Transmission position sensor BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 403 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 3

Fuel Injection I

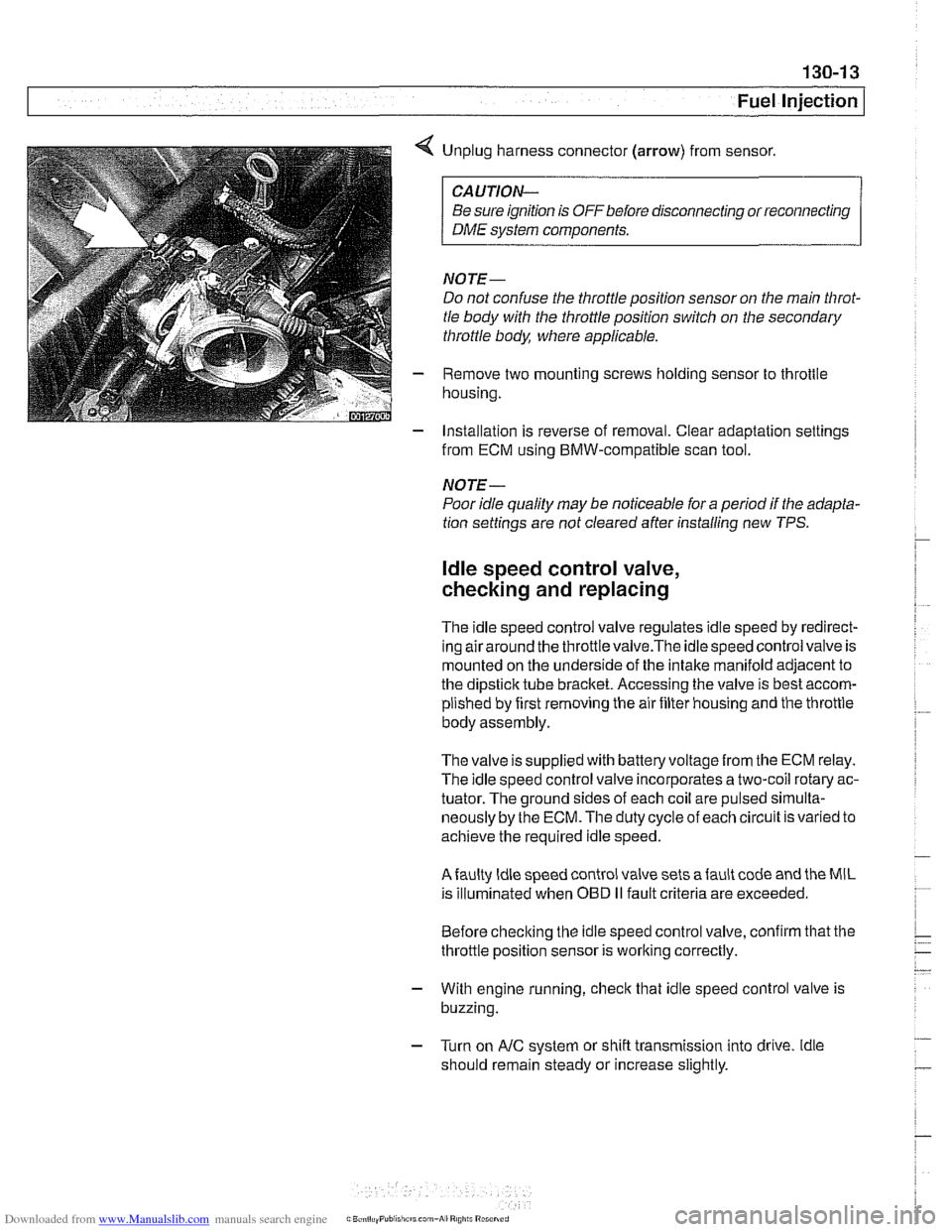

< Unplug harness connector (arrow) from sensor.

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

NOTE-

Do not confuse the throttle position sensor on the main Nirot-

tle body with the throttle position switch on the secondary

throttle body, where applicable.

- Remove two mounting screws holding sensor to throttle

housing.

- Installation is reverse of removal. Clear adaptation settings

from ECM using BMW-compatible scan tool.

NOTE-

Poor idle quality may be noticeable for a period if the adapta-

tion settings are not cleared after installing new TPS.

ldle speed control valve,

checking and replacing

The idle speed control valve regulates idle speed by redirect-

inq airaround the throttlevalve.The idlespeed control valve is

mounted on the underside of the intake manifold adjacent to

the dipstick tube bracket. Accessing the valve is best accom-

plished by first removing the air filter housing and the throttle

body assembly.

The valve issupplied with

batteryvoltagefrom the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed

sirnulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

Afaulty ldle speed control valve sets afault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

Page 428 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-38

Fuel Injection

Throttle cable, adjusting

(MS 42.0)

The throttle assembly on MS 42.0 cars uses a throttle cable.

The cable should be adjusted any time it is disconnected or

replaced. This procedure requires the factory scan tool or an

equivalent to read and adjust throttle angle. It is recommend-

ed the procedure be done by an authorized

BMW dealer ser-

vice department

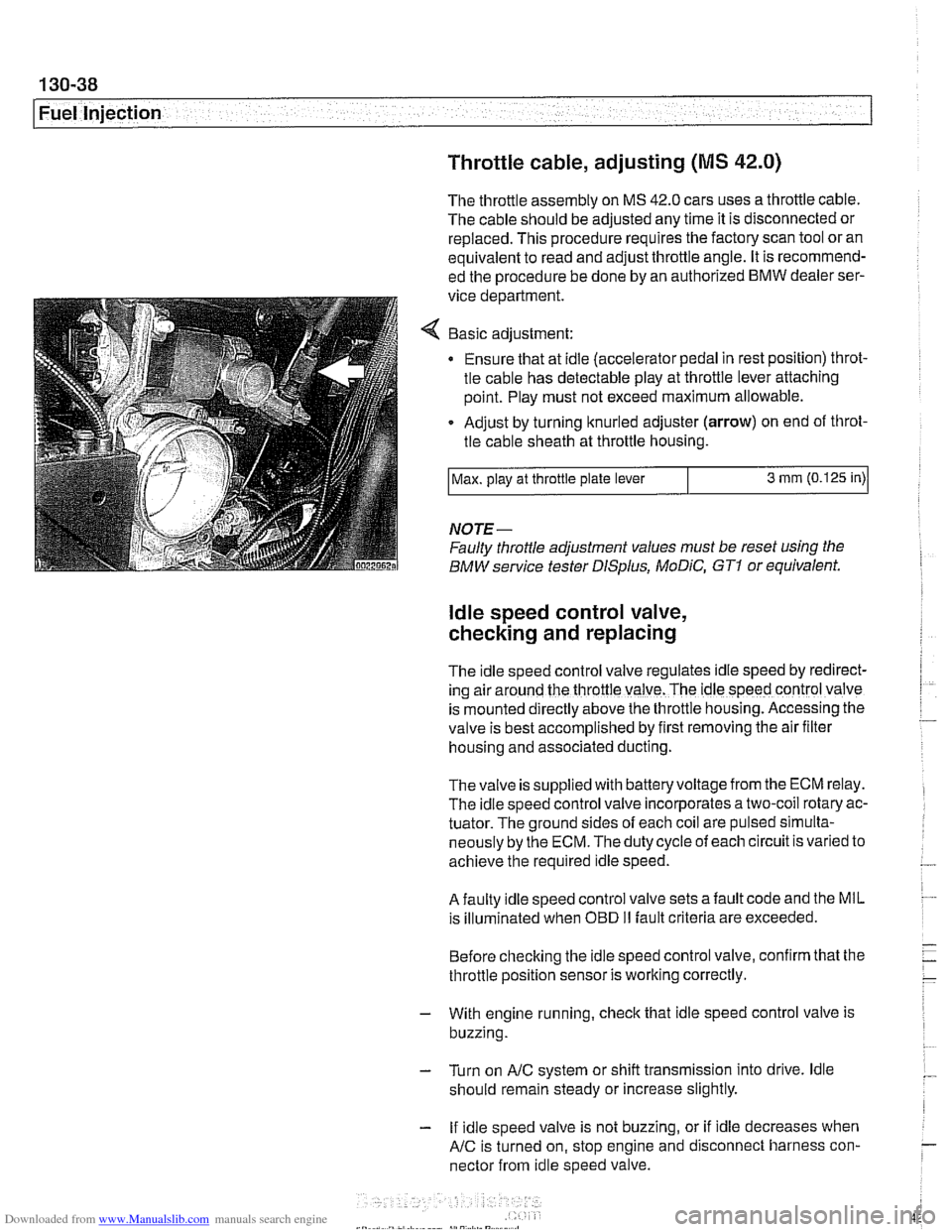

Basic adjustment:

Ensure that at idle (accelerator pedal in rest position) throt-

tle cable has detectable play at throttle lever attaching

point. Play must not exceed maximum allowable.

Adjust by turning knurled adjuster

(arrow) on end of throt-

tle cable sheath at throttle housing.

NOTE-

Faulty throttle adjustment values must be reset using the

BMW service tester

DISplus, MoDiC, GTI or equivalent.

Max.

play at throttle plate lever

ldle speed control valve,

checking and replacing

3 mm (0.125 in)

The Idle speed control valve regulates Idle speed by red~rect-

ing air around the throttle valve. The ldle speed control valve

is mounted

d~rectly above the throttle housing. Accessing the

valve is best accomplished by

flrst removing the air fllter

housing and associated ducting.

Thevalve is supplied with batteryvoltage from the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed simulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

A faulty idle speed control valve sets a fault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

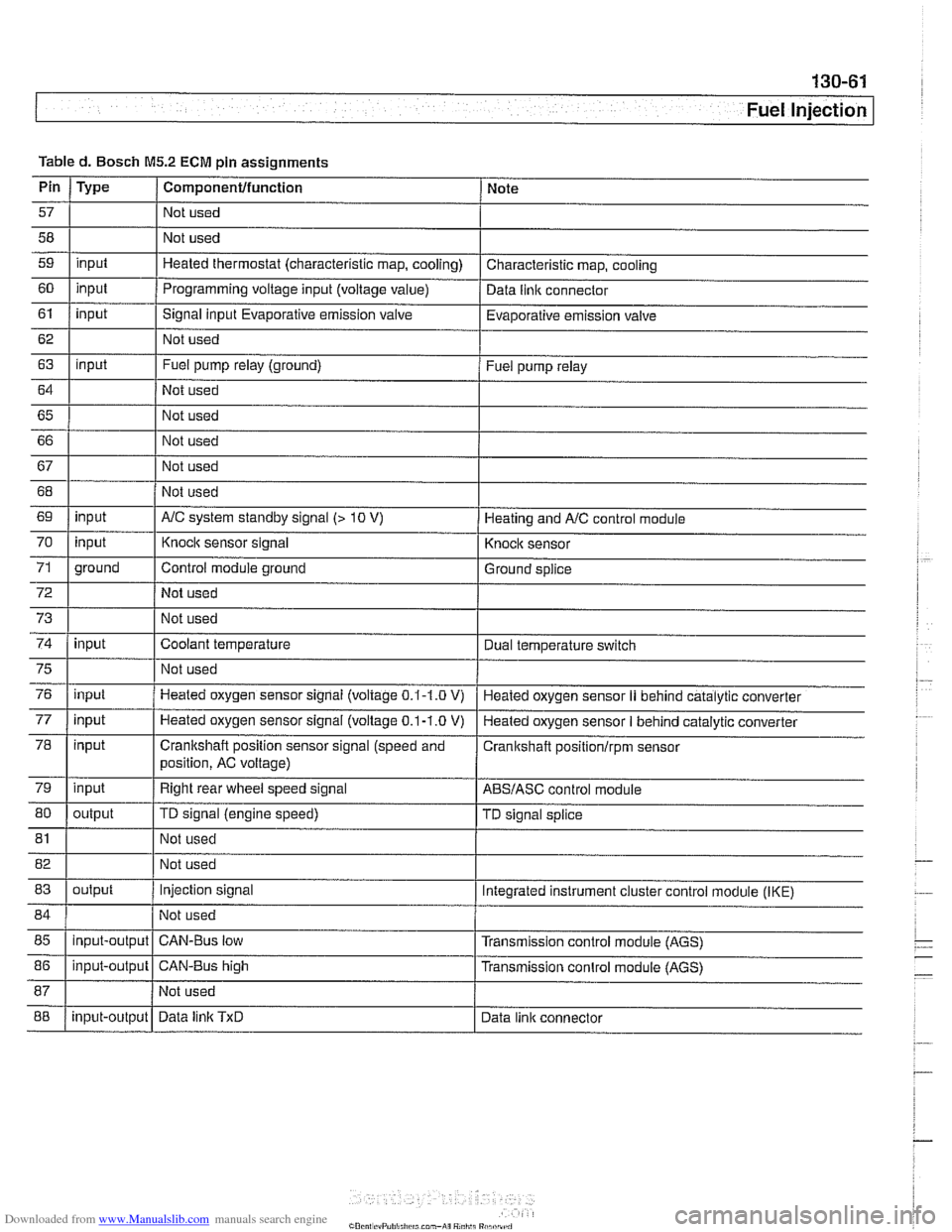

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 916 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anii-Theft

- If the starter engages, the following EWS inputs are function-

ing normally:

Ignition key

Code function

Transmission range switch or clutch position switch

Engine speed sensor

NO JE -

If a vehicle key is lost or stolen, the electronic authorization

for that key

can be cancelled using the BMW scan and di-

agnostic tools

DISplus, GTl or MoDiC.

Force applied to a ley can damage the electronic circuitry

in the key A damaged ley will not start the engine. In that

case, a new key should be purchased and initialized

by an

authorized BMW dealer.

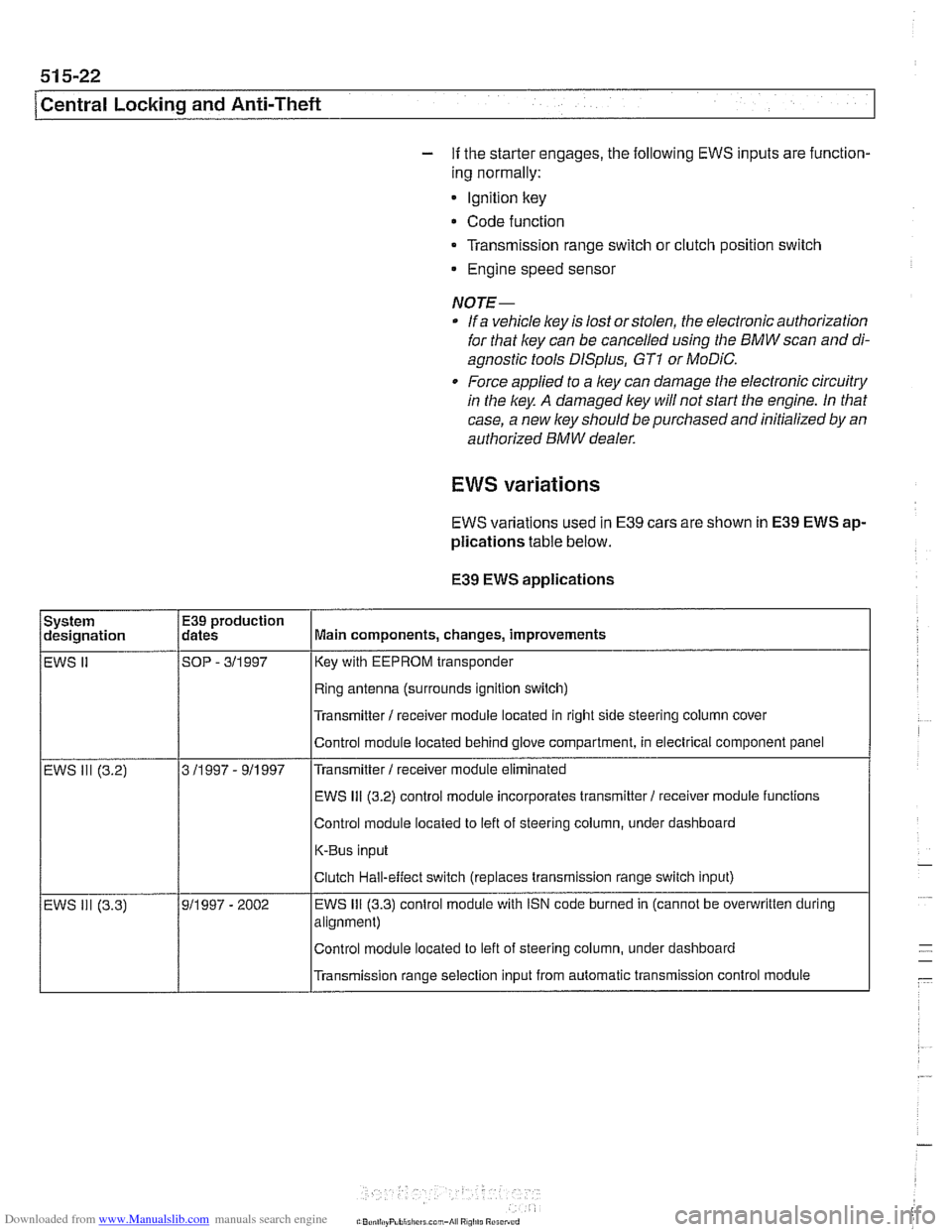

EWS variations

EWS variations used in E39 cars are shown in E39 EWS ap-

plications

table below.

E39

EWS applications

I I Ifling antenna (surrounds ignition switch) I

System

designation

EWS

II

I I l~ransmitter I receiver module located in right side steering column cover I

E39 production

dates

SOP

- 311 997

I I IEWS 111 (3.2) control module incorporates transmitter1 receiver moduie functions /

Main components, changes, improvements

Key with EEPROM transponder

Control moduie located behind glove compartment, in electrical component panel

Control module located to left of steering column, under dashboard

K-Bus input

Transmitter

I receiver module eliminated

EWS 111 (3.2)

Transmission range selection input from automatic transmission control module

3

11997 - 911997

- EWS ill (3.3) Clutch

Hall-effect switch (replaces transmission range switch input)

911997 - 2002 EWS 111 (3.3) control

module with iSN code burned in (cannot be overwritten during

alignment)

Control module located to left of steering column, under dashboard

Page 973 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

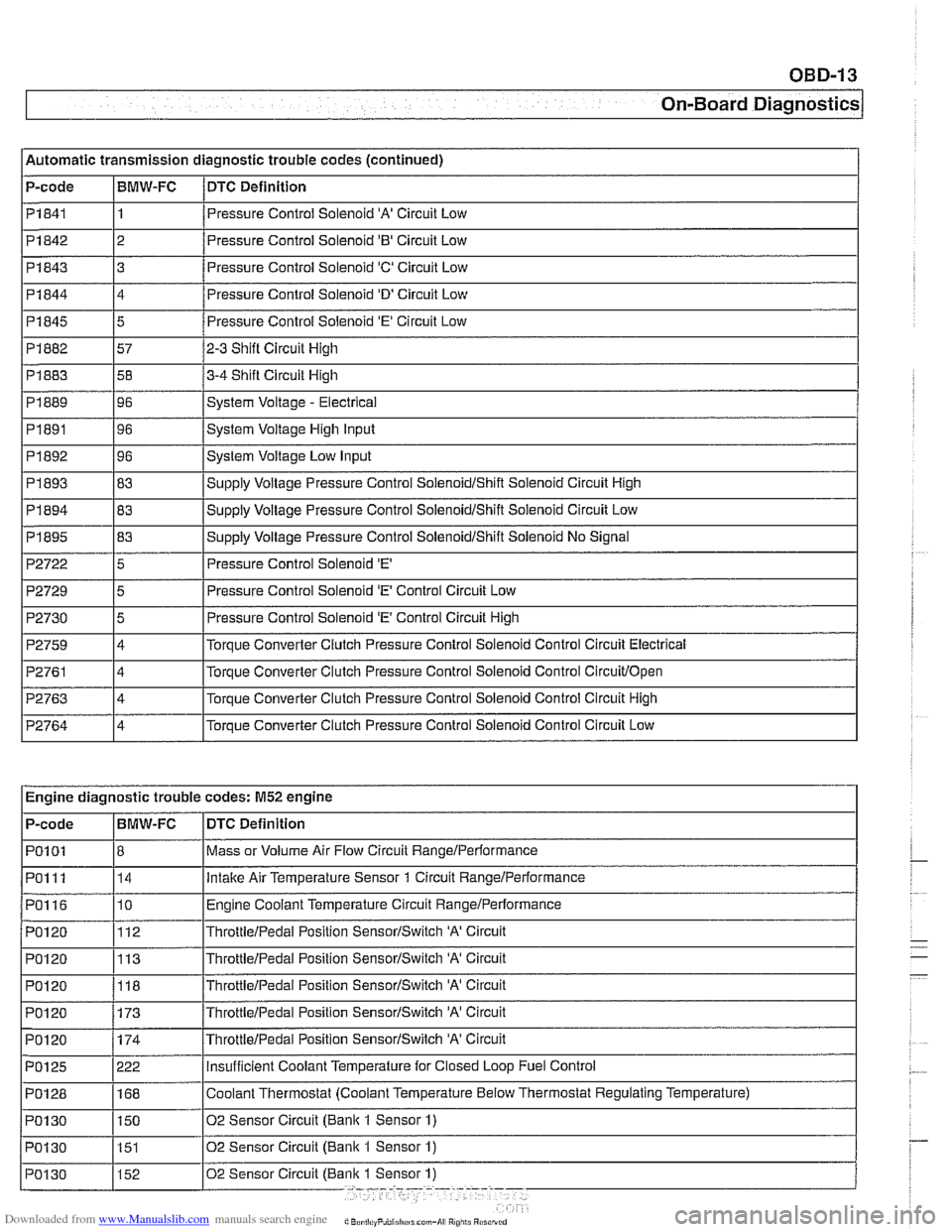

l~utomatic transmission diagnostic trouble codes (continued)

P-code

1 Pi844

I I

14 /Pressure Control Solenoid 'D' Circuit Low

I I PI841 11 /Pressure Control Solenoid 'A' Circuit Low

BMW-FC

Pi842

I

P2722 15 I Pressure Control Solenoid 'E' I

DTC

Definition

Pi 845

Pi 882

Pi 883

PI 889

PI891

PI 892

PI 893

Pi 843 3 8

2 Pressure Control Solenoid '0' Circuit Low

5

57

58

96

96

96

83

P2729

P2730

P2759

P2761

P2763

P2764

Pressure Control Solenoid 'E' Circuit Low

2-3 Shift Circuit High

3-4 Shift Circuit High

System Voltage

- Electrical

System Voltage High Input

System Voltage Low Input

SUDP~V Voltaqe Pressure Control SoienoidIShift Solenoid Circuit High

~~ ~~ ~ Engine diagnostic trouble codes: M52 engine

5

5

4

4

4

4

I I

Pressure Control Solenoid 'E' Control Circuit Low

Pressure Control Solenoid

'E' Control Circuit High

Torque Converter Clutch Pressure Control

Solenoid Control Circuit Electrical

Torque Converter Clutch Pressure Control Solenoid Control

Circuitlopen

Torque Converter Clutch Pressure Control Solenoid Control Circuit High

Torque Converter Clutch Pressure Control Solenoid Control Circuit Low

DTC Definition

Mass or Volume Air

Flow Circuit RangeIPerformance

lntalte Air Temperature Sensor 1 Circuit Rangelperformance

Engine Coolant Temperature Circuit RangeIPerformance

ThrottieIPedai Position SensorISwitch 'A' Circuit

ThrottleIPedai Position SensorISwitch 'A' Circuit

P-code

PO1

01

PO1 11

PO116

PO120

PO120

PO1 20 BMW-FC

8 14

10

112

113

POI 20 1173 /~hrottie/~edal Position SensorISwitch 'A' Circuit

118

ThrottieIPedai Position SensorISwitch 'A' Circuit

Page 996 of 1002

Downloaded from www.Manualslib.com manuals search engine

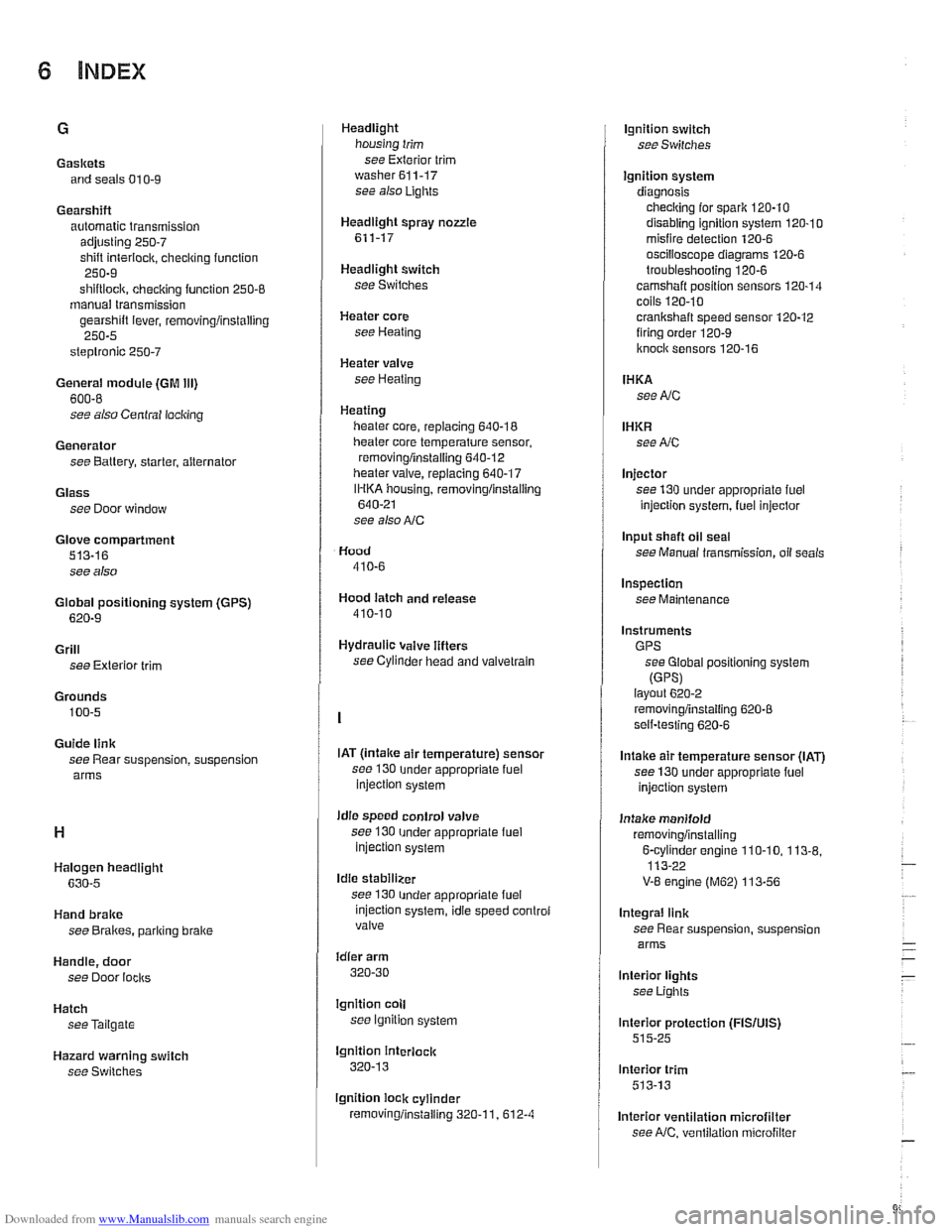

Gaskets and seals 01

0-9

Gearshift automatic transmission

adjusting

250-7

shift interiock. checkino function " 250-9

shiftloclc. checicino function 250-8 - manual transmission

gearshift lever, removingiinstalling

250-5

steptronic 250-7

General module (GM Ill)

600-8

see also Central locking

Generator see Battery, starter, alternator

Glass see Door window

Glove compartment

513-16

see also

Global positioning system

(GPS)

620-9

Grill

see Exterior trim

Grounds

100-5

Guide link

see Rear suspension, suspension

arms

Halogen headlight

630-5

Hand brake

see Brakes, pariring brake

Handle, door

see Door

locks

Hatch seeTailgate

Hazard warning switch

see Switches Headlight

housing trim

see Exterior trim

washer611-17 see also Lights

Headlight spray

nozzle

611-17

Headlight switch

see Switches

Heater core

see Heating

Heater valve

see Heating

Heating lieater core, replacing

640-18

lheater core temperature sensor,

removingiinstalling

640-12 heater valve, replacing 640-17

IHKA housing, removinglinstallin~

640-21

see also NC

Hood

410-6

Hood latch and release

410-10

Hydraulic valve lifters

see Cylinder head and valvetrain

IAT

(lntalce air temperature) sensor

see 130

under appropriate fuel

injection system

idle speed control valve

see 130

under appropriate fuel injection system

Idle stabilizer

see 130

under appropriate fuel

injection system, idie speed controi

valve

idler arm

320-30

lgnition coll

see lgnition system

lgnition interlock

320-13

lgnition lock cylinder

removingiinstalling

320-1 1. 612-4

lgnition switch

seeSwifches

Ignition system

diagnosis checking for

spark 120-10

disabling ignition system 120-10 misfire detection 120-6

oscilioscope diagrams 120.6

troubleshooting 120-6

camshaft position sensors 120-14 coils 120.10

crankshaft speed sensor 120-12 firing order 120-9

knoclc sensors 120-16

IHKA

see NC

IHKR see NC

Injector

see 130 under appropriate

fuel

injection system, luel injector

Input shaft

oil seal

see Manual transmission, oil seals

Inspection

see Maintenance

Instruments GPS see Global positioning system

(GPSI layout 6202

removingiinstalling 620-8 self-testing 620-6

Intake air temperature sensor (IAT)

see 130 under appropriate fuel

injection system

Intake manifold

removingiinstalling

6-cvlinder enoine 110-10. 113-8. 113-22 -

V-8 engine (M62) 113-56

Integral link

see Rear suspension, suspension

arms

lnterior lights

see Lights

lnterior protection

(FISIUIS) 515-25

lnterior trim

513-13

lnterior ventilation microfilter see

NC, ventilation microfiller

Page 998 of 1002

Downloaded from www.Manualslib.com manuals search engine

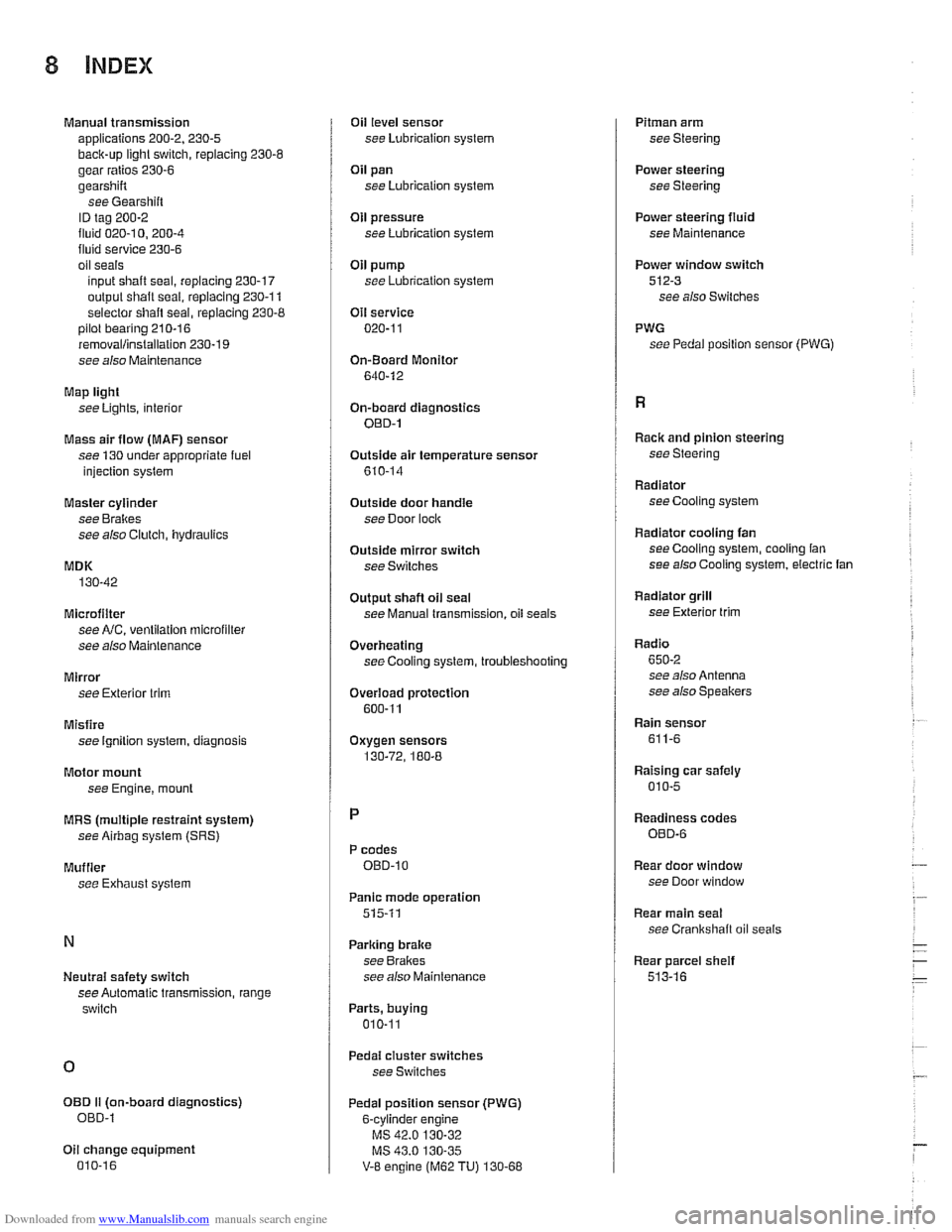

Manual transmission

applications 200-2. 230-5

back-up light switch, replacing 230-6

gear ratios 230-6

gearshift

see Gearshiit

ID tag 200-2

fluid 020-1 0. 200-4 fluid service 230-6

oil seals

input shaft seal, replacing

230-17

output shalt seal, replacing 230-1 1

selector

shaft seal, replacing 230-8 pilot bearing 210-16

removallinstallation 230-19

see also Maintenance

Map light

see Lights, interior

Mass air flow

(MAF) sensor

see 130 under appropriate fuel

injection syslem

Master cylinder

see Brakes

see also Clutch, hydraulics

MDK

130-42

Microfilter see

NC, ventilation microfilter

see also Maintenance

Mirror see Exterior trim

Misfire see Ignition syslem, diagnosis

Motor mount

see Engine,

mounl

MRS (multiple restraint system)

see Airbag system (SRS)

Muffler

see Exhaust syslem

Neutral safety switch

see Automatic transmission, range

switch

OED II (on-board diagnostics)

OED-l

Oil change equipment 010-16

Oil level sensor

see Lubrication system

Oil pan

see Lubrication system

OH pressure

see Lubrication system

Oil pump

see Lubrication system

Oil service 020-1 1

On-Board Monitor

640-12

On-board diagnostics OED-1

Outside air temperature sensor

610-14

Outside door handle

see Door

loclc

Outside mirror switch

see Switches

Output

shaft oil seal

see Manual transmission, oil seals

Overheating

see Cooling system, troubleshooting

Overload protection

600-11

Oxygen sensors

130-72, 180-8

P codes OED-10

Panic mode operation

515-11

Parking brake

see Brakes

see also Maintenance

Parts, buying

010-11

Pedal cluster switches

see Switches

Pedal position sensor (PWG)

6-cvlinder

enqine

V-8 engine (M62 TU) 130-68

Pitman arm

see Steering

Power steering

see Steering

Power steering

fluid

see Maintenance

Power window switch

512-3 see also Switches

PWG see Pedal position sensor

(PWG)

Racic and pinion steering

see Steering

Radiator see Cooling system

Radiator cooling fan seeCooling system, cooling fan

see also Cooling system, electric fan

Radiator grill

see Exterior

trim

Radio

650-2 see also Antenna

see also Speakers

Rain sensor

611-6

Raising car safely

010-5

Readiness codes

OED-6

Rear door window

see Door window

Rear main seal

see Crankshalt oil seals

Rear parcel

sheif

513-16

Page 999 of 1002

Downloaded from www.Manualslib.com manuals search engine

INDEX 9

WARNING

Your common sense, good judgemenl, and general alerlness are

crucial lo seie end successful service

ivork. Beiore attempting any work on

your

BMW be sure to read 001

General Warnings and Cautions and llle copyright page at lhe iron1 of

the manual. Review Niese warnings

and caulions each lime you prepare

lo work on your BMW Please also

read any warnings and caulions lllal accompany the procedures in the

manual.

Rear suspension

ball joints

330-19

bushings 330-13

control arms

seesuspension arms, below

description

300-5

electronic height control (EHC)

330-44

ride height 300-14 ride height sensor 330-46

shoclr absorbers end springs 330-9

stabilizer bar 330-42

struts and springs 330-5 subframe 330.13

suspension arms 330-13

variations 330-4 wheel bearing, replacing 330-32

see also Maintenance

see also Drive axles

see also Final drive

Rear window (Sport Wagon)

see

Tailgate

Rear window defroster 610-17

Receiverldrter

see NC

Relay positions

see Electrical component tocations

table 610-3

Remote entry (FZV)

see Central locking

Reversing light switch

see

Baclc-up light switch

Ride height

300-14

Ride height sensor

see Rear suspension

Ring antenna

see EWS (electronic immobilizalion)

Rotor

see Brakes

Roundel see Exterior trim

Running tosses

(312-way) valve

see Fuel

tenlr

SCA (soft close)

seeTailgate, soft close

see also Trunk lid. soft close

Scan tools

OED-3

Seals gaskets and 010-9

see also Crankshaft seals

Seat front,

removing/instelling 520-10

memory system 520-4 rear 520-13

see also Seat belt

Seat beit front 720-4

rear 720-8

troubleshooting 7202

see also Maintenance

Secondary air injection

see 130 under appropriate

iuel

injection system

Selector shaft seat

see Manual transmission, oil

Seals

Self-adjusting ctulch (SAC)

see Clutch, variations

Service indicator see Maintenance

Shift interlock see Gearshift

Shift lever

see

Gearshift

Shift linkage see Gearshift

Shiftlock see Gearshilt

Shack absorber see Rear suspension

/ Side turn signal assembly

see Lights

Sill trim panel

411-10

Slave cylinder

see Clutch, lhydraulic

Steep mode

600-1 1

Soft close

(SCA) see Tailgate

see also

Trunk lid

Solenoid 121-23

Sound system

650-2

Spare parts kit

010-21

Spark plugs

see Maintenance

Speakers

650-4

Specifications, fluid

020-4

Sport wagon

400-4

Springs

see Front suspension

see also Rear suspension

SRS (supplemental restraint system)

see

Airbag system (SRS)

Stabilizer bar see Front suspension

see also Rear suspension

Starter see Battery, starter, alternator

Page 1000 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering description 300-10

liuid see Maintenance

gearbox

320-25

idler arm 320-30

lock 320-12

pitman arm 320-28 power steering pump 320-17

rack & pinion 320-19

steering column 320-10 motors 320-16

removinglinstalling 320-14

trim 320-10

steerino wheei 320-7 tie rods-

6-cvlinder, reelacinq 320-22

V- center tie' rod, replacing 320-32

variations 310-5

Steering box

see Steering, gearbox

Steering column switches

see Switches

Steering column

see Steering

Steering lock

see Steering

Steering

wheei switches

see Switches

Stepper motor

see

AIC

Steptronic transmission

see Gearshift

Strut see Front suspension

see also Rear suspension

Subframe see Rear suspension

Sunroof initializing

540-2

adiustinq 540-5 . . cornponents, removingiinstailing

540-9

emergency closing 540-4

Suspension, front

see Front suspension

see also

Aluminum suspension

cornponents

Suspension, rear

see Rear suspension

see also Aluminum suspension

cornponents

Swing arm

see Rear suspension, suspension

arms

Switches

ASCIDSC 612-12 back-ue

manual transmission 230-8

automatic transmission, see

Automatic transmission, range

switch

center console switches

612-11

central ioci(ing 612-1 1

hazard 612-1 I headlight 612-9

ignition cylinder 320-1 1. 612-6

outside mirror 612-11

pedal cluster switches 612-8 seat heater 612.12

steering column positioning 612-7

steering column switches 612-6 steering wheel switches 612-2

turn signaliheadlight dimmer 612-6

window 612-1 1

wipers 612-6

Tailgate

412-6 emergency release 400-4,412-6,

515-21

taiigatelrear window

loclring 515-14 see also Trunldtaiioate ioclr - see also Central ioclcing

Taillights

see Lights

Tape player

650-3

TCM (transmission control module)

see Automatic transmission

Tension strut

see Front suspension

Thermostat see Cooling system

see also Electrically heated

thermostat

Throttie body

see 130 under appropriate

fuel injection system

Throttie

cable

130-38

Throttie position sensor

see 130 under appropriate luel

injection system

Throw-out bearing

see Clutch, mechanical

Thrust arm

see Front suspension

Tie rod

see Steering

Tightening fasteners

010-8

Tilt sensor 515-24

Timing chain

see

Camshaft timing chain

Tire, changing

010-18

Tires

300-1 1

see also Maintenance

Toe

320-34

Tools

010-13