check engine light BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 8 of 1002

Downloaded from www.Manualslib.com manuals search engine

I General Warnings and Cautions

WARNINGS (continued)

. The air conditioning system is filled with chemical refrigerant,

which is hazardous. The AIC system should be serviced only by

trained technicians using approved refrigerant recoverylrecycling

equipment, trained in related safety precautions, and familiar with

regulations governing the discharging and disposal of automotive

chemical refrigerants.

. Do not expose any part of the AIC system to high temperatures

such as open flame. Excessive heat will increase system pres-

sure and may cause the system to burst.

Some aerosol tire inflators are highly flammable. Be extremely

cautious when repairing a tire that may have been inflated using

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away

from the tire repair area. Inflate and deflate the

tire at least four

times before breaking the bead from the rim.

Completely remove the tire from the rim before attempting any re-

pair.

Cars covered by this manual are equipped with a supplemental

restraint system (SRS), that automatically deploys

airbags and

pyrotechnic seat belt tensioners

In the event oi a frontal or side

impact. These are explosive devices. Handled improperly or with-

out adequate safeguards, they can be accidently activated and

cause serious injury.

- The ignition system produces high voltages that can be fatal.

Avoid contact with exposed terminals and use extreme care when

working on a car with the engine running or the ignition switched

on.

. Place jack stands only at locations specified by the manufacturer.

The vehicle

illtino iack su~olied with the vehicle is intended fortire -. , . changes only. A heavy duty floor jack should be used lo lift vehicle

before installing

jacl( stands. See 010 General.

- Battery acid (electrolyte) can cause severe burns. Flush contact

area

with water, seek medical attention.

Aerosol cleaners and solvents may contain hazardous or deadly

vapors and are highly flammable. Use only in a well ventilated ar-

ea. Do not use on hot surfaces (engines, brakes, etc.).

Do not remove

coolant reservoir or radiator cap with the engine

hot. Danger of burns and engine damage.

CAUTIONS-

See also WARNINGS

- if you lack the slqills, tools and equipment, or a suitable worl(shop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

BMW is constantly improving its cars and sometimes these

changes, both in parts and specifications, are made applicable to

earlier models. Therefore, part numbers listed in this manual are

for reference only. Always check with your authorized BMW deal-

er parts department for the latest information.

Before starting a job, make certain that you have all the neces-

sary tools and parts on hand. Read ail the instructions thorough-

ly, and do not attempt shortcuts. Use tools appropriate to the

work and use only replacement parts meeting BMW specifica-

tions.

Use pneumatic and electric tools only to loosen threaded parts

and fasteners. Never use these tools to tighten fasteners, espe-

cially on light alloy parts. Always use a torque wrench to tighten

fasteners to the tightening torque specification listed.

Be mindful of the environment and ecology. Before you drain the

crankcase, find out the proper way to dispose of the

oil. Do not

pour

oil onto the ground, down a drain, or into a stream, pond or

lake. Dispose of waste in accordance with Federal, State and

Local laws.

The control module for the anti-lock brake system

(ABS) cannot

withstand temperatures from a paint-drying booth or a heat

lamp

in excess of 203" F (95°C) and should not be subjected to tem-

peratures in excess of 185°F

(8S°C) for more than two hours.

- Before doing any electrical welding on cars equipped with ABS,

disconnect the battery negative

(-) terminal (ground strap) and

the ABS control module connector.

- Always make sure ignition is off before disconnecting battery.

Label battery cables before disconnecting. On some models, bat-

tery cables are not color coded.

Disconnecting the battery may erase fault code@) stored in control

module memory. Using special BMW diagnoslic equipment, check

lor

iauit codes prior to disconnecting the battery cables. If the mal-

I.mct on ndicator Ignt (MIL) s I. ..minaled. see OBD On-Board

Diaanostics

Tl11s iant is iuenlfted as lne Check Ena~ne oht

(1997-2000 models jor~ervlce Engine Soon light (2061 andlater

models). If any other system iaults have been detected (indicated

by an illuminated warning light), see an authorized BMW dealer.

If a normal

or rapid charger is used to charge battery, the battery

must be disconnected and removed from the vehicle in order to

avoid damaging the vehicle.

- Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

* Connect and disconnect a battery charger only with the battery

charger switched off.

- Sealed or "maintenance free" batteries should be slow-charged

only, at an amperage rate that is approximately 10% of the bat-

tery's ampere-hour (Ah)

rating.

. Do not allow battery charging voltage to exceed 16.5 volts. If the

battery begins producing gas or boiling violently, reduce the

charging rate.

Boosting a sulfated battery at a high charging rate

can cause an explosion.

Page 29 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Cars with discharged or dead batteries can be jump-started

using the good battery from another car. See owner's manual

for proper instruction on jump starting. When jump-starling

the engine, always note the following warnings.

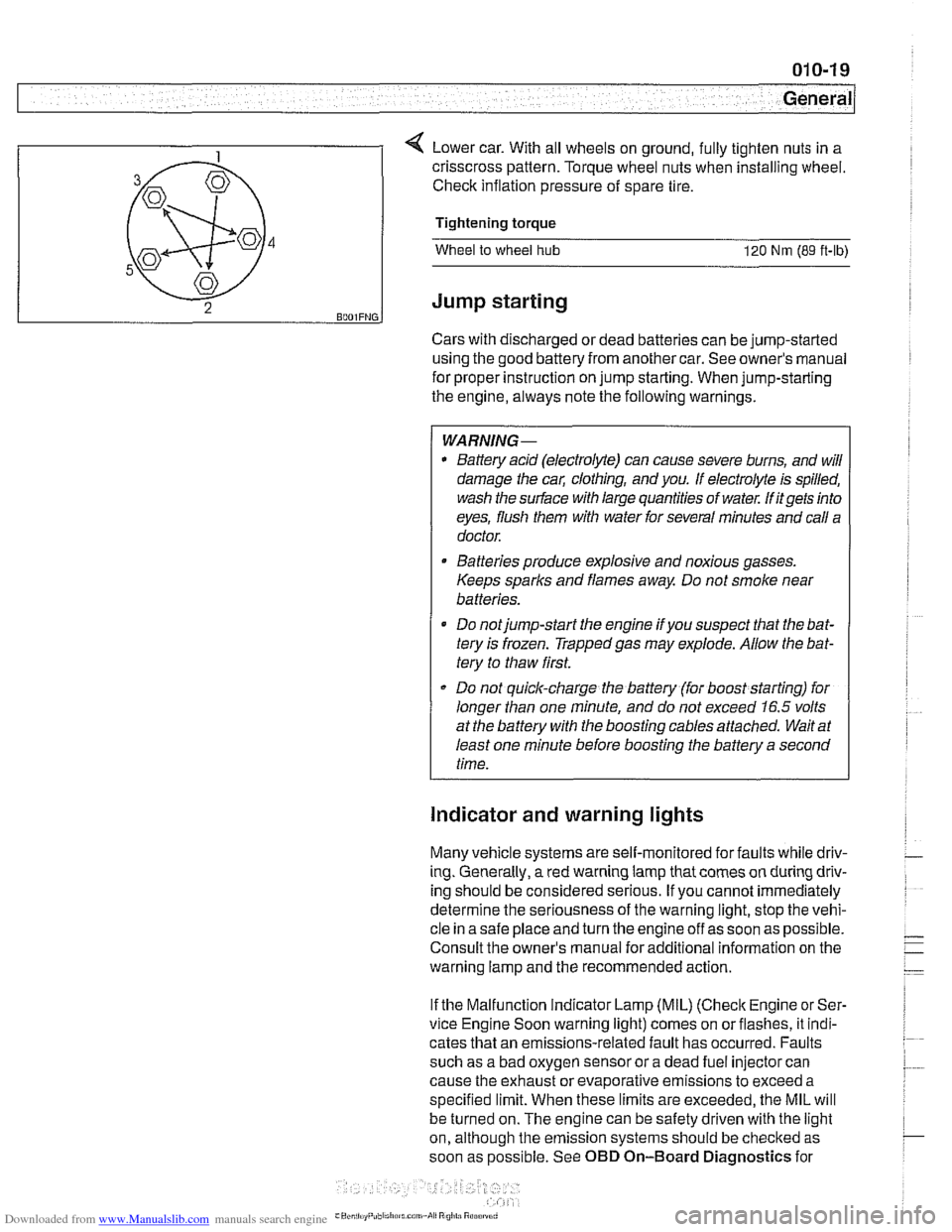

4 Lower car. With all wheels on ground, fully tighten nuts in a

WARNING-

* Battery acid (electrolyte) can cause severe burns, and will

damage the

cal; clothing, and you. If electrolyte is spilled,

wash the surface with large quantities of water.

M itgets into

eyes, flush them with water for several minutes and call a

doctor.

B4

5

43

2 BOOIFNG.

Batteries produce explosive and noxious gasses.

Keeps sparks and flames away. Do not smoke near

batteries.

Do notjump-start the engine

ifyou suspect that the bat-

tery is frozen. Trappedgas may explode. Allow the bat-

tery to thaw first.

Do not quick-charge the battery (for boost starting) for

longer than one minute, and do not exceed

16.5 volts

at the battery with the boosting cables attached. Wait at

least one minute before boosting the battery a second

time.

crisscross pattern.

Torque wheel nuts when installing wheel.

Check inflation pressure of spare tire.

Tightening torque

Wheel to wheel hub 120 Nm (89 ft-ib)

Jump starting

Indicator and warning lights

Many vehicle systems are self-monitored for faults while driv-

ing. Generally,

a red warning lamp that comes on during driv-

ing should be considered serious. If you cannot immediately

determine the seriousness of the warning light, stop the vehi-

cle in a safe place and turn the engine off as soon as possible.

Consult the owner's manual for additional information on the

warning lamp and the recommended action.

If the Malfunction Indicator Lamp (MIL)

(Check Engine or Ser-

vice Engine Soon warning light) comes on orflashes, it indi-

cates that an emissions-related fault has occurred. Faults

such as a bad oxygen sensor or a dead fuel injector can

cause the exhaust or evaporative emissions to exceed a

specified limit. When these limits are exceeded, the MIL will

be turned on. The engine can be safety driven with the light

on, although the emission systems should be

checked as

soon as possible. See OBD On-Board Diagnostics for

Page 30 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-20

General

more information on the Check Engine Light and the on-

board diagnostic system.

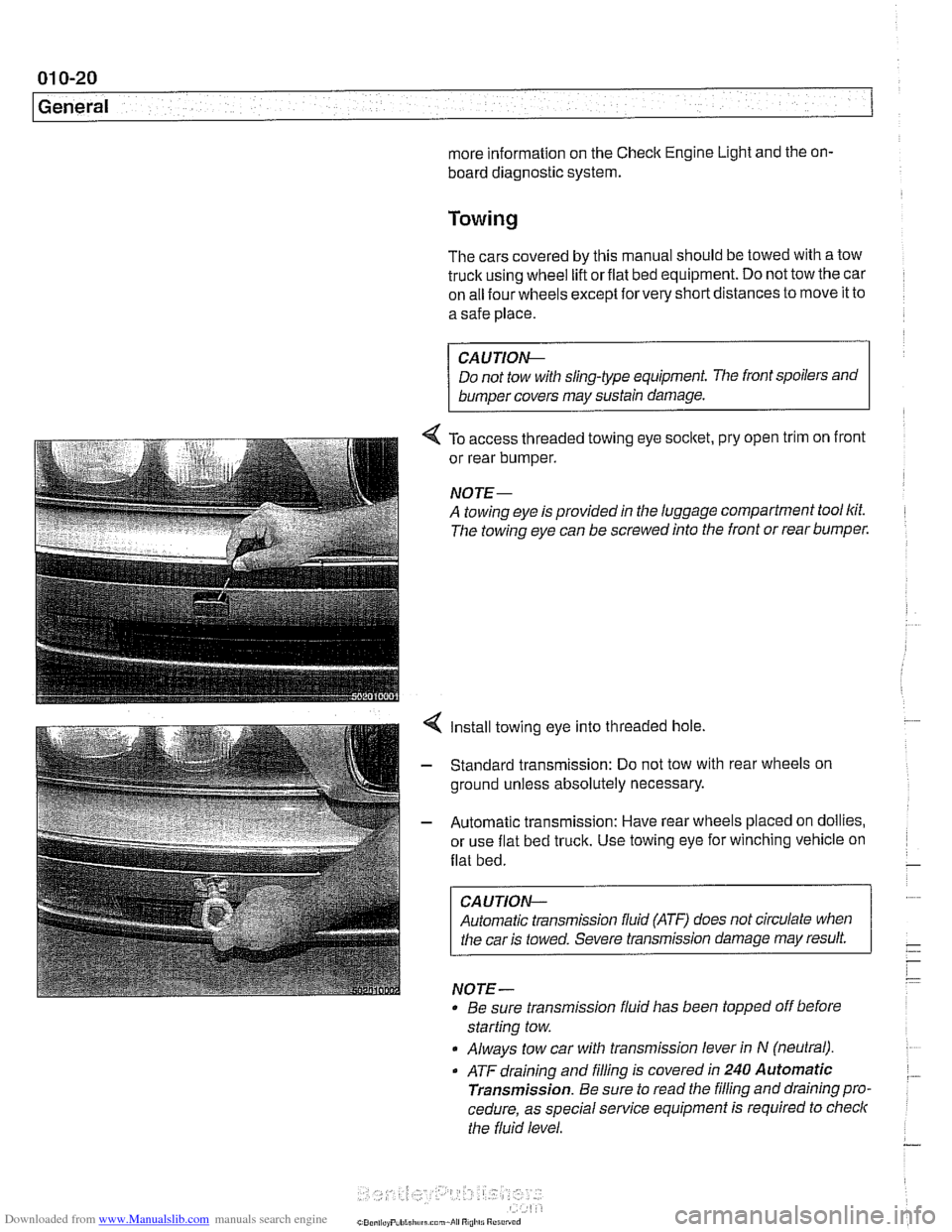

Towing

The cars covered by this manual should be towed with a tow

truck using wheel lift or flat bed equipment. Do not tow the car

on all four wheels except

forvery short distances to move it to

a safe place.

CA U JION-

Do not tow with sling-type equipment The front spoilers and

b~m~er covers may sustain damage.

4 To access threaded towing eye socltet, pry open trim on front

or rear bumper.

NOJE-

A towing eye is provided in the luggage compartment tool lcit.

The towing eye can be screwed into the front or rear bumper.

4 Install towing eye into threaded hole.

- Standard transmission: Do not tow with rear wheels on

ground unless absolutely necessary.

- Automatic transmission: Have rear wheels placed on dollies,

or use flat bed truck. Use towing eye for winching vehicle on

flat bed.

CAUTION-

Automatic transmission fluid (ATF) does not circulate when

I the car is towed. Severe transmission damage may result.

NOTE-

Be sure transrnission fluid has been topped off before

starting tow.

Always tow car with transrnission lever in

N (neutral).

. ATF draining and filling is covered in 240 Automatic

Transmission.

Be sure to read the filling and draining pro.

cedure, as special service equipment is required to

checlc

the fluid level.

Page 40 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

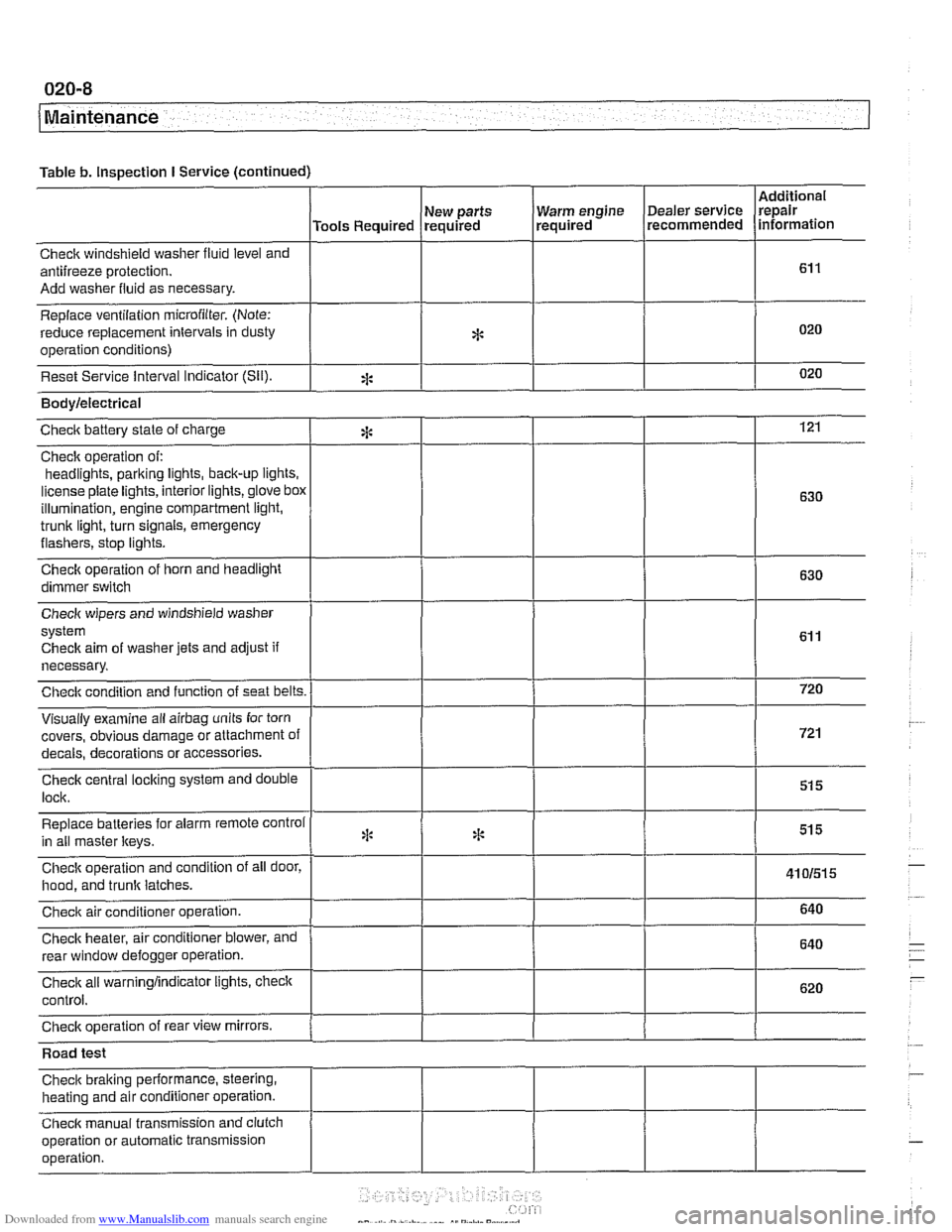

Table b. Inspection I Service (continued)

I I I I

Warm engine Dealer service

required recommended

Check windshield

washer fluid level and

antifreeze protection.

Add washer fluid as necessary.

Replace ventilation

microfilter. (Note:

reduce replacement intervals in dusty

operation conditions)

Reset Service interval Indicator

(Sil).

Additional

repair

information

Tools Required

*

eck aim of washer jets and adjust if

necessary.

covers, obvious damage or attachment o

s or accessories.

Road test

Check braking performance, steering,

heating and air conditioner operation.

Check manual transmission and clutch

operation or automatic transmission

operation. New

parts

required

*

Bodylelectrical

121

630

630

Checic battery state of charge

Check operation of:

headlights,

parking iights, back-up lights.

license plate lights, interior lights,

glove box

illumination, engine compartment light,

trunk light, turn signals, emergency

flashers, stop iights.

Check operation of horn and headlight

dimmer switch

:i:

Page 46 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 4

Maintenance

- When oil flow has diminished to an occasional drip, reinstall

drain plug with a new metal sealing washer and torque plug.

Tightening torque Engine oil drain plug to oil pan

25 Nrn (1.8 ft-lb)

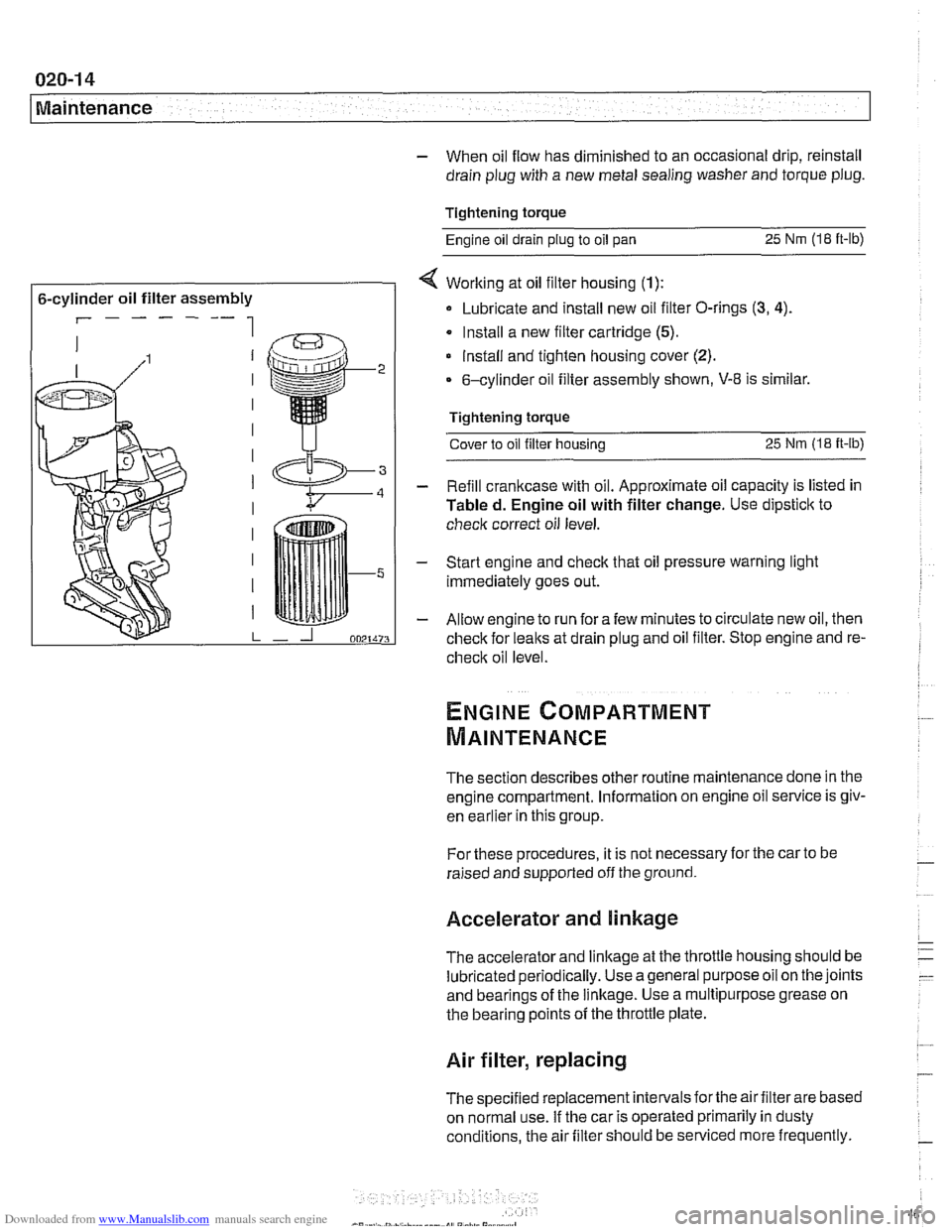

6-cylinder oil filter assembly

r------ 1

< Working at oil filter housing (1):

Lubricate and install new oil filter O-rings (3, 4).

Install a new filter cartridge (5).

lnstall and tighten housing cover (2).

6-cylinder oil filter assembly shown, V-8 is similar.

Tightening torque Cover to oil filter housing

25 Nm (1.8 it-lb)

- Refill crankcase with oil. Approximate oil capacity is listed in

Tabled. Engine oil with filter change. Use dipstick to

check correct oil level.

- Start engine and check that oil pressure warning light

immediately goes out.

- Allow engine to run fora few minutes to circulate new oil, then

check for leaks at drain plug and oil filter. Stop engine and re-

check oil level

The section describes other routine maintenance done in the

engine compartment. Information on engine oil service is

giv-

enkar~ier inthis group.

For these procedures, it is not necessary for the car to be

raised and supported off the ground.

Accelerator and linkage

The accelerator and linkage at the throttle housing should be

lubricated periodically. Use ageneral purposeoil on the joints

and bearings of the linkage. Use a multipurpose grease on

the bearing points of the throttle plate.

Air filter, replacing

The specified replacement intervals forthe air filter are based

on normal use. If the car is operated primarily in dusty

conditions, the air filter should be serviced more frequently.

Page 54 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-22 Maintenance

1

- Installation is reverse of removal, bearing in mind the

following:

Lightly lubricate new

spark plug threads with

copper-based anti-seize compound.

Thread plugs into cylinder head by hand to prevent

cross-threading.

. Be sure to reinstall and tighten coil grounds.

Tightening torque Spark plug

to cylinder head 25 Nm (18 It-lb)

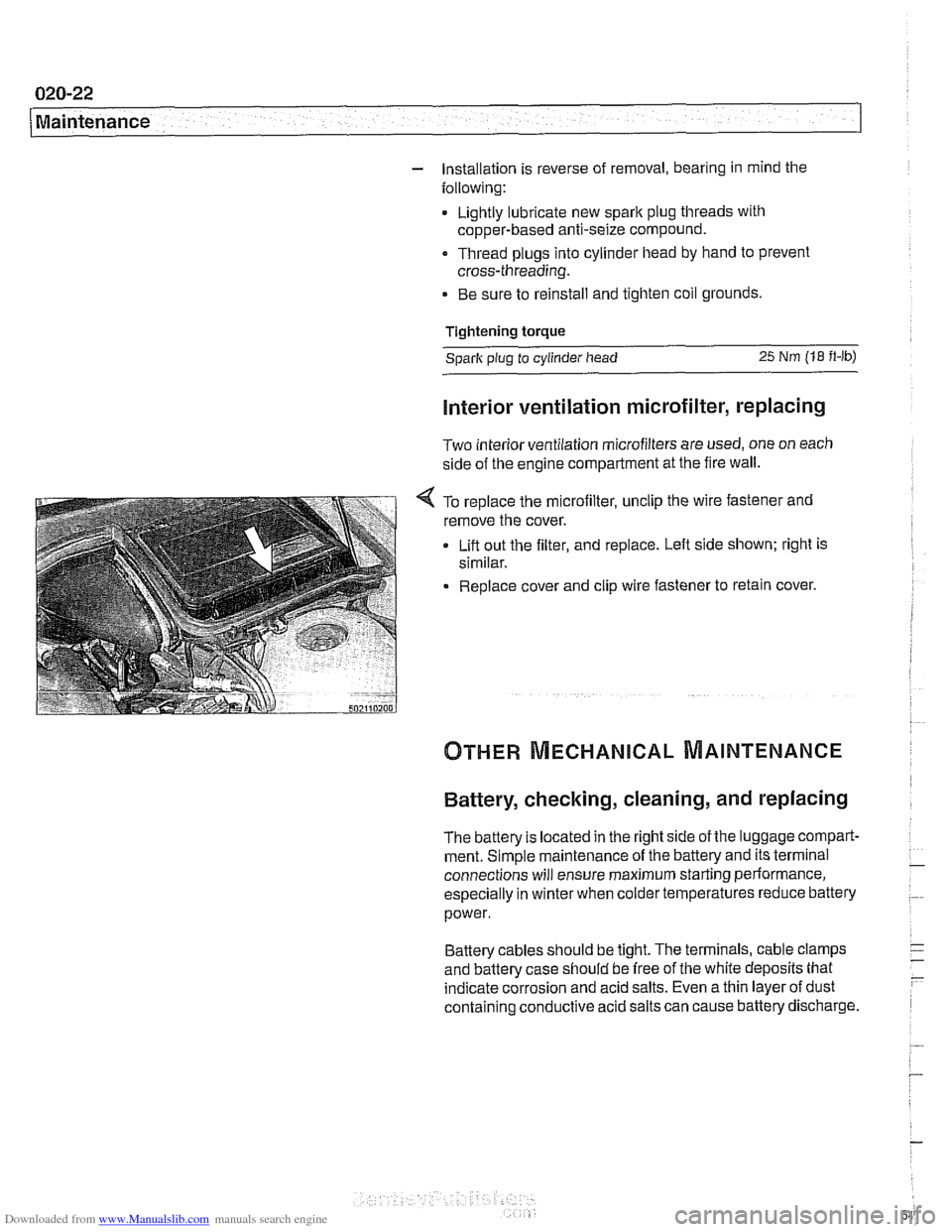

Interior ventilation microfilter, replacing

Two interior ventilation microfilters are used, one on each

side of the engine compartment at the fire wall.

< To replace the microfilter, unclip the wire fastener and

remove the cover.

Lift out the filter, and replace. Left side shown; right is

similar.

Replace cover and clip wire fastener to retain cover.

Battery, checking, cleaning, and replacing

The battery Is located in the right side of the luggage compart-

ment. Simple maintenance of the battery and its terminal

connections will ensure maximum starting periormance,

especially in winter when colder temperatures reduce battery

power.

Battery cables should be tight. The terminals, cable clamps

and battery case should be free of the white deposits that

indicate corrosion and acid salts. Even a thin layer of dust

containing conductive acid salts can cause battery discharge.

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 75 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-3

Engine Removal and lnstallationl

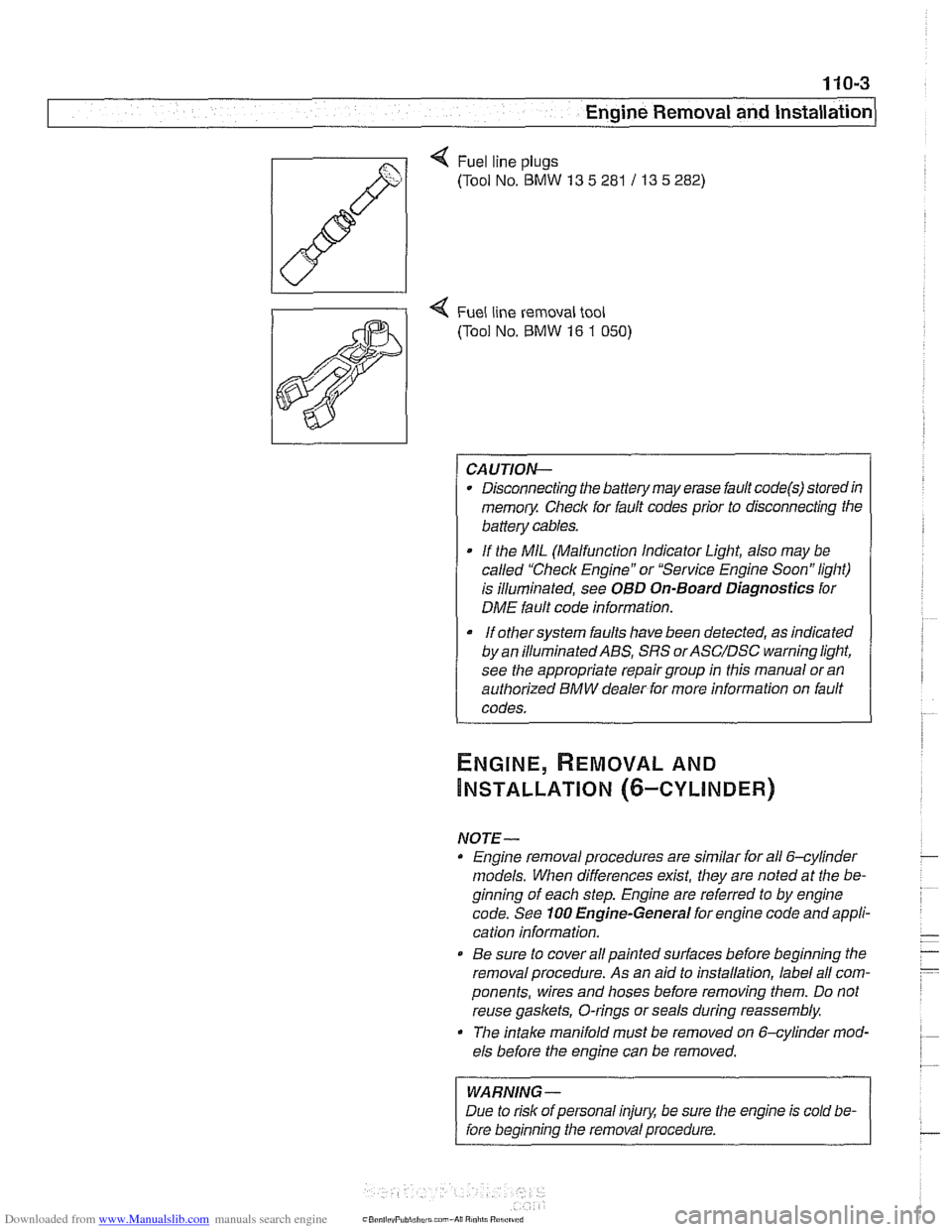

Q Fuel line plugs

(Tool No.

BMW 13 5 281 / 13 5 282)

4 Fuel line removal tool

(Tool No.

BMW 16 1 050)

CAUTION-

Disconnecting the battery may erase fault code@) storedin

memoiy Check for fault codes prior to disconnecting the

battery cables.

If the MIL (Malfunction Indicator Light, also may be

called "Check Engine" or "Service Engine Soon" light)

is illuminated, see

OBD On-Board Diagnostics for

DME fault code information.

It orhersysrem faults have been detected, as indicated I

by an ~llum~nated ABS, SRS orASC/DSC ~arning light,

see the appropriate repair group in this manual or an

authorized BMW dealer for more information on fault

codes.

NOTE- Engine removal procedures are similar for all 6-cylinder

models. When differences

exist, they are noted at the be-

ginning of each step. Engine are referred to by engine

code. See

100 Engine-General for engine code and appli-

cation information.

@ Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse

gaskets, O-rings or seals during reassembly.

The

intake manifold must be removed on &cylinder mod-

els before the engine can be removed.

WARNING-

Due to risk of personal injury, be sure the engine is cold be-

fore beginning the removal procedure.

Page 99 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-5

Cylinder Head Removal and Installation I

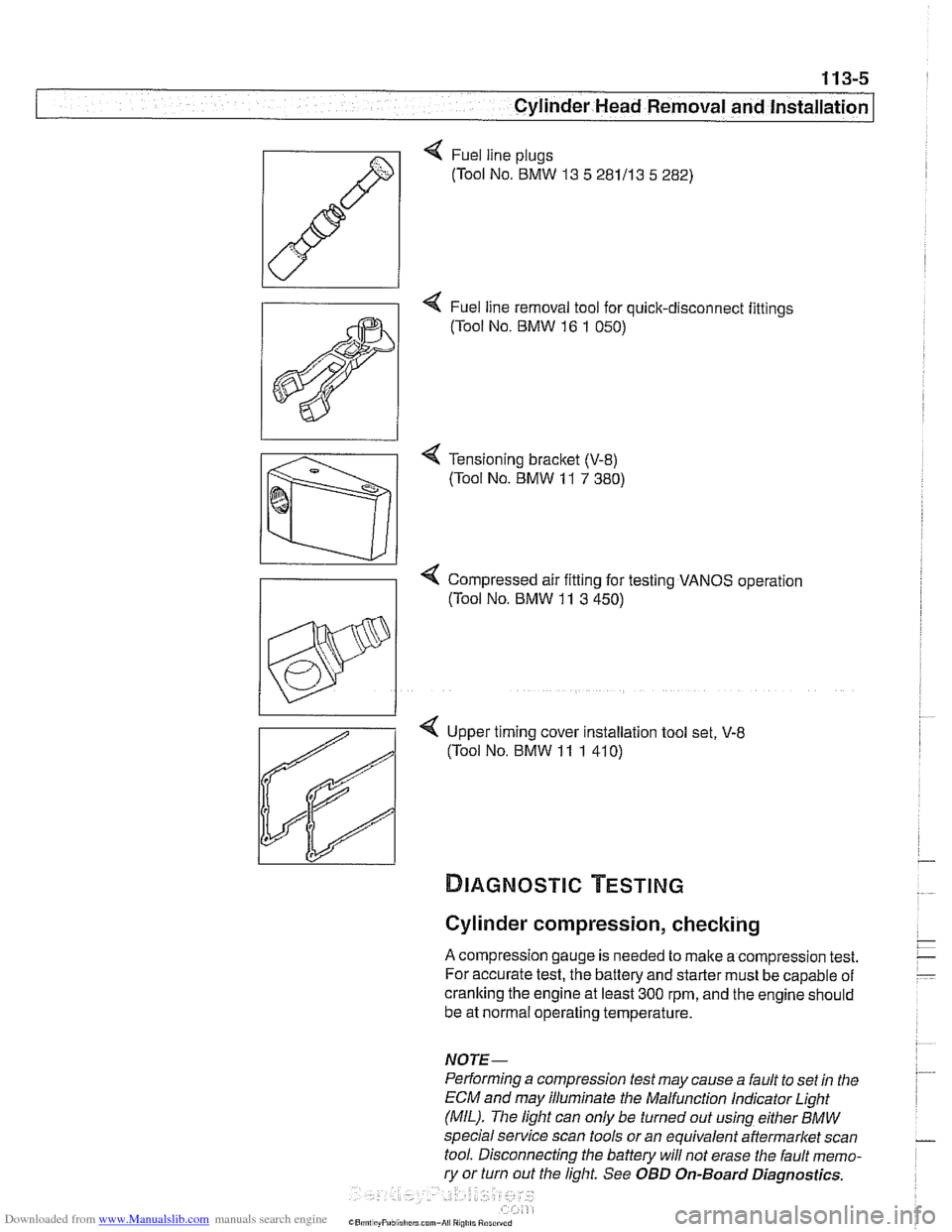

< Fuel line plugs

(Tool No.

BMW 13 5 281113 5 282)

4 Fuel line removal tool for quick-disconnect fittings

(Tool No.

BMW 16 1 050)

< Tensioning bracket (V-8)

(Tool No. BMW 11 7 380)

Compressed air fitting for testing VANOS operation

((Tool No.

BMW 11 3 450)

< Upper timing cover installation tool set, V-8

(Tool No. BMW 11 1 41 0)

Cylinder compression, checking

A compression gauge is needed to make a compression test.

For accurate test, the battery and starter must be capable of

cranking the engine at least

300 rpm, and the engine should

be at normal operating temperature.

NOTE-

Performing a compression test may cause a fault to set in the

ECM and may illuminate the Malfunction

Indicator Light

(MIL). The light can only be turned out using either

BMW

special service scan tools or an equivalent aftermarket scan

tool. Disconnecting the battery will not erase the fault memo-

ry or turn out the light. See OBD On-Board Diagnostics.

Page 112 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation

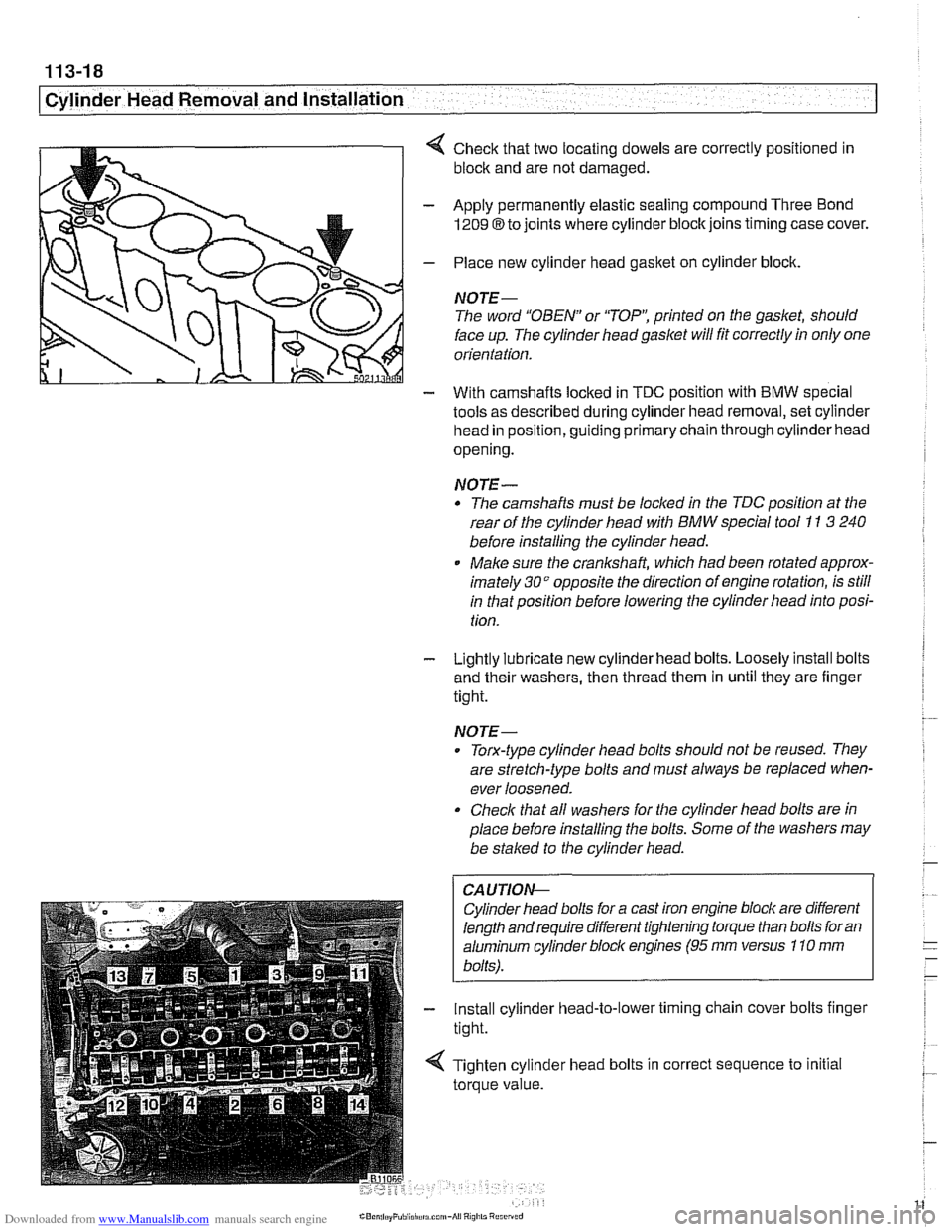

4 Check that two locating dowels are correctly positioned in

block and are not damaged.

- Apply permanently elastic sealing compound Three Bond

1209 8 to joints where cylinder block joins timing case cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or 'TOP': printed on the gasket, should

face up. The cylinder head

gasket will fit correctly in only one

orientation.

- With camshafts locked in TDC oosition with BMW soecial

tools as described during cylinder head removal,

seicylinder

head in position, guiding primary chain through cylinder head

opening.

NOTE-

* The camshafts must be locl(ed in the TDC position at the

rear of the cylinder head with

BMW special tool I1 3 240

before installing the cylinder head.

Make sure the

cranksha% which had been rotated approx-

imately

30" opposite the direction of engine rotation, is still

in that position before lowering the cylinder head into posi-

tion.

- Lightly lubricate new cylinder head bolts. Loosely install bolts

and their washers, then thread them in until they are finger

tight.

NOTE-

. Torx-type cylinder head bolts should not be reused. They

are stretch-type bolts and must always be replaced when-

ever loosened.

Check that all washers for the cylinder head bolts are in

place before installing the bolts. Some of the washers may

be

stalced to the cylinder head.

CAUTIOI\C

Cylinder head bolts for a cast iron engine block are different

length and require different tightening torque than bolts for an

aluminum cylinder bloclc engines

(95 rnm versus 110 rnm

bolts).

- Install cylinder head-to-lower timing chain cover bolts finger

tight.

< Tighten cylinder head bolts in correct sequence to initial

torque value.