Oul BMW 540i 1999 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 111 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal -- and lnstallati~i

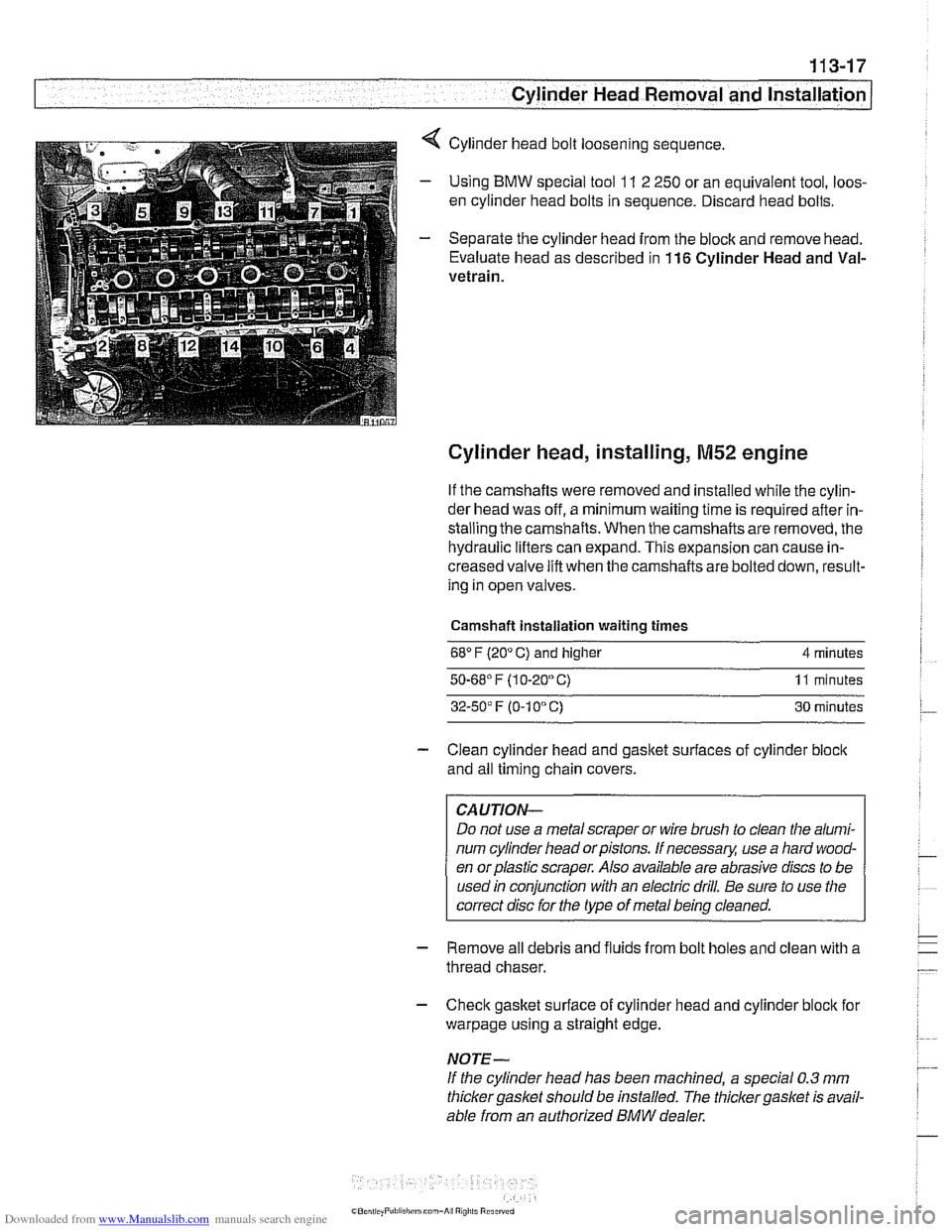

4 Cylinder head bolt loosening sequence.

- Using BMW special tool 11 2 250 or an equivalent tool, loos-

en cylinder head bolts in sequence. Discard head bolts.

- Separate the cylinder head from the block and remove head.

Evaluate head as described in

116 Cylinder Head and Val-

vetrain.

Cylinder head, installing, M52 engine

If the camshafts were removed and installed while the cylin-

der head was off, a minimum waiting time is required after in-

stalling the camshafts. When the camshafts are removed, the

hydraulic lifters can expand. This expansion can cause in-

creased valve lift when the camshafts are bolted down, result-

ing in open valves.

Camshaft installation waiting times

68" F (20" C) and higher 4 minutes

50.68' F (1 0-20" C) 11 minutes

32-50' F (0-1 0" C) 30 minutes

- Clean cylinder head and gasket surfaces of cylinder block

and all timing chain covers.

CAUTION-

Do not use a metal scraper or wire brush to clean the alumi-

num cylinder head orpistons. If necessary, use a hard wood-

en orplastic scraper. Also available are abrasive discs to be

used in conjunction with an electric drill. Be sure to use the

correct disc for the type of metal being cleaned.

- Remove all debris and fluids from bolt holes and clean with a

thread chaser.

- Check gasket surface of cylinder head and cylinder block for

warpage using a straight edge.

NOTE-

If the cylinder head has been machined, a special 0.3 mm

thicker gasket should be installed. The thicker

gasket is avail-

able from an authorized

BMW dealer.

Page 112 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation

4 Check that two locating dowels are correctly positioned in

block and are not damaged.

- Apply permanently elastic sealing compound Three Bond

1209 8 to joints where cylinder block joins timing case cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or 'TOP': printed on the gasket, should

face up. The cylinder head

gasket will fit correctly in only one

orientation.

- With camshafts locked in TDC oosition with BMW soecial

tools as described during cylinder head removal,

seicylinder

head in position, guiding primary chain through cylinder head

opening.

NOTE-

* The camshafts must be locl(ed in the TDC position at the

rear of the cylinder head with

BMW special tool I1 3 240

before installing the cylinder head.

Make sure the

cranksha% which had been rotated approx-

imately

30" opposite the direction of engine rotation, is still

in that position before lowering the cylinder head into posi-

tion.

- Lightly lubricate new cylinder head bolts. Loosely install bolts

and their washers, then thread them in until they are finger

tight.

NOTE-

. Torx-type cylinder head bolts should not be reused. They

are stretch-type bolts and must always be replaced when-

ever loosened.

Check that all washers for the cylinder head bolts are in

place before installing the bolts. Some of the washers may

be

stalced to the cylinder head.

CAUTIOI\C

Cylinder head bolts for a cast iron engine block are different

length and require different tightening torque than bolts for an

aluminum cylinder bloclc engines

(95 rnm versus 110 rnm

bolts).

- Install cylinder head-to-lower timing chain cover bolts finger

tight.

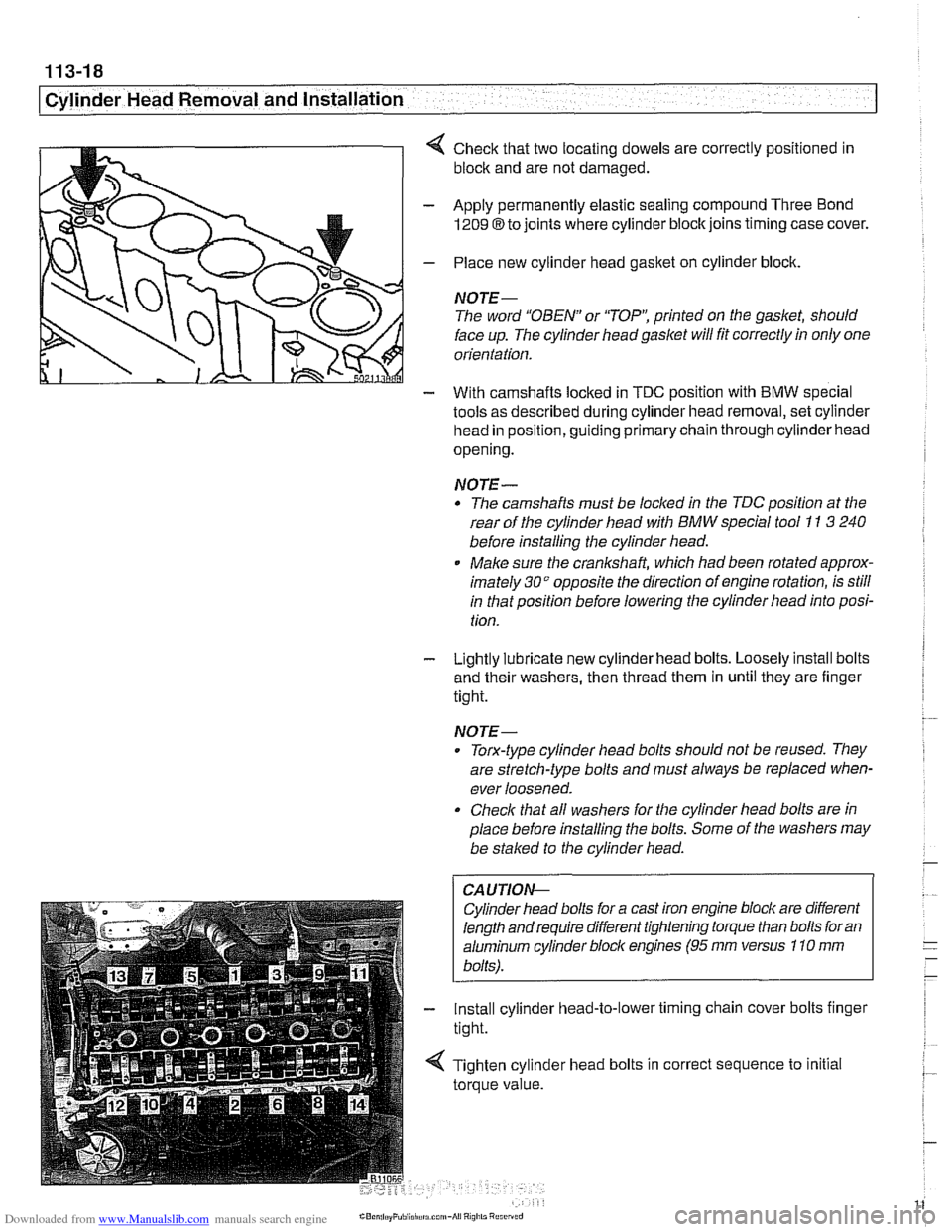

< Tighten cylinder head bolts in correct sequence to initial

torque value.

Page 113 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head Removal and Installation I

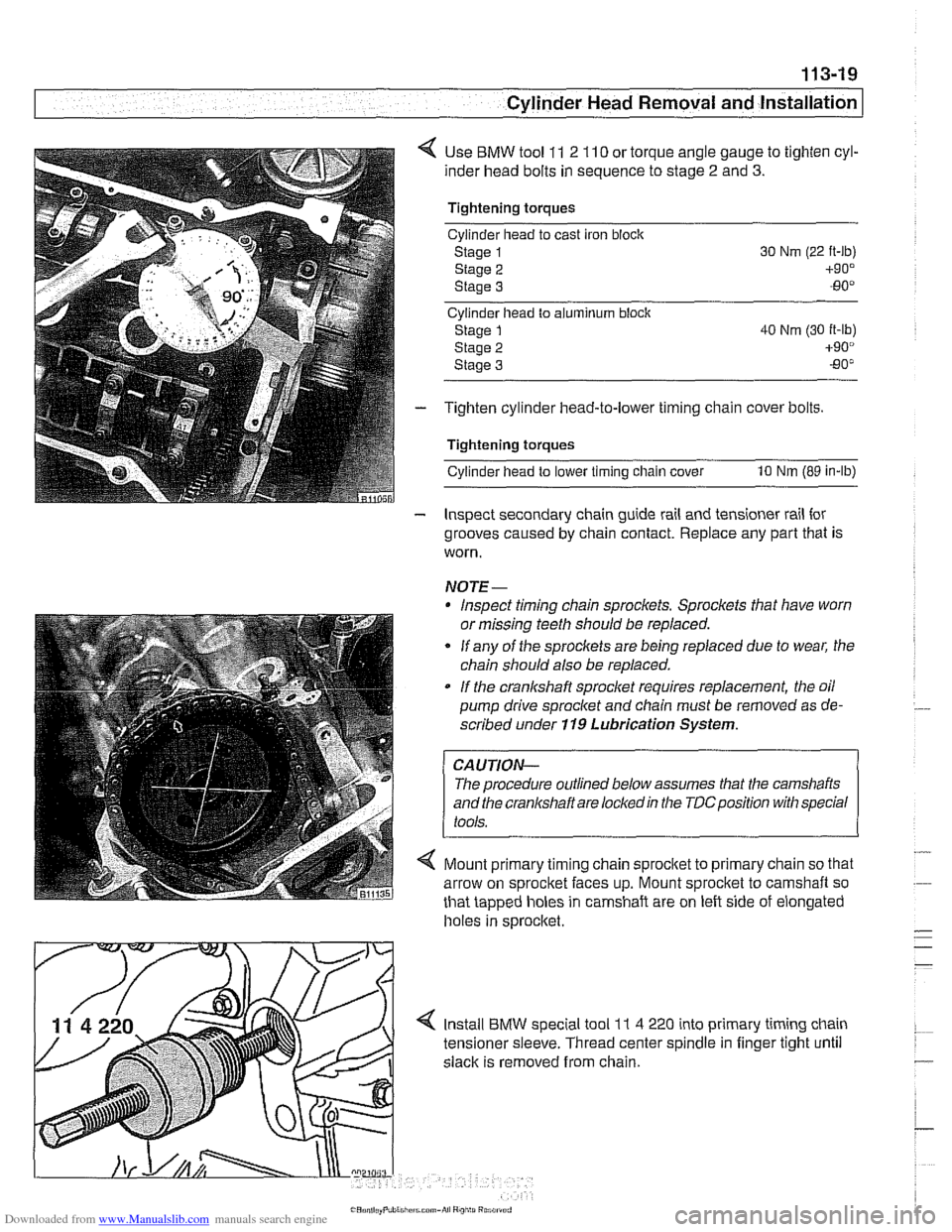

< Use BMW tool 11 2 110 or torque angle gauge to tighten cyl-

inder head bolts in sequence to stage

2 and 3.

Tightening torques

Cylinder head to cast iron

bloclc

Staoe 1

staie 2

Stage 3

Cyllnder head to aiumlnum block

Stage

1 40 Nm (30 it-lb)

Stage 2 +90°

Staoe 3 -80"

- Tighten cylinder head-to-lower timing chain cover bolts.

Tightening torques

cylinderhead to lower timing chain cover 10 Nm (89 in-lb)

- Inspect secondary chain guide rail and tensioner rail for

grooves caused by chain contact. Replace any part that is

worn.

NOTE-

Inspect timing chain sprocl(ets. Sprockets that have worn

or missing teeth should be replaced.

* If any of the sprockets are being replaced due to wear, the

chain should also be replaced.

If the crankshaft sproclet requir?s replacement, the oil

pump drive sprocket and chain must be removed as de-

scribed under

119 Lubrication System.

The procedure outlined below assumes that the camshafts

and the

cranl(shaft are locledin the TDCposition with special

4 Mount primary timing chain sprocltet to primary chain so that

arrow on sprocket faces up. Mount sprocket to camshaft so

that tapped holes in camshaft are on left side of elongated

holes in sprocltet

Install BMW special tool

1 I 4 220 into primary timing chain

tensioner sleeve. Thread center spindle in finger tight

until

slack is removed from chain.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

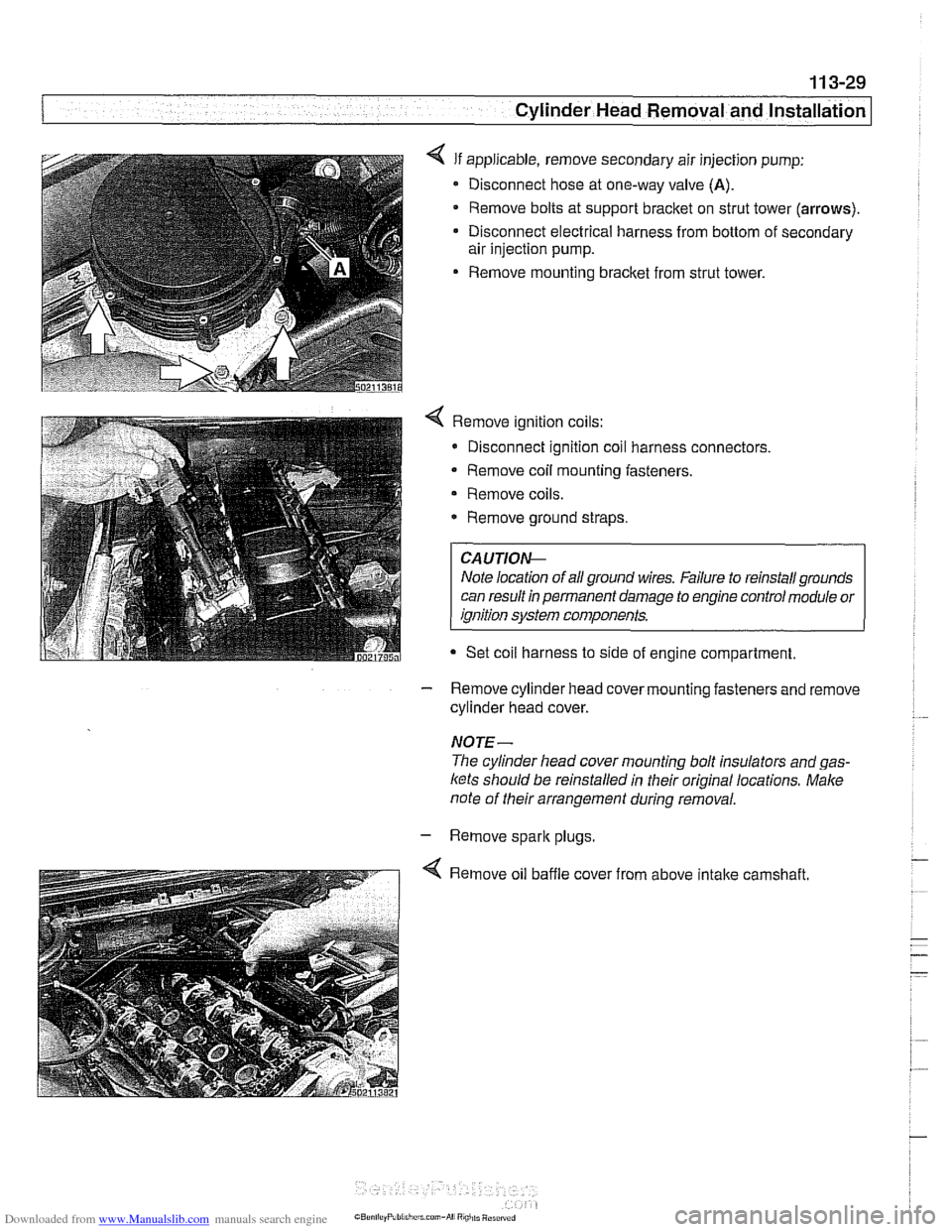

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 130 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-36

Cylinder Head Removal and Installation

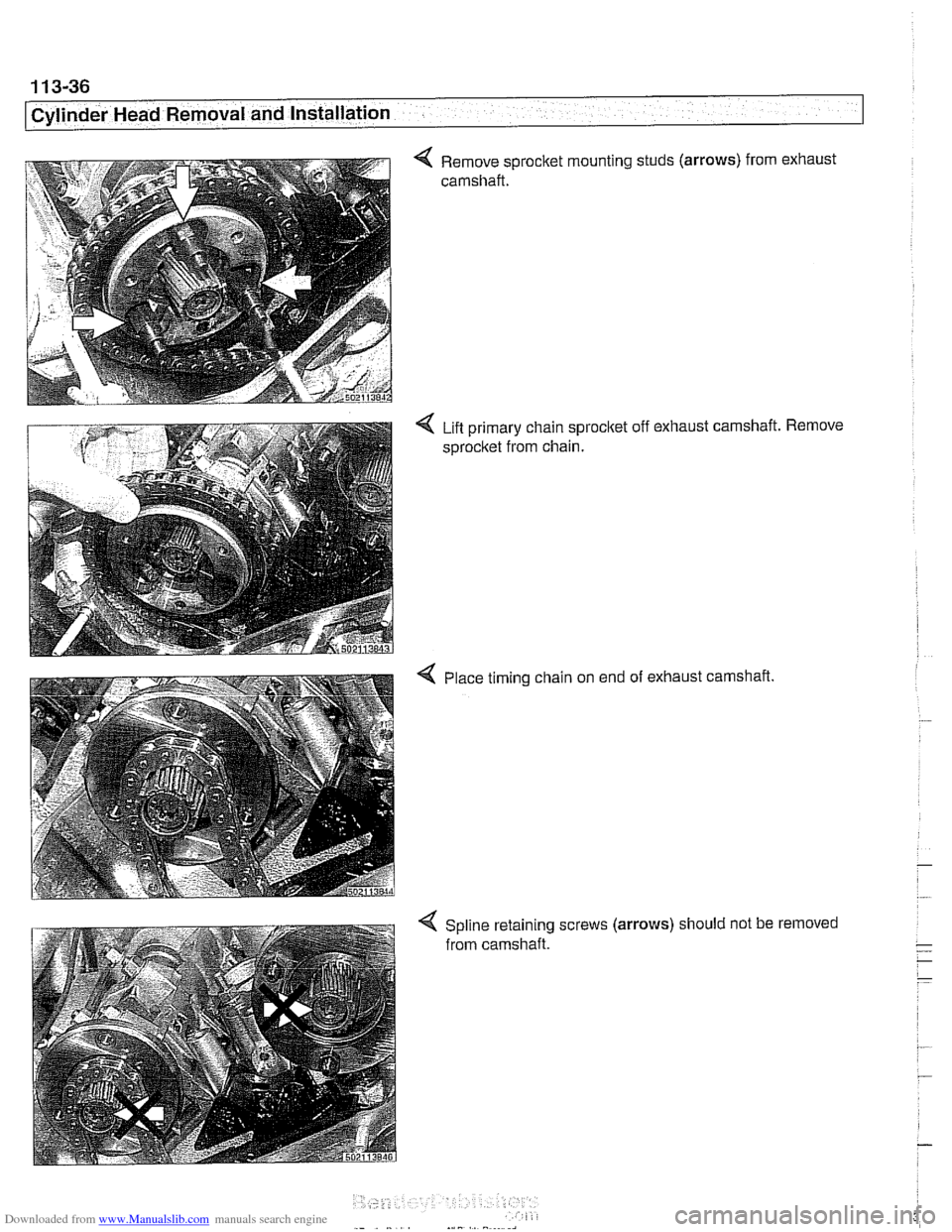

4 Remove sprocket mounting studs (arrows) from exhaust

camshaft.

Lift primary chain sprocltet off exhaust camshaft.

sprocket from chain.

4 Place timing chain on end of exhaust camshaft Remove

4 Spline retaining screws (arrows) should

not be removed

from camshaft.

Page 132 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-38

I Cylinder Head Removal and Installation

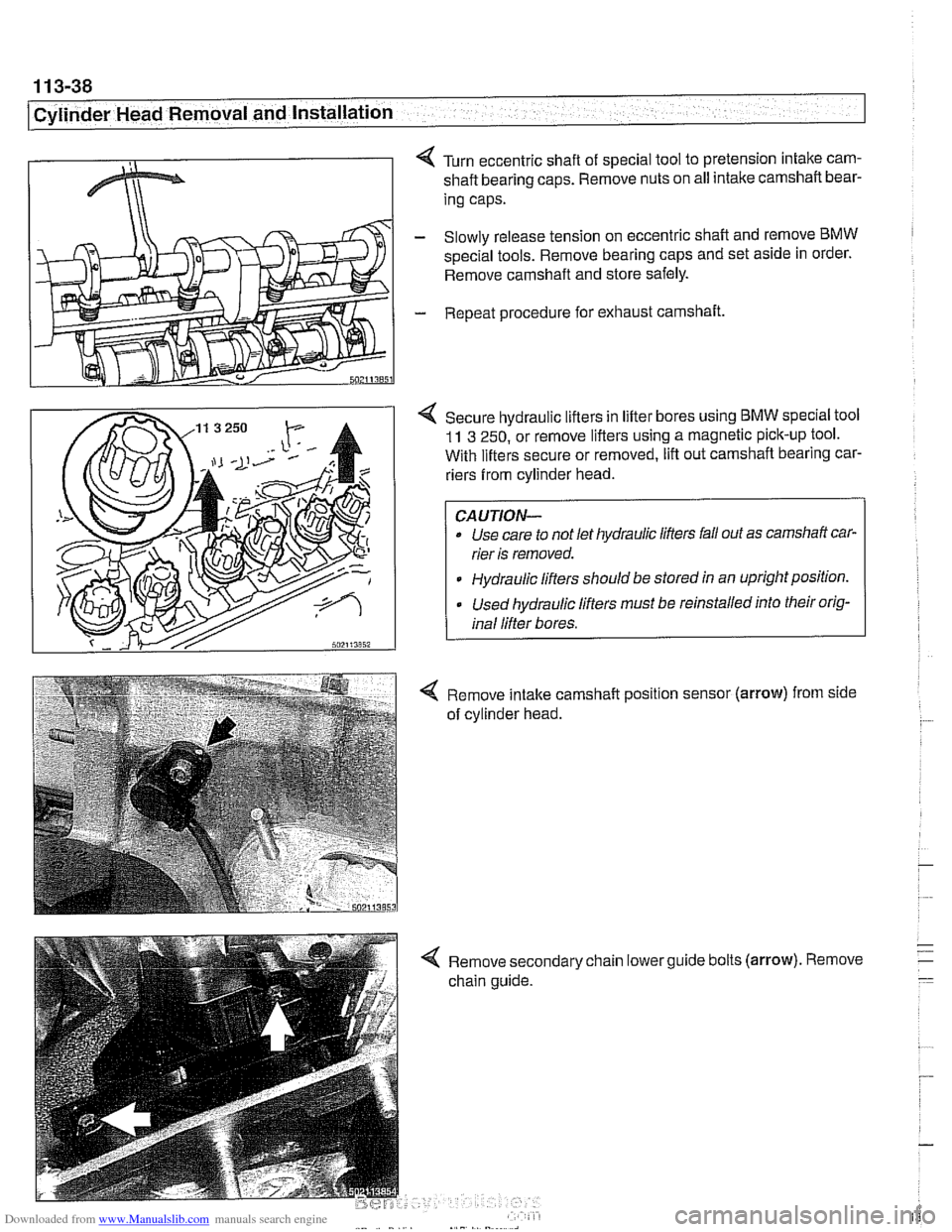

< Turn eccentric shaft of special tool to pretension intake cam-

shaft bearing caps. Remove nuts on all intake camshaft bear-

ing caps.

- Slowly release tension on eccentric shaft and remove BMW

spec~al tools. Remove bearing caps and set as~de in order.

Remove camshaft and store safely.

- Repeat procedure for exhaust camshaft.

4 Secure hydraulic lifters in lifter bores using BMW speclal tool

11 3 250, or remove lifters using a magnetic pick-up tool.

With lifters secure or removed, lift out camshaft bearing car-

riers from cylinder head.

Use care to not let hydraulic lifters fall out as camshaft car-

rier is removed.

Hydraulic lifters should be stored

ln an uprightpositlon.

Used hydraulic lifters must be reinstalled into their orig-

inal lifter bores.

4 Remove intake camshaft position sensor (arrow) from side

of cylinder head.

4 Remove secondary chain lowerguide bolts (arrow). Remove

chain guide.

Page 133 of 1002

Downloaded from www.Manualslib.com manuals search engine

. - -- -

Cylinder Head Removal and Installation --

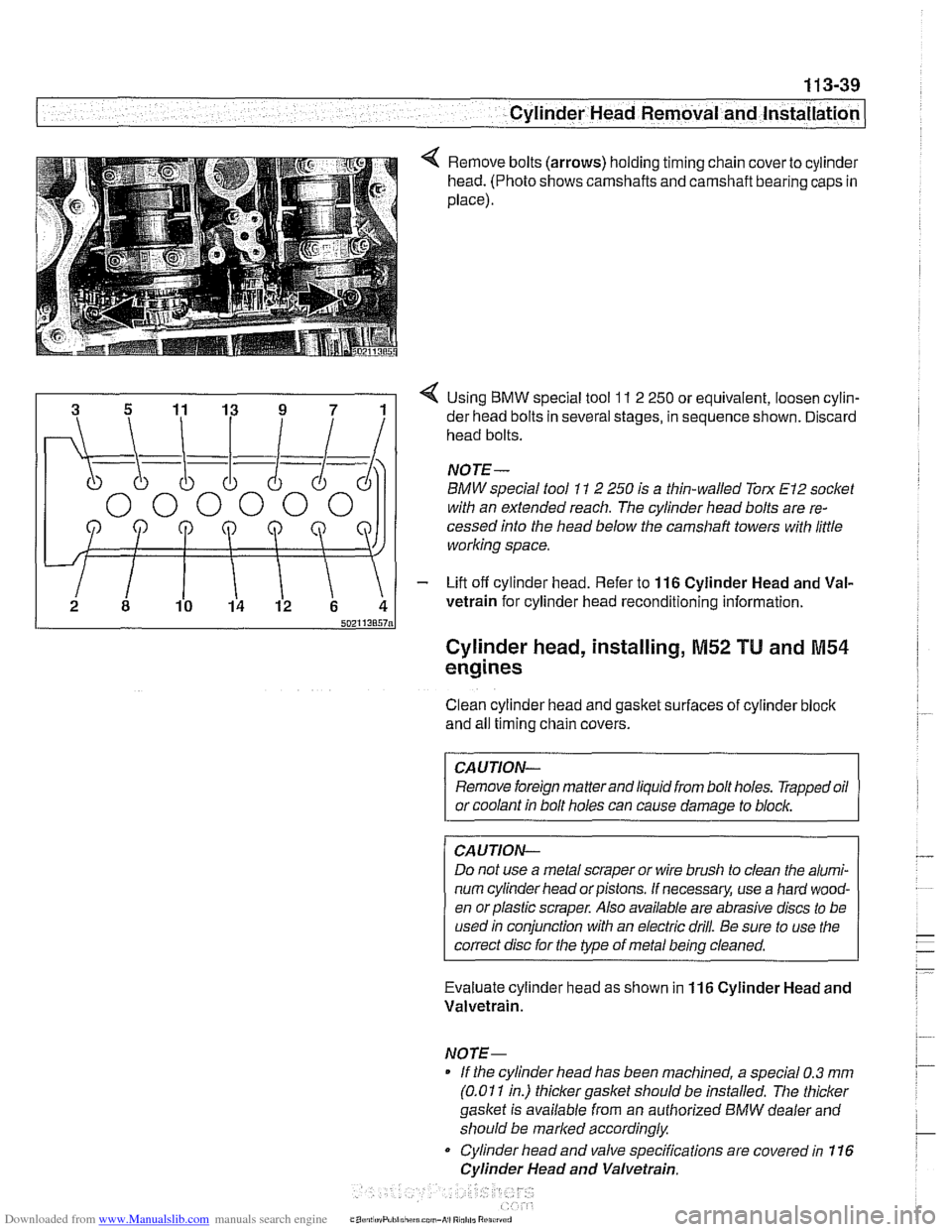

Remove bolts (arrows) holding timing chain cover to cylinder

head. (Photo shows camshafts and camshaft bearing caps in

place).

4 Using BMW special tool 11 2 250 or equivalent, loosen cylin-

der head bolts in several stages, in sequence shown. Discard

head bolts.

NOJE-

BMW special tool 11 2 250 is a thin-walled Torx El2 socket

with an extended reach. The cylinder head bolts are re-

cessed into the head below the

camshaft towers with little

working space.

- Lift off cylinder head. Refer to 116 Cylinder Head and Val-

vetrain for cylinder head reconditioning information.

Cylinder head, installing, M52 TU and M54

engines

Clean cylinder head and gasket surfaces of cylinder bloclc

and all timing chain covers.

CAUTION- Remove foreign matter and liquid from bolt holes. Trapped oil

or coolant in bolt holes can cause damage to

blocl~,

CAUJION-

Do not use a metal scraper or wire brush to clean the alumi-

num cylinder head or pistons. If necessary, use a hard wood-

en orplastic scraper. Also available are abrasive discs to be

used in conjunction with an electric drill. Be sure to use the

correct disc for the type of metal being cleaned.

Evaluate cylinder head as shown in

116 Cylinder Head and

Valvetrain.

NOTE- If the cylinder head has been machined, a special 0.3

mm

(0.01 1 in.) thicker gasket should be installed. The thicker

gasket is available from an authorized

BMW dealer and

should be marked accordingly

Cylinder head and valve specifications are covered in 116

Cylinder Head and Valvetrain.

Page 134 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-40

I Cylinder Head Removal and Installation

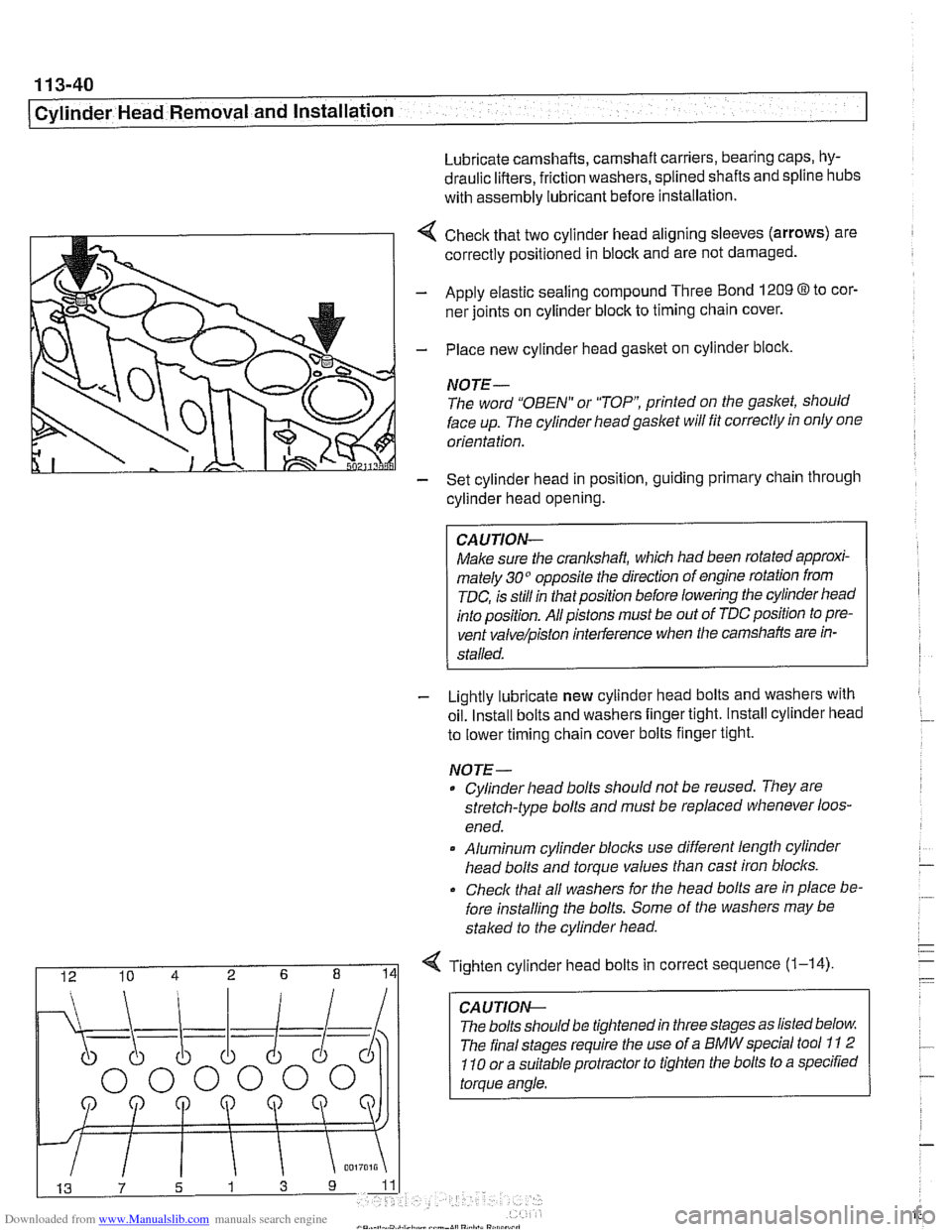

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

4 Check that two cylinder head aligning sleeves (arrows) are

correctly positioned in block and are not damaged.

- Apply elastic sealing compound Three Bond 1209 8 to cor-

ner joints on cylinder block to timing chain cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or "TOP printed on the gasket, should

face up. The cylinder headgaslet will fit correctly in only one

orientation.

- Set cylinder head in position, guiding primary chain through

cylinder head opening.

CAUJION-

Make sure the crankshaft, which had been rotated approxi-

mately 30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the cylinder head

into position. All pistons must be out of TDC position to pre-

vent

valve/piston interference when the camshafts are in-

stalled.

- Lightly lubricate new cylinder head bolts and washers with

oil. Install bolts and washers finger tight. Install cylinder head

to lower timing chain cover bolts finger tight.

NOJE-

Cylinder head bolts should not be reused. They are

stretch-type bolts and must be replaced whenever loos-

ened.

* Aluminum cylinder blocls use different length cylinder

head bolts and torque values than cast iron blocks.

Check that all washers for

Nle head bolts are in place be-

fore installing the bolts. Some of the washers may be

staked to the cylinder head.

I 12 10 4 2 6 8 141 Tighten cylinder head bolts in correct sequence (1-14)

CA U TIOW-

The bolts should be tightened in three stages as listed below

The final stages require the use of a BMW special tool

11 2

110 or a suitable protractor to tighten the bolts to a specified

torque angle.

Page 157 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- --

Cylinder Head Removal and Installation I

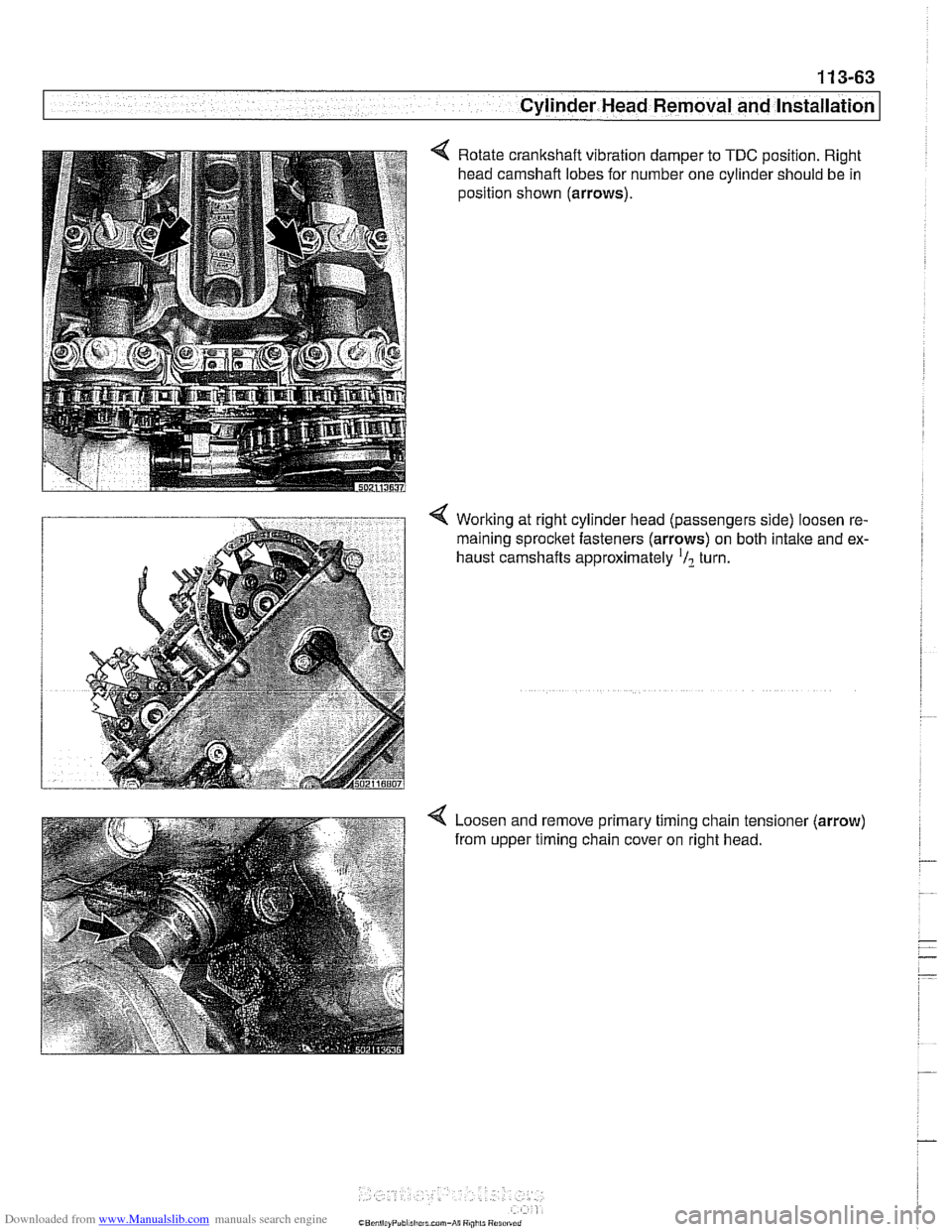

4 Rotate crankshaft vibration damper to TDC position. Right

head camshaft lobes for number one cylinder should be in

position shown (arrows).

Working at right cylinder head (passengers side) loosen re-

maining

sprocltet fasteners (arrows) on both intake and ex-

haust camshafts approximately

'/? turn.

4 Loosen and remove primary timing chain tensioner (arrow)

from upper timing chain cover on right head.

Page 160 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

I Cylinder Head Removal and Installation

- Evaluate cylinder head as described in 116 Cylinder head

and valvetrain.

Left cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket

debris, making sure no debris drops into coolant or oil pas-

sages.

- Clean cylinder head bolt holes and check condition of

threads.

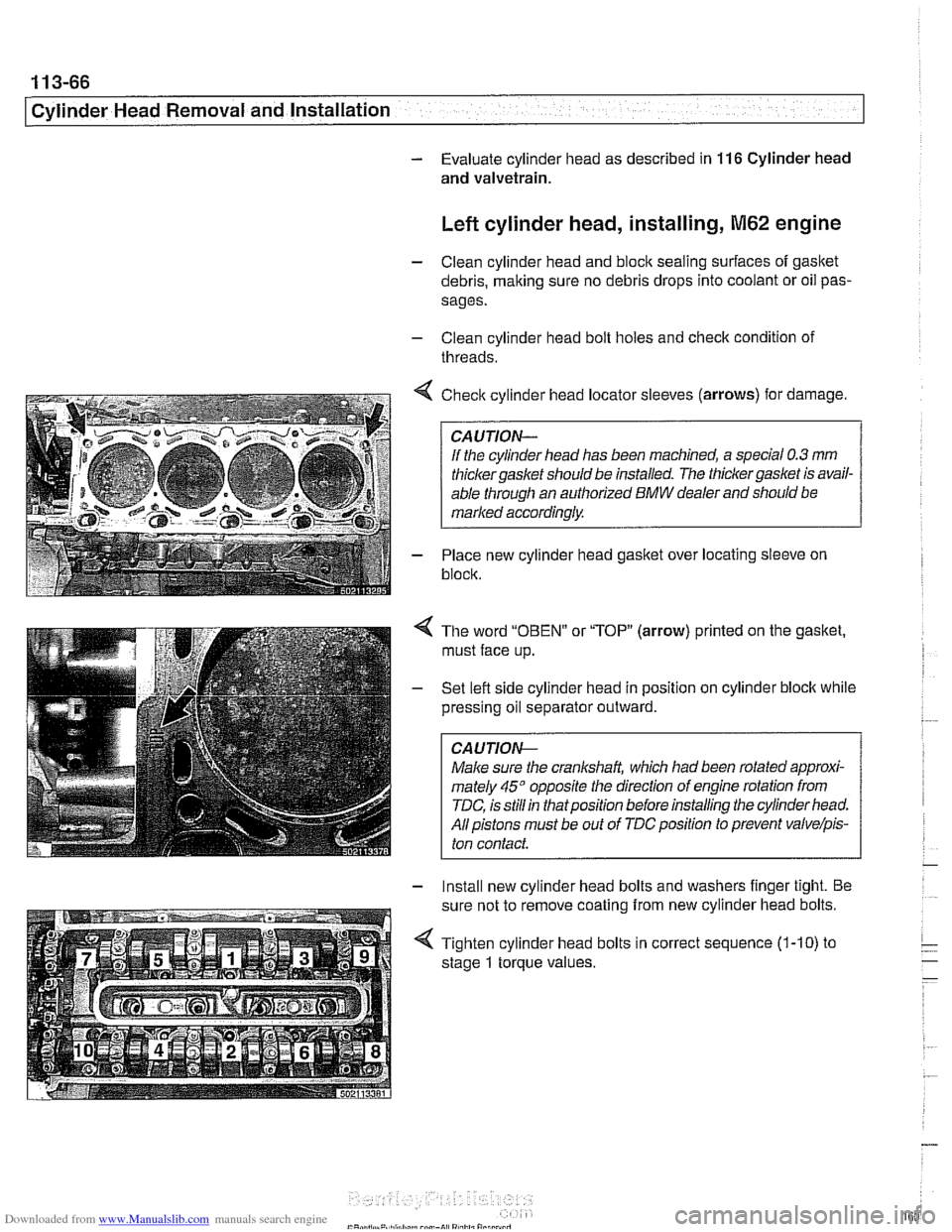

< Check cylinder head locator sleeves (arrows) for damage.

If the cylinder head has been machined, a special

0.3 mm

thicker gasket should be installed. The thicker gasket is avail-

able through an authorized

BMW dealer and should be

marked accordingly.

- Place new cylinder head gasket over locating sleeve on

block.

The word

"OBEN" or "TOP" (arrow) printed on the gasket,

must face up.

Set lefl side cylinder head in position on cylinder block while

pressing oil separator outward.

CAUJION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is still in thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valvelpis-

ton contact.

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from new cylinder head bolts.

4 Tighten cylinder head bolts in correct sequence (1-10) to

stage

1 torque values.