M62 BMW 540i 1999 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 523 of 1002

Downloaded from www.Manualslib.com manuals search engine

180 Exhaust System

General Exhaust System

. . . . . . . . . . . . . . . . .

Exhaust system, removing and installing

Muffler, replacing..

. . . . . . . . . . . . . . . . .

Exhaust Manifolds . . . . . . . . . . . . . . .

Exhaust manifolds, removing

and installing (M52 engine)

. . . . . . . . . .

Exhaust manifolds, removing and

installing (M52

TU and M54 engines) . . .

Exhaust manifolds, removing

and installing (M62 engine)

. . . . . . . . . .

Oxygen Sensors. . . . . . . . . . . . . . . . . . . . 180-9

Oxygen sensors (precatalyst),

replacing

(M52 TU and M54) . . . . . . . . . . . . 180-9

Oxygen sensors (post-catalyst),

replacing (M52

TU and M54) . . . . . . . . . . . . 180-9

Oxygen sensor, replacing

(M52 and M62 engine) . . . . . . . . . . . . . . . 180-10

Exhaust System Diagrams . . . . . . . . . 180-1 1

M52 engine (528i 1997-1 998) . . . . . . . . . . 180-1 1

M52

TU and M54 engines

(528i 1999-2000 and 5251 2001-2003) . . . 180-1 2

M54 engine

(530i 2001-2003) . . . . . . . . . . 180-1 3

M62 engine

(540i 1997-1 998) . . . . . . . . . . 180-1 4

M62

TU engine (540i 1999-2003 . . . . . . . 180-1 5

Page 529 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Exhaust ~vsteml

NOTE-

The front exhaust manifold must be removed before the rear

manifold.

- Installation is reverse of removal.

Coat exhaust mounting studs with CRC or equivalent cop-

per paste.

Use new gasltets and self-locking nuts.

Tightening torques Exhaust manifold to cylinder head 20 Nm

(15 ft-lb)

Front exhaust pipe to manifold 30 Nm

(22 ft-lb)

Oxygen sensor to manifold 50

Nrn (37 ft-lb)

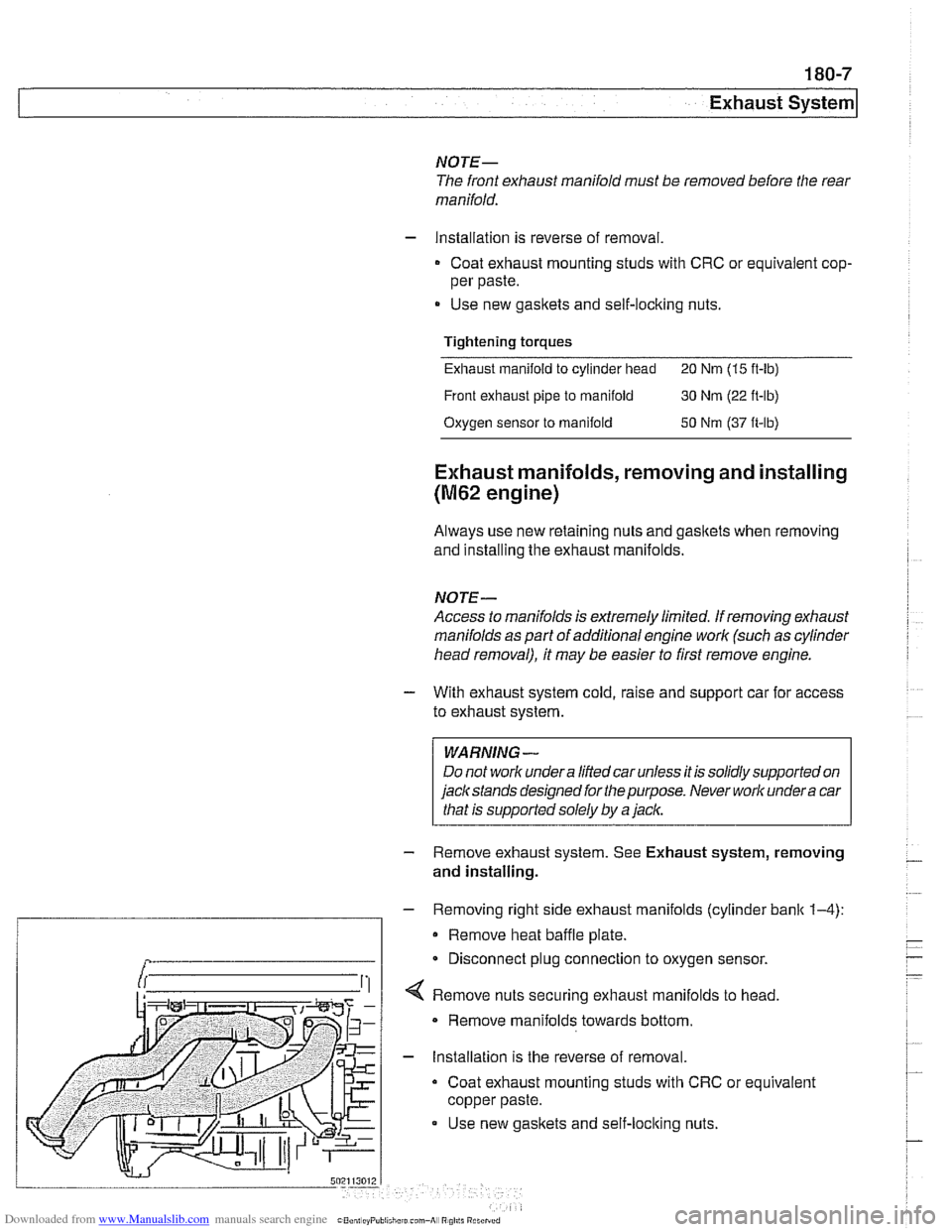

Exhaust manifolds, removing and installing

(M62 engine)

Always use new retaining nuts and gasltets when removing

and installing the exhaust manifolds.

NOTE-

Access to manifolds is extremely limited. If removing exhaust

manifolds as part of additional engine worlc (such as cylinder

head removal), it may be easier to first remove engine.

- With exhaust system cold, raise and support car for access

to exhaust system.

WARNING -

Do not work undera lifted car unless it is solidly supported on

jaclt stands designed for the purpose. Never worlc undera car

that is supportedsolely

by a jack.

- Remove exhaust system. See Exhaust system, removing

and installing.

- Removing right side exhaust manifolds (cylinder bank 1-4):

Remove heat baffle plate.

Disconnect plug connection to oxygen sensor.

securing exhaust manifolds to head.

Remove manifolds towards bottom.

- Installation is the reverse of removal.

Coat exhaust mounting studs with CRC or equivalent

copper paste.

Use new gasltets and self-loclting nuts.

Page 532 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust System

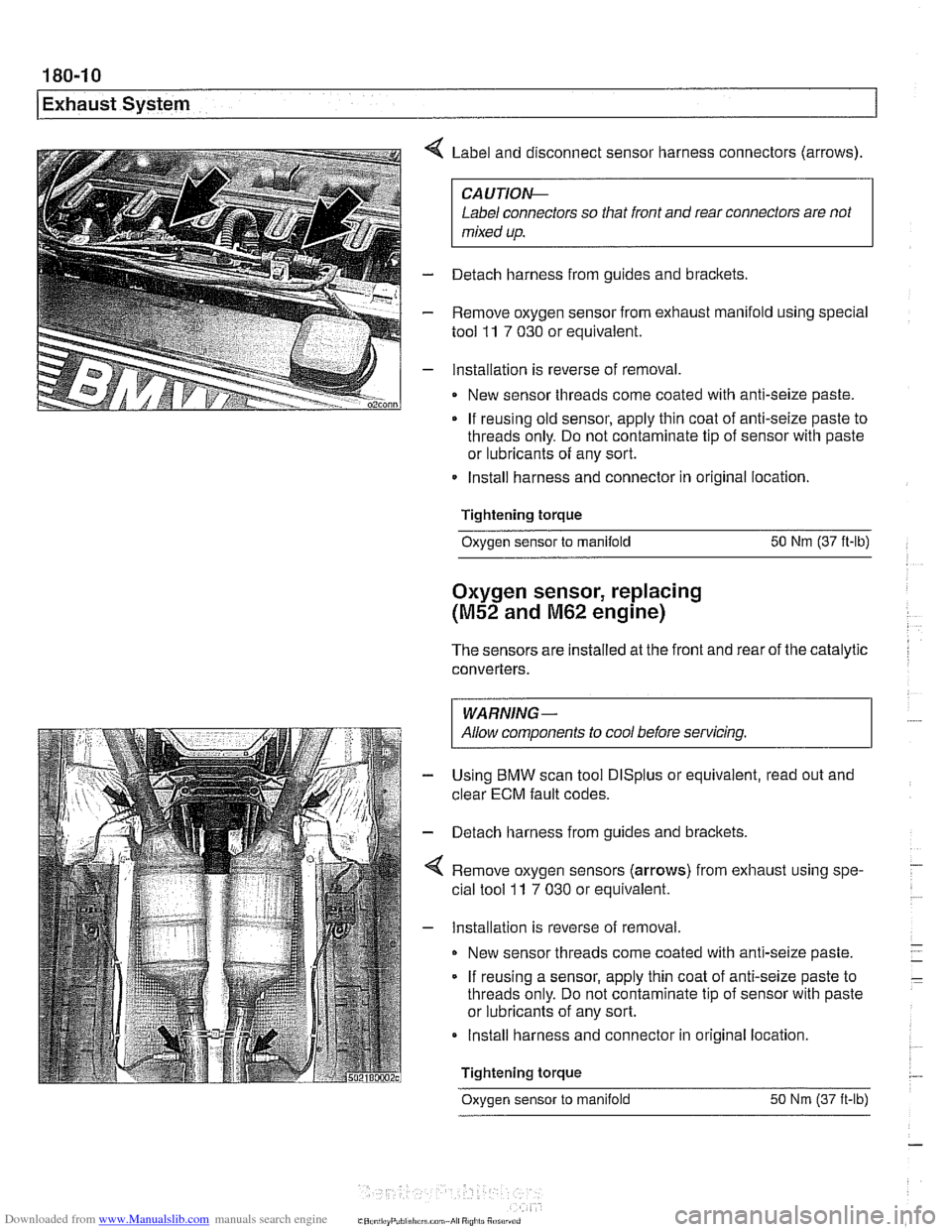

Label and disconnect sensor harness connectors (arrows).

CAUTlOI\C

Label connectors so that front and rear connectors are not

mixed up.

- Detach harness from guides and brackets.

- Remove oxygen sensor from exhaust manifold using special

tool

11 7 030 or equivalent.

- Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing old sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

Oxygen sensor to manifold 50 Nm (37 ft-lb)

Oxygen sensor, replacing

(M52 and M62 engine)

The sensors are installed at the front and rear of the catalytic

converters.

I WARNING- I

I Allow components to cool before servicing. I

Using BMW scan tool DlSplus or equivalent, read out and

clear

ECM fault codes.

Detach harness from guides and brackets.

Remove oxygen sensors (arrows) from exhaust using spe-

cial tool

ll 7 030 or equivalent.

Installation is reverse of removal

New sensor threads come coated with anti-seize paste.

If reusing a sensor, apply thin coat of anti-seize paste to

threads only. Do not contaminate tip of sensor with paste

or lubricants of any sort.

Install harness and connector in original location.

Tightening torque

Oxvaen sensor to manifold 50 Nm (37 it-lb)

Page 536 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Exhaust System

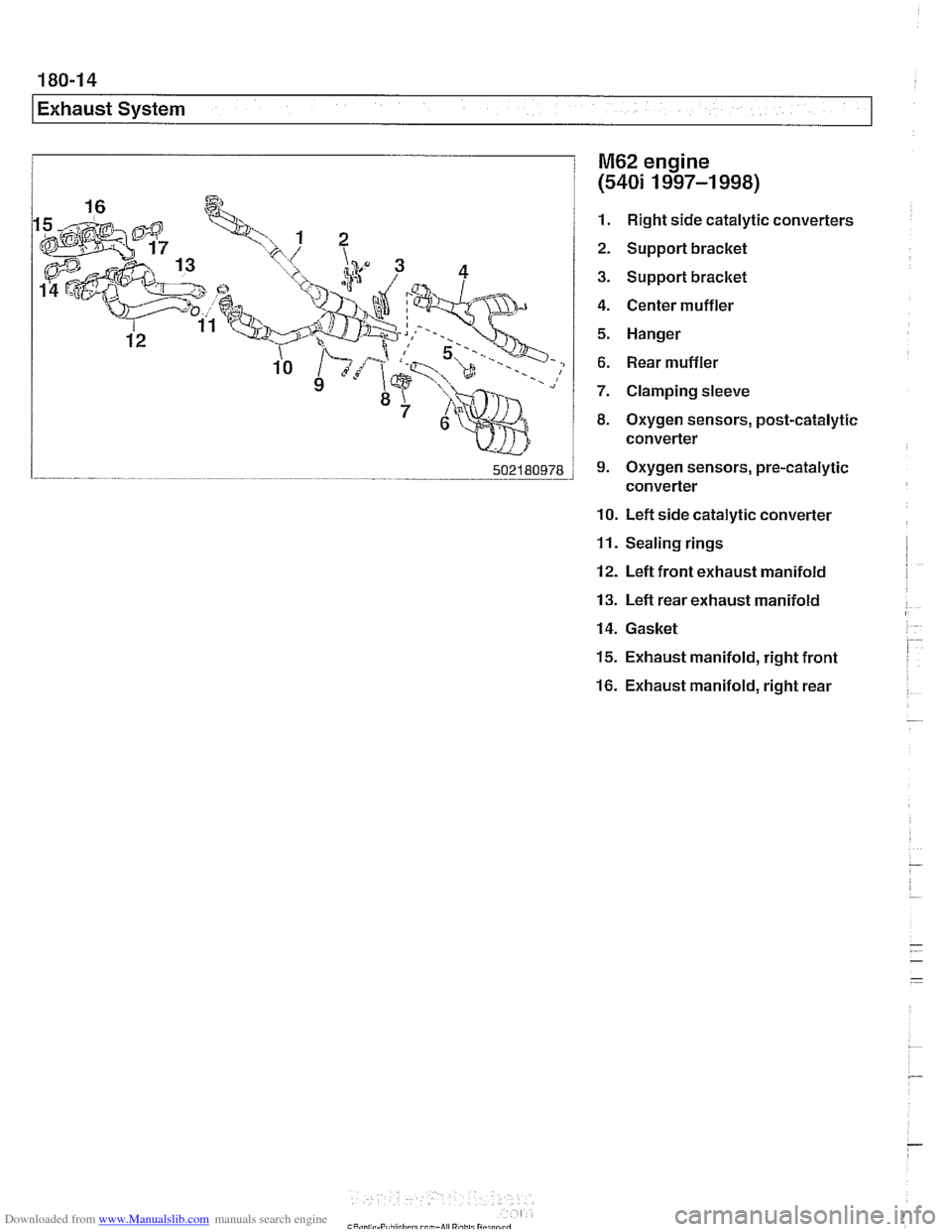

M62 engine

(540i 1997-1 998)

1. Right side catalytic converters

2. Support bracket

3. Support bracket

4. Center muffler

5. Hanger

6. Rear muffler

7. Clamping sleeve

8. Oxygen sensors, post-catalytic

converter

9. Oxygen sensors, pre-catalytic

converter

10. Left side catalytic converter

11. Sealing rings

12. Left front exhaust manifold

13. Left rear exhaust manifold

14. Gasket

15. Exhaust manifold, right front

16. Exhaust manifold, right rear

Page 537 of 1002

Downloaded from www.Manualslib.com manuals search engine

Exhaust systeml

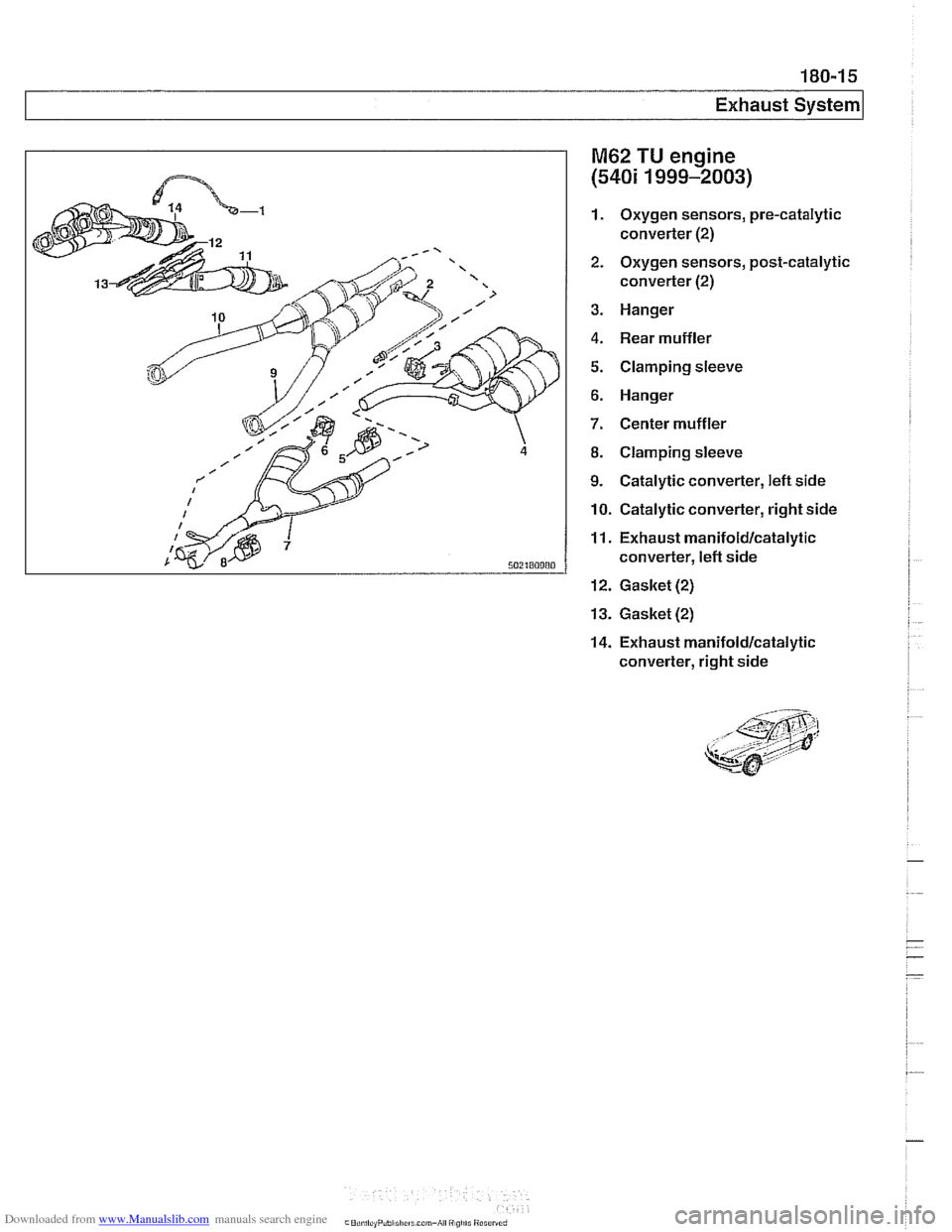

M62 TU engine

(540i 1999-2003)

1. Oxygen sensors, pre-catalytic

converter

(2)

2.

Oxygen sensors, post-catalytic

converter

(2)

3.

Hanger

4. Rear muffler

5. Clamping sleeve

6. Hanger

7. Center muffler

8. Clamping sleeve

9. Catalytic converter, left side

10. Catalytic converter, right side

11. Exhaust manifoldlcatalytic

converter,

left side

12. Gasket (2)

13.

Gasket (2)

14.

Exhaust manifoldlcatalytic

converter, right side

Page 541 of 1002

Downloaded from www.Manualslib.com manuals search engine

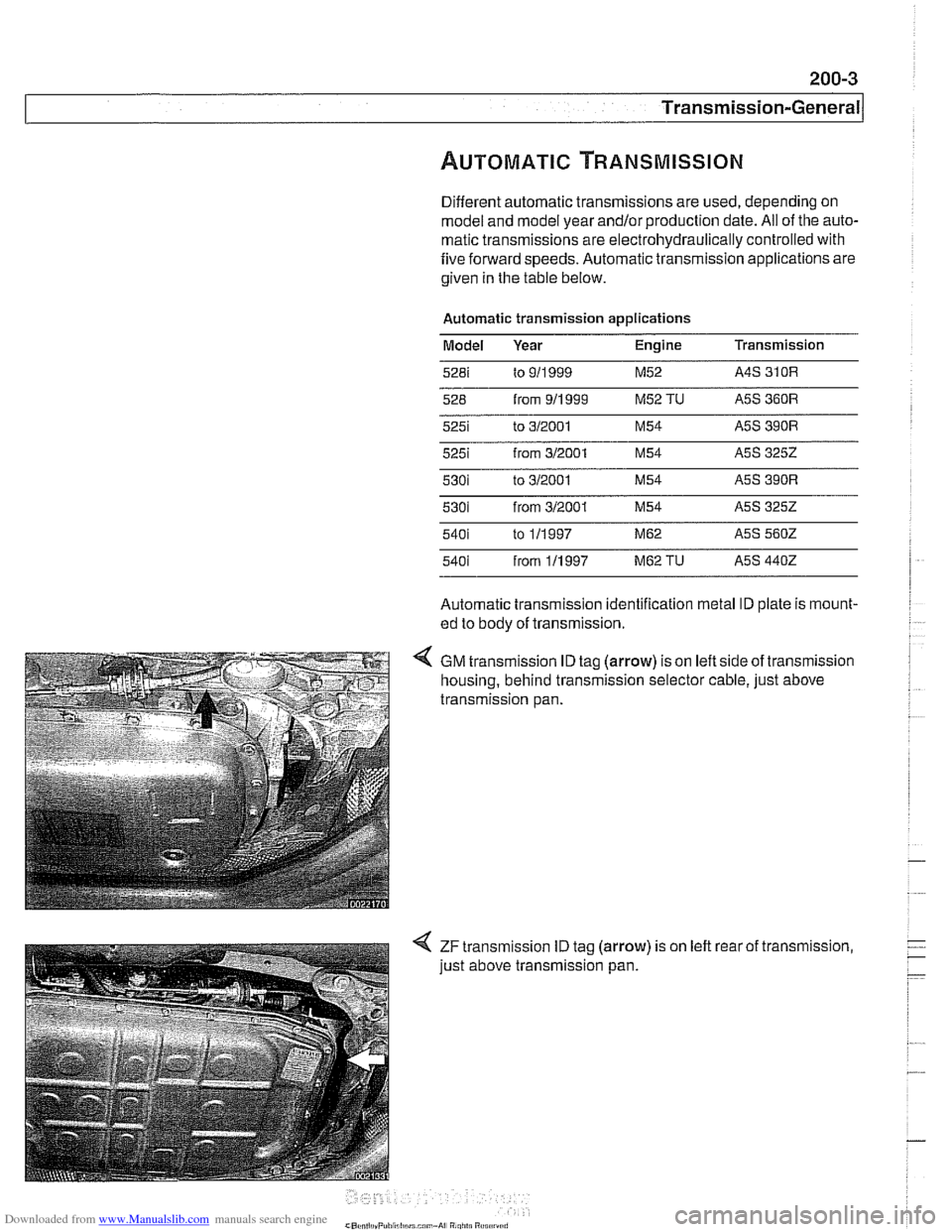

Different automatic transmissions are used, depending on

model and model year

and/orproduction date. All of the auto-

matic transmissions are electrohydraulically controlled with

five forward speeds. Automatic transmission applications are

given in the table below.

Automatic transmission applications Model Year Engine Transmission

526 from 911 999 M52 TU ASS 360R

5251 from 312001 M54 ASS 3252

5301 to 312001 M54 ASS 390R

530i from 312001 M54 ASS 3252

540i

from 111 997 M62 TU ASS 4402

Automatic transmission identification metal ID plate is mount-

ed to body of transmission.

4 GM transmission ID tag (arrow) is on left side of transmission

housing, behind transmission selector cable, just above

transmission pan.

< ZF transmission ID tag (arrow) is on left rear of transmission,

just above transmission pan.

Page 569 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-5

Manual Transmission

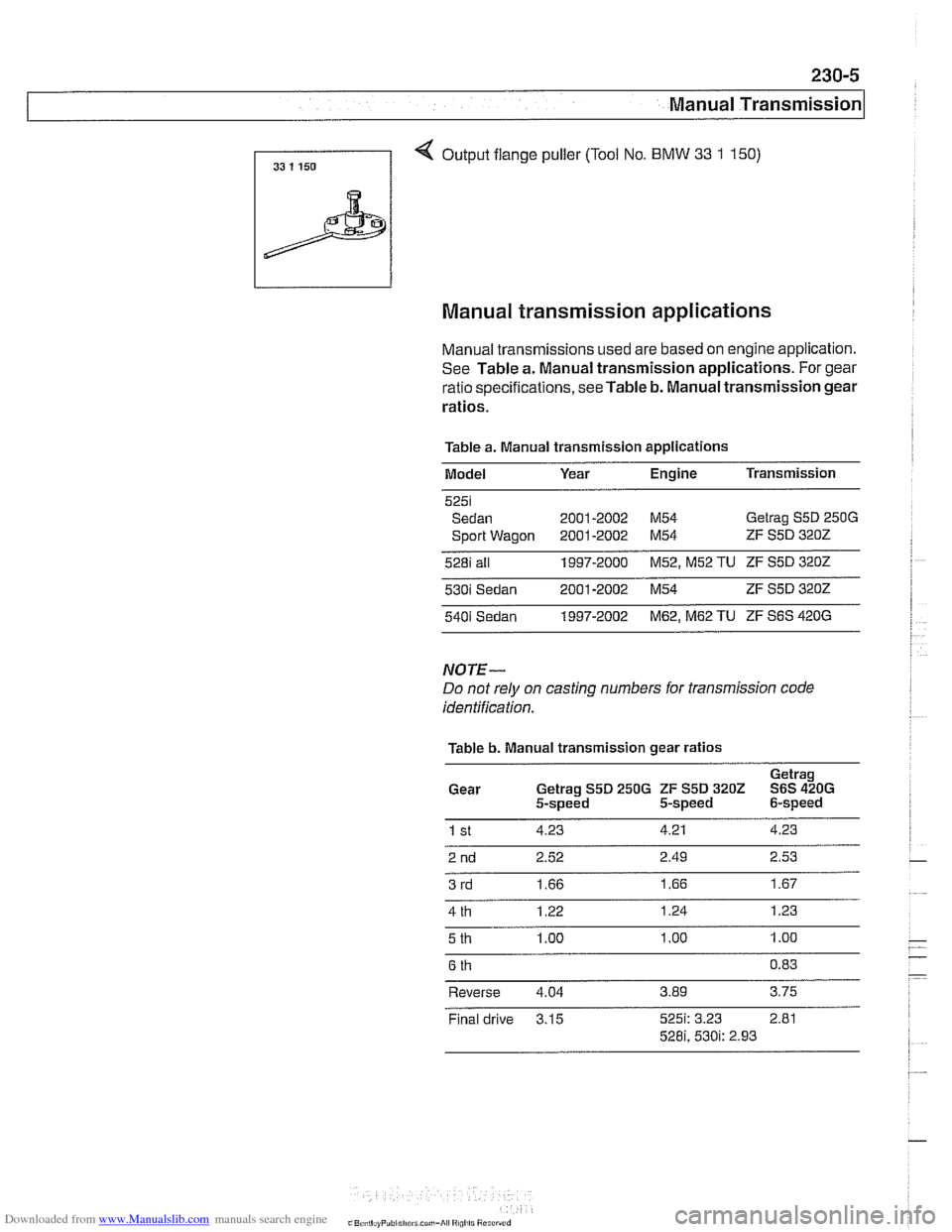

Manual transmission applications

Manual transmissions used are based on engine application.

See Table a. Manual transmission applications. For gear

ratio specifications,

seeTable b. Manual transmission gear

ratios.

Table a. Manual transmission applications

Model Year Engine Transmission

5251

Sedan 2001 -2002 M54 Getrag S5D 250G

Sport Wagon 2001-2002

M54 ZF S5D 3202

5281 all 1997-2000 M52, M52 TU ZF S5D 3202

530i Sedan 2001

-2002 M54 ZF

S5D 3202

540i Sedan

1997-2002 M62, M62 TU ZF S6S 420G

NOTE-

Do not rely on casting numbers for transmission code

identification.

Table b. Manual transmission gear ratios

-

Getrag Gear Getrag S5D 250G ZF S5D 3202 S6S 420G 5-speed 5-speed 6-speed

6 th 0.83

Reverse 4.04 3.89 3.75

Final drive 3.15

523: 3.23 2.81

5281 530i: 2.93

Page 588 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

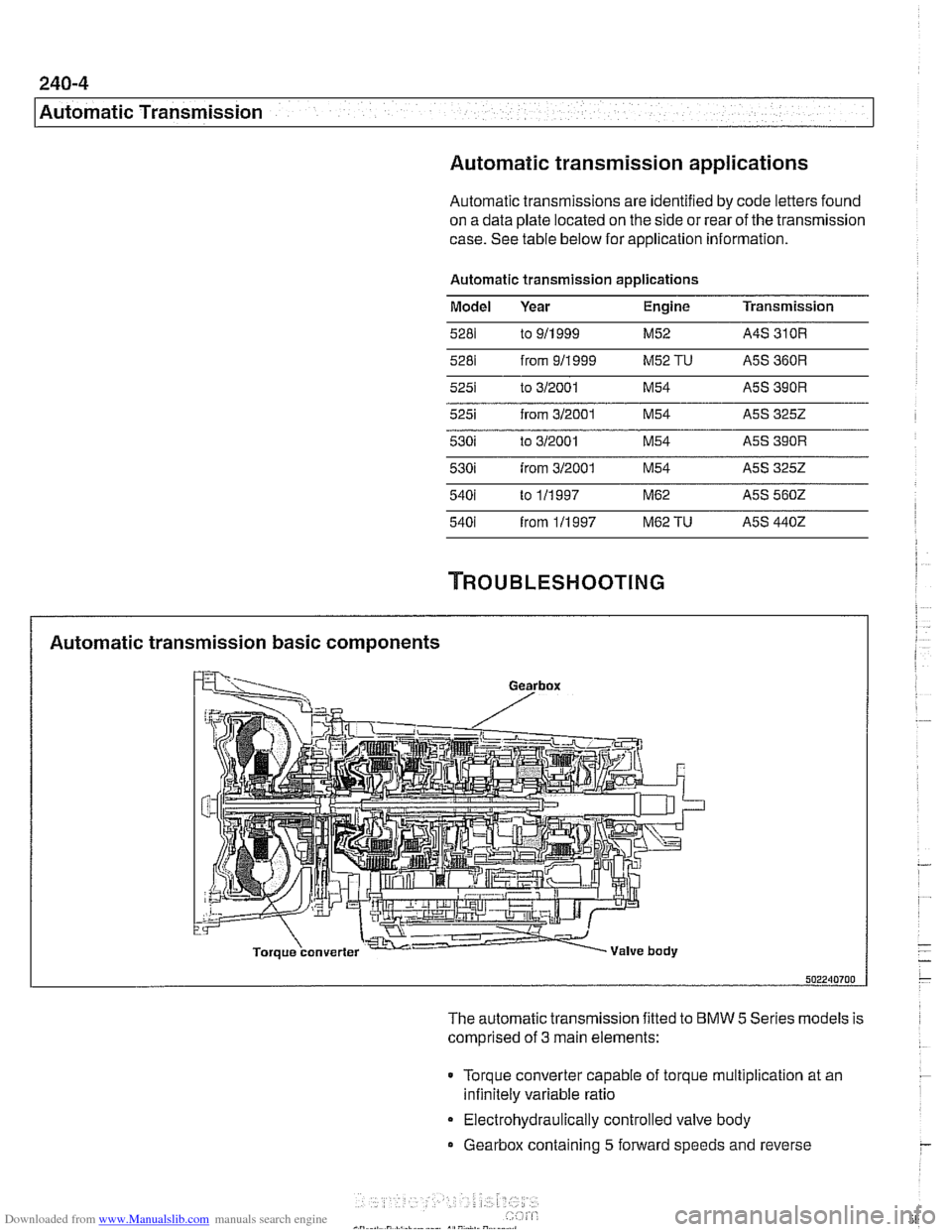

Automatic transmission applications

Automatic transmissions are identified by code letters found

on a data plate located on the side or rear of the transmission

case. See table below for application information.

Automatic transmission applications

Model Year Engine Transmission

5281 to 911999 M52 A4S 310R

5281 from 911999

M52 TU A5S 360R

5251 to 312001 M54 A5S 390R

5251 from 312001 M54 ASS 3252

530i to 312001 M54

ASS 390R

530i from 312001 M54

A5S 3252

540i from 111997 M62

TU A5S 4402

Automatic transmission basic components

The automatic transmission fitted to BMW 5 Series models is

comprised of

3 main elements:

0 Torque converter capable of torque multiplication at an

infinitely variable ratio

Electrohydraulically controlled valve body

0 Gearbox containing 5 forward speeds and reverse

Page 798 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-4

I Bodv-General

Bumpers

The front and rear bumpers are clad in high quality

deform-

able plastic and, at solid barrier impact speeds of 4 kph (2.5

mph), provide protection with virtually no damage to the

bumper

orthe vehicle. In addition to hydraulic dampeners.

which absorb the initial impact energy, these bumpers are

backed by compressible tubes. These deform in a controlled

manner at impact speeds greaterthan that

forwhich bumpers

and hydraulic dampeners are designed. This helps avoid ex-

pensive damage to the body at impact speeds up to 14 kph (9

mph).

The E39 Sport Wagon was introduced to the US market in

911 998 (model year 1999). It shares many components with

the E39 sedan and is identical to it from the B-pillar forward.

US

marltet 5 Series Sport Wagons are available in two vari-

ants:

6-cylinder

(5251, 528i) powered by the 2.8 liter M52 TU en-

gine (1 999) or the 2.5 liter M54 engine (2000 and later)

* V-8 (540i) powered by the 4.4 liter M62 TU engine

The wheelbase of the Sport Wagon is the same as the sedan.

Howeverthe body is 30

mm (1.2 in) longer and 10 mm (0.4 in)

higher.

The Sport Wagon rear suspension was redesigned to elimi-

nates the upper rear spring strut mounting on the E39 sedan.

The use of separate coil springs and

shoclc absorbers results

in a flat, wide floor in the cargo area. See

300 Suspension,

Steering and Brakes-General.

The self-leveling air spring suspension system (electronic

height control or EHC) is standard on Sport Wagon V-8 mod-

els and optional on 6-cylinder models.

Sport Wagon cargo capacities are shown below.

Sport Wagon load capacities

Cargo capacity

Rear seat up 909 liters (32.1 cu ft)

Rear seat folded down I809 liters (63.9 cu ft)

Load limit

Cargo compartment

460 Kg (1014 lb)

Roof

I00 Kg (220 lb)

Page 961 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD On-Board Diagnostics

I I

General ........................... OBD-1 Diaqnostic Trouble Codes (DTCs) . . OBD-9

On-Board Diagnostics (OBD I!) ..... OBD-I

Malfunction Indicator Light (MIL)

........ OBD-2

Scan tools and scan tool display.

........ OBD-3

Diagnostic monitors

.................. OED-4

Drive cycle

......................... OED-6

Readiness codes

.................... OBD-6

Diagnostic trouble codes

(DTCs) ........ OBD-7

-

Automatic transmission diagnostic

trouble codes

....................... OBD-9

Engine diagnostic trouble

codes: M52 engine.

................. OED-13

Engine diagnostic trouble

codes: M54 engine.

................. OBD-17

Engine diagnostic trouble

codes: M62 engine.

................. OBD-24

This chapter outlines the fundamentals and equipment

requirements of On-Board Diagnostics

I1 (OBD 11) standards

as they apply to BMW vehicles. Also covered here is a listing

of BMW and OBD

I1 diagnostic trouble codes (DTCs).

ON-BOARD DIAGNOSTICS (QBD !I)

OBD II standards were developed by the SAE (Society of

Automotive Engineers) and CARB (California Air Resources

Board).

OED I1 is the second generation of on-board self-

diagnostic equipment requirements. These standards were

originally mandated for California vehicles. Since

1996 they

have been applied

toall passengervehicles sold in the United

States.

On-board diagnostic capabilities are incorporated into the

hardware and soflwareof the enginecontrol module

(ECM) to

monitor virtually every component that can affect vehicle

emissions. The

OED I1 system works to ensure that

emissions remain as clean as possible over the life of the

vehicle.

Each emission-influencing component is checked by a

diagnostic routine (called a monitor) to verify that it is

functioning properly.

If a problem or malfunction is detected,

the

diagnostic executive built into the OBD I1 system

illuminates a malfunction indicator light (MIL) on the

instrument panel.

The OBD

I1 system also stores diagnostic trouble codes

(DTCs) about the detected malfunction in the ECM so that a

repair technician can accurately find and fix the problem.