length BMW 540i 2000 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 583 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

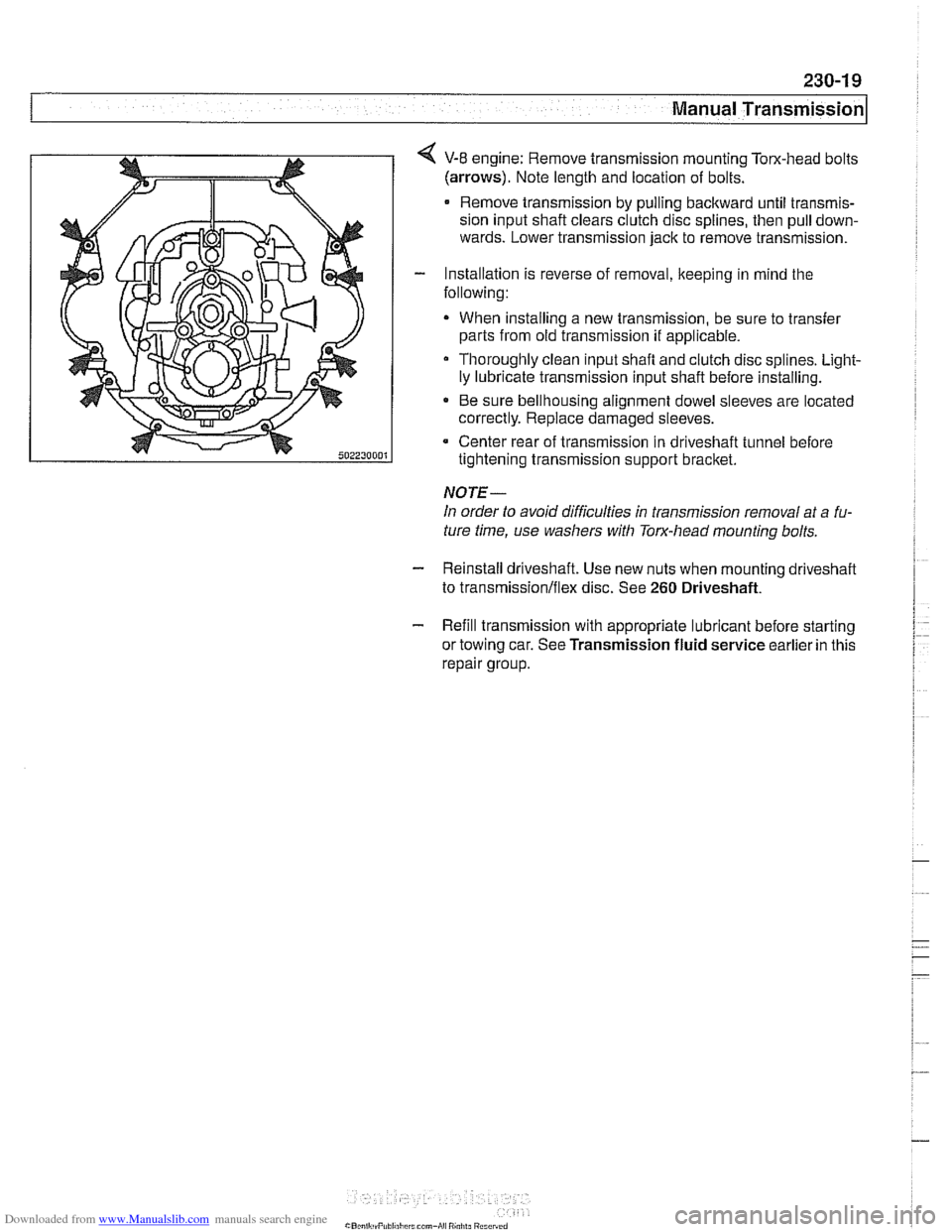

4 V-8 engine: Remove transmission mounting Tom-head bolts

(arrows). Note length and location of bolts.

Remove transmission by pulling backward until transmis-

sion input shaft clears clutch disc splines, then pull down-

wards. Lower transmission jack to remove transmission.

- Installation is reverse of removal, keeping in mind the

following:

When installing a new transmission, be sure to transfer

parts from old transmission

if applicable.

Thoroughly clean input shafl and clutch disc splines. Light-

ly lubricate transmission input shaft before installing.

* Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Center rear of transmission in driveshaft tunnel before

tightening transmission support bracket.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

- Reinstall driveshaft. Use new nuts when mounting driveshaff

to transmission/flex disc. See 260 Driveshaft.

- Refill transmission with appropriate lubricant before starting

or towing car. See Transmission fluid service earlier in this

repair group.

Page 690 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-32

Steering and Wheel Alignment

Center tie

rod, replacing

- Raise front of car. Remove splash shield from under engine.

WARNING-

Make sure tlie car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

cliassis points. Do not place jack stands under suspension

parts.

- Measure length of left and right (outer) tie rods. Write down

measurements.

NOTE-

Accurate measurement of the tie rod end with reference to

the center tie rod will help approximate correct wheel align-

ment when new parts are installed.

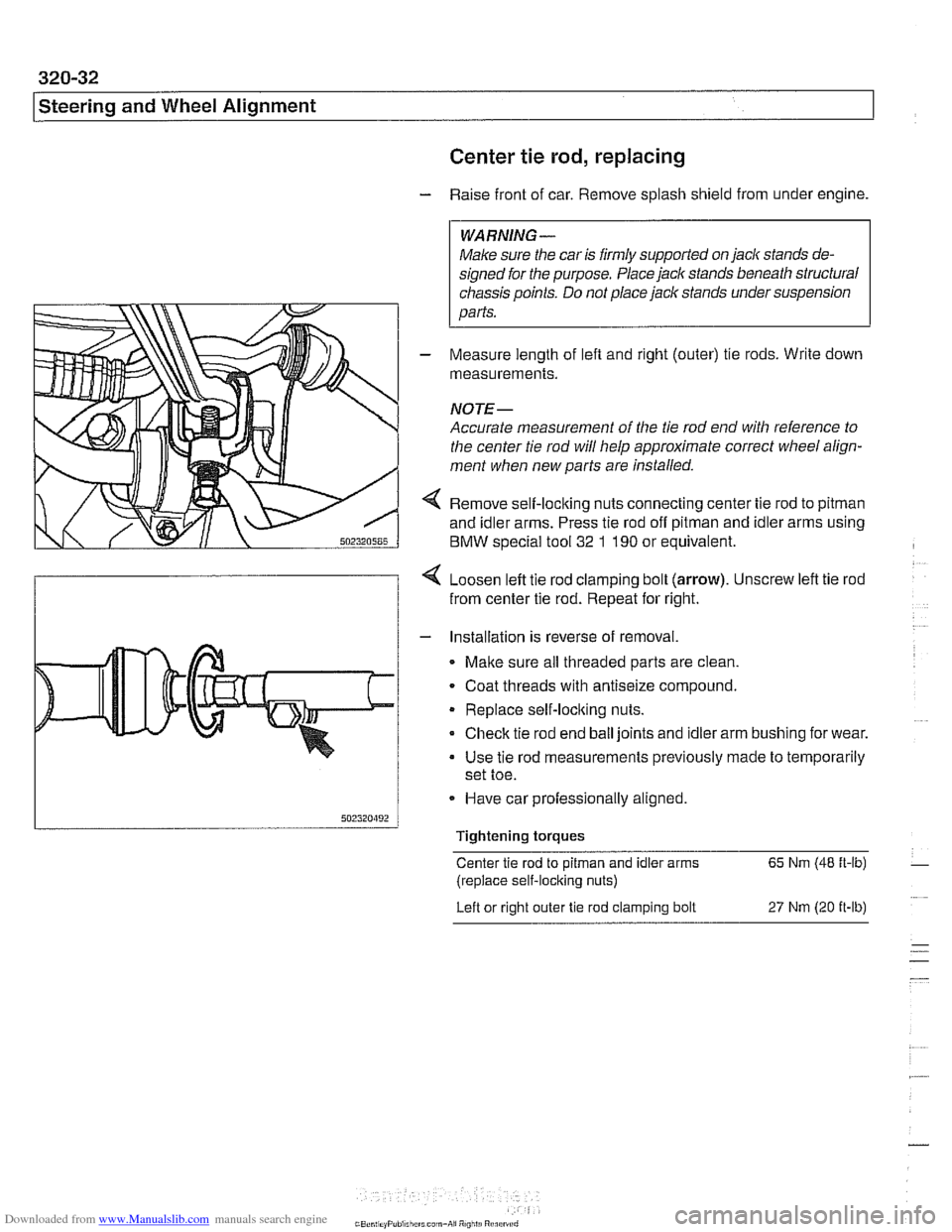

4 Remove self-loclting nuts connecting center tie rod to pitman

and idler arms. Press tie rod off pitman and idler arms using

BMW special tool

32 1 190 or equivalent.

4 Loosen left tie rod clamping bolt (arrow). Unscrew left tie rod

from center tie rod. Repeat for right.

- Installation is reverse of removal.

Malte sure all threaded parts are clean.

. Coat threads with antiseize compound.

Replace self-loclting nuts.

Check tie rod end ball joints and idler arm bushing for wear.

Use tie rod measurements previously made to temporarily

set toe.

- Have car professionally aligned.

Tightening torques

Center tie rod to

pitman and idler arms 65 Nm (48 ft-lb)

(replace self-locking nuts)

Left or right outer

tie rod clamping bolt 27 Nm (20 it-lb)

Page 692 of 1002

Downloaded from www.Manualslib.com manuals search engine

320-34

I Steerins and Wheel Alignment

Front toe and toe difference angle

Toe is the difference in the distance between the front of the

front wheels and the rear of the front wheels. It is adjusted by

altering the length of the tie rods.

Toe difference angle determines the progressively different

paths taken by the front wheels as the car is turning. In

V-8

models, it is set by the pitman arm adjustment, but depends

on accurate setting of the toe.

Toe adjustments should only be made on specialized align-

ment equipment and only with the car in normal loaded posi-

tion, described below.

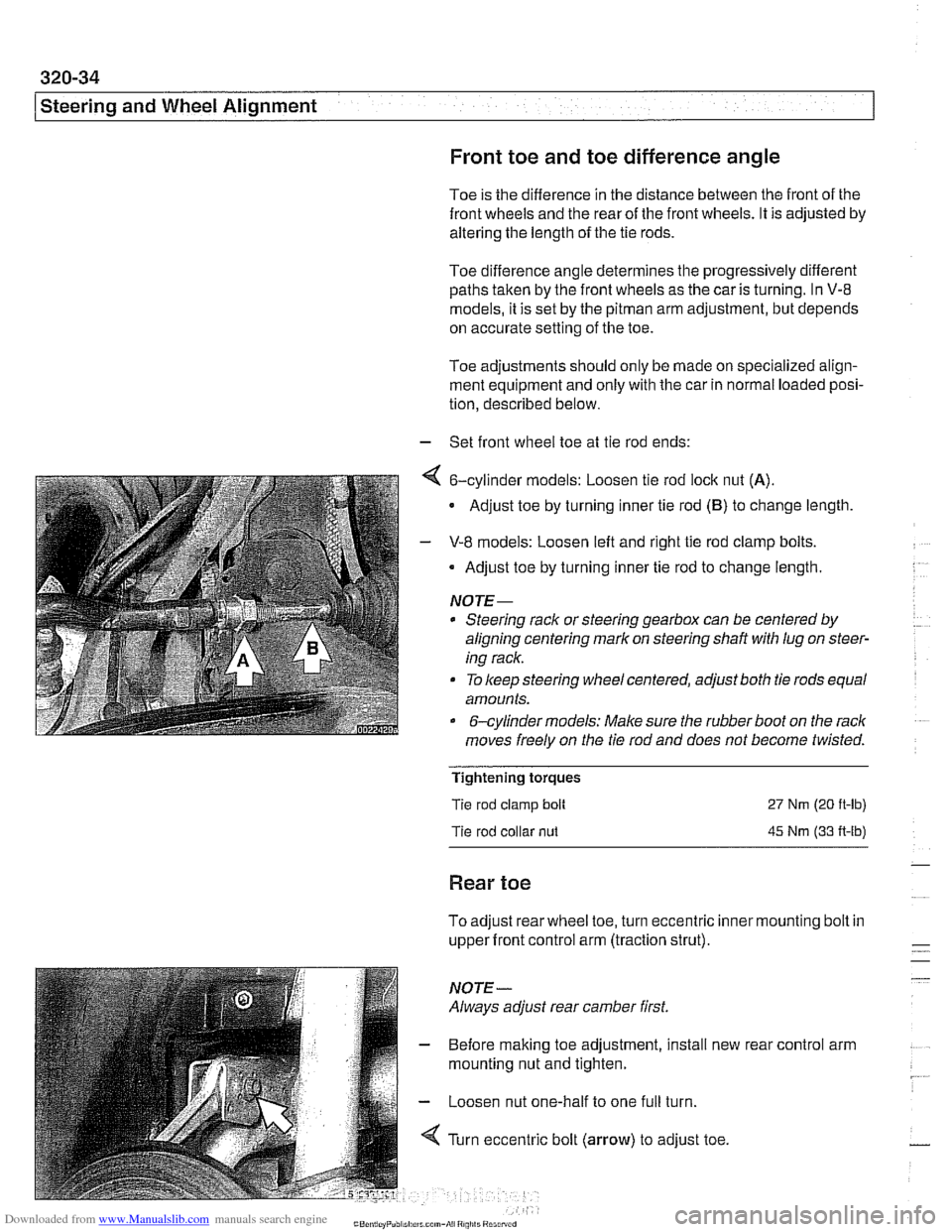

- Set front wheel toe at tie rod ends:

4 6-cylinder models: Loosen tie rod lock nut (A).

Adjust toe by turning inner tie rod (B) to change length

- V-8 models: Loosen left and right tie rod clamp bolts.

Adjust toe by turning inner tie rod to change length.

NOTE-

* Steering rack or steering gearbox can be centered by

aligning centering mark on steering shaft

with lug on steer-

ing rack.

To keep steering wheel centered, adjust both tie rods equal

amounts.

&cylinder models: Make sure the rubber boot on the rack

moves freely on the tie rod and does not become twisted.

Tightening torques

Tie rod clamp bolt

Tie rod collar

nut

27 Nm (20 ft-lb)

45 Nm (33 A-lb)

Rear toe

To adjust rear wheel toe, turn eccentric inner mounting bolt in

upper front control arm (traction strut).

NOTE-

Always adjust rear camber first.

- Before making toe adjustment, install new

mounting nut and tighten.

- Loosen nut one-half to one full turn.

4 Turn eccentric bolt (arrow) to adjust toe. rear

control arm

Page 703 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear ~us~ensionl

Rear strut assembly, disassembling and

assembling

Replace struts and coil springs in pairs only

Replacing the upper strut mount, spring or strut requires that

the strut assembly first be removed from the car, as described

earlier. Strut disassembly requires a spring compressor.

WARNING-

Do not attempt to disassemble the strut without a spring com-

pressor designed specifically for the job.

- Remove strut assembly from car as described in Rear strut

assembly, removing

bnd installing

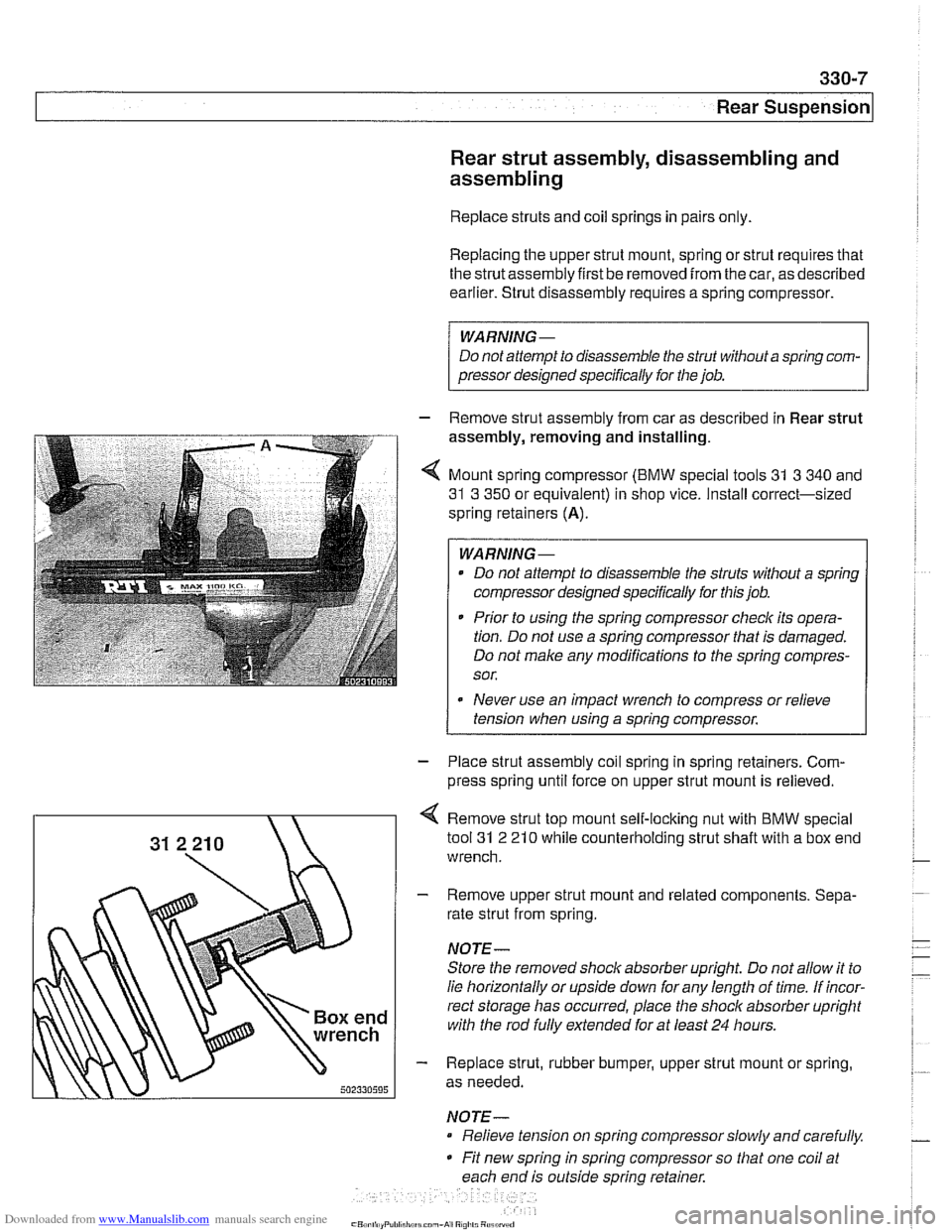

4 Mount spring compressor (BMW special tools 31 3 340 and

31 3 350 or equivalent) in shop vice. Install correct-sized

spring retainers

(A).

WARNING-

Do not attempt to disassemble the struts without a spring

compressor designed specifically for this job.

* Prior to using the spring compressor checlc its opera-

tion. Do not use a spring compressor that is damaged.

Do not make any modifications to the spring compres-

sor.

Never use an impact wrench to compress or relieve

tension when using a spring compressor.

1

- Place strut assembly coil spring in spring retainers. Com-

press spring until force on upper strut mount is relieved.

Remove strut top mount self-locking nut with BMW special

tool

31 2 21 0 while counterholding strut shaft with a box end

wrench.

- Remove upper strut mount and related components. Sepa-

rate strut from spring.

NOTE-

Store the removed shock absorber upright Do not allow it to

lie horizontally or upside down for any length of time. If incor-

rect storage has occurred, place the

shoclc absorber upright

with the rod

fully extended for at least 24 hours.

- Replace strut, rubber bumper, upper strut mount or spring,

as needed.

NOTE- Relieve tension on spring compressor slowly and carefully.

Fit new spring in spring compressor so that one coil at

each end is outside spring retainer.

Page 817 of 1002

Downloaded from www.Manualslib.com manuals search engine

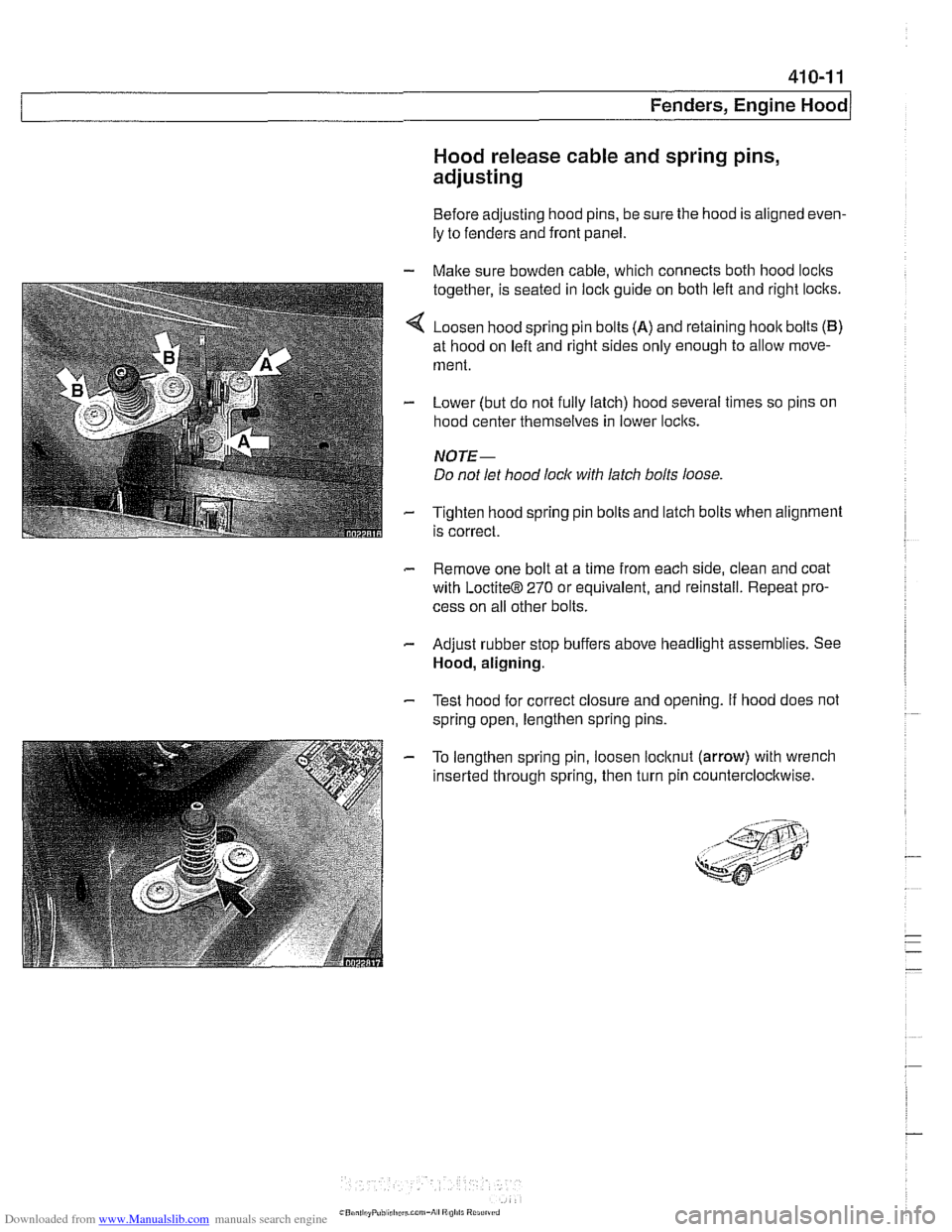

Fenders, Ensine HOO~I

Hood release cable and spring pins,

adjusting

Before adjusting hood pins, be sure the hood is aligned even-

ly to fenders and front panel.

- Malte sure bowden cable, which connects both hood loclts

together, is seated in lock guide on both left and right loclts.

4 Loosen hood spring pin bolts (A) and retaining hoolt bolts (B)

at hood on left and right sides only enough to allow move-

ment.

- Lower (but do not fully latch) hood several times so pins on

hood center themselves in lower loclts.

NOTE-

Do not let hood lock with latch bolts loose

- Tighten hood spring pin bolts and latch bolts when alignment

is correct.

- Remove one bolt at a time from each side, clean and coat

with

LoctiteB 270 or equivalent, and reinstall. Repeat pro-

cess on all other bolts.

- Adjust rubber stop buffers above headlight assemblies. See

Hood, aligning.

- Test hood for correct closure and opening. If hood does not

spring open, lengthen spring pins.

- To lengthen spring pin, loosen locltnut (arrow) with wrench

inserted through spring, then turn pin counterclocltwise.

Page 846 of 1002

Downloaded from www.Manualslib.com manuals search engine

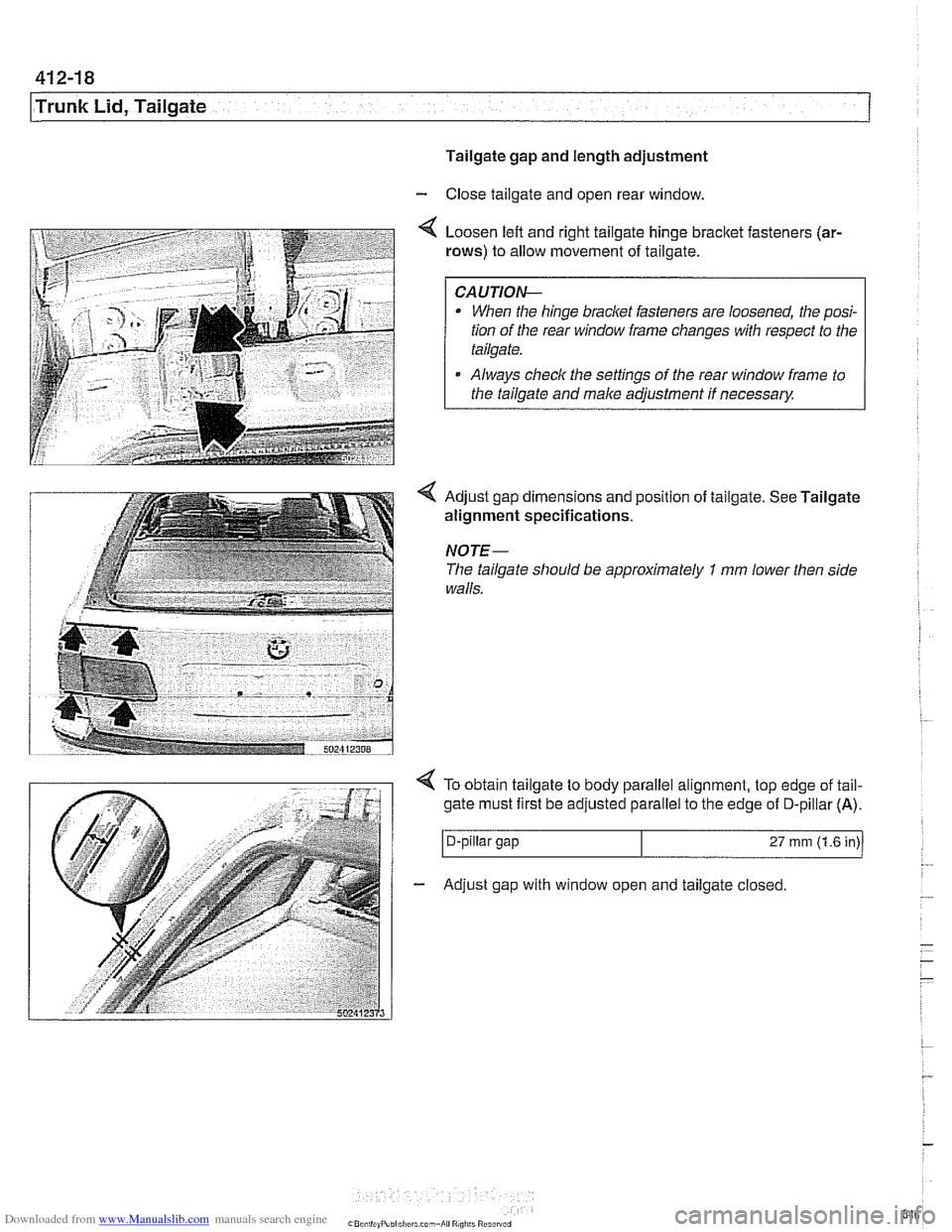

41 2-1 8

Trunk Lid, Tailgate

Tailgate gap and length adjustment

- Close tailgate and open rear window.

Loosen left and right tailgate hinge

bracket fasteners (ar-

rows)

to allow movement of tailgate.

CAUTION-

When the hinge bracket fasteners are loosened, the posi-

tion of the rear window frame changes with respect to the

tailgate.

Always

check the settings of the rear window frame to

the tailgate and

make adjustment if necessary

NOTE-

The tailgate should be approximately I mm lower then side

walls.

4 To obtain tailgate to body parallel alignment, top edge of tail-

gate must first be adjusted parallel to the edge

of D-pillar (A).

I D-pillar gap 27 rnrn (1.6 in)/

- Adjust gap with window open and tailgate closed.

Page 923 of 1002

Downloaded from www.Manualslib.com manuals search engine

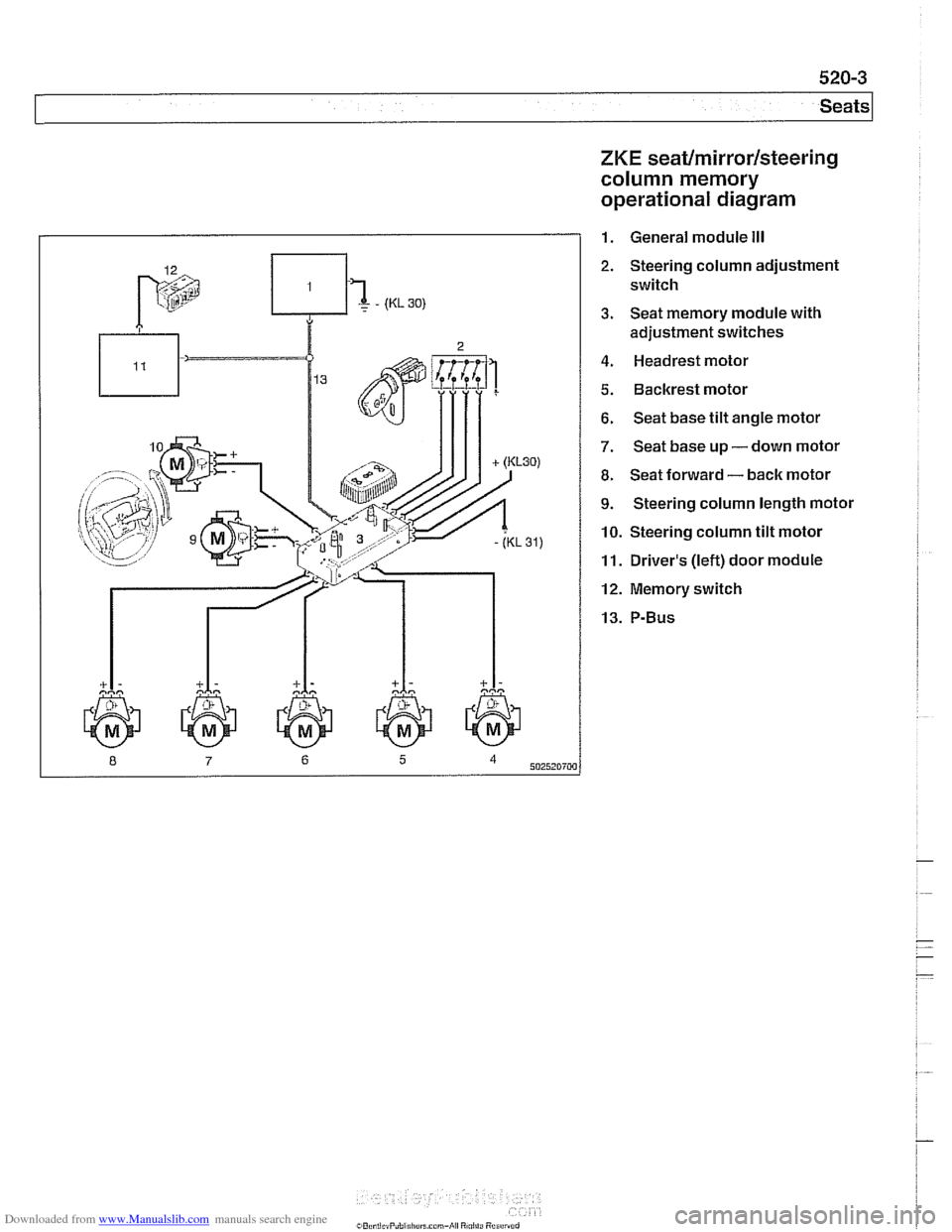

ZKE seat/mirror/steering

column memory

operational diagram

1. General module Ill

2. Steering column adjustment

switch

3. Seat memory module with

adjustment switches

4. Headrest motor

5. Backrest motor

6. Seat base tilt angle motor

7. Seat base up - down motor

8. Seat forward - back motor

9. Steering column length motor

10. Steering column tilt motor

11. Driver's (left) door module

12. Memory switch