trim BMW 540i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 936 of 1002

Downloaded from www.Manualslib.com manuals search engine

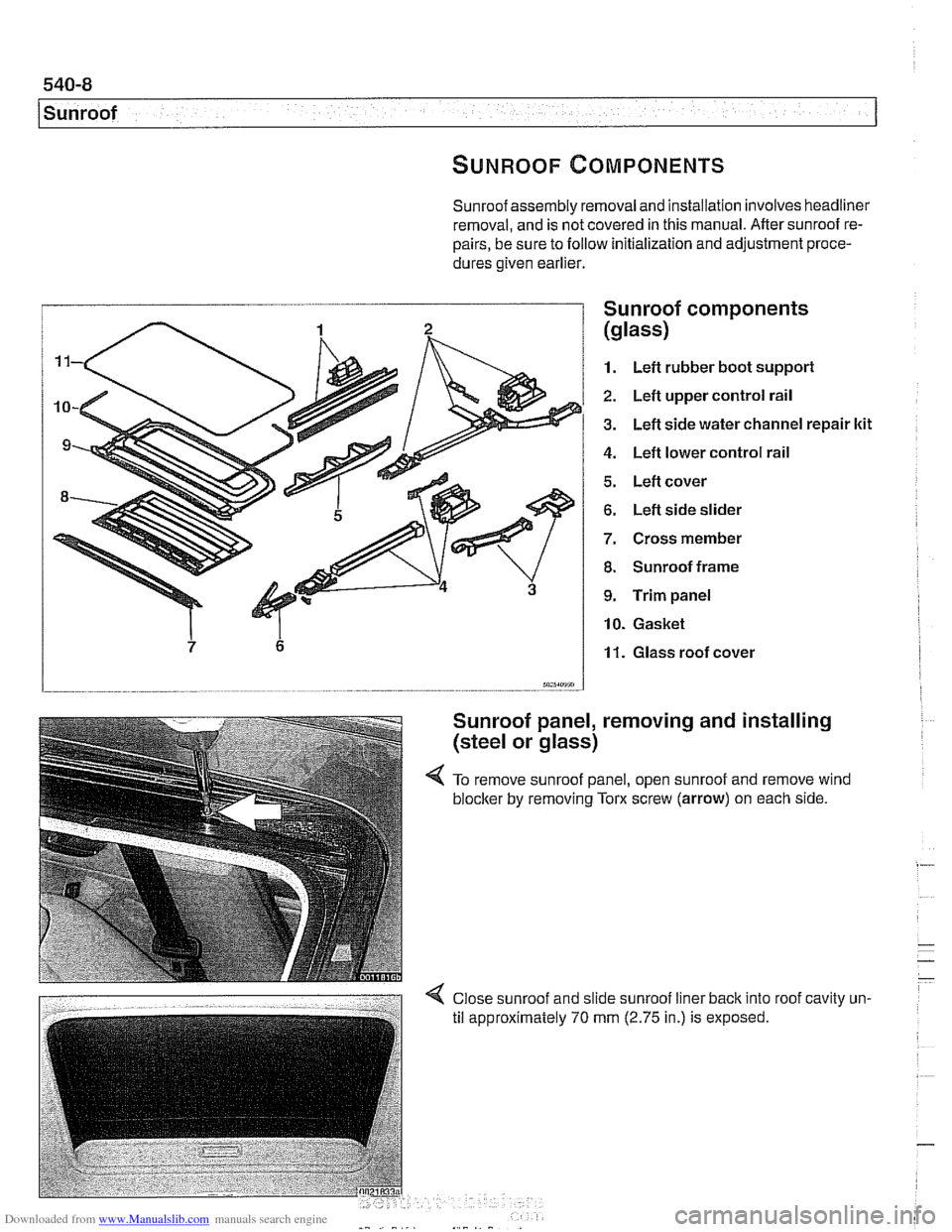

1 Sunroof

Sunroof assembly removal and installation involves headliner

removal, and is not covered in this manual. After sunroof re-

pairs, be sure to follow initialization and adjustment proce-

dures given earlier.

I Sunroof comDonents

1. Left rubber boot suppori

2. Left upper control rail

3. Left side water channel repair ltit

4. Left lower control rail

5. Left cover

6. Left side slider

7. Cross member

8. Sunroof frame

9. Trim panel

10. Gasket

11. Glass roof cover

m5sm.7 - -.

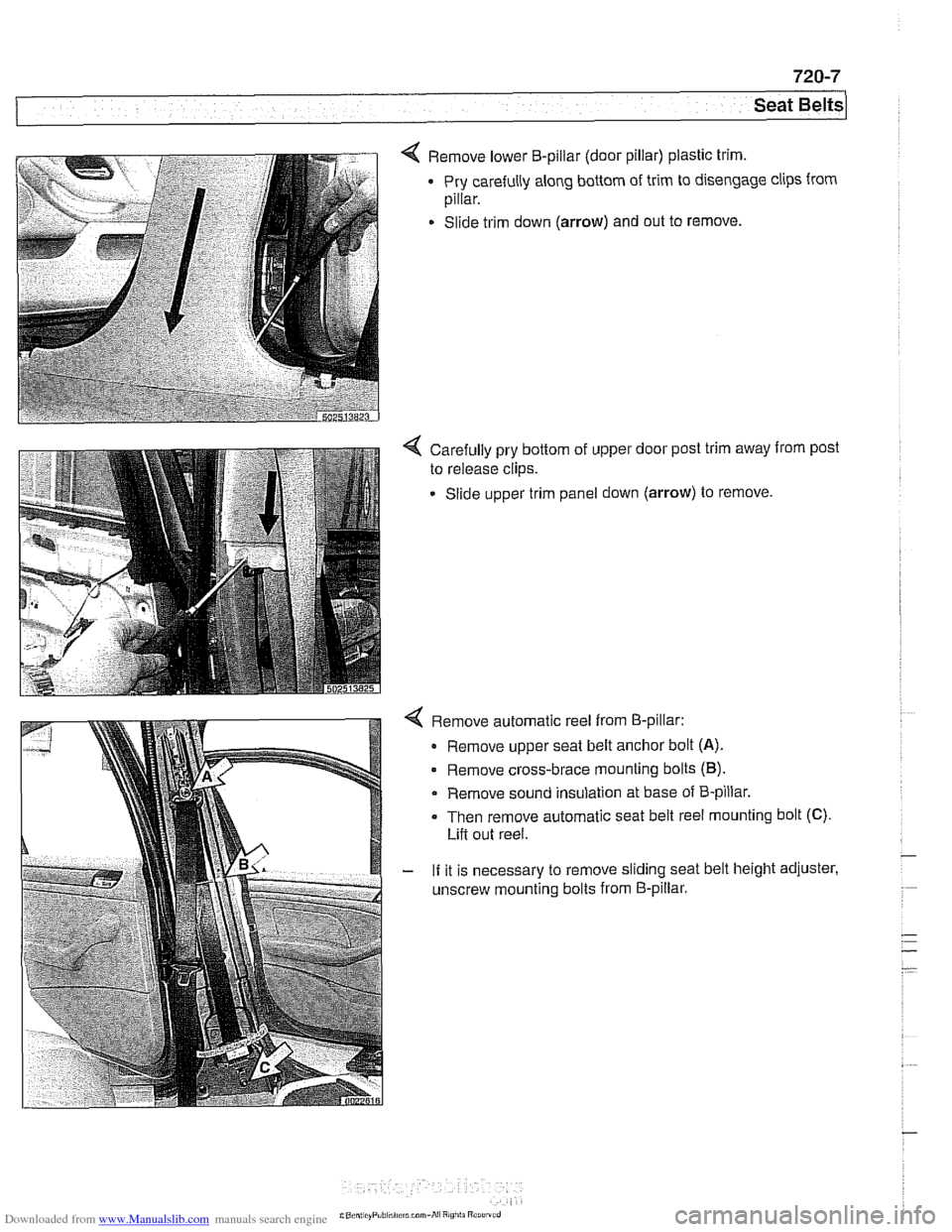

Sunroof panel, removing and installing

(steel or glass)

4 To remove sunroof panel, open sunroof and remove wind

blocker

by removing Tom screw (arrow) on each side.

Page 945 of 1002

Downloaded from www.Manualslib.com manuals search engine

Seat Belts

Remove lower B-pillar (door pillar) plastic trim

Pry carefully along bottom of trim to disengage

pillar.

Slide trim down (arrow) and out to remove. clips

from

4 Carefully pry bottom of upper door post trim away from post

to release clips.

Slide upper trim panel down (arrow) to remove.

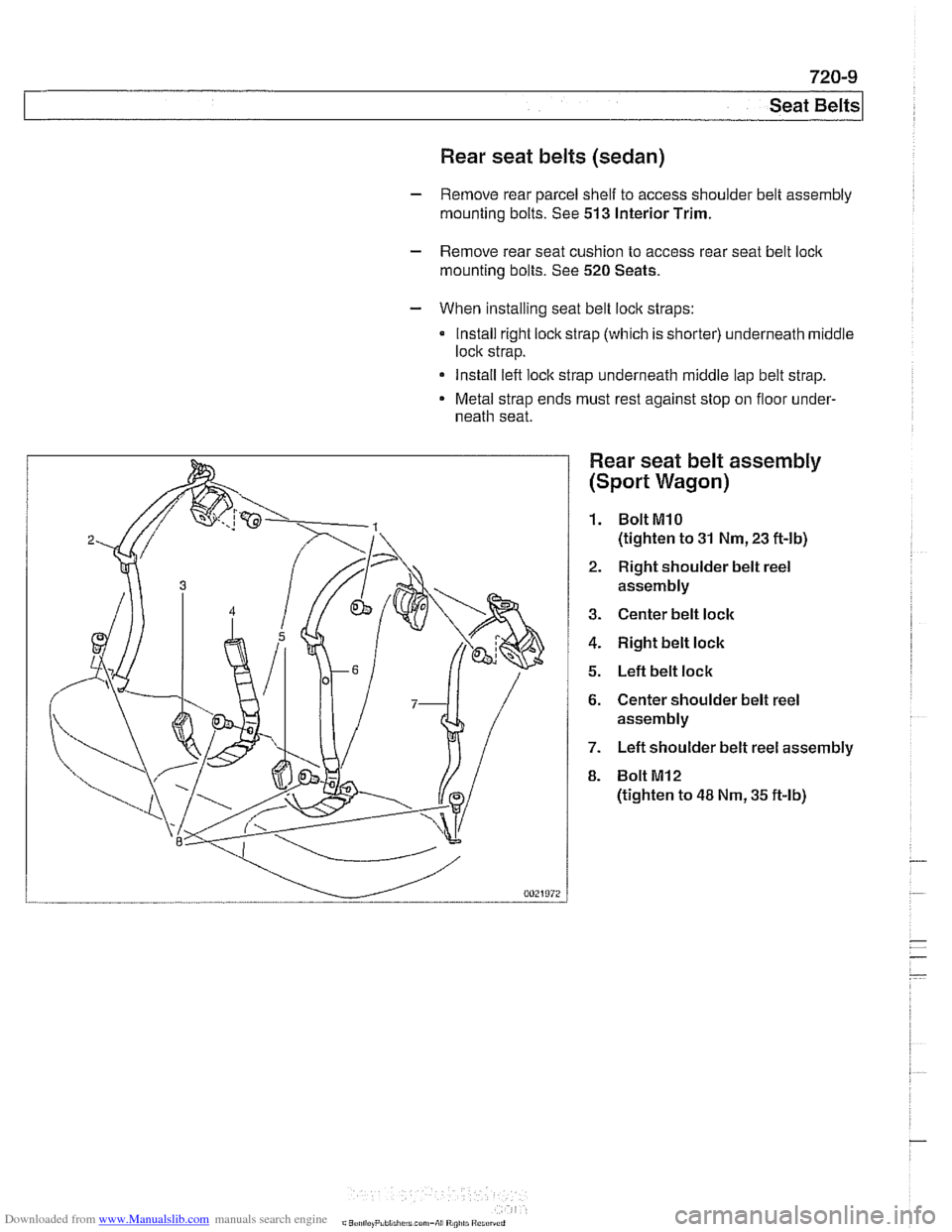

Remove automatic reel from B-pillar:

- Remove upper seat belt anchor bolt (A).

Remove cross-brace mounting bolts (B).

Remove sound insulation at base of 8-pillar.

Then remove automatic seat belt reel mounting bolt

(C).

Lift out reel.

If it is necessary to remove sliding seat belt height adjuster,

unscrew mounting bolts from B-pillar.

Page 947 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Seat Belts

Rear seat belts (sedan)

- Remove rear parcel shelf to access shoulder belt assembly

mounting bolts. See 513 Interior Trim.

- Remove rear seat cushion to access rear seat belt lock

mounting bolts. See 520 Seats.

- When installing seat belt lock straps:

Install right lock strap (which is shorter) underneath middle

lock strap.

Install left lock strap underneath middle lap belt strap.

Metal strap ends must rest against stop on floor under-

neath seat.

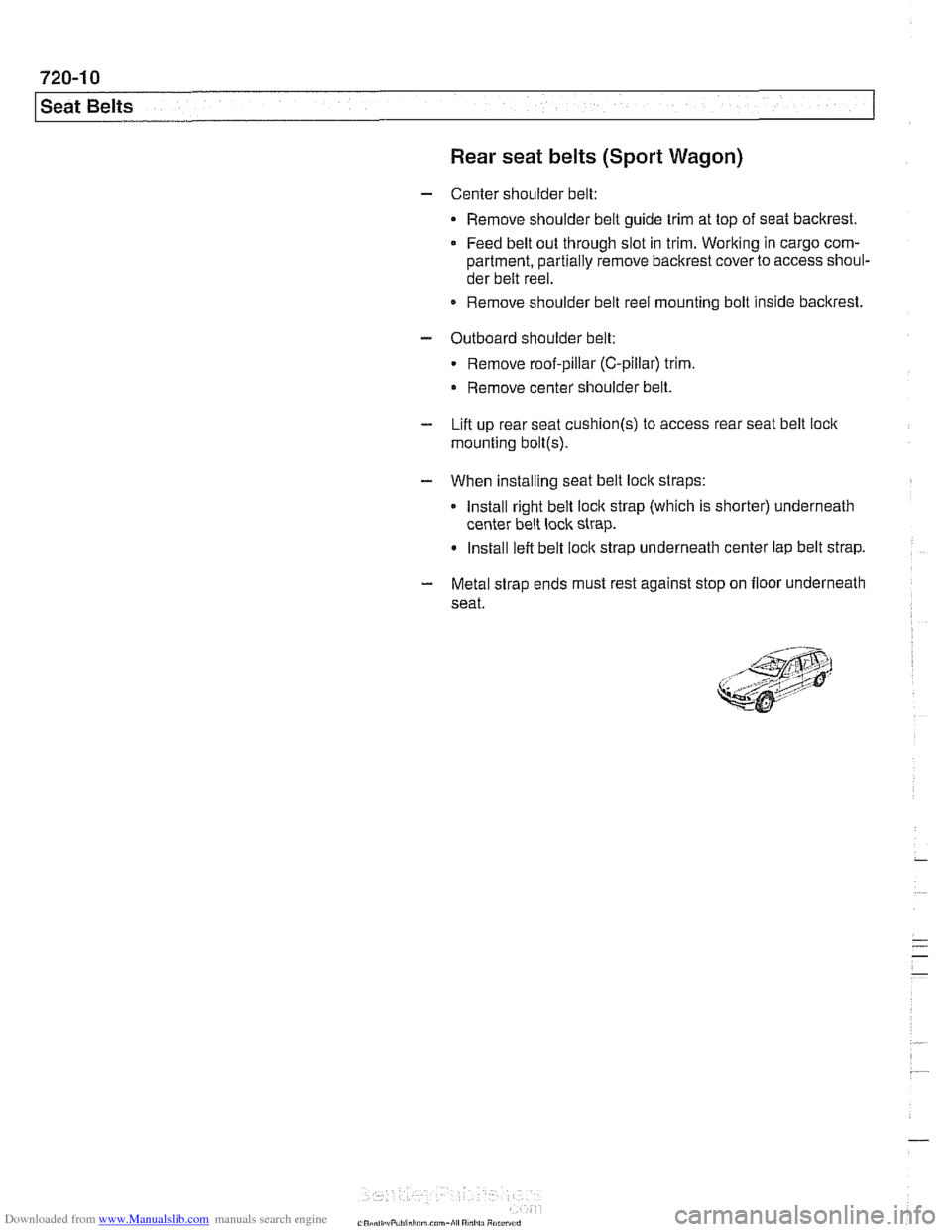

Rear seat belt assembly

(Sport Wagon)

1. BoltMlO

(tighten to 31 Nm, 23 ft-lb)

2. Right shoulder belt reel

assembly

3. Center belt lock

4. Right belt lock

5. Left belt lock

6. Center shoulder belt reel

assembly

7. Left shoulder belt reel assembly

8. Bolt

MI2

(tighten to 48 Nm, 35 ft-lb)

Page 948 of 1002

Downloaded from www.Manualslib.com manuals search engine

720-1 0

Seat Belts

Rear seat belts (Sport Wagon)

- Center shoulder belt:

Remove shoulder belt guide trim at top of seat backrest.

Feed belt out through slot in trim. Working in cargo com-

partment, partially remove backrest cover to access shoul-

der belt reel.

Remove shoulder belt reel mounting bolt inside backrest.

- Outboard shoulder belt:

Remove roof-pillar (C-pillar) trim.

Remove center shoulder belt.

- Lift up rear seat cushion(s) to access rear seat belt loclc

mounting

bolt(s).

- When installing seat belt loclc straps:

Install right belt loclc strap (which is shorter) underneath

center belt lock strap.

Install left belt loclc strap underneath center lap belt strap.

- Metal strap ends must rest against stop on floor underneath

seat.

Page 955 of 1002

Downloaded from www.Manualslib.com manuals search engine

Airbag System (SRS)~

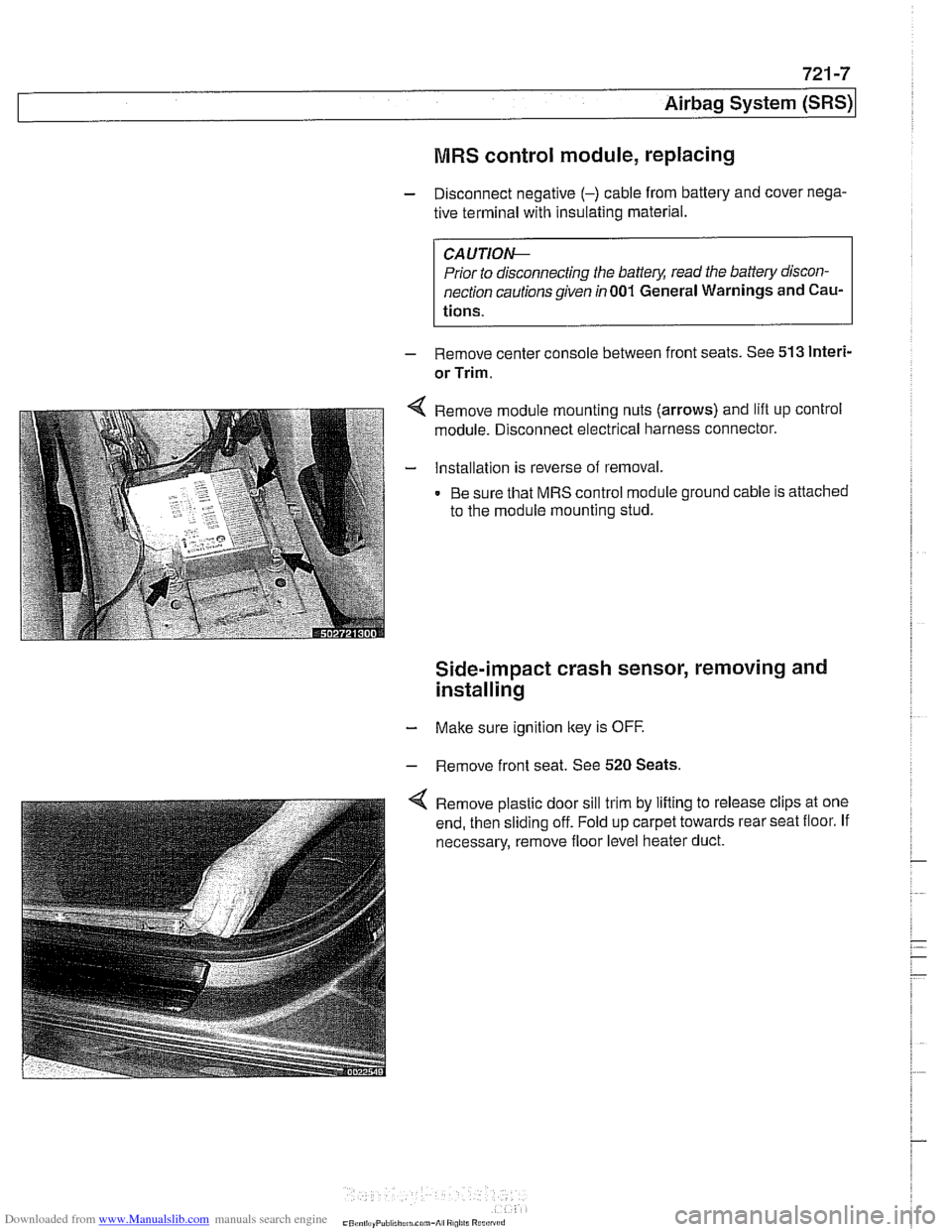

MRS control module, replacing

- Disconnect negative (-) cable from battery and cover nega-

tive terminal with insulating material.

CAUTIOI\C

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven in001 General Warnings and

Cau-

tions.

- Remove center console between front seats. See 513 lnteri-

or Trim.

Remove module mounting nuts (arrows) and lift up control

module. Disconnect electrical harness connector.

Installation is reverse of removal.

Be sure that MRS control module ground cable is attached

to the module mounting stud.

Side-impact crash sensor, removing and

installing

- Make sure ignition key is OFF.

- Remove front seat. See 520 Seats.

Remove plastic door sill trim by lifting to release clips at one

end, then sliding off. Fold up carpet towards rear seat floor. If

necessary, remove floor level heater duct.

Page 960 of 1002

Downloaded from www.Manualslib.com manuals search engine

721-12

Airbag System (SRS)

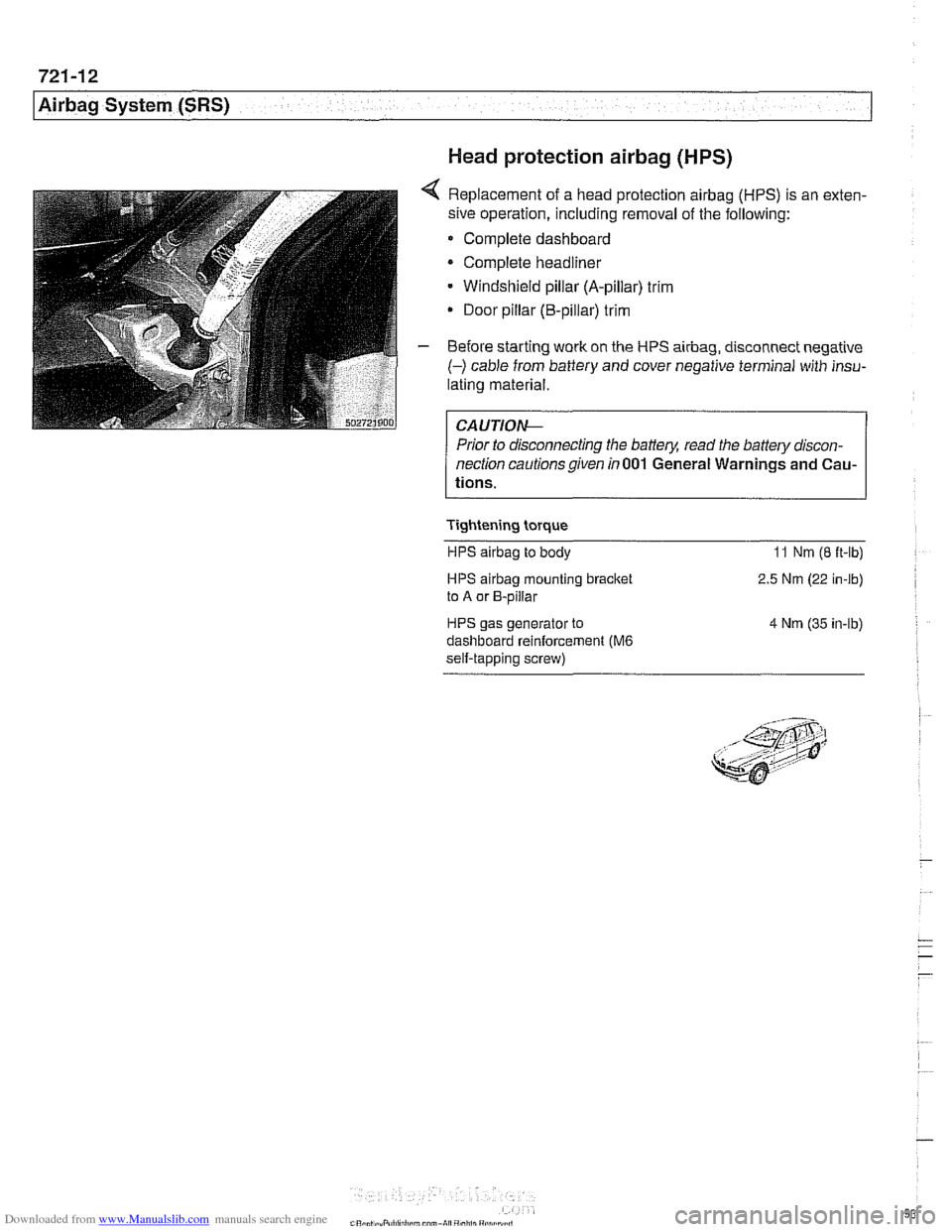

Head protection airbag (HPS)

4 Replacement of a head protection airbag (HPS) is an exten-

sive operation, including removal of the following:

Complete dashboard

Complete headliner

Windshield pillar (A-pillar) trim

Door pillar (B-pillar) trim

- Before starting work on the HPS airbag, disconnect negative

(-) cable from battery and cover negative terminal with insu-

lating material.

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven in001 General Warnings and Cau-

tions.

Tightening torque HPS

airbag to body 11 Nm (8 ft-lb)

HPS airbag mounting bracket

to A or B-pillar

HPS gas generator to

dashboard reinforcement

(M6

self-tapping screw) 2.5

Nm (22 in-lb)

4 Nm (35 in-lb)

Page 966 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-6

On-Board Diagnostics

Fuel system monitoring. This monitor looks at the fuel

delivery needed (long

/short term fuel trim) for proper engine

operation based on programmed data. If too much or not

enough fuel is delivered over a predetermined time, a DTC is

set and the MIL illuminates.

Fuel trim refers to adiustments to base fuel schedule.

Lono- ., term fuel trim refers to gradual adjustments to the fuel

calibration adjustment as compared to short term fuel trim.

Long term fuel trim adjustments compensate for gradual

changes that occur over time.

Fuel system monitoring monitors the calculated injection time

(ti) in relation to enginespeed, load and precatalyticconverter

oxygen

sensor(s) signals.

Using this data, the system optimizes fuel delivery for all

engine operating conditions.

Evaporative system monitoring. This monitor checks the

the fuel storage system and related fuel lines for leaks. It can

detect very small leaks anywhere in the system.

A leak detection unit (LDP or DMTL) is used to pressurize the

evaporative control system on a continuous basis (as the

drive cycle allows) and to

check system integrity.

Drive cycle

The OED II drive cycle is an important concept in

understanding OBD

II requirements. The purpose of the drive

cycle is to run ail of the emission-related on-board diagnostics

over a broad range of driving conditions.

A drive cycle is considered complete when all of the

diagnostic monitors have run their tests without interruption.

~ora drive cycle to be initiated, the vehicle must be started

cold and brought up to

1 60°F and at least 40°F above its

original starting temperature.

Readiness codes

Inspection/maintenance (I/M) readiness codes are mandated

as part of OBD

II. The readiness code is stored aftercomplete

diagnostic monitoring of specified components and systems

is carried out. The readiness code function was designed to

prevent manipulating an

I/M emission test procedure by

clearing faults codes or disconnecting the ECM or battery.

Page 968 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-8

I On-Board Diagnostics

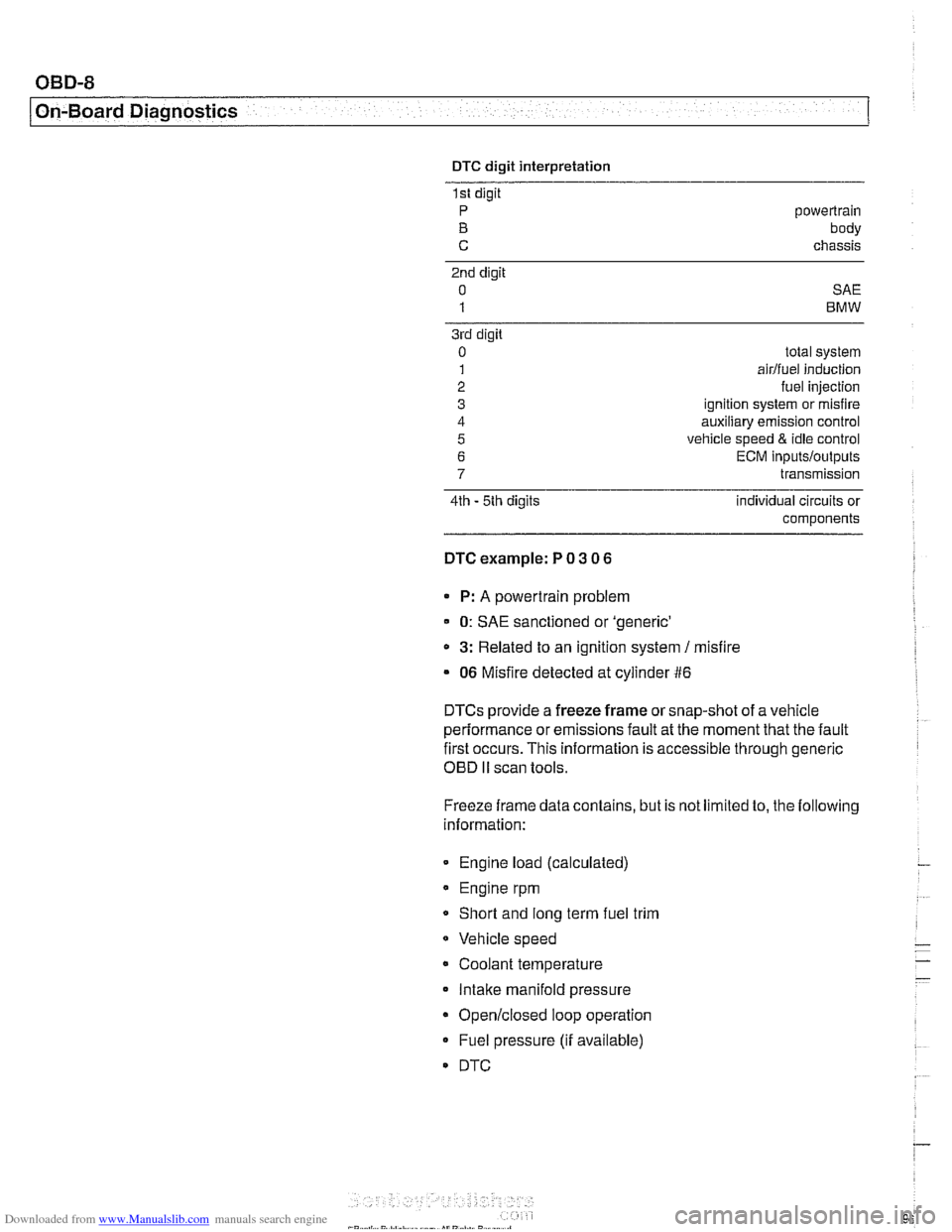

DTC digit interpretation

1st digit

P powertrain

B body

C chassis

2nd digit

0 SAE

1 BMW

3rd digit

0

1

2

3

4

5

6

7

4th - 5th digits total

system

airlfuei induction

fuel injection

ignition system or misfire

auxiliary emission control

vehicle speed

& idle control

ECM

inputs/outputs

transmission

individual circuits or

components

DTC example: P 0 3 0 6

P: A powertrain problem

0: SAE sanctioned or 'generic'

a 3: Related to an ignition system / misfire

06 Misfire detected at cylinder #6

DTCs provide a freeze frame or snap-shot of a vehicle

performance or emissions fault at the moment that the fault

first occurs. This information is accessible through generic

OED I1 scan tools.

Freeze frame data contains, but is not limited to, the following

information:

Engine load (calculated)

Engine rpm

Short and

long term fuel trim

Vehicle speed

Coolant temperature Intake manifold pressure

Open/closed loop operation

Fuel pressure (if available)

DTC

Page 974 of 1002

Downloaded from www.Manualslib.com manuals search engine

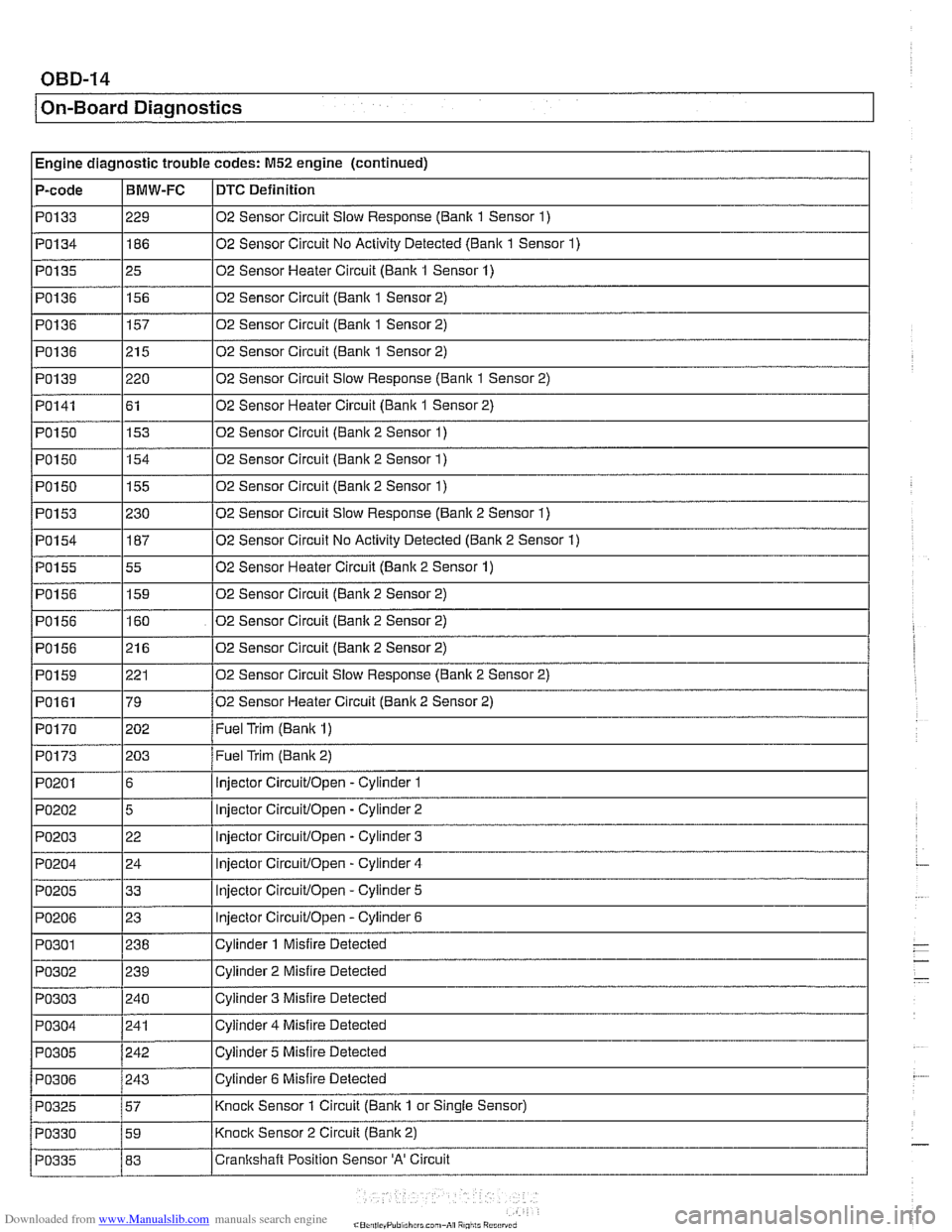

OBD-14

I On-Board Diagnostics

I Engine diagnostic trouble codes: M52 engine (continued) - - -

P-code IBMW-FC ~DTC Definition

PO133

PO134

PO135

PO136

PO136

PO136

PO139

PO141

I I

PO150 1155 102 Sensor Circuit (Bank 2 Sensor 1)

I

I

229

186

25

156

157

215

220 61

PO150 02

Sensor Circuit

Slow Response (Banlc 1 Sensor 1)

02 Sensor Circuit No Activity Detected

(Bank 1 Sensor 1)

02 Sensor Heater Circuit (Bank 1 Sensor 1)

02 Sensor Circuit

(Banlc 1 Sensor 2)

02 Sensor Circuit (Bank 1 Sensor 2)

02 Sensor Circuit (Bank 1 Sensor 2)

02 Sensor Circuit Slow Response

(Bank 1 Sensor 2)

02 Sensor Heater Circuit

(Bank 1 Sensor 2)

PO153

PO154

PO155

PO156

PO156

PO156

PO150 1154 102 Sensor Circuit (Bank 2 Sensor 1)

153

PO159

PO161

PO170

02

Sensor Circuit (Banic 2 Sensor 1)

230

187

55

159

160

21 6

p~-~~--~ PO173

PO201

PO202

PO203

PO204

PO205

PO206

02 Sensor Circuit Slow Response (Banlc 2 Sensor 1)

02 Sensor Circuit No Activity Detected (Bank 2 Sensor

1)

02 Sensor Heater Circuit (Bank 2 Sensor 1)

02 Sensor Circuit (Bank 2 Sensor 2)

02 Sensor Circuit (Banlc 2 Sensor 2)

02 Sensor Circuit (Banlc 2 Sensor 2)

221

79

202 02

Sensor Circuit Slow Response (Banic 2 Sensor 2)

02 Sensor Heater Circuit

(Banic 2 Sensor 2)

Fuel Trim

(Banic 1)

203

6

5

22

24

33

23

Fuel Trim (Banic 2)

injector

Circuitlopen -Cylinder 1

injector

Circuitlopen - Cylinder 2

injector

Circuitlopen -Cylinder 3

Injector

Circuitlopen - Cylinder 4

injector

Circuitlopen - Cylinder 5

lniector

CircuitlOpen - Cvlinder 6

Page 975 of 1002

Downloaded from www.Manualslib.com manuals search engine

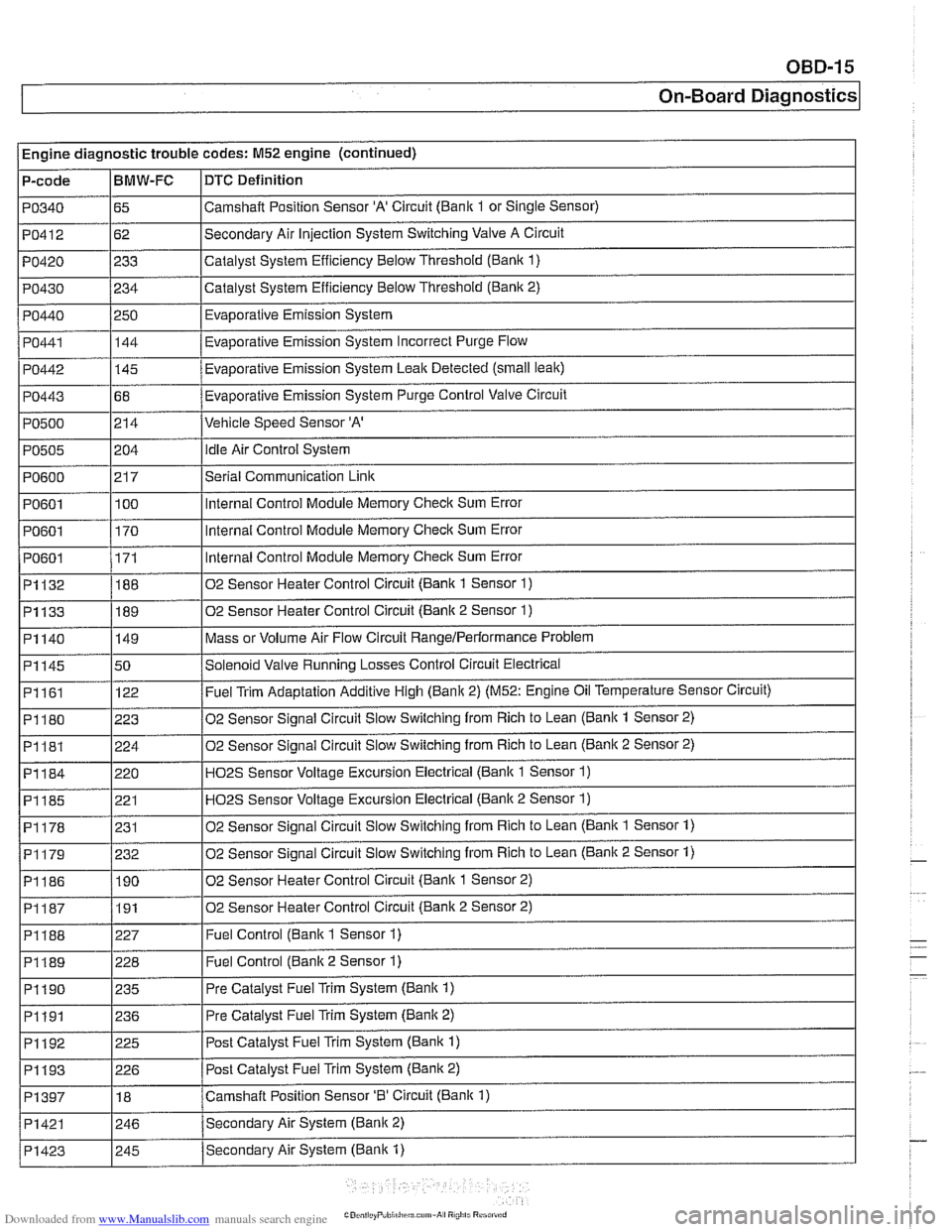

OBD-15

On-Board ~iagnosticsl

Engine diagnostic trouble codes: M52 engine (continued)

P-code

PO340

PO412

PO420

PO430

PO440

PO441

PO442

PO443

PO500

PO505

PO600

PO601

PO601

I PO601

~1132

~1133

BMW-FC

65

62

233

234

250 144

-

145

68

214

i I

DTC Definition

Camshalt Position Sensor 'A' Circuit (Bank 1 or Single Sensor)

Secondary Air Injection System Switching Valve A Circuit

Catalyst System Efficiency Below Threshold

(Bank 1)

Catalyst System Efficiency Below Threshold (Bank 2)

Evaporative Emission System

Eva~orative Emission Svstem Incorrect Purge Flow .

Evaporative Emission System Leak Detected (small leak)

Evaporative Emission System Purge Control Valve Circuit

Vehicle Speed Sensor 'A'

204

21 7

100

170

171

188

189

PI161

PI180

PI181

PI184

PI185

PI178

02 Sensor Heater Control Circuit (Bank 2 Sensor 2) I

idle Air Control System

Serial Communication

Link

Internal Control Module Memory Check Sum Error

Internal Control Module Memory

Check Sum Error

Internal Control Module Memory

Check Sum Error

02 Sensor Heater Control Circuit (Bank 1 Sensor

1)

02 Sensor Heater Control Circuit (Bank 2 Sensor 1)

Mass or Volume Air Flow Circuit RangeIPerlormance Problem PI140

I

I I

P1188 1227 I Fuel Control (Bank 1 Sensor 1)

PI145 150 /Solenoid Valve Running Losses Control Circuit Electrical

149

122

223

224

220 221

231

I I

P1189 1228 I Fuel Control (Banlc 2 Sensor 1)

Fuel Trim Adaptation Additive High (Bank 2) (M52: Engine Oil Temperature Sensor Circuit)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 1 Sensor 2)

02 Sensor Signal Circuit Slow Switching from Rich to Lean

(Bank 2 Sensor 2)

H02S Sensor Voltage Excursion Electrical (Banlc 1 Sensor 1)

HO2S Sensor Voltage Excursion Electrical (Banlc 2 Sensor 1)

02 Sensor Sianai Circuit Slow Switchina from Rich to Lean (Bank 1 Sensor 1)

02 Sensor Signal Circuit Slow Switching from Rich to Lean (Bank 2 Sensor 1) PI179

I I

PI190 1235 I Pre Catalyst Fuel Trim System (Banlc 1)

PI186 1190 102 Sensor Heater Control Circuit (Banlc 1 Sensor 2)

232

I I

PI191 1236 I Pre

Catalyst Fuel Trim System (Banlc 2)

PI192

. . -- - i Pi193 1226 I Post Catalvst Fuel Trim Svstem (Bank 2)

225

PI397

I I

Post Catalyst Fuel Trim System (Bank 1)

PI421 1246 /Secondarv Air System (Bank 2)

18

Secondary Air System (Bank

1) PI423

Camshaft Position Sensor '0' Circuit (Bank 1)

I 245