Ac system BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 666 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-8

Steering and Wheel Alignment

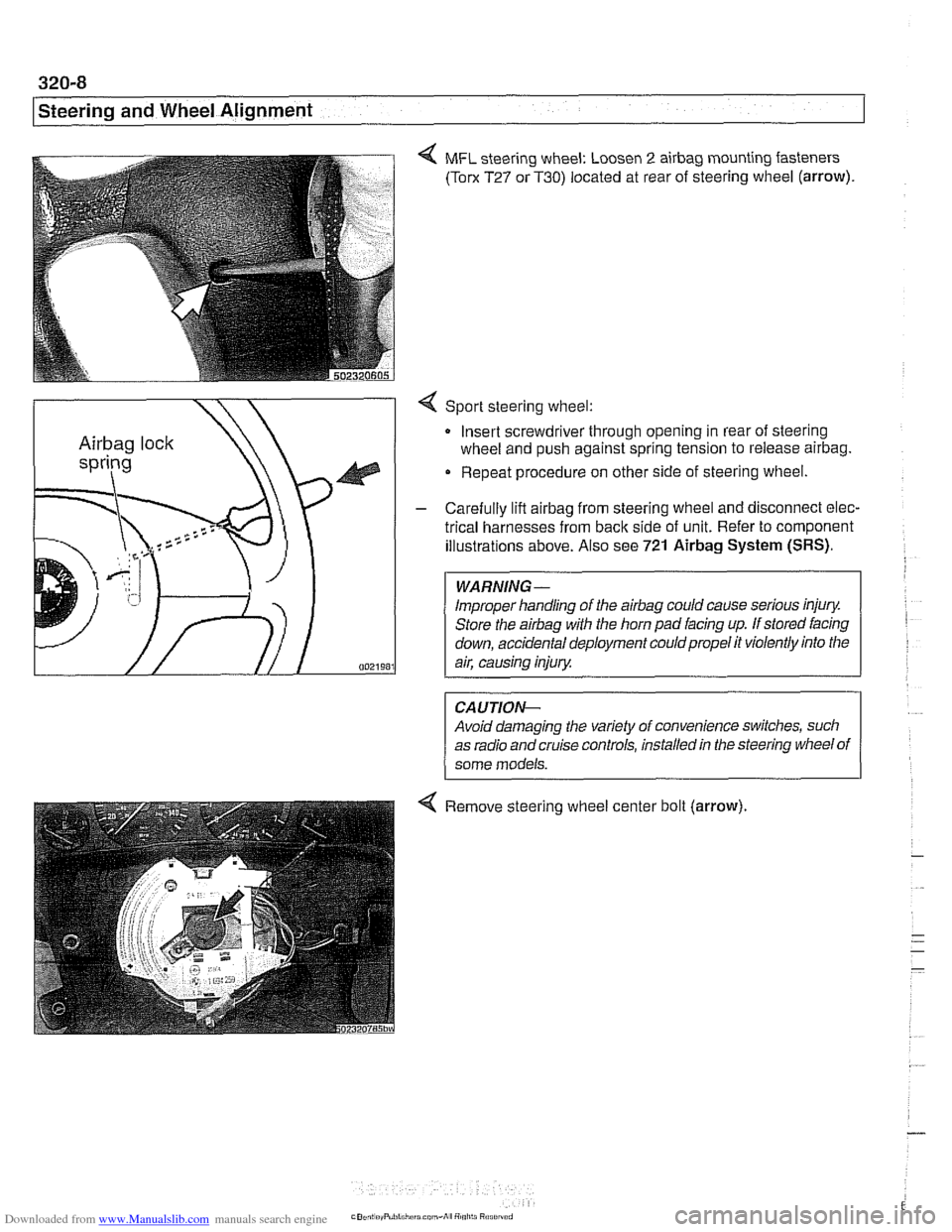

4 MFL steering wheel: Loosen 2 airbag mounting fasteners

(Torx T27 or T30) located at rear of steering wheel (arrow).

4 Sport steering wheel:

Insert screwdriver through opening in rear of steering

wheel and push against spring tension to release

airbag.

Repeat procedure on other side of steering wheel.

- Carefully lift airbag from steering wheel and disconnect elec-

trical harnesses from

back side of unit. Refer to component

illustrations above. Also see

721 Airbag System (SRS).

Improper handling of the airbag could cause serious injury.

Store the

airbag with the horn pad facing up. If stored facing

down, accidental deployment couldpropel it violently into the

Avoid damaging the variety of convenience switches, such

as radio and cruise controls, installed in the steering wheel of

4 Remove steering wheel center bolt (arrow).

Page 667 of 1002

Downloaded from www.Manualslib.com manuals search engine

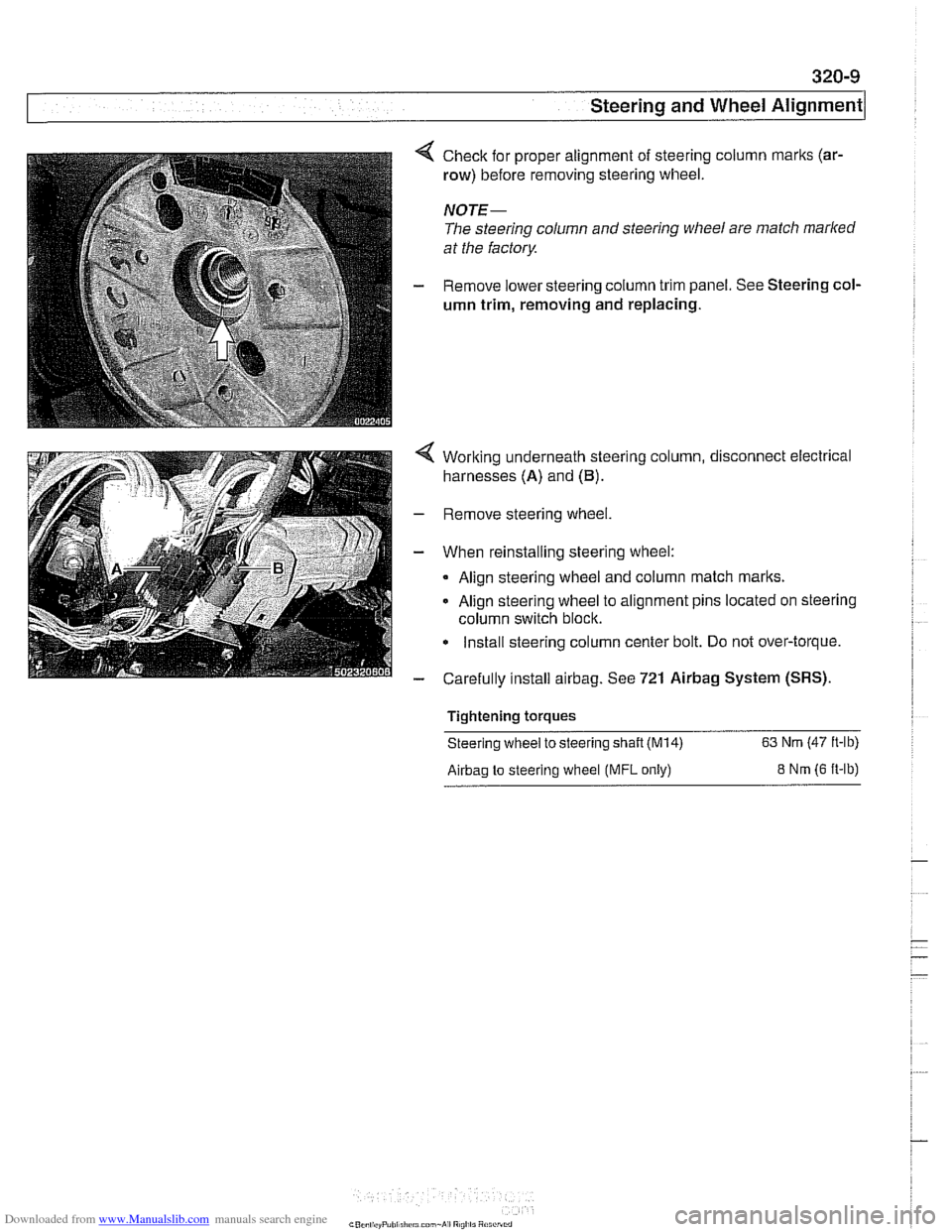

Check for proper alignment of steering column marks (ar-

row) before removing steering wheel.

NOTE-

The steering column and steering wheel are match marked

at the factory

Remove lower steering column trim panel. See Steering col-

umn trim, removing

and replacing.

Working underneath steering column, disconnect electrical

harnesses (A) and

(B).

Remove steering wheel.

When reinstalling steering wheel:

Align steering wheel and column match

marks.

Align steering wheel to alignment pins located on steering

column switch block.

Install steering column center bolt. Do not over-torque.

Carefully install

airbag. See 721 Airbag System (SRS).

Tightening torques

Steering wheel to steering

shaft (M14) 63 Nm (47 ft-lb)

Airbag to steering wheel (MFL only) 8 Nm (6 ft-lb)

Page 674 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Steering and Wheel Alignment

- Installation is reverse of removal, noting the following:

Replace shear bolts at steering column mounting bracket.

Tighten until bolt heads shear off.

Make sure

interlock cable snaps into place.

When installing column top trim panel, replace expansion

nut for trim retaining screw.

NOTE-

The steering angle sensor must be coded using a BMW scan

tool if it has been replaced.

A steering angle offset check

must then be carried out using the same

BMW scan tool.

CAUTION-

Check steering system for freedom of movement through en-

tire steering column

adiustment range.

Tightening torques Steering shaft coupler

to steering shaft 25 Nm (18 ft-lb)

(replace bolt)

Steering column to body

22 Nm (16 ft-lb)

Steering column adjustment motors,

removing and installing

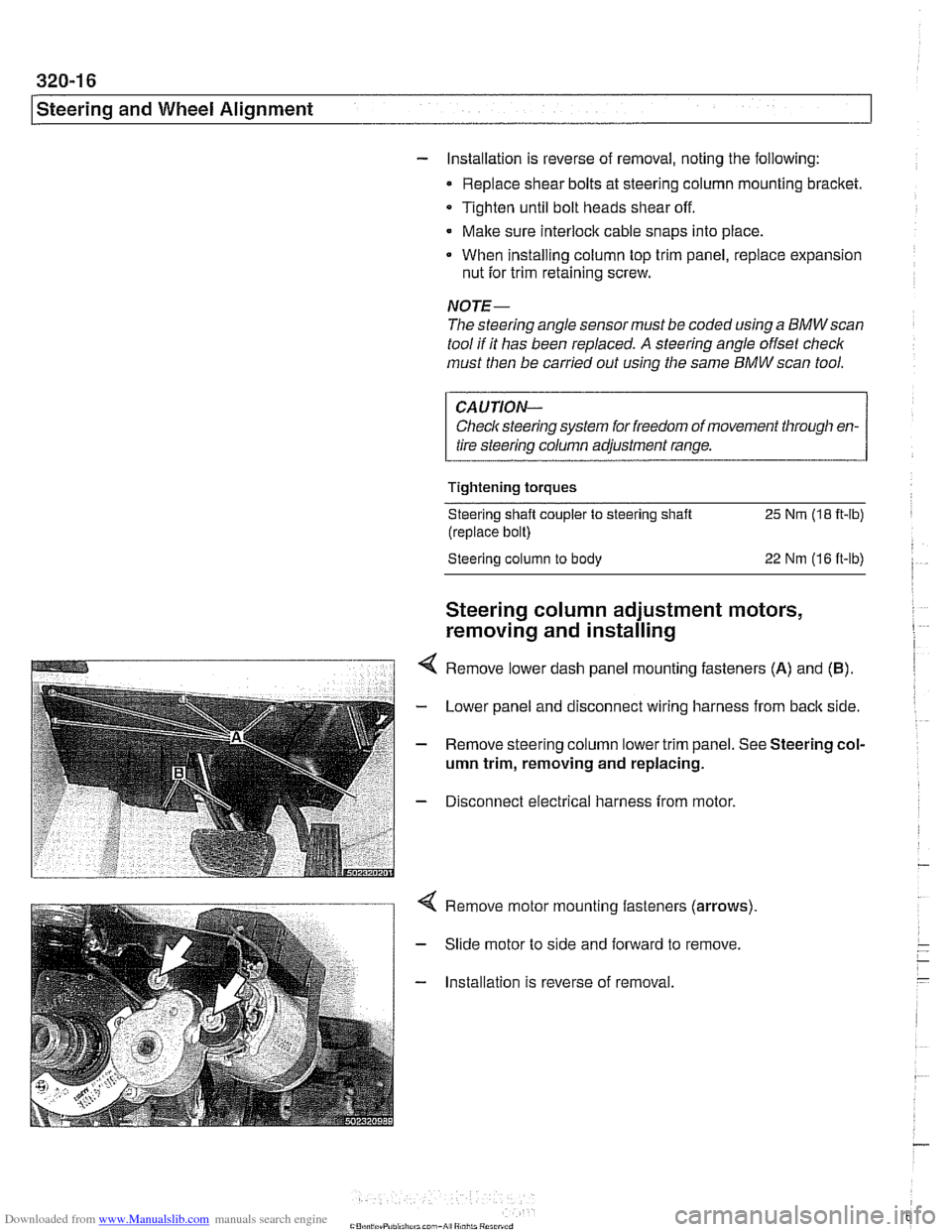

Remove lower dash panel mounting fasteners (A) and (B).

- Lower panel and disconnect wiring harness from back side.

- Remove steering column lower trim panel. See Steering col-

umn trim, removing and replacing.

- Disconnect electrical harness from motor.

Remove motor mounting fasteners (arrows)

Slide motor to side and forward to remove.

Installation is reverse of removal.

Page 676 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

-steering and wheel -. Alignment I

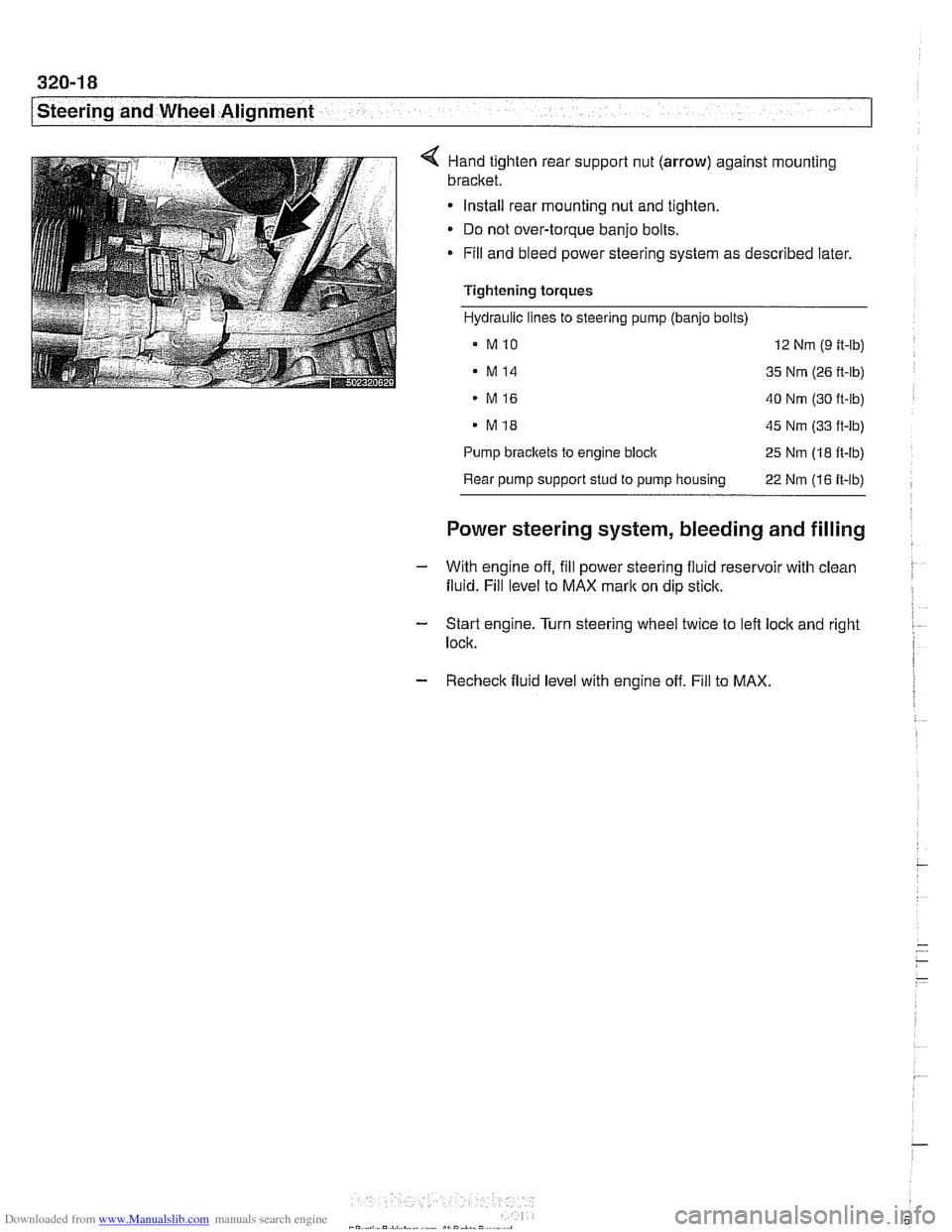

< Hand tighten rear suppoll nut (arrow) against mounting

bracket.

Install rear mounting nut and tighten.

Do not over-torque banjo bolts.

* Fill and bleed power steering system as described later.

Tightening torques

Hydraulic lines to steering pump (banjo bolts)

a MlO 12 Nm (9 ft-lb)

. M14 35 Nm (26 ft-lb)

MI6 40 Nm (30 ft-lb)

. MI8 45 Nm (33 ft-lb)

Pump

brackets to engine block 25 Nm (18 ft-lb)

Rear pump support stud to pump housing

22 Nm (16 ft-lb)

Power steering system, bleeding and filling

- With engine off, fill power steering fluid reservoir with clean

fluid. Fill level to MAX

mark on dip stick.

- Start engine. Turn steering wheel twice to left lock and right I

lock.

- Recheck fluid level with engine off. Fill to MAX.

Page 679 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~lignmentl

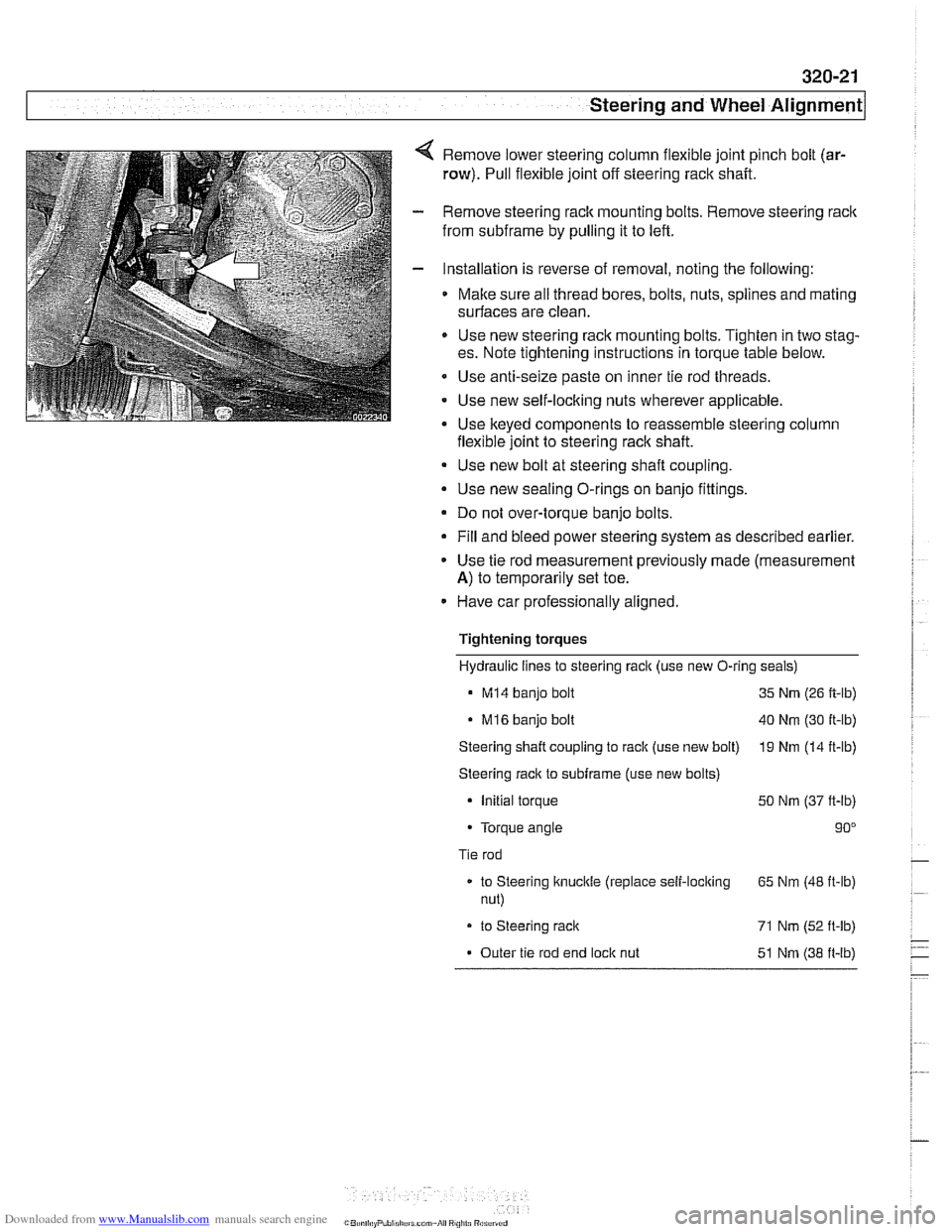

Remove lower steering column flexible joint pinch bolt (ar-

row). Pull flexible joint off steering rack shaft.

Remove steering rack mounting bolts. Remove steering

raclc

from subframe by pulling it to left.

Installation is reverse of removal, noting the following:

Make sure all thread bores, bolts, nuts, splines and mating

surfaces are clean.

Use new steering rack mounting bolts. Tighten in two stag-

es. Note tightening instructions in torque table below.

Use anti-seize paste on inner tie rod threads.

Use new self-loclting nuts wherever applicable.

Use keved

comDonents to reassemble steerino column

flexible\oint to ;teering raclt shaft. u

Use new bolt at steering shaft coupling.

Use new sealing O-rings on banjo fittings.

Do not over-torque banjo bolts.

Fill and bleed power steering system as described earlier.

Use tie rod measurement previously made (measurement

A) to temporarily set toe.

Have car professionally aligned.

Tightening torques Hydraulic lines to steering rack (use new O-ring

seals)

M14 banjo bolt 35 Nrn (26 ft-lb)

. M16 banjo bolt 40 Nm (30 ft-lb)

Steering shaft coupling

to rack (use new bolt) 19 Nm (14 it-lb)

Steering rack to subframe (use new bolts)

- initial torque 50 Nm (37 ft-lb)

Torque angle 90"

Tie rod

to Steering knuckle (replace self-locking

65 Nm (48 ft-lb)

nut)

- to Steering rack 71 Nm (52 ft-ib)

Outer tie rod end lock nut

51 Nm (38 ft-lb)

Page 682 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

Tightening torques

Tie rod

to Steering knuckle (replace self-locking nut) 65 Nm (48 it-lb)

to Steering rack 71 Nrn (52 ft-lb)

Outer tie rod end lock nut 51 Nrn (38 ft-lb)

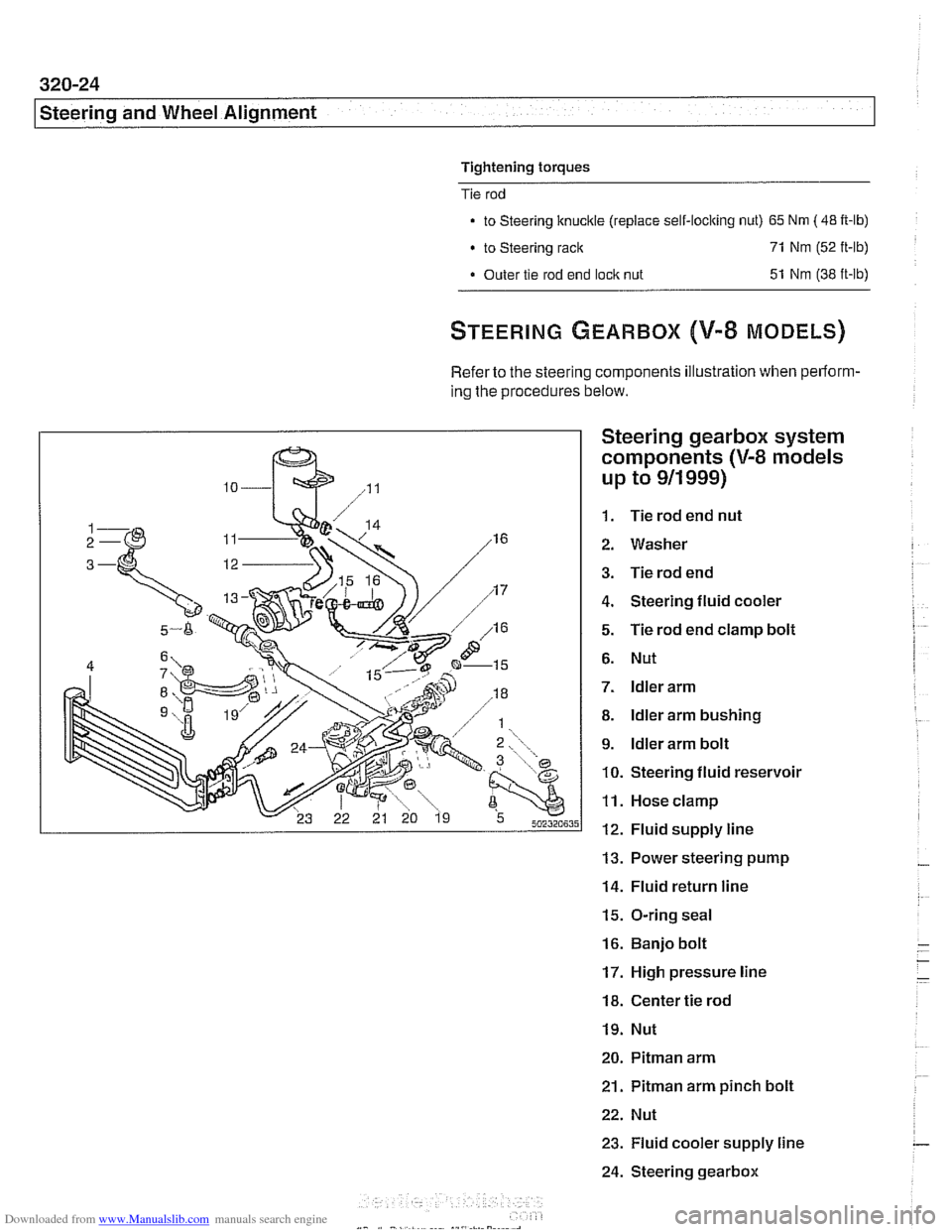

Refer to the steering components illustration when perform-

ing the procedures below.

Steering gearbox system

components

(V-8 models

up to

911 999)

1. Tie rod end nut

2. Washer

3. Tie rod end

4. Steering fluid cooler

5. Tie rod end clamp bolt

6. Nut

7. ldler arm

8. ldler arm bushing

9. ldler arm bolt

10. Steering fluid reservoir

11. Hose clamp

12. Fluid supply line

13. Power steering pump

14. Fluid return line

15. O-ring seal

16. Banjo bolt

17. High pressure line

18. Center tie rod

19. Nut

20. Pitman arm

21.

Pitman arm pinch bolt

22. Nut

23. Fluid cooler supply line

24. Steering gearbox

Page 683 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel ~li~nrnentl

Steering gearbox, removing and installing

- Disconnect negative (-) battery cable. See 020 Mainte-

nance.

CAUTION-

Prior to disconnecting the battew read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove airbag unit from steering wheel. See 721 Airbag

System (SRS).

WARNING -

Improper handling of the airbag could cause serious injury

Store the

airbag with the horn pad facing up. If stored lacing

down, accidental deployment couldpropel it violently info the

air, causing

injuv

- Remove steering wheel as described earlier.

- Drain power steering system reservoir.

- Raise front of car.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

Darts.

- Remove heat shield from left side of subframe.

- Remove fluid hoses from top of steering gearbox. Immedi-

ately plug all fluid openings.

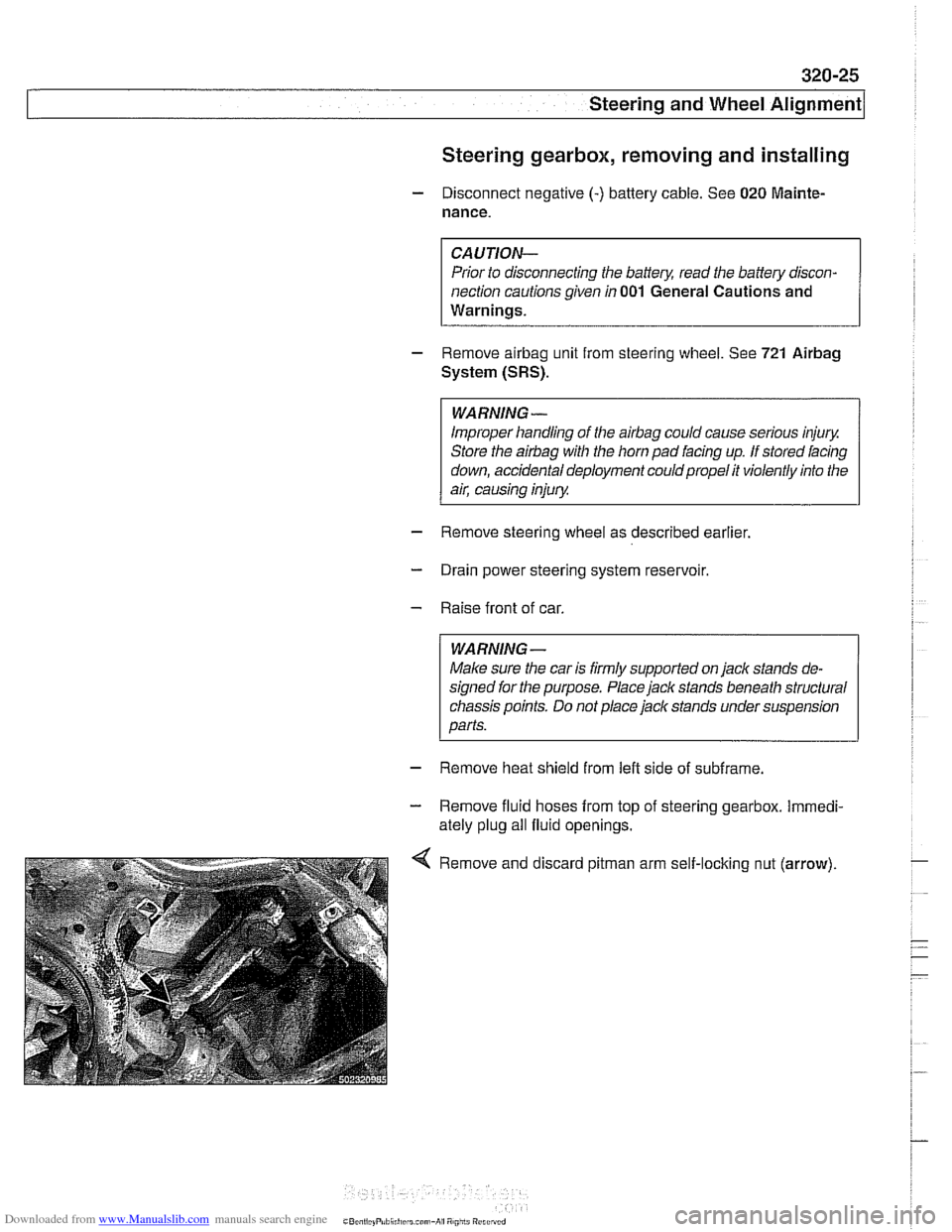

Remove and discard

pitman arm self-loclting nut (arrow).

Page 685 of 1002

Downloaded from www.Manualslib.com manuals search engine

L.. Steering and Wheel ~li~nrnentl ~

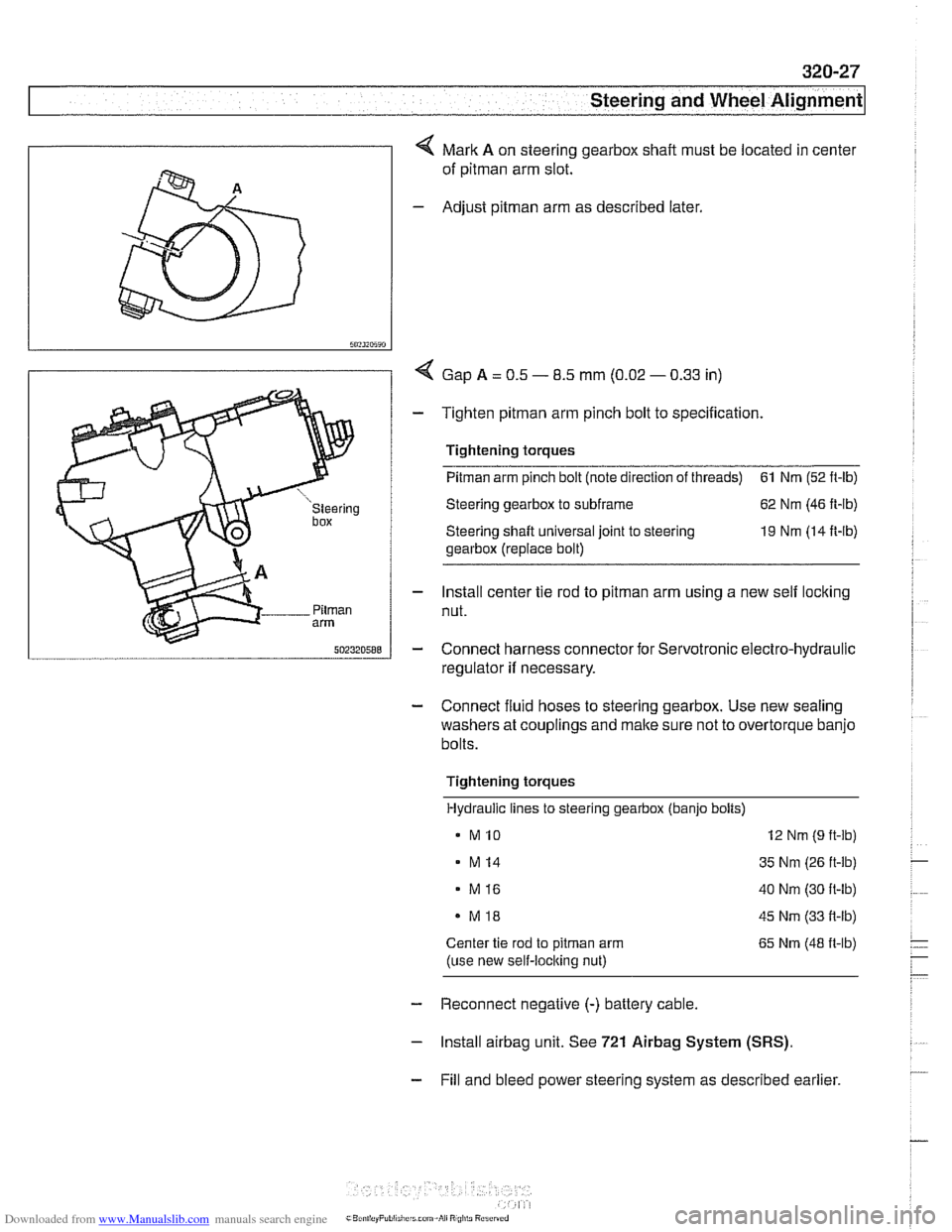

4 Mark A on steering gearbox shaft must be located in center

of

pitman arm slot.

- Adjust pitman arm as described later.

I 5"?~~5~"

I / < Gap A = 0.5 - 8.5 mm (0.02 - 0.33 in)

- Tighten pitman arm pinch bolt to specification.

' 1 Tightening torques

I u "steering Steering gearbox to subframe 62 Nm (46 ft-lb)

box Steering shaft universal joint to steering 19 Nm (14 It-lb)

gearbox (replace bolt)

- Install center tie rod to pitman arm using a new self locking

Pilrnan nut. arm

5nz3zn588 - Connect harness connector for Servotronic electro-hydraulic

regulator

if necessary.

- Connect fluid hoses to steering gearbox. Use new sealing

washers at couplings and make sure not to overtorque banjo

bolts.

Tightening torques Hydraulic lines to steering gearbox (banjo bolts)

MI0 12 Nm (9 ft-lb)

- M14 35 Nm (26 ft-lb)

. M16 40 Nm (30 ft-lb)

MI8 45 Nm (33 it-lb)

Center tie rod to pitrnan arm 65 Nm (48 it-lb)

(use new self-loclting nut)

- Reconnect negative (-) battery cable.

- lnstall airbag unit. See 721 Airbag System (SRS).

- Fill and bleed power steering system as described earlier.

Page 698 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-2

I Rear Suspension

This repair group covers removal and replacement of E39

rear suspension components. A general description of sus-

pension systems and ride height specifications can be found

in 300 Suspension, Steering and Brakes - General.

CAUTIOI\C

Some E39 models are equipped with aluminum suspen-

sion components. The following cautions apply:

Due to the chemical and corrosion characteristics of

aluminum, do not bring into contact with battery acid.

- Do not clean with wire brushes with brass or iron bris-

tles. Only use brushes with stainless steel bristles.

Do not expose to flying

sparl~s from grinding/cutting op-

erations.

* Do not subject to steel welding splashes.

0 Do not expose to temperatures over 80°C (176°F).

even for shortperlods. Temperatures in painting facili-

ties are not a problem.

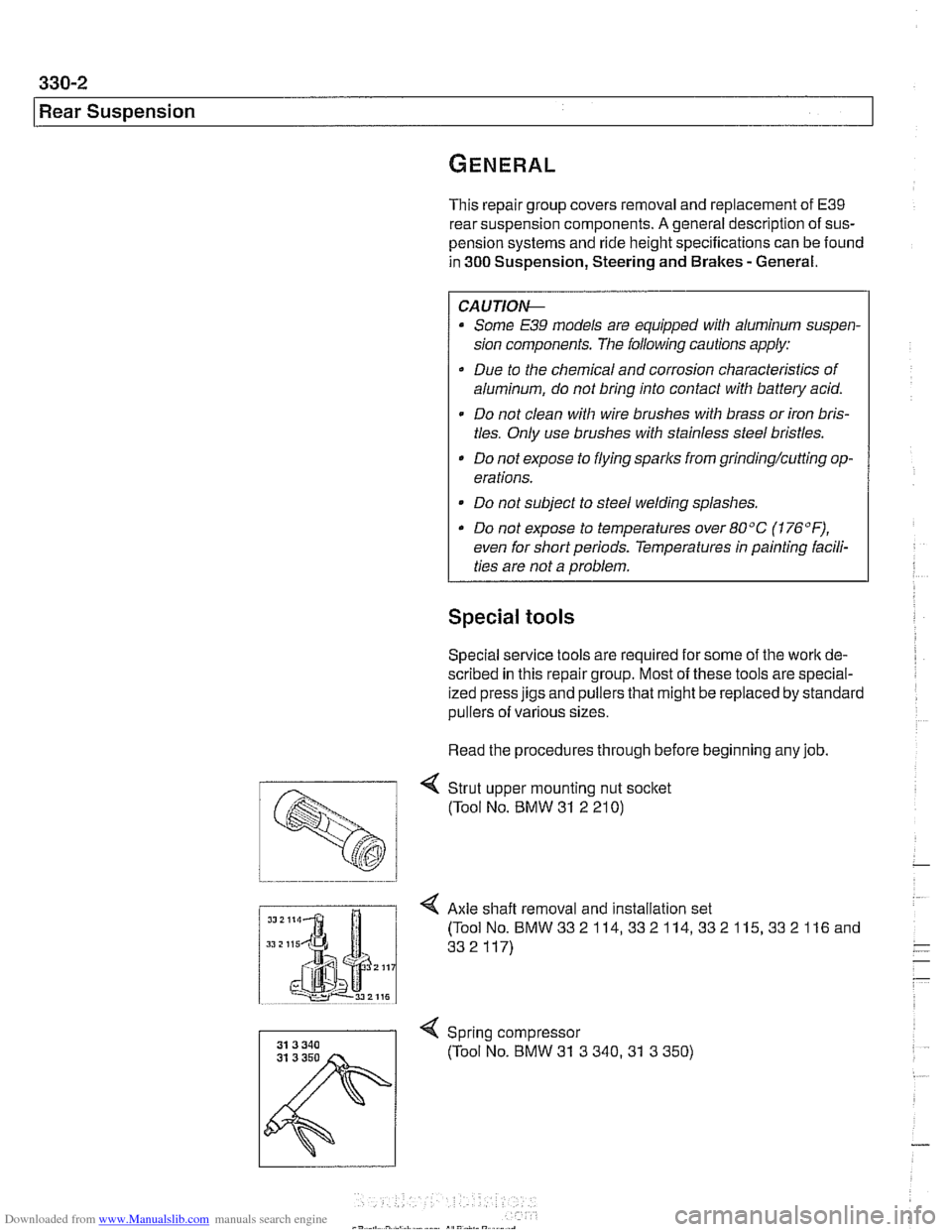

Special tools

Special service tools are required for some of the work de-

scribed in this repair group. Most of these tools are special-

ized press jigs and pullers that might be replaced by standard

pullers of various sizes.

Read the procedures through before beginning any job.

< Strut upper mounting nut socket

(Tool No. BMW

31 2 21 0)

I Axle shaft removal and installation set

Spring compressor (Tool No. BMW

31 3 340.31 3 350)

Page 705 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

C. -- -- - -- Rear ~us~ensionl

Depending on year and model applications, the Sport Wagon

rear suspension may be equipped with:

Conventional shock absorbers and coil springs

Electronic height control (EHC) system which incorporates

air springs

NOTE-

. Suspension and EHC troubleshooting is covered in 300

Suspension, Steering and Brakes-General.

EHC system repairs, other than air spring replacement,

are covered in Electronic height control

(EHC) compo-

nent replacement.

Replace shock absorbers and springs in pairs only.

Rear shock absorber, removing and

installing

- Raise car and remove rear wheels,

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jack stands under

suspension parts.

CAUTION-

If working on a vehicle with compressedairshock absorbers,

disable air supply pump by disconnecting electrical plug be-

fore performing any repairs. Pump is located beneath a cover

under the spare tire in the floor of the cargo compartment.

- Support swing arm from below

CAUTIOG

The shock absorber prevents the drive axle and wlieel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting fasteners prevents damage to the

brake hose,

parking

brake cable and drive axle CVjoints.

- Working in cargo compartment, remove carpet. Remove tri-

angular upper shock mount covers located beside spare tire

well.

- If applicable: Detach air supply line from shock absorber.

Plug ports and lines to keep out dirt.