Aid BMW 540i 1999 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1999, Model line: 540i, Model: BMW 540i 1999 E39Pages: 1002

Page 75 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-3

Engine Removal and lnstallationl

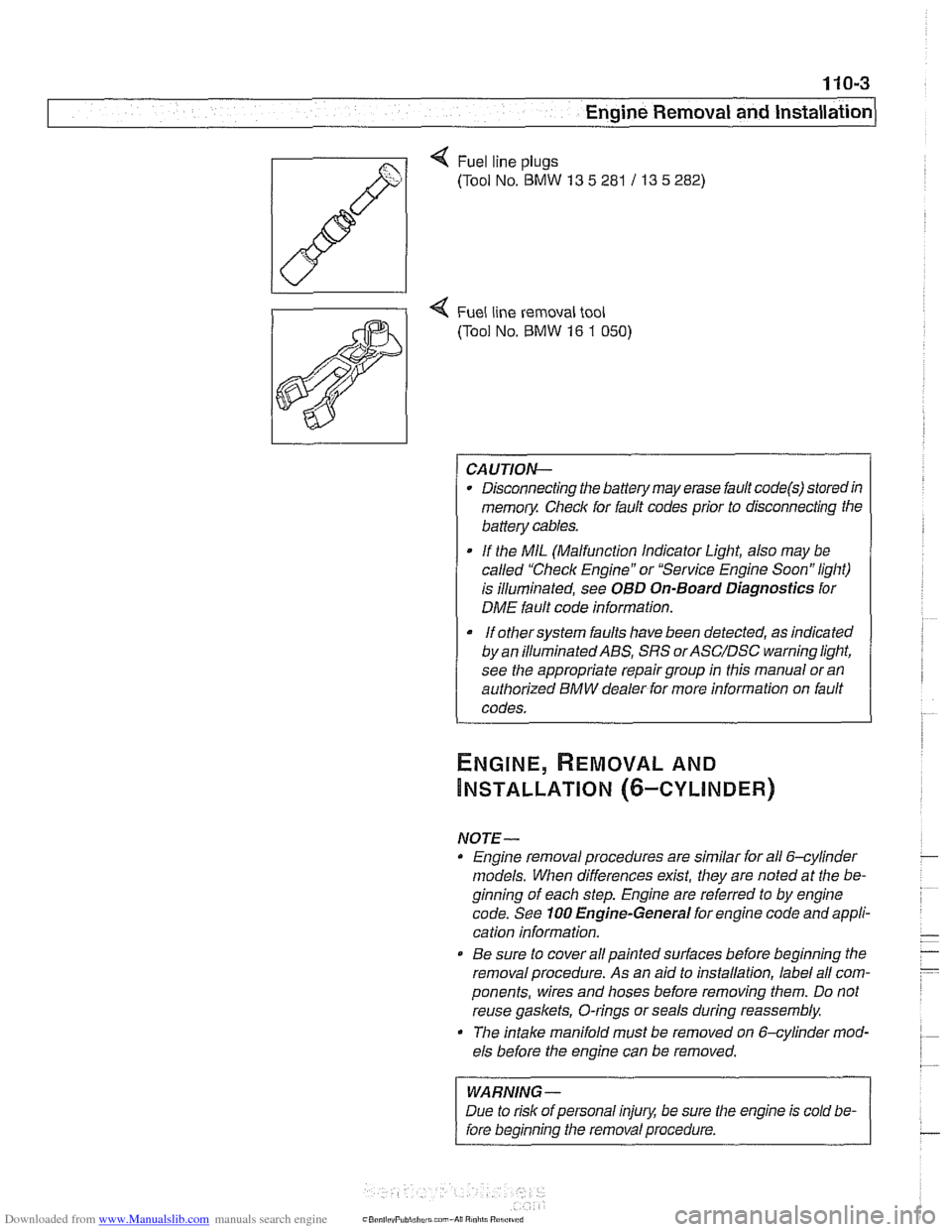

Q Fuel line plugs

(Tool No.

BMW 13 5 281 / 13 5 282)

4 Fuel line removal tool

(Tool No.

BMW 16 1 050)

CAUTION-

Disconnecting the battery may erase fault code@) storedin

memoiy Check for fault codes prior to disconnecting the

battery cables.

If the MIL (Malfunction Indicator Light, also may be

called "Check Engine" or "Service Engine Soon" light)

is illuminated, see

OBD On-Board Diagnostics for

DME fault code information.

It orhersysrem faults have been detected, as indicated I

by an ~llum~nated ABS, SRS orASC/DSC ~arning light,

see the appropriate repair group in this manual or an

authorized BMW dealer for more information on fault

codes.

NOTE- Engine removal procedures are similar for all 6-cylinder

models. When differences

exist, they are noted at the be-

ginning of each step. Engine are referred to by engine

code. See

100 Engine-General for engine code and appli-

cation information.

@ Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse

gaskets, O-rings or seals during reassembly.

The

intake manifold must be removed on &cylinder mod-

els before the engine can be removed.

WARNING-

Due to risk of personal injury, be sure the engine is cold be-

fore beginning the removal procedure.

Page 88 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-16

Engine Removal and Installation

ENGINE, REMOVAL AND

INSTALLATION (V-8 MODELS)

NOTE-

Engine removal procedures are similar for all V-8 models.

When differences exist, they are noted at the beginning of

each step. Engine are referred to by engine code. If neces-

sary, See

100 Engine-General for engine code andappli-

cation information.

Be sure to cover all painted surfaces before beginning the

removal procedure. As an aid to installation, label all com-

ponents, wires and hoses before removing them. Do not

reuse gaskets, O-rings or seals during reassembly

WARNING

-

Due to risk ofpersonal injury, be sure the engine is cold be-

fore beginning the

removal procedure.

- Disconnect negative (-) cable from battery.

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove engine hood or place hood in service position. See

410 Fenders, Engine Hood.

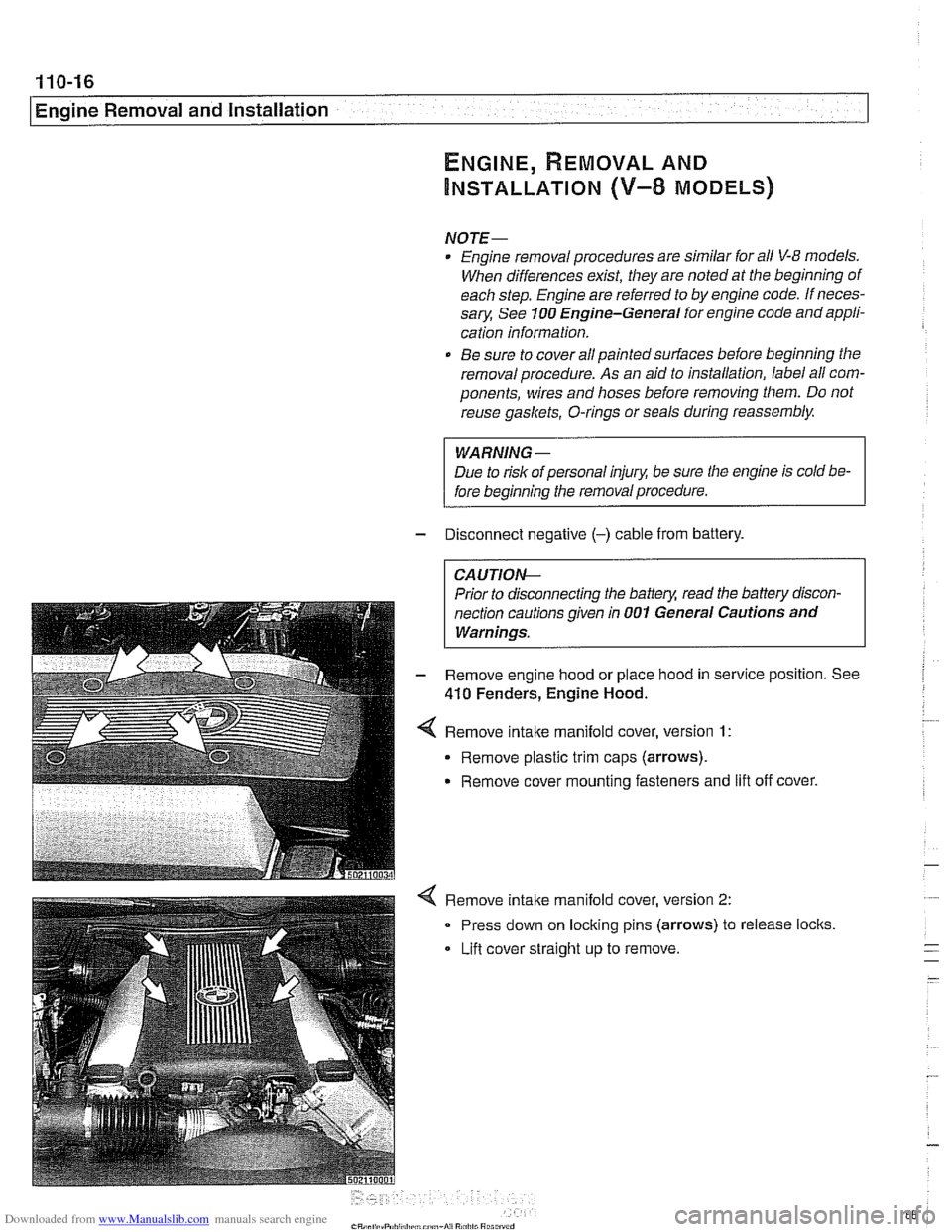

Remove

intake manifold cover, version 1:

Remove plastic trim caps (arrows).

Remove cover mounting fasteners and

lift off cover.

Remove intake manifold cover, version

2:

Press down on locking pins (arrows) to release locks

Lifl cover straight

up to remove.

Page 232 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 16-56

Cylinder Head and Valvetrain

This section covers valve removal and reconditioning, includ-

ing valve guides, seats, springs, and valve stem oil seals.

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes,

check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Valves, removing and installing

- Remove cylinder head as described in 113 Cylinder Head

Removal and Installation.

CAUTIOI\C

(M52 TU/M54 engines only) Do not let the hydraulic lifters

fall out as the camshaft carrier is removed. Special suction

cups are available from

BMW to hold the hydraulic lifters in

place during carrier removal.

* Hydraulic cam lifters should be stored m an uprfght po-

sition. If necessary, use a magnetic tool to

aidin remov-

al of the lifters.

- Remove valves using a valve spring compressor.

CAUTIOI\C

Label each valve assembly as it is removed so it can be in-

stalled in its original position.

-

- Remove and discard valve stem oil seals from valve guides.

See Valve stem oil seals later in this section.

- Valve installation is reverse of removal. Remove carbon de- - -

posits from the valves using a wire brush or wire wheel. -

-

Valve specifications are listed in Table c. Valve specifica-

tions.

Page 313 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

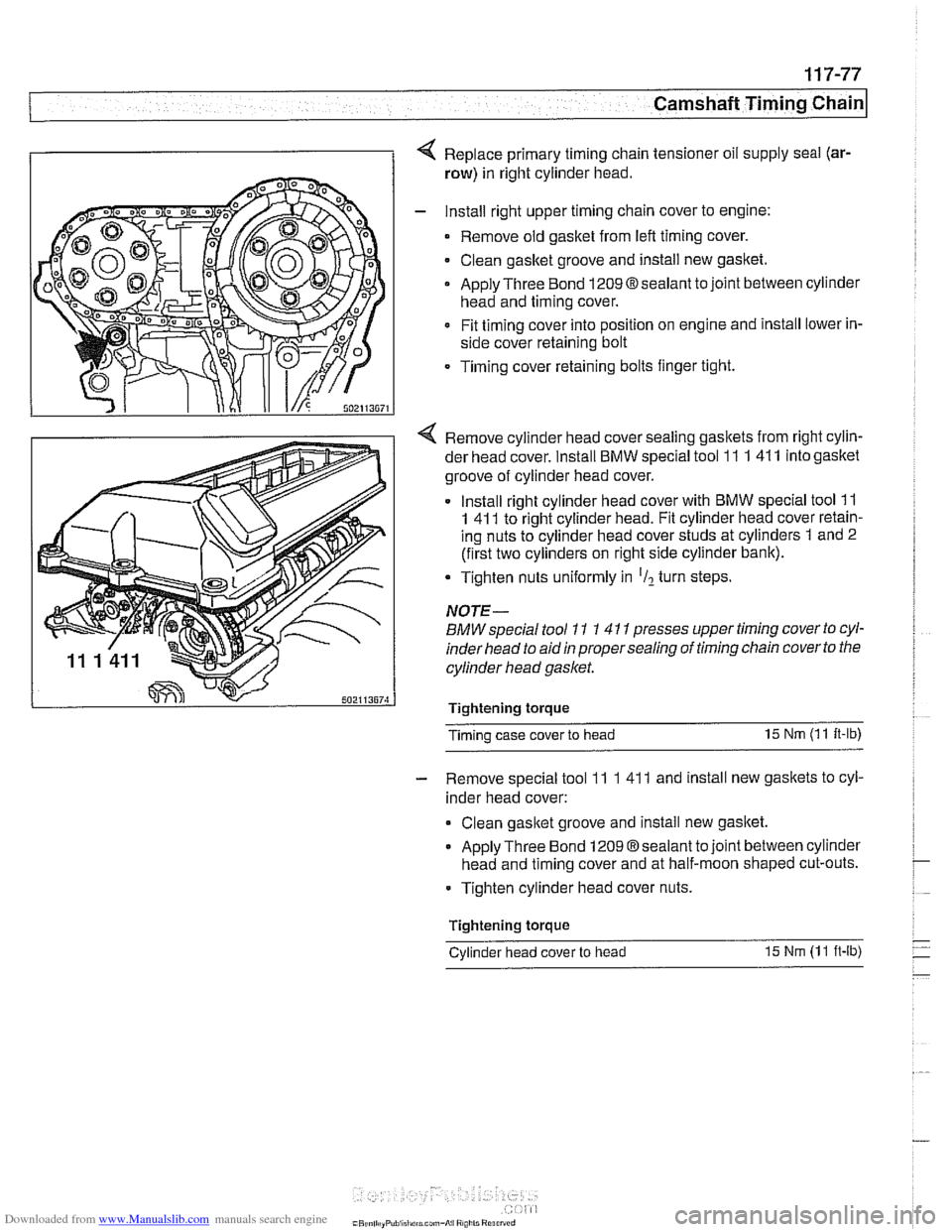

4 Replace primary timing chain tensioner oil supply seal (ar-

row) in right cylinder head.

- Install right upper timing chain cover to engine:

Remove old gasket from

left timing cover.

Clean gasket groove and install new gasket.

Apply Three Bond

1209Osealant to joint between cylinder

head and timing cover.

Fit timing cover into position on engine and install lower in-

side cover retaining bolt

Timing cover retaining bolts finger tight.

4 Remove cylinder head cover sealing gaskets from right cylin-

der head cover. Install

BMW special tool 11 1 41 1 into gasltet

groove of cylinder head cover.

Install right cylinder head cover with

BMW special tool 11

1 41 1 to right cylinder head. Fit cylinder head cover retain-

ing nuts to cylinder head cover studs at cylinders 1 and 2

(first two cylinders on right side cylinder bank).

Tighten nuts uniformly in

'Il turn steps.

NOTE-

BMW special tool 11 1 4 11 presses upper timing cover to cyl-

inder head to aid

in proper sealing of timing chain cover to the

cylinder head gasket.

Tightenlng torque

Timing case cover to head 15

Nm (1 1

It-lb)

- Remove special tool 11 1 41 1 and install new gaskets to cyl-

inder head cover:

Clean gasltet groove and install new gasltet.

Apply Three Bond 1209 Osealant to joint between cylinder

head and timing cover and at half-moon shaped cut-outs.

Tighten cylinder head cover nuts.

Tightenlng torque

-

Cylinder head cover to head 15 Nm (1 1 ft-lb)

Page 575 of 1002

Downloaded from www.Manualslib.com manuals search engine

230-1 1

Manual ~ransmissionl

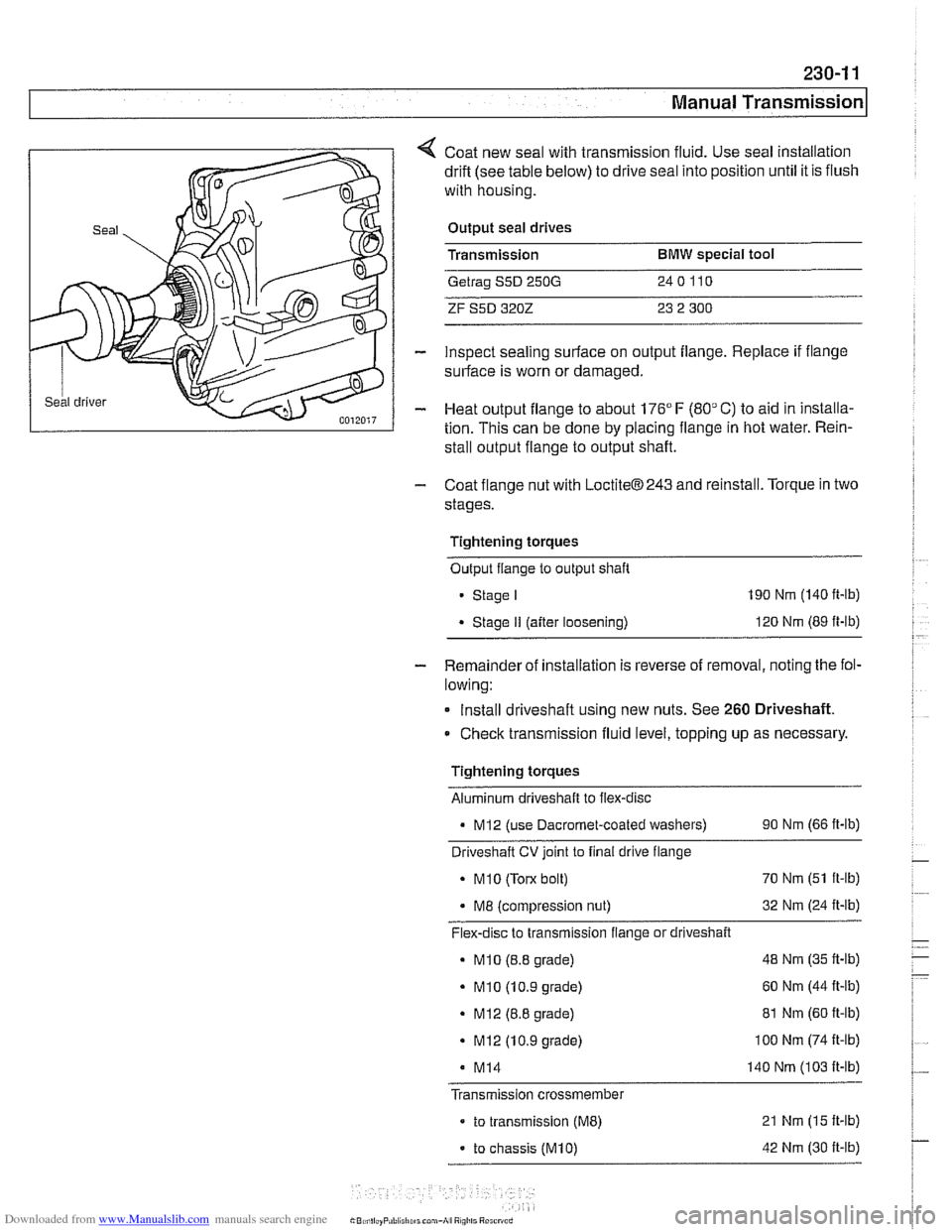

Coat new seal with transmission fluid. Use seal installation

drift (see table below) to drive seal into position until it is flush

with housing.

Output seal drives

Transmission

BMW special tool

Getrag S5D 250G 240110

ZF S5D 3202 23 2 300

inspect sealing surface on output flange. Replace if flange

surface is worn or damaged.

Heat output flange to about 176"

F (80" C) to aid in installa-

tion. This can be done by placing flange in hot water. Rein-

stall output flange to output shaft.

- Coat flange nut with LoctiteB243 and reinstall. Torque in two

stages.

Tightening torques Output flange to output shaft

Stage I 190 Nm (140 ft-lb)

Stage II (after loosening) 120

Nm (89 ft-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Install driveshaft using new nuts. See

260 Driveshaft.

Check transmission fluid level, topping up as necessary

Tightening torques Aluminum driveshaft to flex-disc

- MI2 (use Dacromet-coated washers) 90 Nm (66 ft-lb)

Driveshaft

CV joint to final drive flange

. MI0 (Torx bolt) 70

Nm (51 ft-lb)

. M8 (compression nut) 32

Nm (24 ft-lb)

Flex-disc to transmission flange or driveshaft

- MI0 (8.8 grade) 48

Nm (35 ft-lb)

- MI0 (10.9 grade) 60

Nm (44 It-lb)

. MI2 (8.8 grade) 81 Nm (60 ft-lb)

. MI2 (10.9 grade) I00 Nm (74 It-lb)

M14 140 Nm (103 It-lb)

Transmission crossmember

- to transmission (ME) 21 Nm (15 It-lb)

- to chassis (M10) 42 Nm (30 It-lb)

Page 797 of 1002

Downloaded from www.Manualslib.com manuals search engine

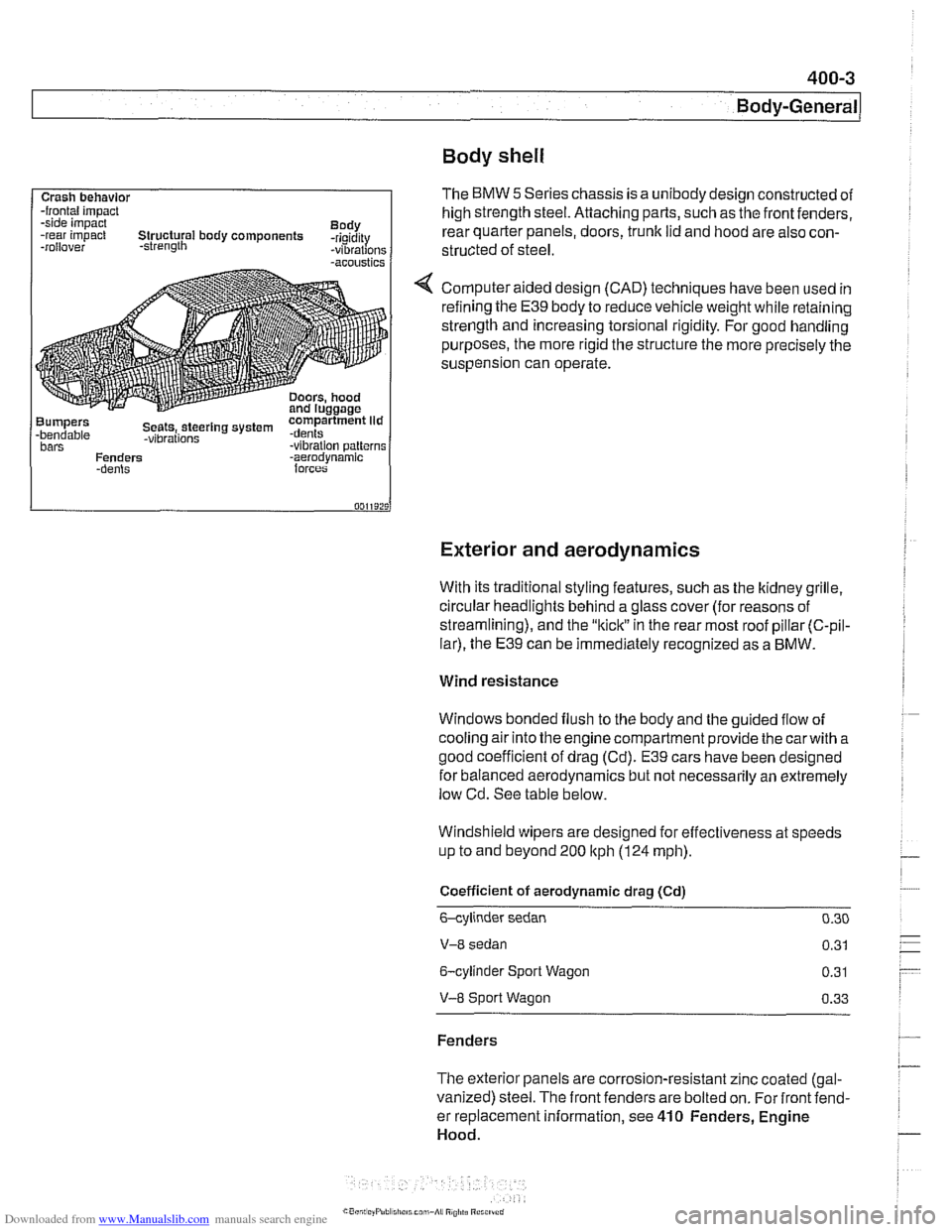

Body shell

Exterior and aerodynamics

Crash behavlor -frontal impact

-side impact

Body

-rear impact Structural body components -rigidity

-rollover -strength -vibrations -acoustics

Bumpers compartment lid -bendable Seets,.steerlng system .dents -vibrations bars -vibration patterns

Fenders -aerodvnamic

With its traditional styling features, such as the ltidney grille.

circular headlights behind a glass cover (for reasons of

streamlining), and the

"kiclt" in the rear most roof pillar (C-pil-

lar), the E39 can be immediately recognized as a BMW.

The BMW 5 Series chassis is a unibody design constructed of

high strength steel. Attaching parts, such as the front fenders,

rear quarter panels, doors,

trunk lid and hood are also con-

structed of

steel.

Computer aided design (CAD) techniques have been used in

refining the

E39 body to reduce vehicle weight while retaining

strength and increasing torsional rigidity. For good handling

purposes, the more rigid the structure the more precisely the

suspension can operate.

Wind resistance

Windows bonded flush to the body and the guided flow of

cooling air into the engine compartment provide the

carwith a

good coefficient of drag (Cd).

E39 cars have been designed

for balanced aerodynamics but not necessarily an extremely

low Cd. See table below.

Windshield wipers are designed for effectiveness at speeds

up to and beyond 200

ltph (124 mph).

Coefficient of aerodynamic drag (Cd)

6-cylinder sedan 0.30

V-8 sedan 0.31

6-cylinder Sport Wagon 0.31

V-8 Sport Wagon 0.33

Fenders

The exterior panels are corrosion-resistant zinc coated (gal-

vanized) steel. The front fenders are bolted on. For front fend-

er replacement information, see

410 Fenders, Engine

Hood.