Bolt Torque BMW 540i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 134 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-40

I Cylinder Head Removal and Installation

Lubricate camshafts, camshaft carriers, bearing caps, hy-

draulic lifters, friction washers, splined shafts and spline hubs

with assembly lubricant before installation.

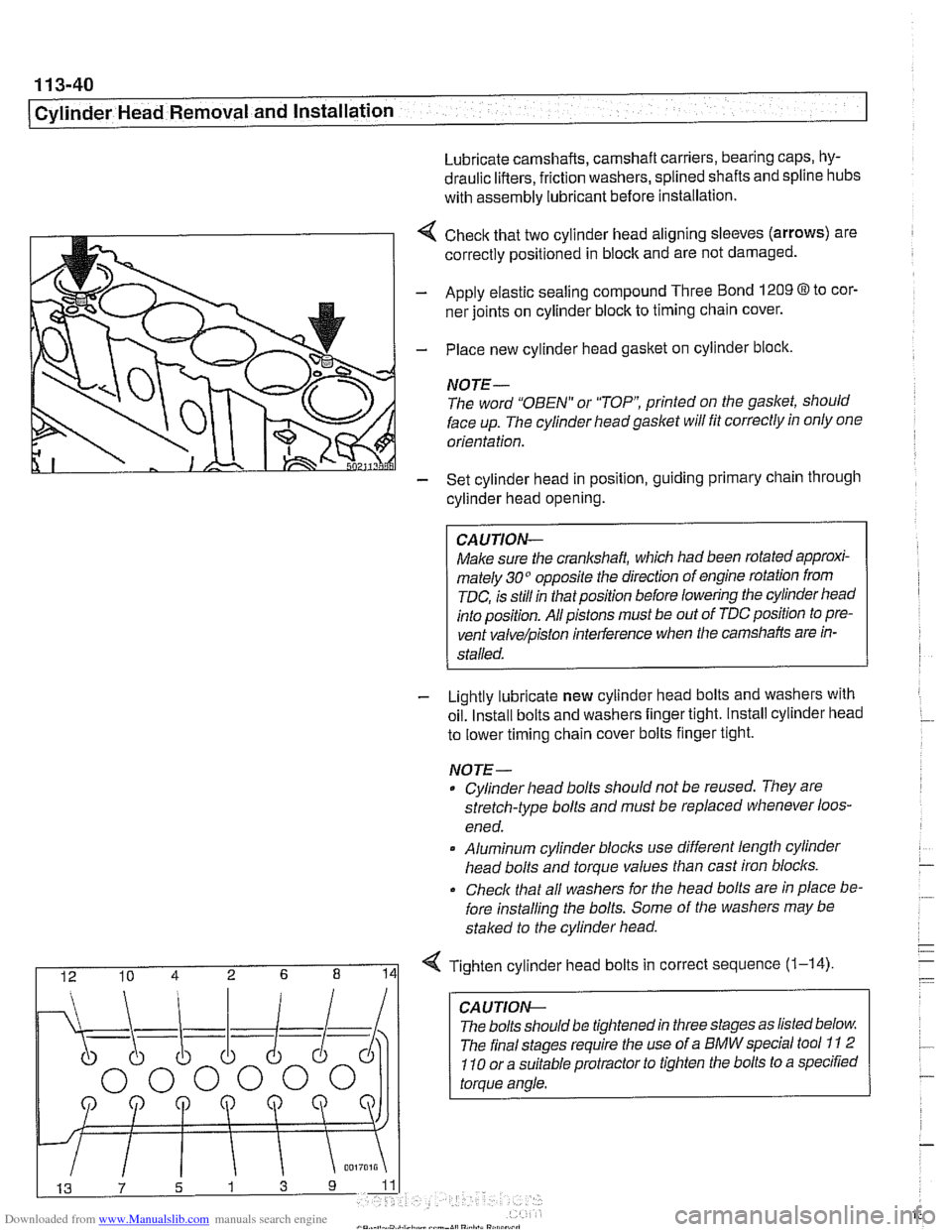

4 Check that two cylinder head aligning sleeves (arrows) are

correctly positioned in block and are not damaged.

- Apply elastic sealing compound Three Bond 1209 8 to cor-

ner joints on cylinder block to timing chain cover.

- Place new cylinder head gasket on cylinder block.

NOTE-

The word "OBEN" or "TOP printed on the gasket, should

face up. The cylinder headgaslet will fit correctly in only one

orientation.

- Set cylinder head in position, guiding primary chain through

cylinder head opening.

CAUJION-

Make sure the crankshaft, which had been rotated approxi-

mately 30" opposite the direction of engine rotation from

TDC, is still in thatposition before lowering the cylinder head

into position. All pistons must be out of TDC position to pre-

vent

valve/piston interference when the camshafts are in-

stalled.

- Lightly lubricate new cylinder head bolts and washers with

oil. Install bolts and washers finger tight. Install cylinder head

to lower timing chain cover bolts finger tight.

NOJE-

Cylinder head bolts should not be reused. They are

stretch-type bolts and must be replaced whenever loos-

ened.

* Aluminum cylinder blocls use different length cylinder

head bolts and torque values than cast iron blocks.

Check that all washers for

Nle head bolts are in place be-

fore installing the bolts. Some of the washers may be

staked to the cylinder head.

I 12 10 4 2 6 8 141 Tighten cylinder head bolts in correct sequence (1-14)

CA U TIOW-

The bolts should be tightened in three stages as listed below

The final stages require the use of a BMW special tool

11 2

110 or a suitable protractor to tighten the bolts to a specified

torque angle.

Page 135 of 1002

![BMW 540i 2000 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

T BMW 540i 2000 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

T](/img/1/2822/w960_2822-134.png)

Downloaded from www.Manualslib.com manuals search engine

. - ..

Cylinder Head Removal and installation] --

- Secure cylinder head bolts by torquing an additional 90"

each for Stage 2 and 3.

Tightening torques

Cylinder head to engine block

(aluminum block)

Stage

1 40 Nm (30 it-lb)

Stage 2 +90°

Stage 3 80'

4 lnstall intake camshaft position sensor (arrow).

4 Install lower secondary chain guide. Tighten tom bolts to

specifications. The bolt on the intake camshaft side is long

and extends into the engine block.

4 Install and tighten cylinder head-to-lower timing chain cover

bolts (arrows). (Photo shows camshafts in place).

Tightening torque Secondary chain guide to cylinder head

10 Nm (89 in-lb)

Cylinder head to lower timing chain cover

M6 10 Nm (89 in-lb)

M7 15 Nm (1 1 it-lb)

Page 137 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

Cylinder Head Removal and Installation

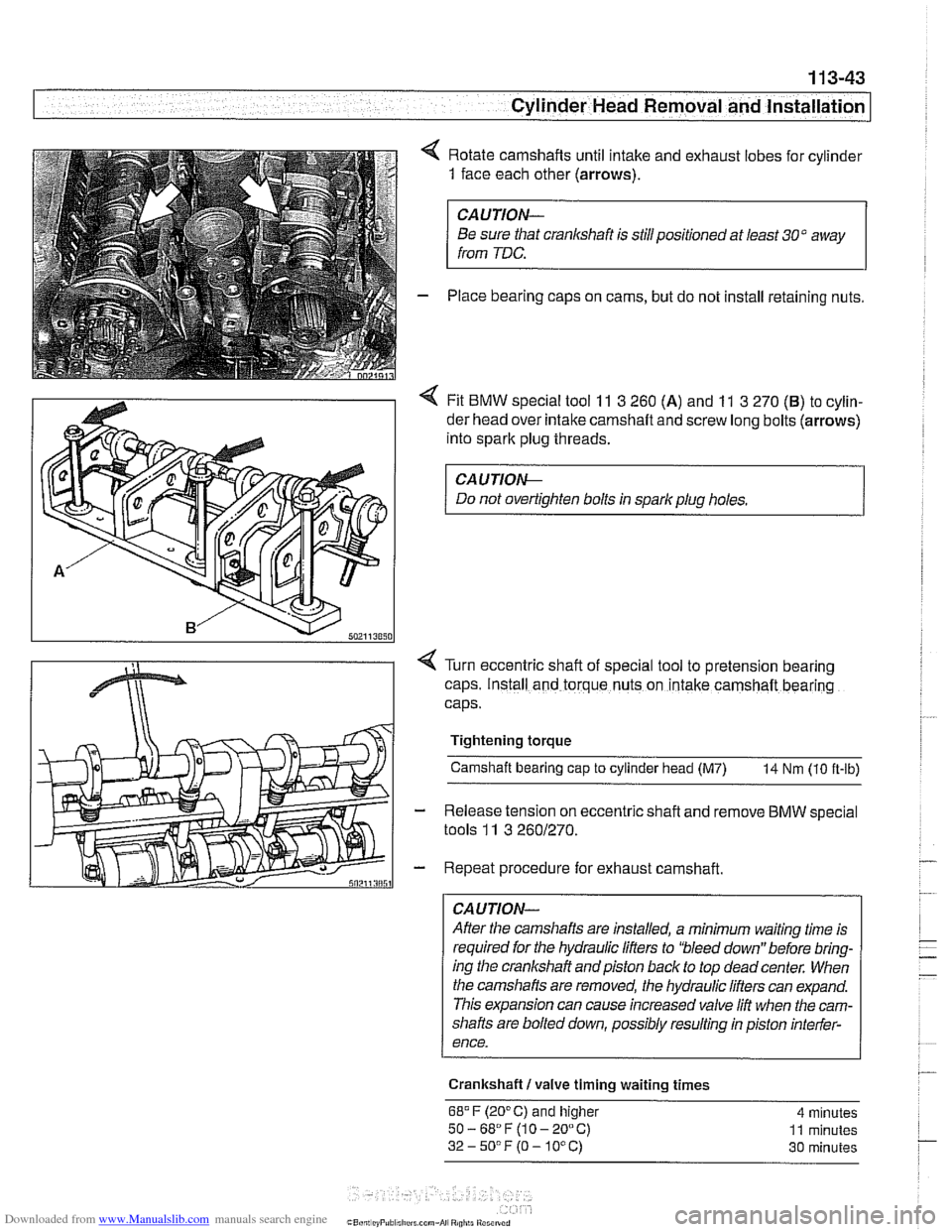

4 Rotate camshafts until intake and exhaust lobes for cylinder

1 face each other (arrows).

CAUTION-

Be sure that cranlcshaft is stillpositioned at least 30" away

from

TDC.

- Place bearing caps on cams, but do not install retaining nuts.

4 Fit BMW special tool 11 3 260 (A) and 11 3 270 (B) to cylin-

der head over intake camshaft and screw long bolts (arrows)

into spark plug threads.

CAUTIOI\C

Do not overtighten bolts in spark plug holes.

Turn eccentric shaft of special tool to pretension

bearing

caps. Install and torque nuts on intake camshaft bearing

caps.

Tightening torque Camshaft bearing

cap to cylinder head (M7) 14 Nm (10 ft-lb)

Release tension on eccentric

shaft and remove BMW special

tools

11 3 2601270.

Repeat procedure for exhaust camshaft.

CAUTION-

After the camshafts are installed, a minimum waiting time is

required for the hydraulic lifters to 'bleed down" before bring-

ing the crankshaft andpiston back to top

deadcenter. When

the camshafts are removed, the hydraulic lifters can expand.

This expansion can cause increased valve lift when the cam-

shafts are bolted down, possibly resulting in piston interfer-

ence.

Crankshaft

I valve timing waiting times

68.F (20°C) and higher 4 minutes

50-68"F(10-20°C) 11 minutes

32-5O0F(O-10°C) 30 minutes

Page 148 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." ".

[Cylinder Head Removal and Installation - .. - -1 -

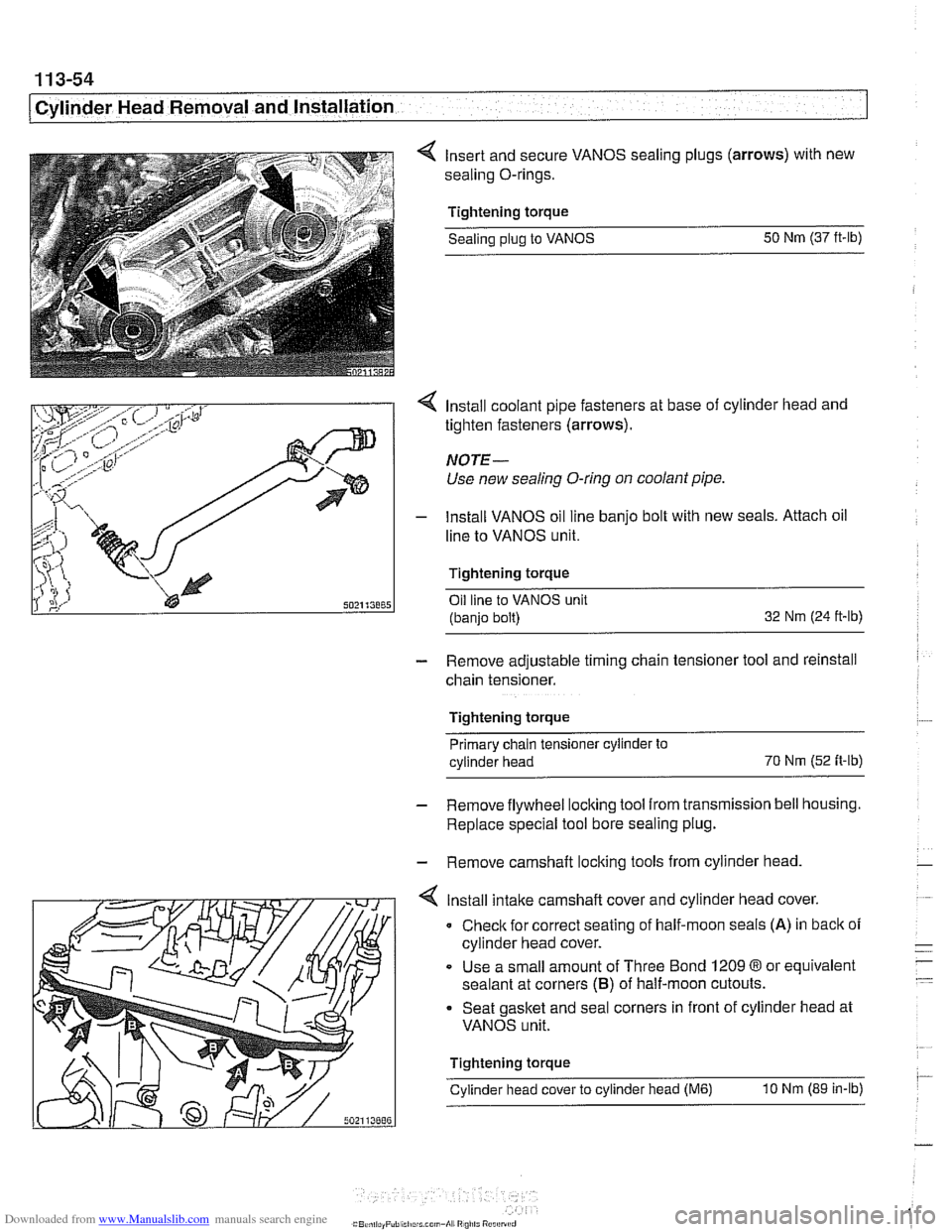

4 Insert and secure VANOS sealing plugs (arrows) with new

sealing O-rings.

Tightening torque Sealing

plug to VANOS 50

Nm (37 ft-lb)

4 Install coolant pipe fasteners at base of cylinder head and

tighten fasteners (arrows).

NOTE-

Use new sealing O-ring on coolant pipe.

- lnstall VANOS oil line banjo bolt with new seals. Attach oil

line to VANOS unit.

Tightening torque Oil line to VANOS unit

(banjo bolt) 32

Nm (24 ft-ib)

- Remove adjustable timing chain tensioner tool and reinstall

chain tensioner.

Tightening torque Primary chain tensioner cylinder to

cylinder head 70

Nm

(52 fi-ib)

- Remove flywheel locking tool from transmission bell housing.

Replace special tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

4 lnstall intake camshaft cover and cylinder head cover.

0 Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

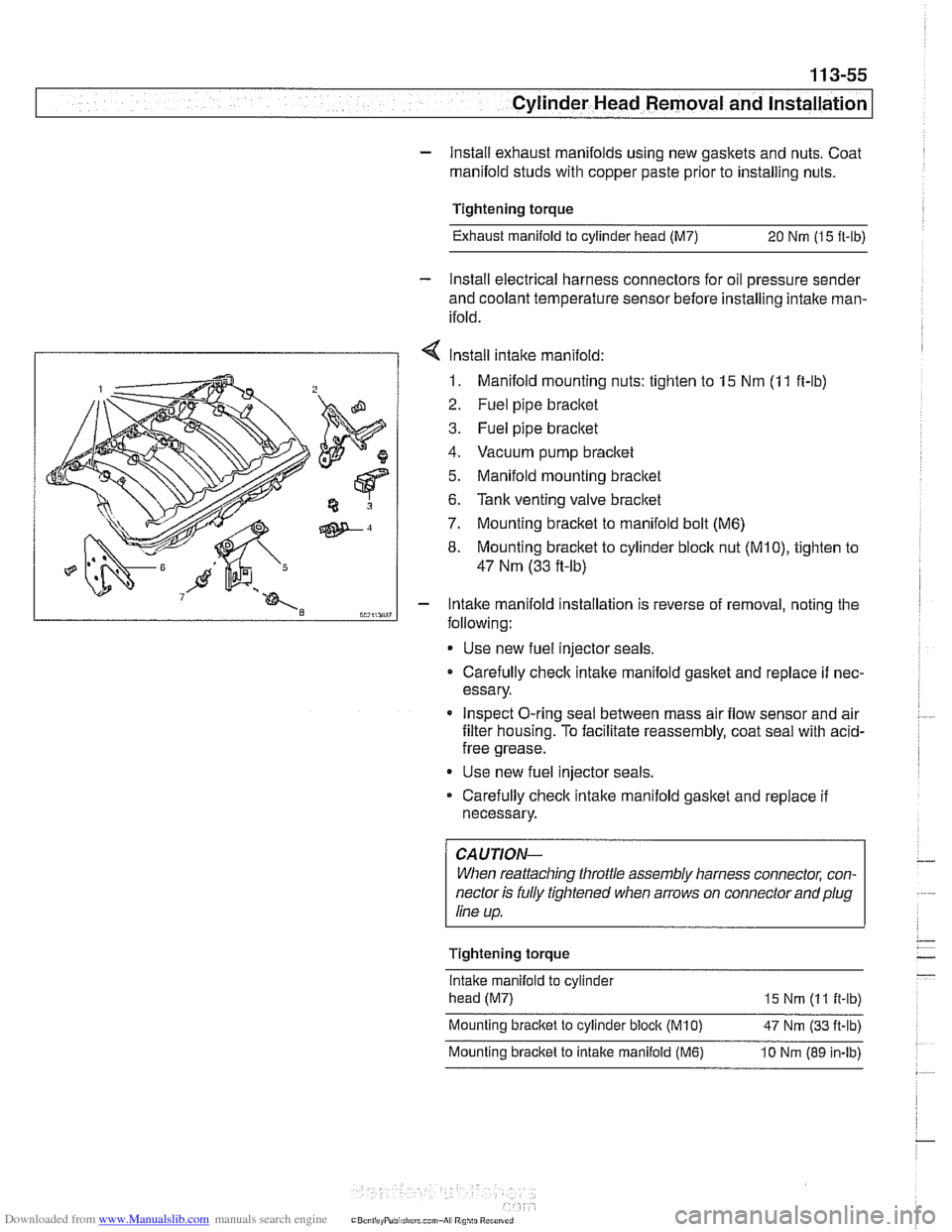

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)

Page 160 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

I Cylinder Head Removal and Installation

- Evaluate cylinder head as described in 116 Cylinder head

and valvetrain.

Left cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket

debris, making sure no debris drops into coolant or oil pas-

sages.

- Clean cylinder head bolt holes and check condition of

threads.

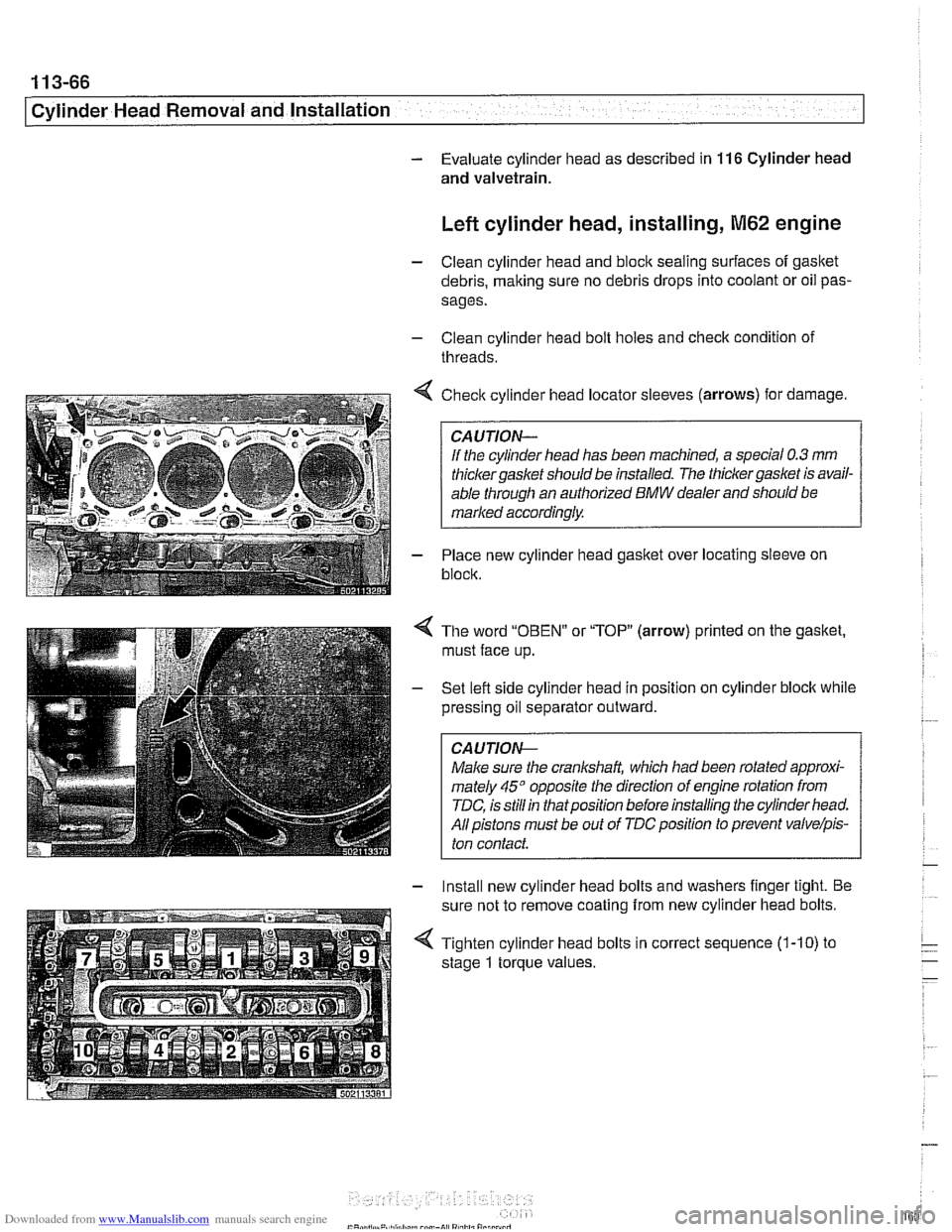

< Check cylinder head locator sleeves (arrows) for damage.

If the cylinder head has been machined, a special

0.3 mm

thicker gasket should be installed. The thicker gasket is avail-

able through an authorized

BMW dealer and should be

marked accordingly.

- Place new cylinder head gasket over locating sleeve on

block.

The word

"OBEN" or "TOP" (arrow) printed on the gasket,

must face up.

Set lefl side cylinder head in position on cylinder block while

pressing oil separator outward.

CAUJION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is still in thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valvelpis-

ton contact.

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from new cylinder head bolts.

4 Tighten cylinder head bolts in correct sequence (1-10) to

stage

1 torque values.

Page 161 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-67

Cylinder Head Removal and lnstaKI --

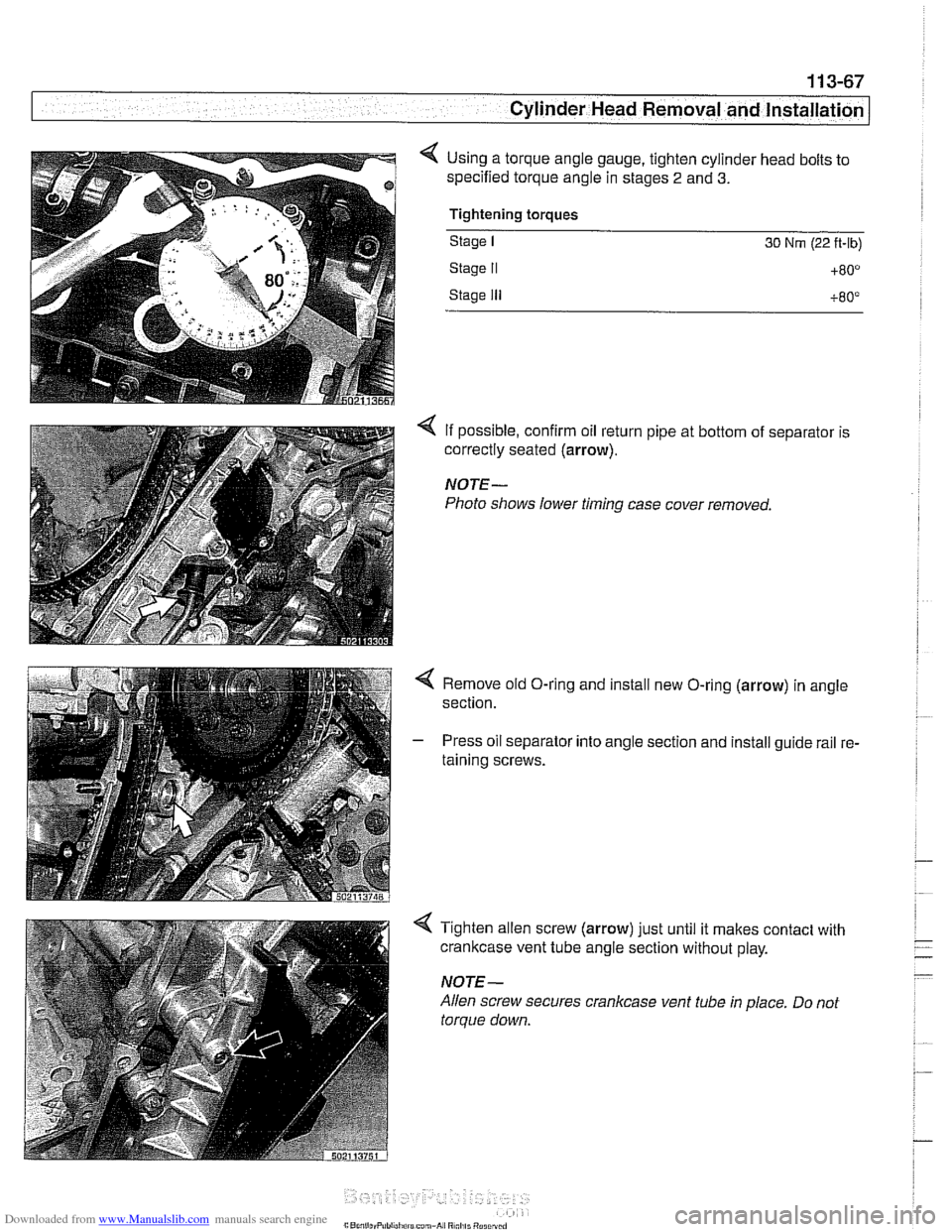

< Using a torque angle gauge, tighten cylinder head bolts to

specified torque angle in stages

2 and 3.

Tightening torques

Stage I 30 Nrn (22 ft-lb)

Stage II +80°

Stage Ill +80°

4 If possible, confirm oil return pipe at bottom of separator is

correctly seated

(arrow).

NOTE-

Photo shows lower timing case cover removed.

< Remove old O-ring and install new O-ring (arrow) in angle

section.

- Press oil separator into angle section and install guide rail re-

taining screws.

4 Tighten allen screw (arrow) just until it makes contact with

crankcase vent tube angle section without play.

NOTE-

Allen screw secures crankcase vent tube in place. Do not

torque down.

Page 163 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-69

Cylinder Head Removal and Installation

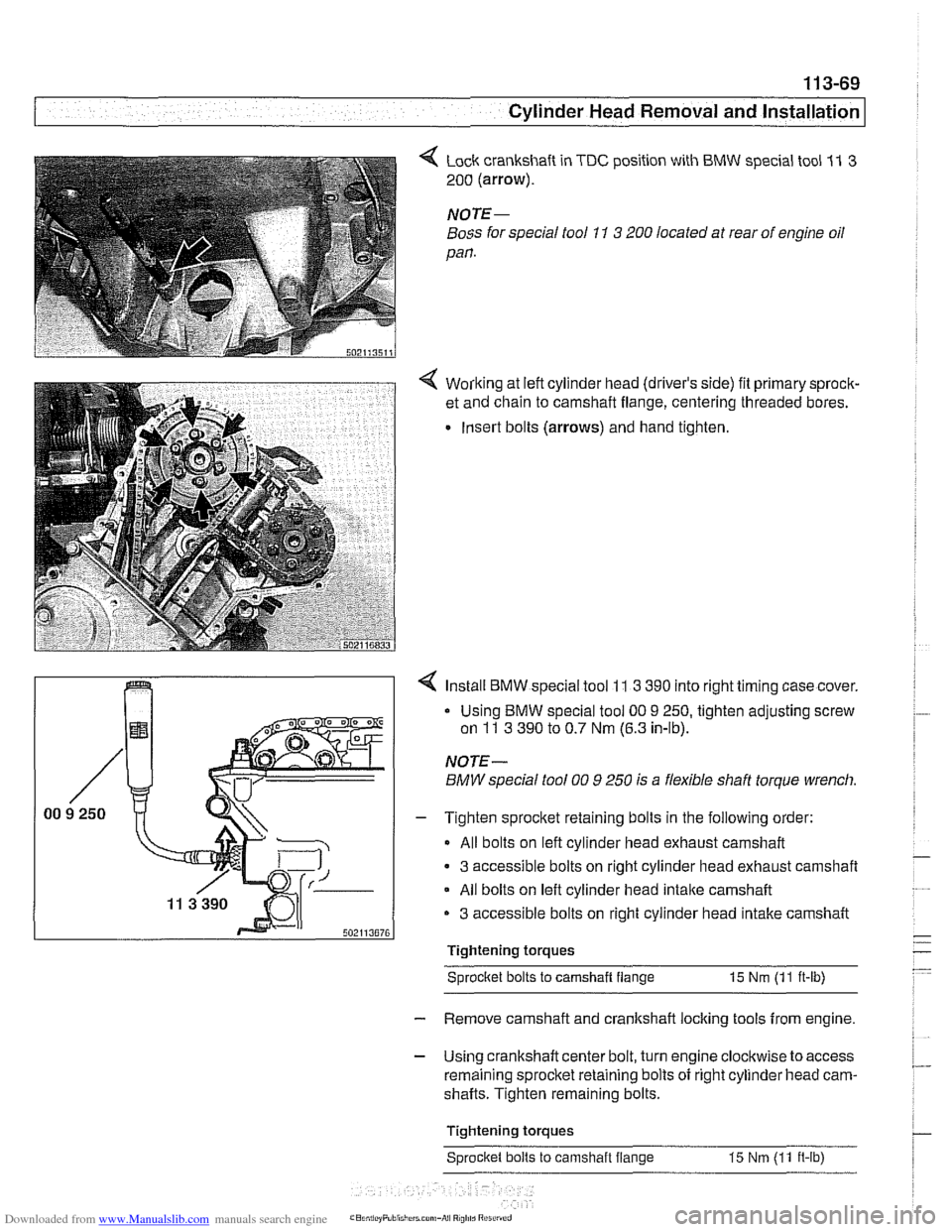

4 Lock crankshaft in TDC position with BMW special tool 11 3

200 (arrow).

NOTE-

Boss for special tool 11 3 200 located at rear of engine oil

pan.

4 Working at left cylinder head (driver's side) fit primary sprock-

et and chain to camshaft flange, centering threaded bores.

Insert bolts (arrows) and hand tighten.

?-I I 4 Install BMW special tool 11 3 390 into right timing case cover.

NOTE-

BMW special tool 00 9 250 is a flexible shaft torque wrench.

I - Tighten sprocket retaining bolts in the following order:

All bolts on left cylinder head exhaust camshaft

3 accessible bolts on right cylinder head exhaust camshaft

All bolts on left cylinder head

intake camshaft

3 accessible bolts on right cylinder head intake camshaft r"".."..7n

Tightening torques

Sprocltet bolts to camshait flange

15 Nm (11 ft-lb)

- Remove camshaft and crankshaft locking tools from engine.

- Using crankshaft center bolt, turn engine clockwise to access

remaining sprocket retaining bolts of right cylinder head cam-

shafts. Tighten remaining bolts.

Tightening torques Sprocket bolts to camshaft flange 15 Nm

(11 ft-lb)

Page 165 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." . .

I - Cylinder Head Removal - and instard --

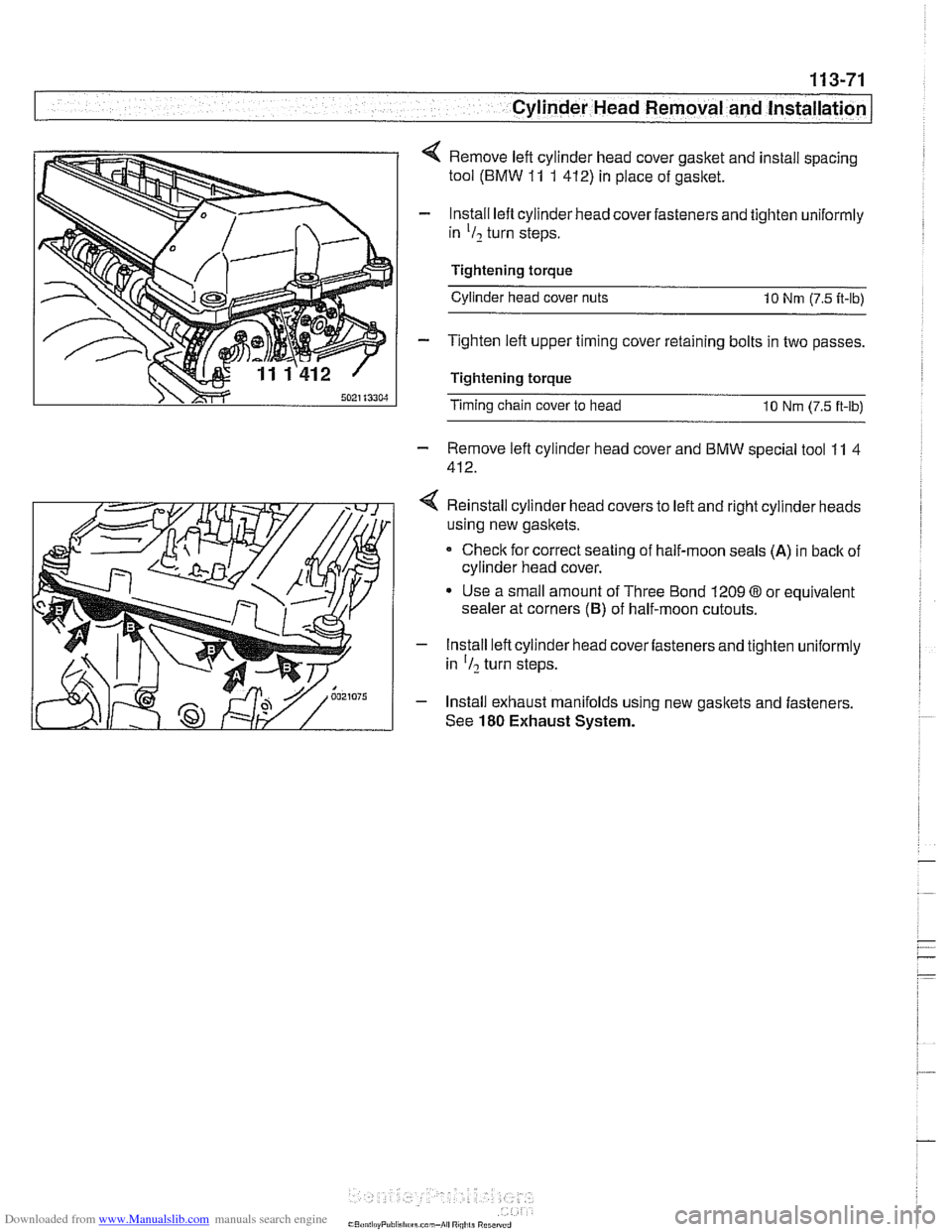

4 Remove left cylinder head cover gasket and install spacing

tool (BMW

11 1 412) in place of gasket.

- lnstall lefl cylinder head cover fasteners and tighten uniformly

in

'I2 turn steps.

Tightening torque Cylinder head cover nuts

10 Nrn (7.5 it-lb)

- Tighten left upper timing cover retaining bolts in two passes.

Tightening torque

Timing chain cover to head 10 Nrn (7.5 ft-lb)

- Remove lefl cylinder head cover and BMW special tool 11 4

412.

4 Reinstall cylinder head covers to left and right cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

03 or equivalent

sealer at corners

(6) of half-moon cutouts.

- Install left cylinder head cover fasteners and tighten uniformly

in

'I? turn steps.

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.

Page 171 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cvlinder Head Removal and Installation /

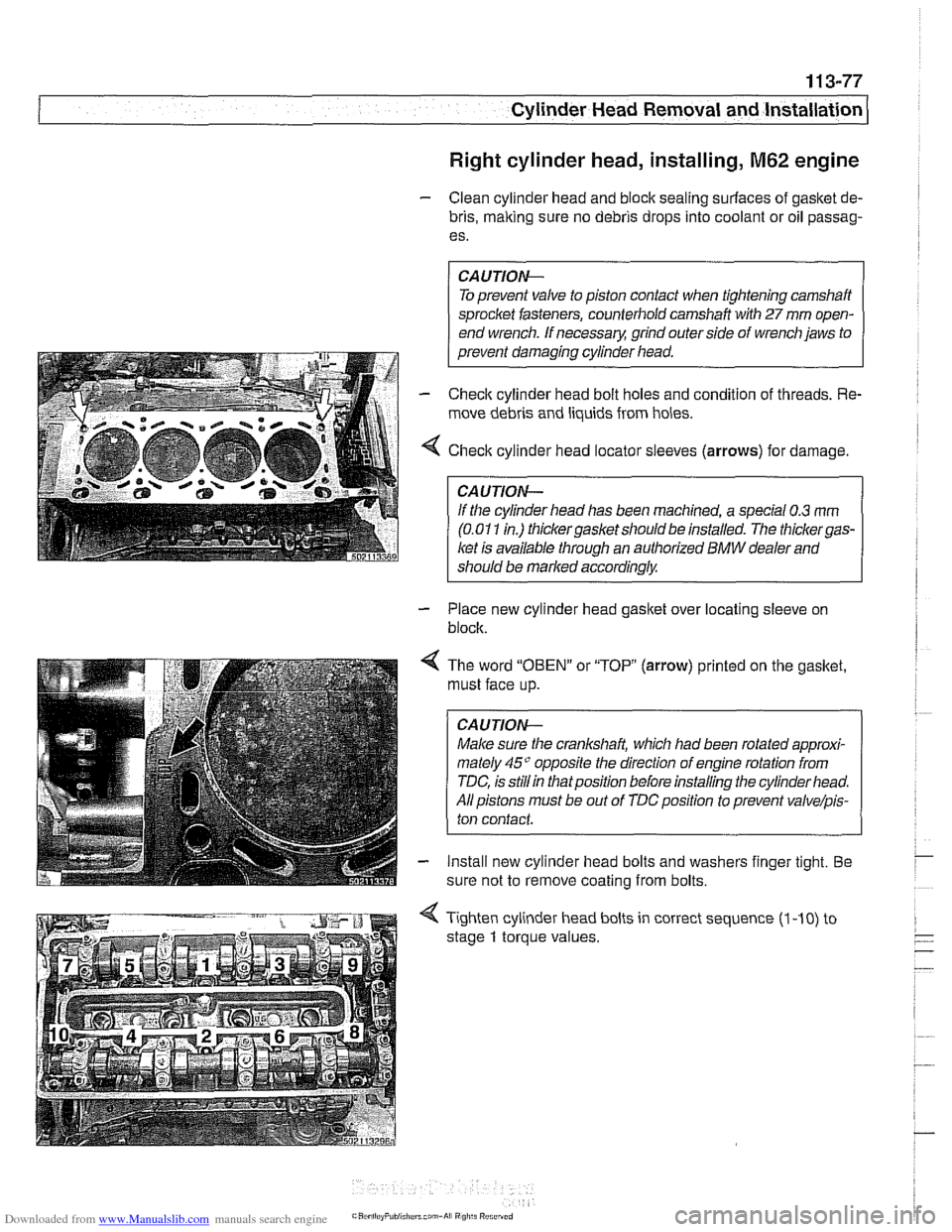

Right cylinder head, installing, M62 engine

- Clean cylinder head and block sealing surfaces of gasket de-

bris, making sure no debris drops into coolant or oil passag-

es.

CA UTIOW-

To prevent valve to piston contact when tightening camshaft

sprocket fasteners, counterhold camshaft with

27 mm open-

end wrench. If

necessarq: grind outer side of wrench jaws to

prevent damaging cylinder head.

- Check cylinder head bolt holes and condition of threads. Re-

move debris and liquids from holes.

4 Check cylinder head locator sleeves (arrows) for damage

CAUTION-

lithe cylinder head has been machined, a special 0.3 rnm

(0.01 1 in.) thickergasket should be installed. The thickergas-

ket is available through an authorized BMW dealer and

should be marked

accordinglw

- Place new cylinder head gasket over locating sleeve on

block.

< The word "OBEN" or "TOP (arrow) printed on the gasket.

must face up.

CAUTION-

Male sure the crankshaft, which had been rotated approxi-

mately

45" opposite the direction of engine rotation from

TDC, is

stillin thatposition before installing the cylinder head.

All pistons must be out of

TDCposition to prevent valve/pis-

ton contact

- Install new cylinder head bolts and washers finger tight. Be

sure not to remove coating from bolts.

4 Tighten cylinder head bolts in correct sequence (1 -10) to

stage

1 torque values.