HEAD LIGHT BMW 540i 1997 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

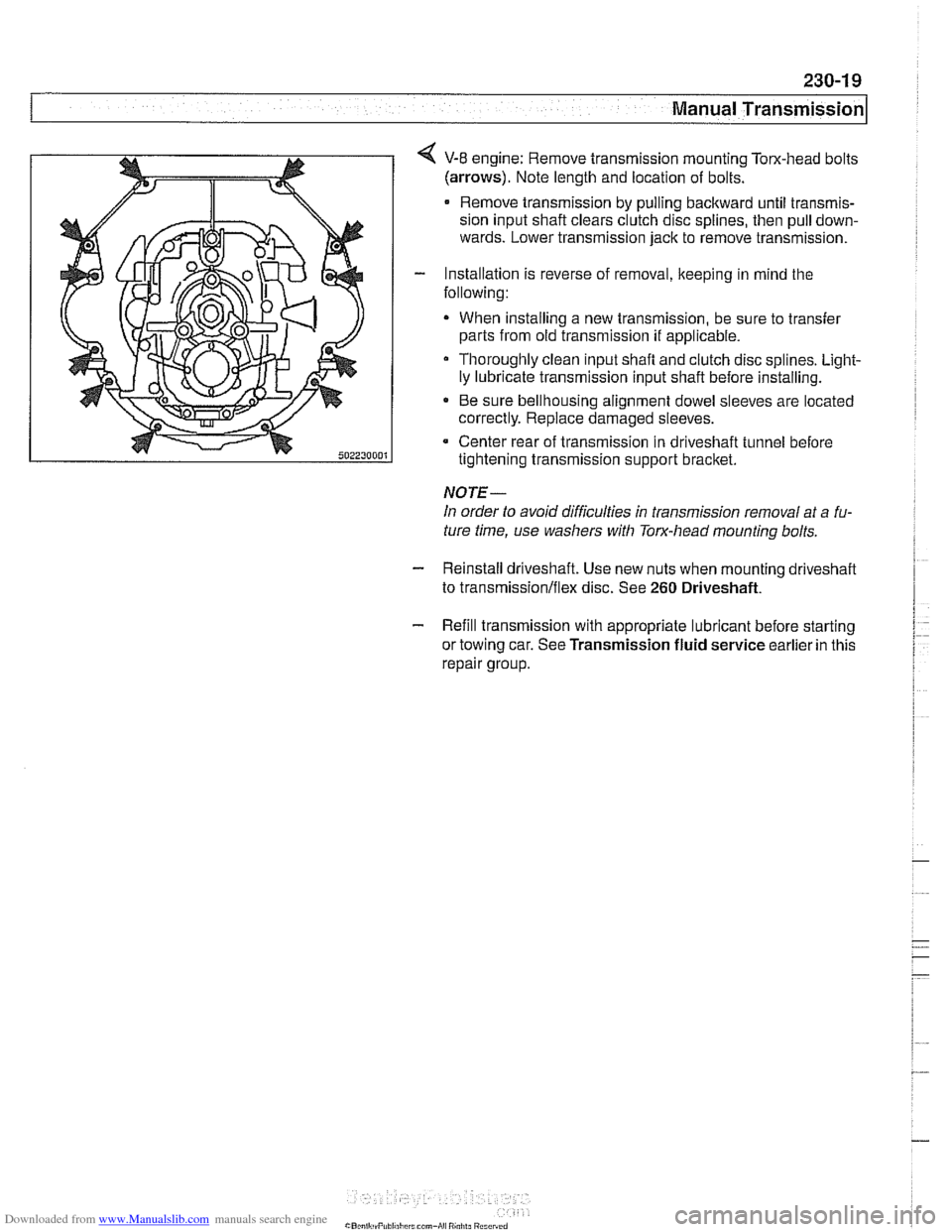

Manual Transmission

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 617 of 1002

Downloaded from www.Manualslib.com manuals search engine

Driveshaft

- Road test vehicle to check for noise or vibration

CAUTION-

Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

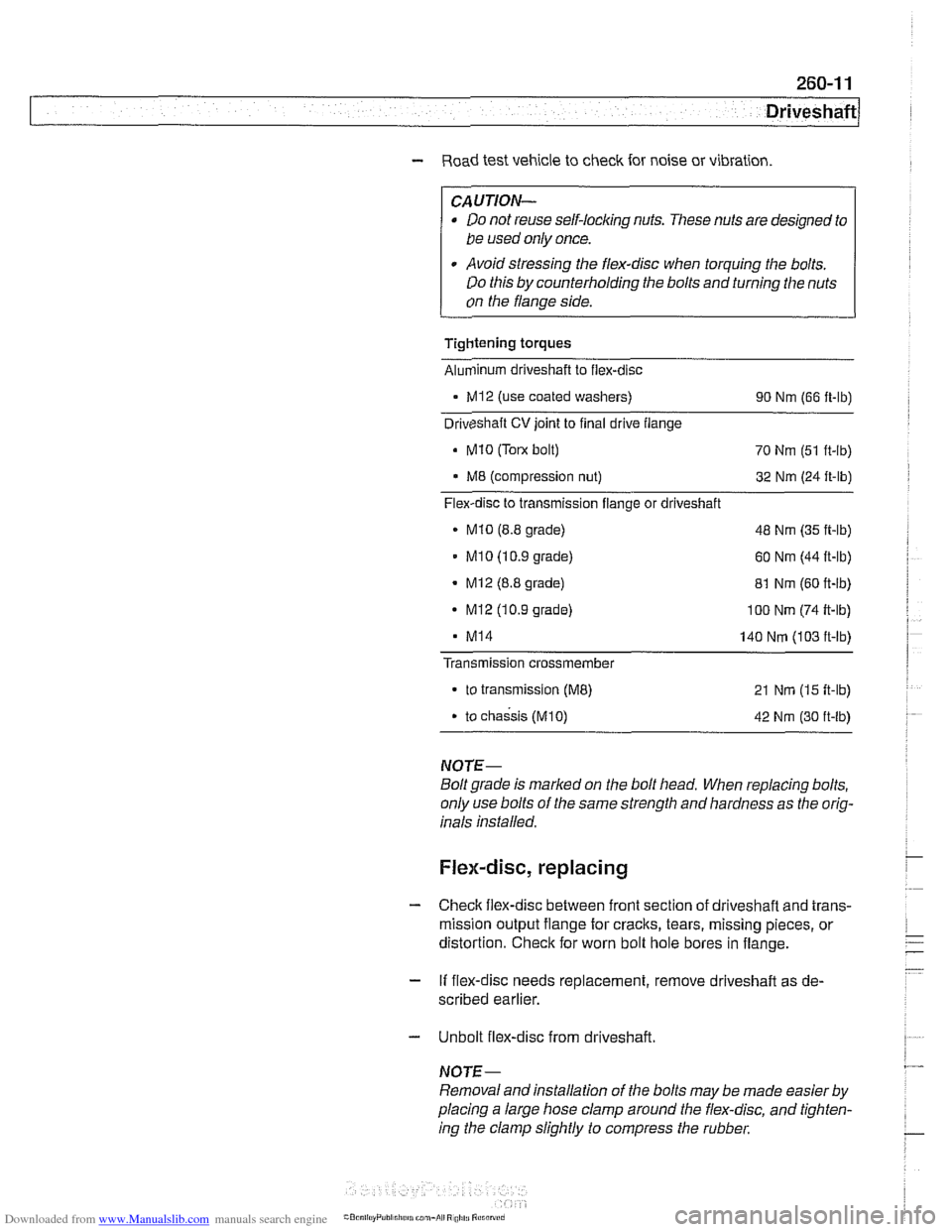

Tightening torques

Alunlinum driveshaft to flex-disc

- MI2 (use coated washers)

90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

Mi0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI 0 (1 0.9 grade) 60 Nm (44 ft-lb)

- Mi2 (8.8 grade)

81 Nm (60 ft-lb)

- MI2 (10.9 grade) I00 Nm (74 ft-lb)

MI4 140 Nm (103 ft-lb)

Transmission

crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

NOTE-

Boltgrade is marked on the bolt head. When replacing bolts,

only use bolts of the same strength and hardness as the orig-

inals installed.

Flex-disc, replacing

- Checlc flex-disc between front section of driveshafl and trans-

mission output flange for craclts, tears, missing pieces, or

distortion. Check for worn bolt hole bores in flange.

- If flex-disc needs replacement, remove driveshafl as de-

scribed earlier.

- Unbolt flex-disc from driveshaft.

NOTE-

Removal andinstallation of the bolts may be made easier by

placing a large hose clamp around the flex-disc, and tighten-

ing the clamp slightly to compress the rubber.

Page 641 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-5

Front ~uspensionl

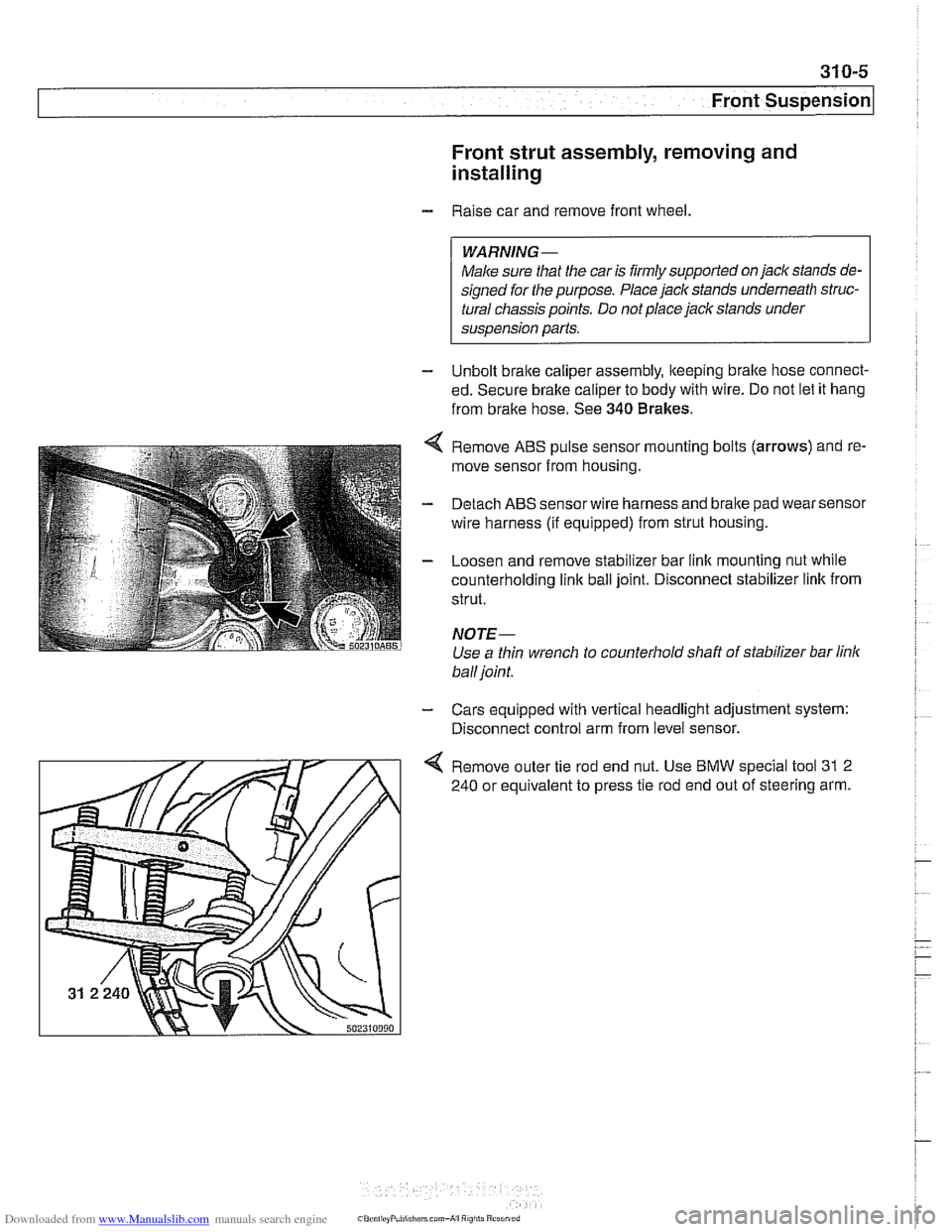

Front strut assembly, removing and

installing

- Raise car and remove front wheel.

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension

parts.

- Unbolt bralte caliper assembly, lkeeping bralte hose connect-

ed. Secure brake caliper to body with wire. Do not let it hang

from brake hose. See

340 Brakes.

Remove ABS pulse sensor mounting bolts (arrows) and re-

move sensor from housing.

Detach ABS sensor wire harness and bralte pad wear sensor

wire harness (if equipped) from strut housing.

Loosen and remove stabilizer bar link mounting nut while

counterholding

link ball joint. Disconnect stabilizer link from

strut.

NOTE-

Use a thin wrench to counterhold shaft of stabilizer bar link

ball joint.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

4 Remove outer tie rod end nut. Use BMW special tool 31 2

240 or equivalent to press tie rod end out of steering arm.

Page 648 of 1002

Downloaded from www.Manualslib.com manuals search engine

/~ront Susaension

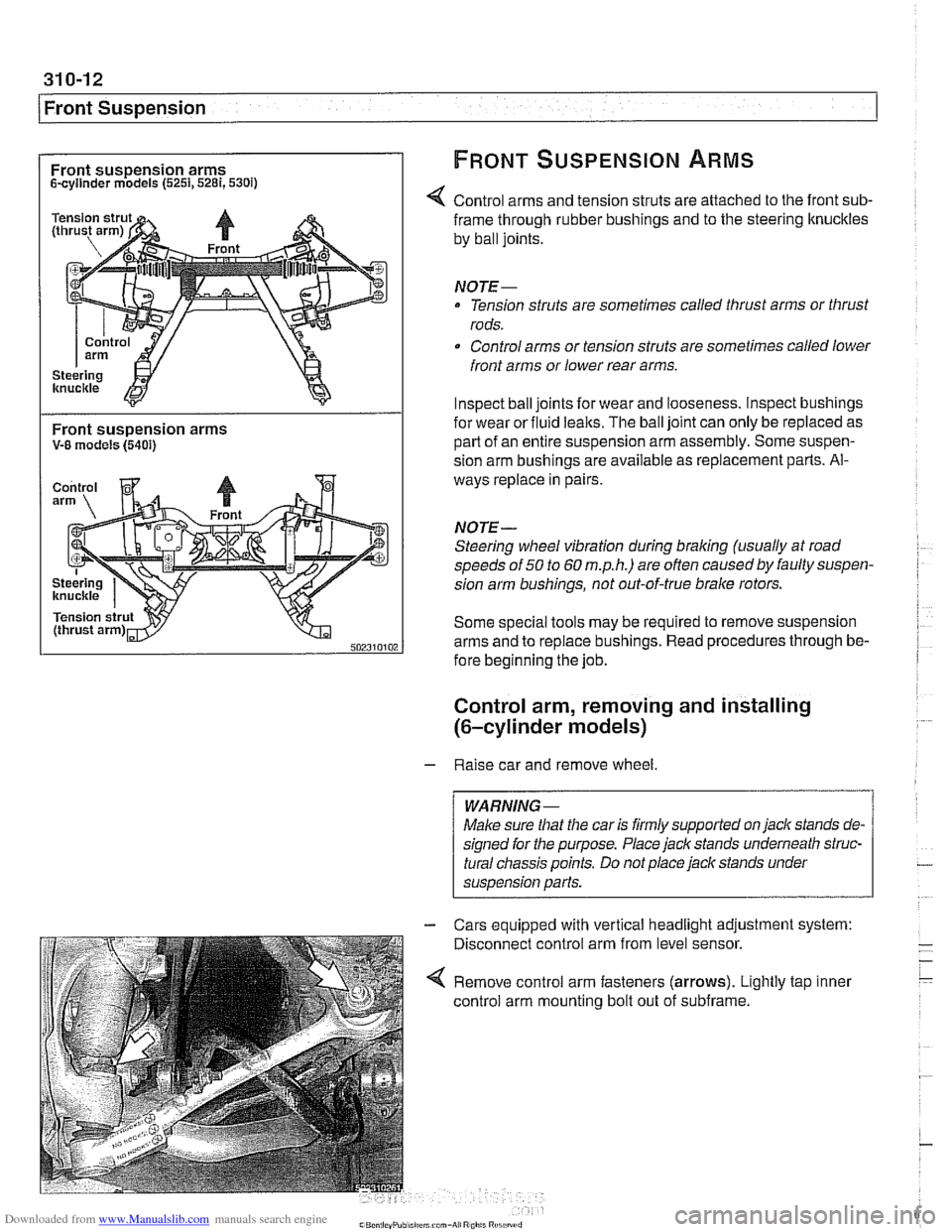

Front suspension arms FRONT SUSPENSION ARMS

Scyllnder models (5251,5281,530i)

Control arms and tension struts are attached to the front sub-

Front suspension arms V-8 models (5401)

frame through rubber bushings and to the steering ltnuckles

by ball joints.

NOTE-

Tension struts are sometimes called thrust arms or thrust

rods.

Control arms or tension struts are sometimes called lower

front arms or lower rear arms.

Inspect ball joints for wear and looseness. lnspect bushings

for wear or fluid

lealts. The ball joint can only be replaced as

part of an entire suspension arm assembly. Some suspen-

sion arm

bushinas are available as re~lacement Darts. Al-

ways replace in pairs

NOTE-

Steering wheel vibration during braking (usually at road

speeds of

50 to 60 m.p.h.) are often causedby faulty suspen-

sion arm bushings, not out-of-true brake rotors.

Some special tools may be required to remove suspension

arms and to replace bushings. Read procedures through be-

fore beginning the job.

Control arm, removing and installing

(6-cylinder models)

- Raise car and remove wheel

Male sure

that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension

parfs.

Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

Remove control arm fasteners (arrows). Lightly tap inner

control arm mounting bolt out of subframe.

Page 649 of 1002

Downloaded from www.Manualslib.com manuals search engine

Front Suspension

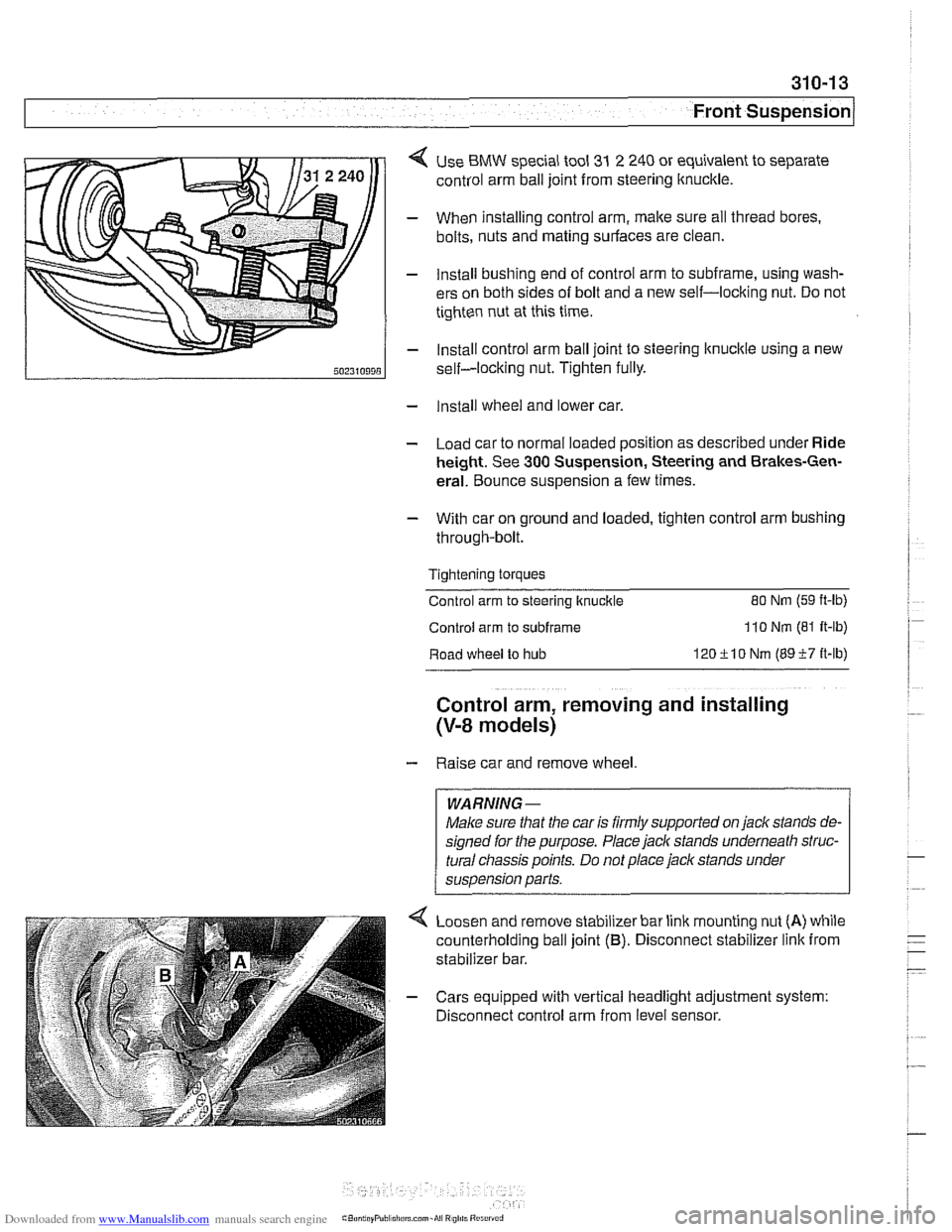

< Use BMW special tool 31 2 240 or equivalent to separate

control arm ball joint from steering ltnuckle.

- When installing control arm, make sure all thread bores.

bolts, nuts and mating surfaces are clean.

- Install bushing end of control arm to subframe, using wash-

ers on both sides of bolt and a new self-locking nut. Do not

tighten nut at this time.

- Install control arm ball joint to steering lknucltle using a new

self-locking nut. Tighten fully.

- Install wheel and lower car.

- Load car to normal loaded position as described under Ride

height. See

300 Suspension, Steering and Brakes-Gen-

eral. Bounce suspension a few times.

- With car on ground and loaded, tighten control arm bushing

through-bolt.

Tightening torques

Control arm to steering ltnuckle

80 Nm (59 ft-lb)

Control arm to subframe 110 Nm (81 It-lb)

Road wheel to hub 120ilO Nm (8957 it-lb)

Control arm, removing and installing

(V-8 models)

- Raise car and remove wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural

cliassis points. Do not place jack stands under

suspension parts.

Loosen and remove stabilizer bar link mounting nut

(A) while

counterholding ball joint

(B). Disconnect stabilizer link from

stabilizer bar.

- Cars equipped with vertical headlight adjustment system:

Disconnect control arm from level sensor.

Page 797 of 1002

Downloaded from www.Manualslib.com manuals search engine

Body shell

Exterior and aerodynamics

Crash behavlor -frontal impact

-side impact

Body

-rear impact Structural body components -rigidity

-rollover -strength -vibrations -acoustics

Bumpers compartment lid -bendable Seets,.steerlng system .dents -vibrations bars -vibration patterns

Fenders -aerodvnamic

With its traditional styling features, such as the ltidney grille.

circular headlights behind a glass cover (for reasons of

streamlining), and the

"kiclt" in the rear most roof pillar (C-pil-

lar), the E39 can be immediately recognized as a BMW.

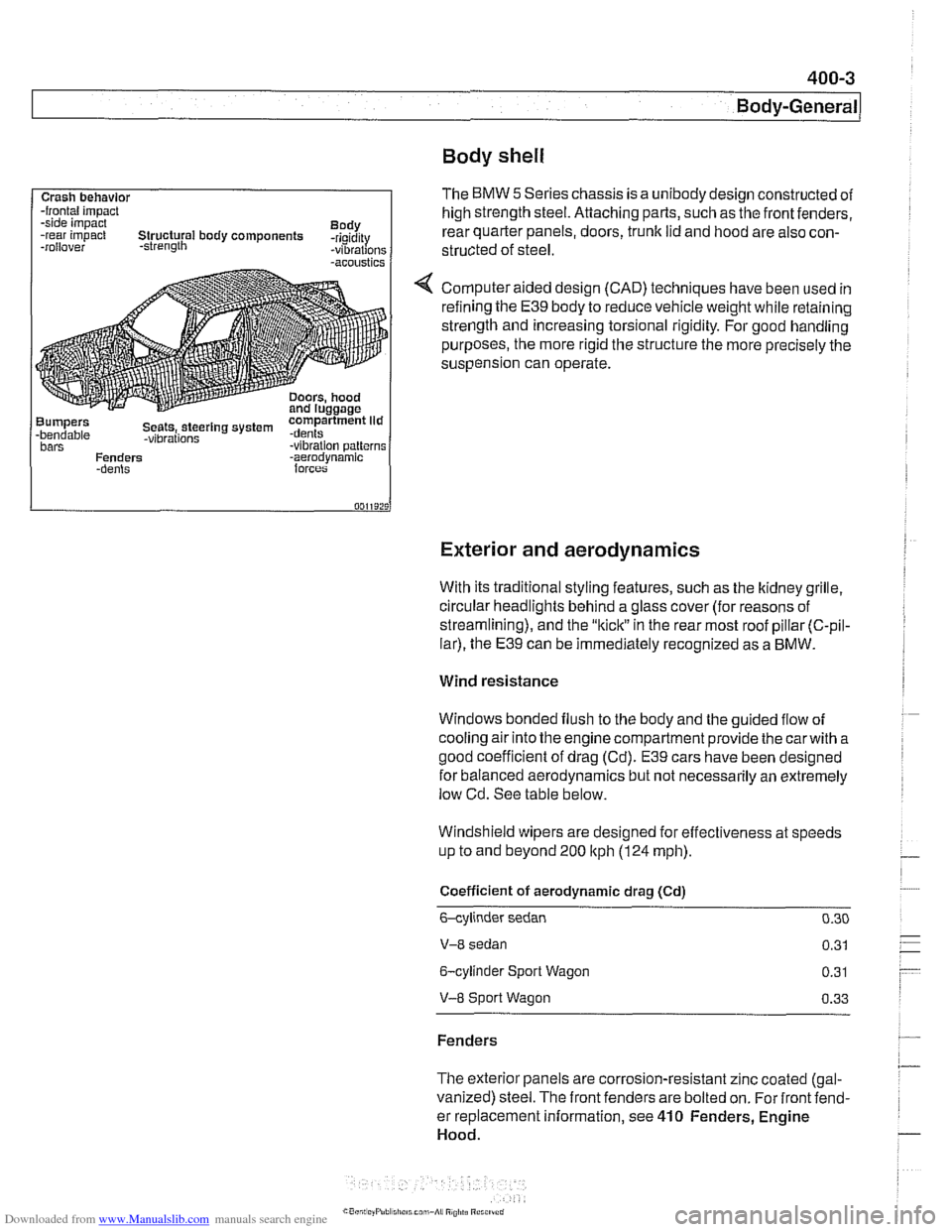

The BMW 5 Series chassis is a unibody design constructed of

high strength steel. Attaching parts, such as the front fenders,

rear quarter panels, doors,

trunk lid and hood are also con-

structed of

steel.

Computer aided design (CAD) techniques have been used in

refining the

E39 body to reduce vehicle weight while retaining

strength and increasing torsional rigidity. For good handling

purposes, the more rigid the structure the more precisely the

suspension can operate.

Wind resistance

Windows bonded flush to the body and the guided flow of

cooling air into the engine compartment provide the

carwith a

good coefficient of drag (Cd).

E39 cars have been designed

for balanced aerodynamics but not necessarily an extremely

low Cd. See table below.

Windshield wipers are designed for effectiveness at speeds

up to and beyond 200

ltph (124 mph).

Coefficient of aerodynamic drag (Cd)

6-cylinder sedan 0.30

V-8 sedan 0.31

6-cylinder Sport Wagon 0.31

V-8 Sport Wagon 0.33

Fenders

The exterior panels are corrosion-resistant zinc coated (gal-

vanized) steel. The front fenders are bolted on. For front fend-

er replacement information, see

410 Fenders, Engine

Hood.

Page 802 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-8

Body-General

Airbags

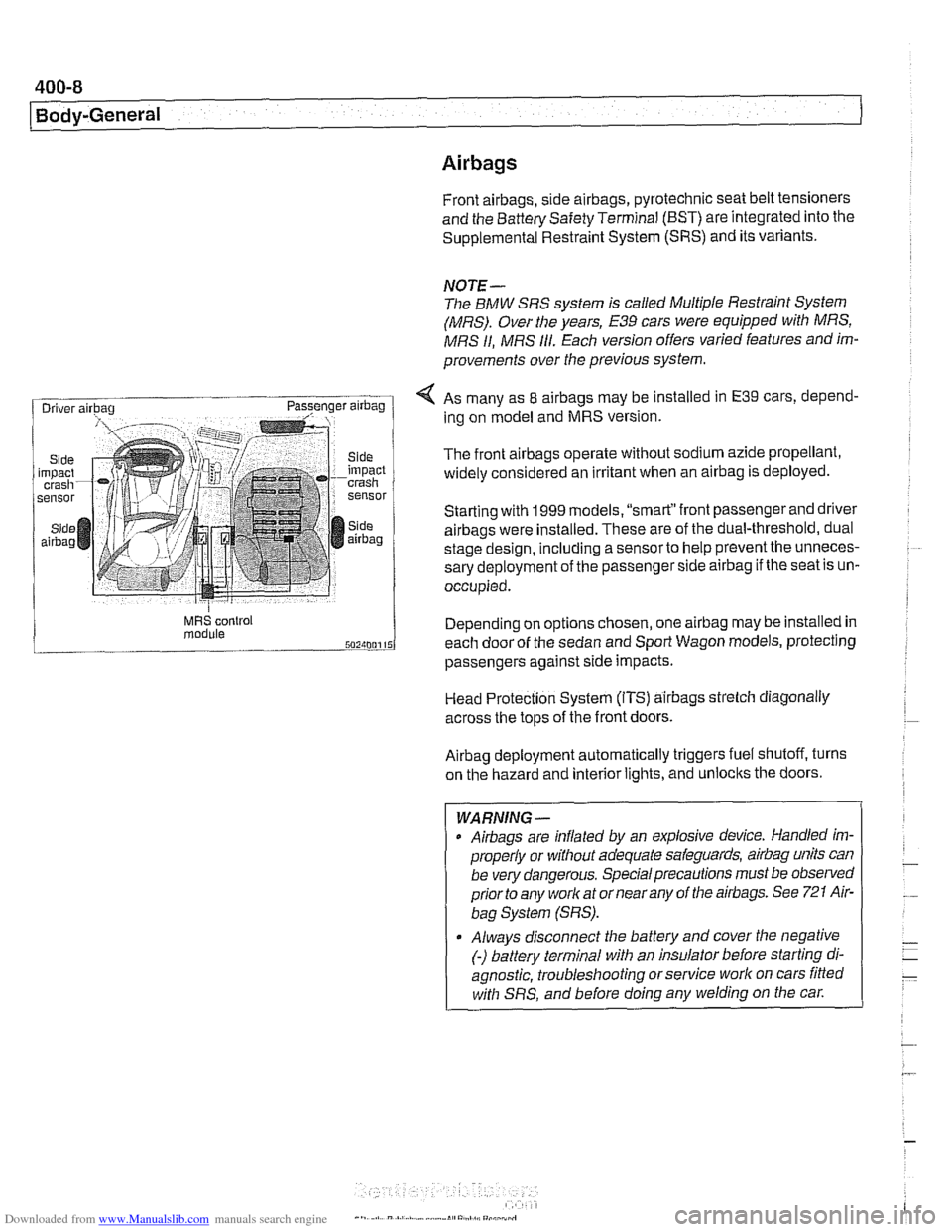

Front airbags, s~de a~rbags, pyrotechnic seat belt tensioners

and the Battery Safety Terminal (BST) are integrated into the

Supplemental Restraint System (SRS) and its variants.

NOTE-

The BMW SRS system is called Multiple Restra~nt System

(MRS). Over the years,

E39 cars were equipped with MRS,

MRS

11, MRS 111. Each version offers varied features and im-

provements over the previous system.

< As many as 8 airbags may be installed in E39 cars, depend-

ing on model and MRS version.

The front

airbags operate without sodium azide propellant,

widely considered an irritant when an

airbag is deployed.

Starting with

1999 models. "smart"front passenger and driver

airbags were installed. These are of the dual-threshold, dual

stage design, including a

sensorto help prevent the unneces-

sary deployment of the passenger side

airbag if the seat is un-

occupied.

MRS control Depend~ng on options chosen, one airbag may be installed in module each door of the sedan and Sport Wagon models, protecting

passengers against

s~de impacts.

Head Protection System (ITS)

airbags strelch diagonally

across the tops of the front doors.

Airbag deployment automatically triggers fuel shutoff, turns

on the hazard and interior lights, and unlocks the doors.

- -

WARNING -

Airbags are inflated by an explosive device. Handled im-

properly or without adequate safeguards,

airbag units can

be very dangerous. Special precautions must be observed

prior to any worlc at or near any of the airbags. See

721 Air-

bag System (SRS).

Always disconnect the battery and cover the negative

(-) battery terminal with an insulator before starting di-

agnostic, troubleshooting or service work on cars fitted

with SRS, and before doing any welding on the

car.

Page 809 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-3

Fenders, Engine ~oodl

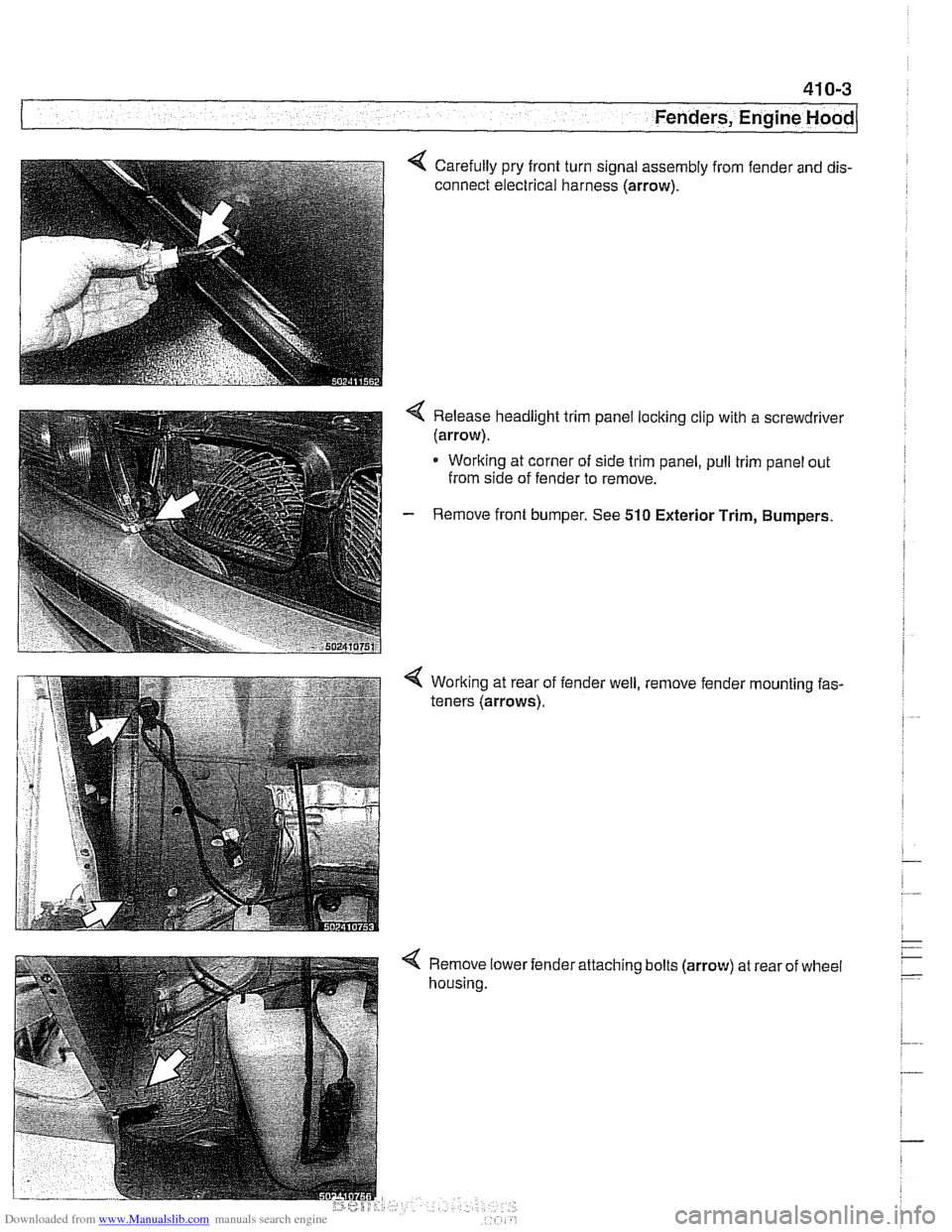

Carefully pry front turn signal assembly from fender and dis-

connect electrical harness (arrow).

< Release headlight trim panel locking clip with a screwdrivel

(arrow).

* Working at corner of side trim panel, pull trim panel out

from side of fender to remove.

- Remove front bumper. See 510 Exterior Trim, Bumpers.

Working at rear of

teners (arrows). fender

well, , remove

fender

'mounting fas-

< Remove lower

housing. 'attaching

bolts

(arrow) at rear of wheel

Page 817 of 1002

Downloaded from www.Manualslib.com manuals search engine

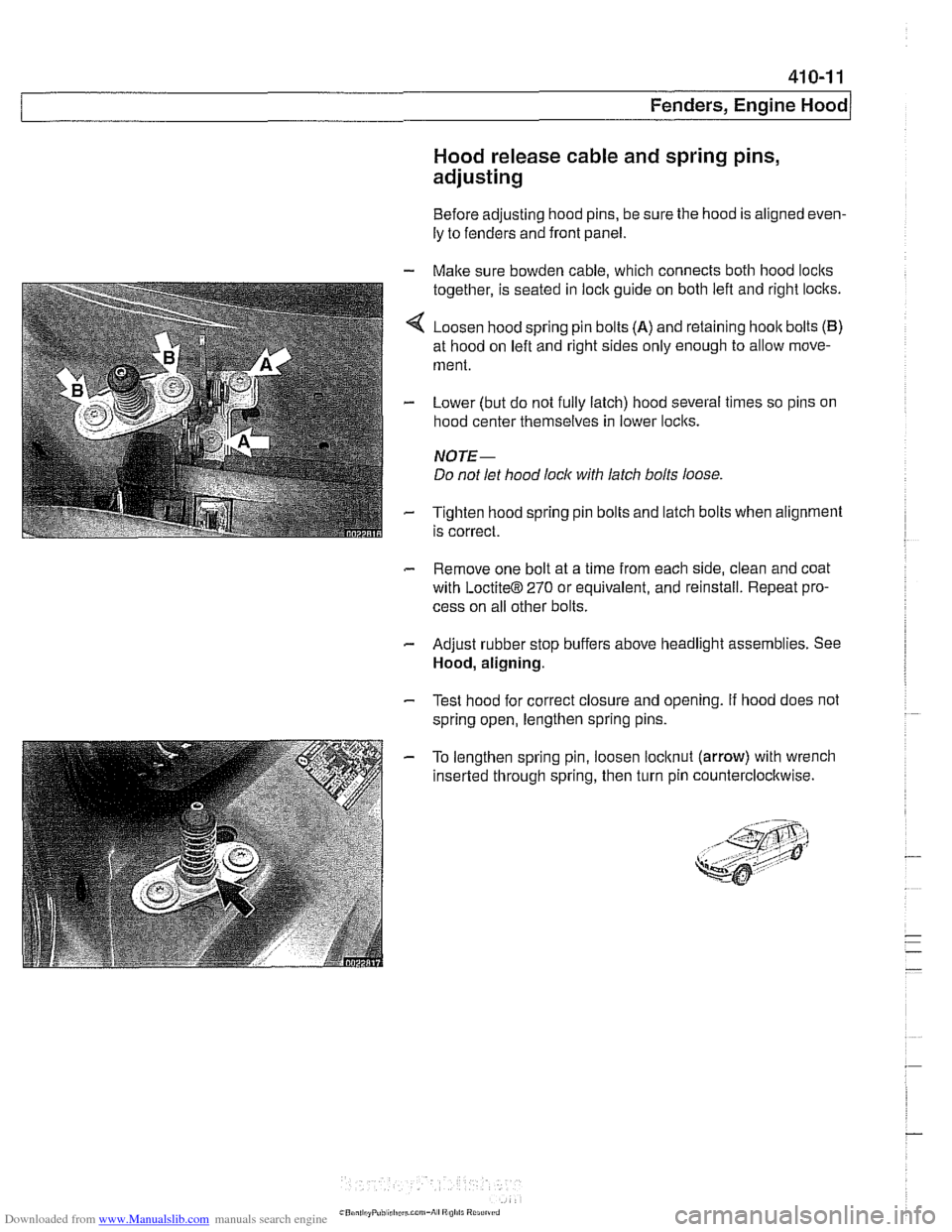

Fenders, Ensine HOO~I

Hood release cable and spring pins,

adjusting

Before adjusting hood pins, be sure the hood is aligned even-

ly to fenders and front panel.

- Malte sure bowden cable, which connects both hood loclts

together, is seated in lock guide on both left and right loclts.

4 Loosen hood spring pin bolts (A) and retaining hoolt bolts (B)

at hood on left and right sides only enough to allow move-

ment.

- Lower (but do not fully latch) hood several times so pins on

hood center themselves in lower loclts.

NOTE-

Do not let hood lock with latch bolts loose

- Tighten hood spring pin bolts and latch bolts when alignment

is correct.

- Remove one bolt at a time from each side, clean and coat

with

LoctiteB 270 or equivalent, and reinstall. Repeat pro-

cess on all other bolts.

- Adjust rubber stop buffers above headlight assemblies. See

Hood, aligning.

- Test hood for correct closure and opening. If hood does not

spring open, lengthen spring pins.

- To lengthen spring pin, loosen locltnut (arrow) with wrench

inserted through spring, then turn pin counterclocltwise.

Page 851 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 0 Exterior Trim. Bumpers

General ........................... .51 0.2 Exterior Trim ...................... 51 0-1 3

Outside Rear View Mirrors

Outside mirror glass. replacing

Outside mirror housing.

removing and installing

......

Outside mirror assemblv .

BMW emblem. removing and installing ... 510-13 .......... .51 0.2

Body side molding. replacing ........... 51 0-13 .......... .51 0.2

Radiator grill. removing and installing .... 51 0-1 4

Headlight housing trim panel.

.......... .51 0.3

removing and installing ............... 510-14 . .

removing and installing ................ .51 0.4

Bumpers ......................... .51 0.5

Front bumper assembly

............... .51 0.6

Front bumper, removing and installing

.... .51 0.7

Front bumper impact absorber. replacing

. .51 0.8

Rear bumper assembly ............... .51 0.9

Rear bumper. removing and installing

... .51 0.10

Rear bumper impact absorber. replacing

. .51 0.1 1

Front bumper height. adjusting

......... .51 0.12