spark plugs BMW 540i 1998 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 166 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Cylinder Head Removal and Installation

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Use new gaskets when mounting intake

manifold. Tighten

nuts finger tight first, then torque to specification in stages

working diagonally from center out.

Be sure to reinstall ignition coil ground straps at cylinders

no.

3 and no. 7. See 120 Ignition System.

Reinstall cooling fan and shroud. See

170 Radiator and

Cooling System.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

Change engine oil and filter as described in

020 Mainte-

nance.

CA UTIOG

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening torques

Camshaft sprocket to camshaft 15

Nm (11 H-lb)

Coolant manifold to cylinder head 10 Nm (7.5 H-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mounts to subirame 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Right cylinder head, removing, M62 engine

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Remove intake manifold. See Intake manifold, removal

and installation,

M62 engine.

- Drain engine coolant. See 170 Radiator and Cooling Sys-

tem.

WARNING-

Use extreme caution when draining and disposing of engine

coolant.

Coolanl is poisonous andlellial lo liumans andpels.

Pets are

altracled to coolant because of 11s sfieet smell and

fasle. Seelc medcal anenfion immed~alely if coolant is ingesl-

. .-

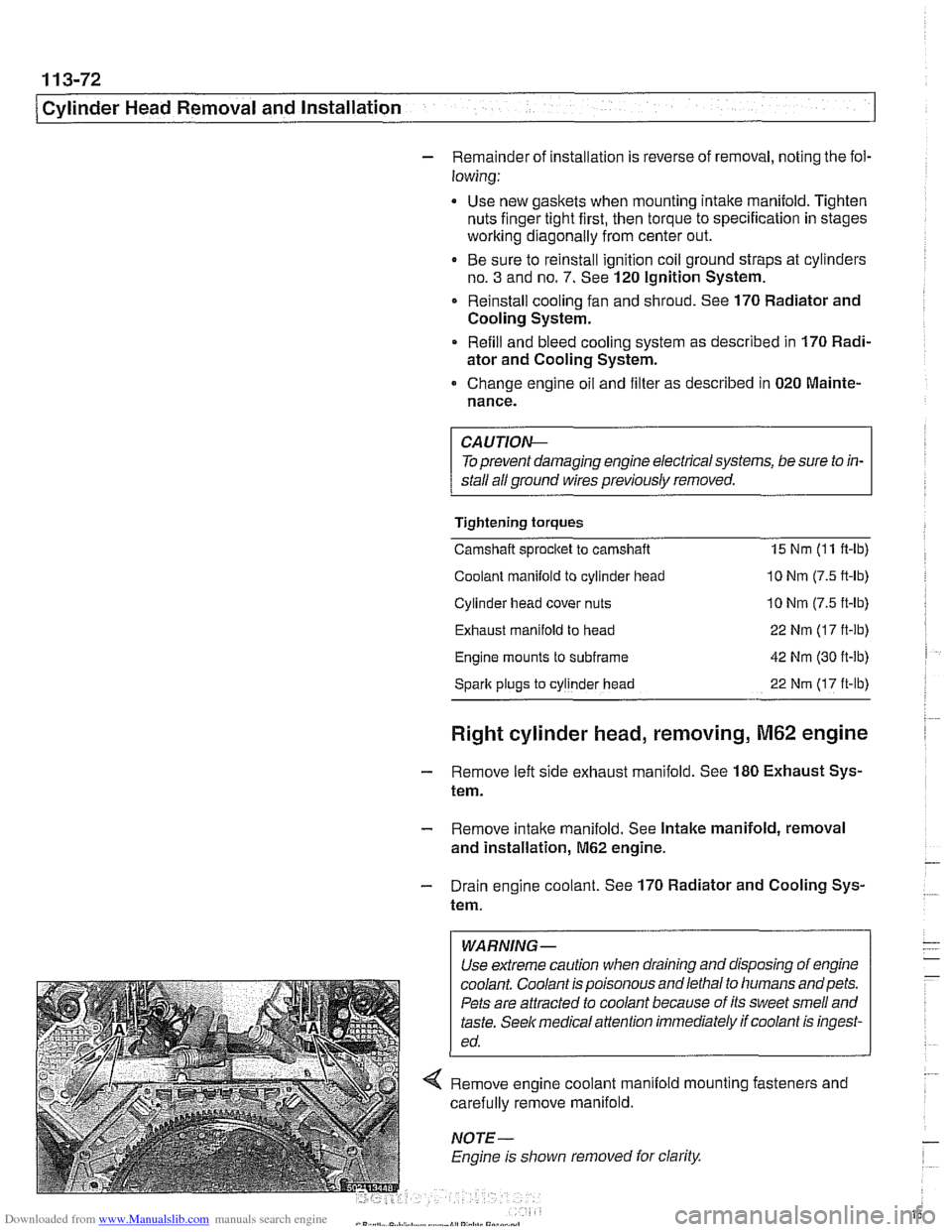

< Remove engine coolant manlold mo~nlng fasreners and

carei~lly remove manifo d.

. I

NOTE

Engine 8s slioivn removed lor clarify

Page 176 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-82

1 Cylinder Head Removal and Installation

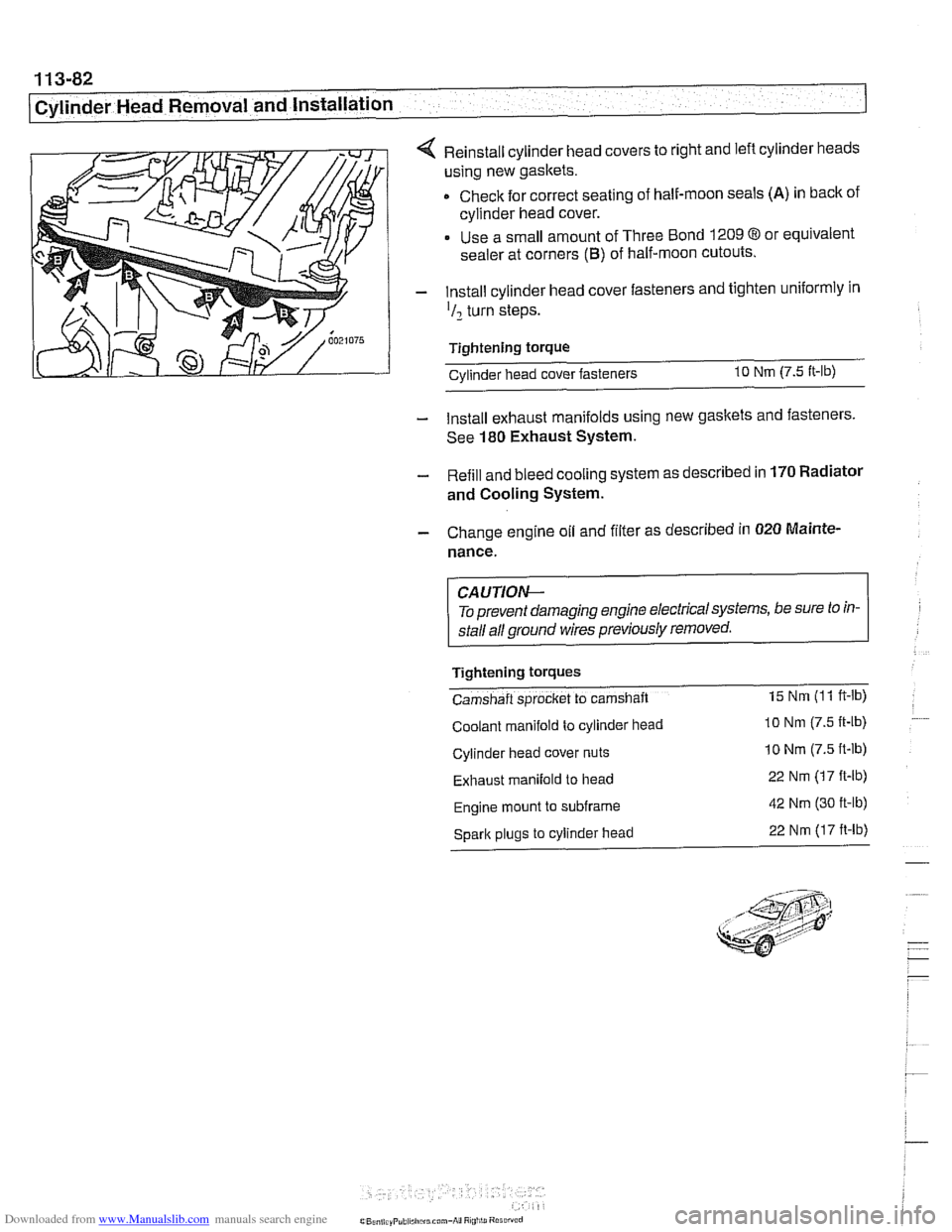

4 Reinstall cylinder head covers to right and left cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealer at corners

(B) of half-moon cutouts.

- Install cylinder head cover fasteners and tighten uniformly in

'I2 turn steps.

Tightening torque Cvlinder head cover fasteners

10 Nm (7.5 It-lb)

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.

- Refill and bleed cooling system as described in 170 Radiator

and Cooling System.

- Change engine oil and filter as described in 020 Mainte.

nance.

CA UTIOW-

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening

tOrqUeS

Camshaft sprocket to camshaft 15 Nm (1 1 ft-lb)

Coolant manifold to cylinder head lo Nm (7.5 It-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mount to subframe 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Page 182 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-6

Cylinder Head and Valvetrain

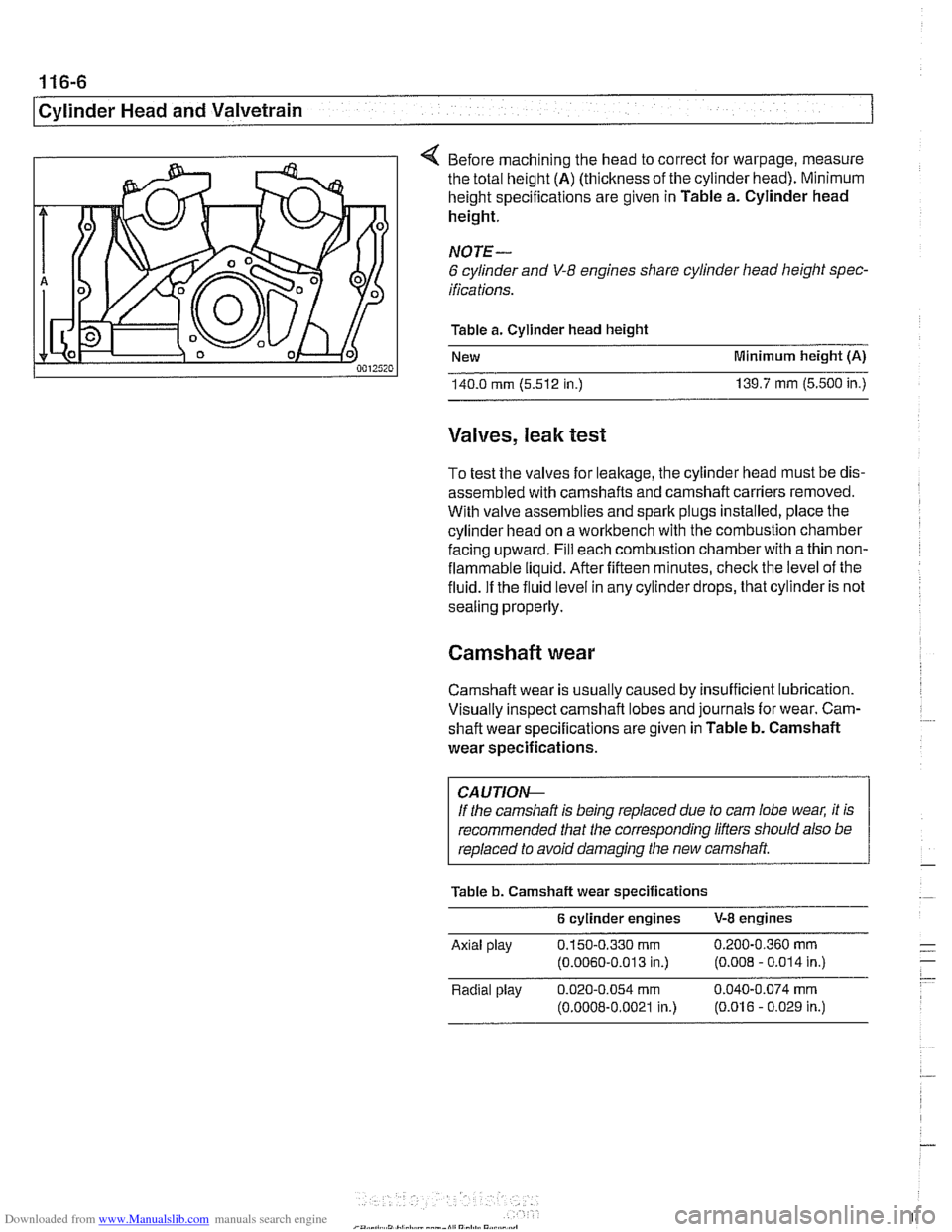

4 Before machining the head to correct for warpage, measure

the total height

(A) (thickness of the cylinder head). Minimum

height specifications are given in Table a. Cylinder head

height.

NOTE-

6 cylinder and V-8 engines share cylinder head height spec-

ifications.

Table a. Cylinder head height

New Minimum height

(A)

140.0 rnrn (5.512 in.) 139.7 rnrn (5.500 in.)

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes, check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Camshaft wear

Camshaft wear is usually caused by insufficient lubrication.

Visually inspect camshaft lobes and journals for wear. Cam-

. ~~ shaft wear specifications are given in Table b. Camshaft

wear specifications.

CA UTIOI\C

If the camshaft is being replaced due to cam lobe wear, it is

recommended that the corresponding lifters should also be

replaced to avoid damaging the new camshaft

Table b. Camshaft wear specifications

6 cylinder engines V-8 engines

Axlal play 0.150-0.330 rnrn 0 200-0 360 rnrn - .-

(0.0060-0 013 in.) (0.008 - 0.014 in ) - - Radlal play 0.020-0.054 rnrn 0.040-0.074 rnrn

(0.0008-0.0021 in.) (0.016 - 0.029 in.)

Page 185 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-9

Cvlinder Head and valvetrain1

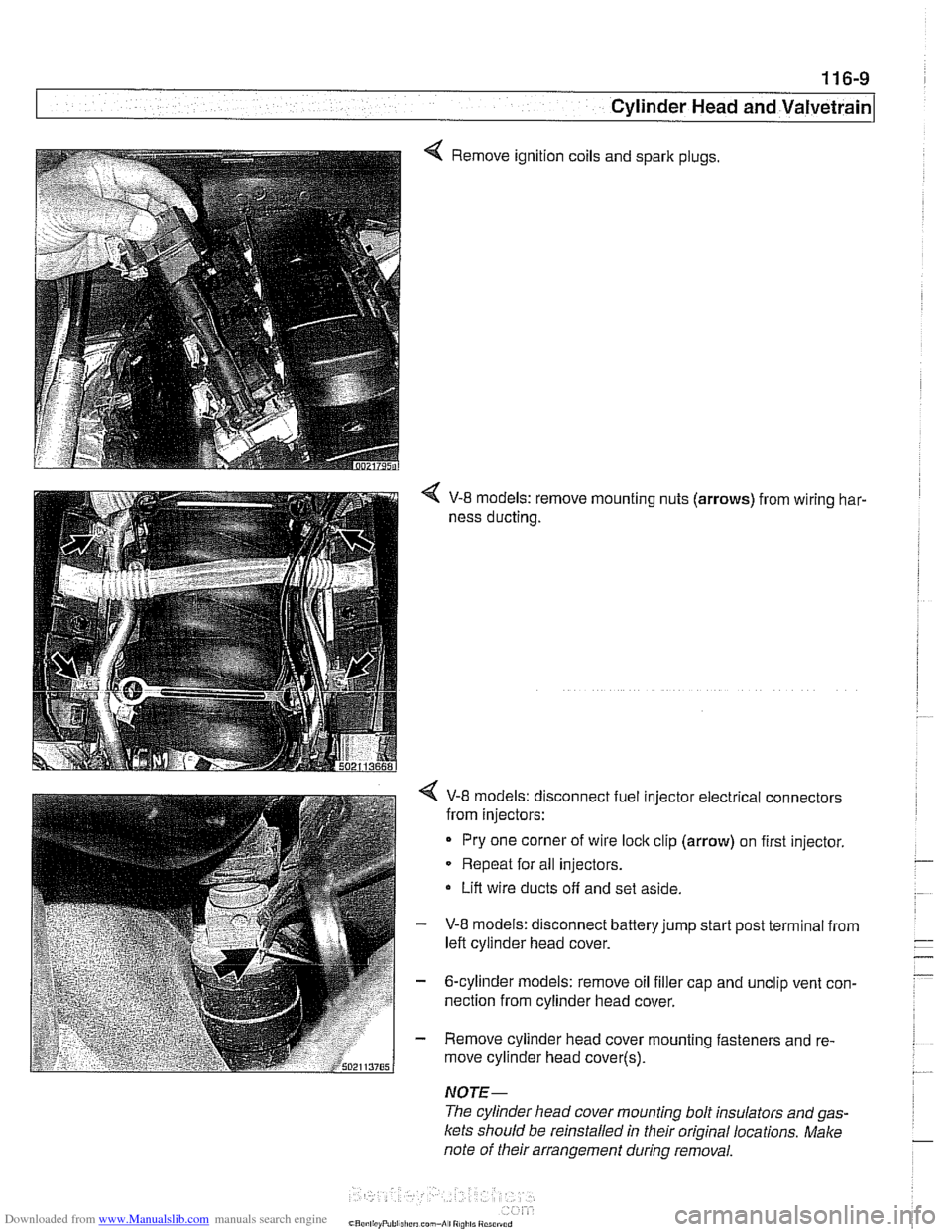

4 Remove ignition coils and spark plugs.

V-8 models: remove mounting nuts (arrows) from wiring har-

ness ducting.

< V-8 models: disconnect fuel injector electrical connectors

from injectors:

Pry one corner of wire

loclc clip (arrow) on first injector.

Repeat for all injectors.

Lift wire ducts off and set aside.

- V-8 models: disconnect battery jump start post terminal from

left cylinder head cover.

- 6-cylinder models: remove oil filler cap and unclip vent con-

nection from cylinder head cover.

- Remove cylinder head cover mounting fasteners and re-

move cylinder head cover(~).

NOTE-

The cylinder head cover mounting bolt insulators and gas-

Icets should be reinstalled in their original locations. Make

note of their arrangement

during removal.

Page 192 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

Cylinder Head and Valvetrain

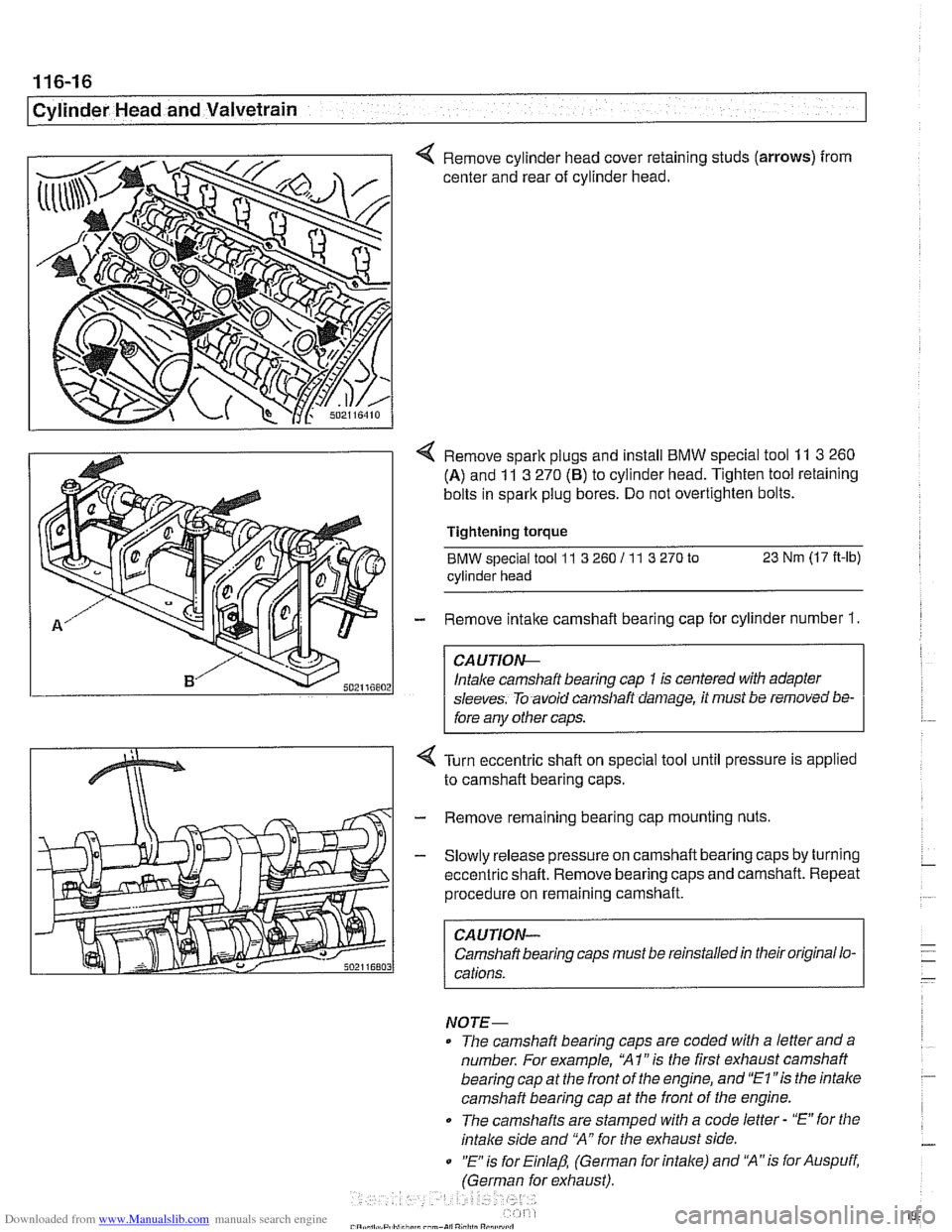

< Remove cylinder head cover retaining studs (arrows) from

center and rear of cylinder head.

< Remove spark plugs and install BMW special tool 11 3 260

(A) and 11 3 270 (6) to cylinder head. Tighten tool retaining

bolts in spark plug bores. Do not overtighten bolts.

Tightening

torque

BMW special tool 11 3 260 I1 1 3 270 to 23 Nm (17 It-lb)

cylinder head

- Remove intake camshaft bearing cap for cylinder number 1.

CA UTIOG

Intake camshaft bearing cap 1 is centered with adapter

sleeves. To avoid

can~sllaft daniage, it must be removed bs-

fore any other caps.

Turn eccentric shaft on special tool until pressure is applied

to camshaft bearing caps.

- Remove remaining bearing cap mounting nuts

- Slowly release pressure on camshaft bearing caps by turning

eccentric shaft. Remove bearing caps and camshaft. Repeat

procedure on remaining camshaft.

CAUTION-

Camshaft bearing caps must be reinstalled in their original lo-

cations.

NOTE-

The camshaft bearing caps are coded with a letter anda

number. For example,

'XI" is the first exhaust camshaft

bearing cap at the front of the engine, and

"El "is the intalce

camshaft bearing cap at the front of the engine.

0 The camshafts are stamped with a code letter - "E" for the

intake side and 'MA" for the exhaust side.

0 "E is for Einlap, (German for intake) and 'XA"is for Auspuff,

(German for exhaust).

Page 217 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

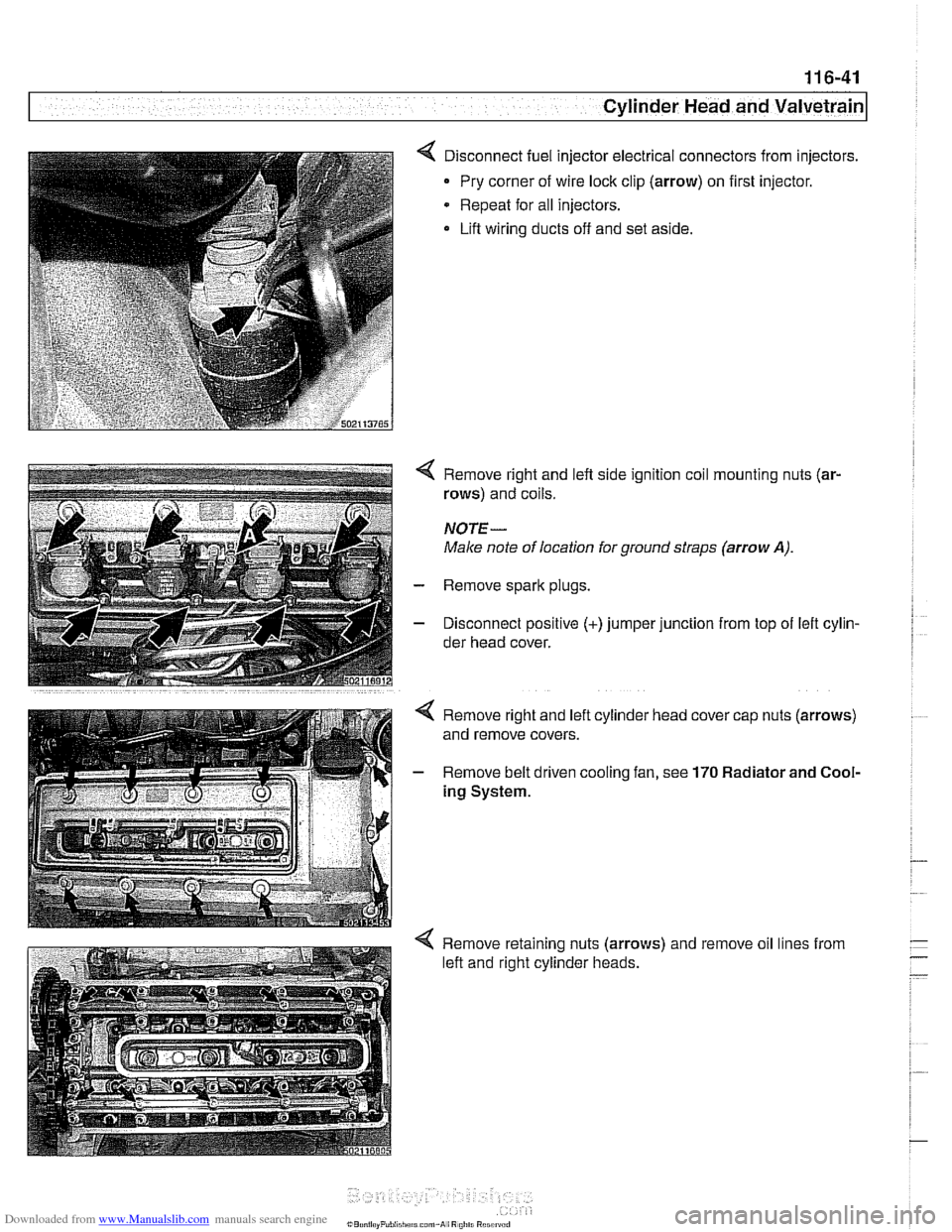

< Disconnect fuel injector electrical connectors from injectors.

Pry corner of wire lock clip (arrow) on first injector.

* Repeat for all injectors.

Lift wiring ducts off and set aside.

4 Remove right and left side ignition coil mounting nuts (ar-

rows) and coils.

NOTE-

Male note of location for ground straps (arrow A).

- Remove spark plugs.

- Disconnect positive (+)jumper junction from top of lefl cylin-

der head cover.

4 Remove retaining nuts (arrows) and remove oil lines from

left and right cylinder heads.

Page 232 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 16-56

Cylinder Head and Valvetrain

This section covers valve removal and reconditioning, includ-

ing valve guides, seats, springs, and valve stem oil seals.

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes,

check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Valves, removing and installing

- Remove cylinder head as described in 113 Cylinder Head

Removal and Installation.

CAUTIOI\C

(M52 TU/M54 engines only) Do not let the hydraulic lifters

fall out as the camshaft carrier is removed. Special suction

cups are available from

BMW to hold the hydraulic lifters in

place during carrier removal.

* Hydraulic cam lifters should be stored m an uprfght po-

sition. If necessary, use a magnetic tool to

aidin remov-

al of the lifters.

- Remove valves using a valve spring compressor.

CAUTIOI\C

Label each valve assembly as it is removed so it can be in-

stalled in its original position.

-

- Remove and discard valve stem oil seals from valve guides.

See Valve stem oil seals later in this section.

- Valve installation is reverse of removal. Remove carbon de- - -

posits from the valves using a wire brush or wire wheel. -

-

Valve specifications are listed in Table c. Valve specifica-

tions.

Page 251 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timina chain1

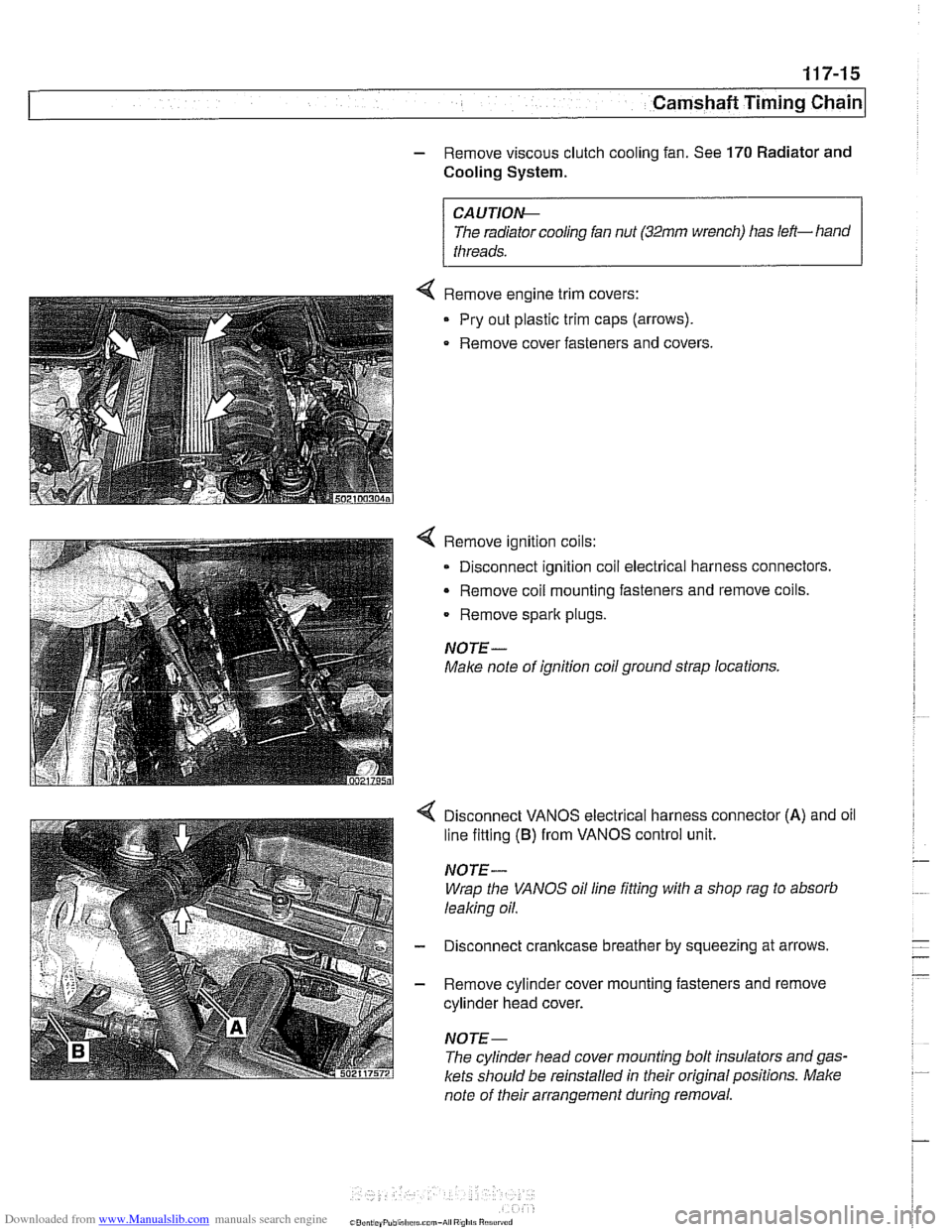

- Remove viscous clutch cooling fan. See 170 Radiator and

Cooling

System.

CA UTlOEIC

The radiator cooling fan nut (32mm wrench) has left- hand

threads.

.

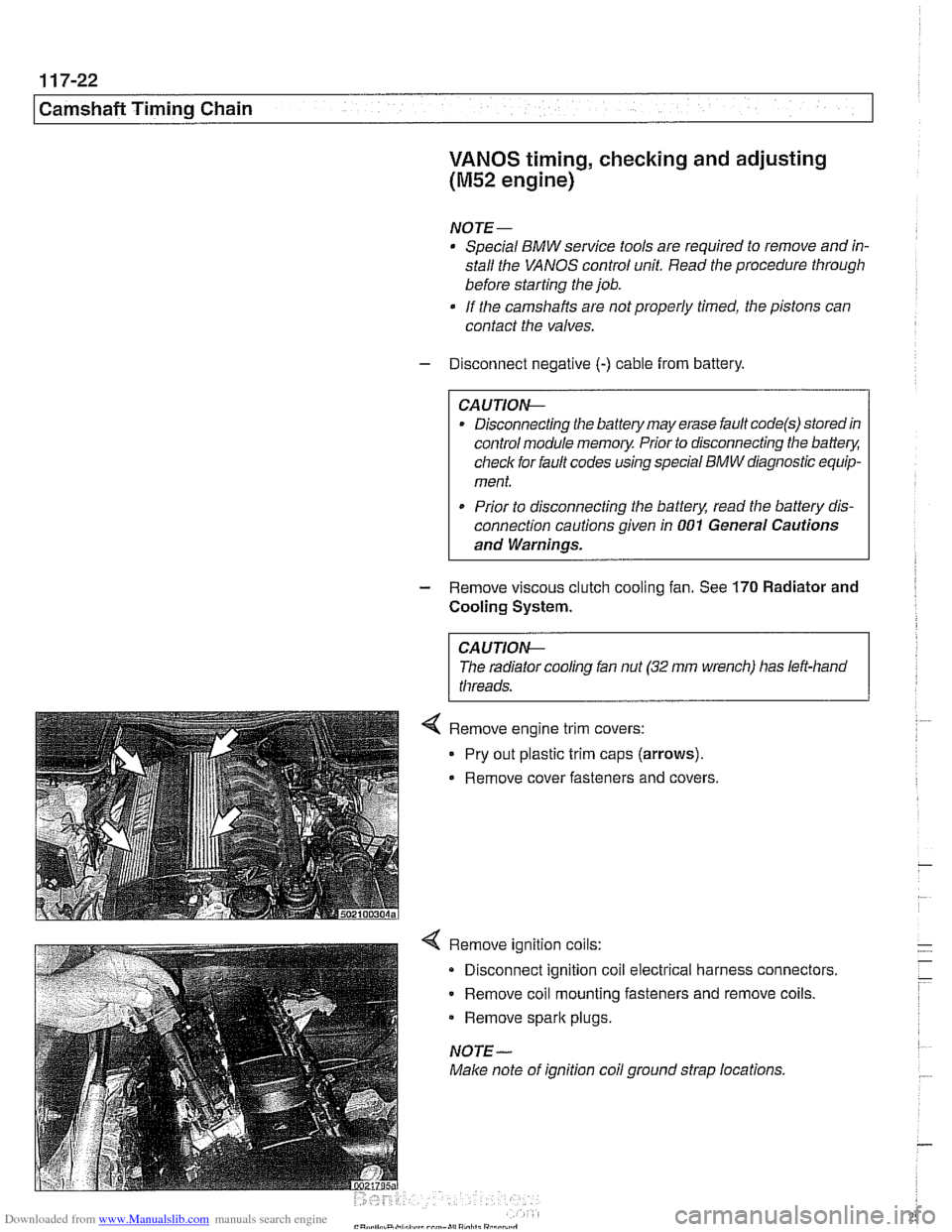

< Remove engine trim covers:

Pry out plastic trim caps (arrows).

. Remove cover fasteners and covers.

4 Remove ignition coils:

0 Disconnect ignition coil electrical harness connectors

Remove

coil mounting fasteners and remove coils.

Remove spark plugs.

NOTE-

Make note of ignition coil ground strap locations.

Disconnect VANOS electrical harness connector

(A) and oil

line fitting

(B) from VANOS control unit.

NOTE-

Wrap the VANOS oil line fitting with a shop rag to absorb

leaking oil.

- Disconnect cranltcase breather by squeezing at arrows,

- Remove cylinder cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas.

kets should be reinstalled in their original positions. Make

note of their arrangement during removal.

Page 258 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

VANOS timing, checking and adjusting

(M52 engine)

NOTE-

* Special BMW service tools are required to remove and in-

stall the VANOS control unit. Read the procedure through

before starting the job.

If the camshafts are not properly timed, the pistons can

contact the valves.

- Disconnect negative (-) cable from battery.

CAUTIOG Disconnecting the battery may erase

faultcode(s) storedin

control module memory. Prior to disconnecting the battery,

checlc for fault codes using special BMW diagnostic equip-

ment.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Cautions

and Warnings.

- Remove viscous clutch cooling fan. See 170 Radiator and

Cooling

System.

CAUTIOG The radiator cooling fan nut

(32 mm wrench) has left-hand

threads.

4 Remove ignition coils:

Disconnect ignition coil electrical harness connectors.

Remove coil mounting fasteners and remove coils.

Remove

spark plugs.

NOTE-

Make note of ignition coil ground strap locations.

Page 273 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

VANOS control unit, removing

(M52 TU and M54 engines)

This procedure includes removal of the Double VANOS con-

trol unit.

NOTE-

If the Double VANOS control unit is being replaced, camshaft

timing must be checked. This procedure requires multiple

special tools. Be sure to read the procedures through before

beginning the repair.

- Working inside luggage compartment, disconnect negative

(-) battery cable.

Prior to disconnecting the

batteg read the battery discon-

nection cautions given in

001 General Cautions and

Remove engine cooling fan assembly. See 170 Radiator

and Cooling System.

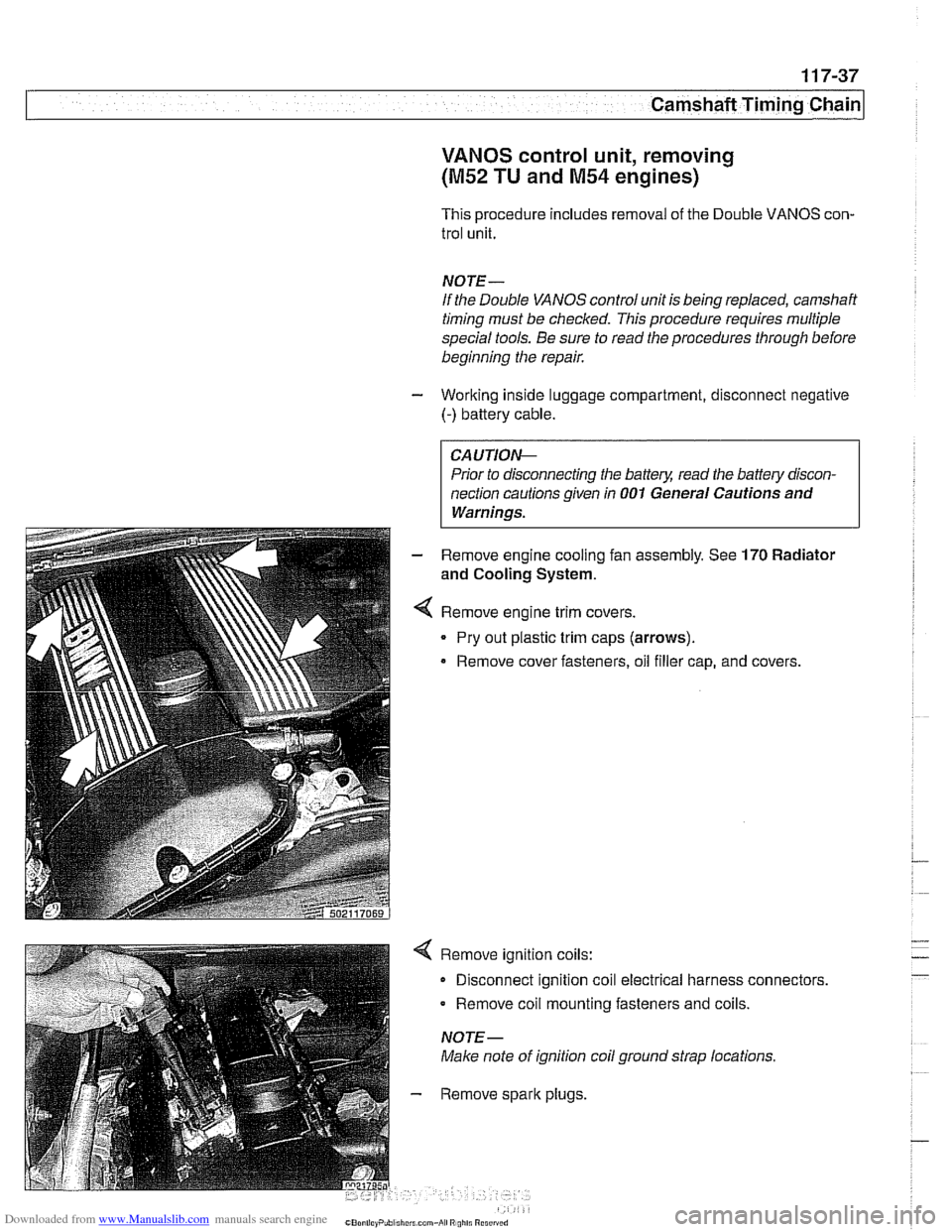

Remove engine trim covers.

Pry out plastic trim caps (arrows).

Remove cover fasteners, oil filler cap, and covers.

Remove ignition coils:

Disconnect ignition coil electrical harness connectors.

Remove coil mounting fasteners and coils.

NOTE-

Make note of ignition coil ground strap locations.

Remove spark plugs,