transmission fluid BMW 540i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 570 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-6

Manual Transmission

Manual transmissions installed in the 5 Series are normally

filled with a "Lifetime" manual transmission fluid

(BMW MTF

LT-I) and do not require periodic fluid changes. Transmis-

sions filled with MTF LT-I lifetime oil are identified with a yel-

low label near the transmission fill plug labeled "Lifetime Oil

MTF-LT-1".

Transmission fluid level, checking

- Drive vehicle for a few miles to warm transmission.

- Raise and safely support vehicle to access transmission

filler plug.

CAUTION-

Make sure the car is stable and well supporfedat all times.

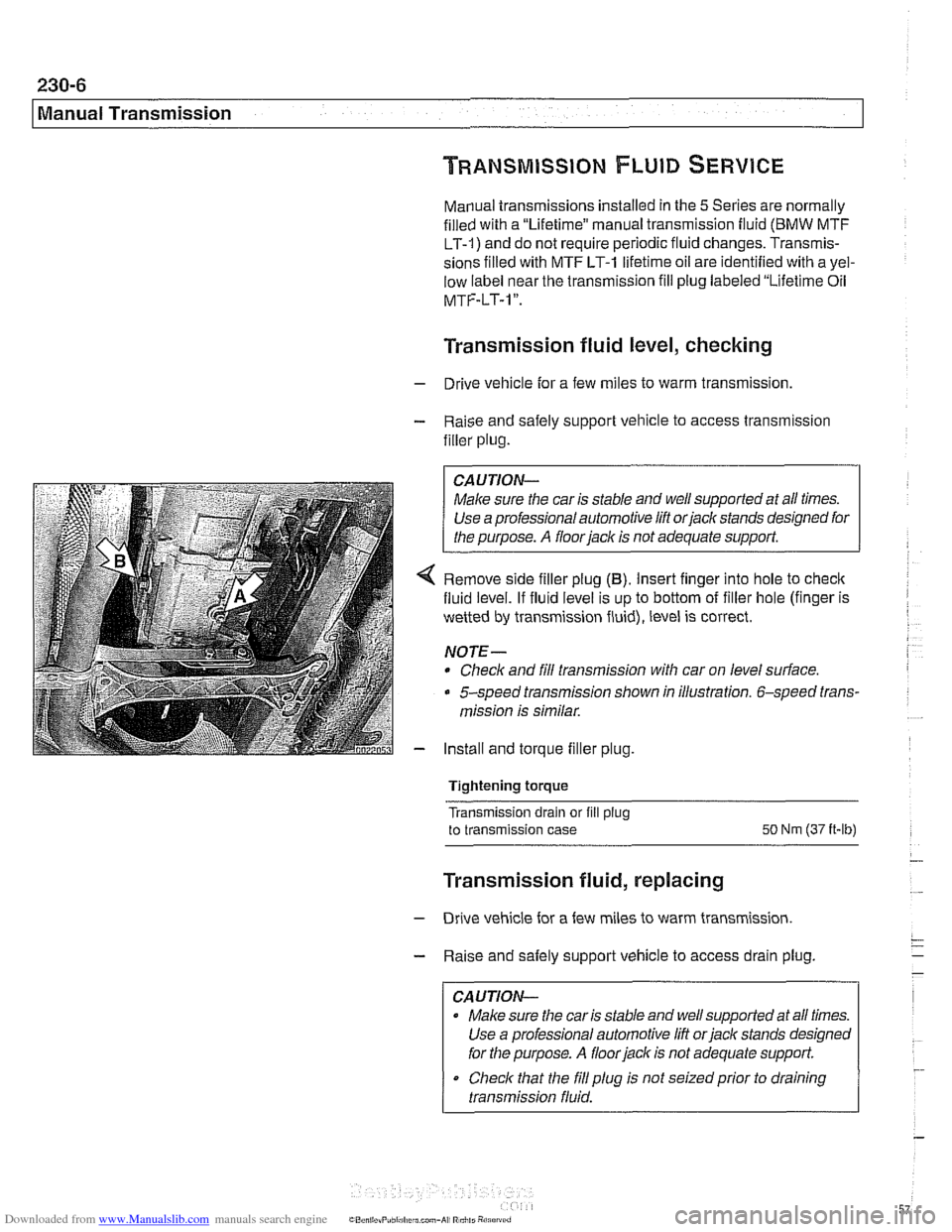

4 Remove side filler plug (B). Insert finger into hole to check

fluid level. If fluid level is up to bottom of filler hole (finger is

wetted by transmission fluid), level is correct.

NOTE-

* Check and fill transmission with car on level surface.

5-speed transmission shown in illustration. 6-speed trans-

mission is similar.

- Install and torque filler plug.

Tightening torque

Transmission drain or fill

plug

to transmission case SO Nm (37 it-lb)

Transmission fluid, replacing

- Drive vehicle for a few miles to warm transmission.

- Raise and safely support vehicle to access drain plug.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed

for the purpose.

A floor jack is not adequate support.

Check that the

fill plug is not seizedprior to draining

transmission fluid.

Page 571 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-7

Manual Transmission

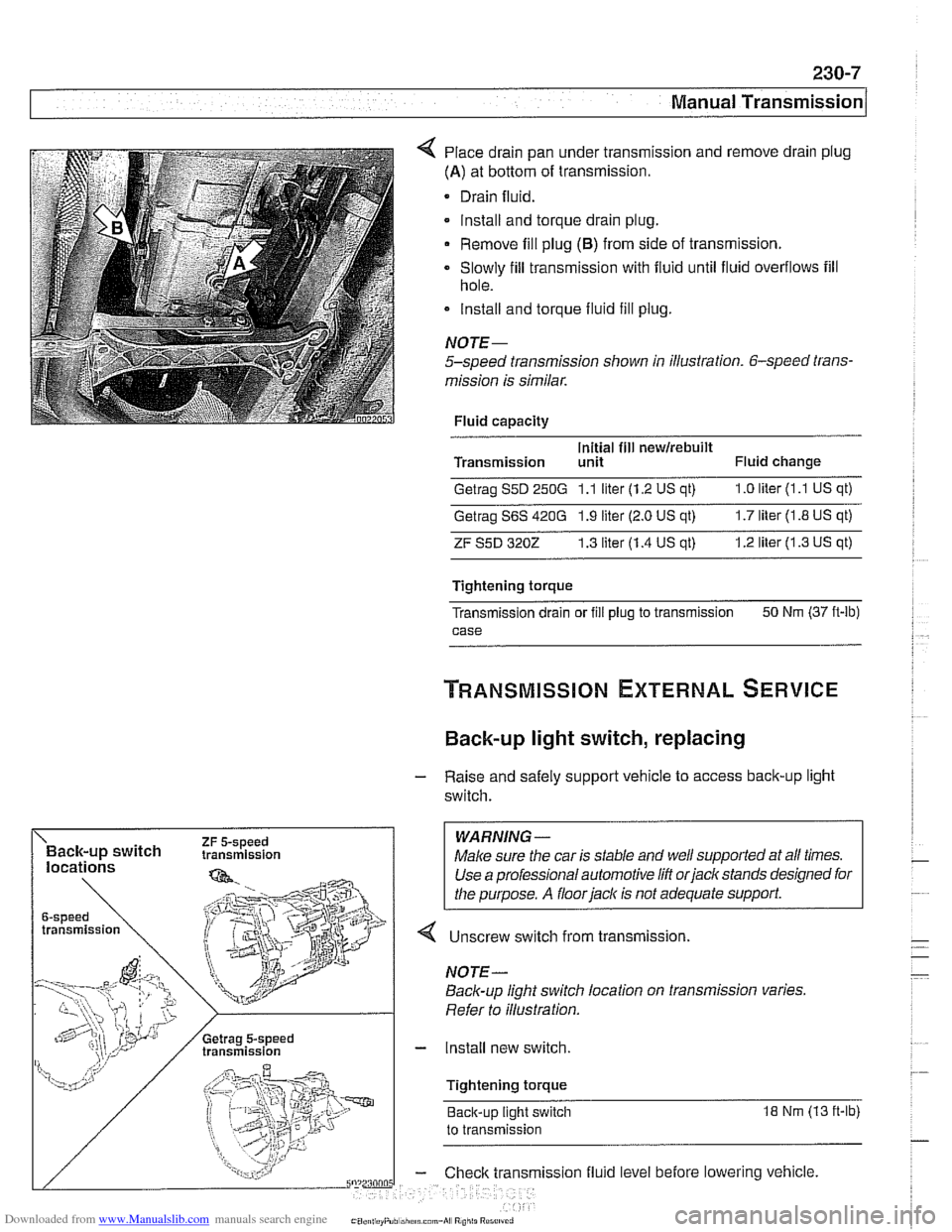

Place drain pan under transmission and remove drain plug

(A) at bottom of transmission.

Drain fluid.

lnstall and torque drain plug.

Remove fill plug

(6) from side of transmission.

Slowly fill transmission with fluid until fluid overflows fill

hole.

lnstall and torque fluid fill

plug.

NOJE-

5-speed transmission shown in illustration. 6-speed trans-

mission is similar.

Fluid capacity

Initial fill

newirebuilt Transmission unit Fluid change

Getrag S5D 250G 1.1 liter (1.2 US qt) 1.0 liter (1 .l US qt)

Getrag S6S 420G 1.9 liter (2.0 US qt) 1.7 liter (1.8 US qt)

ZF S5D 3202 1.3 liter (1.4 US at) 1.2 liter (1.3 US qt)

Tightening torque

Transmission drain or

fill plug to transmission 50

Nm (37 ft-lb)

case

Back-up light switch, replacing

- Raise and safely support vehicle to access back-up light

switch.

WARNING -

4 Unscrew switch from transmission.

Back-up light switch location on transmission varies.

Refer to illustration.

- Install new switch.

Tightening torque Back-up light switch

18 Nm (13 ft-lb)

to transmission

ission fluid level before lowering vehicle.

Page 573 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-9

Manual ~ransmissionl

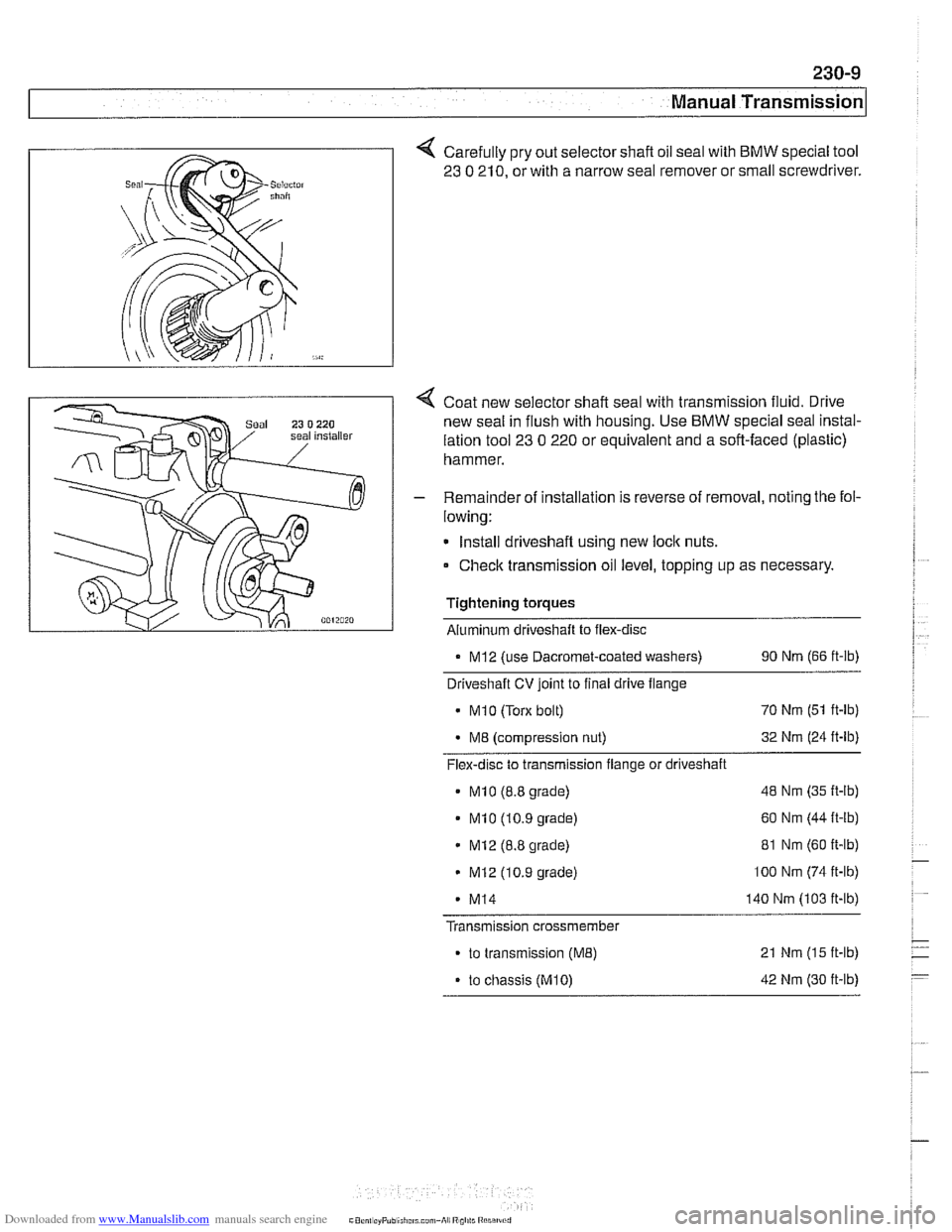

Carefully pry out selector shaft oil seal with BMW special tool

23

0 210, or with a narrow seal remover or small screwdriver.

Coat new selector shaft seal with transmission fluid. Drive

new seal in flush with housing. Use

BMW special seal instal-

lation tool

23 0 220 or equivalent and a soft-faced (plastic)

hammer.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new

loclc nuts.

Check transmission oil level, topping up as necessary.

Tightening torques Aluminum driveshaft to flex-disc

. MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft CV joint to final drive flange

MI 0 (Torx bolt) 70

Nm (51 ft-lb)

M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

MI0 (8.8 grade) 48 Nm (35 ft-lb)

MI0 (10.9 grade) 60

Nm (44 it-lb)

MI2 (8.8 grade) 81

Nm (60 ft-lb)

MI2 (10.9 grade) lo0 Nm (74 ft-lb)

- MI4 140 Nm (103 ft-lb)

Transmission crossmember

to transmission (ME) 21 Nm (15 ft-lb)

. to chassis (M10) 42 Nm (30 ft-lb)

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

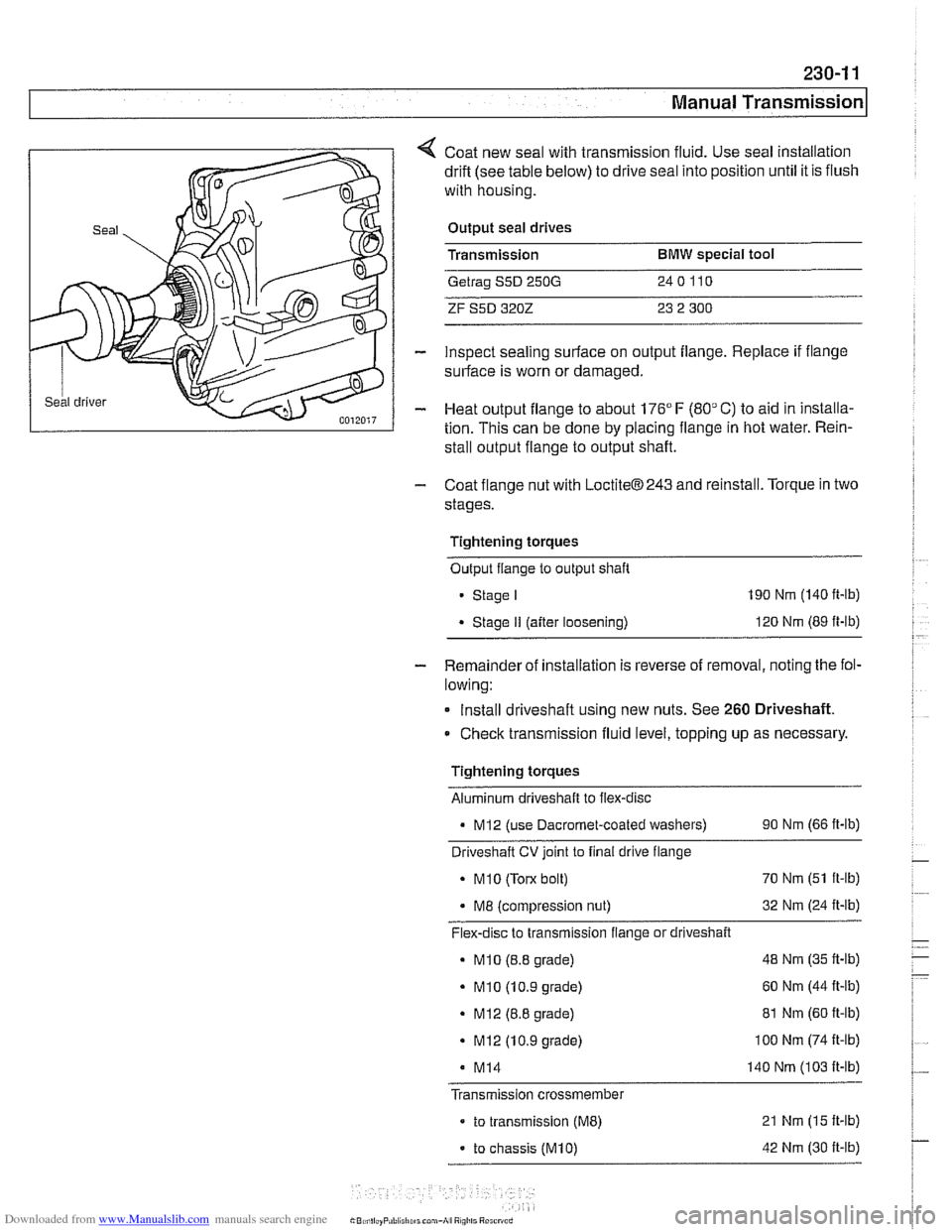

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 577 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 3

Manual ~ransmissionl

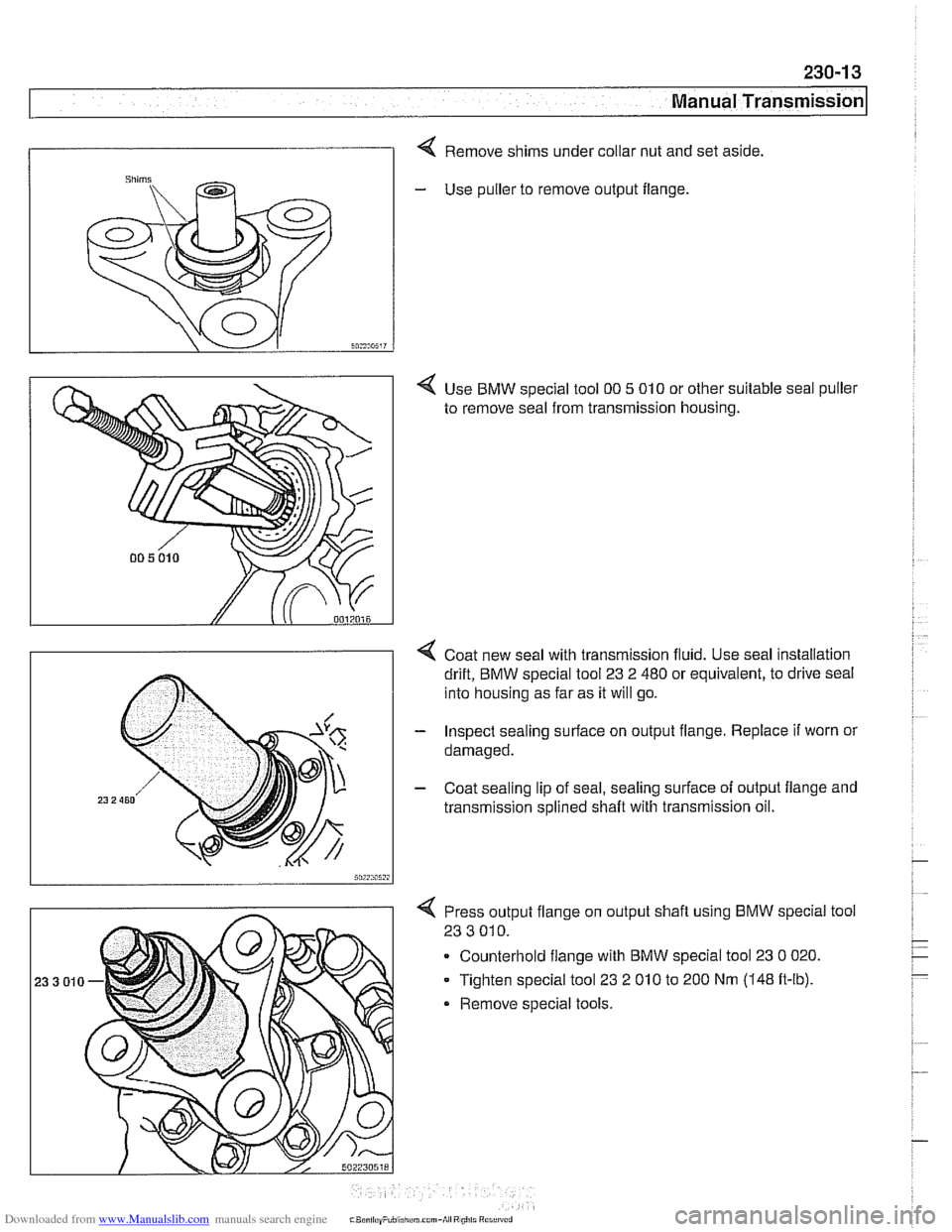

I 4 Remove shims under collar nut and set aside.

- Use puller to remove output flange

4 Use BMW special tool 00 5 010 or other suitable seal puller

to remove seal from transmission housing.

4 Coat new seal with transmission fluid. Use seal installation

drift, BMW special tool 23 2 480 or equivalent, to drive seal

into housing as far as it will go.

- Inspect sealing surface on output flange. Replace if worn or

damaged.

- Coat sealing lip of seal, sealing surface of output flange and

transmission splined shaft with transmission oil.

4 Press output flange on output shafl using BMW special tool

23 3

010.

. Counterhold flange with BMW special tool 23 0 020.

Tighten special tool 23 2 010 to 200 Nm

(148 ft-lb).

Remove

special tools.

Page 578 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-14

I Manual Transmission

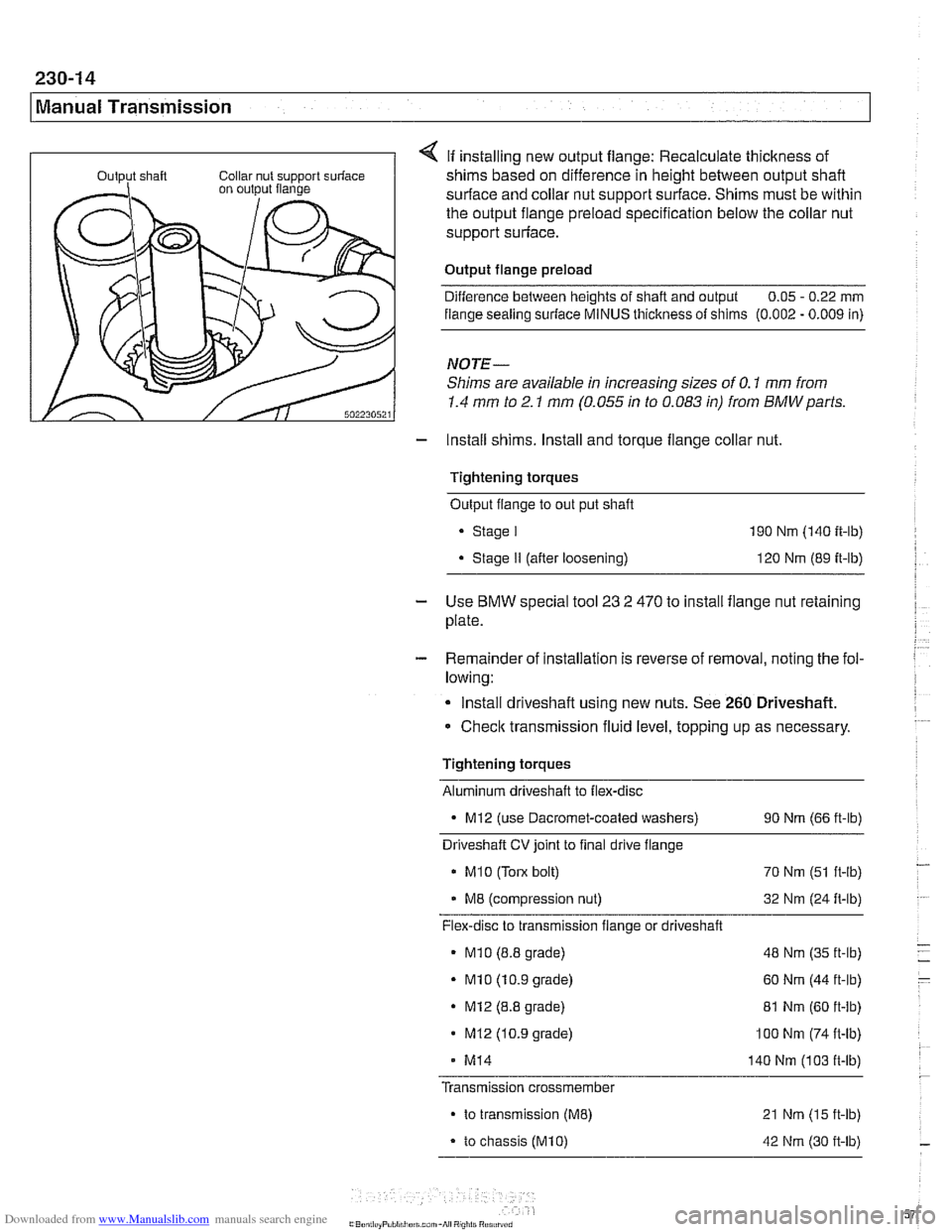

If installing new output flange: Recalculate thickness of

shims based on difference in height between output shaft

surface and collar nut support surface. Shims must be within

the output flange preload specification below the collar nut

support surface.

Output flange preload Difference between heights of shaft and output 0.05

- 0.22 mm

flange sealing

suriace MINUS thickness of shims (0.002 - 0.009 in)

NOTE-

Shims are available in increasing sizes of 0.1 mm from

1.4 mm to 2.1 mm (0.055 in to 0.083 in) from BMWparts.

- Install shims. Install and torque flange collar nut.

Tightening torques Output flange to out put shaft

. Stage I 190 Nm (140 ft-lb)

. Stage II (after loosening) 120 Nm (89 it-lb)

- Use BMW special tool 23 2 470 to install flange nut retaining

plate.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Checlc transmission fluid level, topping up as necessary.

Tightening torques

Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

MI0 (Tom bolt)

70 Nm (51 ft-lb)

M8 (compression nut) 32 Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

* MI0 (8.8 grade) 48 Nm (35 ft-lb)

- MI0 (10.9 grade) 60 Nm (44 ft-lb)

. MI2 (8.8 grade)

81 Nm (60 ft-lb)

MI2 (10.9 grade) 100 Nm (74 ft-lb)

- MI4 140 Nm (1 03 ft-lb)

Transmission

crossmembe~

to transmission (ME)

to chassis (M10)

21 Nm (15 ft-lb)

42 Nm (30 it-lb)

Page 582 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 8

Manual Transmission

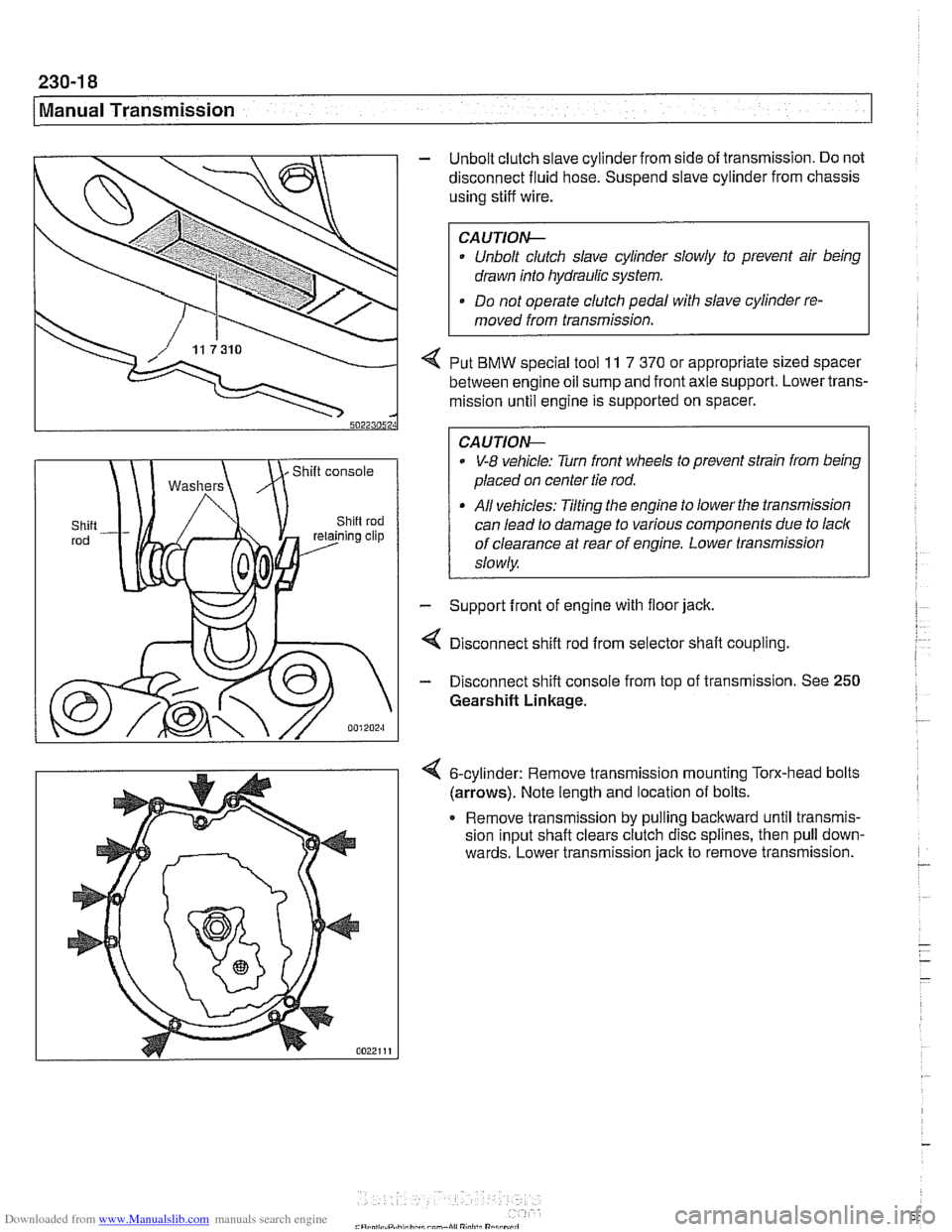

- Unbolt clutch slave cylinder from side of transmission. Do not

disconnect fluid hose. Suspend slave cylinder from chassis

using stiff wire.

CA UTIOG

Unbolt clutch slave cylinder slowly to prevent air being

drawn into hydraulic system.

. Do not operate clutch pedal with slave cylinder re-

moved from transmission.

4 Put BMW special tool 11 7 370 or appropriate sized spacer

between engine oil sump and front axle support. Lower trans-

mission until engine is supported on spacer.

0 V-8 vehicle: Turn front wheels to prevent strain from being

placed on center tie rod.

All vehicles: Tilting the engine to lower the transmission

can lead to damage to various components due to lack

of clearance at rear of engine. Lower transmission

slowly

- Support front of engine with floor jack.

4 Disconnect shift rod from selector shaft coupling

- Disconnect shift console from top of transmission. See 250

Gearshift Linkage.

6-cylinder: Remove transrnisslon mounting Torx-head bolts

(arrows). Note length and locatlon of bolts.

Remove

transrnlssion by pulling backward untll transmls-

sion Input shaft clears clutch d~sc spl~nes, then pull down-

wards. Lower

transmlsslon jack to remove transrnlsslon. -

- - -

-

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

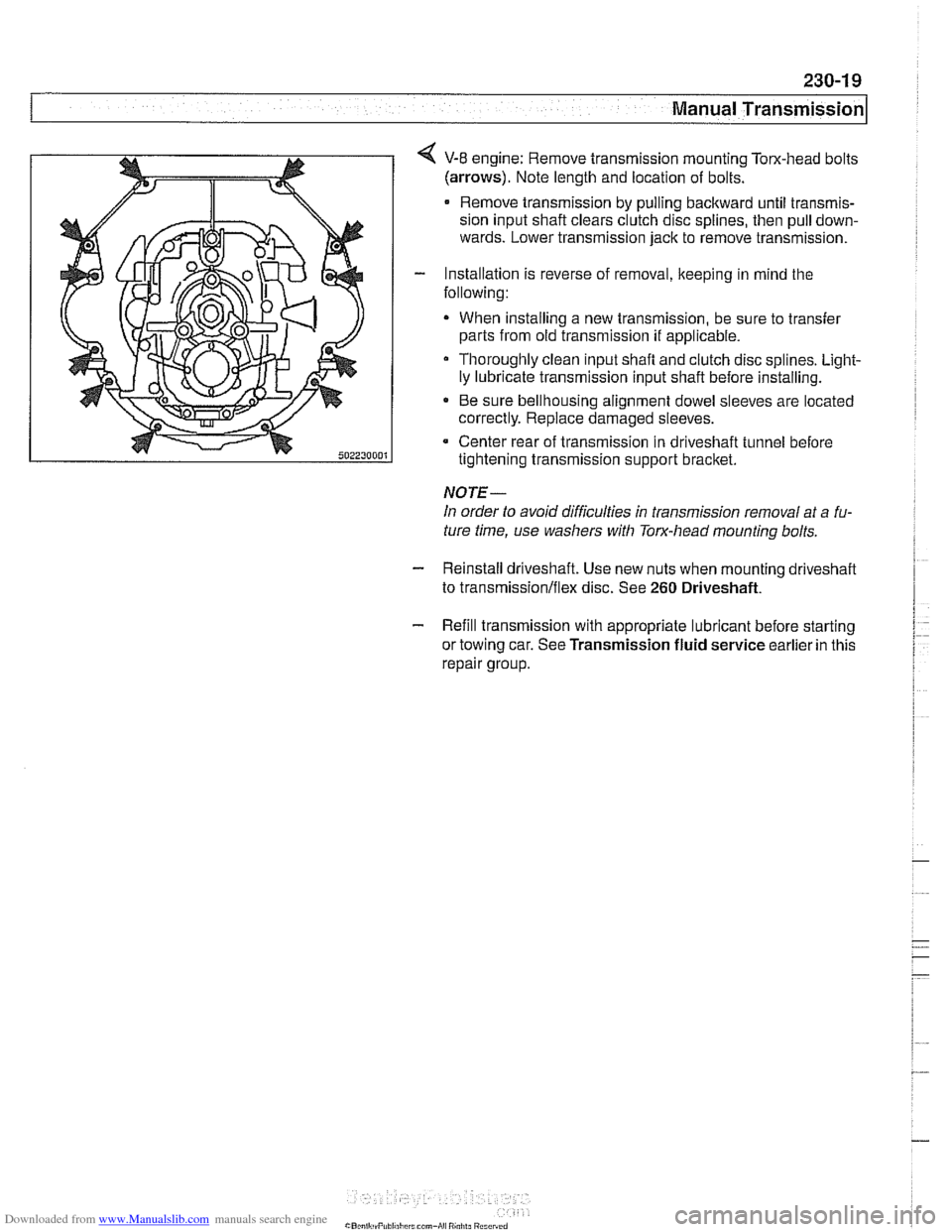

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 585 of 1002

Downloaded from www.Manualslib.com manuals search engine

240 Automatic Transmission

General . . . . . . . . . . . . . . . . . . . . . .

Special tools . . . . . . . . . . . . . . . . . . .

Automatic transmission applications

. . . . . ,240-2 ATF, draining and filling . . . . . . . . . . . . . . . . 240-7

. . . . . ,240-2 Automatic transmission fluid

. . . . . ,240-4 pan and strainer. . . . . . . . . . . . . . . . . . . . . . 240-9

Troubleshooting . . . . . . . . . . . . . . . . . . .240-4 Transmission Removal

and Installation

. . . . . . . . . . . . . . . . . . . 240-10 Automatic Transmission Fluid Transmission, removing and installing . . . 240-10 (ATF) Service . . . . . . . . . . . . . . . . . . . . . ,240-6

Automatic transmission fluid (ATF) . . . . . . . ,240-6

ATF level, checking . . . . . . . . . . . . . . . . . . ,240-6

Page 589 of 1002

Downloaded from www.Manualslib.com manuals search engine

- .- -

Automatic Transmission

Electronics are used to control the operation of these auto-

matic transmissions. Steptronic transmission functions are

also programmed into the transmission control module

(TCM). The TCM monitors transmission operation for faults

and alerts the driver by illuminating the transmission fault indi-

cator on the instrument panel. Diagnostic trouble codes

(DTCs) stored in the TCM may be downloaded and interpret-

ed by trained technicians using special BMW diagnostic

equipment.

Some minor automatic transmission problems can be cor-

rected by changing the automatic transmission fluid (ATF)

and filter. Begin by checking ATF level and condition.

Checlc

to see if the fluid is dirty or has a burned odor indicating over-

heated fluid. The burned odor may be the results of burned

discs in theclutch paclts. The friction material from the burned

disc can clog valve body passages.

NOTE-

The E39 automatic transmission is not equipped with a dip-

stick.

Checking the ATF level must be done while monitoring

the ATF temperature with the engine idling. The

BMW dealer

is equipped with the special equipment to make this check.