Ele BMW 540i 1997 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 119 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-25

Cylinder Head Removal and Installation

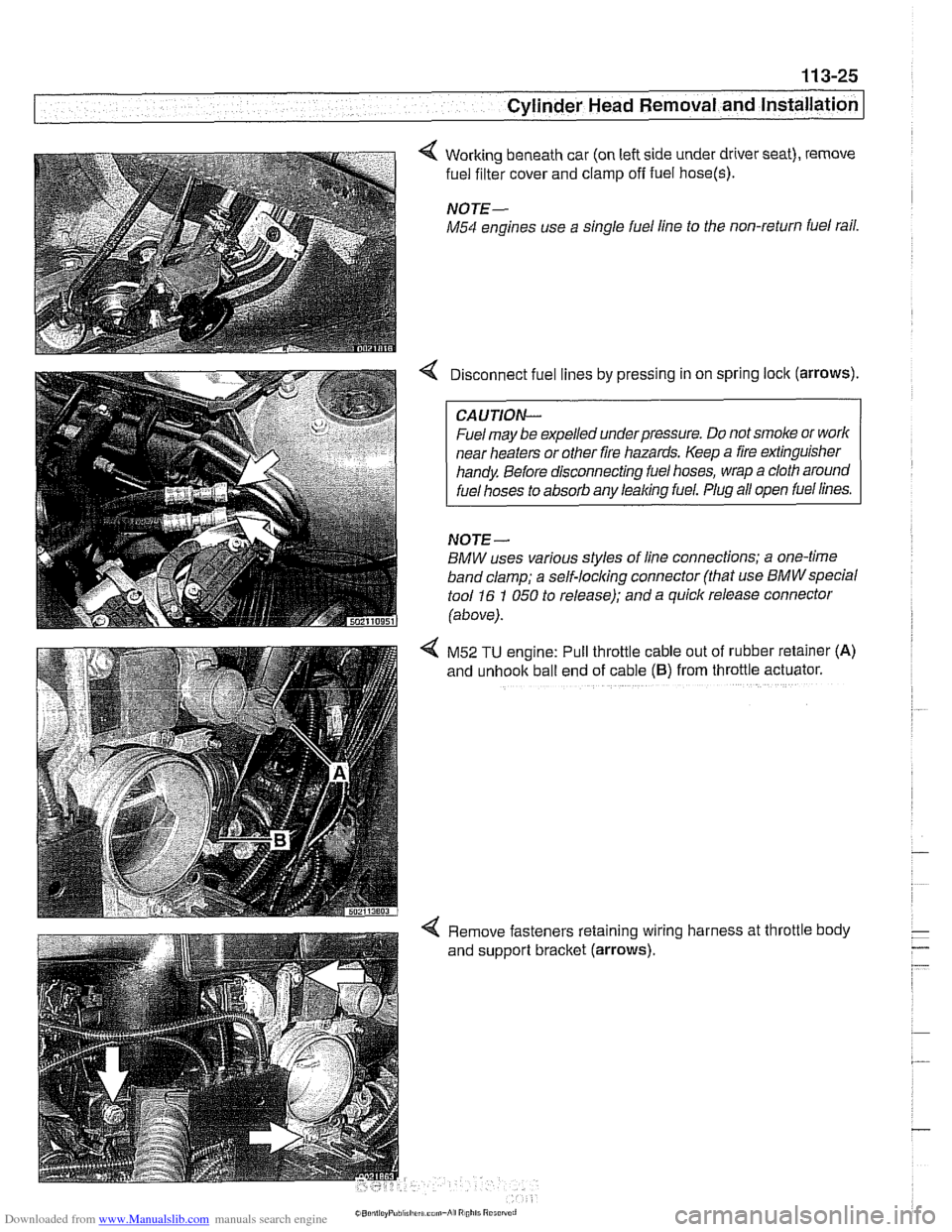

4 Working beneath car (on left side under driver seat), remove

fuel filter cover and clamp

off fuel hose(s).

NOTE-

M54 engines use a single fuel line to the non-return fuel rail.

Disconnect fuel lines by pressing in on spring lock (arrows).

CAUTION--

Fuel may be expelled underpressure. Do not smoke or worlc

near heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth around

fuel hoses to absorb any leaking fuel. Plug all open fuel lines.

NOJE-

BMW uses various styles of line connections; a one-time

band clamp; a

self-locl(ing connector (that use BMWspecial

tool 16 1 050 to release); and a quick release connector

(above).

4 M52 TU engine: Pull throttle cable out of rubber retainer (A)

and unhook ball end of cable (6) from throttle actuator.

4 Remove fasteners retaining wiring harness at throttle body

and support bracket (arrows).

Page 120 of 1002

Downloaded from www.Manualslib.com manuals search engine

. - --

j Cylinder Head Removal and Installation

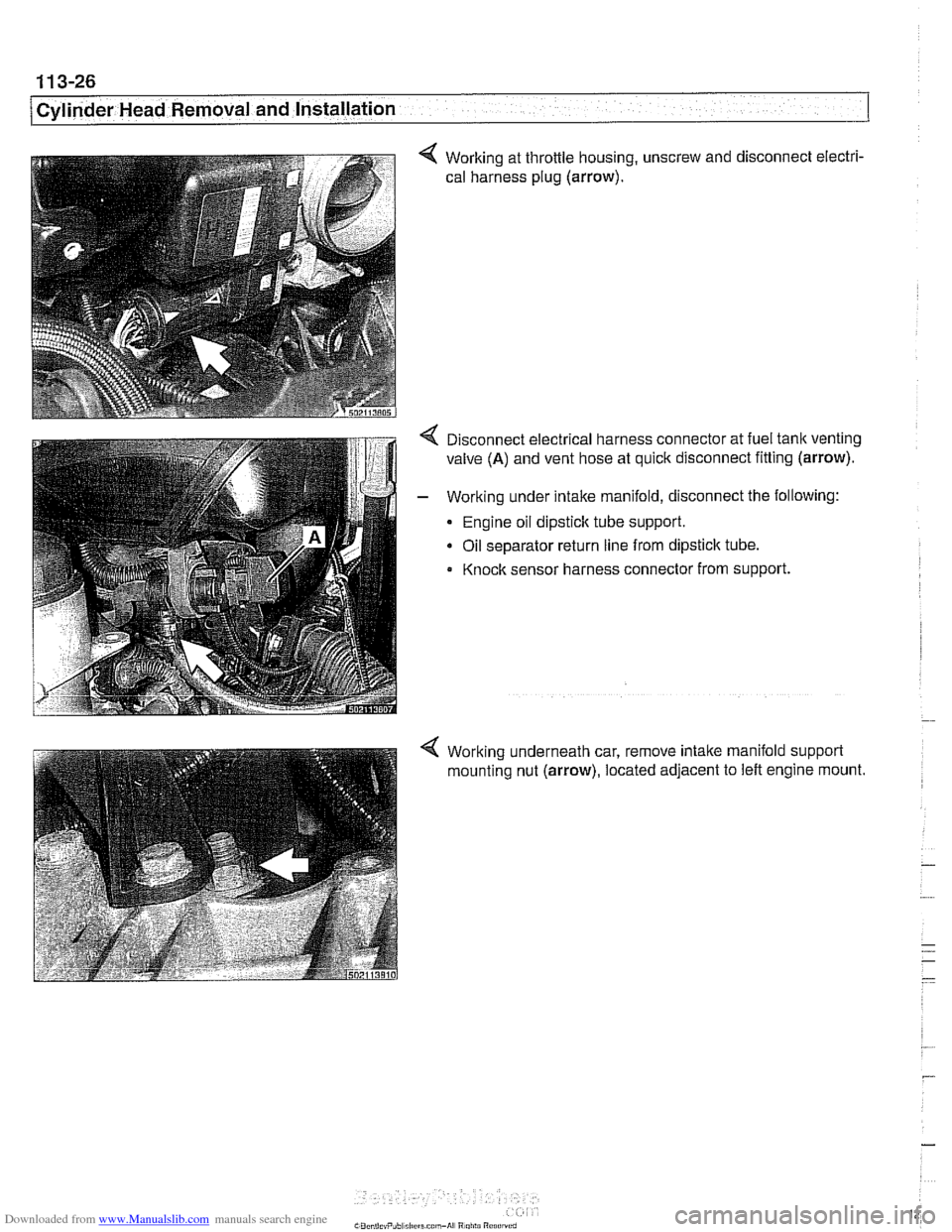

4 Working at throttle housing, unscrew and disconnect electri-

cal harness plug

(arrow).

4 Disconnect electrical harness connector at fuel tank venting

valve

(A) and vent hose at quick disconnect fitting (arrow).

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Knock sensor harness connector from support.

4 Working underneath car, remove intake manifold support

mounting nut

(arrow), located adjacent to left engine mount.

Page 122 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation

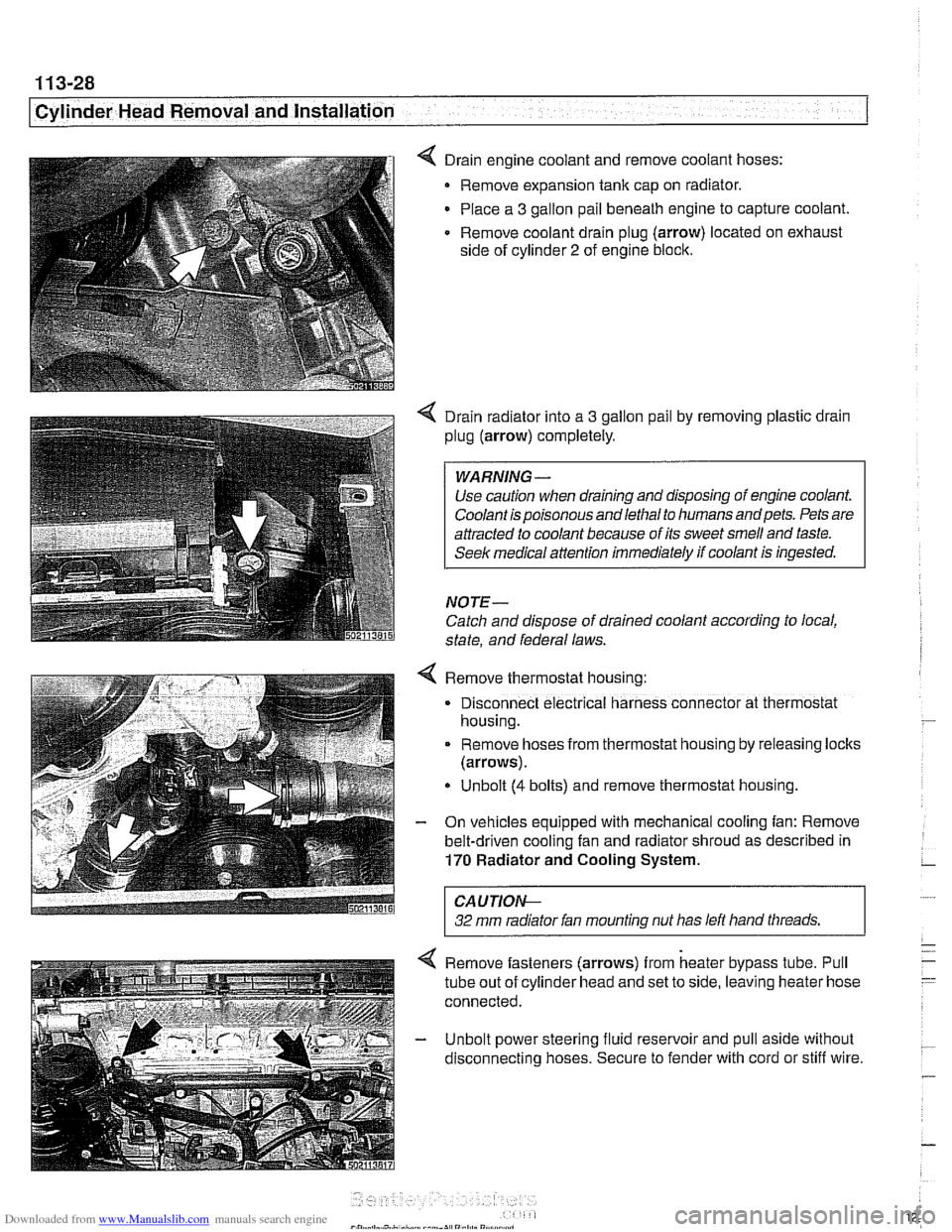

4 Drain engine coolant and remove coolant hoses:

Remove expansion tank cap on radiator.

Place a

3 gallon pail beneath engine to capture coolant

Remove coolant drain plug (arrow) located on exhaust

side of cylinder

2 of engine block.

4 Drain radiator into a 3 gallon pail by removing plastic drain

plug (arrow) completely.

Use caution when draining and disposing of engine coolant.

Coolant is poisonous andlethal to humans andpets. Pets are

attracted to coolant because of its sweet smell and taste.

Seek medical

attention immediately if coolant is ingested.

NOTE-

Catch and dispose of drained coolant according to local,

state, and federal laws.

4 Remove thermostat housing:

. Disconnect electrical harness connector at thermostat

housing.

. Remove hoses from thermostat hous~ng by releasing loclts

(arrows).

Unbolt

(4 bolts) and remove thermostat hous~ng.

- On vehicles equipped with mechanical cooling fan: Remove

belt-driven cooling fan and radiator shroud as described in

170 Radiator and Cooling System.

CAUTIOI\C

32 mm radiator fan mounting nut has left hand threads. r

4 Remove fasteners (arrows) from heater bypass tube. Pull

tube out of cylinder head and set to side, leaving heater hose

connected.

- Unbolt power steering fluid reservoir and pull aside without

disconnecting hoses. Secure to fender with cord or stiff wire.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

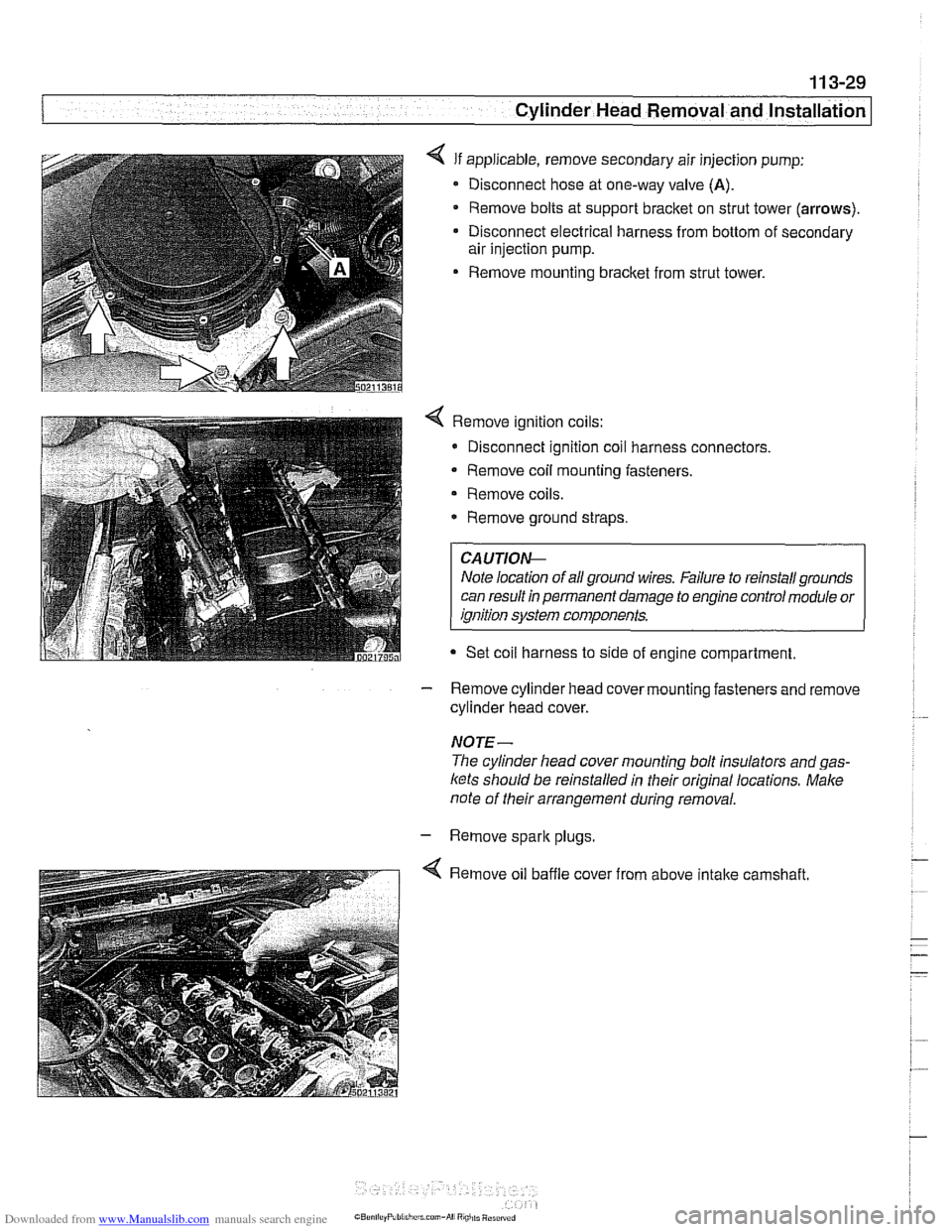

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

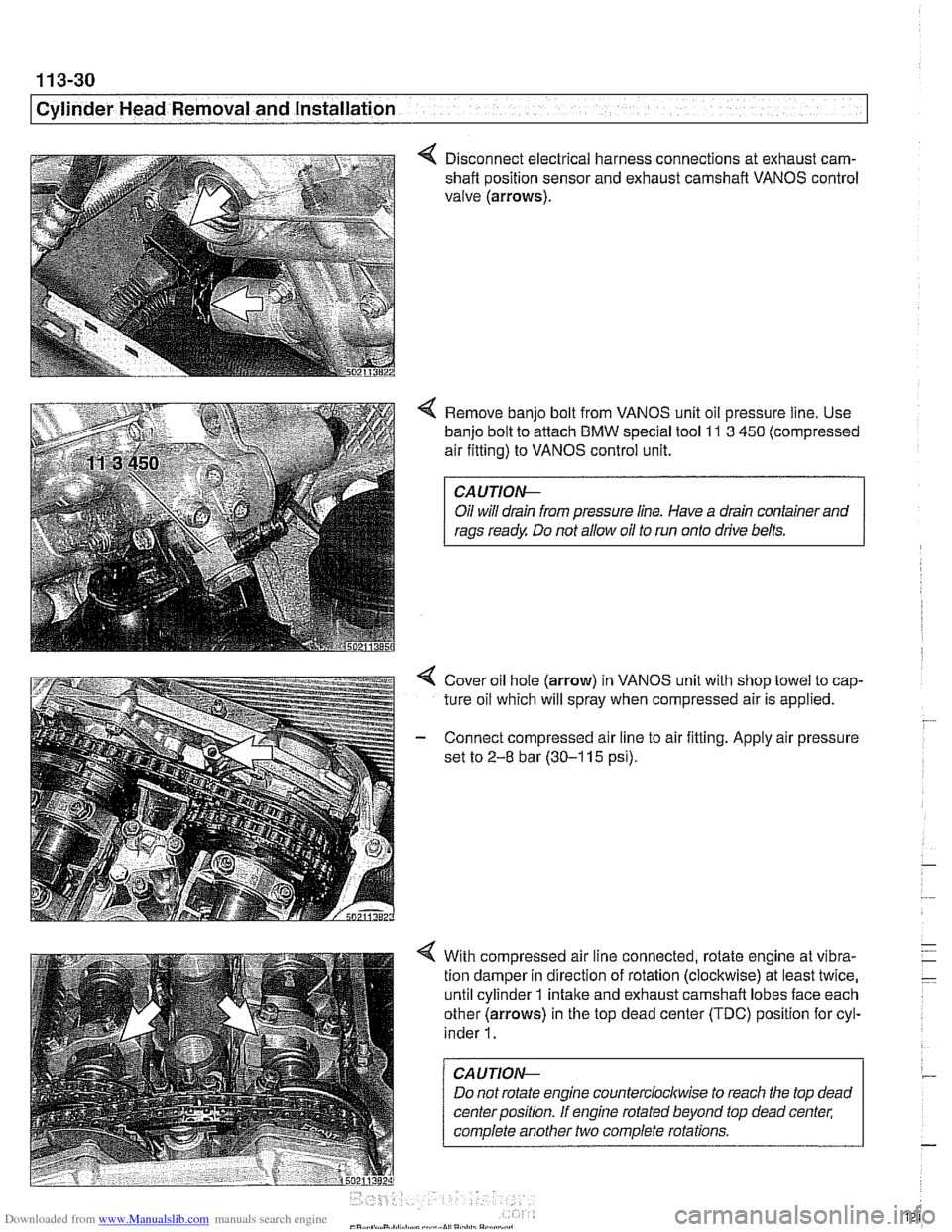

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.

Page 132 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-38

I Cylinder Head Removal and Installation

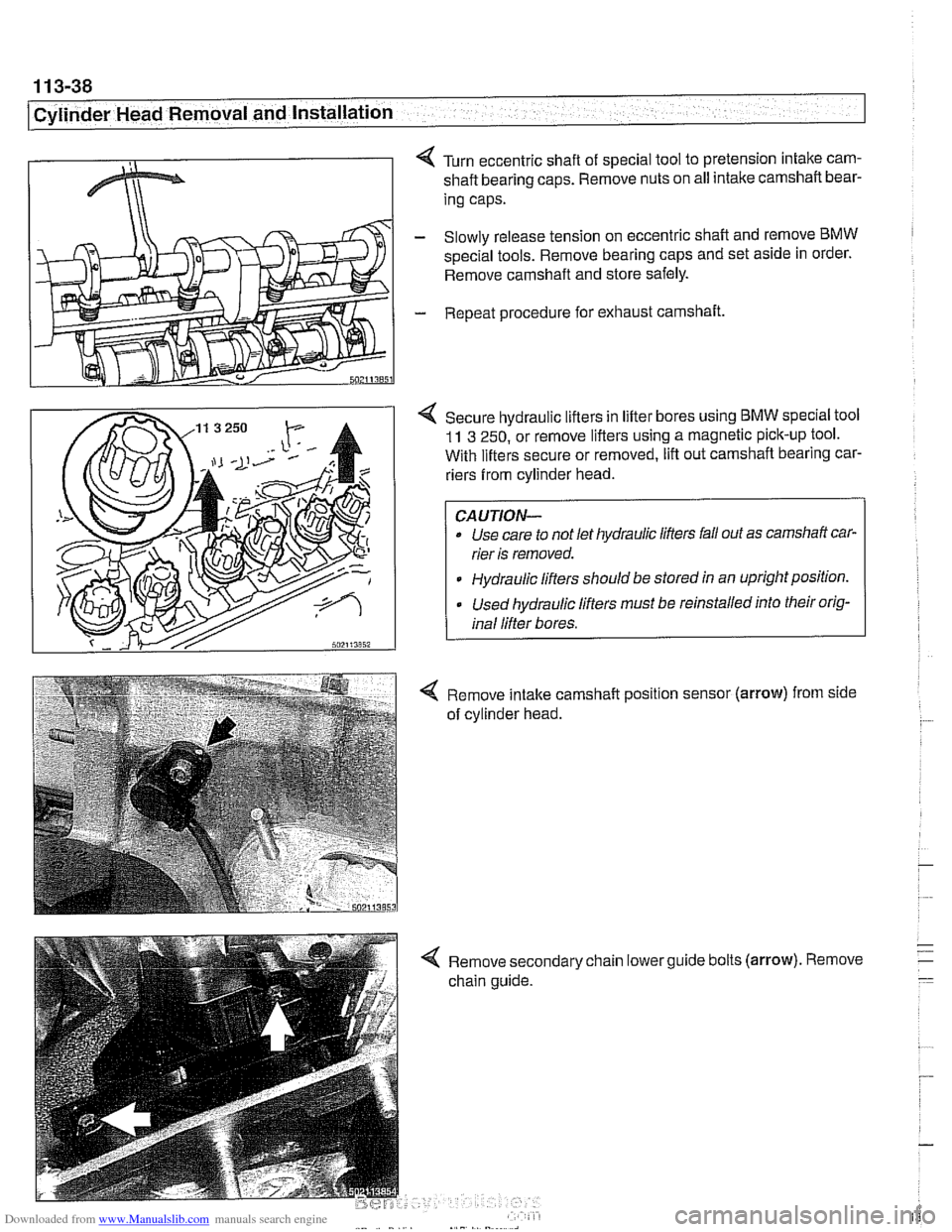

< Turn eccentric shaft of special tool to pretension intake cam-

shaft bearing caps. Remove nuts on all intake camshaft bear-

ing caps.

- Slowly release tension on eccentric shaft and remove BMW

spec~al tools. Remove bearing caps and set as~de in order.

Remove camshaft and store safely.

- Repeat procedure for exhaust camshaft.

4 Secure hydraulic lifters in lifter bores using BMW speclal tool

11 3 250, or remove lifters using a magnetic pick-up tool.

With lifters secure or removed, lift out camshaft bearing car-

riers from cylinder head.

Use care to not let hydraulic lifters fall out as camshaft car-

rier is removed.

Hydraulic lifters should be stored

ln an uprightpositlon.

Used hydraulic lifters must be reinstalled into their orig-

inal lifter bores.

4 Remove intake camshaft position sensor (arrow) from side

of cylinder head.

4 Remove secondary chain lowerguide bolts (arrow). Remove

chain guide.

Page 133 of 1002

Downloaded from www.Manualslib.com manuals search engine

. - -- -

Cylinder Head Removal and Installation --

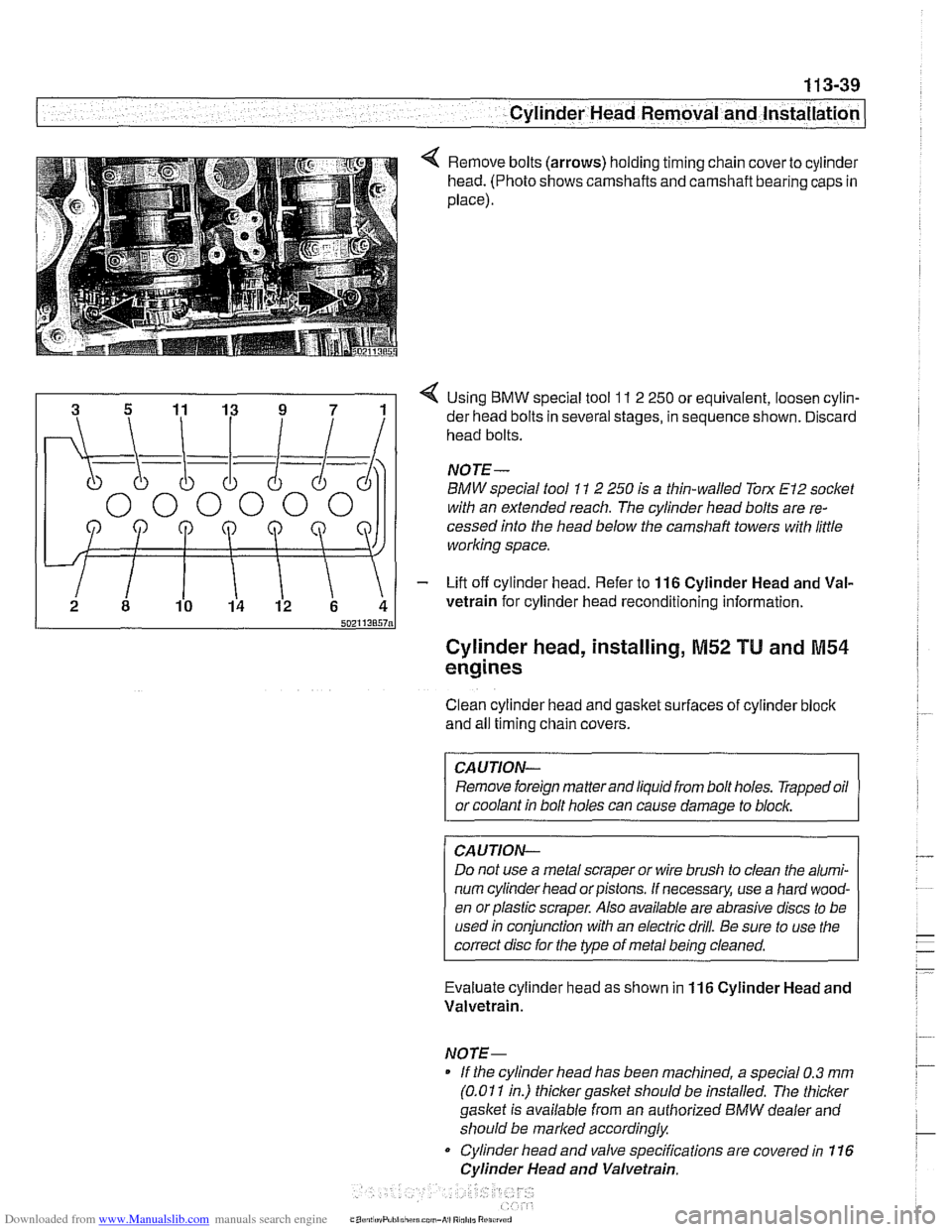

Remove bolts (arrows) holding timing chain cover to cylinder

head. (Photo shows camshafts and camshaft bearing caps in

place).

4 Using BMW special tool 11 2 250 or equivalent, loosen cylin-

der head bolts in several stages, in sequence shown. Discard

head bolts.

NOJE-

BMW special tool 11 2 250 is a thin-walled Torx El2 socket

with an extended reach. The cylinder head bolts are re-

cessed into the head below the

camshaft towers with little

working space.

- Lift off cylinder head. Refer to 116 Cylinder Head and Val-

vetrain for cylinder head reconditioning information.

Cylinder head, installing, M52 TU and M54

engines

Clean cylinder head and gasket surfaces of cylinder bloclc

and all timing chain covers.

CAUTION- Remove foreign matter and liquid from bolt holes. Trapped oil

or coolant in bolt holes can cause damage to

blocl~,

CAUJION-

Do not use a metal scraper or wire brush to clean the alumi-

num cylinder head or pistons. If necessary, use a hard wood-

en orplastic scraper. Also available are abrasive discs to be

used in conjunction with an electric drill. Be sure to use the

correct disc for the type of metal being cleaned.

Evaluate cylinder head as shown in

116 Cylinder Head and

Valvetrain.

NOTE- If the cylinder head has been machined, a special 0.3

mm

(0.01 1 in.) thicker gasket should be installed. The thicker

gasket is available from an authorized

BMW dealer and

should be marked accordingly

Cylinder head and valve specifications are covered in 116

Cylinder Head and Valvetrain.

Page 137 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

Cylinder Head Removal and Installation

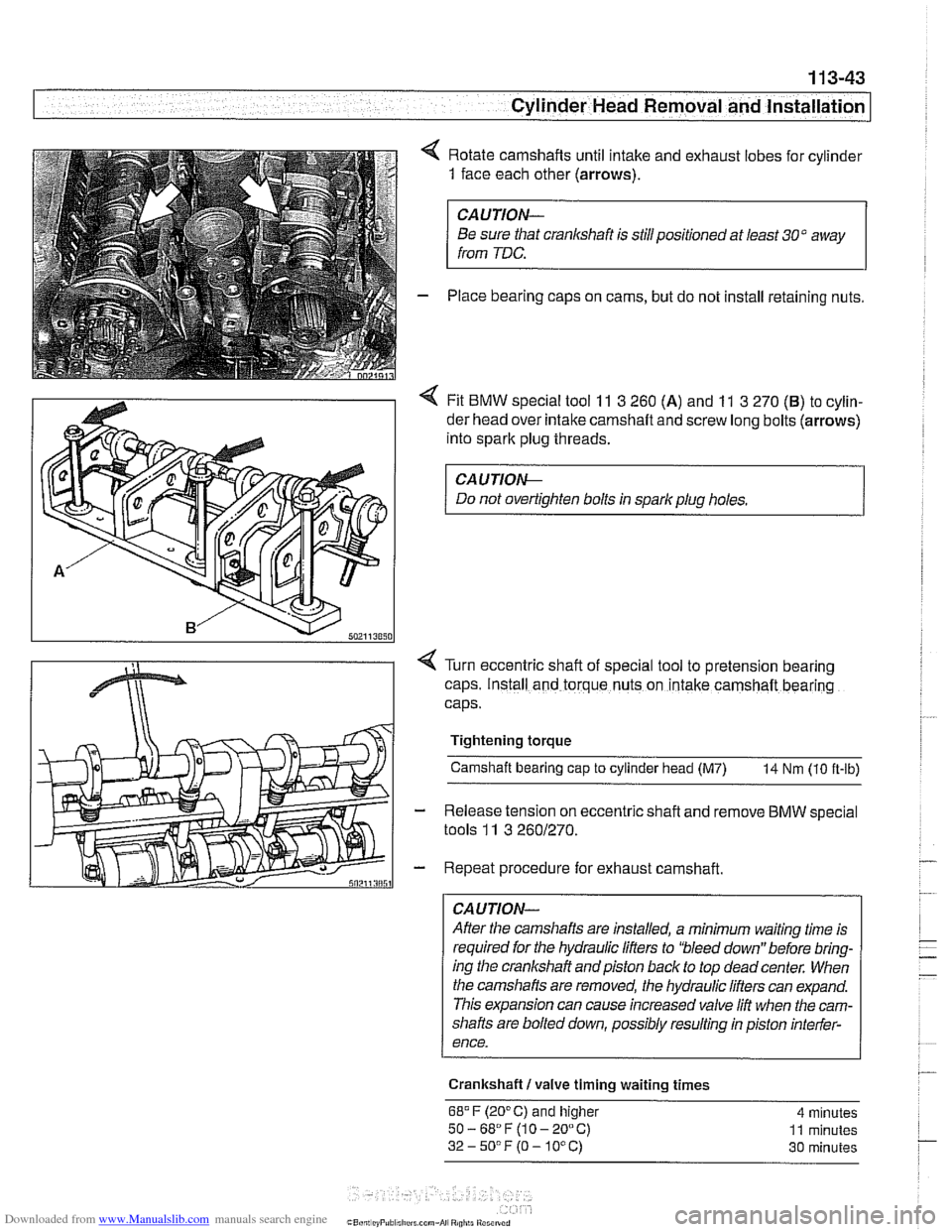

4 Rotate camshafts until intake and exhaust lobes for cylinder

1 face each other (arrows).

CAUTION-

Be sure that cranlcshaft is stillpositioned at least 30" away

from

TDC.

- Place bearing caps on cams, but do not install retaining nuts.

4 Fit BMW special tool 11 3 260 (A) and 11 3 270 (B) to cylin-

der head over intake camshaft and screw long bolts (arrows)

into spark plug threads.

CAUTIOI\C

Do not overtighten bolts in spark plug holes.

Turn eccentric shaft of special tool to pretension

bearing

caps. Install and torque nuts on intake camshaft bearing

caps.

Tightening torque Camshaft bearing

cap to cylinder head (M7) 14 Nm (10 ft-lb)

Release tension on eccentric

shaft and remove BMW special

tools

11 3 2601270.

Repeat procedure for exhaust camshaft.

CAUTION-

After the camshafts are installed, a minimum waiting time is

required for the hydraulic lifters to 'bleed down" before bring-

ing the crankshaft andpiston back to top

deadcenter. When

the camshafts are removed, the hydraulic lifters can expand.

This expansion can cause increased valve lift when the cam-

shafts are bolted down, possibly resulting in piston interfer-

ence.

Crankshaft

I valve timing waiting times

68.F (20°C) and higher 4 minutes

50-68"F(10-20°C) 11 minutes

32-5O0F(O-10°C) 30 minutes

Page 147 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

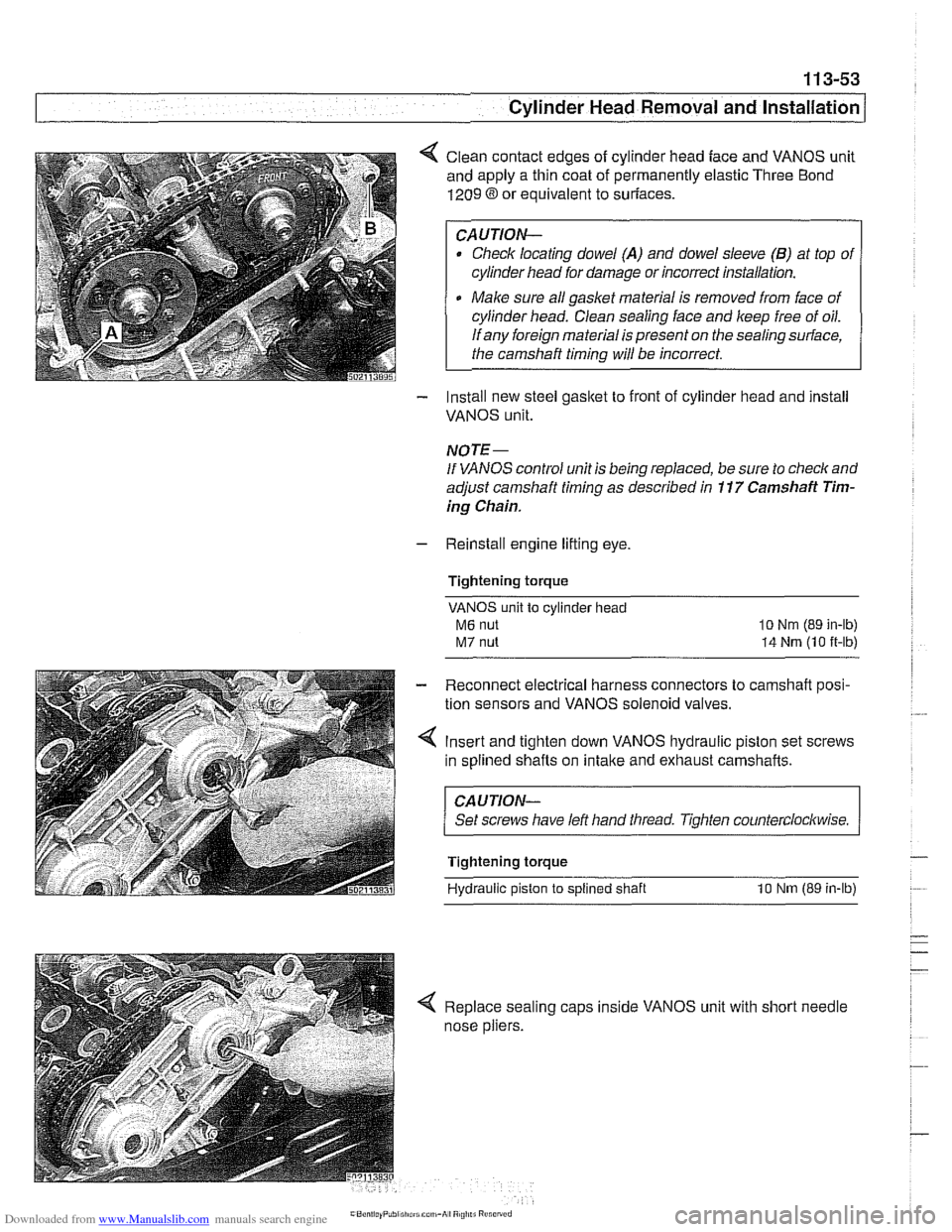

< Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of permanently elastic Three Bond

1209 8 or equivalent to suriaces.

CAUTION-

Check locating dowel (A) and dowel sleeve (B) at top of

cylinder head for damage or incorrect installation.

Make sure all gasket material is removed from face of

cylinder head. Clean sealing face and keep free of oil.

If any foreign material is present on the sealing surface,

the camshaft timing will be incorrect.

- Install new steel gasket to front of cylinder head and install

VANOS unit.

NOTE -

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in

11 7 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

Tightening torque

VANOS unit to cylinder head

M6 nut

M7 nut

lo Nm (89 in-lb)

14 Nrn (10 it-lb)

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and VANOS solenoid valves.

4 Insert and tighten down VANOS hydraulic piston set screws

in splined shafts on

intake and exhaust camshafts.

CAUJION-

Set screws have left hand tliread. Tighten counterclockwise.

Tightening torque

Hydraulic piston

to splined shaft 10 Nm (89 in-lb)

< Replace sealing caps inside VANOS unit with short needle

nose pliers.

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

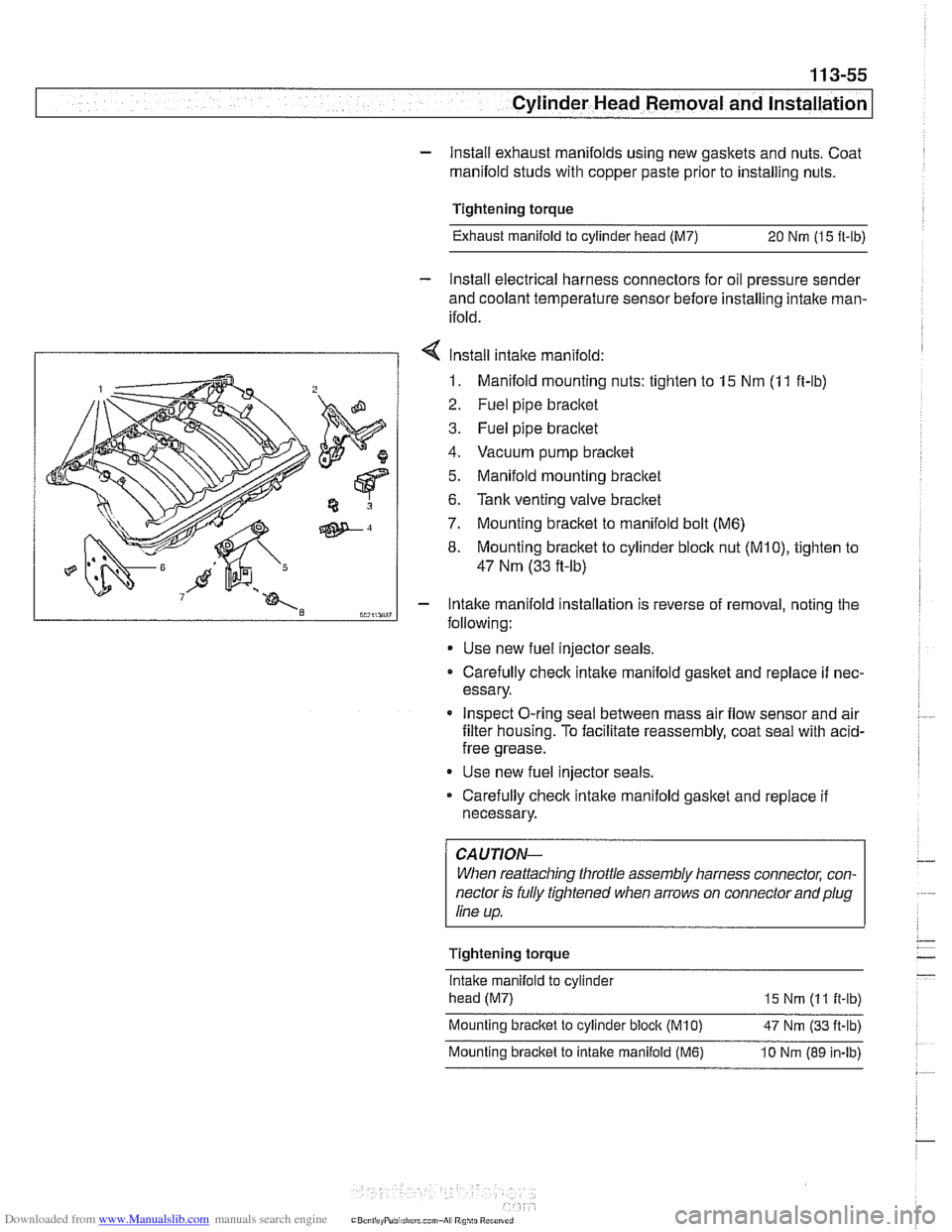

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)