Crankshaft BMW 540i 1997 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 540i, Model: BMW 540i 1997 E39Pages: 1002

Page 265 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

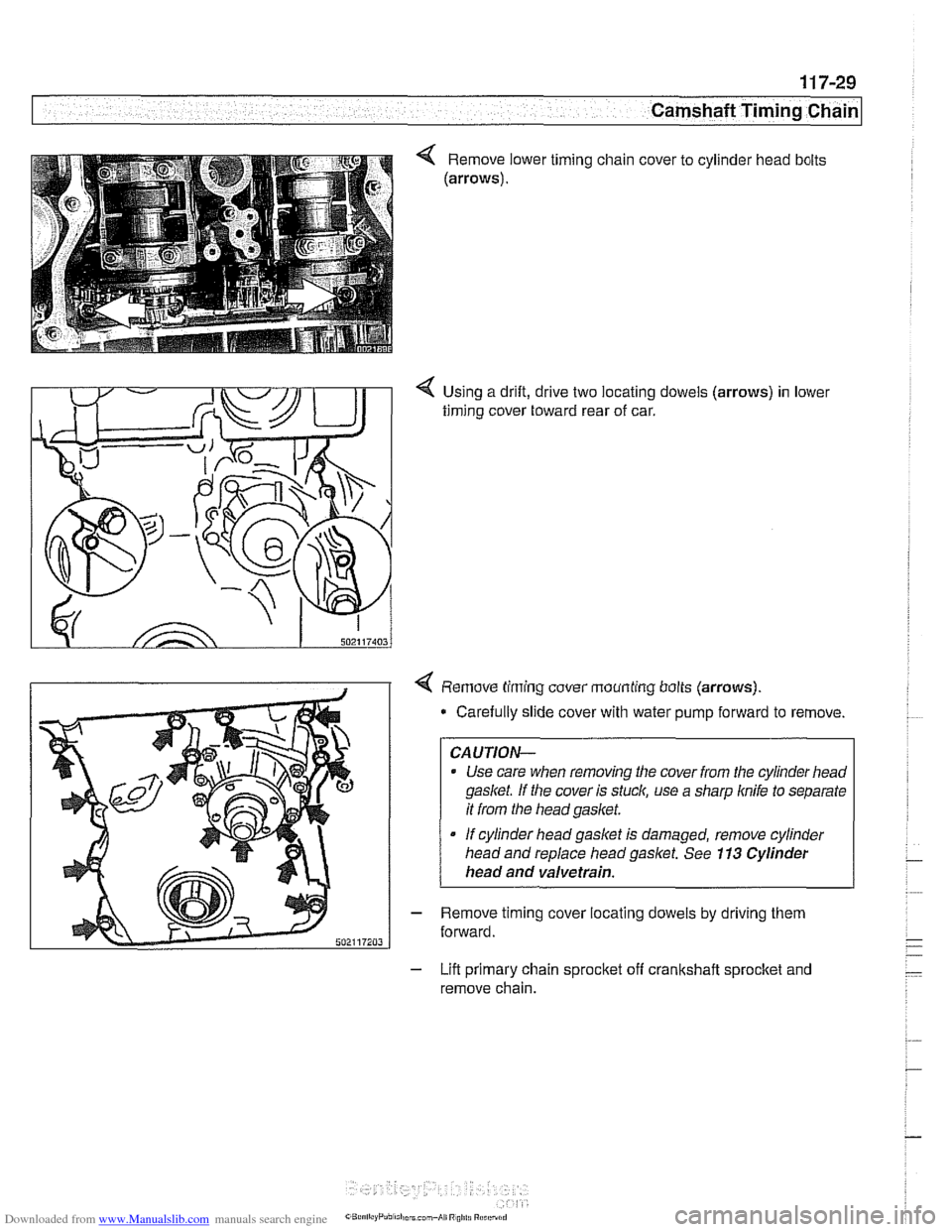

Using a drift, drive two locating dowels (arrows) in lower

timing cover toward rear of car.

4 Remove timing cover mounting bolts (arrows).

* Carefully slide cover with water pump forward to remove

CAUTION-

Use care when removing the cover from the cylinder head

gasket If the cover is stuck, use a sharp knife to separate

it from the head gasket.

If cylinder head gasket is damaged, remove cylinder

head and replace head

gaslet. See 113 Cylinder

head and valvetrain.

- Remove timing cover locating dowels by driving them

forward.

- Lift primary chain sprocket off crankshaft sprocket and

remove chain.

Page 266 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-30

I Camshaft Timing Chain

Timing chain, installing

(M52 engine)

CAUTION-

The procedure outlined below assumes that the camshafts

and the crankshaft are

lockedin the TDCposition with BMW

special tools.

- Inspect timing chain and sprocltets and guide rails for wear.

Replace worn parts.

NOTE-

If any of the sprockets are being replaced due to wear, the

chain should also be replaced.

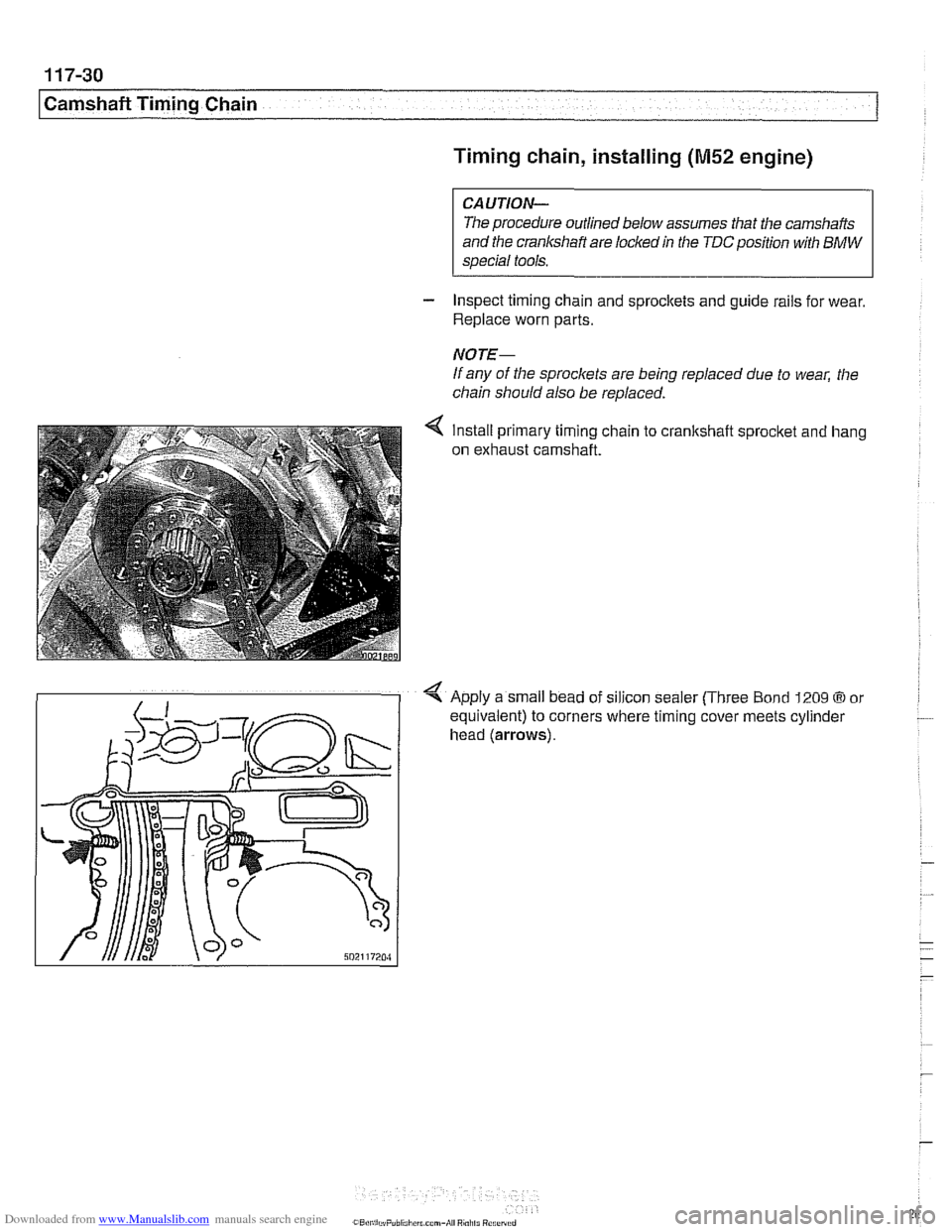

Install primary timing chain

on exhaust camshaft. to crankshait

sprocket and hang

4 Apply a small bead oi silicon sealer (Three Bond 1209 @or

equivalent) to corners where tim~ng cover meets cylinder

head

(arrows).

Page 267 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

Tap locating dowels into cover until they protrude 2 to 3 mm

from sealing surface.

- Using new gaskets, install lower timing chain cover:

Tap cover into position to engage dowels.

Install timing chain cover fasteners and tighten to

5 Nm (44

in-lb).

Drive dowels in flush to front of cover.

. Tighten cover mounting bolts alternately and in stages.

Install cylinder head to timing chain cover fasteners and

tighten.

Tightening torques Lower timing chain cover to block

M7 15 Nm (1 1 ft-lb)

ME 20 Nm (15 it-lb)

- Replace front crankshaft radial seal. See Crankshaft oil

seal, front, replacing

(M52 engine).

Install engine oil pan using

a new gasket. See 119 Lubrica-

tion System.

Mount primary timing chain sprocket to primary

cha~n so that

arrow on sprocket faces up. Mount sprocket to camshafl so

that tapped holes in camshaft are on left side of elongated

holes in sprocket.

4 Install adjustable timing chain tensioner (BMW special tool

11 4 220). Thread tool in finger tight until slack is removed

from chain.

NOTE-

BMW special tool 11 4 220 is an adjustable timing chain ten-

sioner that simulates the function of the hydraulic tensioner.

- Check that elongated holes in primary sprocket are centered

to bolt holes in camshafl and chain is free of slack.

- Install secondary timing chain guide and secondary chain

tensioner. Tighten mounting bolts (tensioner remains

locited

down).

F81.,,l,ryT-iib.l>nii,:oni-Aii Ri"ilti R

Page 268 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Chain 1

- Install cylinder identification trigger plate to front of intake

camshaft.

- Install spacer to front of intake camshaft

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

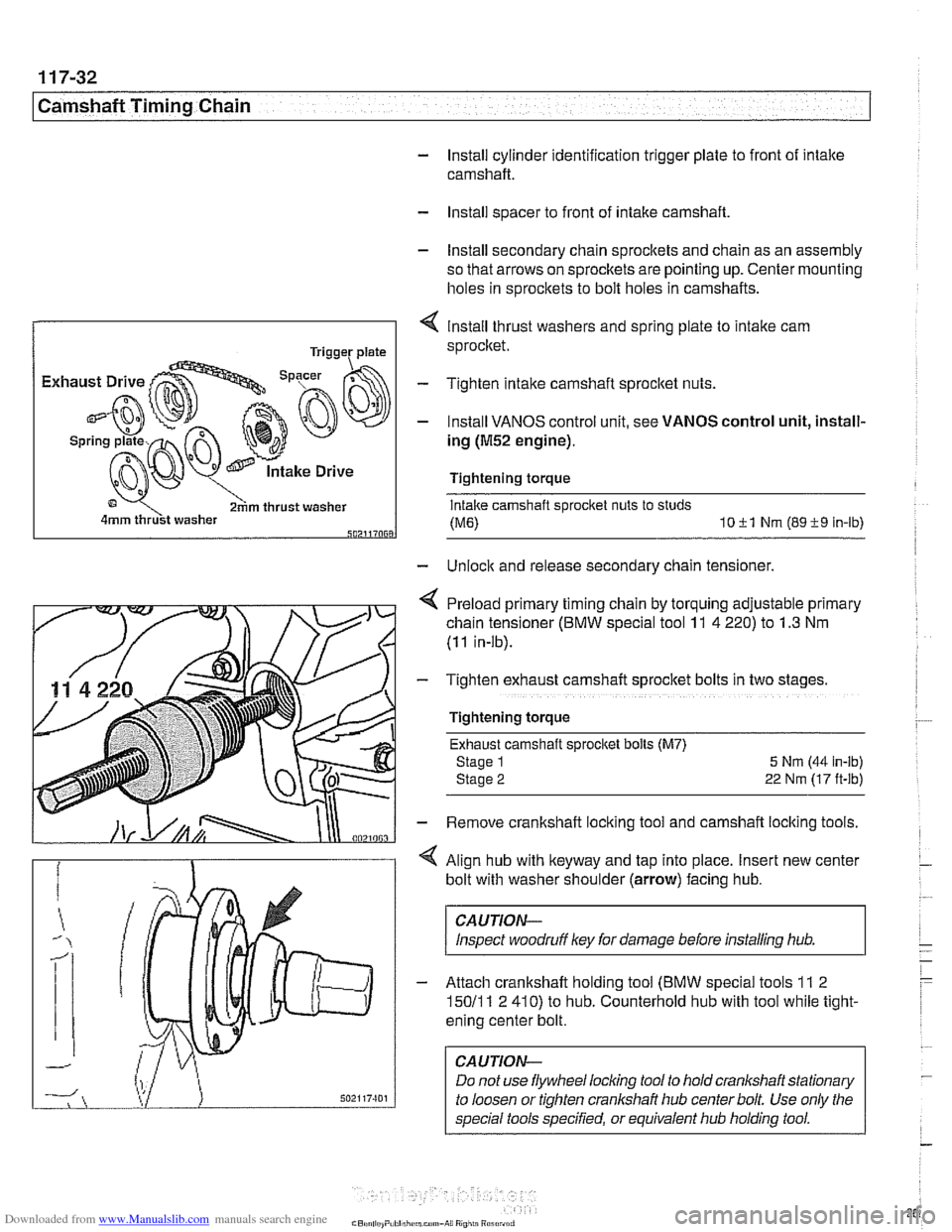

4 lnstall thrust washers and spring plate to intake cam

sprocket.

Tighten intake camshaft sprocket nuts.

- Install VANOS control unit, see VANOS control unit, install-

ing

(M52 engine).

Tightening torque

Intake camshaft sprocket nuts to studs

(ME) 1011 Nm (8919 In-lb) 502117068

- Unlock and release secondary chain tensioner,

4 Preload primary timing chain by torquing adjustable primary

chain tensioner (BMW special tool

11 4 220) to 1.3 Nm

(11 in-lb).

- Tighten exhaust camshaft sprocket bolts in two stage

Tightening torque Exhaust camshaft sprocket bolls (M7)

Stage 1

5 Nrn (44 in-lb)

Stage

2 22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tools.

< Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder (arrow) facing hub.

CAUTION-

Inspect woodruff ley for damage before installing hub.

- Attach crankshaft holding tool (BMW special tools 11 2

15011 1 2 410) to hub. Counterhold hub with tool while tight-

ening center bolt.

CAUTION-

Do not use flywheel locling tool to hold crankshaft stationary

to loosen or tighten

cranlshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

Page 269 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- Camshaft Timing Chain -- -

Tightening torque

Vibration damper hub to crankshaft

410 Nm (300 ft-lb)

4 Install cranltshaft hub and vibration damper while aligning

locating hole (arrow) in damper with dowel pin in hub.

Tightening torque

Vibration damper and

pulley to

cranltshaft hub

22 Nm (17 ft-lb)

- Turn engine over by hand in direction of rotation at least two

full rotations. Reinstall camshaft and crankshaft locking

toois

to recheck engine timing. Remove locking tools if no faults

are found.

- Remove BMW special tool 11 3 390 (dummy tensioner) from

side of cyiinder head.

- Install primary chain tensionerso that cutout in tensioner pis-

ton engages chain rail.

Tightening torque

Timing chain tensioner to tensioner sleeve

70 Nm (52 ft-ib)

- Install cylinder head cover mounting studs, camshaft cover,

and cylinder head cover.

Tightening torque Cylinder head cover to cyiinder head

M6 nut 10 Nm (89 in-lb)

MB bolt 22 Nm (17 ft-lb)

- installation of remaining parts is reverse of removal, noting

the following:

When installing thermostat, make sure arrow or vent hole

faces up, if applicable.

Refill cooling system as described in

170 Radiator and

Cooling System.

Fill engine with oil and install new

oil filter as described in

020 Maintenance.

Tightening torque Upper timing chain cover to cylinder head

M6 nut 10 Nm (89 in-lb)

MB bolt 22 Nm (17 ft-lb)

VANOS oil supply pipe to VANOS control

unit banjo bolt

32 Nm (24 ft-ib)

Page 275 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-39

Camshaft Timing Chain

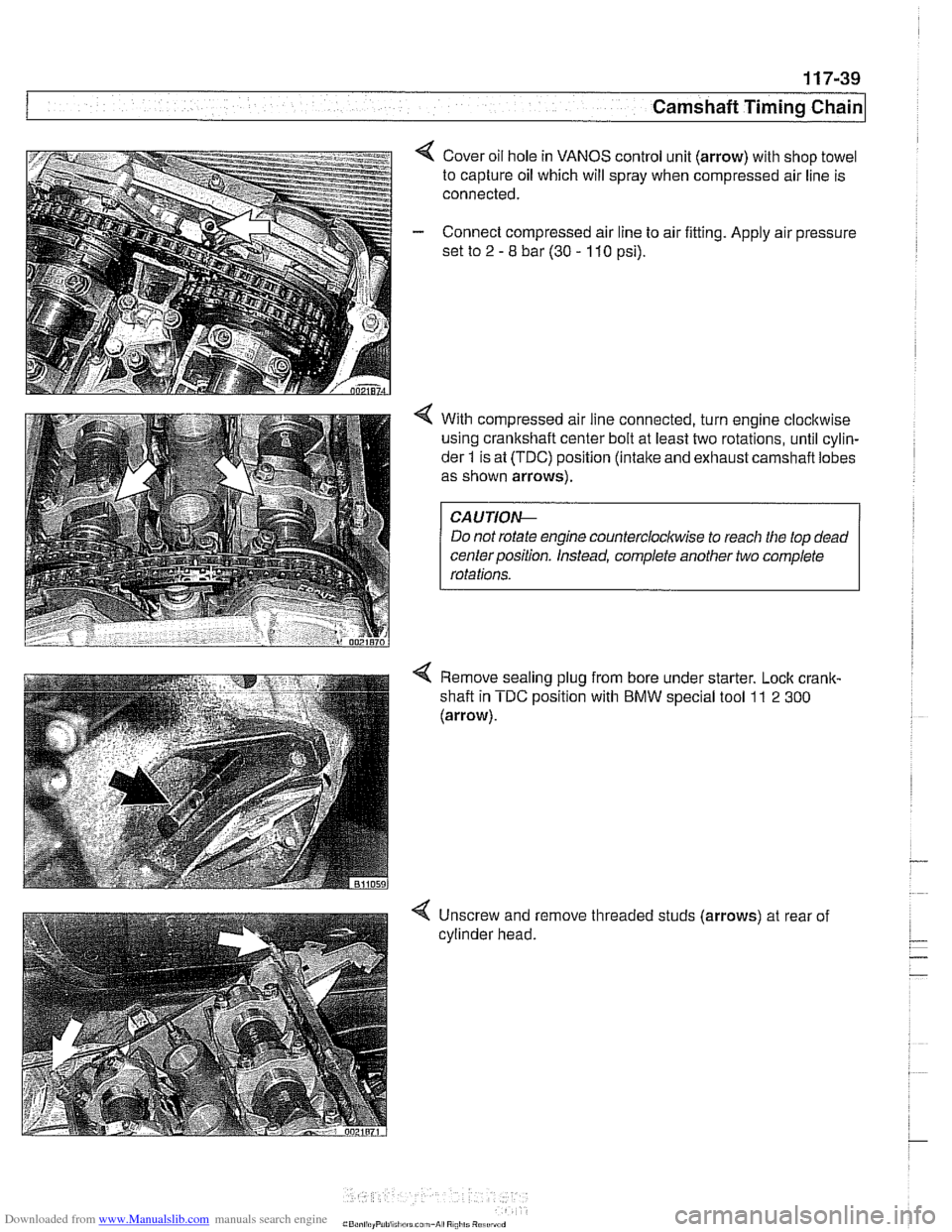

4 Cover oil hole in VANOS control unit (arrow) with shop towel

to capture oil which will spray when compressed air line is

connected.

- Connect compressed air line to air fitting. Apply air pressure

set to

2 - 8 bar (30 - 110 psi).

4 With compressed air line connected, turn engine clocltwise

using crankshaft center bolt at least two rotations, until cylin-

der

1 is at (TDC) position (intake and exhaust carnshafl lobes

as shown arrows).

Do not rotate engine

countercloclwise to reach the top dead

centerposition. Instead, complete another two complete

Remove sealing plug from bore under starter. Lock

crank-

shafl in TDC position with BMW special tool 11 2 300

(arrow).

-

4 Unscrew and remove threaded studs (arrows) at rear of

cylinder head.

Page 284 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Camshaft Timing Chain - --

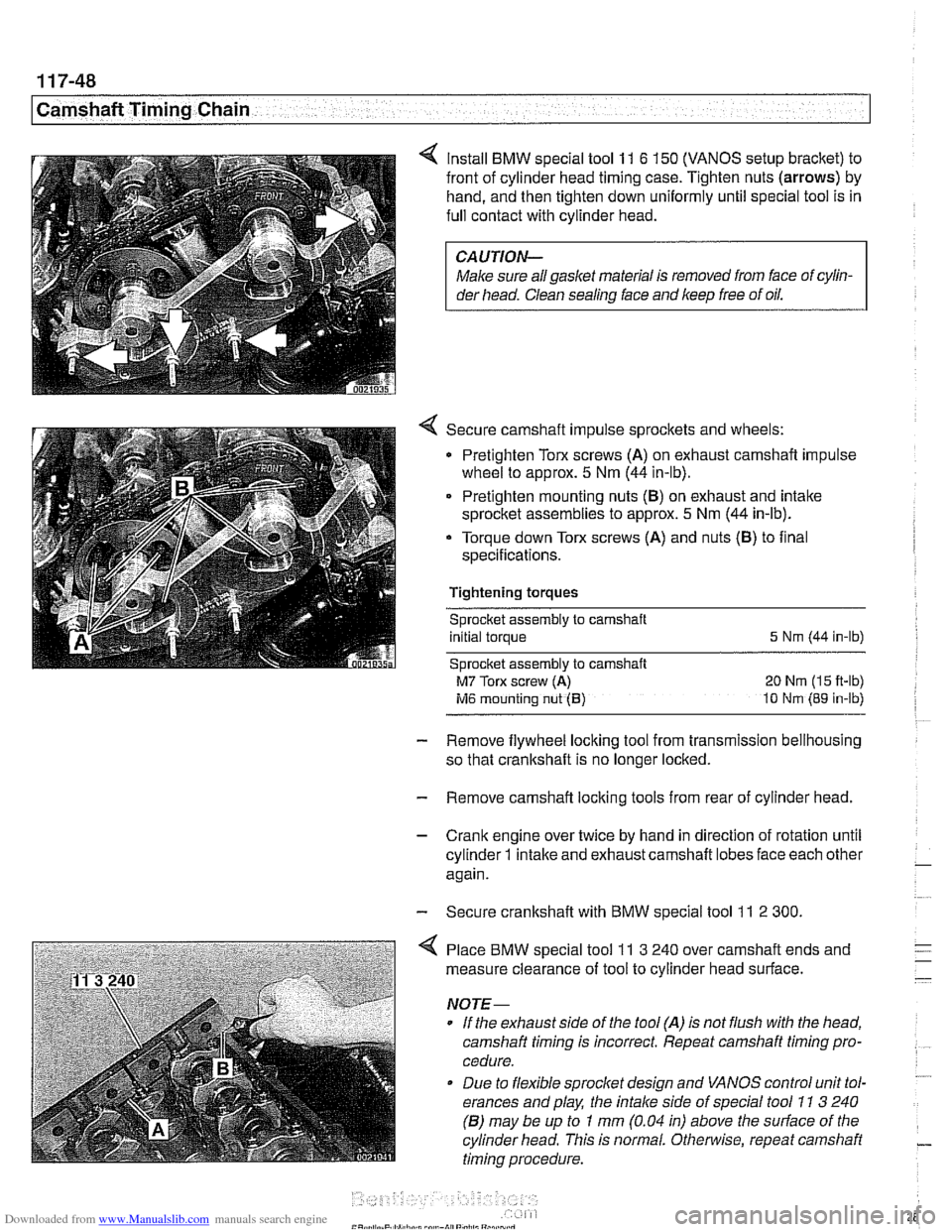

Install BMW special tool 11 6 150 (VANOS setup bracket) to

front of cylinder head timing case. Tighten nuts

(arrows) by

hand, and then tighten down uniformly until special tool is in

full contact with cylinder head.

CAUTION-

Male sure all gasket material is removed from face of cylin-

der head. Clean

sealins face and keep free of oil.

Secure camshaft impulse sprockets and wheels:

Pretighten Torx screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Pretighten mounting nuts

(B) on exhaust and intake

sprocket assemblies to approx.

5 Nm (44 in-lb).

- Torque down Torx screws (A) and nuts (8) to flnal

specifications.

Tightening torques Sprocket assembly

to camshaft

initial torque

5 Nm (44 in-lb)

Sprocket assembly to camshaft

M7 Torx screw (A) 20 Nm (15 fl-lb)

ivl6 mounting nut (B) 10 tdm (89 in-lb)

- Remove flywheel locking tool from transmission bellhousing

so that crankshaft is no longer locked.

- Remove camshaft locking tools from rear of cylinder head.

- Crank engine over twice by hand in direction of rotation until

cylinder

1 intake and exhaust camshaft lobes face each other - again.

- Secure crankshaft with BMW special tool 11 2 300.

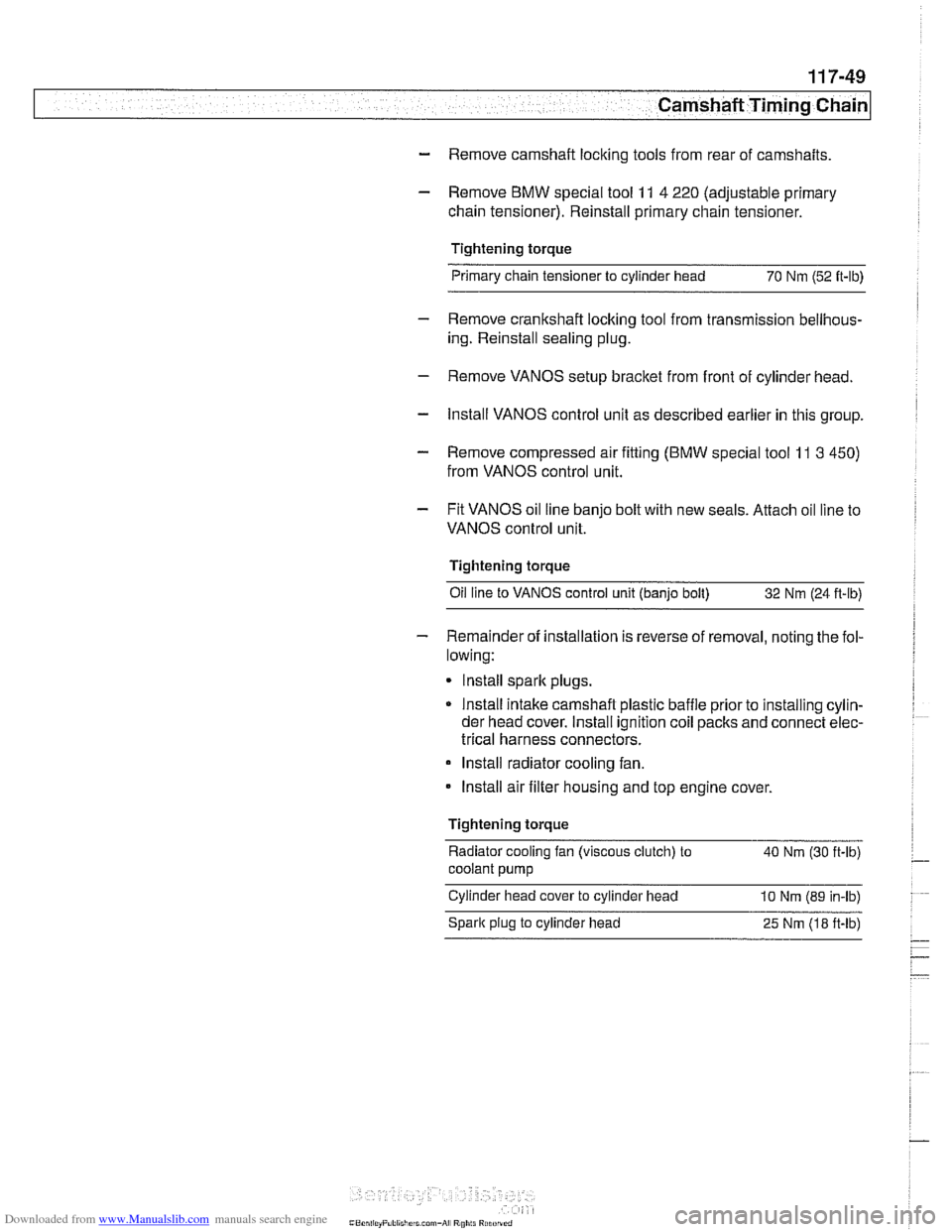

4 Place BMW special tool 11 3 240 over camshaft ends and

measure clearance of tool to cylinder head surface.

NOJE-

If the exhaust side of the tool (A) is not flush with the head,

camshaft timing

Is incorrect. Repeat camshaft timing pro-

cedure.

* Due to flexible sprocket design and VANOS control unit tol-

erances and play, the

intake side of special tool 11 3 240

(6) may be up to 1 mm (0.04 in) above the sudace of the

cylinder head. This is normal. Otherwise, repeat camshaft

timing procedure.

Page 285 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- - -- - -- Camshaft Timing chain1

- Remove camshaft locking tools from rear of camshafts

- Remove BMW special tool 11 4 220 (adjustable primary

chain tensioner). Reinstall primary chain tensioner.

Tightening torque Primary chain tensioner to cylinder head

70

Nm (52 it-lb)

- Remove crankshaft locking tool from transmission bellhous-

ing. Reinstall sealing plug.

- Remove VANOS setup bracket from front of cylinder head

- lnstall VANOS control unit as described earlier in this group.

- Remove compressed air fitting (BMW special tool 11 3 450)

from VANOS control unit.

- Fit VANOS oil line banjo bolt with new seals. Attach oil line to

VANOS control unit.

Tightening torque

Oil line to VANOS control unit (banjo bolt) 32 Nm (24 H-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

lnstall spark plugs.

* lnstall intake camshaft plastic baffle prior to installing cylin-

der head cover. lnstall ignition coil packs and connect elec-

trical harness connectors.

Install radiator cooling fan.

- lnstall air filter housing and top engine cover.

Tightening torque Radiator cooling fan

(VISCOUS clutch) to 40 Nm (30 ft-lb)

coolant pump

Cyitnder head cover to cylinder head 10 Nm (89 in-lb)

Sparlc plug to cylinder head 25 Nm (18 ft-lb)

Page 286 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-50

/Camshaft Timing Chain

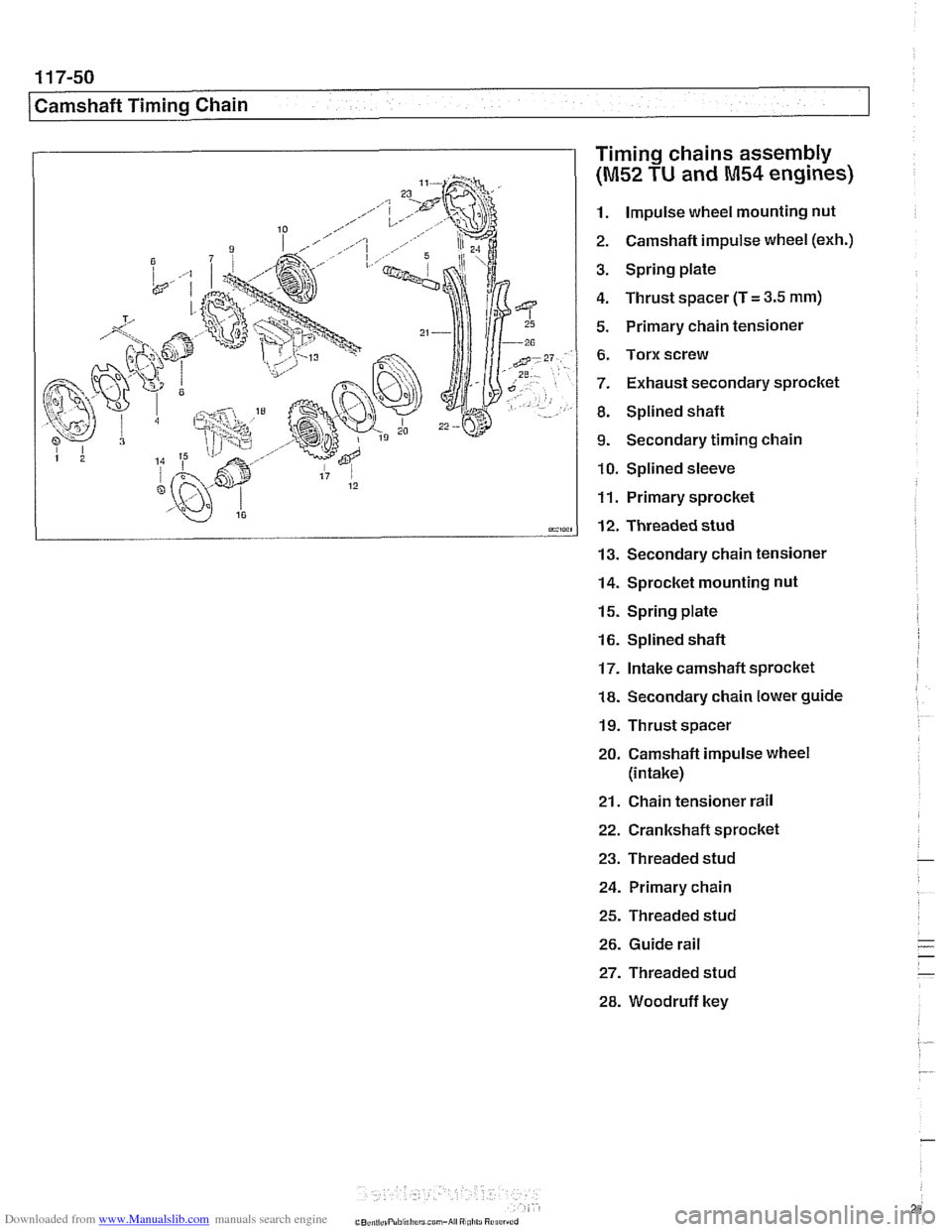

Timing chains assembly

(M52 TU and M54 engines)

1. Impulse wheel mounting nut

2. Camshaft impulse wheel

(exh.)

3. Spring plate

4. Thrust spacer (T

= 3.5 mm)

5. Primary chain tensioner

6. Torx screw

7. Exhaust secondary sprocket

8. Splined shaft

9. Secondary timing chain

10. Splined sleeve

11. Primary sprocket

12. Threaded stud

13. Secondary chain tensioner

14. Sprocket mounting nut

15. Spring plate

16. Splined shaft

17. Intake camshaft sprocket

18. Secondary chain lower guide

19. Thrust spacer

20. Camshaft impulse wheel

(intake)

21. Chain tensioner rail

22. Crankshaft sprocket

23. Threaded stud

24. Primary chain

25. Threaded stud

26. Guide rail

27. Threaded stud

28. Woodruff key

Page 287 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

Camshaft Timing chain1

Timing chains, removing

(M52 TU and M54 engines)

Camshaft timing chain removal requires that the oil pan be re-

moved. See

119 Lubrication System. Also required is re-

moval of the VANOS control

unit and disassembly of the

intake and exhaust camshaft sprocket assemblies as de-

scribed earlier in this repair group.

Special BMW

service tools are needed for timing chain re-

moval and installation. The special tools assure proper timing

of the valvetrain. Precise

marlts to set the timing on the cam:

shafts are not provided for reassembly. Read the procedures

through before beginning the job.

CA

UTION-

If the camshafts are not properly timed, the pistons can con-

tact the valves.

- D~sconnect negative (-) cable from battery.

CAUTION-

* Disconnecting the battery may erase fault code@) stored in

control module memory. Check for fault codes using spe-

cial

BMW diagnostic equipment.

Prior to disconnecting the battery, read the battery dis-

connection

cautfons given in 001 General Cautions

and

Warninqs.

- Remove VANOS control unit. See VANOS control unit, re-

moving

(M52 TU and M54 engines).

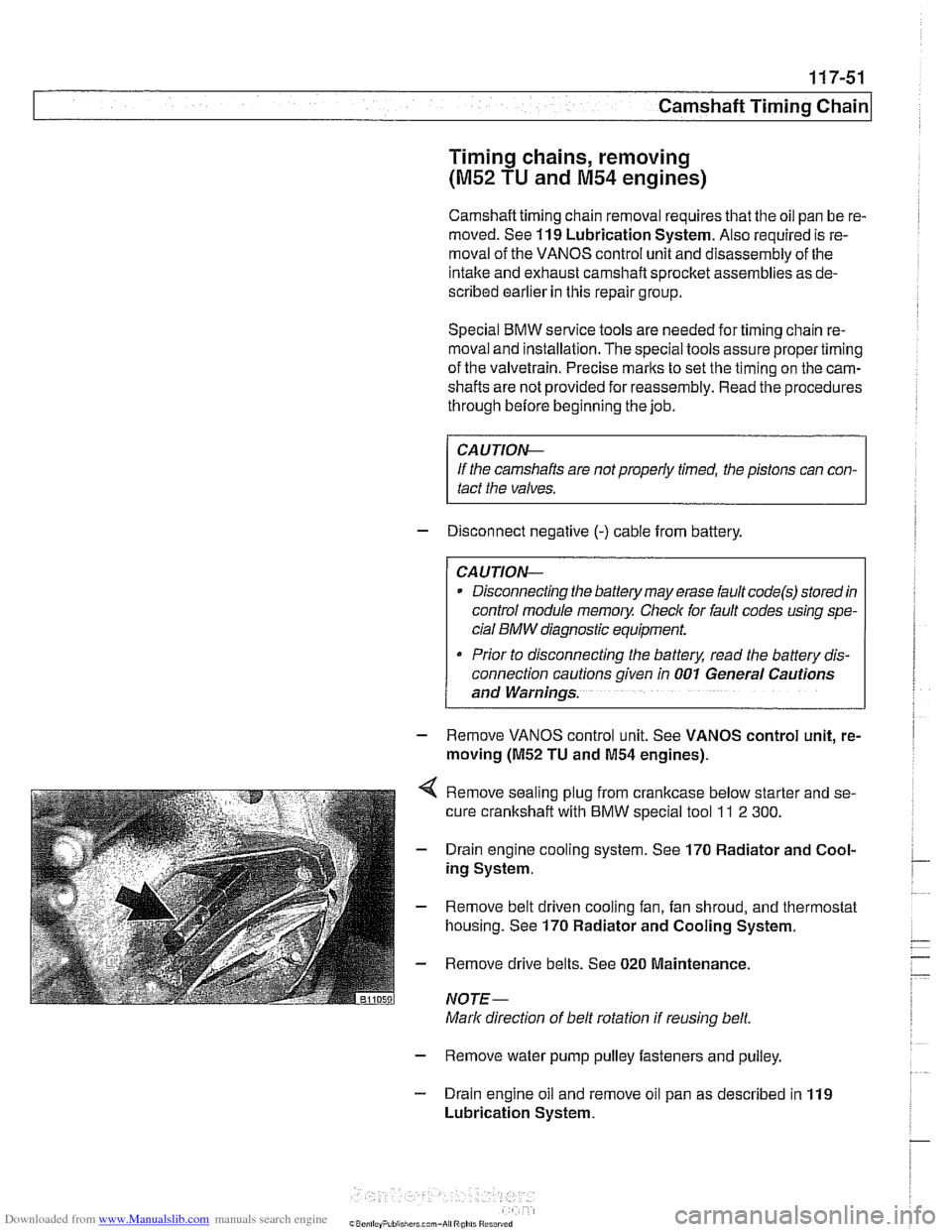

Remove sealing plug from crankcase below starter and se-

cure crankshaft with

BMW special tool ll 2 300.

Drain engine cooling system. See 170 Radiator and Cool-

ing System.

Remove belt driven cooling fan, fan shroud, and thermostat

housing. See

170 Radiator and Cooling System.

Remove drive belts. See

020 Maintenance.

NOTE-

Mark direction of belt rotation if reusing belt.

- Remove water pump pulley fasteners and pulley.

- Drain engine oil and remove oil pan as described in 119

Lubrication System.