol,sl, SAE ISBN 0-8376-0861-9

I'acrat Ser\,irc hl.>nu.~l: 1998-2004.1.81. lurbu, 2.RL Vb, .l.IIL \\'8, inrludinl: tv.~gc>n and 4blOTION Giiitlc!/ P~iiblislicrs ISBN 0-8376-0360-2 Zora Arkus-Duntov:Thc Lcgcnd Behind corvt.ttc Je1.q Birl-1011 ISBN 0-8376-0858-9

Ci~evmlcl by the Numbers 1965-1969: The

Essential Chcvrolct Paris Refcrcncc illn,i Cnl2i11 ISBN 0-8376-0956-9

Passat. Passat Waron 1998-2005 Official

Gnlf,

GTI, Jctta 1993-1999, Cabrio 199% 2002 Official Factory Repair Manual on

CD-ROM

Volhsiraigu>t oJA,rtrricn ISBN 978-0-8376-1263-8

Jetta, Golf, GTI: 1993-1999,

Cabtio: 1995- 2002 Scrvicc Manual ll~iillcy I'trblisln.~~~ ISBN 0-8376-0366-8

Alfa Romco All-Alloy Twin Cam

Companion 195G1994 1'nl Bncdulr ISBN 0-8376.0275-0

Alfa Romco Owner's Bibl~'~' 1'1~1 Bmrlul! ISBN 0-8376-0707-8

Ford

Ford Fuel Injection and Electronic Engine

Control: 1988-1993

Clinrlcs 0. Pmirsl, SrlE ISBN 0-8376-03Lll-3 Arldi

Audi A4 Repair Manual: 1996-2001.1.8L lurbo, 2.8L. including Avant and quatlro Buirile!/ Ptrhlislters ISBN 0-8376-0371-.I

EuroVan Official Factory Rcp.,ir Manual:

1992-1999

I/~llhio~sar, ifAii!wicn ISBN 0-8376-0335-8

Tbc Official Ford Mustang 5.0 Technical

Reference & I'crformancc Handbook:

1979-1993

A1 l

1998-2004, Avant 1999- 2004, allroad quallro 2001-2005, 56 Avant 2002-2004, RS6 2003-2004 Official

Factory Rcpair Manual on CD-ROM

Ai!dioJ/in,er.ini ISBN 978-0-8376-1257-7

Jccp CJ Rubuildcr's Manual: 1972-1986 MOSI~S Lltii~l ISBN 0-8376-0151-7

Jccp Owner's Biblen', Third Edition Moscs Lzrdel ISBN 0-8376-1117-2 Automotive Reference

Bcnlluy Publishers has published iewicc manualsand autornohilcboolissinrc 1950. Plcasc write to us at 1734 Mniincliusctts Ave..Cnmbridge, kIA02138,i~isit ourivcb sitc, ol-c,lll 1-800-12345'15 ini a free copy ofnurcolaiog.

BMW

BMW 23 Sarvicc Manual: 1996-2002. including 23 Roadster, 23 Coupe, M

Roadster, M Coupe

Be~illq Pi,blislicis ISBN 0-8376-1250-0

BMW 3 Scrics (Ed61 Scrvicc Manual:

Mcrcedes-Bcnz Technical C~mpanion'~~' Bu,rllu!! P,rlilislio.i ISBN 11-8376-1033-8

Mcrccdcs-Bcnz E-Class (W124) O~vner's BibleT>' : 1986-1995 llu~tilc!~ Pi~lriisiieis ISBN 11-8376-0230-(1

Urlilii-!~ P~~Blisi~~rs ISBN 11-8376-11772

Page 7 of 1002

Downloaded from www.Manualslib.com manuals search engine

001 General Warnings and Cautions

PLEASE READ THESE WARNINGS AND CAUTIONS

BEFORE PROCEEDING

WITH MAINTENANCE AND REPAIR WORK.

WARNINGS-

See also CAUTIONS

- Some repairs may be beyond your capability. If you lack the skills, - Catch draining fuel, oil, or brake fluid in suitable containers. Do

tools and equipment, or a suitable workplace for any procedure

not use

foodor beverage containers that might mislead someone

described in this manual, we suggest you leave such repairs to

into

drinking from them. Store flammable fluids away from fire

an authorized BMW dealer service department or other qualified

hazards. Wipe up spills at once, but do not store the oily rags,

shop. which can ignite and burn spontaneously.

. Do not reuse any fasteners that are worn or deformed. Many fas- Always observe good worRshop practices. Wear qoqqles when

teners are designed to be used only once and become

unreliable you operate machine tools or work with battery acid:kloves or

and mav fail when used a second time. This includes, but is not other

~rotective clothino should be worn whenever the iob re-

limited io, nuts, bolts, washers, self-locking nuts or bolts, clrclips yires' working with harmful substances.

and cotter pins. Always replace these fasteners with new parts.

Greases, lubricants and other automotive chemicals contain toxic

. Never work under a lifted car unless it is solidly supported on

substances, many of which are absorbed directly through the

stands

desiqned for the purpose. Do not supeort a car on cinder

skin. Read the manufacturer's instructions and warninos careful-

blochs, hollow tiles orotherbrops that may drurnbie undercontin-

uous toad. Never work under a car that is supported solely by a

iack. Never work under the car

while the enqine is runninq. - -

If you aregoing to work underacaron the ground, makesure that

the ground is level. Block the wheels to

keep the car from rolling.

Disconnect the battery negative

(-) terminal to prevent others

from starting the car while you are under it.

- Never run the engine unless the work area is well ventilated. Car-

bon monoxide kills.

Rings, bracelets and other jewelry should be removed so that

they cannot cause electrical shorts, get caught in running ma-

chinery, or be crushed by heavy parts.

- Tie long hair behind your head. Do not wear a necktie, a scarf.

loose clothing, or a necklace when you work near machine tools

or running engines. if your hair, clothing, or jewelry were to get

caught in the machinery, severe injury could result.

DO not attempt to

work on your car if you do not feel well. You in-

crease the

danger of injuryto yourseliand others if you are tired,

uDset or have taken medication or anv other substance that mav

keep you from being fully alert.

Illuminate your work area adequately but safely. Use a portable

iy. Use hand and eye protection. Avoid direct skin conGct.

Disconnect the battery negative (-) terminal whenever you work

on the fuel system

orthe electrical system. Do not smokeorwork

near heaters or other fire hazards. Keep an approved fire extin-

guisher handy.

. Friction materials (such as brake pads or shoes or clutch discs)

contain asbestos fibers or other friction materials. Do not create

dust by grinding, sanding, or by cleaning with compressed air.

Avoid breathing dust. Breathing any

friclion material dust can

lead to serious diseases and may result in death.

Batteries

giveoff explosive hydrogen gas during charging. Keep

sparks, lighted matches and open flame away from the top of the

battery. If hydrogen gas escaping from the cap vents is ignited, it

will ignite gas trapped in the cells and cause the battery to ex-

plode.

Connect and disconnect battery cables, jumper cables or a bat-

tery charger only wilh the ignition switched off. Do not disconnect

the battery while the engine is running.

Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

. . safety lighiforworking lnsideor under the car. Make sure the bulb - Do not allow battery charging vollage to exceed 16.5 volts. If the

is enclosed bv a wire caoe. The hot filament of an accidentallv

batten! beoins ~roducina oas or boilino violentiv, reduce the

broken bulb can ignite spilled

fuel, vapors or oil. , - - - charglng rate. ~oostlng a sutfaled battery at a igh charging rate

can cause an

explosion.

-

Continued on next page

Page 14 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

General

WARNING-

Never run the engine in tile work area unless it is well-ven-

tilated. The exhaust should be vented to the outside. Car-

bon monoxide (CO) in exhaust kills.

Remove all neckties,

scarfs, loose clothing, or jewelry

when working near a running engine or power tools.

Tuck in shirts. Tie long hair and secure it under a cap.

Severe injury can result from these things being

caugiit

in rotating parts.

Remove rings, watches, and bracelets. Aside from the

dangers of moving parts, metallic jewelry conducts

electricity and may cause shorts, sparks, burns, or

damage to the electricalsystem when accidentally con-

tacting the battery or other electrical terminals.

Disconnect the battery negative

(-) cable whenever

working on or near the fuel system or anything that is

electrically powered. Accidental electrical contact may

damage the electrical system or cause a fire.

Fuelis highly flammable. When working around fuel, do

not

smoke or work near heaters or other fire hazards.

Keep an approved fire extinguisher handy.

The fuel system is designed to retain pressure even

when the ignition is off When worlcing with the

fuelsys-

tem, loosen the fuel lines slowly to allow the residual

pressure to dissipate gradually. Take precautions to

avoid spraying fuel.

. Illuminate the worlc area adequately and safely Use a

portable safety light for worlcing inside or under the car.

A fluorescent type

light is best because it gives off less

heat. If using a light with a normal incandescent bulb,

use rough service bulbs to avoid

breakage. The hot fil-

ament of an accidentally broken bulb can ignite spilled

fuel or oil.

Keep sparks, lighted matches, and any open flame

away from the top of the battery. Hydrogen gas

emitted

by the battery is highly flammable. Any nearby source

of ignition may cause the battery to explode.

Never lay

tools or parts in the engine compartment or

on top of the battery. They may

fallinto confinedspaces

and be difficult to retrieve, become caught in belts or

other rotating parts when the engine is started, or

cause electrical shorts and damage to the electrical

system.

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 46 of 1002

Downloaded from www.Manualslib.com manuals search engine

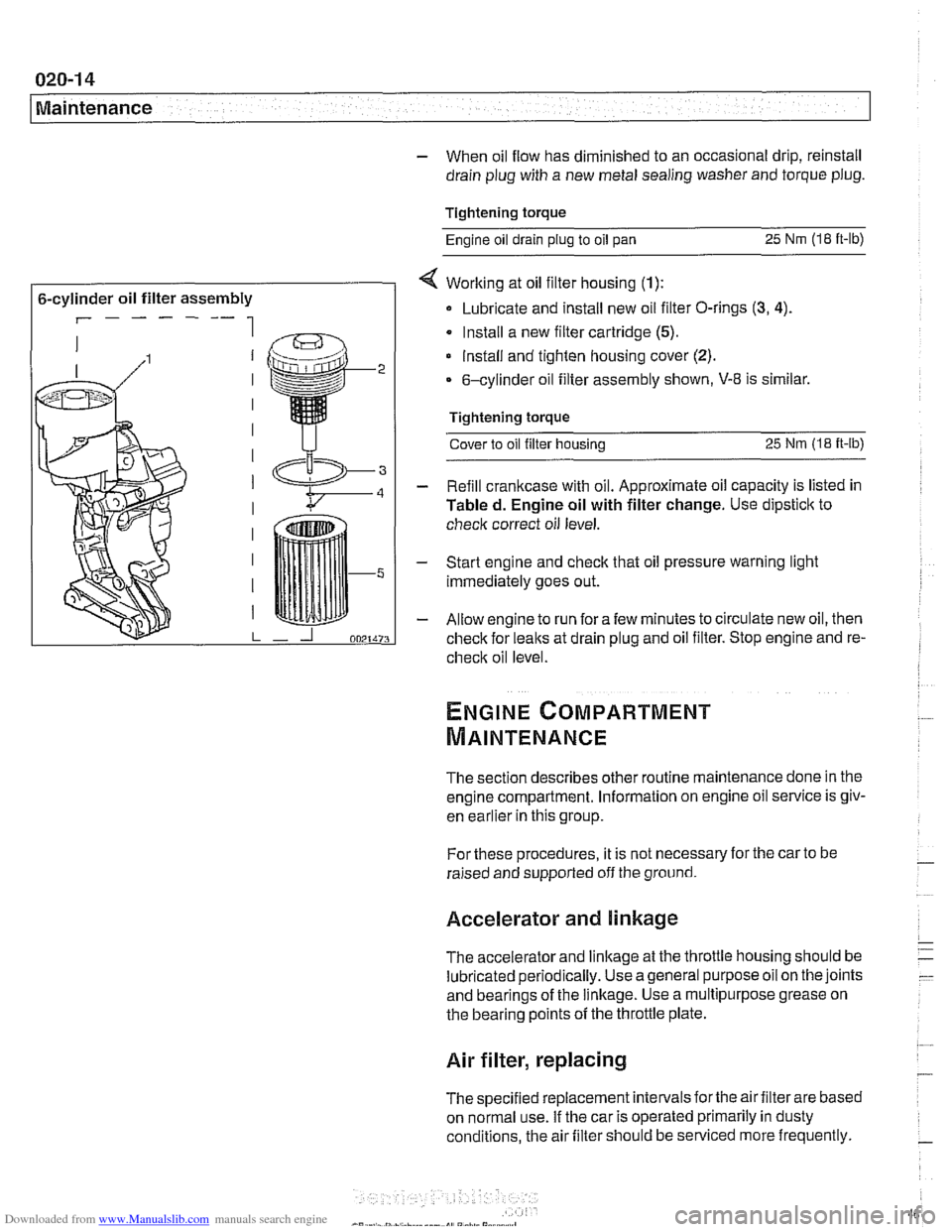

020-1 4

Maintenance

- When oil flow has diminished to an occasional drip, reinstall

drain plug with a new metal sealing washer and torque plug.

Tightening torque Engine oil drain plug to oil pan

25 Nrn (1.8 ft-lb)

6-cylinder oil filter assembly

r------ 1

< Working at oil filter housing (1):

Lubricate and install new oil filter O-rings (3, 4).

Install a new filter cartridge (5).

lnstall and tighten housing cover (2).

6-cylinder oil filter assembly shown, V-8 is similar.

Tightening torque Cover to oil filter housing

25 Nm (1.8 it-lb)

- Refill crankcase with oil. Approximate oil capacity is listed in

Tabled. Engine oil with filter change. Use dipstick to

check correct oil level.

- Start engine and check that oil pressure warning light

immediately goes out.

- Allow engine to run fora few minutes to circulate new oil, then

check for leaks at drain plug and oil filter. Stop engine and re-

check oil level

The section describes other routine maintenance done in the

engine compartment. Information on engine oil service is

giv-

enkar~ier inthis group.

For these procedures, it is not necessary for the car to be

raised and supported off the ground.

Accelerator and linkage

The accelerator and linkage at the throttle housing should be

lubricated periodically. Use ageneral purposeoil on the joints

and bearings of the linkage. Use a multipurpose grease on

the bearing points of the throttle plate.

Air filter, replacing

The specified replacement intervals forthe air filter are based

on normal use. If the car is operated primarily in dusty

conditions, the air filter should be serviced more frequently.

Page 69 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine identifying features

4 The M52 engine (MY97-98 528i) used a single on-off vari-

able intake valve timing system (called VANOS). The cylinder

block is cast iron and the cylinder head is aluminum. The en-

gine management system is Siemens MS 41

.I and features

NGK-type (0-5 volt) oxygen sensors.

NOTE-

VANOS is an acronym based on the German words Variable

Nocltenwellen Steuerung (variable camshaft timing).

4 The M52 TU engine (MY99-00 5281) and the M54 engines

(MY01-02 525il530i) are fitted with double VANOS. The en-

gine

blocits are constructed of aluminum alloy with cast iron

cylinder sleeves.

4 The double VANOS (variable camshaft control) system incor-

porates true variable control of both the

intake and exhaust

camshafts, as compared to the single VANOS system on the

M52 engine

(onloff control of the intaite camshaft only).

The M54 engines use a fully electronic throttle control (drive

by wire). There is no accelerator cable connecting the throttle

pedal to the throttle housing in these cars.

Page 70 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-4

I Engine-General

The M62 90" V8 engine uses four valves per cylinder, double

overhead camshafts and light alloy cylinder head and cylin-

der

bloclc engine construction.

On 1997 and 1998 540i models, Bosch engine management

systems are utilized. Table a lists engine management sys-

tem applications.

4 For the 1999 model year, the M62 TU VANOS engine was in-

troduced to the 540i models. This engine is primarily a carry-

over from the earlier M62 engine, but contains many unique

identifying components and technology:

Variable camshaft timing (VANOS) for the intake valves.

Bosch ME 7.2 engine management system with electronic

throttle control. There is no accelerator cable connecting

the throttle pedal to the throttle housing in these cars.

Compact water-cooled generator (alternator).

E39 vehicles are equipped with sophisticated self-diagnostic

engine management systems. These systems monitor and

store diagnostic fault information. If the malfunction indicator

lamp (MIL) illuminates, the first diagnostic test should be to

connect a dedicated scan tool for BMW automobiles and in-

terrogate the fault memory.

If the malfunction indicator light (MIL) comes on orflashes, it

indicates that an emissions-related fault has occurred and

that fault information is stored in memory within the ECM.

4 The MIL in E39 cars displays one of these warning graphics

in the instrument cluster.

The diagnostic capabilities of these systems have the poten-

tial to save hours of diagnostic time and prevent incorrect

5 placement. See OBD On-Board Diagnostics.

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

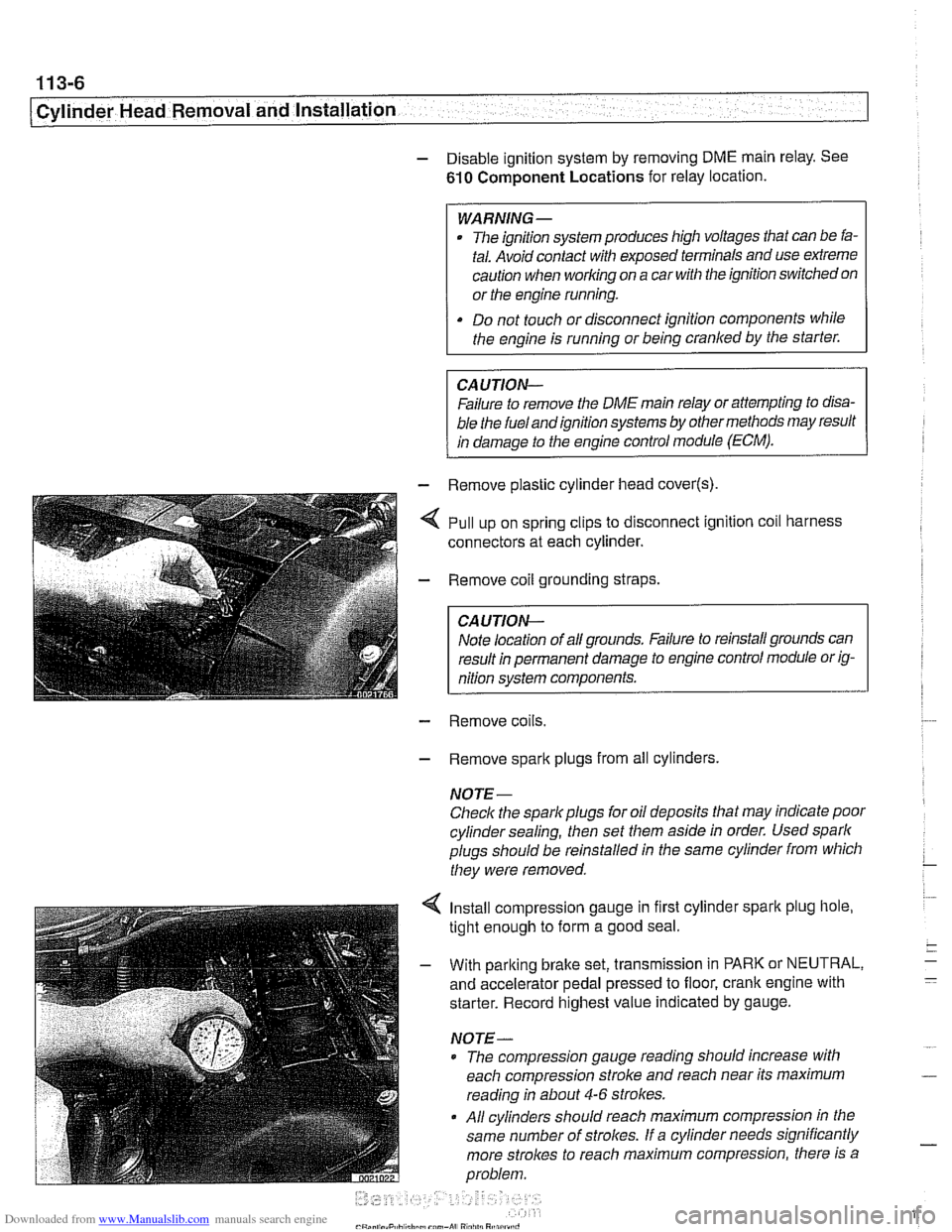

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 115 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Cylinder Head Removal and lnstallation

NOTE-

Be Sure the secondary timing chain tensioner is locked down

and the exhaust

camshaif mounting bolts are loose before

proceeding.

- Install VANOS control unit. See VANOS control unit, install-

ing

(M52 engine) in 117 Camshaft Timing Chain.

CAUTION--

Incorrect installation ofthe VANOS control may result in dam-

age to the engine valvefrain.

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

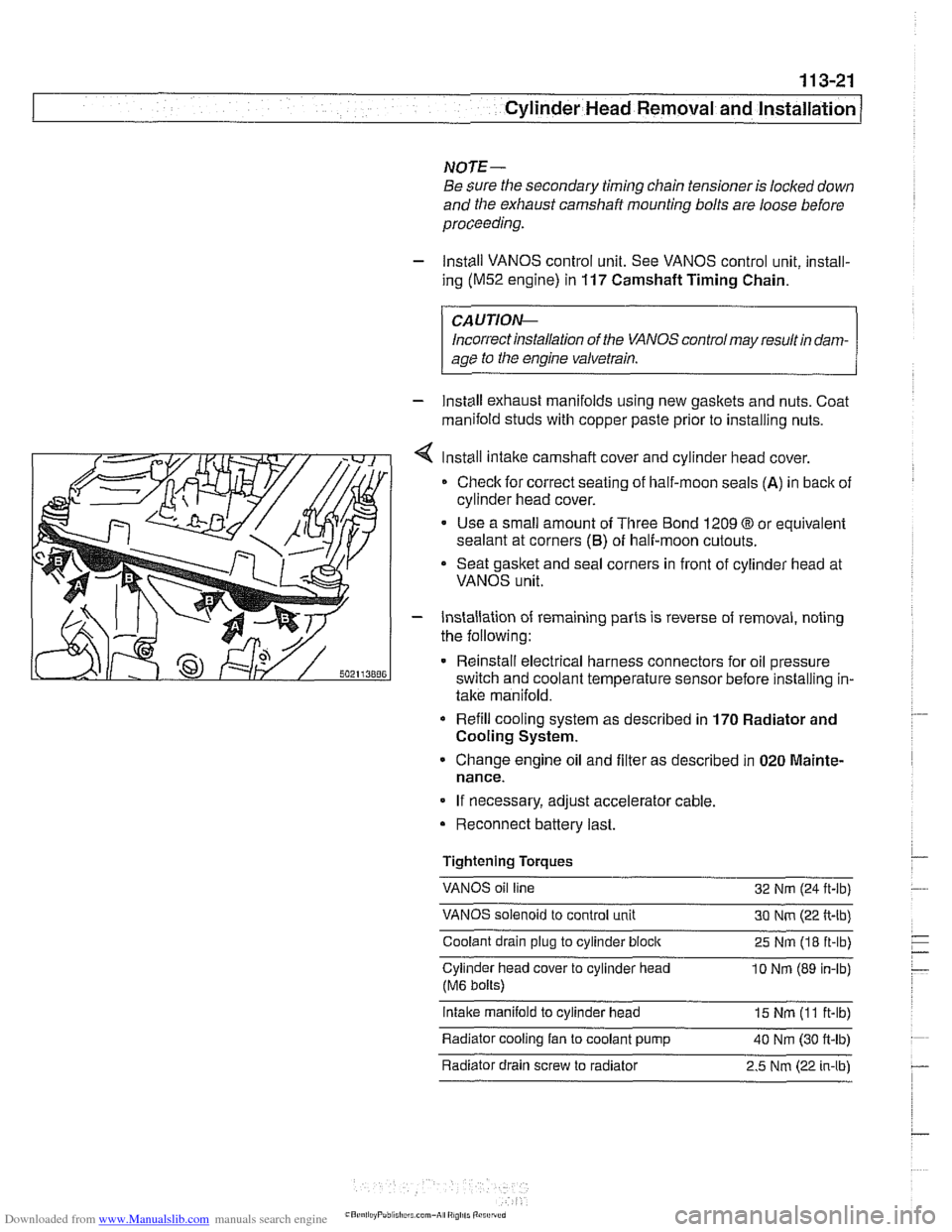

Install intake camshaft cover and cylinder

head cover.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(6) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

- Installation of remaining parts is reverse of removal, noting

the following:

Reinstall electrical harness connectors for oil pressure

switch and coolant temperature sensor before installing in-

take manifold.

Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in 020 Mainte-

nance.

If necessary, adjust accelerator cable.

Reconnect battery last.

Tightening Torques

VANOS oil line

32 Nm (24

ft-lb)

VANOS solenoid to control unit 30 Nm (22 ft-lb)

Coolant drain plug to cylinder

block 25 Nm (18 ft-lb)

Cylinder head cover to cylinder head

10 Nrn (89 in-lb)

(M6 bolts)

intake manifold to cylinder head 15 Nm (I 1 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb) - . .

Radiator drain screw to radiator 2.5 Nm (22 in-lbl

Page 150 of 1002

Downloaded from www.Manualslib.com manuals search engine

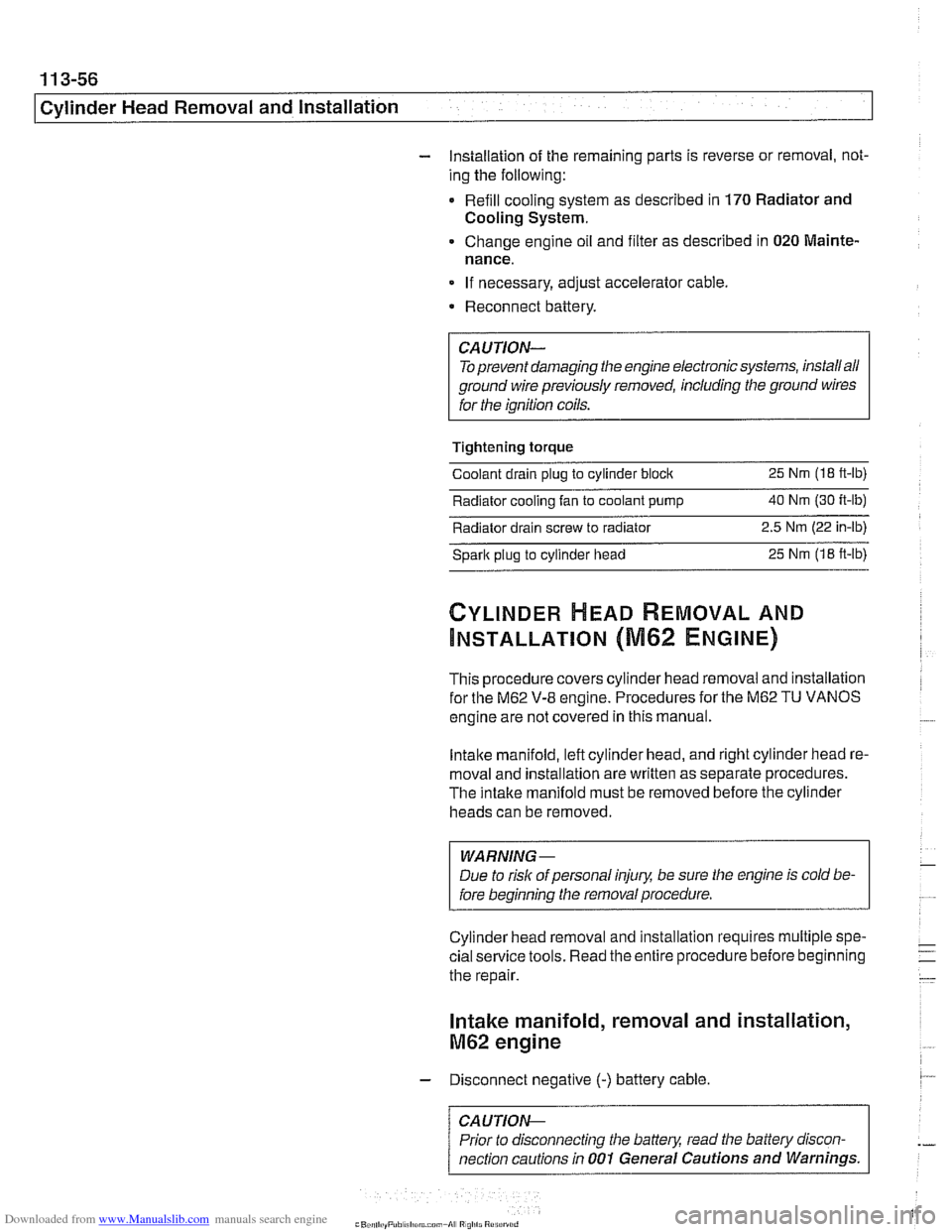

11 3-56

I Cvlinder Head Removal and Installation

- Installation of the remaining parts is reverse or removal, not-

ing the following:

- Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

If necessary, adjust accelerator cable.

a Reconnect battery.

CAUTION- To prevent damaging the engine electronic systems, installall

ground wire previously removed, including the ground wires

for the

ionition coils.

Tightening torque Coolant drain

pluq to cylinder bloclc 25 Nm (1 8 ft-lb)

Radiator cooling fan to coolant pump 40 Nm (30 ft-lb) -

Radiator drain screw to radiator 2.5

Nm (22 in-lb)

spark plug to cylinder head 25

Nm (1 8 ft-lb)

CYLINDER MEAD REMOVAL AND

INSTALLATION (M62 ENGINE)

This procedure covers cylinder head removal and installation

for the

M62 V-8 engine. Procedures forthe M62 TU VANOS

engine are not covered in this manual.

Intake manifold, left cylinder head, and right cylinder head re-

moval and installation are written as separate procedures.

The intake manifold must be removed before the cylinder

heads can be removed.

WARNING

-

Due to risk of personal injuv be sure the engine is cold be-

fore beginning the removal procedure.

Cylinder head removal and installation requires multiple spe-

cial service tools. Read the entire procedure before beginning

the repair.

Intake manifold, removal and installation,

M62 engine

- Disconnect negative (-) battery cable.

CAUTION- Prior to disconnecting the

batterj read the baitery discon-

nection cautions

in 001 General Cautions and Warnings.