Ele BMW 540i 1997 E39 Owners Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 259 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

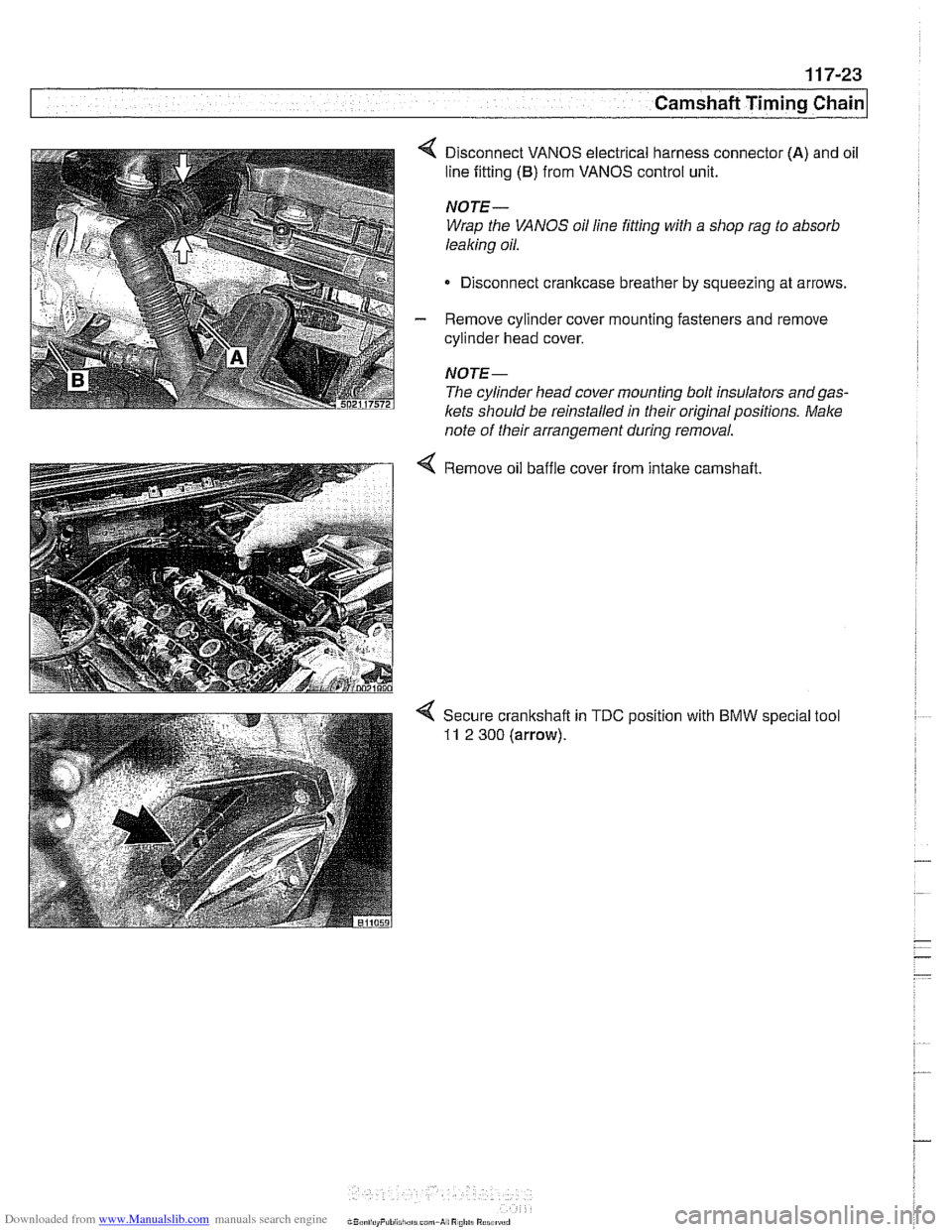

4 Disconnect VANOS electrical harness connector (A) and oil

line fitting

(B) from VANOS control unit.

NOTE-

Wrap the VANOS oil line fitting with a shop rag to absorb

leaking oil.

Disconnect cranltcase breather by squeezing at arrows.

- Remove cylinder cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators andgas-

lets should be reinstalled in their original positions. Make

note of their arrangement during removal.

4 Remove oil baffle cover from intake camshaft

Page 268 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Chain 1

- Install cylinder identification trigger plate to front of intake

camshaft.

- Install spacer to front of intake camshaft

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

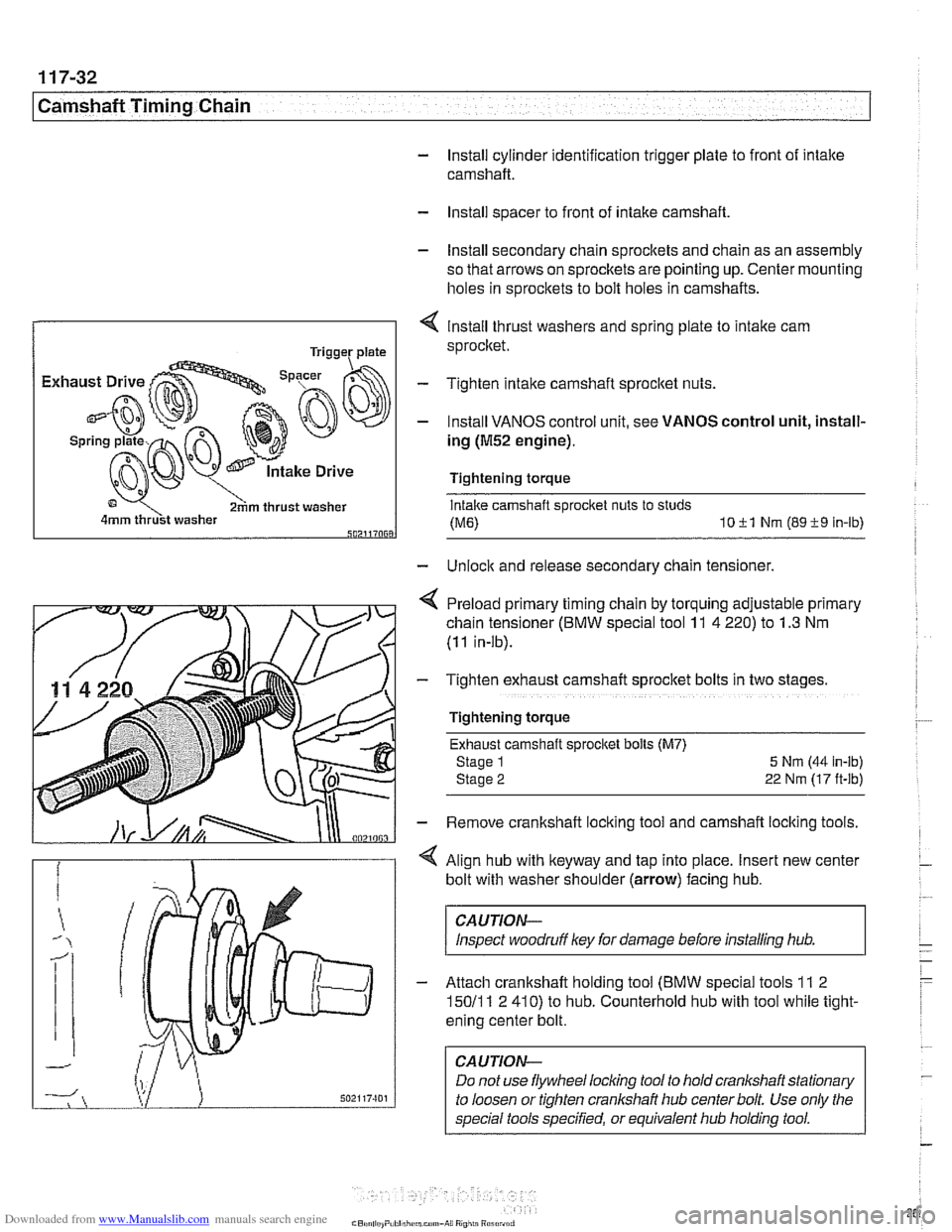

4 lnstall thrust washers and spring plate to intake cam

sprocket.

Tighten intake camshaft sprocket nuts.

- Install VANOS control unit, see VANOS control unit, install-

ing

(M52 engine).

Tightening torque

Intake camshaft sprocket nuts to studs

(ME) 1011 Nm (8919 In-lb) 502117068

- Unlock and release secondary chain tensioner,

4 Preload primary timing chain by torquing adjustable primary

chain tensioner (BMW special tool

11 4 220) to 1.3 Nm

(11 in-lb).

- Tighten exhaust camshaft sprocket bolts in two stage

Tightening torque Exhaust camshaft sprocket bolls (M7)

Stage 1

5 Nrn (44 in-lb)

Stage

2 22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tools.

< Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder (arrow) facing hub.

CAUTION-

Inspect woodruff ley for damage before installing hub.

- Attach crankshaft holding tool (BMW special tools 11 2

15011 1 2 410) to hub. Counterhold hub with tool while tight-

ening center bolt.

CAUTION-

Do not use flywheel locling tool to hold crankshaft stationary

to loosen or tighten

cranlshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

Page 271 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

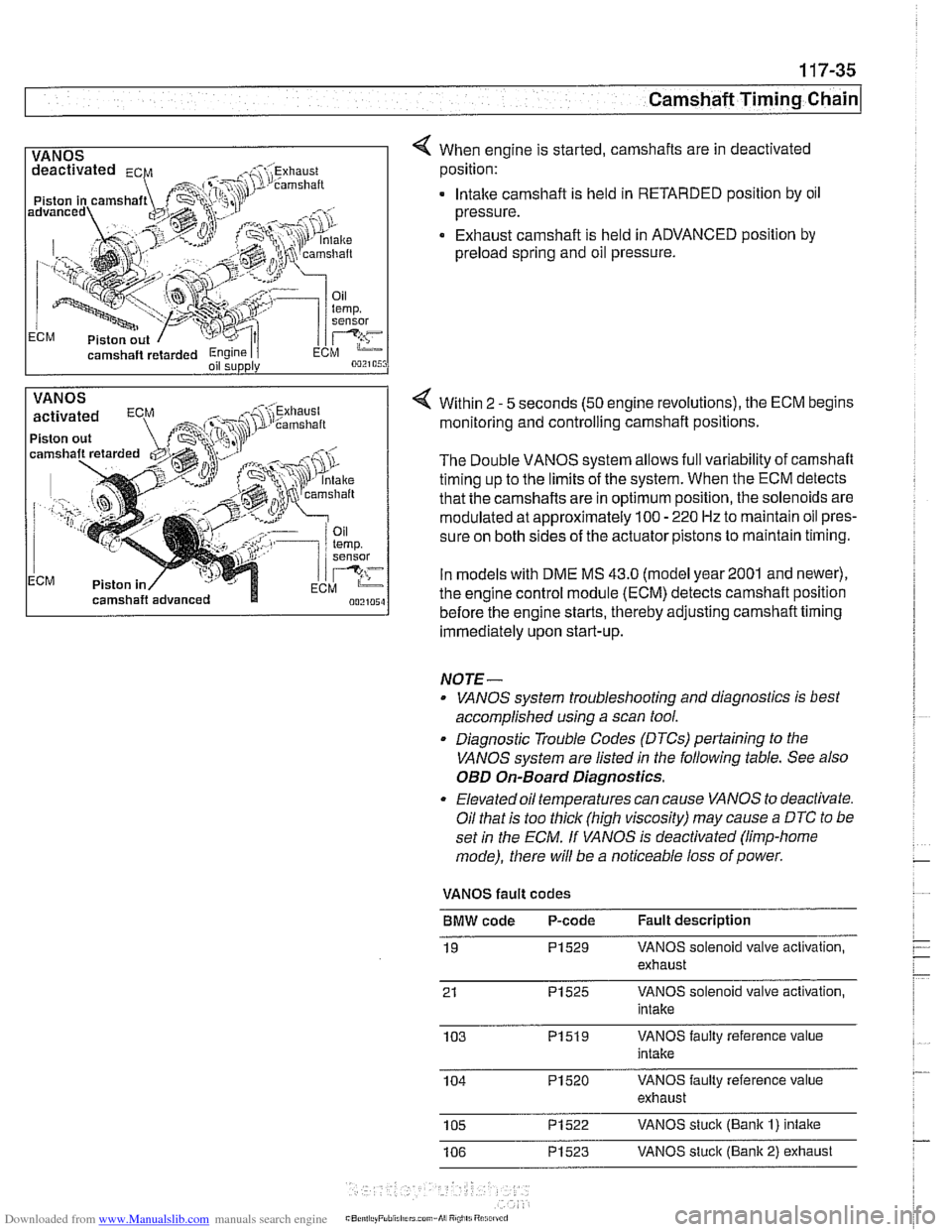

1 VANOS I 4 When engine is started, camshafts are in deactivated

camshaft

retarded Engine I i oil supply

position:

. lntalte camshaft is held in RETARDED position by oil

pressure.

Exhaust camshaft is held in ADVANCED position by

preload spring and oil pressure.

VANOS

Piston out

ECM Piston in Within 2

- 5

seconds (50 engine revolutions), the ECM begins

monitoring and controlling camshaft positions.

The Double VANOS system allows full variability of camshaft

timing up to the limits of the system. When the ECM detects

that the camshafts are in optimum position, the solenoids are

modulated at approximately 100

- 220 Hz to maintain oil pres-

sure on both sides of the actuator pistons to maintain timing.

In models with DME

MS 43.0 (model year2001 and newer),

the engine control module (ECM) detects camshaft position

before the engine starts, thereby adjusting camshaft timing

immediately upon start-up.

NOTE-

. VANOS system troubleshooting and diagnostics is best

accomplished using a scan tool.

. Diagnostic Trouble Codes (DTCs) pertaining to the

VANOS system are listed

in the following table. See also

OED On-Board Diagnostics.

Elevated oil temperatures can cause VANOS to deactivate.

Oil that is too thick (high viscosity) may cause

a DTC to be

set

in the ECM. If VANOS is deactivated (limp-home

mode), there will be a noticeable loss of power.

VANOS fault codes

BMW code P-code Fault description

19

PI529 VANOS solenoid valve activation,

exhaust

21

PI525 VANOS solenoid valve activation,

intake

103

PI519 VANOS faulty reference value

intake

104

PI520 VANOS faulty reference value

exhaust

105

PI522 VANOS stuck (Bank I) intake

106

PI523 VANOS stuck (Bank 2) exhaust

Page 273 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

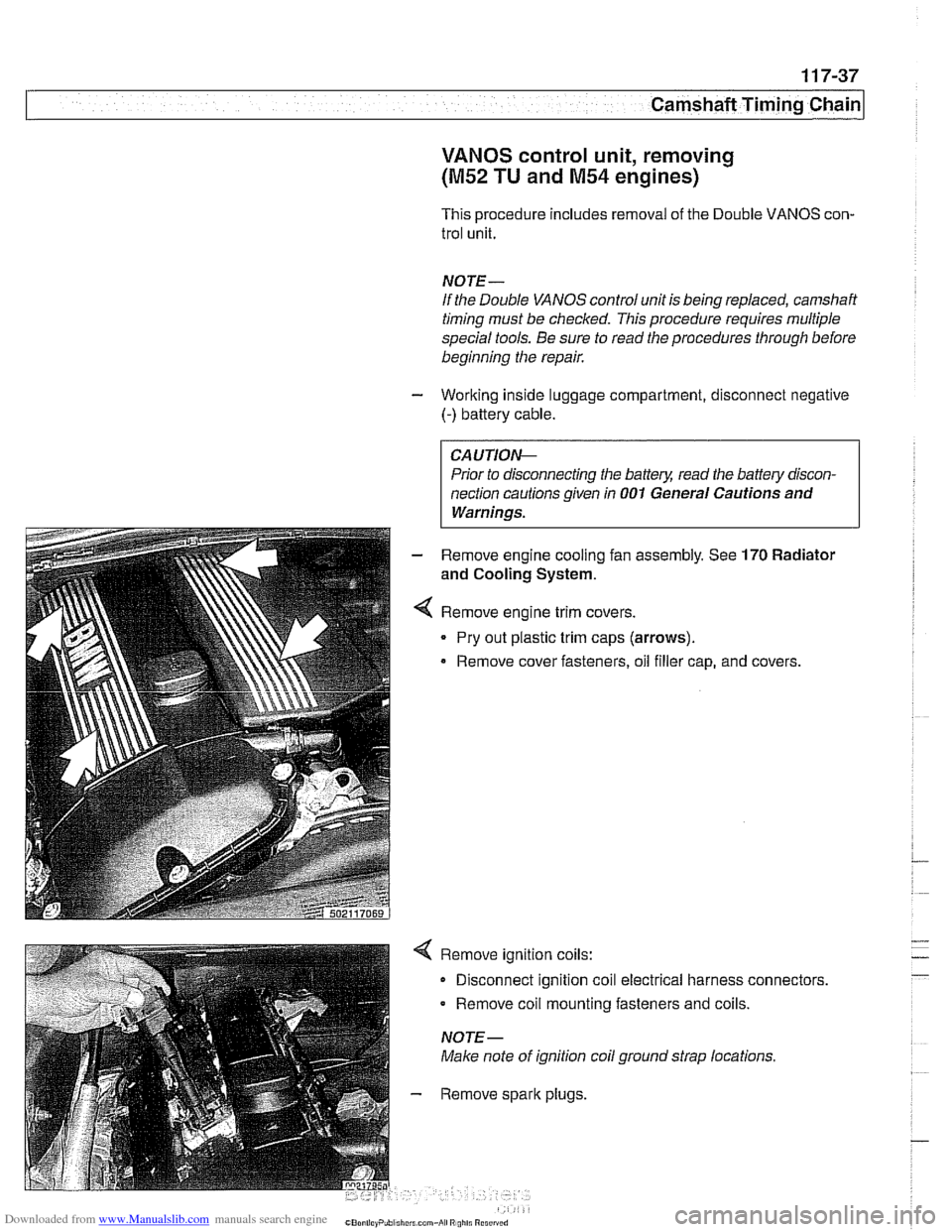

VANOS control unit, removing

(M52 TU and M54 engines)

This procedure includes removal of the Double VANOS con-

trol unit.

NOTE-

If the Double VANOS control unit is being replaced, camshaft

timing must be checked. This procedure requires multiple

special tools. Be sure to read the procedures through before

beginning the repair.

- Working inside luggage compartment, disconnect negative

(-) battery cable.

Prior to disconnecting the

batteg read the battery discon-

nection cautions given in

001 General Cautions and

Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

Remove engine trim covers.

Pry out plastic trim caps (arrows).

Remove cover fasteners, oil filler cap, and covers.

Remove ignition coils:

Disconnect ignition coil electrical harness connectors.

Remove coil mounting fasteners and coils.

NOTE-

Make note of ignition coil ground strap locations.

Remove spark plugs,

Page 274 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-38

[Camshaft Timing Chain

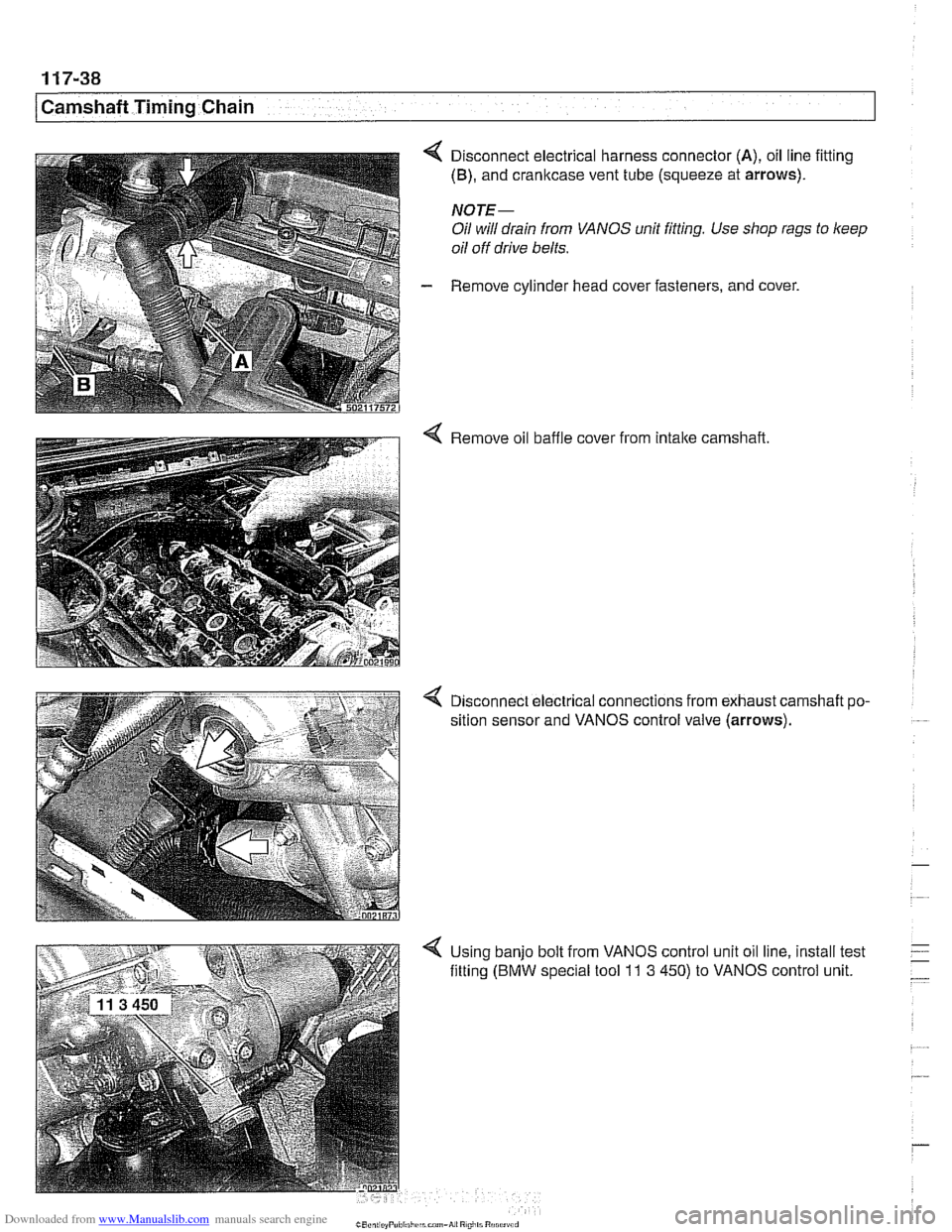

4 Disconnect electrical harness connector (A), oil line fitting

(B), and cranltcase vent tube (squeeze at arrows).

NOJE-

Oil will drain from VANOS unit fitting. Use shop rags to keep

oil off drive belts.

- Remove cylinder head cover fasteners, and cover.

4 Remove oil baffle cover from intake camshaft

4 D~sconnect electrical connections from exhaust camshaft po-

sition sensor and VANOS control valve (arrows).

4 Using banjo bolt from VANOS control unit oil line, install test

fitting

(BMW special tool 11 3 450) to VANOS control unit.

Page 279 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

- Connect electrical harness connectors to camshaft position

sensors and VANOS solenoid valves.

- Remove BMW special locking tools from rear of cylinder

head.

- Remove cranltshaft locking tool and replace sealing plug.

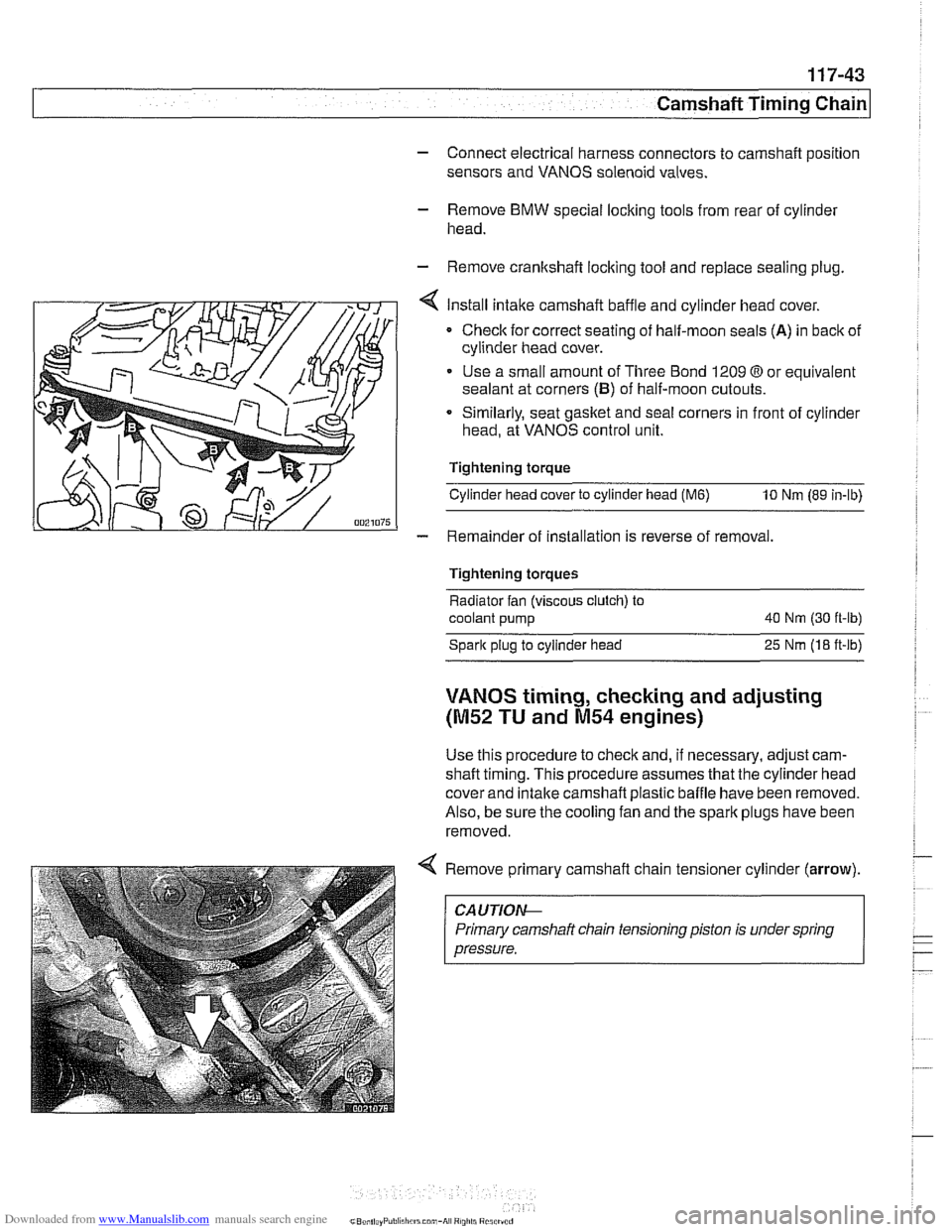

Install intake camshaft baffle and cylinder head cover.

Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(B) of half-moon cutouts.

Similarly, seat gasket and

seal corners in front of cylinder

head, at VANOS control unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

- Remainder of installation is reverse of removal.

Tightening torques

Radiator fan (viscous clutch) to

coolant pump 40

Nm (30 ft-lb)

Spark plug to cylinder head

25 Nrn (18 ft-lb)

VANOS timing, checking and adjusting

(M52 TU and M54 engines)

Use this procedure to check and, if necessary, adjust cam-

shaft timing. This procedure assumes that the cylinder head

cover and intake

camshaft plastic baffle have been removed.

Also, be sure the cooling fan and the spark plugs have been

removed.

Remove primary camshaft chain tensioner cylinder

(arrow).

~~ ~ ~~ ~--~

CA UTlOAC

Primary camshaft chain tensioning piston is under spring

pressure.

Page 282 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-46

Camshaft Timing Chain

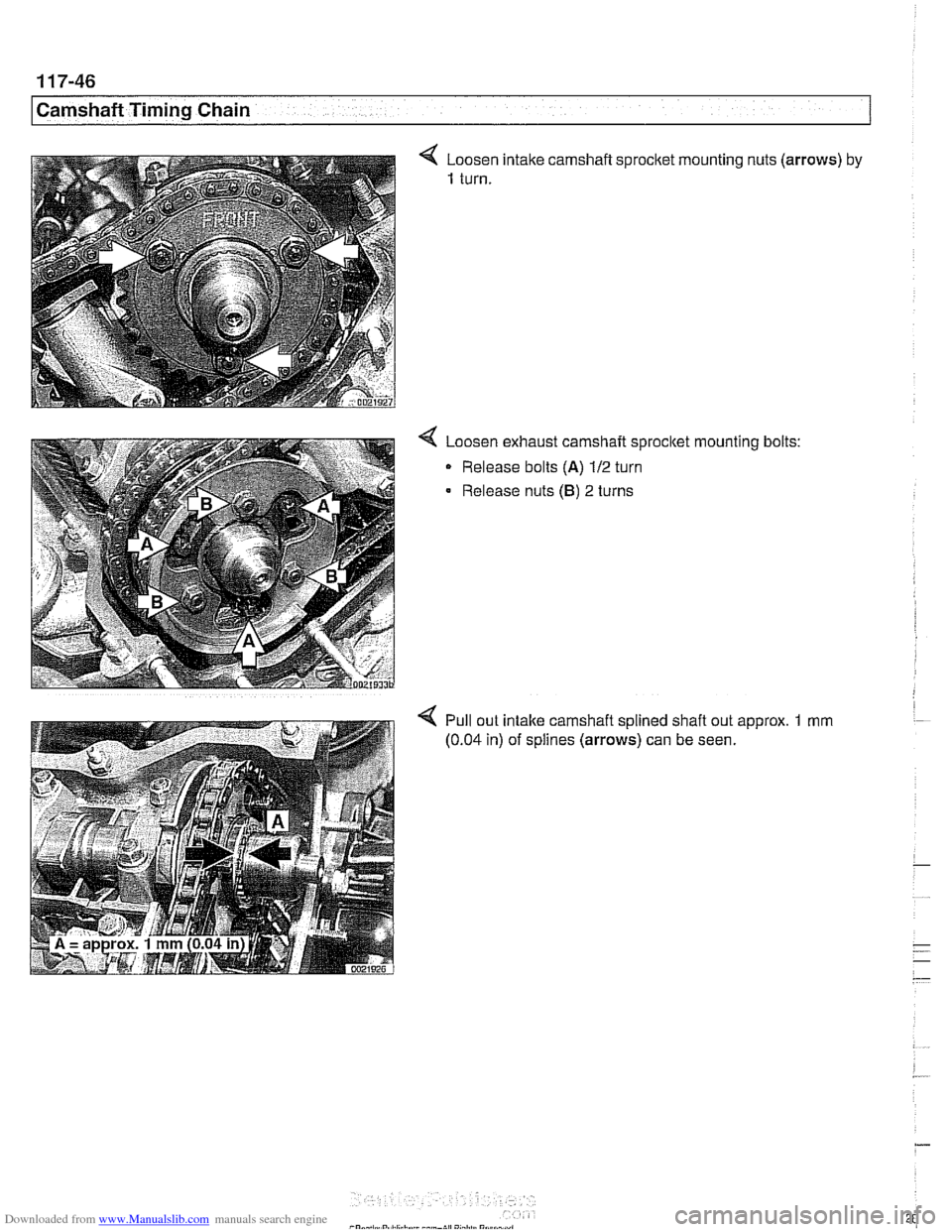

4 Loosen intake camshaft sprocket mounting nuts (arrows) by

1 turn.

Loosen exhaust camshaft sprocltet mounting bolts:

Release bolts

(A) 112 turn

Release nuts

(B) 2 turns

Pull out intake camshaft splined shaft out approx.

1 mm

(0.04 in) of splines (arrows) can be seen.

Page 285 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- - -- - -- Camshaft Timing chain1

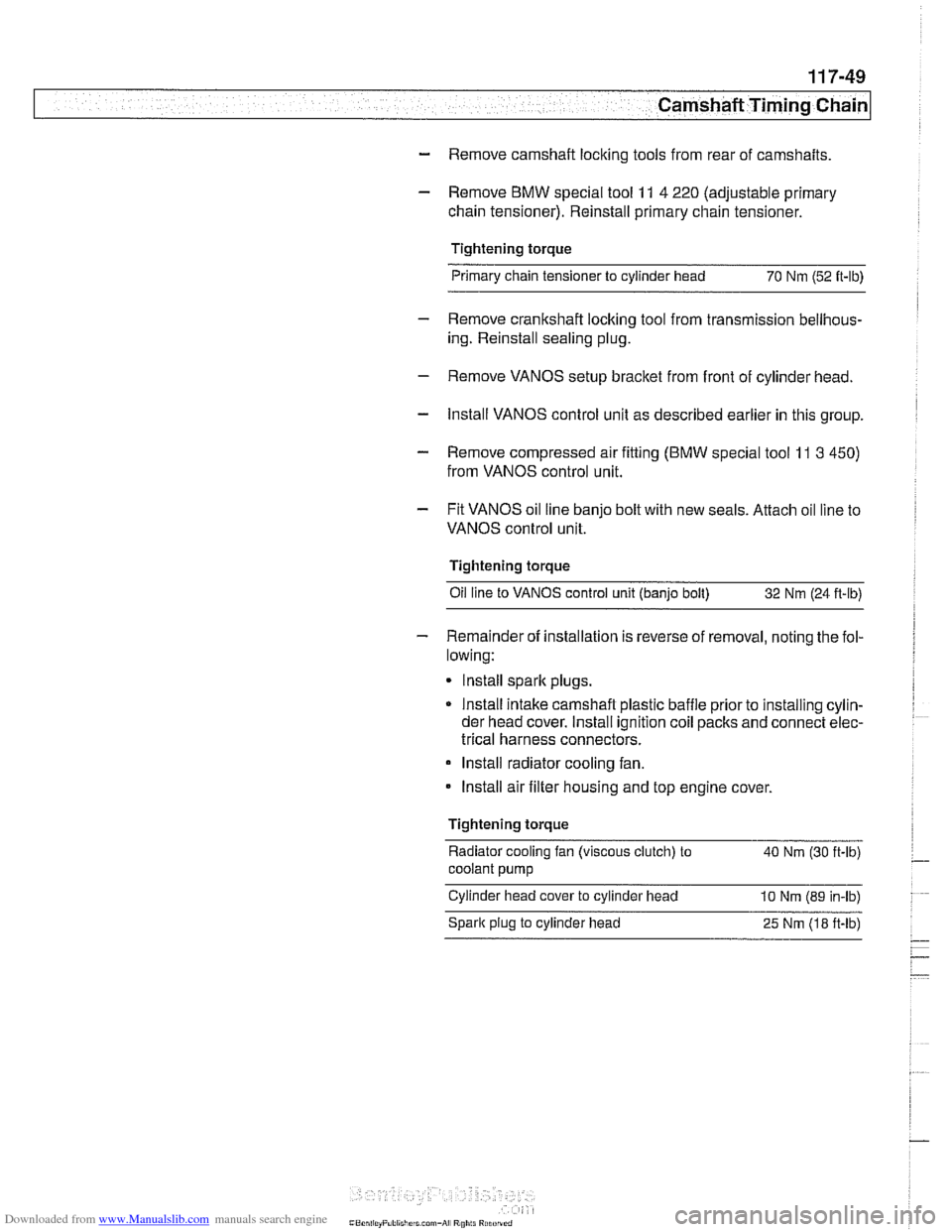

- Remove camshaft locking tools from rear of camshafts

- Remove BMW special tool 11 4 220 (adjustable primary

chain tensioner). Reinstall primary chain tensioner.

Tightening torque Primary chain tensioner to cylinder head

70

Nm (52 it-lb)

- Remove crankshaft locking tool from transmission bellhous-

ing. Reinstall sealing plug.

- Remove VANOS setup bracket from front of cylinder head

- lnstall VANOS control unit as described earlier in this group.

- Remove compressed air fitting (BMW special tool 11 3 450)

from VANOS control unit.

- Fit VANOS oil line banjo bolt with new seals. Attach oil line to

VANOS control unit.

Tightening torque

Oil line to VANOS control unit (banjo bolt) 32 Nm (24 H-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

lnstall spark plugs.

* lnstall intake camshaft plastic baffle prior to installing cylin-

der head cover. lnstall ignition coil packs and connect elec-

trical harness connectors.

Install radiator cooling fan.

- lnstall air filter housing and top engine cover.

Tightening torque Radiator cooling fan

(VISCOUS clutch) to 40 Nm (30 ft-lb)

coolant pump

Cyitnder head cover to cylinder head 10 Nm (89 in-lb)

Sparlc plug to cylinder head 25 Nm (18 ft-lb)

Page 303 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

- Disconnect negative cable (-) from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 General Cautions and

Warnings.

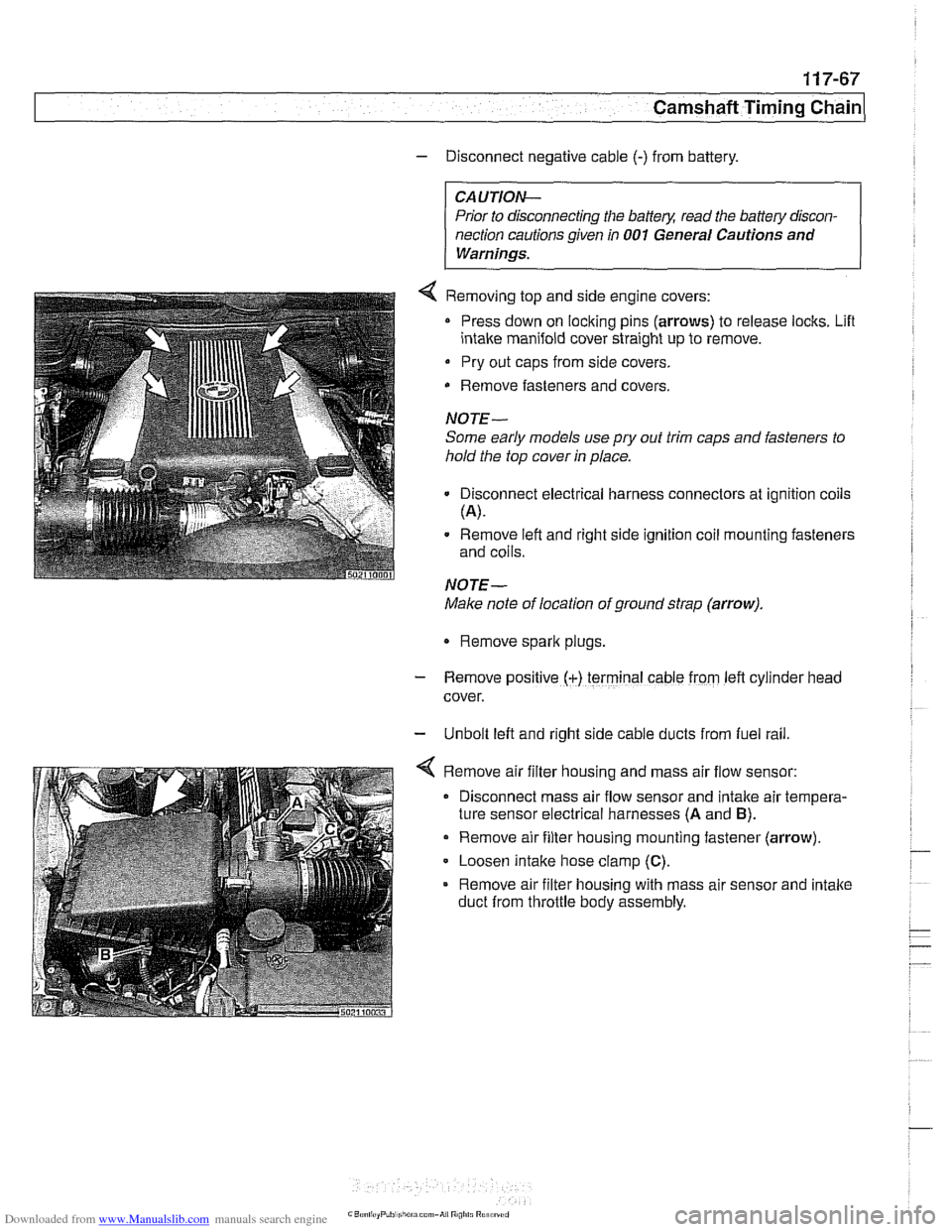

4 Removing top and side engine covers:

Press down on locking pins (arrows) to release locks. Lifl

intake manifold cover straight up to remove.

Pry out caps from side covers.

Remove fasteners

and covers.

NOTE-

Some early models use

pry out trim caps and fasteners to

hold the top cover in place.

Disconnect electrical harness connectors at ignition coils

(A).

Remove left and right side ignition coil mounting fasteners

and coils.

NOTE-

Make note of location of ground strap (arrow).

Remove spark plugs.

- Remove posltlve (+) terminal cable from left cylrnder head

cover.

- Unbolt left and right side cable ducts from fuel rail

Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor and intake air tempera-

ture sensor electrical harnesses

(A and B).

Remove air filter housing mounting fastener (arrow)

Loosen intake hose clamp

(C).

Remove air filter housing with mass air sensor and intake

duct from throttle body assembly.

Page 304 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-68

Camshaft Timing Chain

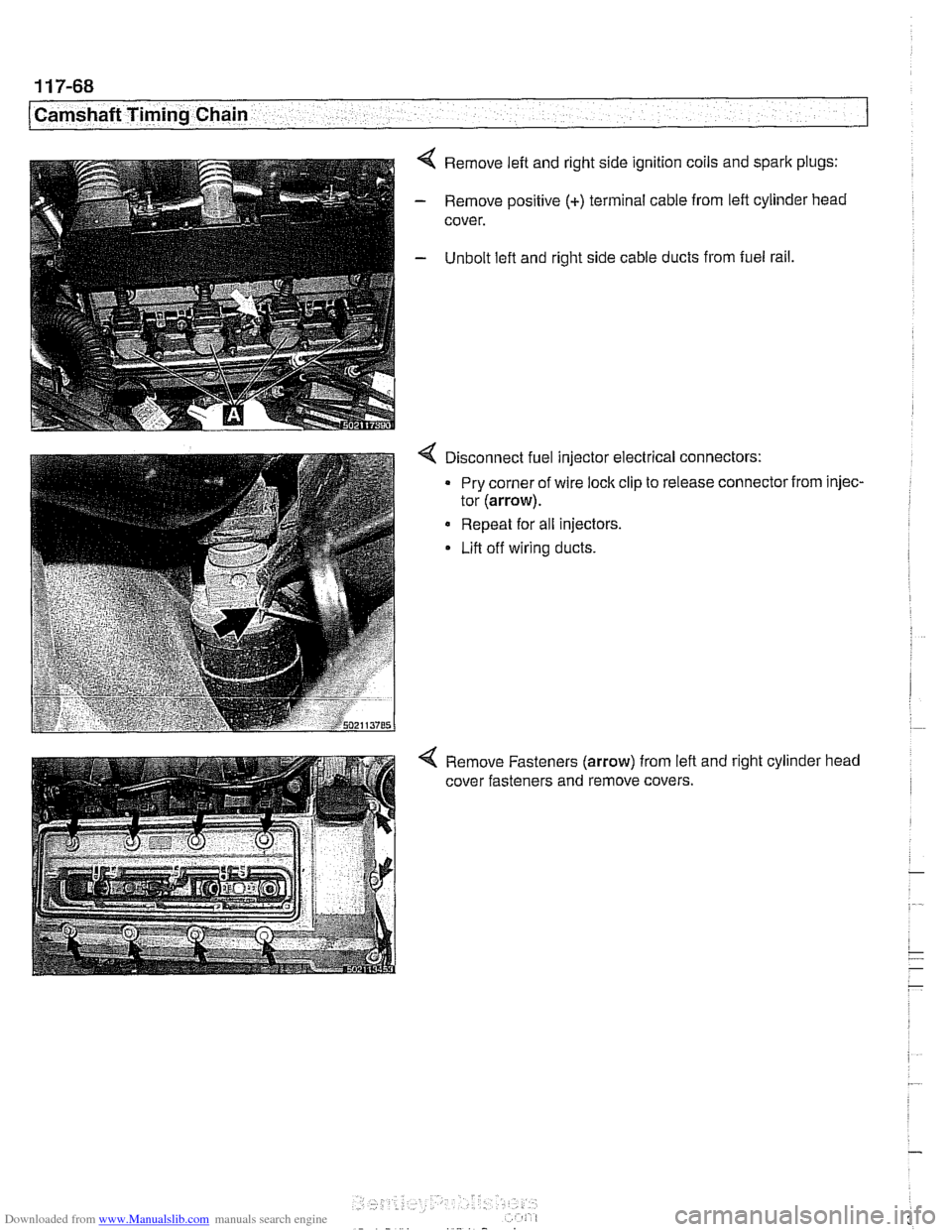

4 Remove left and right side ignition coils and spark plugs:

- Remove positive (+) terminal cable from left cylinder head

cover.

- Unbolt lefl and right side cable ducts from fuel rail,

4 Disconnect fuel injector electrical connectors:

Pry corner of wire lock clip to release connector from injec-

tor

(arrow).

Repeat for all injectors.

Lift off wiring ducts.

4 Remove Fasteners (arrow) from lefl and right cylinder head

cover fasteners and remove covers.