relay BMW 540i 1999 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 483 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump

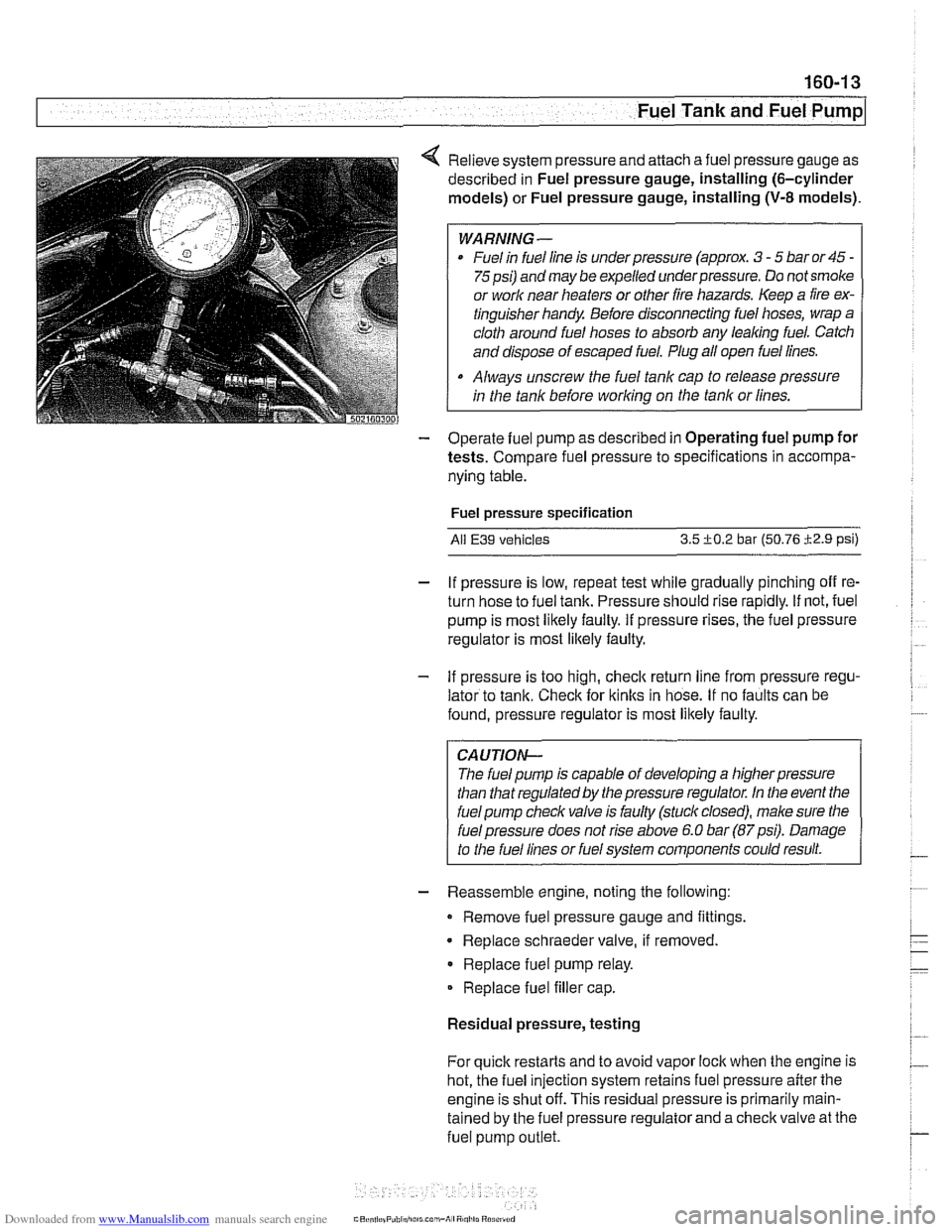

4 Relieve system pressure and attach a fuel pressure gauge as

described in Fuel pressure gauge, installing (6-cylinder

models) or Fuel pressure gauge, installing

(V-8 models).

WARNING-

Fuel in fuel line is under pressure (approx. 3 - 5 bar or 45 -

75psi) and may be expelled underpressure. Do not smoke

or

worlc near heaters or other fire hazards. Keep a fire ex-

tinguisher handy Before disconnecting fuel hoses, wrap a

cloth around fuel hoses to absorb any

leaking fuel. Catch

and dispose of escaped fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

in the tank before

working on the tank or lines.

- Operate fuel pump as described in Operating fuel pump for

tests. Compare fuel pressure to specifications in accompa-

nying table.

Fuel pressure specification

All E39 vehicles 3.5 +0.2 bar (50.76 i2.9 psi)

- If pressure is low, repeat test while gradually pinching off re-

turn hose to fuel tank. Pressure should rise rapidly. If not, fuel

pump is most likely faulty. If pressure rises, the fuel pressure

regulator is most

likely faulty.

- If pressure is too high, checlc return line from pressure regu-

lator to tank. Check for

ltinks in hose. If no faults can be

found, pressure regulator is most likely faulty.

CAUTION-

The fuel pump is capable of developing a higher pressure

than that regulated by the pressure regulator. In the event the

fuel pump checlc valve is faulty (stuck closed), male sure the

I fuel pressure does not rise above 6.0 bar (87psi). Damage

to the fuel lines or fuel system components could result.

- Reassemble engine, noting the following:

Remove fuel pressure gauge and fittings.

Replace schraeder valve, if removed

Replace fuel pump relay.

Replace fuel filler cap.

Residual pressure, testing

For quick restarts and to avoid vapor lock when the engine is

hot, the fuel injection system retains fuel pressure after the

engine is shut off. This residual pressure is primarily

rnain-

tained by the fuel pressure regulator and a checlc valve at the

fuel pump

outlet.

Page 697 of 1002

Downloaded from www.Manualslib.com manuals search engine

330 Rear Suspension

General . . . . . . . . . . . . . . . . . . . . . . . . . . . ,330-2

Special tools . . . . . . . . . . . . . . . . . . . . . . . . ,330-2

Rear suspension variations . . . . . . . . . . . . ,330-4

Rear Struts and Springs

(sedan models)

. . . . . . . . . . . . . . . . . . . . ,330-5

Rear strut assembly, removing

and installing

. . . . . . . . . . . . . . . . . . . . . . . ,330-5

Rear strut assembly, disassembling

and assembling

. . . . . . . . . . . . . . . . . . . . . ,330-7

Rear Shock Absorbers and

Springs (Sport Wagon models)

. . . . . ,330-9

Rear shock absorber, removing

and installing

. . . . . . . . . . . . . . . . . . . . . . . ,330-9

Coil spring, removing and installing . . . . . ,330-1 1

Air spring, removing and installing

. . . . . . ,330-12

Rear Suspension Arms,

Subframe and Bushings . . . . . . . . . . ,330-13

Rear suspension arm components . . . . . . ,330-1 3

Swing arm, removing and installing (sedan models)

. . . . . . . . . . . . . . . . . . . . . ,330-1 4

Swing arm, removing and installing (Sport Wagon models)

. . . . . . . . . . . . . . . ,330-16

Swing arm ball joint, replacing . . . . . . . . . ,330-1 9

Upper rear control arm, removing

and installing (sedan models)

. . . . . . . . . . .330-22

Upper rear control arm, removing

and installing (Sport Wagon models)

. . . . .330-23

Upper front control arm (traction strut),

removing and installing

. . . . . . . . . . . . . . . ,330-25

Rear axle assembly, removing and

installing (sedan models)

. . . . . . . . . . . . . ,330-26

Rear axle assembly, removing and

installing (Sport Wagon models)

. . . . . . . ,330-28

Rear subframe mounting bushings,

removing and installing

. . . . . . . . . . . . . . . .330-31

Rear Wheel Bearings . . . . . . . . . . .

Rear wheel bearing carrier, removing

and installing (sedan models)

. . . . . . .

Rear wheel bearing carrier, removing

and installing (Sport Wagon models)

. .

Rear wheel bearing, replacing . . . . . . .

Rear Stabilizer Bar

Stabilizer bar, removing and installing .

Stabilizer bar link, removing

and installing

. . . . . . . . . . . . . . . . . . . .

Electronic Height Control (EHC)

Component Replacement

. . . . . . .

Electronic height control (EHC)

components

.....................

Air compressor pump relay, removing

and installing

. . . . . . . . . . . . . . . . . . . .

EHC control module, removing

and installing

. . . . . . . . . . . . . . . . . . . .

Air supply unit, removing and installing

Ride height sensor, removing

and installing

. . . . . . . . . . . . . . . . . . . .

Page 740 of 1002

Downloaded from www.Manualslib.com manuals search engine

---

Rear Suspension

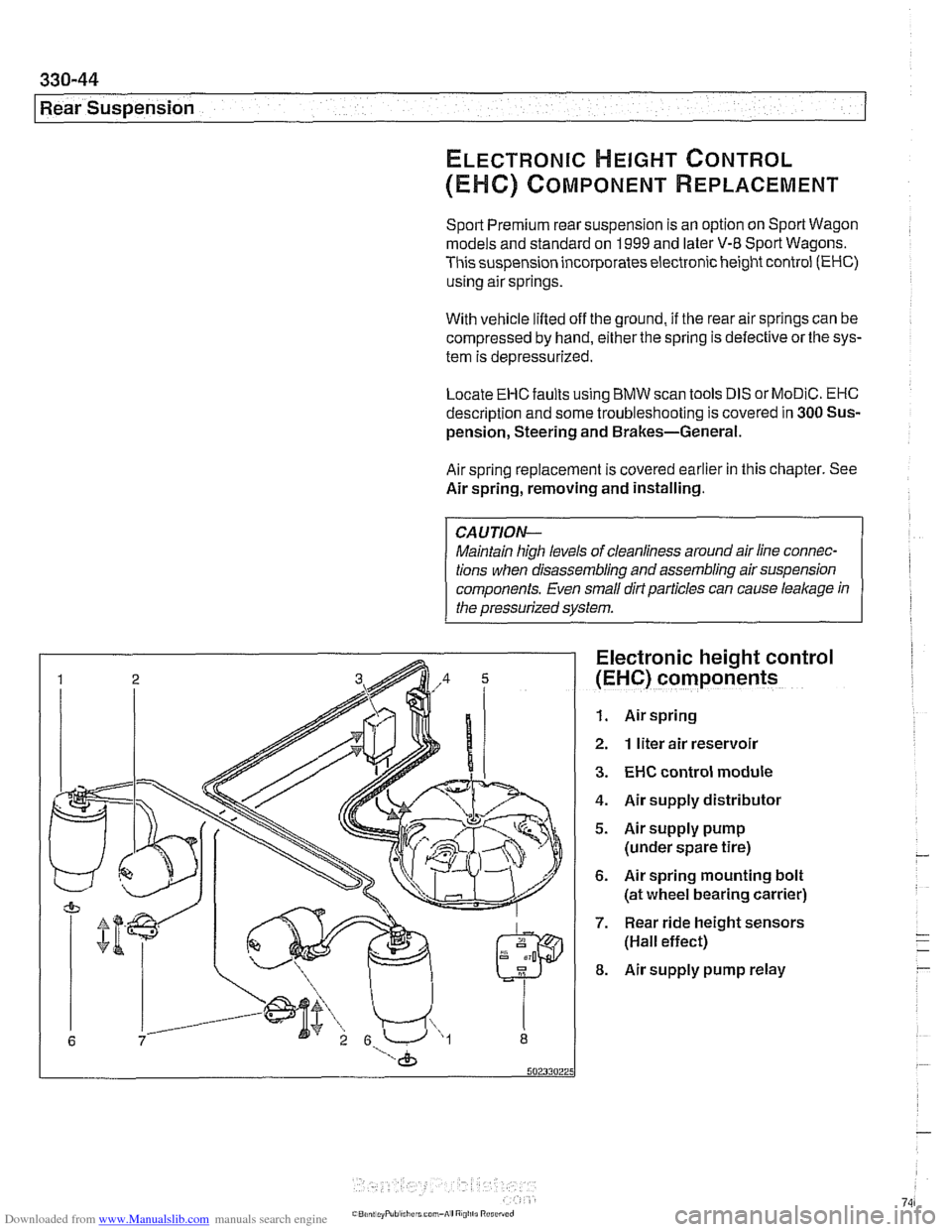

ELECTRONIC HEIGHT CONTROL

(EHC) COMPONENT REPLACEMENT

Sport Premium rear suspension is an option on Sport Wagon

models and standard on

1999 and later V-8 Sport Wagons.

This suspension incorporates electronic height control

(EHC)

using air springs.

With vehicle lifted off the ground,

if the rear air springs can be

compressed by hand, either the spring is defective or the sys-

tem is depressurized.

Locate

EHC faults using BMW scan tools DIS or MoDiC. EHC

description and some troubleshooting is covered in 300 Sus-

pension, Steering and Brakes-General.

Air spring replacement is covered earlier in this chapter. See

Air spring, removing and installing.

CAUTION-

Maintain high levels of cleanliness around air line connec-

tions when disassembling and assembling air suspension

components. Even

small dirt particles can cause leakage in

the pressurized system.

Electronic height control

(EHC) components

1. Air spring

2. 1 liter air reservoir

3. EHC control module

4. Air supply distributor

5. Airsupply pump

(under spare tire)

6. Air spring mounting bolt

(at wheel bearing carrier)

7. Rear ride height sensors

(Hall effect)

8. Air supply pump relay

Page 741 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- I

I: ... . -. Rear Suspension! -- .- -

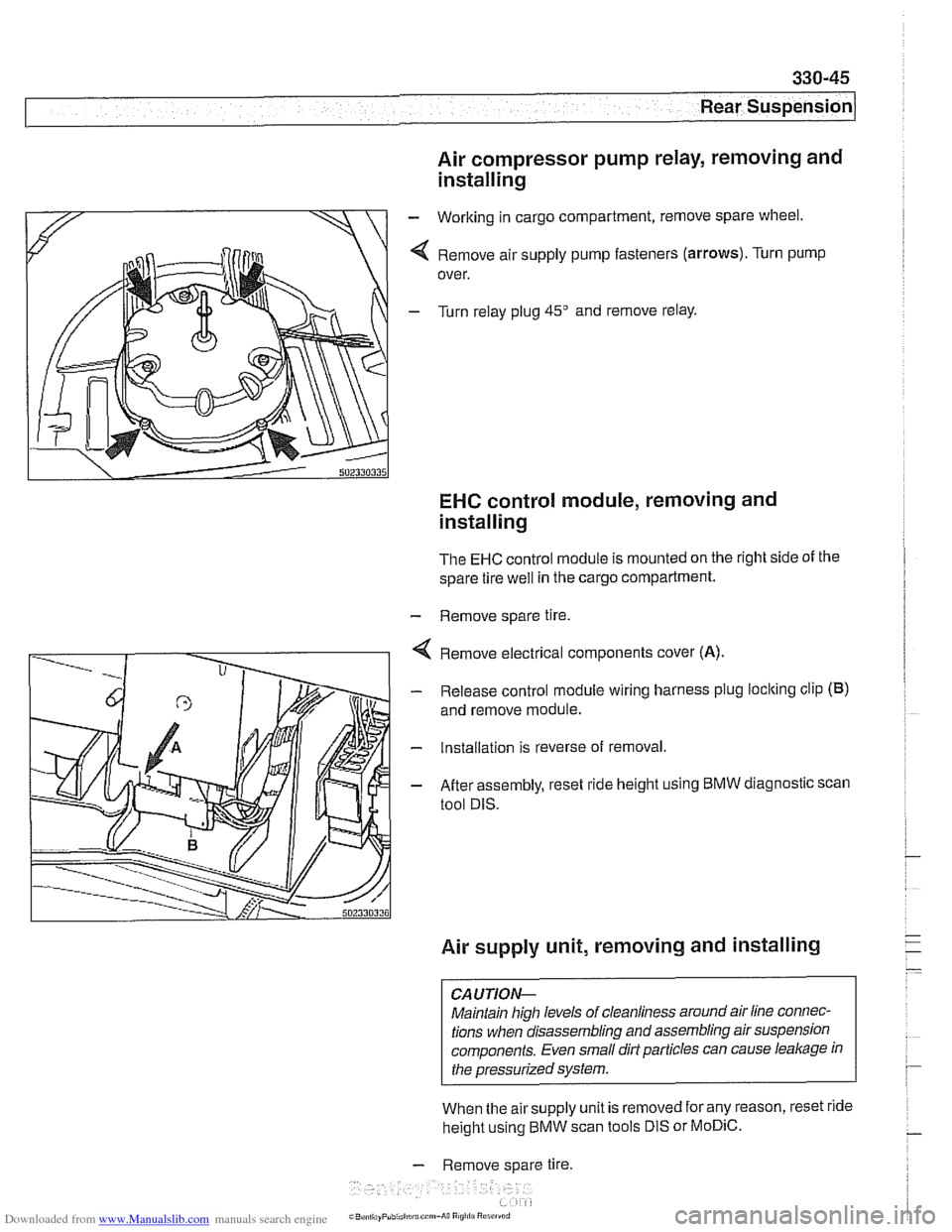

Air compressor pump relay, removing and

installing

- Working in cargo compartment, remove spare wheel.

4 Remove air supply pump fasteners (arrows). Turn pump

over.

- Turn relay plug 45" and remove relay.

EHC control module, removing and

installing

The EHC control module is mounted on the right side of the

spare tire

well in the cargo compartment.

- Remove spare tire.

4 Remove electrical components cover (A).

- Release control module wiring harness plug loclting clip (B)

and remove module.

- Installation is reverse of removal.

- After assembly, reset ride height using BMW diagnostic scan

tool DIS.

Air supply unit, removing and installing

CAUTION-

Maintain high levels of cleanliness around air line connec-

tions when disassembling and assembling air suspension

components. Even small dirt particles can cause

leakage in

the pressurized system.

When the airsupply unit is removed for any reason, reset ride

height using BMW scan tools DIS or

MoDiC.

- Remove spare tire.

i~B,!n,,ayPubi.l,c~u.c~"~-A~~ R

Page 799 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-5

Body-General

Tailgate

The E39 Sporl Wagon tailgate is large with a low sill for easy

cargo loading. The tailgate opens to an angle of

88" mea-

sured from the rear roof pillar (D-pillar) and to a height of

2029

mm (79.8 in) measured from the ground to the upper edge of

the raised tailgate.

The rear window is bonded to a load bearing frame and can

be opened separately from the main tailgate. Tailgatesupport

gas springs are recessed into cavities in the roof.

Tailgate lock system

A mechanical tailgate lock cylinder is not used; the tailgate is

opened by the unlock pad above the license plate, the remote

tailgate switch located in the drivers kick panel, or via

FZV

(Iteyless entry) control.

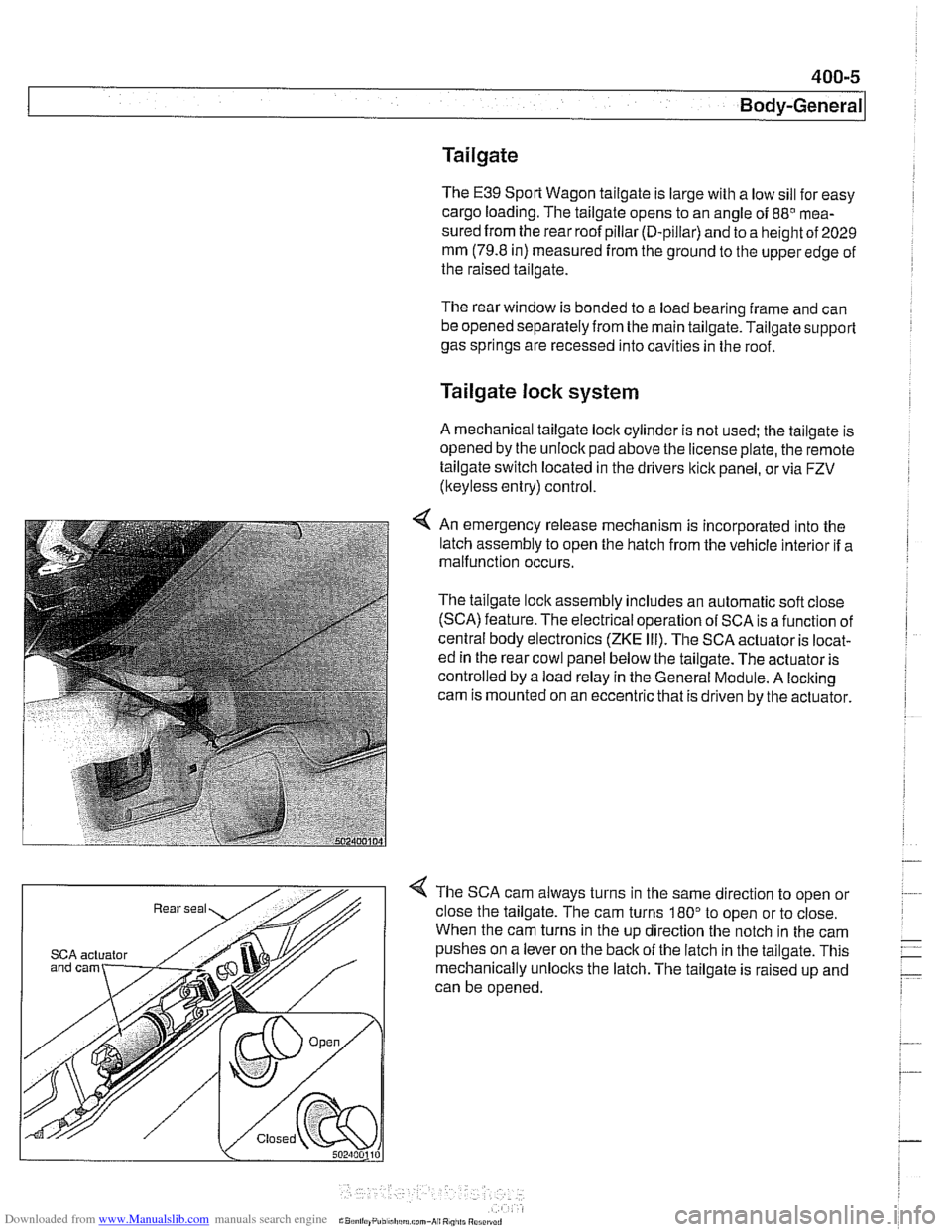

4 An emergency release mechanism is incorporated into the

latch assembly to open the hatch from the vehicle interior if a

malfunction occurs.

The tailgate lock assembly includes an automatic soft close

(SCA) feature. The electrical operation of SCA is a function of

central body electronics

(ZKE Ill). The SCA actuator is locat-

ed in the rear cowl panel below the tailgate. The actuator is

controlled by a load relay in the General Module. A locking

cam is mounted on an eccentric that is driven by the actuator.

4 The SCA cam always turns in the same direction to open or

close the tailgate. The cam turns

180" to open or to close.

When the cam turns in the up direction the notch in the cam

SCA actuator pushes on a lever on the back of the latch in the tailgate. This

mechanically unlocks the latch. The tailgate is raised up and

can be opened.

Page 868 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 2-4

I Door Windows

/ Anti-trap strip

Power window motors

The window motors are mounted on cable regulators. The

window motor control circuit consists of two wires for operat-

ing the motor in both directions.

The motors are activated by relays in the GM

Ill. The relays

provide either power or ground depending on the direction of

window travel. The GM

Ill controls the polarity based on a re-

quest to run the window from a window switch or a conve-

nience

openinglclosing signal.

Convenience openinglclosing

The GM Iii provides the convenience openlclose feature, pro-

viding control of the power windows (and sunroof) from out-

side the vehicle with the key in the driver's door lock. The FZV

(remote key) provides the same function for window opening

only.

Anti-trap protection is active during convenience closing from

the driver's door lock.

If the GM receives a request to operate convenience closing

or opening for more than

110 seconds, the function is deacti-

vated and a

fault code is stored.

Window anti-trap protection

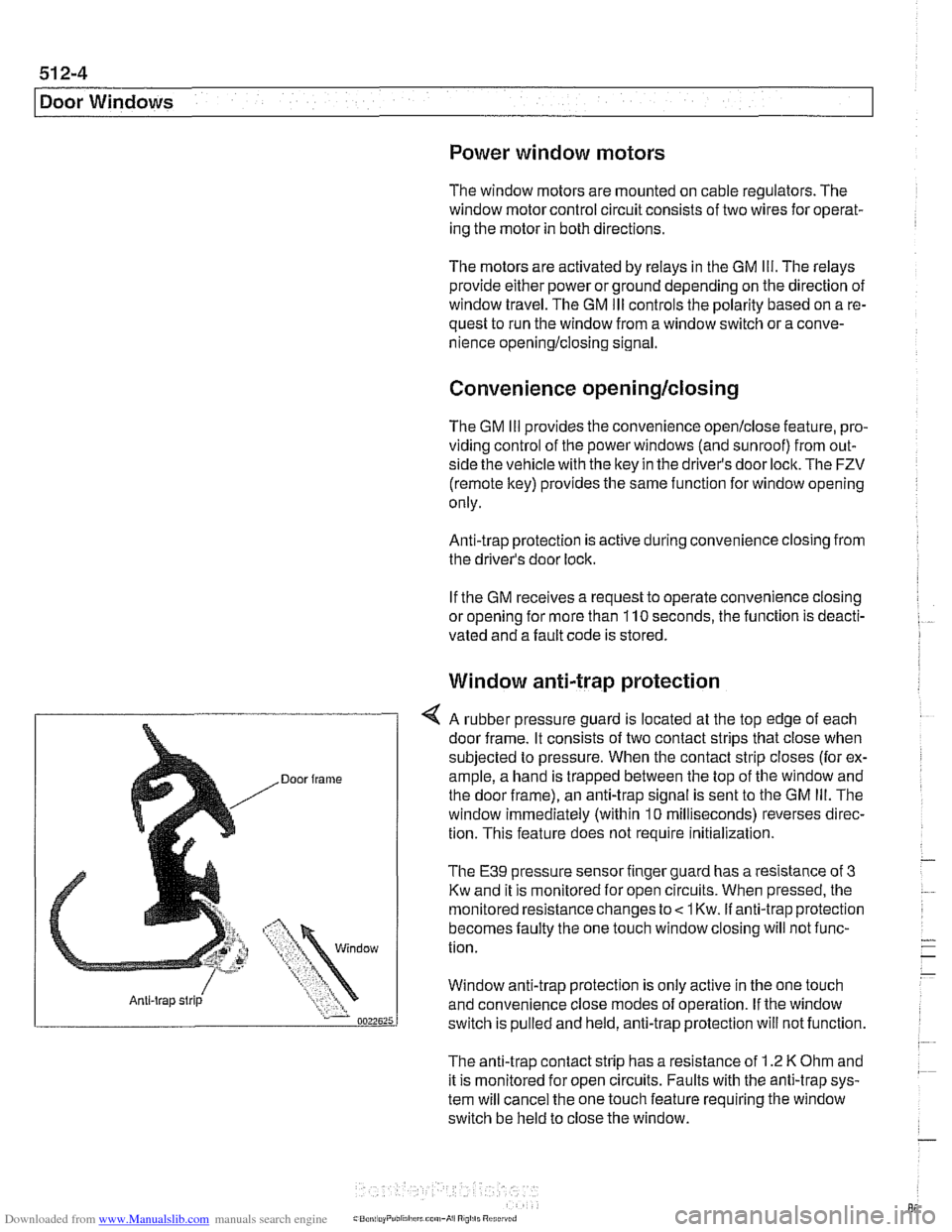

4 A rubber pressure guard is located at the top edge of each

door frame. It consists of two contact strips that close when

subjected to pressure. When the contact strip closes (for ex-

ample, a hand is trapped between the top of the window and

the door frame), an anti-trap signal is sent to the GM

Ill. The

window immediately (within

10 milliseconds) reverses direc-

tion. This feature does not require

initialization.

The E39 pressure sensor finger guard has a resistance of 3

Kw and it is monitored for open circuits. When pressed, the

monitored resistance changes to

< 1 Kw. if anti-trap protection

becomes faulty the one touch window closing will not func-

tion.

Window anti-trap protection is

only active in the one touch

and convenience close modes of operation. If the window

switch is pulled and held, anti-trap protection will not function.

The anti-trap contact strip has a resistance of

1.2 K Ohm and

it is monitored for open circuits. Faults with the anti-trap sys-

tem will cancel the one touch feature requiring the window

switch be held to close the window.

Page 869 of 1002

Downloaded from www.Manualslib.com manuals search engine

Door windows1

Window motor limit stop function

If repeated window activation (upldown cycles) exceeds one

minute, the

GM Ill deactivates the internal relays and disre-

gards any further

upldown requests. The GM Ill provides mo-

tor activation after a short duration but not for the full one

minute monitoring cycle.

The

GM Ill monitors the number of times a window motor is

activated. It counts each cycle and stores the number in

memory. Afler the stop function limit is reached and the win-

dow motor is deactivated, the

GM Ill slowly reverses the

stored count of activation until the stored number equals

0,

thus allowing the window motor to cool down.

WARNING-

* Always wear hand and eye protection when working with

brolen glass.

If a window is brolen, all of the glass bits should be

vacuumed out of the door cavity. Use a blunt

so-ewdi-iv-

er to clean out any remaining glass pieces from the

window guide rails.

When servicing the door windows, the harness con-

nector to the window regulator should always be dis-

connected to prevent pinching fingers in the moving

window mechanism.

Sedan and Sport Wagon doors are similar. Use the following

procedures for window service on these models.

WARNING-

E39 cars are iitted with side-impact airbags in the front

doors. Some are equipped with

airbags in the rear doors

as well. When

servicing the door windows on cars with

side-impact airbags, always disconnect the negative

(-)

battery cable. See 721 Airbag System (SRS) for cau-

tions and procedures relating to the

airbag system.

* Prior to disconnecting the battery, read the battery dis-

connection cautionsgiven

001 General Warnings and

Cautions.

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

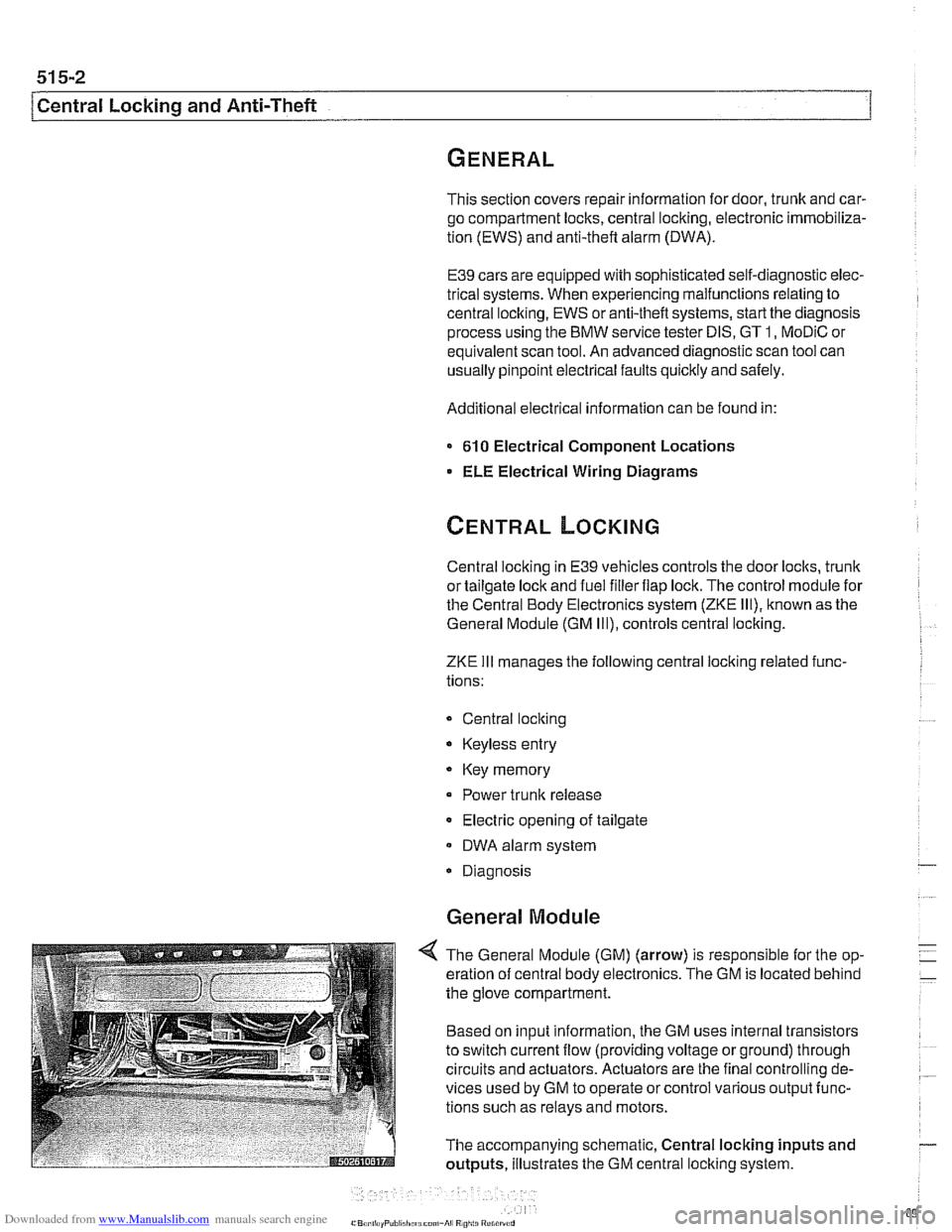

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 907 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

Central Locking and ~nti-~hefil

Key Memory

Whenever one of the FZV keys is used to lock or unlock the

car, the user is identified by the GM. A maximum of four

keys

can be programmed with the Key Memoryfeature. The use of

the personalized key then triggers Car Memory functions

such as heating

I AIC (IHKA) settings or memory seat position

adjustment.

Most programming of Key Memory requires the use of

BMW

scan tools (DISplus, GT1 or MoDiC). However, features such

as

IHKA blower speed and temperature store automatically

without the use of scan tools.

Available Key Memory functions vary based on vehicle equip-

ment. The functions that can be set include:

Automatic locking after start off (vehicle speed)

Selective locking

Heating

1 AJC blower speed, heated or cooled air distribu-

tion, automatic blower setting

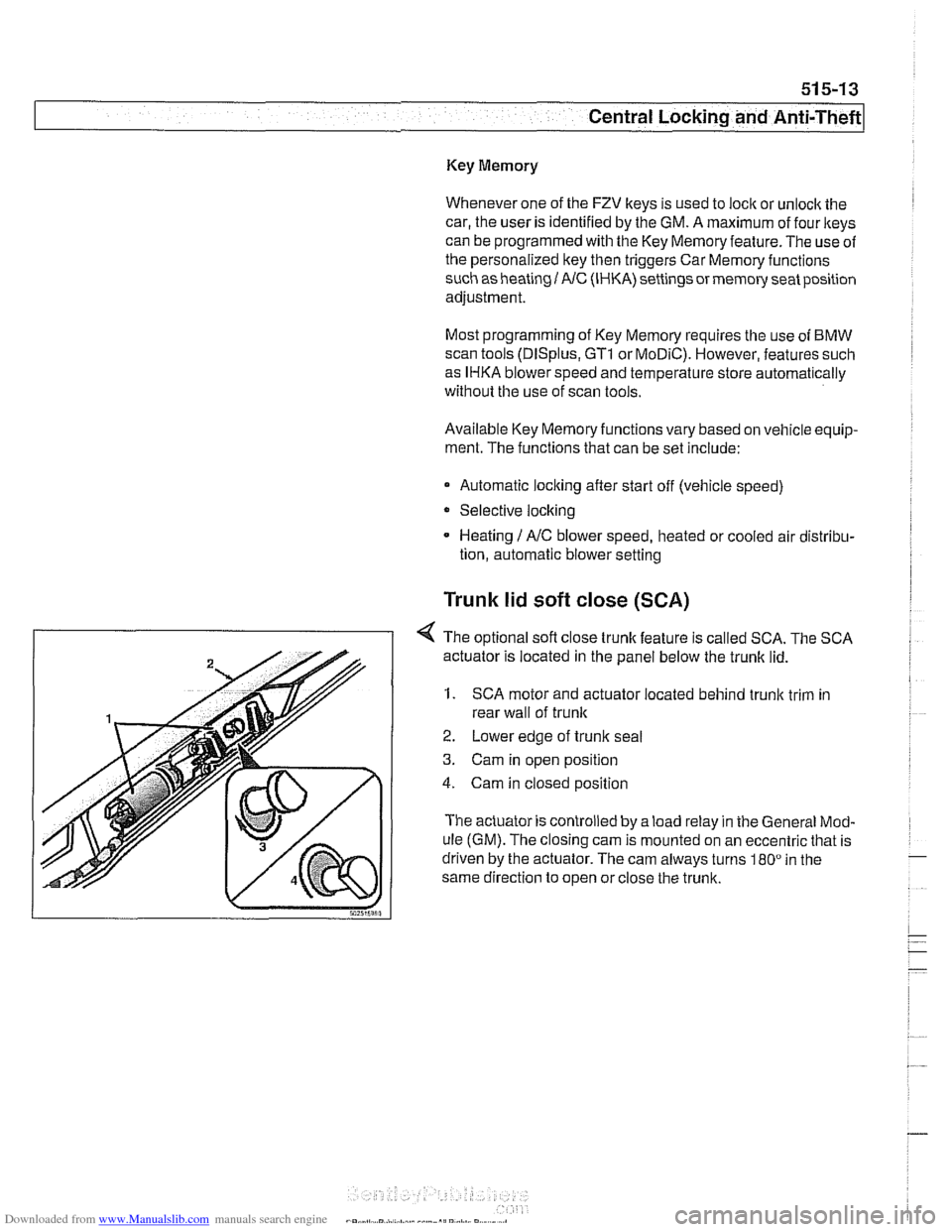

Trunk lid soft close (SCA)

< The optional sofl close trunk feature is called SCA. The SCA

actuator is located in the panel below the trunk lid.

1. SCA motor and actuator located behind trunk trim in

rear wall of

trunlc

2. Lower edge of trunlc seal

3. Cam in open position

4. Cam in closed position

The actuator is controlled by a load relay in the General Mod-

ule (GM). The closing cam is mounted on an eccentric that is

driven by the actuator. The cam always turns

180" in the

same direction to open or close the trunk.

Page 909 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-1 5

Central Locking and Anti-Theft

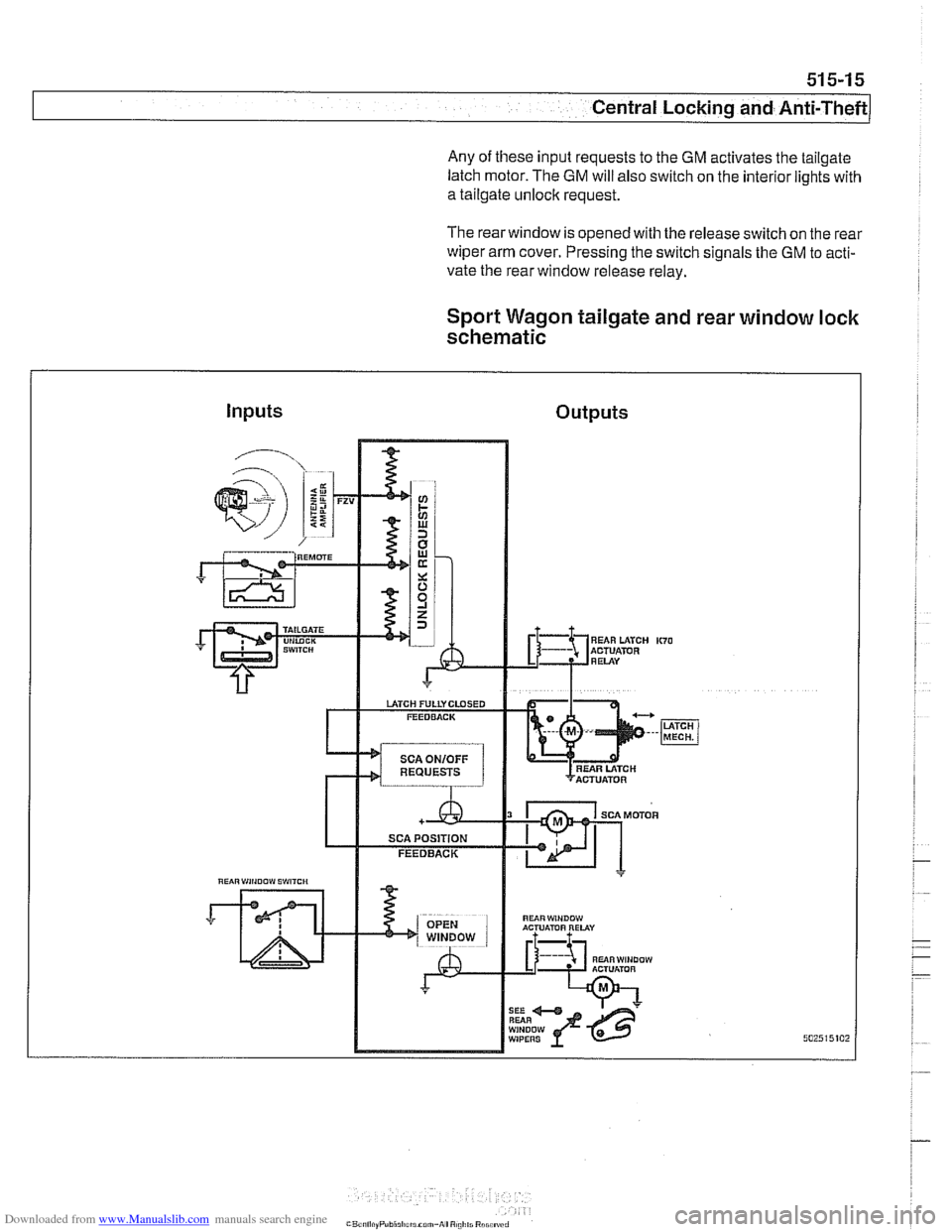

Any of these input requests to the GM activates the tailgate

latch motor. The

GM will also switch on the interior lights with

a tailgate unlock request.

The rearwindow is opened with the release switch on the rear

wiper arm cover. Pressing the switch signals the GM to acti-

vate the rear window release relay.

Sport Wagon tailgate and rear window lock

schematic

Inputs Outputs

"UiRWiNOOW ACTUATOR RELAY

RUiRWINDOW ACTUlimR A L

WIPERS