Camshaft position BMW 540i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 271 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

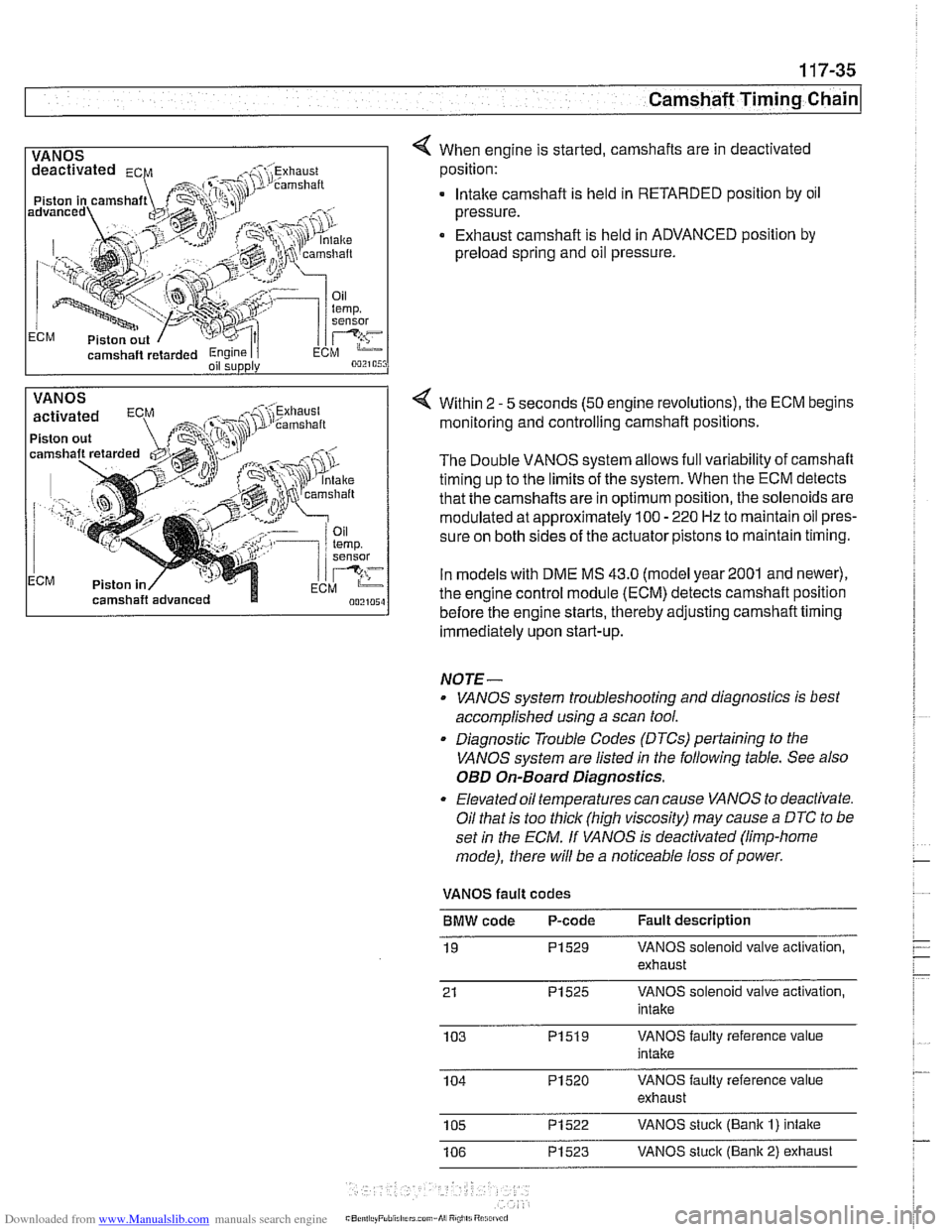

1 VANOS I 4 When engine is started, camshafts are in deactivated

camshaft

retarded Engine I i oil supply

position:

. lntalte camshaft is held in RETARDED position by oil

pressure.

Exhaust camshaft is held in ADVANCED position by

preload spring and oil pressure.

VANOS

Piston out

ECM Piston in Within 2

- 5

seconds (50 engine revolutions), the ECM begins

monitoring and controlling camshaft positions.

The Double VANOS system allows full variability of camshaft

timing up to the limits of the system. When the ECM detects

that the camshafts are in optimum position, the solenoids are

modulated at approximately 100

- 220 Hz to maintain oil pres-

sure on both sides of the actuator pistons to maintain timing.

In models with DME

MS 43.0 (model year2001 and newer),

the engine control module (ECM) detects camshaft position

before the engine starts, thereby adjusting camshaft timing

immediately upon start-up.

NOTE-

. VANOS system troubleshooting and diagnostics is best

accomplished using a scan tool.

. Diagnostic Trouble Codes (DTCs) pertaining to the

VANOS system are listed

in the following table. See also

OED On-Board Diagnostics.

Elevated oil temperatures can cause VANOS to deactivate.

Oil that is too thick (high viscosity) may cause

a DTC to be

set

in the ECM. If VANOS is deactivated (limp-home

mode), there will be a noticeable loss of power.

VANOS fault codes

BMW code P-code Fault description

19

PI529 VANOS solenoid valve activation,

exhaust

21

PI525 VANOS solenoid valve activation,

intake

103

PI519 VANOS faulty reference value

intake

104

PI520 VANOS faulty reference value

exhaust

105

PI522 VANOS stuck (Bank I) intake

106

PI523 VANOS stuck (Bank 2) exhaust

Page 272 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-36

Camshaft Timing Chain

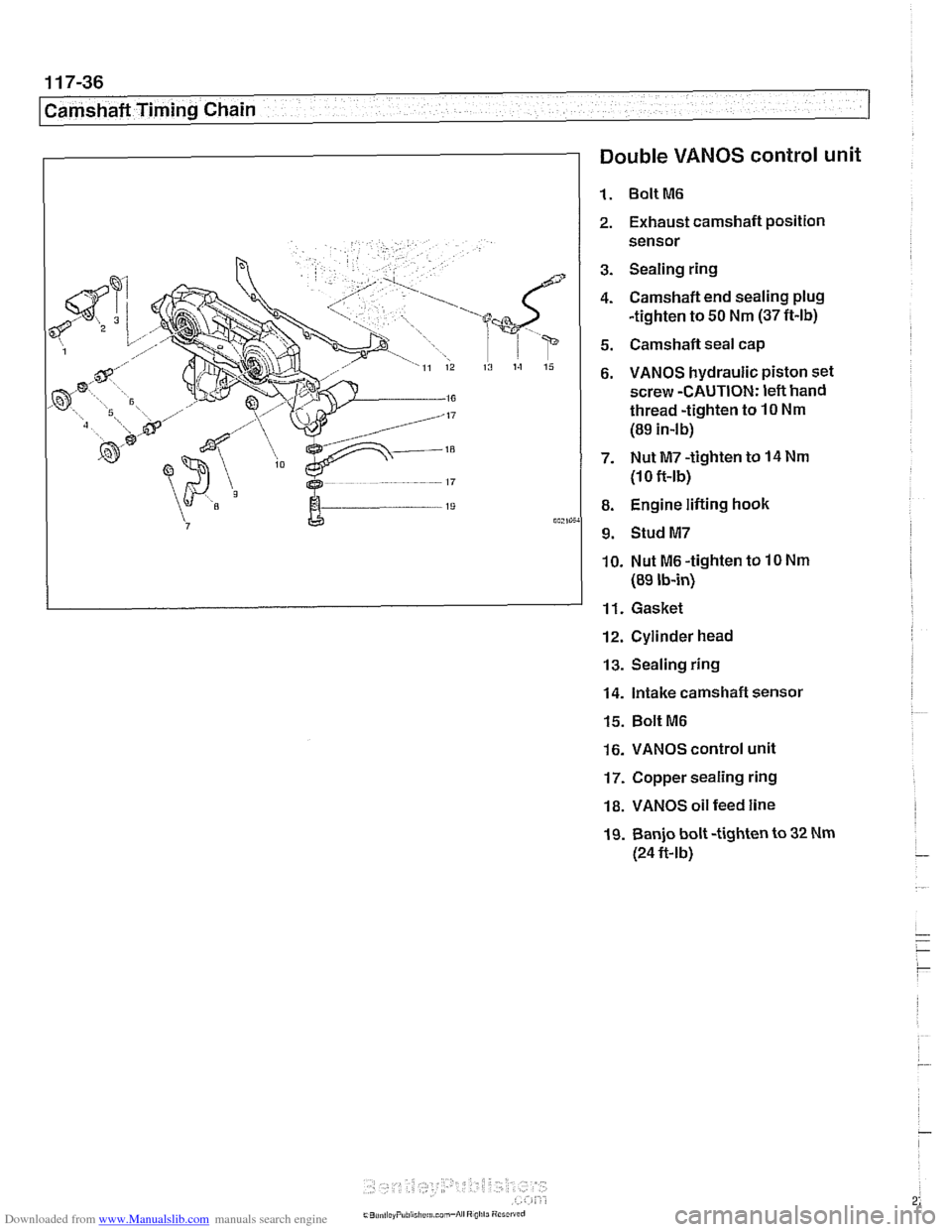

1 Double VANOS control unit

1. BoltM6

2. Exhaust camshaft position

sensor

3. Sealing ring

4. Camshaft end sealing plug

-tighten to 50 Nm (37 ft-lb)

5. Camshaft seal cap

6. VANOS hydraulic piston set

screw -CAUTION: left hand

thread -tighten to

10 Nm

(89 in-lb)

7. Nut M7 -tighten to

14 Nm

(1 0 ft-lb)

8. Engine lifting hook

9. Stud M7

10. Nut

M6 -tighten to 10 Nm

(89 lb-in)

11. Gasket

12. Cylinder head

13. Sealing ring

14. Intake camshaft sensol

15. Bolt M6

16. VANOS control unit

17. Copper sealing ring

18. VANOS oil feed line

19. Banjo bolt -tighten to 32 Nm

(24ft-lb)

Page 275 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-39

Camshaft Timing Chain

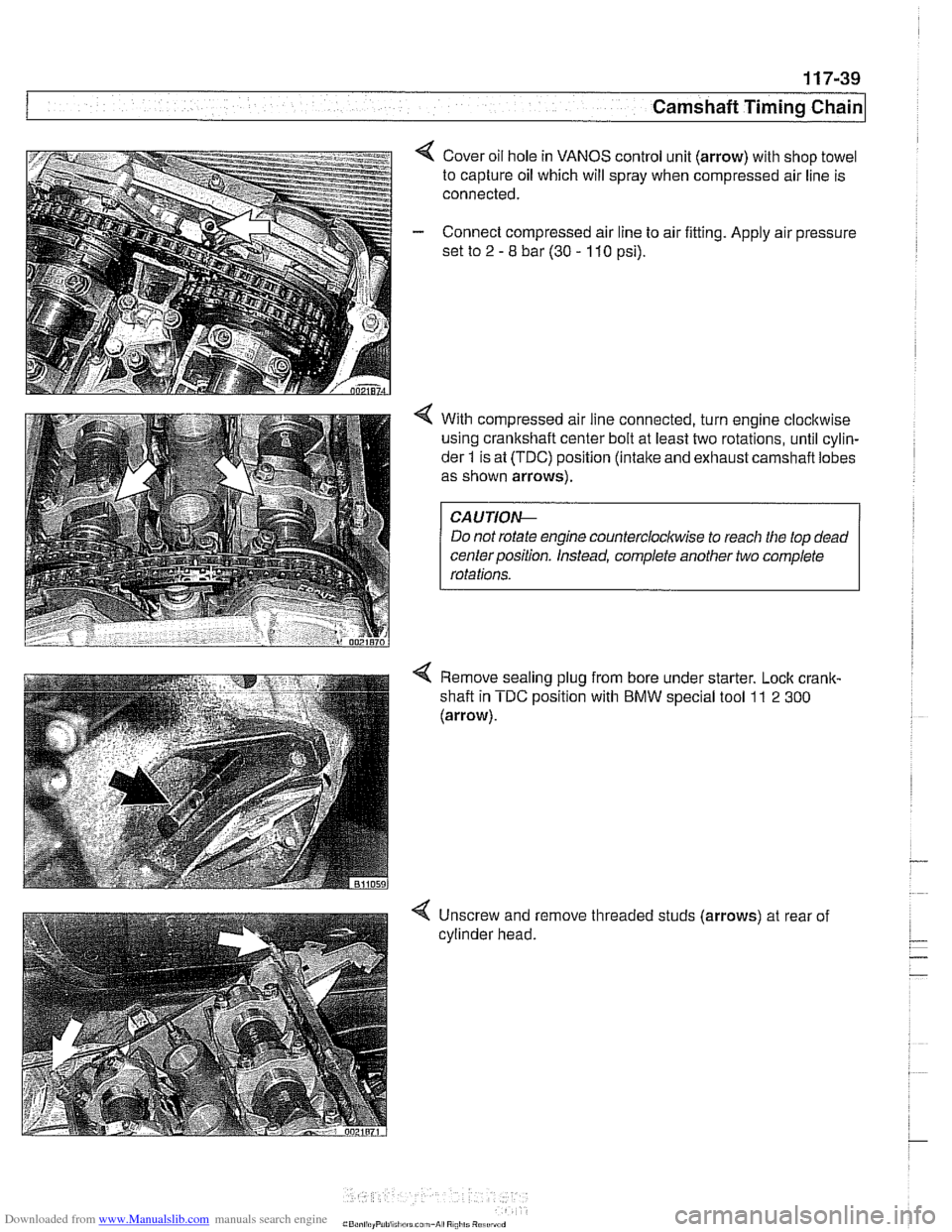

4 Cover oil hole in VANOS control unit (arrow) with shop towel

to capture oil which will spray when compressed air line is

connected.

- Connect compressed air line to air fitting. Apply air pressure

set to

2 - 8 bar (30 - 110 psi).

4 With compressed air line connected, turn engine clocltwise

using crankshaft center bolt at least two rotations, until cylin-

der

1 is at (TDC) position (intake and exhaust carnshafl lobes

as shown arrows).

Do not rotate engine

countercloclwise to reach the top dead

centerposition. Instead, complete another two complete

Remove sealing plug from bore under starter. Lock

crank-

shafl in TDC position with BMW special tool 11 2 300

(arrow).

-

4 Unscrew and remove threaded studs (arrows) at rear of

cylinder head.

Page 276 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .. ~-

Camshaft Timing Chain -

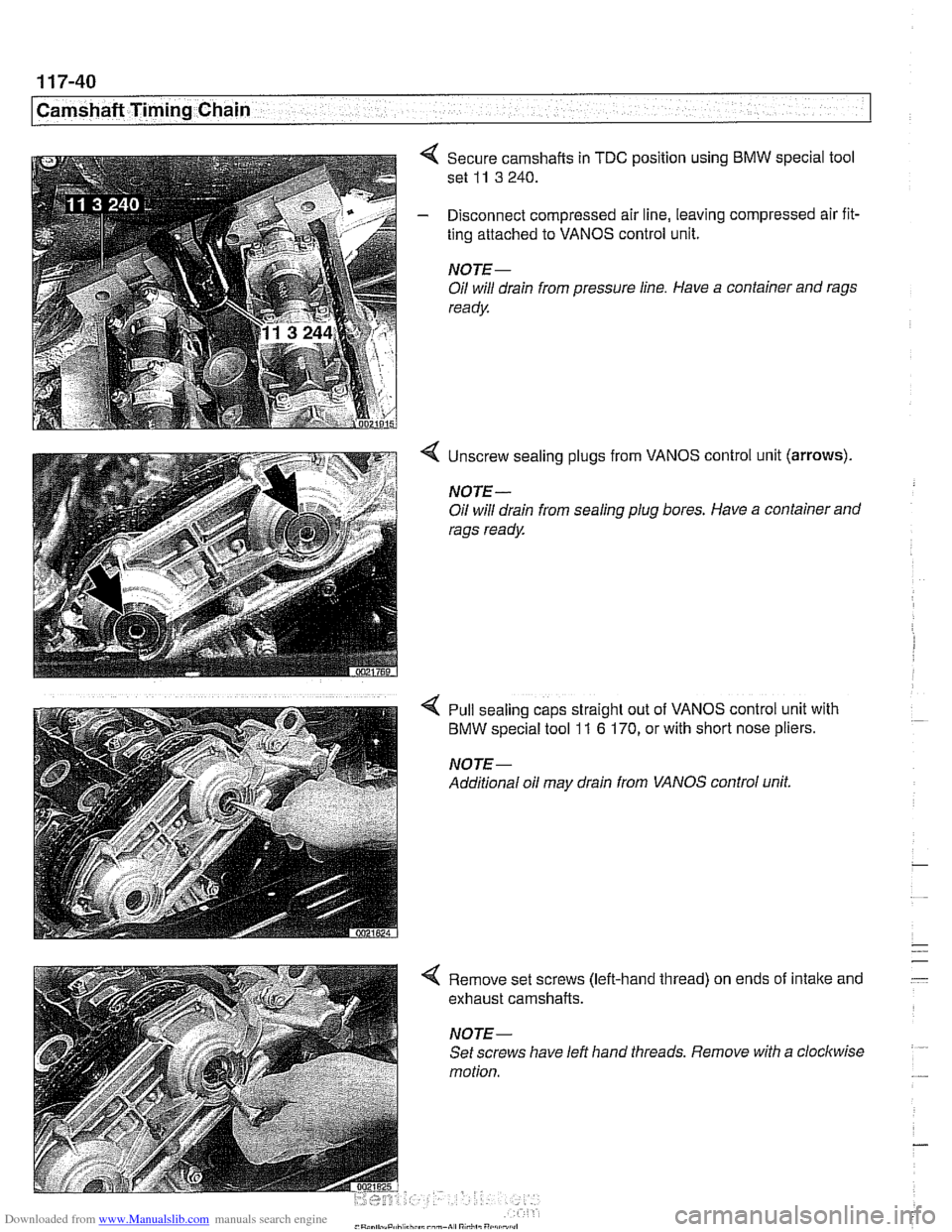

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

- Disconnect compressed air line, leaving compressed air fit-

ting attached to VANOS control unit.

NOTE -

Oil will drain from pressure line. Have a container and rags

ready

4 Unscrew sealing plugs from VANOS control unit (arrows).

NOTE-

Oil will drain from sealing plug bores. Have a container and

rags ready

4 Pull sealing caps straight out of VANOS control unit with

BMW special tool 11 6 170, or with short nose pliers.

NOTE-

Additional oil may drain from VANOS control unit.

4 Remove set screws (left-hand thread) on ends of intake and

exhaust camshafts.

NOTE-

Set screws have left hand threads. Remove with a clockwise

motion.

Page 279 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

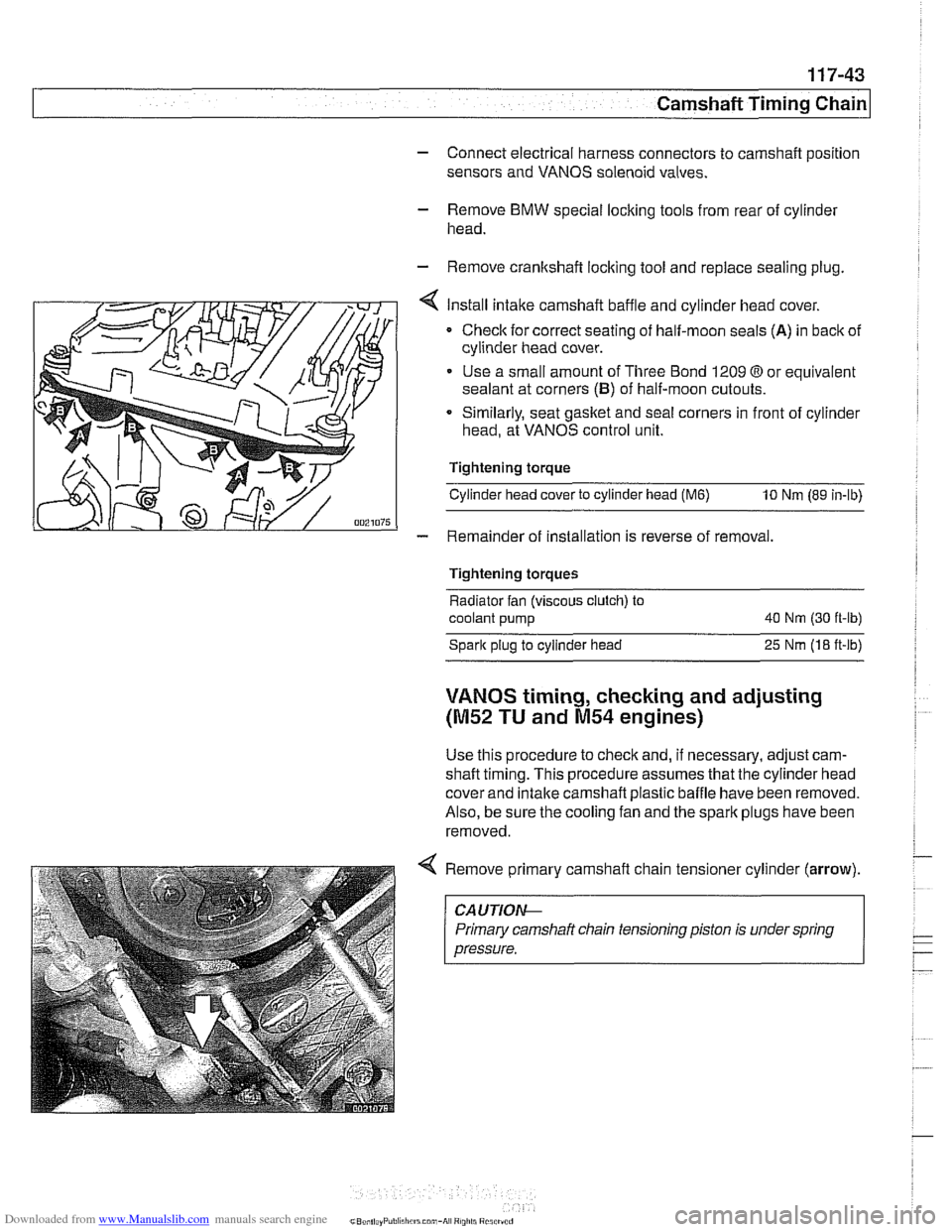

- Connect electrical harness connectors to camshaft position

sensors and VANOS solenoid valves.

- Remove BMW special locking tools from rear of cylinder

head.

- Remove cranltshaft locking tool and replace sealing plug.

Install intake camshaft baffle and cylinder head cover.

Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(B) of half-moon cutouts.

Similarly, seat gasket and

seal corners in front of cylinder

head, at VANOS control unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

- Remainder of installation is reverse of removal.

Tightening torques

Radiator fan (viscous clutch) to

coolant pump 40

Nm (30 ft-lb)

Spark plug to cylinder head

25 Nrn (18 ft-lb)

VANOS timing, checking and adjusting

(M52 TU and M54 engines)

Use this procedure to check and, if necessary, adjust cam-

shaft timing. This procedure assumes that the cylinder head

cover and intake

camshaft plastic baffle have been removed.

Also, be sure the cooling fan and the spark plugs have been

removed.

Remove primary camshaft chain tensioner cylinder

(arrow).

~~ ~ ~~ ~--~

CA UTlOAC

Primary camshaft chain tensioning piston is under spring

pressure.

Page 281 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

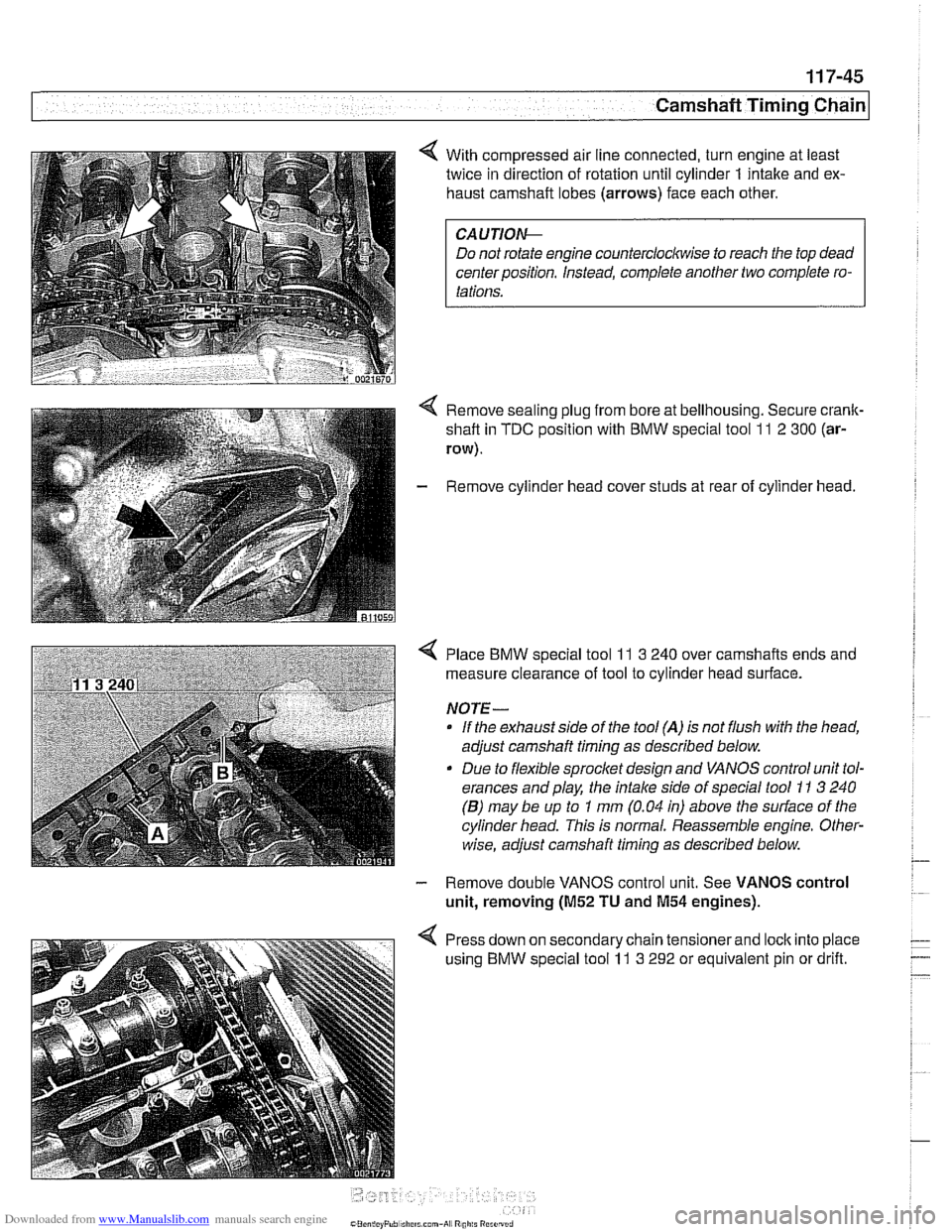

< With compressed air line connected, turn engine at least

twice in direction of rotation until cylinder

1 intake and ex-

haust camshaft lobes (arrows) face each other.

Do not rotate engine counterclockwise to reach the top dead

center position. Instead, complete another two complete ro-

Remove sealing plug from bore at bellhousing. Secure crank-

shaft in

TDC position with BMW special tool 11 2 300 (ar-

row).

- Remove cylinder head cover studs at rear of cylinder head.

< Place BMW special tool 11 3 240 over camshafts ends and

measure clearance of tool to cylinder head surface.

NOTE-

If the exhaust side of the tool (A) is not flush with the head,

adjust camshaft timing as described below.

Due to flexible sprocket design and VANOS control unit tol-

erances and play, the

intake side of special tool 11 3 240

(B) may be up to 1 mm (0.04 in) above the surface of the

cylinder head. This is normal. Reassemble engine. Other-

wise, adjust camshaft timing as described below.

- Remove double VANOS control unit. See VANOS control

unit, removing

(M52 TU and M54 engines).

< Press down on secondary chain tensionerand lock into place

using BMW special tool

11 3 292 or equivalent pin or drift.

Page 283 of 1002

![BMW 540i 1998 E39 Repair Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Pull out exhaust camshaft splined shaft to stop.

- Make sure camshafts are secured in TDC position using

BMW s BMW 540i 1998 E39 Repair Manual Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Pull out exhaust camshaft splined shaft to stop.

- Make sure camshafts are secured in TDC position using

BMW s](/img/1/2822/w960_2822-282.png)

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain]

4 Pull out exhaust camshaft splined shaft to stop.

- Make sure camshafts are secured in TDC position using

BMW soecial tools 11 3 240 and 11 3 244.

4 Preload primary chain tensioning rail:

Tighten adjusting screw on

BMW special tool 11 4 220.

Tightening torque

Primary chain tensioner preload

0.7 Nm (6 in-lb)

4 Preload exhaust camshaft spring plate by pressing on im-

pulse wheel. Tighten mounting nuts

(arrows) by hand. Do

not tighten fully.

Page 293 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

rpp- --- Camshaft Timing Chain1

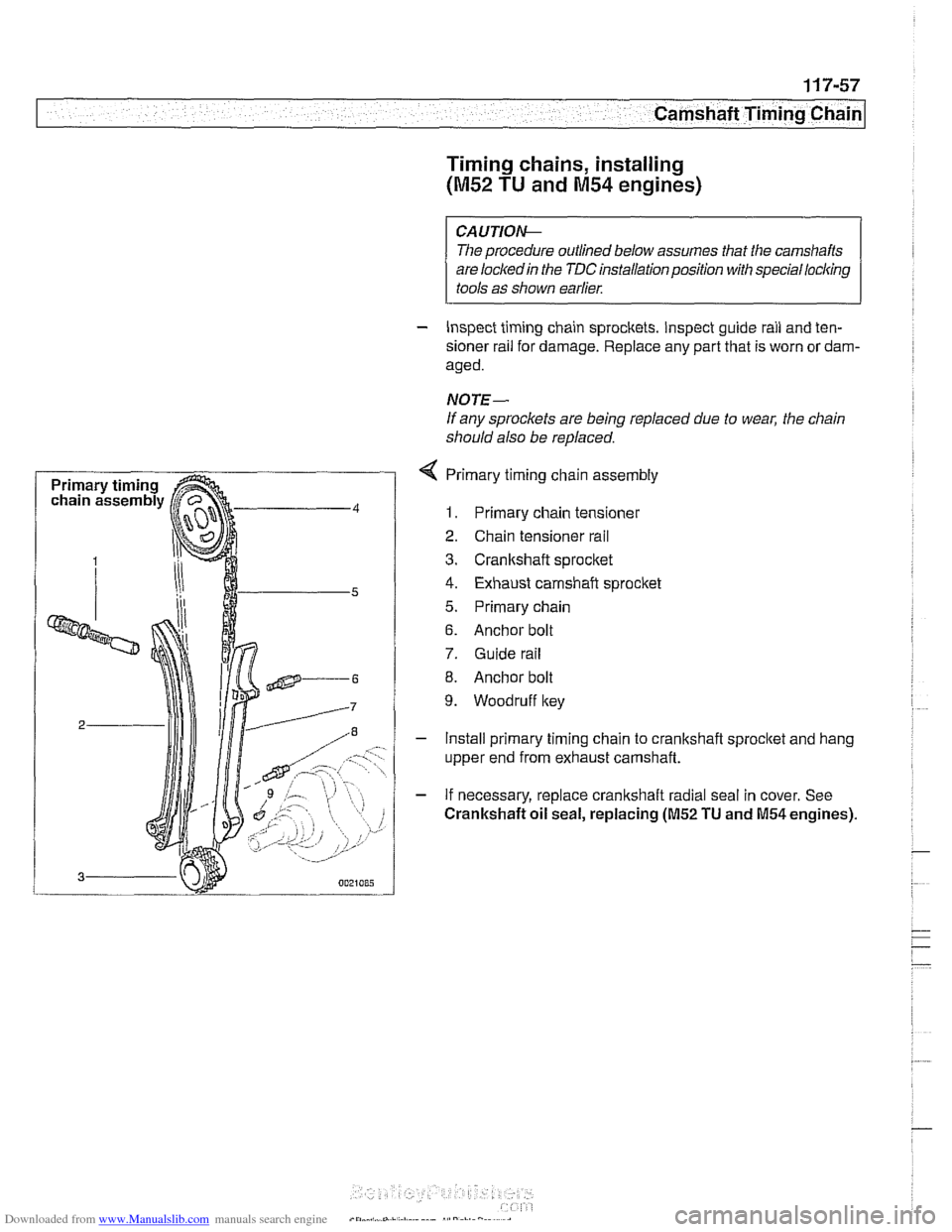

Timing chains, installing

(M52 TU and M54 engines)

CAUTIOI\C

The procedure outlined below assumes that the camshaits

are lockedin the

TDC installation position with speciallocling

tools as shown earliel:

- inspect timing chain sprockets. Inspect guide rail and ten-

sioner rail for damage. Replace any part that is worn

or dam-

aged.

NOTE-

If any sprockets are being replaced due to wear, the chain

should also be replaced.

4 Primary timing chain assembly

1. Primary chain tensioner

2. Chain tensioner rail

3. Cranltshaft sprocket

4. Exhaust camshaft sprocket

5. Primary chain

6. Anchor bolt

7. Guide rail

8. Anchor bolt

9. Woodruff key

- Install primary timing chain to crankshaft sprocltet and hang

upper end from exhaust camshaft.

- If necessary, replace crankshaft radial seal in cover. See

Crankshaft oil seal, replacing (M52 TU and M54 engines).

Page 294 of 1002

Downloaded from www.Manualslib.com manuals search engine

(camshaft Timing Chain

- To install lower timing case cover:

- Clean cover and cylinder block sealing surfaces

Use new

gaskets and coolant pipe O-ring.

Remove timing chain cover dowel pins from engine block.

Drive timing cover dowels in until they just protrude slightly

from sealing surface.

Apply a small bead of silicon sealer (Three Bond 1209

63

or equivalent) to corners of cylinder head where timing

cover meets cylinder head and engine block.

Tap cover into position until firmly seated.

lnstall all bolts hand tight, including two Torx bolts from

above.

Install secondary chain lower guide.

Tighten cover mounting bolts alternately and in stages.

Tightening torque

Lower timing cover to cylinder

bloclc (M6) 10 Nrn (89 in-lb)

- Install oil pan with new gasket. See 119 Lubrication Sys-

tem.

Tightening torque

Oil pan

to engine bloclc (M6)

8.8 grade

10.9 grade 10 Nrn (89 in-lb)

12 Nm

(9 ft-lb)

- Align damper assembly with lteyway and tap into place. In-

sert new center bolt with washer.

CAUTION-

Inspect woodruff key for damage before installing hub

assembly.

- Attach special tools 11 8 20011 1 8 190 to damper assembly.

Counterhold damper with

11 8 190 while tightening center

bolt.

CAUTION-

Do not use BMW special tool 1 I 2 300 to hold crankshaft

stationary to tighten cranl(shaft hub center bolt. Use only

the special tools specified, or equivalent hub holding tool.

Have a second person hold special tool

11 8 190 while

tightening center crankshaft bolt.

Tightening torque Crankshaft hub to crankshaft 410 Nrn

(300

ft-lb)

Page 295 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

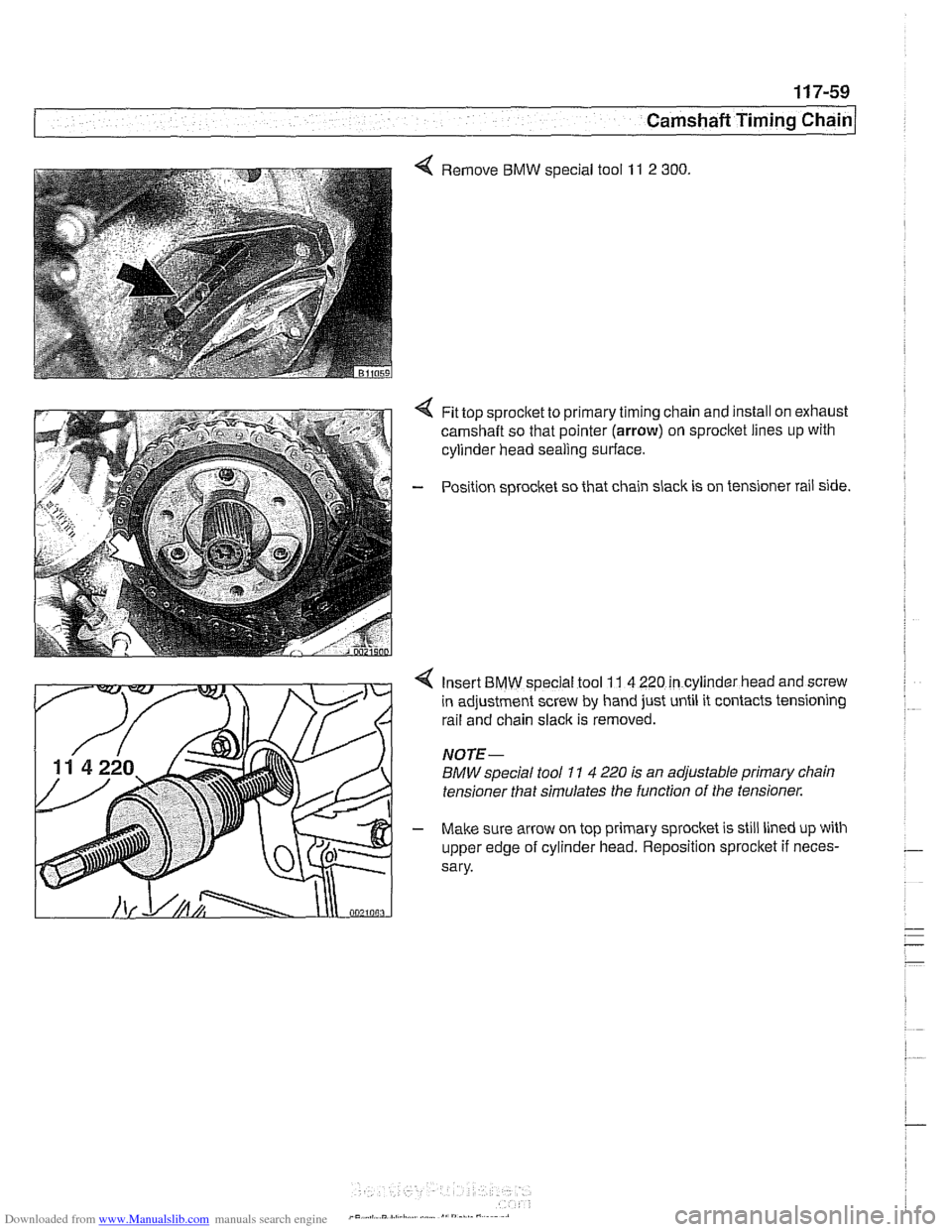

Fit top sprocltet to primary timing chain and install on exhaust

camshaft so that pointer (arrow) on sprocltet lines up with

cylinder head sealing surface.

Position sprocket so that chain slack is on tensioner rail side.

4 Insert BMW special tool 11 4 220 in cylinder head and screw

in adjustment screw

by hand just until it contacts tensioning

rail and chain slack is removed.

NOTE-

BMW special tool 71 4 220 is an adjustable primary chain

tensioner that simulates the function of the tensioner.

- Make sure arrow on top primary sprocket is still lined up with

upper edge of cylinder head. Reposition sprocket if neces-

sary.