locking BMW 540i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 7 of 1002

Downloaded from www.Manualslib.com manuals search engine

001 General Warnings and Cautions

PLEASE READ THESE WARNINGS AND CAUTIONS

BEFORE PROCEEDING

WITH MAINTENANCE AND REPAIR WORK.

WARNINGS-

See also CAUTIONS

- Some repairs may be beyond your capability. If you lack the skills, - Catch draining fuel, oil, or brake fluid in suitable containers. Do

tools and equipment, or a suitable workplace for any procedure

not use

foodor beverage containers that might mislead someone

described in this manual, we suggest you leave such repairs to

into

drinking from them. Store flammable fluids away from fire

an authorized BMW dealer service department or other qualified

hazards. Wipe up spills at once, but do not store the oily rags,

shop. which can ignite and burn spontaneously.

. Do not reuse any fasteners that are worn or deformed. Many fas- Always observe good worRshop practices. Wear qoqqles when

teners are designed to be used only once and become

unreliable you operate machine tools or work with battery acid:kloves or

and mav fail when used a second time. This includes, but is not other

~rotective clothino should be worn whenever the iob re-

limited io, nuts, bolts, washers, self-locking nuts or bolts, clrclips yires' working with harmful substances.

and cotter pins. Always replace these fasteners with new parts.

Greases, lubricants and other automotive chemicals contain toxic

. Never work under a lifted car unless it is solidly supported on

substances, many of which are absorbed directly through the

stands

desiqned for the purpose. Do not supeort a car on cinder

skin. Read the manufacturer's instructions and warninos careful-

blochs, hollow tiles orotherbrops that may drurnbie undercontin-

uous toad. Never work under a car that is supported solely by a

iack. Never work under the car

while the enqine is runninq. - -

If you aregoing to work underacaron the ground, makesure that

the ground is level. Block the wheels to

keep the car from rolling.

Disconnect the battery negative

(-) terminal to prevent others

from starting the car while you are under it.

- Never run the engine unless the work area is well ventilated. Car-

bon monoxide kills.

Rings, bracelets and other jewelry should be removed so that

they cannot cause electrical shorts, get caught in running ma-

chinery, or be crushed by heavy parts.

- Tie long hair behind your head. Do not wear a necktie, a scarf.

loose clothing, or a necklace when you work near machine tools

or running engines. if your hair, clothing, or jewelry were to get

caught in the machinery, severe injury could result.

DO not attempt to

work on your car if you do not feel well. You in-

crease the

danger of injuryto yourseliand others if you are tired,

uDset or have taken medication or anv other substance that mav

keep you from being fully alert.

Illuminate your work area adequately but safely. Use a portable

iy. Use hand and eye protection. Avoid direct skin conGct.

Disconnect the battery negative (-) terminal whenever you work

on the fuel system

orthe electrical system. Do not smokeorwork

near heaters or other fire hazards. Keep an approved fire extin-

guisher handy.

. Friction materials (such as brake pads or shoes or clutch discs)

contain asbestos fibers or other friction materials. Do not create

dust by grinding, sanding, or by cleaning with compressed air.

Avoid breathing dust. Breathing any

friclion material dust can

lead to serious diseases and may result in death.

Batteries

giveoff explosive hydrogen gas during charging. Keep

sparks, lighted matches and open flame away from the top of the

battery. If hydrogen gas escaping from the cap vents is ignited, it

will ignite gas trapped in the cells and cause the battery to ex-

plode.

Connect and disconnect battery cables, jumper cables or a bat-

tery charger only wilh the ignition switched off. Do not disconnect

the battery while the engine is running.

Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

. . safety lighiforworking lnsideor under the car. Make sure the bulb - Do not allow battery charging vollage to exceed 16.5 volts. If the

is enclosed bv a wire caoe. The hot filament of an accidentallv

batten! beoins ~roducina oas or boilino violentiv, reduce the

broken bulb can ignite spilled

fuel, vapors or oil. , - - - charglng rate. ~oostlng a sutfaled battery at a igh charging rate

can cause an

explosion.

-

Continued on next page

Page 17 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

ADVICE FOR THE BEGINNER

The tips that follow are general advice to help the do-it-your-

self BMW owner

periorm repairs and maintenance taslts

more easily and more professionally.

Planning ahead

Know what the whole job requires before starting. Read the

procedure thoroughly, from beginning to end, in

orderto know

just what to expect and what parts will have to be replaced.

Workshop practices

Keeping things organized, neat, and clean is essential to do-

ing a good job. When working under the hood, iender covers

will protectthe finish from scratches and otherdamage. Make

sure the car finish is clean so that dirt under the cover does

not scratch the iinish.

Any repair job will be less troublesome if the parts are clean

For cleaning old parts, there are many solvents and parts

cleaners commercially available.

For cleaning parts prior to assembly, commercially available

aerosol cans of parts cleaner or brake cleaner are handy to

use, and the cleaner will evaporate completely.

WARNING-

Most solvents used for cleaning parts are highly flammable

as well as toxic, especially in aerosol form. Use with extreme

care. Do not smoke. Do not use these products indoors or

near any source of heat, sparks or flame.

Non reusable fasteners

Many fasteners used on the cars covered by this manual

must be replaced with new ones once they are removed.

These include but are not limited to: bolts, nuts (self-locking,

nylock, etc.), roll pins, clips and washers. Genuine BMW

parts should be the only replacement parts used for this pur-

pose.

Some bolts are designed to stretch during assembly and are

permanently altered, rendering them unreliable once re-

moved. These are known as torque-to-yield fasteners. Al-

ways replace fasteners where instructed to do so. Failure to

replace these fasteners could cause personal injury

orvehi-

cle damage. See an authorized BMW dealer for applications

and ordering information.

Page 25 of 1002

Downloaded from www.Manualslib.com manuals search engine

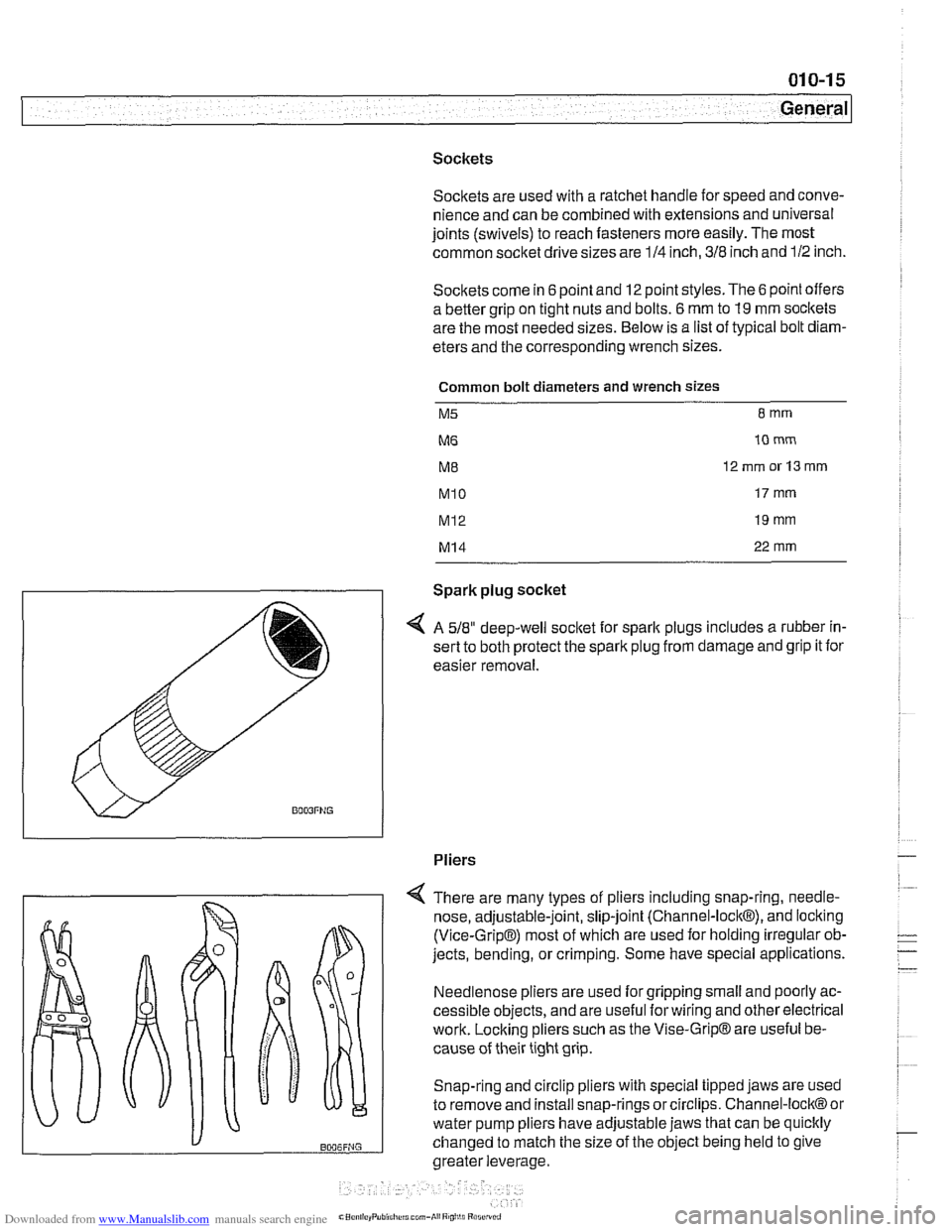

Sockets Socltets are used with a ratchet handle for speed and conve-

nience and can be combined with extensions and universal

joints (swivels) to reach fasteners more easily. The most

common socket drive sizes are

114 inch, 318 inch and 112 inch.

Sockets come in

6 point and 12 point styles. The 6 point offers

a better grip on tight nuts and bolts.

6 mm to 19 mm socltets

are the most needed sizes. Below is a list of typical bolt

diarn-

eters and the corresponding wrench sizes.

Common bolt diameters and wrench sizes

M5 8 rnrn

M6

10 rnm

M8 12rnrnor13rnrn

MI 0 17 rnrn

MI2 19 rnrn

M14 22 mm

Spark plug socket

4 A 518" deep-well socket for sparlt plugs includes a rubber in-

sert to both protect the spark plug from damage and grip it for

easier removal.

Pliers

There are many types of pliers including snap-ring,

needle-

nose, adjustable-joint, slip-joint (Channel-lock@), and locking

(Vice-Grip@) most of which are used for holding irregular ob-

jects, bending, or crimping. Some have special applications.

Needlenose pliers are used for gripping small and poorly ac-

cessible objects, and are useful forwiring and other electrical

work. Locking pliers such as the Vise-Grip@ are useful be-

cause of their tight grip.

Snap-ring and circlip pliers with special tipped jaws are used

to remove and install snap-rings or circlips. Channel-lock@ or

water pump pliers have adjustable jaws that can be quicltly

changed to match the size of the object being held to give

greater leverage,

Page 60 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-28

1 Maintenance

- When replacing fuel filter:

Use appropriate hose clamping device to clamp off filter

inlet and outlet hoses to lessen fuel spillage.

Loosen center clamping bracket and hose clamps on

either end of filter.

Note arrow or markings indicating direction of flow on

new filter.

Install new filter using new hose clamps

- Drain fuel filter from inlet side into a container and inspect

drained fuel.

Checlc for rust, moisture and contamination.

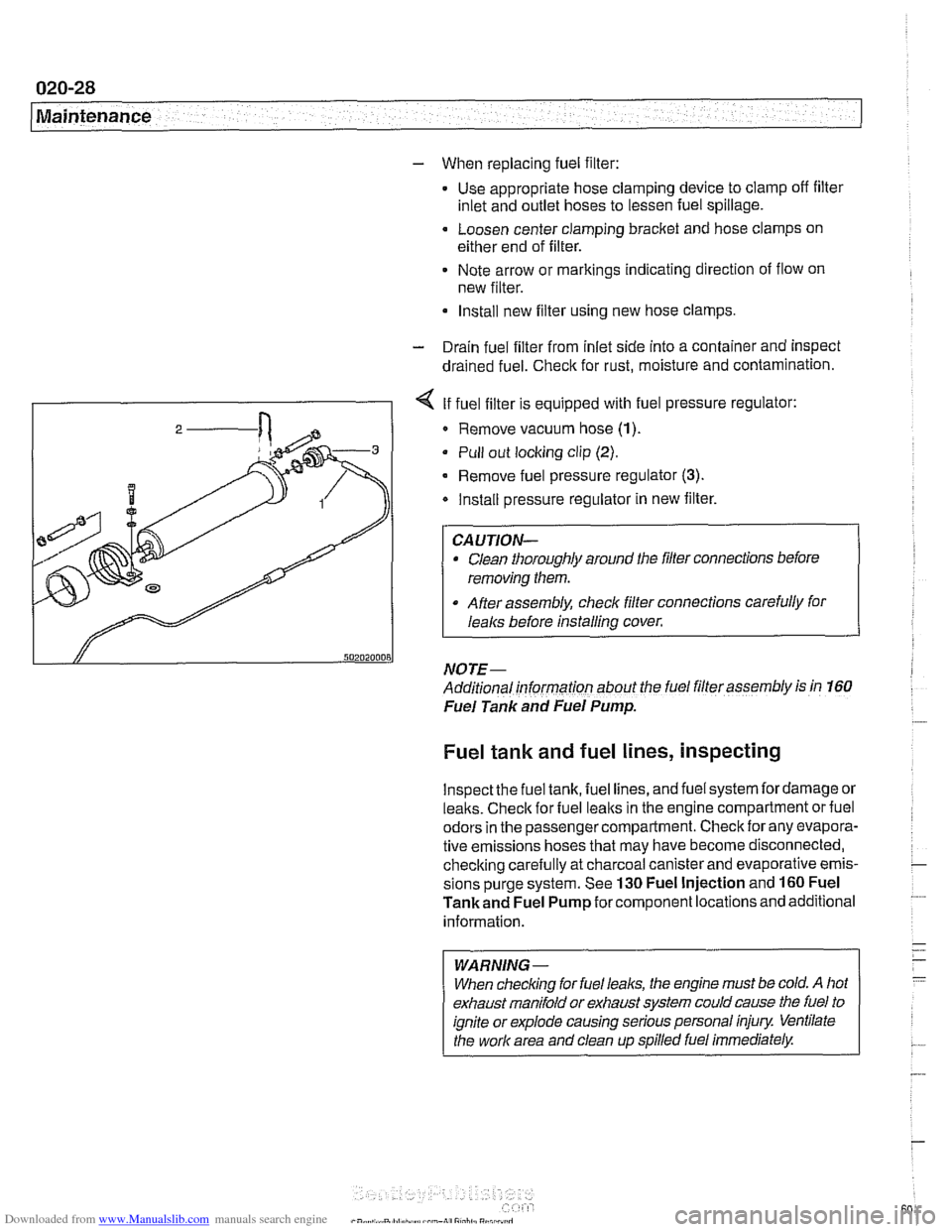

I - I < If fuel filter is equipped with fuel pressure regulator:

I 2 / Remove vacuum hose (1)

Pull out locking clip (2).

- Remove fuel pressure regulator (3).

Install pressure regulator in new filter.

Clean thoroughly around the filler connections before

removing them.

After assembly, check filter connections carefully for

I

I lealcs before installing cover.

NOTE- ~-

Additional informarion about the fuel filler assembly is in 160

Fuel Tank and Fuel Pump.

Fuel tank and fuel lines, inspecting

lnspectthe fuel tank, fuel lines, and fuel system fordamage or

lealts. Checlc for fuel lealts in the engine compartment or fuel

odors in the passenger compartment. Check for any evapora-

tive emissions hoses that may have become disconnected,

checking carefully at charcoal canister and evaporative emis-

sions purge system. See

130 Fuel Injection and 160 Fuel

Tankand Fuel Pump for component locations and additional

information.

WARNING-

When checlcing for fuel leal(s, the engine must be cold. A hot

exhaust manifold or exhaust system could cause the fuel to

ignite or explode causing serious personal injury Ventilate

the work area and clean up spilled fuel immediately.

Page 76 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 0-4

/Engine Removal and Installation

- Disconnect negative (-) cable from battery.

CAUTION- Prior to disconnecting the

batteg read the battery discon-

nection cautions

in 001 General Cautions and Warnings.

- Remove engine hood, or place in service position. See 410

Fenders, Engine Hood.

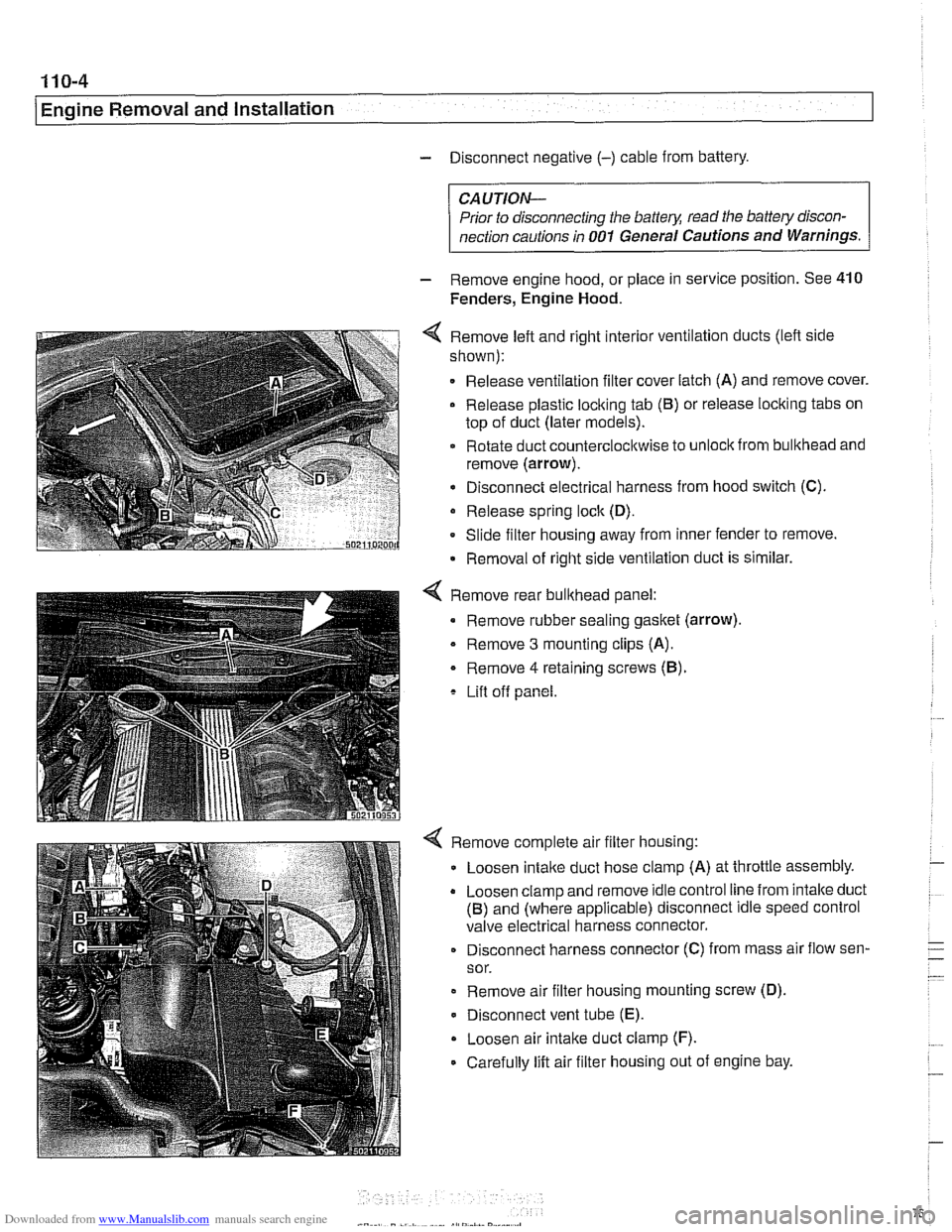

4 Remove left and right interior ventilation ducts (lefl side

shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic loclting tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclocltwise to

unloclt from bulkhead and

remove (arrow).

Disconnect electrical harness from hood switch (C).

Release spring

loclt (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel:

Remove rubber sealing gasket (arrow).

- Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift off panel.

Remove complete air filter housing:

Loosen

intalte duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control line from intalte duct

(6) and (where applicable) disconnect idle speed control

valve electrical harness connector.

Disconnect harness connector (C) from mass air flow sen-

sor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Page 78 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

I Engine Removal and Installation I

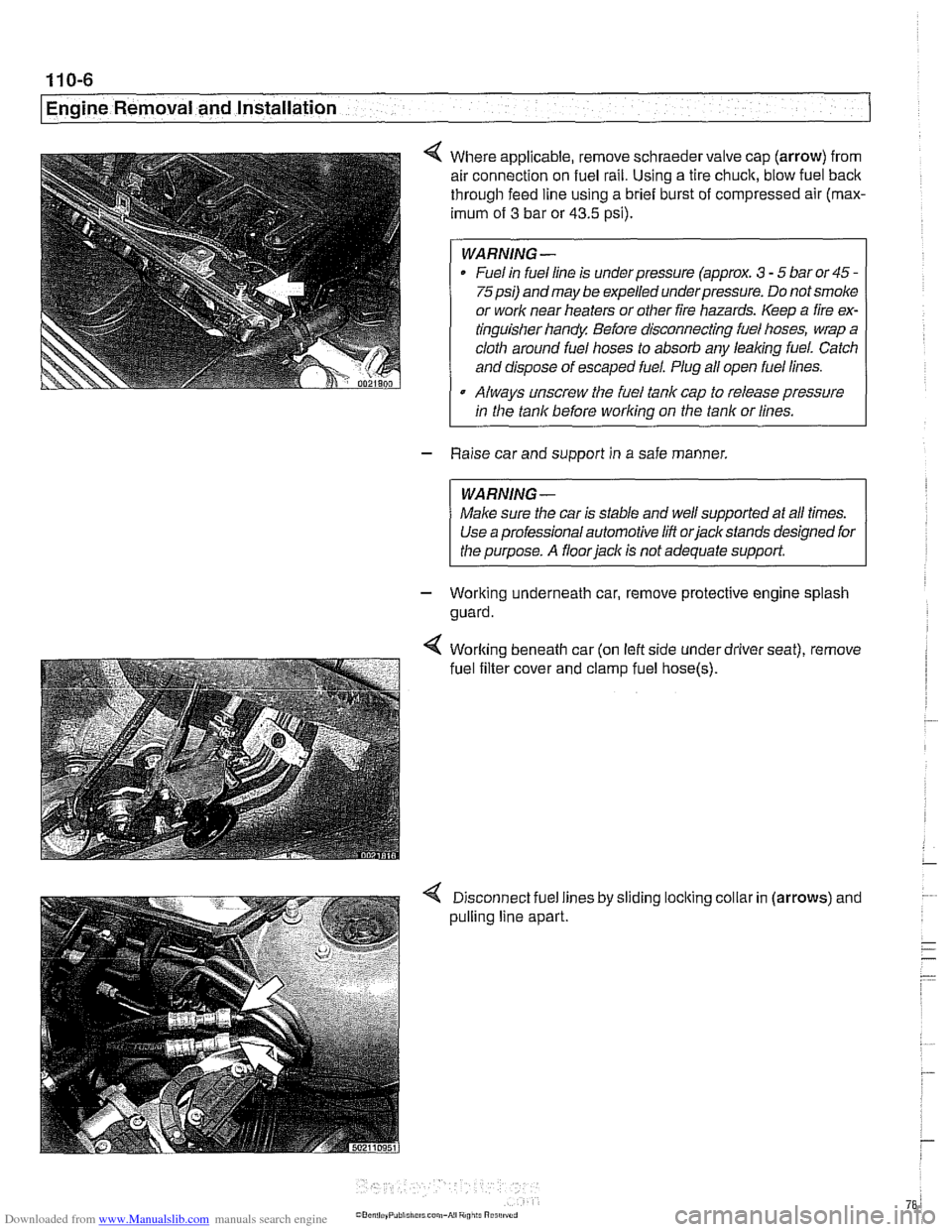

4 Where applicable, remove schraedervalve cap (arrow) from

air connection on fuel rail. Using a tire chuck, blow fuel back

through feed line using a brief burst of compressed air

(rnax-

imum of 3 bar or 43.5 psi).

WARNING -

Fuel in fuel line is under pressure (approx. 3 - 5 bar or 45 -

75psi) andmay be expelled underpressure. Do not smoke

or work near heaters or other fire hazards. Keep a fire ex-

tinguisher handy Before disconnecting fuel hoses, wrap

a

cloth around fuel hoses to absorb any leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

Alwavs unscrew the Fuel tank cao to release

oressure

I in the tank before working on the tank or lines. I

- Raise car and support in a safe manner.

WARNING-

Male sure the car is stable and we/ supported at all times.

Use a professional automotive lift orjackstands designed for

the purpose. A floor jack is not adequate support

- Working underneath car, remove protective engine splash

guard.

4 Disconnect fuel lines by sliding locking collar in (arrows) and

pulling line apart.

Page 79 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and lnstallationl

NOTE-

BMW uses three styles of fuel line connections; a one-time

single use clamp, a locking fitting that uses special tool

16 1

050 to release, and a quick release sleeve (arrow) that dis-

connects the line when depressed.

WARNING-

Fuel may be expelled under pressure. Do not smoke or work

near heaters or other fire hazards. Keep a fire extinguisher

handy Before disconnecting fuel hoses, wrap a cloth around

fuel hoses to absorb any leaking fuel. Plug all

oDen fuel lines.

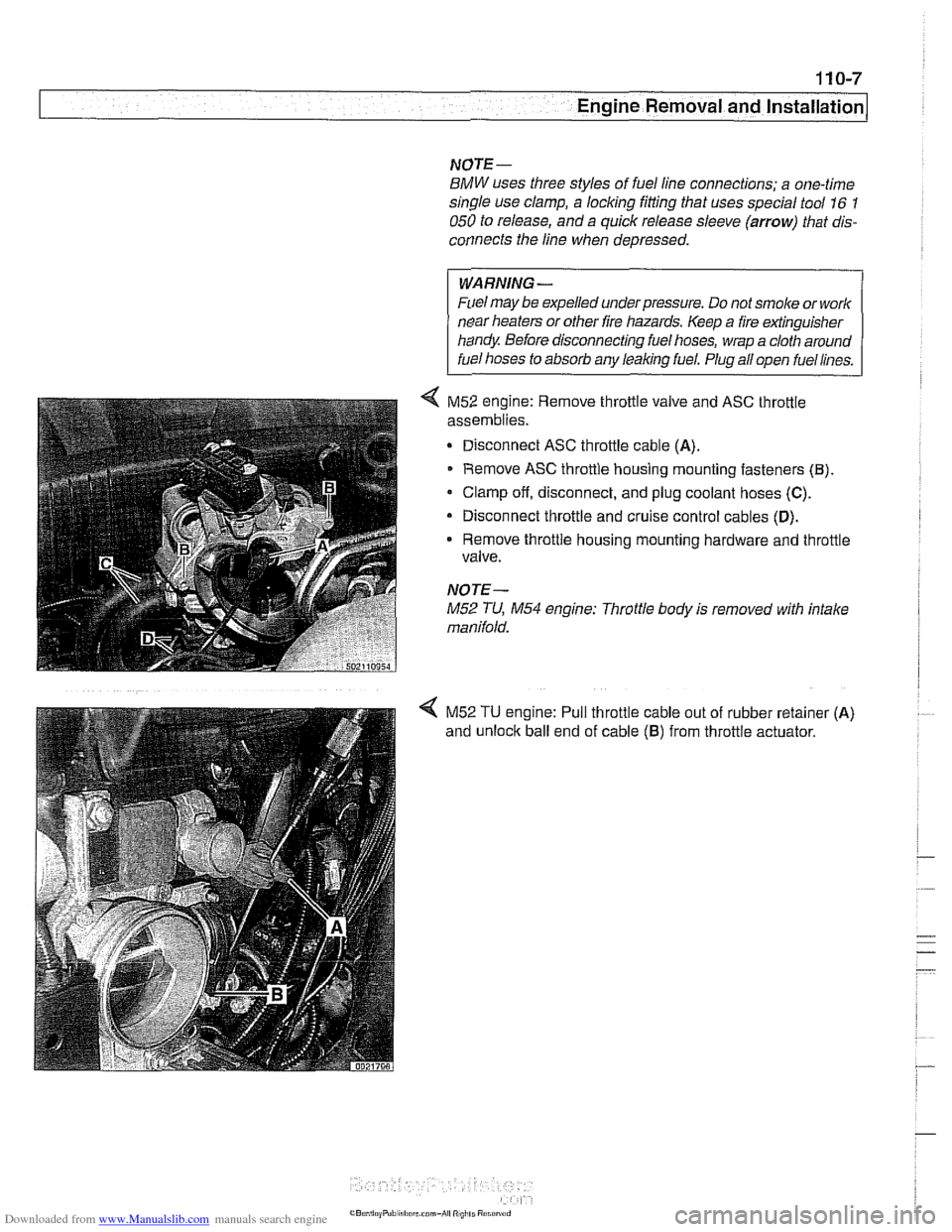

< M52 engine: Remove throttle valve and ASC throttle

assemblies.

Disconnect ASC throttle cable

(A).

Remove ASC throttle housing mounting fasteners (El).

Clamp off, disconnect, and plug coolant hoses (C).

Disconnect throttle and cruise control cables (D).

Remove throttle housing mounting hardware and throttle

valve.

NOTE-

M52 TU, M54 engine: Throttle body is removed with intake

manifold.

< M52 TU engine: Pull throttle cable out of rubber retainer (A)

and unloclc ball end of cable (6) from throttle actuator.

Page 88 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-16

Engine Removal and Installation

ENGINE, REMOVAL AND

INSTALLATION (V-8 MODELS)

NOTE-

Engine removal procedures are similar for all V-8 models.

When differences exist, they are noted at the beginning of

each step. Engine are referred to by engine code. If neces-

sary, See

100 Engine-General for engine code andappli-

cation information.

Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse gaskets, O-rings or seals during reassembly

WARNING

-

Due to risk ofpersonal injury, be sure the engine is cold be-

fore beginning the

removal procedure.

- Disconnect negative (-) cable from battery.

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove engine hood or place hood in service position. See

410 Fenders, Engine Hood.

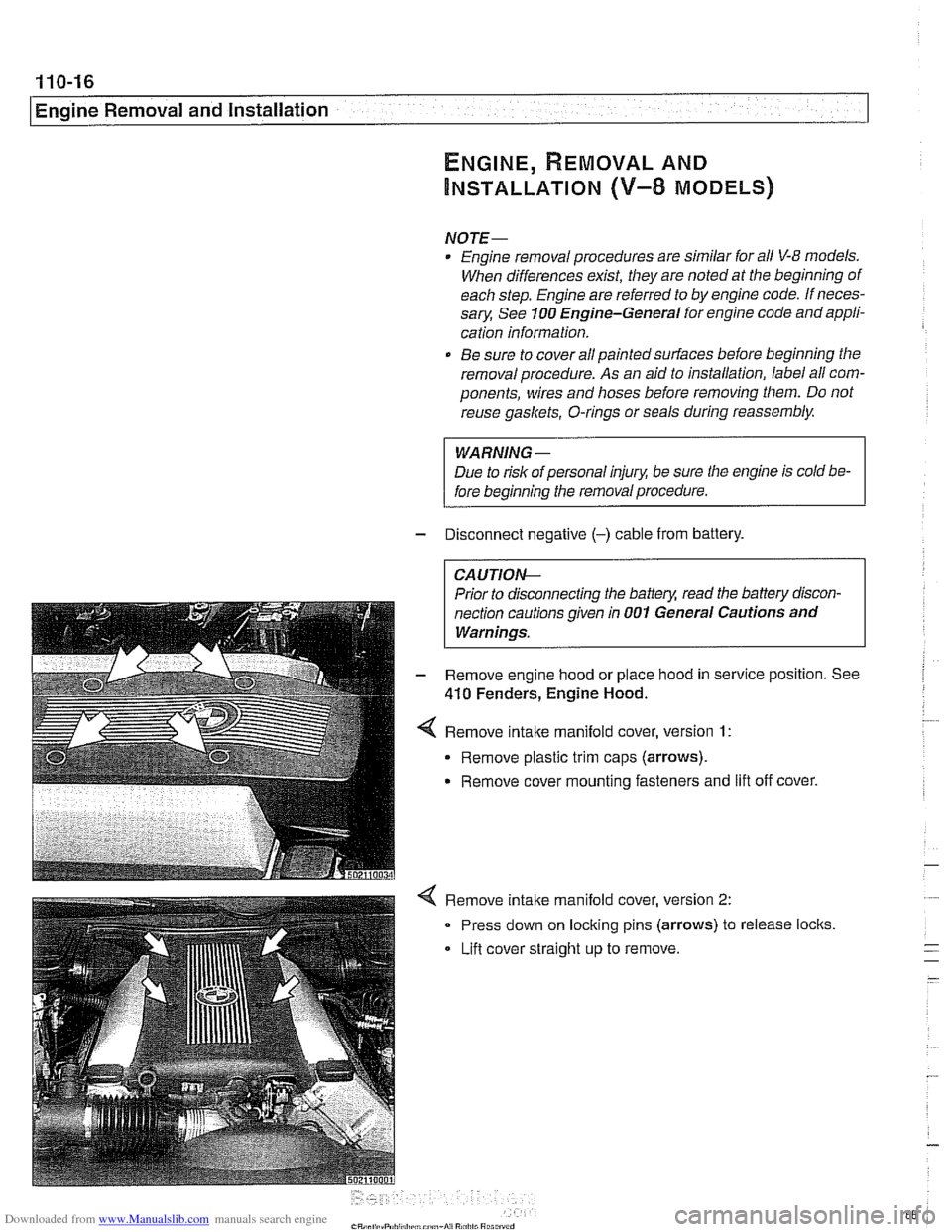

Remove

intake manifold cover, version 1:

Remove plastic trim caps (arrows).

Remove cover mounting fasteners and

lift off cover.

Remove intake manifold cover, version

2:

Press down on locking pins (arrows) to release locks

Lifl cover straight

up to remove.

Page 89 of 1002

Downloaded from www.Manualslib.com manuals search engine

- .. -.

-. Engine Removal and in=/

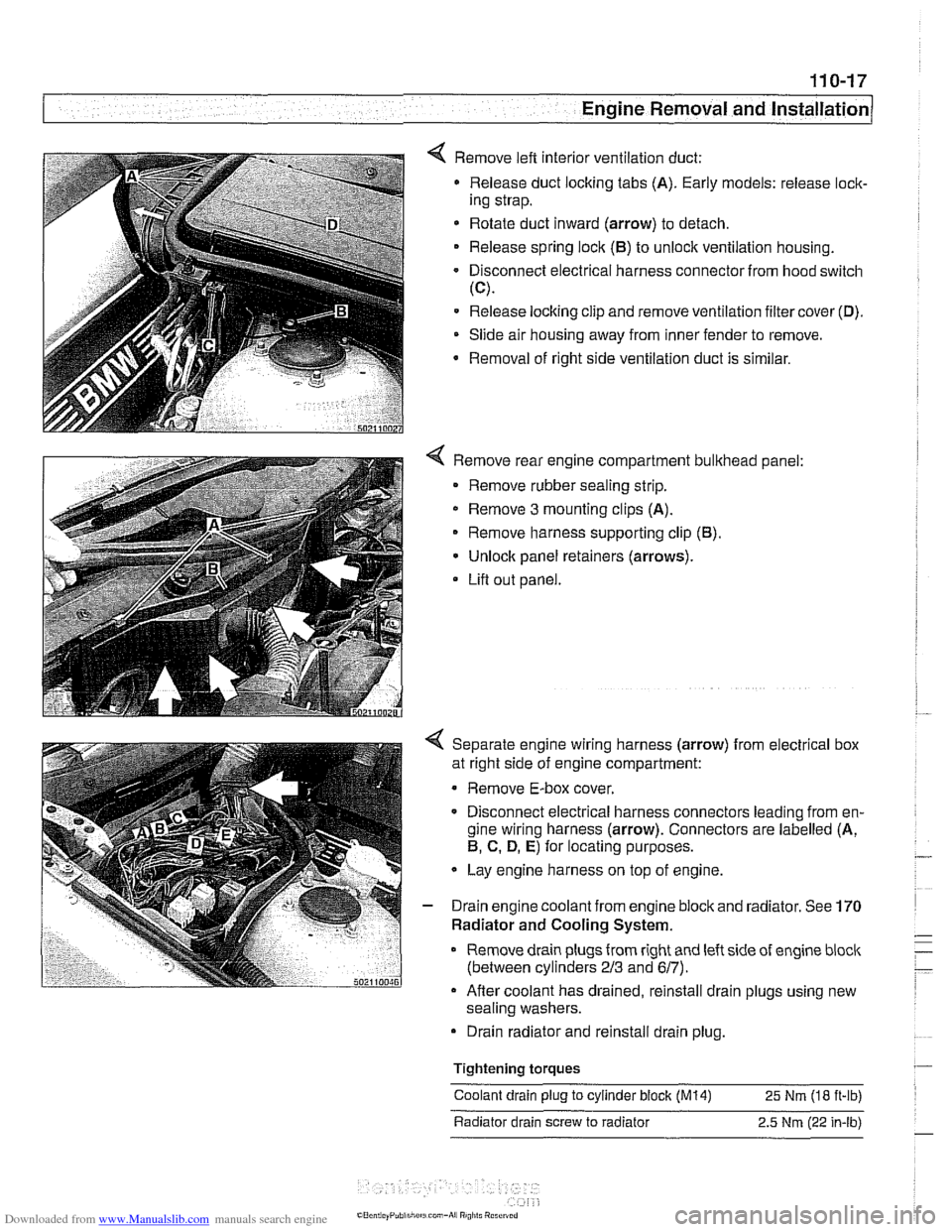

4 Remove left interior ventilation duct:

Release duct locking tabs (A). Early models: release

loclc

ing strap.

* Rotate duct inward (arrow) to detach.

Release spring

loclc (El) to unlock ventilation housing.

Disconnect electrical harness connector from hood switch

(C).

Release locking clip and remove ventilation filter cover (D).

Slide air housing away from inner fender to remove.

Removal

of right side ventilation duct is similar.

4 Remove rear engine compartment bulkhead panel:

Remove rubber sealing strip.

* Remove 3 mounting clips (A).

Remove harness supporting clip

(El).

Unlock panel retainers (arrows).

Lifl out panel.

< Separate engine wiring harness (arrow) from electrical box

at right side of engine compartment:

Remove E-box cover.

Disconnect electrical harness connectors leading from en-

gine wiring harness (arrow). Connectors are labelled (A,

El, C. D, E) for locating purposes.

Lay engine harness on top of engine.

- Drain engine coolant from engine block and radiator. See 170

Radiator and Cooling System.

Remove drain plugs from right and left side of engine

bloclc

(between cylinders 213 and 617).

Afler coolant has drained, reinstall drain plugs using new

sealing washers.

Drain radiator and reinstall drain plug.

Tightening

torques

Coolant drain plug to cylinder block (M14) 25 Nm (18 ft-ib)

Radiator drain screw to radiator 2.5

Nm (22 in-lb)

Page 90 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Engine Removal and Installation

WARNING -

Use extreme caution when draining and disposing of engine

coolant. Coolant is poisonous andlethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste. Seek medical attention immediately if coolant is ingest-

---

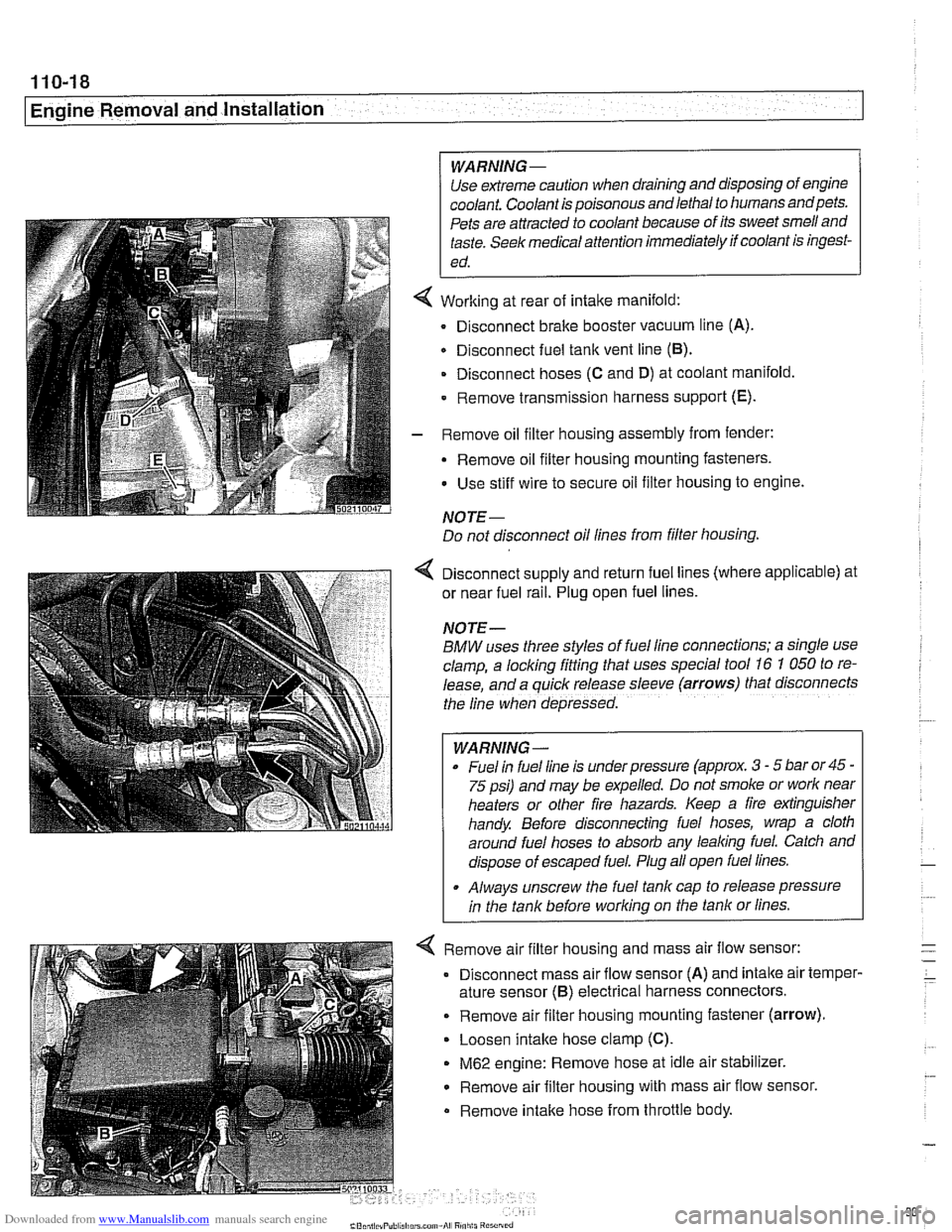

Working at rear of intake manifold:

Disconnect brake booster vacuum line (A).

Disconnect fuel tank vent line

(6).

Disconnect hoses (C and D) at coolant manifold

- Remove transmission harness support (E).

- Remove oil filter housing assembly from fender:

- Remove oil filter housing mounting fasteners.

Use stiff wire to secure oil filter housing to engine.

NOTE-

Do not disconnect oil lines from filter housing.

4 Disconnect supply and return fuel lines (where applicable) at

or near fuel rail. Plug open fuel lines.

NOTE-

BMW uses three styles of fuel line connections; a slngle use

clamp, a locking fitting that uses special tool

16 7 050 to re-

lease, and a

quiclc release sleeve (arrows) that disconnects

the line when depressed.

WARNING-

Fuel In fuel line is under pressure (approx. 3 - 5 bar or45 -

75 psi) and may be expelled. Do not smoke or worlc near

heaters or other fire hazards. Keep a fire extinguisher

handy. Before disconnecting fuel hoses, wrap a cloth

around fuel hoses to absorb any lealcing fuel. Catch and

dispose of escaped fuel. Plug all open fuel lines.

. Always unscrew the fuel tank cap to release pressure

in the tank before worlcing on the tank or lines.

< Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor (A) and

intalte air temper-

ature sensor

(6) electrical harness connectors.

. Remove air filter housing mounting fastener (arrow).

Loosen intake hose clamp (C).

M62 engine: Remove hose at idle air stabilizer.

Remove air filter housing with mass air flow sensor.

Remove intalte hose from throttle body.