Oul BMW 540i 1999 E39 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 259 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

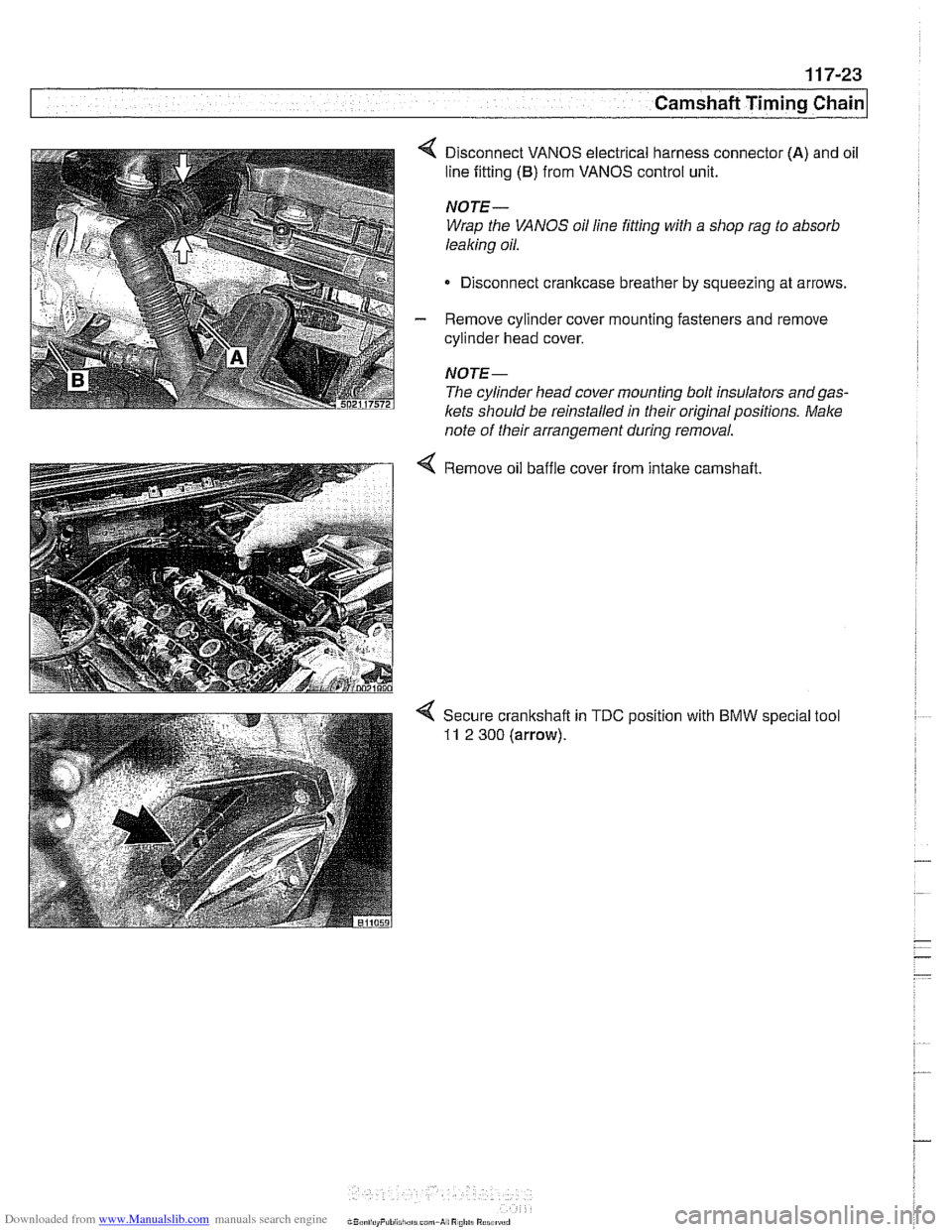

4 Disconnect VANOS electrical harness connector (A) and oil

line fitting

(B) from VANOS control unit.

NOTE-

Wrap the VANOS oil line fitting with a shop rag to absorb

leaking oil.

Disconnect cranltcase breather by squeezing at arrows.

- Remove cylinder cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators andgas-

lets should be reinstalled in their original positions. Make

note of their arrangement during removal.

4 Remove oil baffle cover from intake camshaft

Page 263 of 1002

Downloaded from www.Manualslib.com manuals search engine

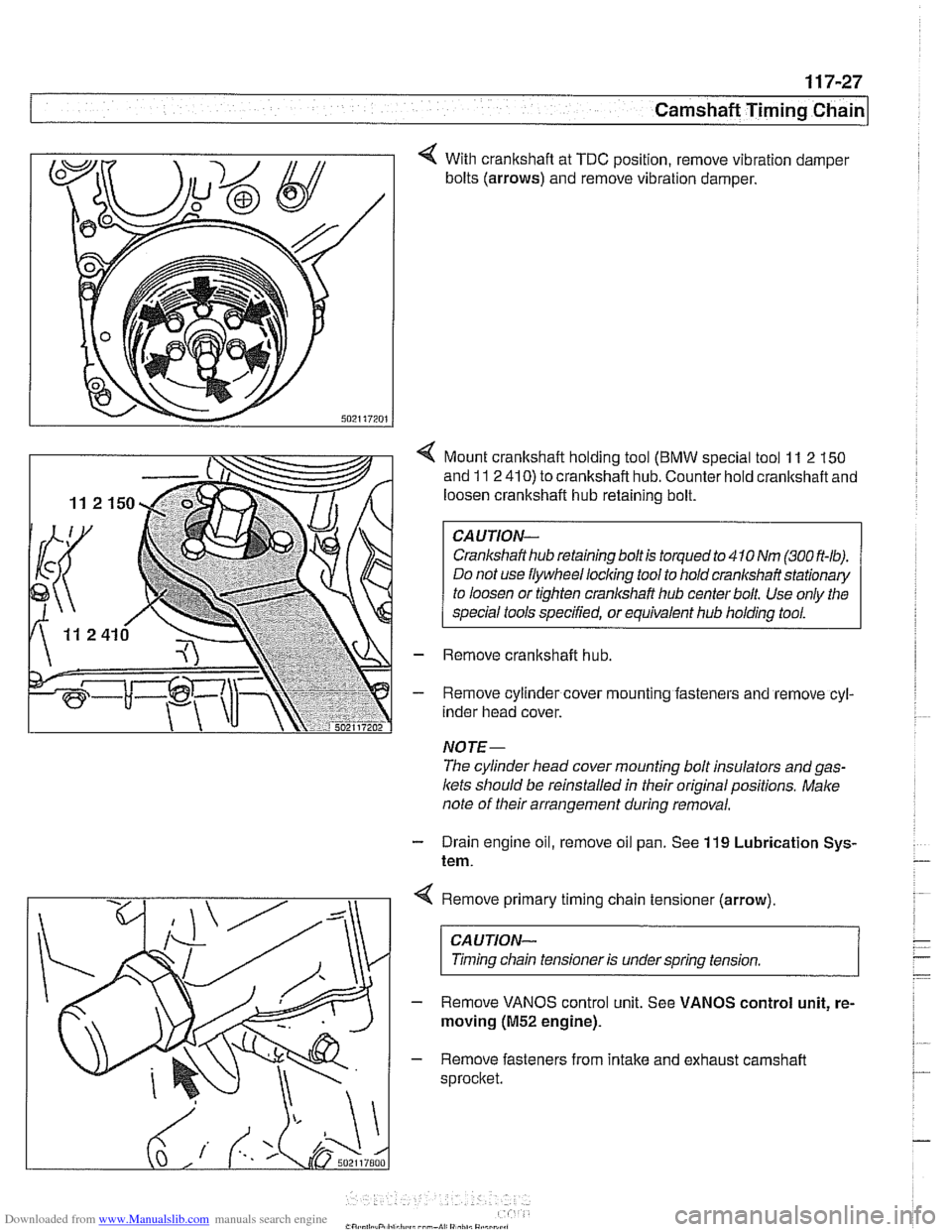

4 With crankshaft at TDC position, remove vibration damper

bolts (arrows) and remove vibration damper.

< Mount crankshaft holding tool (BMW special tool 11 2 150

and

11 2 410) to crankshaft hub. Counter hold crankshaft and

loosen crankshaft hub retaining bolt.

Crankshaft hub retaining bolt is torqued to

410 Nm (300 ft-lb).

Do not use flywheel

locliing tool to hold cranl(shait stationary

to loosen or tighten crankshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

- Remove crankshaft hub.

- Remove cylinder cover mounting fasteners and remove cyl-

inder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

lets should be reinstalled in their original positions. Make

note of their arrangement during removal.

- Drain engine oil, remove oil pan. See 119 Lubrication Sys-

tem.

Remove primary timing chain tensioner (arrow).

CAUTION-

Timing chain tensioner is under spring tension. I

- Remove VANOS control unit. See VANOS control unit, re-

moving

(M52 engine).

- Remove fasteners from intake and exhaust camshaft

sprocket.

Page 266 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 17-30

I Camshaft Timing Chain

Timing chain, installing

(M52 engine)

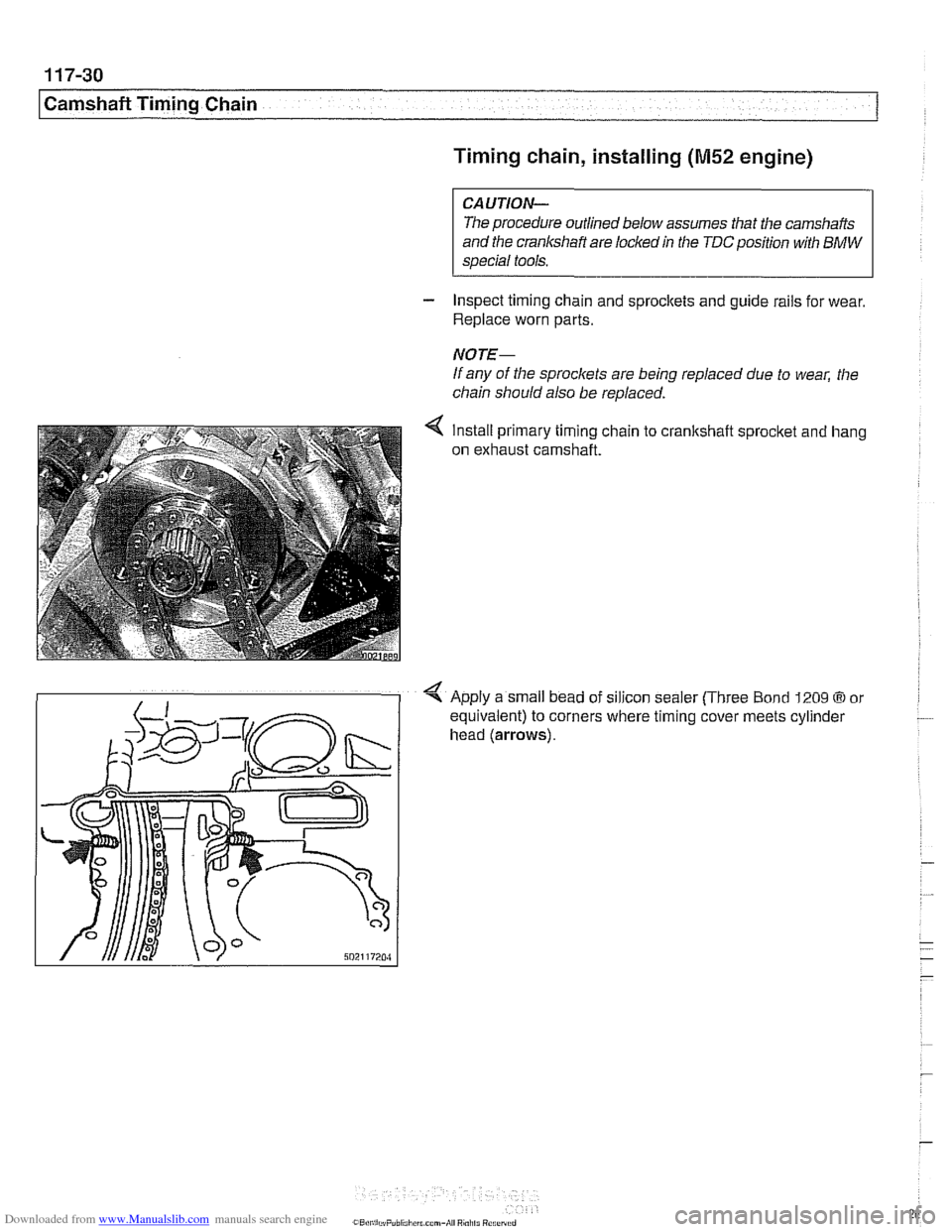

CAUTION-

The procedure outlined below assumes that the camshafts

and the crankshaft are

lockedin the TDCposition with BMW

special tools.

- Inspect timing chain and sprocltets and guide rails for wear.

Replace worn parts.

NOTE-

If any of the sprockets are being replaced due to wear, the

chain should also be replaced.

Install primary timing chain

on exhaust camshaft. to crankshait

sprocket and hang

4 Apply a small bead oi silicon sealer (Three Bond 1209 @or

equivalent) to corners where tim~ng cover meets cylinder

head

(arrows).

Page 268 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- -

Chain 1

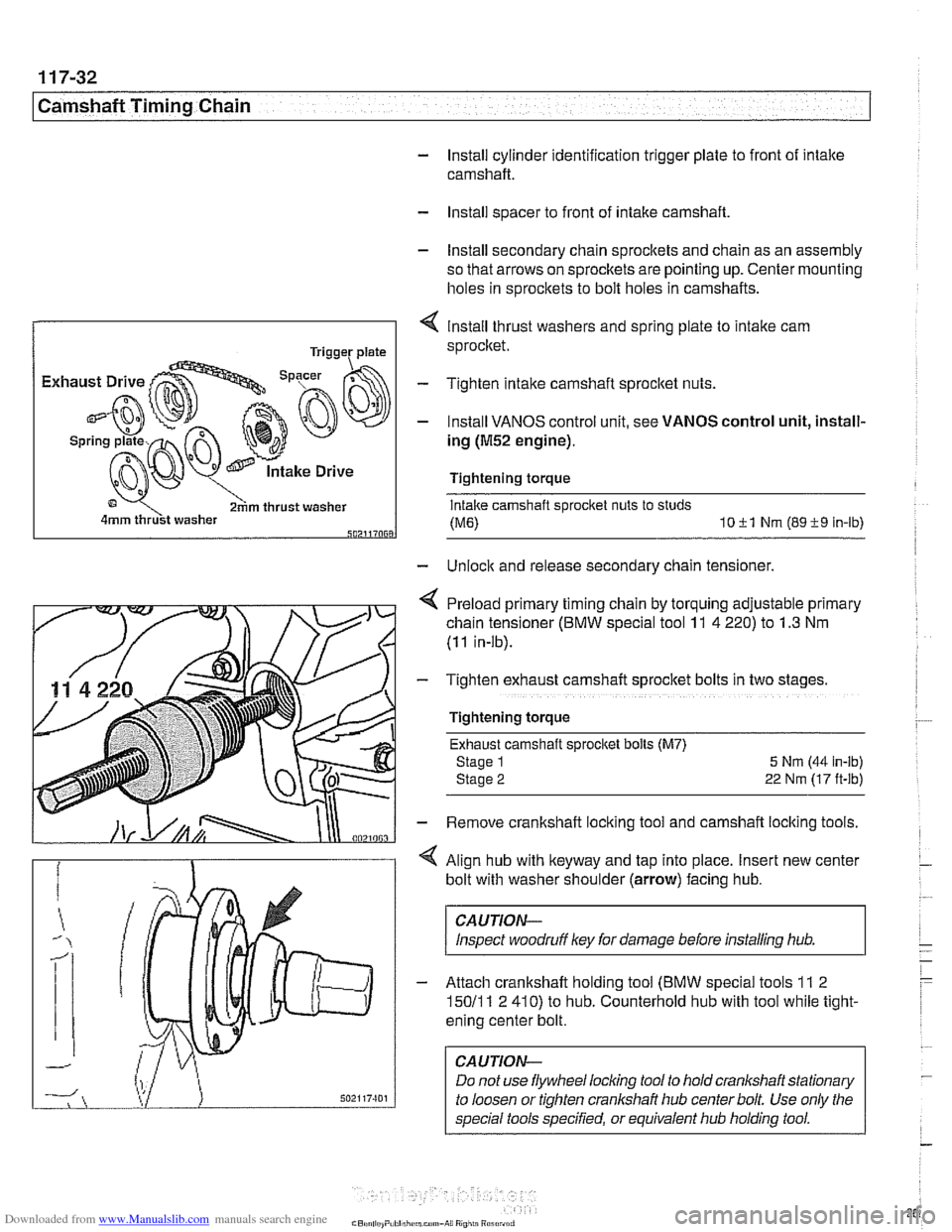

- Install cylinder identification trigger plate to front of intake

camshaft.

- Install spacer to front of intake camshaft

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

4 lnstall thrust washers and spring plate to intake cam

sprocket.

Tighten intake camshaft sprocket nuts.

- Install VANOS control unit, see VANOS control unit, install-

ing

(M52 engine).

Tightening torque

Intake camshaft sprocket nuts to studs

(ME) 1011 Nm (8919 In-lb) 502117068

- Unlock and release secondary chain tensioner,

4 Preload primary timing chain by torquing adjustable primary

chain tensioner (BMW special tool

11 4 220) to 1.3 Nm

(11 in-lb).

- Tighten exhaust camshaft sprocket bolts in two stage

Tightening torque Exhaust camshaft sprocket bolls (M7)

Stage 1

5 Nrn (44 in-lb)

Stage

2 22 Nm (17 ft-lb)

- Remove crankshaft locking tool and camshaft locking tools.

< Align hub with keyway and tap into place. Insert new center

bolt with washer shoulder (arrow) facing hub.

CAUTION-

Inspect woodruff ley for damage before installing hub.

- Attach crankshaft holding tool (BMW special tools 11 2

15011 1 2 410) to hub. Counterhold hub with tool while tight-

ening center bolt.

CAUTION-

Do not use flywheel locling tool to hold crankshaft stationary

to loosen or tighten

cranlshaft hub center bolt. Use only the

special tools specified, or equivalent hub holding tool.

Page 293 of 1002

Downloaded from www.Manualslib.com manuals search engine

... -.

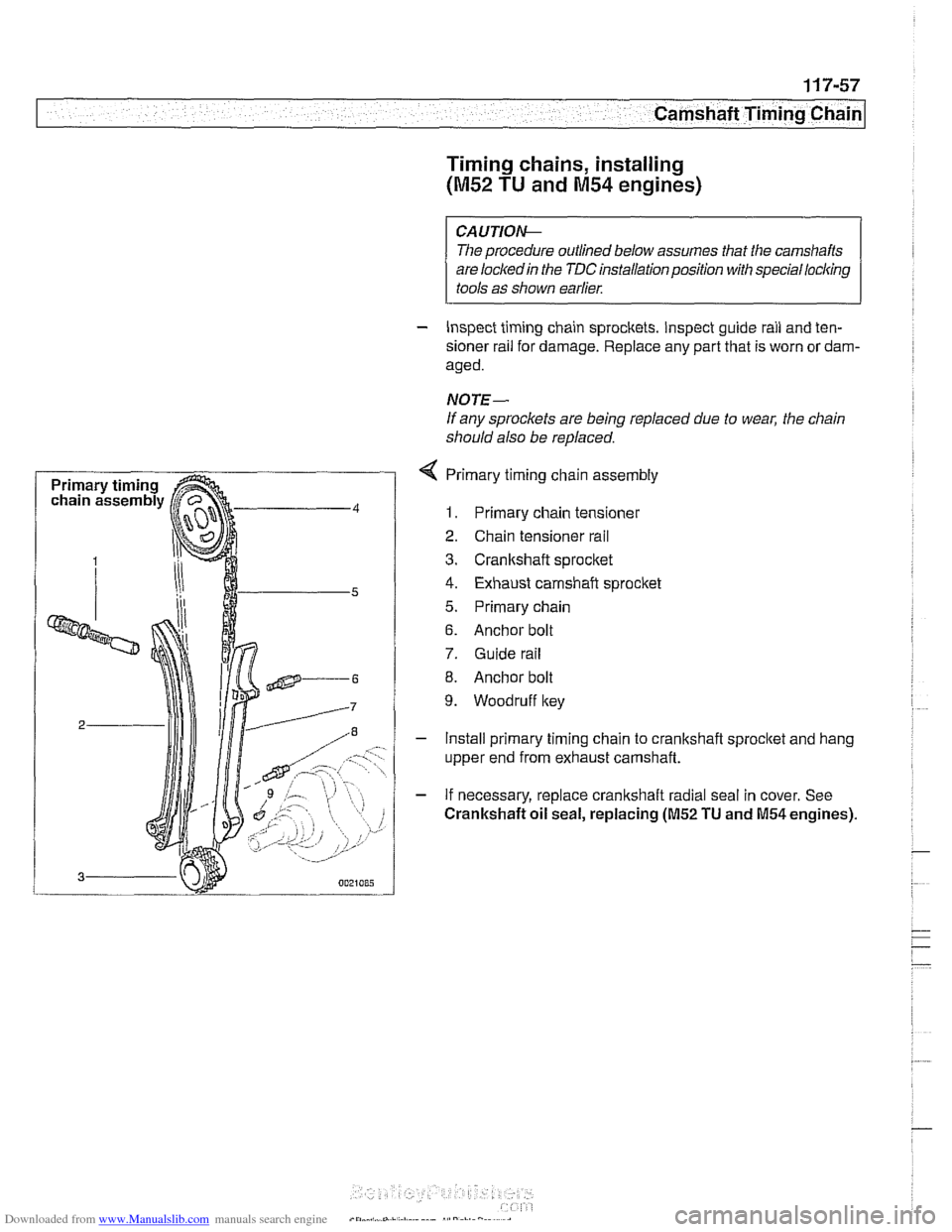

rpp- --- Camshaft Timing Chain1

Timing chains, installing

(M52 TU and M54 engines)

CAUTIOI\C

The procedure outlined below assumes that the camshaits

are lockedin the

TDC installation position with speciallocling

tools as shown earliel:

- inspect timing chain sprockets. Inspect guide rail and ten-

sioner rail for damage. Replace any part that is worn

or dam-

aged.

NOTE-

If any sprockets are being replaced due to wear, the chain

should also be replaced.

4 Primary timing chain assembly

1. Primary chain tensioner

2. Chain tensioner rail

3. Cranltshaft sprocket

4. Exhaust camshaft sprocket

5. Primary chain

6. Anchor bolt

7. Guide rail

8. Anchor bolt

9. Woodruff key

- Install primary timing chain to crankshaft sprocltet and hang

upper end from exhaust camshaft.

- If necessary, replace crankshaft radial seal in cover. See

Crankshaft oil seal, replacing (M52 TU and M54 engines).

Page 310 of 1002

Downloaded from www.Manualslib.com manuals search engine

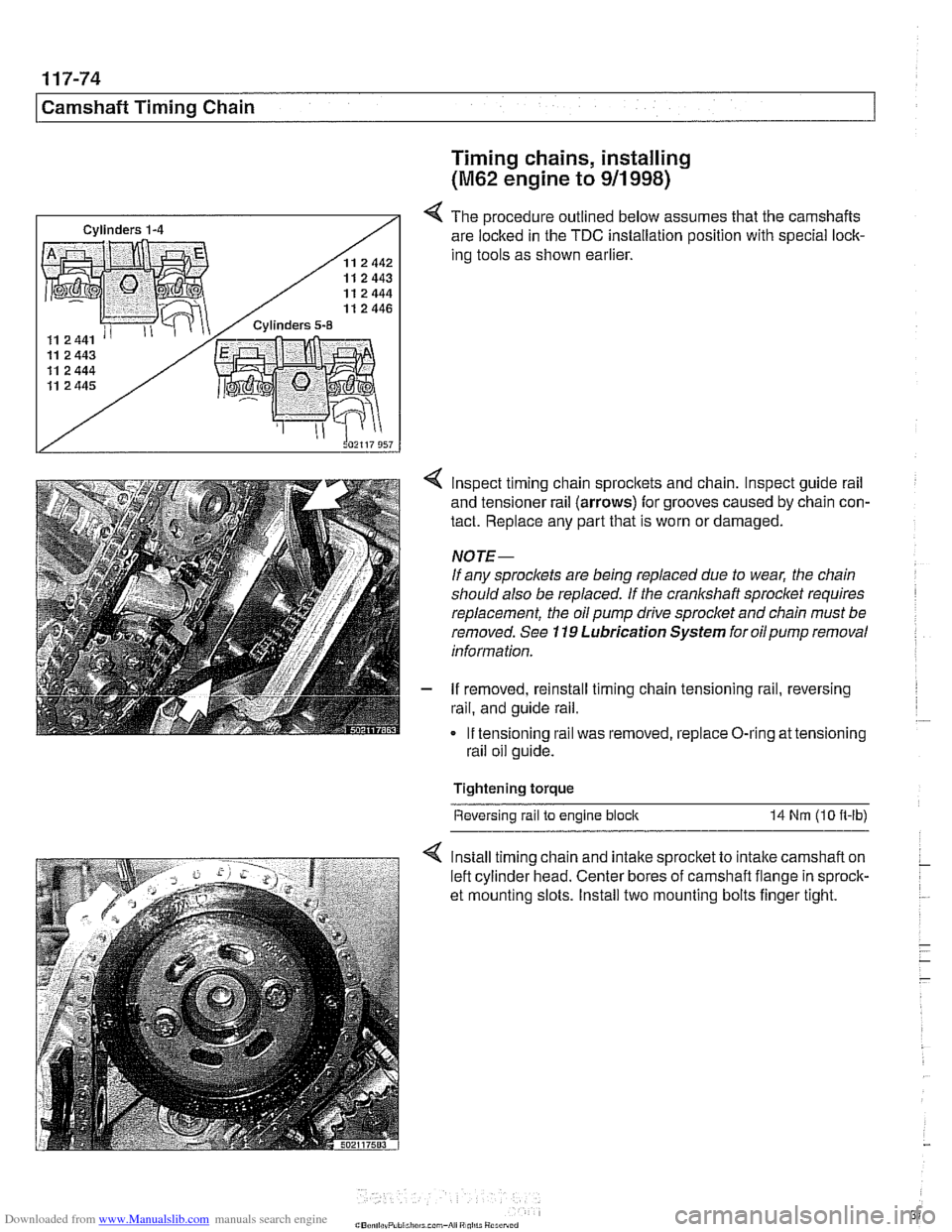

I Camshaft Timina Chain

/ Cylinders 5-8

Timing chains, installing

(M62 engine to 911 998)

4 The procedure outlined below assumes that the camshafts

are locked in the TDC installation position with special lock-

ing tools as shown earlier.

4 lnspect timing chain sprocltets and chain. Inspect guide rail

and tensioner rail

(arrows) for grooves caused by chain con-

tact. Replace any part that is worn or damaged.

NOTE-

If any sprocl(ets are being replaced due to wear, the chain

should also be replaced.

If the crankshaft sprocket requires

replacement, the oil pump

drive sprocket and chain must be

removed. See

119 Lubrication System for oilpump removal

information.

- If removed, reinstall timing chain tensioning rail, reversing

rail, and guide rail.

If tensioning rail was removed, replace O-ring at tensioning

rail oil guide.

Tightening torque Reversing rail

to engine block 14 Nrn (10 n-lb)

4 lnstall timing chain and intalte sprocket to intake camshaft on

left cylinder head. Center bores of camshaft flange in sprock-

et mounting slots. Install two mounting bolts finger tight.

Page 317 of 1002

Downloaded from www.Manualslib.com manuals search engine

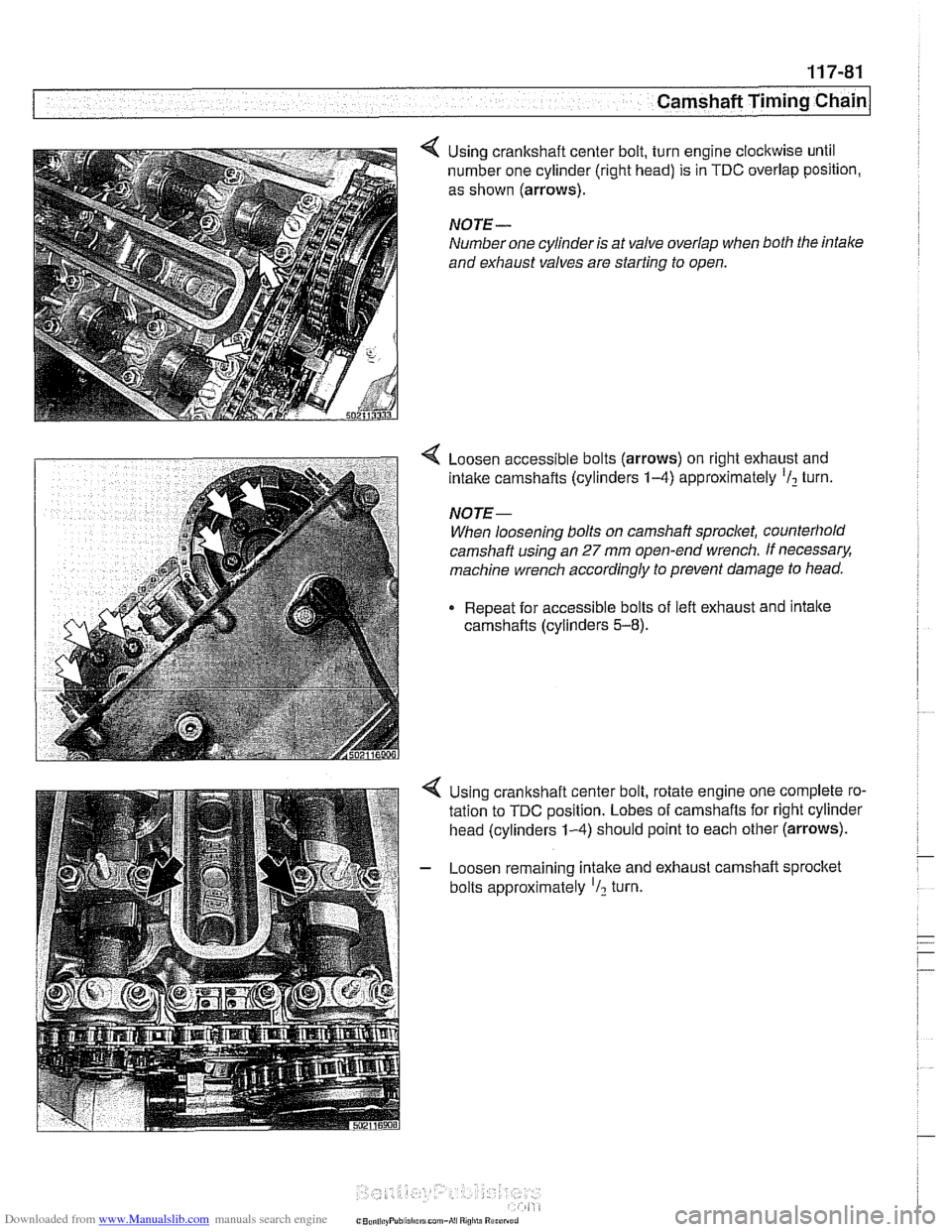

Camshaft Timing chain1 - -- -

Using crankshaft center bolt, turn engine clockwise until

number one cylinder (right head) is in

TDC overlap position,

as shown

(arrows).

NOTE-

Number one cylinder is at valve overlap when both the intale

and exhaust valves are starting to open.

< Loosen accessible bolts (arrows) on right exhaust and

intake camshafts (cylinders

1-4) approximately 'I2 turn.

NOTE-

When loosening bolts on camshaft sprocket, counterhold

camshaft using an

27 mm open-end wrench. If necessary.

machine wrench accordingly to prevent damage

to head.

Repeat for accessible bolts of left exhaust and intake

camshafts (cylinders

5-8).

Using crankshaft center bolt, rotate engine one complete ro-

tation to

TDC position. Lobes of camshafts for right cylinder

head (cylinders

1-4) should point to each other (arrows).

- Loosen remaining intake and exhaust camshaft sprocltet

bolts approximately

'I2 turn.

Page 323 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 19-3

Lubrication System

V-8 crankshaft rear main seal tool

(Tool No. BMW

11 1 230)

I i 4 V-8 crankshaft rear main seal ouide

4 Adapter for BMW oil pressure gauge

(Tool No. BMW

11 4 050)

Engine lubrication

Oil pressure is generated by a gear-type pump bolted to the

bottom oi the engine block. The oil pump is chain driven off

the front of the crankshaft.

Table a. Engine oil capacity (includes oil filter replacement)

6-cylinder 6.5

liters (6.9

US qt)

V-8 7.5 liters (7.9 US qt)

The oil pressure warning system consists of an oil pressure

switch mounted in the oil circuit and an instrument

panel

warning light. Other saiety features include:

Q A filter bypass to provide lubrication should the oil filter be-

come clogged.

An oil pump pressure relief valve to prevent excessive sys-

tem pressure.

CAUTIOI\C

If the red oil pressure warning light comes on or flashes on

while driving, always assume that the oilpressure is low. Stop

the engine immediately and make arrangements to test oil

pressure.

Page 324 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Lubrication System - I

Oil pressure, checking

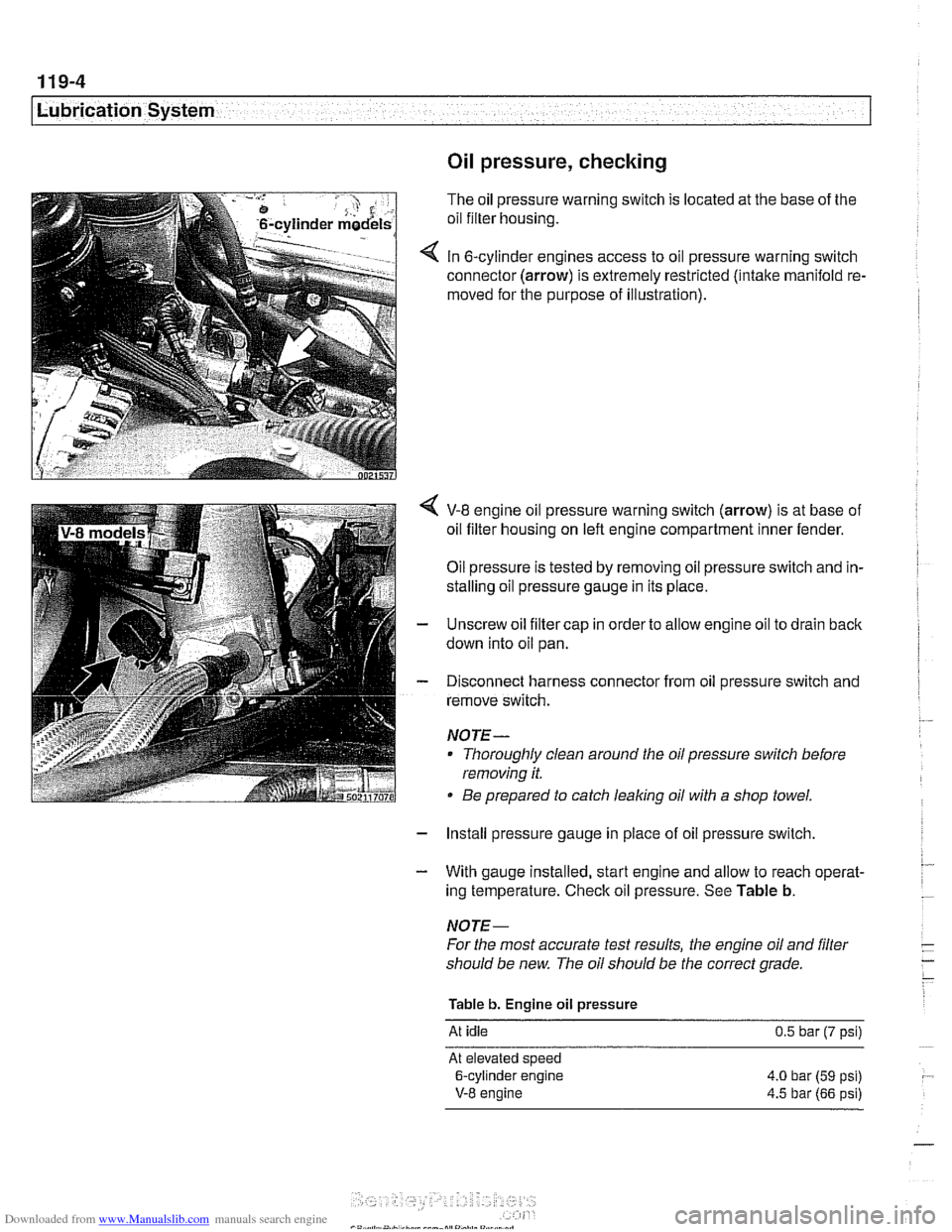

The oil pressure warning switch is located at the base of the

oil filter housing.

In 6-cylinder engines access to oil pressure warning switch

connector (arrow) is extremely restricted (intake manifold re.

moved for the purpose of illustration).

V-8 engine oil pressure warning switch (arrow) is at base of

oil filter housing on left engine compartment inner fender.

Oil pressure is tested by removing oil pressure switch and in-

stalling oil pressure gauge in its place.

Unscrew oil filter cap in order to allow engine oil to drain back

down into oil pan.

Disconnect harness connector from oil pressure switch and

remove switch.

NOJE-

Thoroughly clean around the oil pressure switch before

removing it.

Be prepared to catch leaking oil with a shop towel.

- Install pressure gauge in place of oil pressure switch,

- With gauge installed, start engine and allow to reach operat-

ing temperature. Check oil pressure. See Table b.

NOJE-

For the most accurate test results, the engine oil and filter

should be new. The oil should be the correct grade.

Table b. Engine oil pressure

At idle 0.5 bar (7 psi)

At elevated speed

6-cylinder engine 4.0 bar

(59 psi)

V-8 engine 4.5 bar (66 psi)

Page 325 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

L

- --

- - -. - -- Lubrication ~~stern

- Remove pressure gauge and reinstall pressure switch with

new sealing washer.

Tightening torque

Oil pressure switch to oil filter housing 27 Nm (20 ft-lb)

If testing shows low oil pressure, one or more of the following

conditions may be indicated:

Worn or faulty oil pump or faulty pump pressure relief valve

Worn or damaged engine bearings

Severe engine wear

Any of these conditions indicate the need for major repairs.

Oil pressure warning system, testing

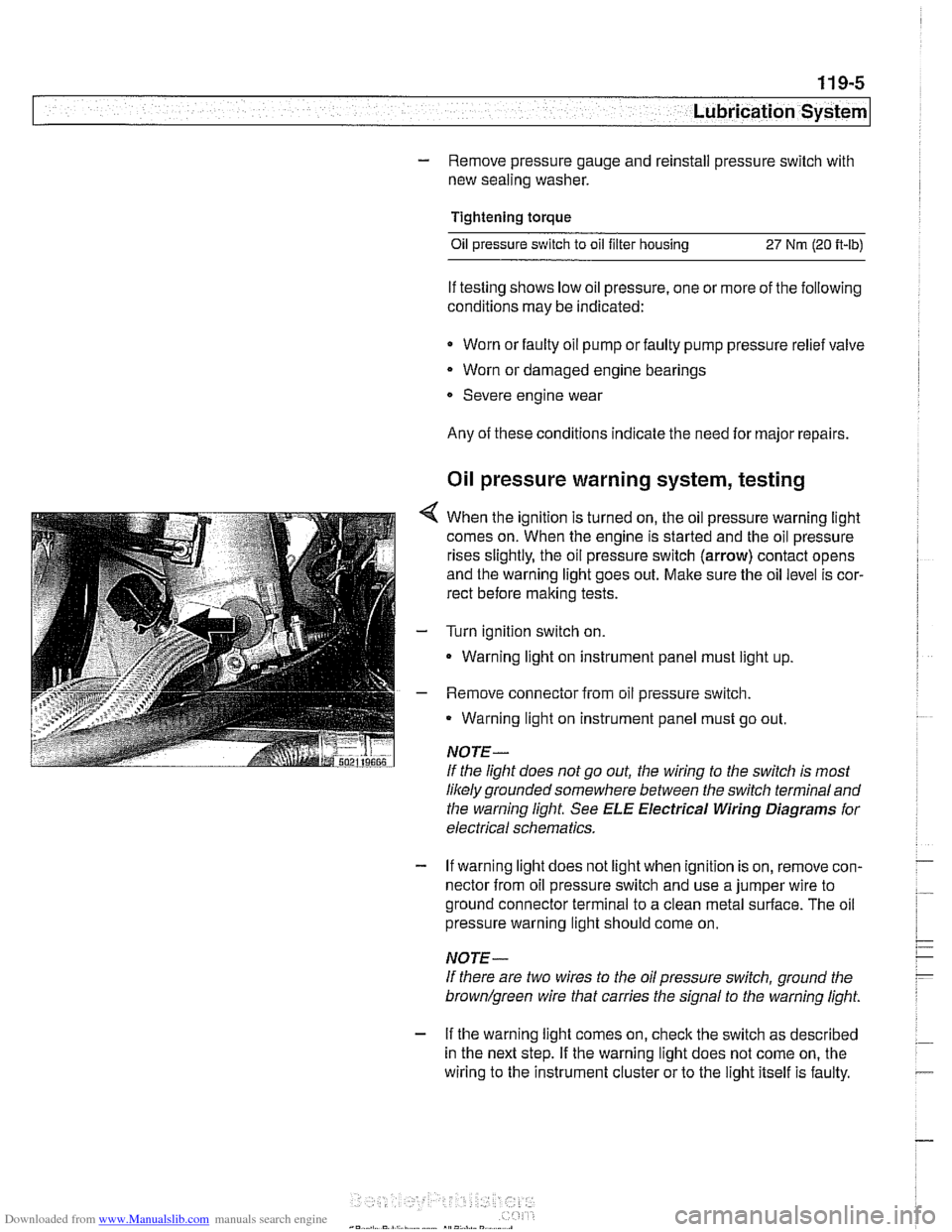

4 When the ignition is turned on, the oil pressure warning light

comes on. When the engine is started and the oil pressure

rises slightly, the oil pressure switch (arrow) contact opens

and the warning light goes out. Make sure the oil level is cor-

rect before making tests.

- Turn ignition switch on.

- Warning light on instrument panel must light up

- Remove connector from oil pressure switch.

Warning light on instrument panel must go out.

NOTE-

If the light does not go out, the wiring to the switch is most

likely grounded somewhere between the switch terminaland

the warning light See

ELE Electrical Wiring Diagrams for

electrical schematics.

- If warning light does not light when ignition is on, remove con-

nector from oil pressure switch and use a jumper wire to

ground connector terminal to a clean metal surface. The oil

pressure warning light should come on.

NOTE-

If there are two wires to the oil pressure switch, ground the

brown/green wire that carries the signal to the warning light.

- If the warning light comes on, check the switch as described

in the next step. If the warning light does not come on, the

wiring to the instrument cluster or to the light itself is faulty.