Air BMW 540I 1997 E39 Central Body Electronics ZKE Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 80, PDF Size: 4.14 MB

Page 4 of 80

4

Central Body Electronics ZKE III

System Components

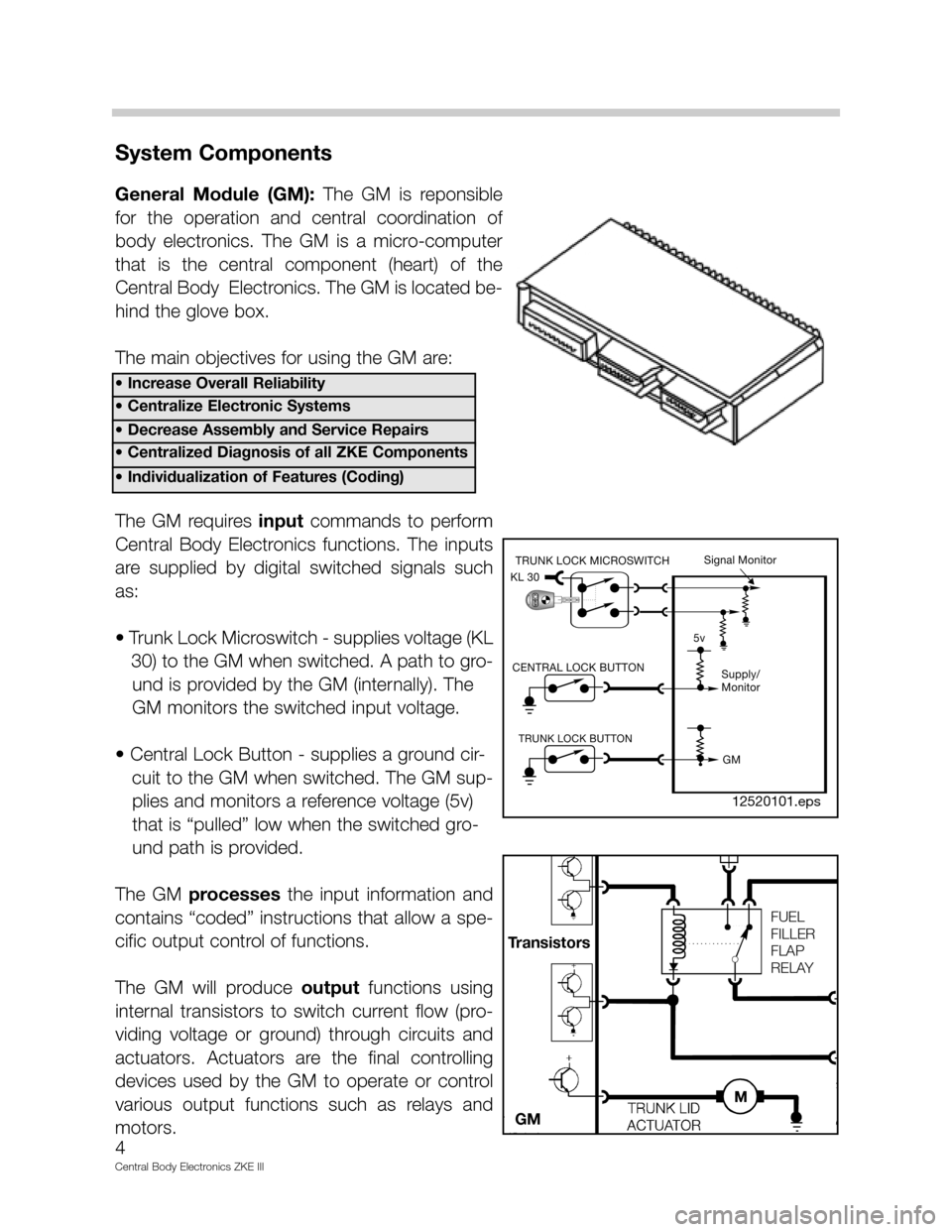

General Module (GM): The GM is reponsible

for the operation and central coordination of

body electronics. The GM is a micro-computer

that is the central component (heart) of the

Central Body Electronics. The GM is located be-

hind the glove box.

The main objectives for using the GM are:

The GM requires inputcommands to perform

Central Body Electronics functions. The inputs

are supplied by digital switched signals such

as:

• Trunk Lock Microswitch - supplies voltage (KL

30) to the GM when switched. A path to gro-

und is provided by the GM (internally). The

GM monitors the switched input voltage.

• Central Lock Button - supplies a ground cir-

cuit to the GM when switched. The GM sup-

plies and monitors a reference voltage (5v)

that is “pulled” low when the switched gro-

und path is provided.

The GM processesthe input information and

contains “coded” instructions that allow a spe-

cific output control of functions.

The GM will produce outputfunctions using

internal transistors to switch current flow (pro-

viding voltage or ground) through circuits and

actuators. Actuators are the final controlling

devices used by the GM to operate or control

various output functions such as relays and

motors.

• Increase Overall Reliability

• Centralize Electronic Systems

• Decrease Assembly and Service Repairs

• Centralized Diagnosis of all ZKE Components

• Individualization of Features (Coding)

CENTRAL LOCK BUTTONCENTRAL LOCK BUTTON

TRUNK LOCK BUTTONTRUNK LOCK BUTTON

KL 30KL 30

TRUNK LOCK MICROSWITCHTRUNK LOCK MICROSWITCHSignal Monitor

5v

Supply/

Monitor

GM

FUEL

FILLER

FLAP

RELAY

Transistors

GM

12520101.eps

Page 8 of 80

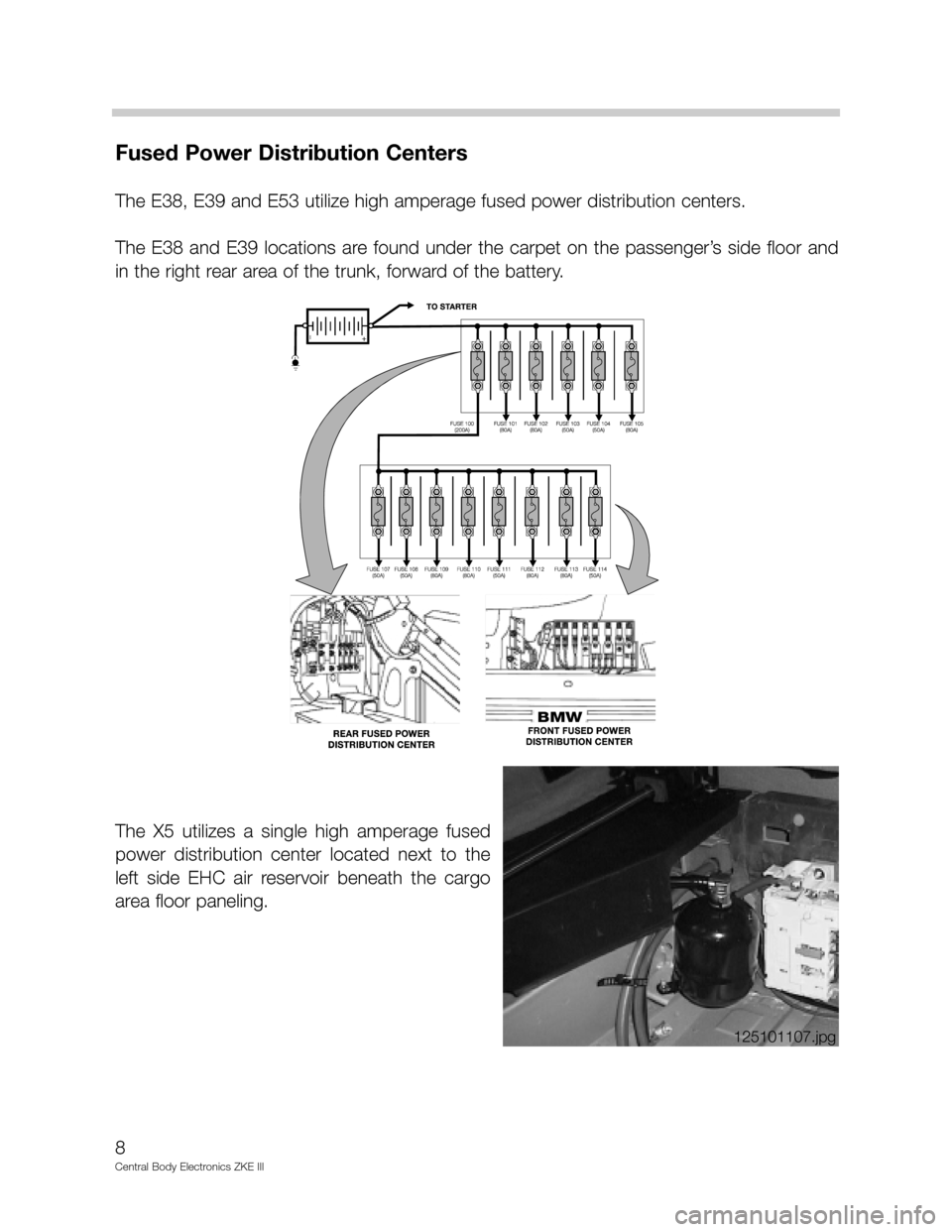

Fused Power Distribution Centers

The E38, E39 and E53 utilize high amperage fused power distribution centers.

The E38 and E39 locations are found under the carpet on the passenger’s side floor and

in the right rear area of the trunk, forward of the battery.

The X5 utilizes a single high amperage fused

power distribution center located next to the

left side EHC air reservoir beneath the cargo

area floor paneling.

8

Central Body Electronics ZKE III

125101107.jpg

Page 13 of 80

13

Central Body Electronics ZKE III

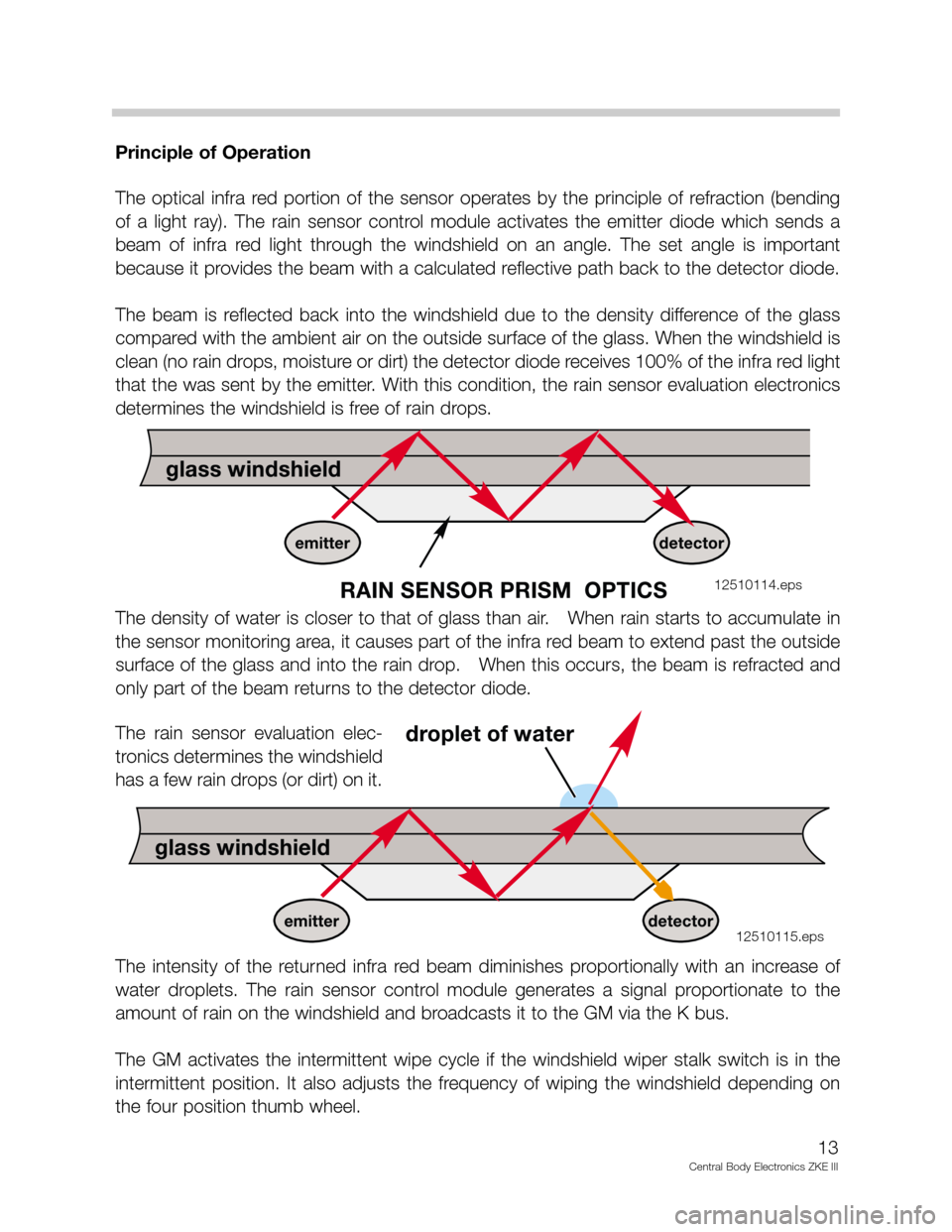

Principle of Operation

The optical infra red portion of the sensor operates by the principle of refraction (bending

of a light ray). The rain sensor control module activates the emitter diode which sends a

beam of infra red light through the windshield on an angle. The set angle is important

because it provides the beam with a calculated reflective path back to the detector diode.

The beam is reflected back into the windshield due to the density difference of the glass

compared with the ambient air on the outside surface of the glass. When the windshield is

clean (no rain drops, moisture or dirt) the detector diode receives 100% of the infra red light

that the was sent by the emitter. With this condition, the rain sensor evaluation electronics

determines the windshield is free of rain drops.

The density of water is closer to that of glass than air. When rain starts to accumulate in

the sensor monitoring area, it causes part of the infra red beam to extend past the outside

surface of the glass and into the rain drop. When this occurs, the beam is refracted and

only part of the beam returns to the detector diode.

The rain sensor evaluation elec-

tronics determines the windshield

has a few rain drops (or dirt) on it.

The intensity of the returned infra red beam diminishes proportionally with an increase of

water droplets. The rain sensor control module generates a signal proportionate to the

amount of rain on the windshield and broadcasts it to the GM via the K bus.

The GM activates the intermittent wipe cycle if the windshield wiper stalk switch is in the

intermittent position. It also adjusts the frequency of wiping the windshield depending on

the four position thumb wheel.

12510114.eps

12510115.eps

Page 63 of 80

Passenger’s Seat (without memory)

Principle of Operation

The passenger seat control switch is purely a mechanical switching module that activates

the passenger seat motors without position monitoring capabilities. Due to the limited op-

eration requirements, the passenger seat control switch is not equipped with on board

diagnostics.

The Passenger Seat control switch is equipped with an overload protection function. If

excessive amperage is drawn due to a defective motor or a switch is stuck driving a motor

to the end limit, the function activates opening the motor control circuit.

Passenger Seat Motors: Each motor is individually controlled by the Seat Control Switch.

Each position motor is connected to the seat position switch by a two wire circuit provid-

ing motor activation in both directions (no position recognition).

Passenger Seat Adjustment: Operation of the passenger seat is always possible regard-

less of the ignition key position. Moving a position switch operates a the motor control con-

tacts directly, the switch applies voltage and ground path directly to operate the motor.

Reversing the switch simply changes the motor polarity. More than one passenger seat

motor can be run simultaneously.

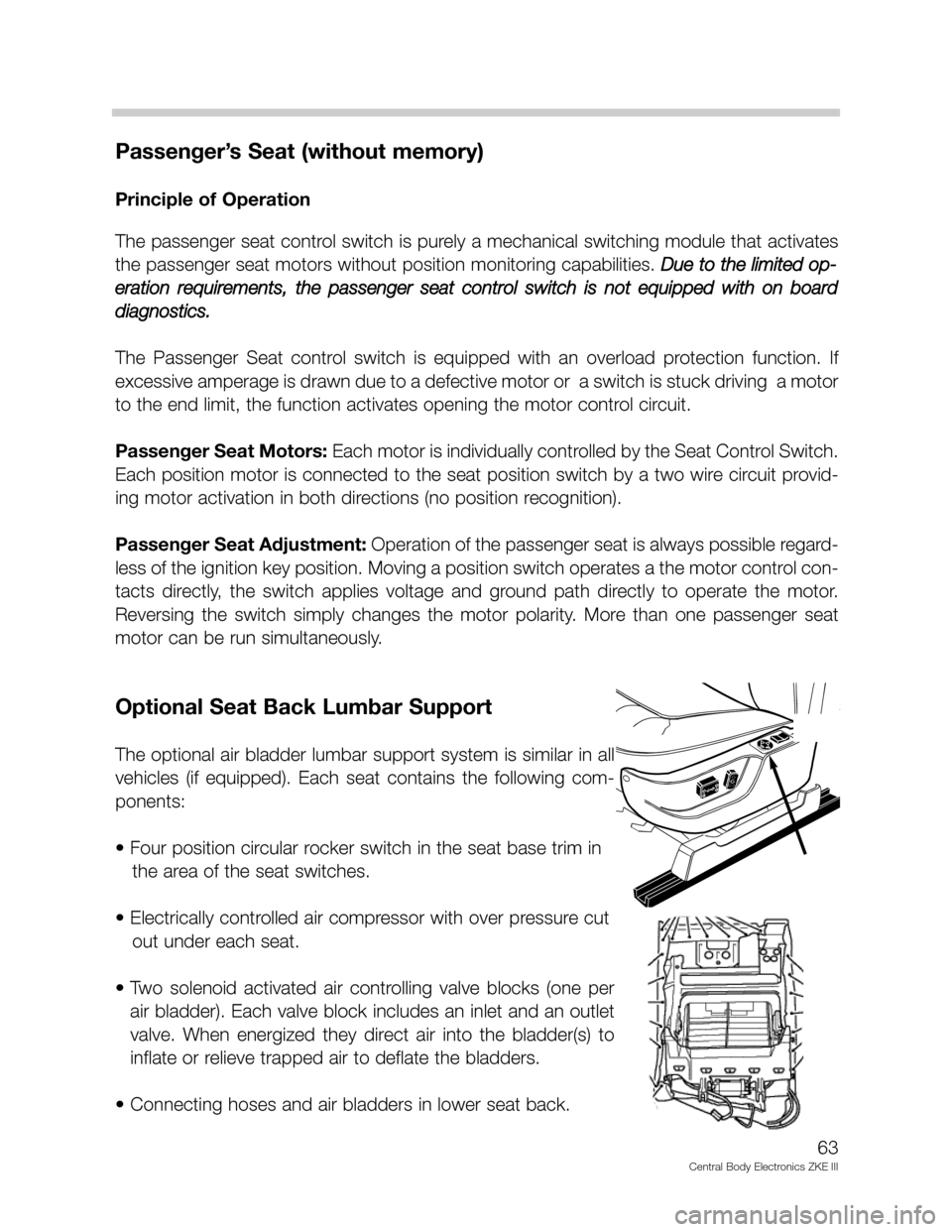

Optional Seat Back Lumbar Support

The optional air bladder lumbar support system is similar in all

vehicles (if equipped). Each seat contains the following com-

ponents:

• Four position circular rocker switch in the seat base trim in

the area of the seat switches.

• Electrically controlled air compressor with over pressure cut

out under each seat.

• Two solenoid activated air controlling valve blocks (one per

air bladder). Each valve block includes an inlet and an outlet

valve. When energized they direct air into the bladder(s) to

inflate or relieve trapped air to deflate the bladders.

• Connecting hoses and air bladders in lower seat back.

63

Central Body Electronics ZKE III

Page 64 of 80

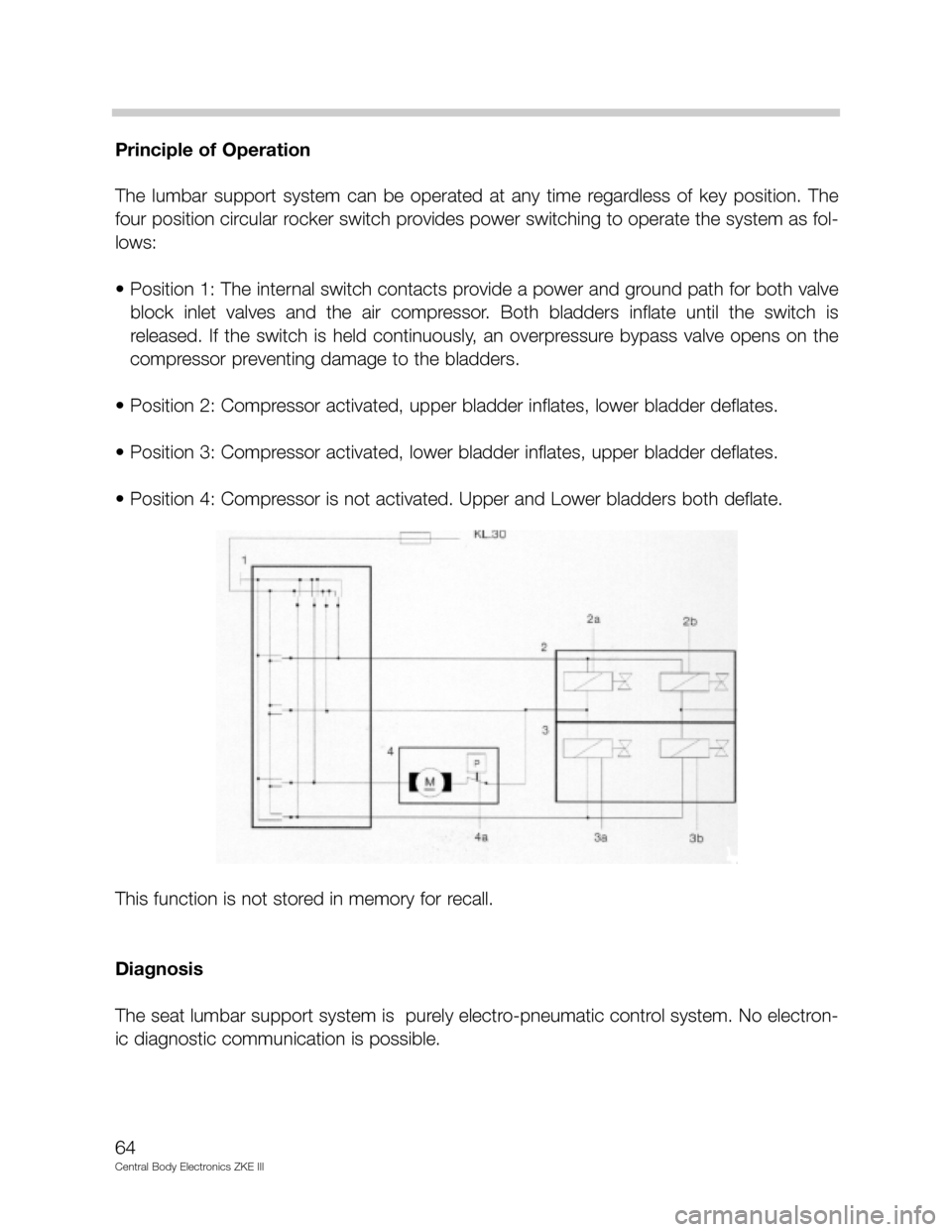

Principle of Operation

The lumbar support system can be operated at any time regardless of key position. The

four position circular rocker switch provides power switching to operate the system as fol-

lows:

• Position 1: The internal switch contacts provide a power and ground path for both valve

block inlet valves and the air compressor. Both bladders inflate until the switch is

released. If the switch is held continuously, an overpressure bypass valve opens on the

compressor preventing damage to the bladders.

• Position 2: Compressor activated, upper bladder inflates, lower bladder deflates.

• Position 3: Compressor activated, lower bladder inflates, upper bladder deflates.

• Position 4: Compressor is not activated. Upper and Lower bladders both deflate.

This function is not stored in memory for recall.

Diagnosis

The seat lumbar support system is purely electro-pneumatic control system. No electron-

ic diagnostic communication is possible.

64

Central Body Electronics ZKE III